1. Introduction

1.1. The Water Shortage Problem in Greece

Several countries such as Greece, Saudi Arabia and Tunisia face serious water shortage issues today [

1]. Increased water demand due to economic growth, irrigation needs, declining precipitation levels and over-abstraction of groundwater are all factors that create fresh water shortage problems; these factors appear even more intense in many regions of Greece and specifically in the Aegean Archipelago islands [

2]. Particularly during the summer period, the population of the islands may be up to five-times more than the winter, thus resulting in severe water shortage problems. This is true due to the following reasons:

In some islands of the South Aegean and the Cyclades, the average annual precipitation is less than half the corresponding value for mainland Greece, which is approximately 700 mm.

During the summer months, most islands experience a heavy seasonal rise in population due to tourism, a higher water demand due to increased temperatures and very limited precipitation that amounts to about 7% of their total annual rainfall.

Most Greek islands and other arid coastal areas have a particularly bold relief with steep slopes, hills and mountains and little forest or green coverage. As a result, surface flows move with great momentum in a torrent-like fashion, cannot be withheld by vegetation—as it is very limited—and cascade their way down to the sea, with only a small percentage of that flow recharging groundwater and aquifers.

Aquifers are usually small and connected to the sea. Intense groundwater pumping to cover fresh water shortage in the islands results in the drop of the water level, which is followed by the influx of seawater, making groundwater brackish and essentially destroying the aquifer.

On the other hand, it is clear that the development and the quality of life in the arid coastal regions of Greece with tourist development depend mainly on the sufficiency of water resources [

3]. Water resources are quite limited, thus restraining the economic development of local societies. To face increased potable water requirements, more than 1,000,000 m

3 of clean water are transported annually to these areas at a cost sometimes approaching the value of eight € per m

3 [

4]. Even if one ignores the high price of transporting water by ships, it is also energy-intensive, thus unsustainable in the long term. On the other hand, wind- or solar-powered desalination plants are suitable for providing desalinated water to communities where renewable energy sources such as wind or solar radiation abounds, as is the case in the Greek islands [

5], or other areas in the Mediterranean with similar characteristics [

6]. However, in many cases, the construction of desalination infrastructure projects is avoided, because of social reactions surrounding the potential environmental impacts of desalination plants. Thus, water continues to be transported by ships. The cost is very high and burdens the State, while at the same time, the local communities suffer from the consequences of the unreliability of water transport.

This paper attempts to show how important proper design of operations is and how current practices need considerable improvement in order to overcome the negative environmental impacts of desalination plants, thus making desalination the number one choice for feasible and environmentally friendly water production in the arid regions of the Mediterranean.

1.2. The Environmental Impacts of Desalination Plants and Mitigation Strategies

Recently, there has been a lot of discussion in the literature on the environmental impact of desalination plants, especially for those in Spain, since the Water National Plan of the country included desalination as one of the technologies for supplying water for human consumption, tourist uses, as well as agricultural or industrial consumption [

7]. European legislation makes an Environmental Impact Assessment (EIA) mandatory for desalination plants producing over 5,000 m

3 of water per day.

Environmental impacts of desalination plants include the indirect impact of creating an increased demand for electricity production. Fossil fuel-powered desalination plants have environmental effects related to the emission of greenhouse gases or other pollutants associated with power generation [

8]. This negative impact could be overcome if renewable energy sources (RESs), such as wind turbines, solar panels, geothermal energy, photovoltaic units, hydrodynamic energy,

etc., are used instead of fossil fuels. Luckily, wind and solar energy are usually abundant in the coastal Mediterranean areas [

4]. Plants that rely exclusively on RESs have already been built and currently operate successfully in Greece.

