Evolution of Water Lifting Devices (Pumps) over the Centuries Worldwide

Abstract

:1. Prolegomena

Water is the driving force of all nature.—Leonardo da Vinci

2. Very Early (Prehistoric) Times

2.1. Eshnunna/Babylonia and Mesopotamian Empire in Modern Day Iraq (ca. 4000–2000 BC)

2.2. Bronze Age (ca. 3200–1100 BC)

2.3. Ancient Egyptians (ca. 3000–67 BC)

2.4. Ancient Persia (ca. 1200–200 BC)

3. Early Chinese Dynasties

4. Historical Times

4.1. Classical and Hellenistic Periods (ca. 480–67 BC)

4.2. Roman Period

5. Late Chinese Dynasties

6. Byzantine Period and Venetian Rule (ca. 330–1600 AD)

7. Pre-Columbian America

8. Modern Times

9. Epilogue

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix

| 4000–3000 BC | Early uses of water power was used for irrigation in Mesopotamia |

| 2500–2000 BC | Minoans invented the shaduf |

| 2000 BC | Egyptians invented the shaduf |

| 1200–800 BC | Early use of gravity fed as water lifting in ancient Persia (Qanat, collection of roof rainfall from roof, and horizontal well) |

| 1600 BC | Chinese invented the Jiégāo (Chinese shaduf). |

| 800–200 BC | Other methods for water pumping in Persian Empire (Persian shaduf, mohte, Persian wheel, zawafa, sakkia, and Persian Noria) |

| 287–212 BC | Archimedes the famous Syracusan scientist and engineer invented the water screw |

| 285–222 BC | The engineer Ktesivius of Alexandria (initially barber) has invented the force pump |

| 260–180 BC | In Hellenistic Alexandria Philon Byzantius has invented the chain pump |