Desalination plants directly impact the marine environment by returning the relatively high temperature concentrated brine to the sea. Einav

et al. [

9] indicated that the extent of vulnerability of the marine environment to salinity differs from place to place. It is measured by the nature of the marine habitat (coral reef, rocky beach or sandy surfaces) and by the origin of the surrounding organisms. Although data that document the effects of the hyper-saline desalination plant effluents are very scarce, it is now clearly documented that, especially in the Mediterranean region, the Posidonia seagrass (

Posidonia oceanica, endemic plant in the Mediterranean sea) habitat is very sensitive to high salinities derived from brine discharge [

6,

10,

11]. If desalination brine were not disposed of to the sea at all, this impact could be eliminated.

Another impact on the marine environment is realized when different products used in chemical cleaning of membranes and pretreatment cleaning are disposed of in the sea. These products are all contained in the desalination brine; therefore, potential negative impacts from disposing of the brine in the sea are avoided if the brine is collected and transported to saltworks. Naturally, if the salt produced is directed for human consumption, appropriate measures should be taken.

Noise pollution around the desalination plants is also an important issue [

12]. High pressure pumps and energy recovery systems, such as turbines, produce significant level of noise—in some cases over 90 dB. Aside from that, the adverse effect on land use cannot be underestimated, as these plants are located on coastal areas that may have tourist interest. Recently, a floating autonomous environmentally friendly and efficient desalination unit was developed by researchers of the Aegean University and currently operates in the Aegean Sea [

13]

. These small plants not only rely on RES to function, but have the added advantage of not being located on the coast, but floating further out at sea; this way the impact related to noise pollution and adverse effect of land use could be overcome.

The idea of constructing a zero effluent desalination plant has been suggested before [

12]. In this paper, we evaluate the option of transporting the brine from desalination plants to saltworks, thus operating existing desalination plants with zero effluent. To our knowledge, the possibility of coupling desalination plants and solar saltworks in order to produce a zero discharge desalination plant, and at the same time, possibly produce a useful product, salt, has not been suggested before. Through our empirical analysis, we explore different transportation routes and collect data on the cost of brine transportation, so as to assess the feasibility of this coupling. We finish our analysis with conclusions and recommendations on how the desalination process should be improved and made more efficient and environmentally friendly with minimal environmental impacts.

2. Materials and Methods

In order to assess the possibility of transferring brine produced by desalination plants to solar saltworks to produce salt, we collected data regarding the locations of both desalination plants and solar saltworks in Greece [

14]. Solar saltworks, both natural and artificial, have existed in Greece for a very long time and are important wetland ecosystems [

15,

16]. There are currently 34 reverse osmosis desalination plants in Greece (

Table 1 [

17]). We prepared a list of potential locations where new desalination plants could be built. Ideal candidates for such locations are relatively large coastal urban centers in Greece that face water shortage issues today and are expected to face a more serious problem in the future due to population increase, tourism, or lack of high-quality potable water resources (or a combination of all of these) [

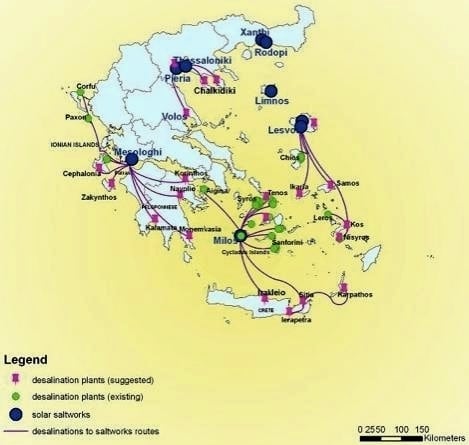

18]. Our initial assessment for choosing such locations was confirmed after consulting with several local officials on the needs and current and future water resource deficits of the coastal urban centers under investigation. In our effort to couple desalination plants with solar saltworks minimizing brine transportation costs from the former to the latter, we imported locations of existing and suggested desalination plants and solar saltworks in Greece into a Geographic Information System (GIS). Mapping the data in a GIS facilitated our analysis relevant to plant and saltworks locations, their respective distance from each other, their proximity to ports or major land transportation routes, and different modes of transportation that need to be used in order to couple them. The solar saltworks (blue circles) and the desalination plants (green circles) that operate in Greece are mapped in

Figure 1, as well as the desalination units that we suggest to have constructed (pins). In

Figure 1, we also show the suggested routes that could be followed for the transport of brine from each desalination plant (origin) to the closest, or most easily accessible saltworks unit (destination). Some routes that connect island units are serviced solely by ships, while others are covered by a combination of ship and truck transfer. The origin-destination pairs and corresponding modes of transportation for each pair are listed in

Table 2.

The locations of desalination plants and solar saltworks are dispersed around the country in such a way that plant-saltwork pairs and connecting routes seem to emerge naturally and make the use of a linear programming model (or a similar optimization model) that would calculate the minimum distance between pairs unnecessary. Thus, all Cyclades islands and Crete plants connect with the Milos saltworks, all Dodecanese islands connect with Lesvos, all Peloponese and Ionian islands plants connect with Mesologhi, and all other northern plants connect with saltworks in Thessaloniki. Whenever there was debate regarding which saltworks a desalination plant should pair with, other factors like transportation schedules made the final decision. For example, one may argue that the Monemvasia plant in the south-eastern Peloponese should pair with Milos based on their physical distance; however, there is no year-around ship service to connect the two locations, so Monemvasia pairs with Mesologhi via truck service.

Table 1.

Desalination plants in Greece (adapted from [

17]).

Table 1.

Desalination plants in Greece (adapted from [17]).

| Desalination Unit | Construction Year | Capacity (m3/d) | Operational Status |

|---|

| Syros 1st (Ermoupoli) | 1992 | 800 | Operational |

| Syros 2nd (Ermoupoli) | 1997 | 800 | Operational |

| Syros 3rd (Ermoupoli) | 2001 | 2×250 | Operational |

| Syros 4th (Ano Syros) | 2000 | 250 | Operational |

| Syros 5th (Ano Syros) | 2002 | 500 | Operational |

| Syros 6th (Ermoupoli) | 2002 | 2000 | Operational |

| Syros 7th (Ano Syros) | 2005 | 1000 | Under construction |

| Syros 8th -9th (Poseidonia ×2) | 2002 | 2×250 | Operational |

| Syros 9th -10th (Poseidonia ×2) | 2005 | 2×500 | Under construction |

| Schoinousa | 2004 | 100 | Under construction |

| Mykonos (Korfou-old) | 1981 | 500 | Operational |

| Mykonos (Korfou-new) | 2001 | 2000 | Operational |

| Paros (Naousa) | 2001 | 1200 | Operational |

| Tenos (Old) | 2001 | 500 | Operational |

| Tenos (New) | 2005 | 500 | Operational |

| Santorini 1st (Oia) | 1994 | 220 | Operational |

| Santorini 2nd (Oia) | 2000 | 320 | Operational |

| Santorini 3rd (Oia) | 2002 | 160 | Operational |

| Sifnos | 2002 | 500 | Operational |

| Chios 1st–2nd (Omiroupoli ×2) | 2005 | 2×1000 | Under construction |

| Chios 3rd (Omiroupoli) | 2000 | 600 | Operational |

| Chios 4th (Omiroupoli) | 2005 | 500 | Under construction |

| Nisyros (Old) | 1991 | 300 | Not operational |

| Nisyros (New) | 2002 | 350 | Operational |

| Cephalonia, Ithaki 1st | 1981 | 620 | Operational |

| Cephalonia, Ithaki 2nd | 2003 | 520 | Operational |

| Leros (municipality) | 2001 | 200 | Operational |

| Corfu (Kassopaion) | 2001 | 500 | Operational |

| Corfu (Ag. Georgios) | 2002 | 500 | Operational |

| Paxon 1st (municipality) | 2005 | 330 | Operational |

| Paxon 2nd (municipality) | 2005 | 150 | Operational |

Figure 1.

GIS map of Greece with desalination plants (suggested and existing), solar saltworks and routes for the transportation of brine.

Figure 1.