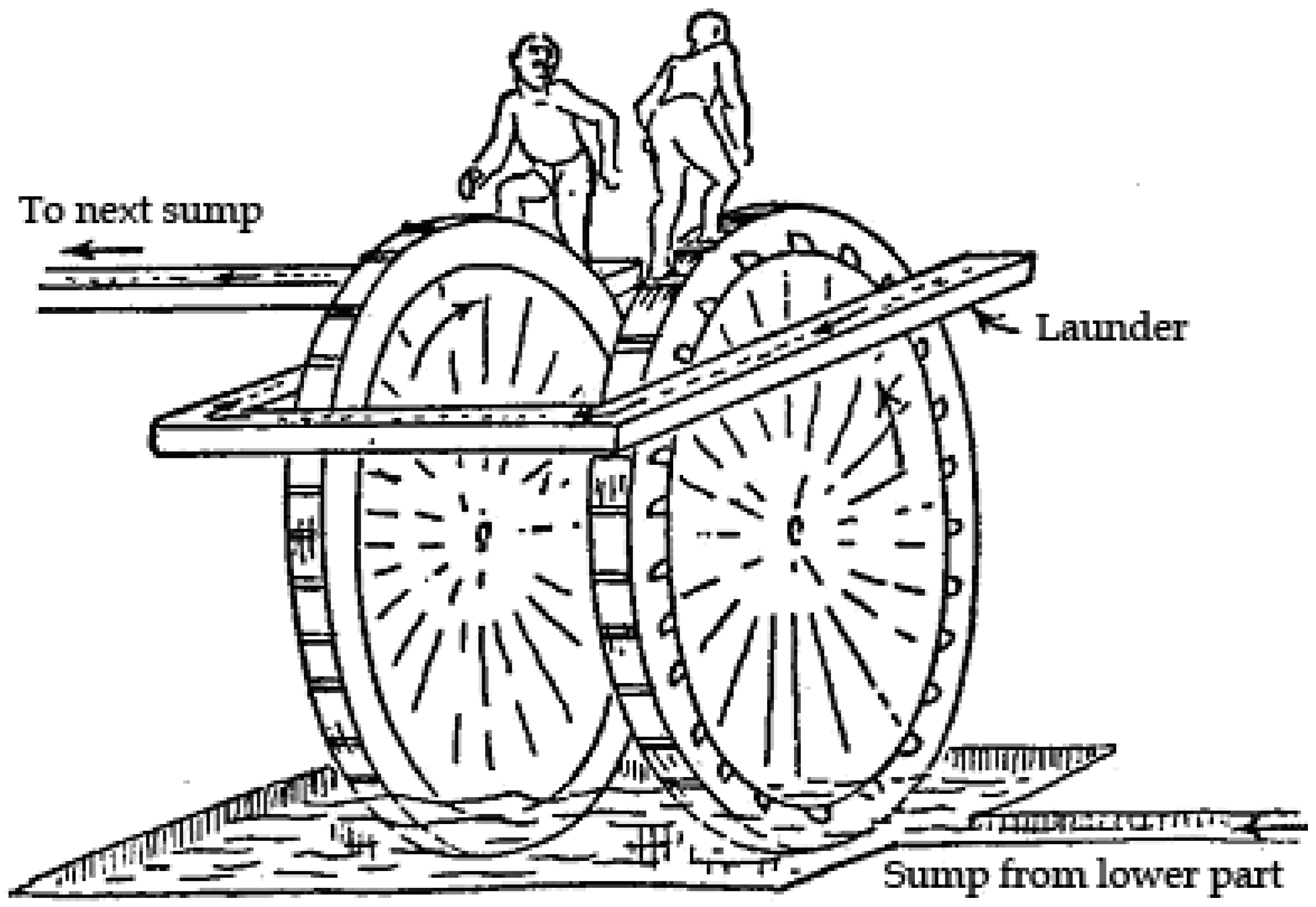

| 200 BC | Waterwheel with pots attached or with compartments for the water |

| 1200 AD | Chinese invented windmill for irrigation |

| 1698 AD | Thomas Avery invented a pump that operated on steam to create a vacuum to draw water. |

| 1580 | Sliding vane pump invented by Ramelli; Serviere invents the gear pump |

| 1650 | Otto van Guericke invents his piston vacuum pump |

| 1674 | Sir Samuel Morland patents the packed plunger pump |

| 1687 | Denis Papin, French inventor, develops the first true centrifugal pump, one with straight vanes used for local drainage |

| 1738 | Ural hydraulic machinery plant established |

| 1790 | Plenty Ltd established Thomas Simpson establishes his pump business in London. Hayward Tyler established |

| 1830 | Screw pump invented by Revillion |

| 1840 | Henry R. Worthington invents the first direct-acting steam pump |

| 1851 | John Gwynne files his first centrifugal pump patent |

| 1857 | Henry R. Worthington produces the first horizontal, duplex, direct-acting steam pumps for boiler feed. |

| 1860 | Allweiler founded—A.S. Cameron invents the first reciprocating stream pump |

| 1870 | Osborne Reynolds, UK Prof., develops an original design of a centrifugal pump |

| 1874 | Charles Barnes of New Brunswick invents the vane pump |

| 1897 | Preston K. Wood makes the first deep well turbine pump in Los Angeles, California |

| 1899 | Robert Blackmer invents rotary vane pump technology, a pump design that was an important departure from the old gear principle and predecessor to today’s sliding vane pumps. |

| 1901 | Byron Jackson develops the first deep well vertical turbine pump |

| 1905 | Multistage centrifugal pumps are developed |

| 1908 | Hayward Tyler creates its first electric motor for use under water and develops the wet stator motor for use as a boiler circulation glandless motor-pump |

| 1916 | Aldrich produces the first direct motor-driven reciprocating pump |

| 1923 | Ruthman Companies designs the world’s first sealless vertical pump |

| 1927 | Aldrich produces the first variable stroke multi-cylinder reciprocating pump |

| 1940 | Axial-flow and jet pumps have been used as compressors in jet engines. Jet pumps are used in wells that are deeper than 60.69 m. |

| 1956 | Flygt introduces the submersible sewage pump |

References

- Zarkadoulas, N.; Koutsoyiannis, D.; Mamassis, N.; Papalexiou, S.M. Climate, water and health in ancient Greece. In European Geosciences Union General Assembly; Geophysical Research Abstracts; European Geosciences Union: Vienna, Austria, 2008; Volume 10. [Google Scholar]