GIS map of Greece with desalination plants (suggested and existing), solar saltworks and routes for the transportation of brine.

Naturally, one of the most important factors in assessing the feasibility of operating a zero discharge seawater desalination plant system is cost. In this case, the largest cost is incurred in transporting the brine from desalination plants to saltworks. In this paper, we make a rough estimate of that amount: adding the cost of transporting brine by ships and/or special trucks. We acquired these figures either from published literature or personal interviews with transportation companies. Specifically, for the cost of transporting brine by truck, we obtained quotes from special truck companies that transfer liquids. The average price is 0.24 €/km/m

3 of brine and we multiply it by the distance traveled to estimate the truck transportation cost, as shown in

Table 2. Regarding transportation by ship, we do not have a price quote per km, but we have two prices per m

3 of brine: one for transporting brine from island to island (estimated at 4.8 €/m

3), and one from the mainland to the islands (8.21 €/m

3) [

19]. The latter cost is also used for the calculation of brine transportation from Karpathos Island to Sitia, Crete, as well as from Irakleio and Sitia, Crete to Milos Island.

Table 2 tabulates all costs for all origin-destination pairs.

Table 2.

Routes and costs of transporting brine from desalination units to solar saltworks.

Table 2.

Routes and costs of transporting brine from desalination units to solar saltworks.

| Desalination plant locations (origin) | Solar saltworks locations (destination) | By ship | By truck | Distance by truck(km) | Cost for transporting brine by ship (€/m3) | Cost for transporting brine by truck (€/m3) | Total Cost (€/m3) |

|---|

| Chios island | Lesvos island | √ | | | 4.8 | | 4.8 |

| Samos island | Lesvos island | √ | | | 4.8 | | 4.8 |

| Ikaria island | Lesvos island | √ | | | 4.8 | | 4.8 |

| Kos island | Lesvos island | √ | | | 4.8 | | 4.8 |

| Nisyros island | Lesvos island | √ | | | 4.8 | | 4.8 |

| Leros island | Lesvos island | √ | | | 4.8 | | 4.8 |

| Aigina island | Milos island | √ | | | 4.8 | | 4.8 |

| All Cyclades island locations | Milos island | √ | | | 4.8 | | 4.8 |

| North Crete (Irakleio) | Milos island | √ | | | 8.21 | | 8.21 |

| South Crete (Ierapetra) | Milos islandvia Sitia | √ | √ | 58 | 8.21 | 13.92 | 22.13 |

| East Crete (Sitia) | Milos island | √ | | | 8.21 | | 8.21 |

| Karpathos island | Milos islandvia Sitia | √ | | | 8.21+8.21 | | 16.42 |

| Nayplio | Mesologhi | | √ | 220 | | 52.8 | 52.8 |

| Monemvasia | Mesologhi | | √ | 372 | | 89.28 | 89.28 |

| Kalamata | Mesologhi | | √ | 259 | | 62.16 | 62.16 |

| Korinthos | Mesologhi | | √ | 164 | | 39.36 | 39.36 |

| All Ionian island locations | Mesologhivia Patra | √ | √ | 44 | 4.8 | 10.56 | 15.36 |

| Volos | Pieria | | √ | 200 | | 48 | 48 |

| Kassandra, Chalkidiki | Thessaloniki | | √ | 86 | | 20.64 | 20.64 |

| Sithonia, Chalkidiki | Thessaloniki | | √ | 125 | | 30 | 30 |

3. Results and Discussion

The cost of operating a zero discharge desalination plant is partially offset by the profits realized from selling the extra salt produced by the desalination effluent brine. Also, with desalination plants becoming zero effluent, there is no need for the construction of a metallic non-corrosive pipe (50 m to 1000 m in length) and diffuser that discharges the effluent brine deep in the sea. The cost of this pipe is estimated at 1,500 €/m, for a total of several thousand €. Needless to say, the largest savings are realized when, with the construction of the desalination plants, the coastal arid sites can become autonomous and will not need to have water brought in. From 2004 to 2006, the Greek government paid approximately 25.5 million € for the transportation of water to the arid islands that face serious water-shortage issues, with 9.5 million € spent for water transportation in 2006 alone. Just for comparison purposes, it is estimated that the 25.5 million € that the government has spent in three years for transporting water could be used for the construction of 15 seawater desalination units with a capacity of 30,000 m

3 per day in total, with an indicative water production cost of 0.4 €/m

3 [

19].

When looking at the data from

Table 2, we see that the cost of transporting brine by truck is prohibitively expensive. Since we have a per-km rate that is relatively high, locations that are a few hundred kilometers away can add up to almost 90 €/m

3 of brine transported. If one compares this cost to the cost of transporting water (the very process that we find unsustainable and we want to avoid) of less than 8 €/m

3, we see that such a transfer is even more expensive and unsustainable.

The question that is relevant here is how much brine is produced for the production of 1 m3 of desalinated water? Currently, using today’s technology, this number is relatively high. Processes vary in efficiency, but usually produce about 1 m3 of brine for every 1 m3 of desalinated water. In order to make desalination an environmentally friendly process, we should re-design the process, using the minimization of the effluent brine as a design criterion. This way, we will ensure that the proper technology is employed in order to produce a design that actually makes less effluent brine, since it is expensive to transfer to a saltworks and dispose of it without any environmental impacts.

Even when transported by ship and taking the most inexpensive of the two cases, it is still going to cost 4.8 €/m3 for the brine transport, which compares to about 0.4 €/m3 for the production of desalinated water. So, in the best case scenario, and given that for every liter of desalinated water produced we produce another liter of brine, the proper disposal of brine to a saltworks still costs about 10-times more than the production of desalinated water. Therefore, to balance out the cost of the useful product (water) with the cost of safe disposal of the process waste (brine), we need to ensure that the technology is such that brine is produced at a rate of 10 to 1, i.e., for every 10 liters of desalinated water produced we make only 1 liter of brine. Nowadays, improved efficiency in the desalination process is usually a result of improved membrane technology that also comes at a lower price. Our analysis showed that to make this process sustainable and environmentally friendly, it is also necessary to significantly reduce the waste (brine) produced, something that has been generally overlooked. This analysis is valid only under the assumption that the water is produced at the location in which it is consumed, i.e., there is no need to transfer the desalinated water. Naturally, this is the preferred practice, as transporting water may give rise to hygienic issues and water quality deterioration due to its transport; moreover, transporting high quality potable water requires the installation and operation of a high quality infrastructure that would prove prohibitively expensive. Therefore, all desalination plants are built where there is a water shortage problem and water produced is only intended to cover the needs locally.

4. Conclusions

Water shortage has become one of the greatest problems of modern society, mostly due to the explosive increase in population, along with the socio-economic development and the climate change. In order to deal with water shortage problems, Greece has resorted to solutions such as transporting water by ships from the mainland to the islands that face a more serious water shortage problem, a practice that is expensive, energy-intensive and unsustainable. The promising process of seawater desalination to supply the country with potable water is suitable for providing desalinated water to arid coastal regions in Greece and other Mediterranean countries that face similar issues. Desalination systems, however, produce concentrated brine that may heavily affect marine biota when it is disposed of in the sea. To avoid this impact, we explore the option of directing the desalination effluent to a solar saltworks for brine concentration and ultimate salt production in order to achieve a zero discharge desalination plant. A survey was conducted on the locations of possible desalination plants and solar saltworks in Greece and the data mapped in a GIS, in order to assess the distances between desalination plants and solar saltworks and to investigate the economic potential of transferring effluent brine to solar saltworks, so that disposal of brine in the sea is avoided. Our analysis showed that brine transfer by trucks is prohibitively expensive and that efforts should be directed into developing a more efficient technology that will result in the production of only a fraction of the brine that is produced from our systems today, in order to make the zero discharge plant economically feasible.