- Antoniou, G.; Lyberatos, G.; Kanetaki, E.I.; Kaiafa, A.; Voudouris, K.; Angelakis, A.N. History of Urban Wastewater Sanitation Technologies in Hellas. In Evolution of Sanitation and Wastewater Management through the Centuries; Angelakis, A., Rose, J., Eds.; IWA Publishing: London, UK, 2014; Chapter 6; pp. 101–148. [Google Scholar]

- Scarborough, V.L. The Flow of Power: Ancient Water Systems and Landscapes; School of American Research Press: Santa Fe, NM, USA, 2003; p. 204. [Google Scholar]

- Ortloff, C.R. Water Engineering in the Ancient World—Archaeological and Climate Perspectives on Societies of Ancient South America, the Middle-East and South-East Asia; Oxford University Press: New York, NY, USA, 2009; p. 433. [Google Scholar]

- Mays, L.W. A brief history of water technology during antiquity: Before Romans. In Ancient Water Technologies; Mays, L.W., Ed.; Springer Science and Business Media: Dordrecht, The Netherlands, 2010; Chapter 1; pp. 1–28. [Google Scholar]

- Ann, C. History of Water Pumps, eHow Contributor. 2009. Available online: http://www.ehow.com/facts_5031932_history-water-pumps.html (accessed on 14 August 2013).

- Oleson, J.P. Greek and Roman Mechanical Water-Lifting Devices: The History of a Technology; University of Toronto Press: Toronto, Canada, 1984. [Google Scholar]

- Tassios, T. Hellenic Ancient Technology; Kathimerini: Thens, Greece, 1998. [Google Scholar]

- Angelakis, A.N.; Mamassis, N.; Defteraios, P. Urban Water Supply, Wastewater, and Stormwater Considerations in Ancient Hellas: Lessons Learned. Environ. Natl. Resour. Res. 2014, 4, 95–102. [Google Scholar] [CrossRef]

- Eubanks, B.M. The Story of the Pump and Its Relatives; Bernard M. Eubanks: Salem, OR, USA, 1971; p. 185. [Google Scholar]

- Lazos, C.D. Hydraulic Equipment and Mechanism; Aeolus: Athens, Greece, 1999. (In Greek) [Google Scholar]

- EU-Shaduf Project. In Annual Report of EU-Shaduf 017-04-500348-29; NAGREF, Institute of Iraklion: Iraklion, Greece, 2004.

- Mays, L.W. Water technology in ancient Egypt. In Ancient Water Technologies; Mays, L.W., Ed.; Springer Science and Business Media. B.V.: Dordrecht, The Netherlands, 2010; Chapter 3; pp. 53–66. [Google Scholar]

- Viollet, P.L. Water Management in the Early Bronze Age Civilization. In Proceedings of the La Ingenieria Y La Gestion Del Agua a Traves de Los Tiempos, Alicante, Spain, 30 May–1 June 2006.

- Joffe, G. Irrigation and Water Supply Systems in North Africa. Moroc. Stud. 1992, 2, 47–55. [Google Scholar]

- Laessoe, J. Reflections on modern and ancient oriental water works. J. Cuneif. Stud. 1935, 7, 5–26. [Google Scholar] [CrossRef]

- Angelakis, A.N.; Dialynas, M.G.; Despotakis, V. Evolution of Water Supply Technologies in Crete, Greece through the Centuries. In Evolution of Water Supply throughout Millennia; Angelakis, A.N., Mays, L.W., Koutsoyiannis, D., Mamassis, N., Eds.; IWA Publishing: London, UK, 2012; Chapter 9; pp. 227–258. [Google Scholar]

- Mays, L.W.; Koutsoyiannis, D.; Angelakis, A.N. A brief history of urban water supply in antiquity. Water Sci. Technol. Water Supply 2007, 7, 1–12. [Google Scholar] [CrossRef]

- Alexiou, S.; University of Crete, Rethimno, Greece. Personal communication, 2013.

- Lu, J.Y. Science and Civilization in China: Mechanical Engineering; Science Press: Beijing, China, 2000; Volume 10. [Google Scholar]

- Bazza, M. Overview of the History of Water Resources and Irrigation Management in the Near East Region. Water Sci. Technol Water Supply 2007, 7, 201–209. [Google Scholar] [CrossRef]

- Postel, S. Pillar of Sand: Can the Irrigation Miracle Last? W.W. Norton Company Ltd.: New York, NY, USA, 1999; p. 313. [Google Scholar]

- Oleson, J.P. Water-Lifting. In Handbook of Ancient Water Technology (Technology and Change in History); Wikander, Ö., Ed.; Brill Publishing: Leiden, The Netherlands, 2000; pp. 217–302. [Google Scholar]

- Cohn, G.S. L’origine des Norias de Fés. Hespéris 1933, 16, 156–157. [Google Scholar]

- Hazen, T.R. Pond Lily Mill Restorations. The Noria Water Wheels 2000. Available online: http://www.angelfire.com/journal/millbuilder/album5.html (accessed on 27 April 2014).

- Molenaar, A. Water Lifting Devices for Irrigation; FAO Paper No.60; FAO: Rome, Italy, 1956; p. 75. [Google Scholar]

- Noria Corporation. The History of the Noria. 2008. Available online: http://www.machinerylubrication.com/Read/1294/noria-history (accessed on 10 August 2014).

- Landels, J.G. Engineering in the Ancient World; University of California: Barkeley, CA, USA, 1981; p. 238. [Google Scholar]

- Jomehpour, M. Qanat irrigation systems as important and ingenious agricultural heritage: Case study of the qanats of Kashan, Iran. Int. J. Environ. Stud. 2009, 66, 297–315. [Google Scholar] [CrossRef]

- Kristoferson, L.A.; Bokalders, V. Water Pumping: An overview. In Renewable Energy Technologies. Their Applications in Developing Countrie; Pergamon Books Inc.: Elmsford, NY, USA, 1986; pp. 283–295. [Google Scholar]

- Koth, P.; Clendenon, C. Pumps, Traditional, Water Encyclopedia, Science and Issues. Available online: http://www.waterencyclopedia.com/Po-Re/Pumps-Traditional.html (assessed on 28 March 2015).

- Howes, M. The potential for groundwater exploitation by solar-powered pumps in Pakistan. Agric. Adm. 1984, 16, 229–248. [Google Scholar] [CrossRef]

- Fraenkel, P.L. Water Lifting Devices; FAO Irrigation and Drainage paper 43: Rome, Italy, 1986; ISBN 92-5-102515-0. [Google Scholar]

- Olley, J. Human- and Animal-Powered Water Lifters for Irrigation Practical Action; The Schumacher Centre: Rugby, UK, 2008. [Google Scholar]

- Roberts, W.; Singh, K. A Text Book of Punjab Agriculture; Civil and Military Gazette Press: Lahore, Pakistan, 1951; p. 464. [Google Scholar]

- Salazar, L. Irrigation Reference Manual; Peace Corps ICE: Washington, DC, USA, 1994; p. 486. [Google Scholar]

- Glick, T.F. Irrigation and Society in Medieval Valencia; 408 pages; Harvard University Press: Harvard, MA, USA, 1970. [Google Scholar]

- Wang, Z.H. Agricultural Books of Ancient China; Preliminary Series Books 1466; Zhonghua Book Company: Beijing, China, 1991; Volume 18, p. 384. [Google Scholar]

- Chuang, T. Sibubeiyao 53; Zhonghua Book Company: Beijing, China, 1989; Volume 5, p. 54. [Google Scholar]

- Zhou, K.Y. Science and Civilization in China: Volume 9, Water Resources Technology; Science Press: Beijing, China, 2002; pp. 403–408. [Google Scholar]

- Tamburrino, A. Water technology in ancient Mesopotamia. In Ancient Water Technologies; Mays, L., Ed.; Springer Dordrecht Heidelberg: London, UK; New York, NY, USA, 2010. [Google Scholar]

- Stefanaki, S. Διδακτική προσέγγιση του εμβαδού της έλλειψης με αναφορά στο έργο Σφαιροειδή και Κωνοειδή του Αρχιμήδη. Master’s Thesis, University of Athens, Athens, Greece, University of Cyprus, Nicosia, Cyprus, February 2008. [Google Scholar]

- Drachmann, A.G. The Screw of Archimedes. In Proceedings of the Actes du VIII Congrès International d’ Histoire des Sciences, Florence, Milan, Italy, 3–9 September 1956; Vinci (Firenze): Paris, France, 1958; Volume 3, pp. 940–943. [Google Scholar]

- Lazos, C.D. Αρχιμήδης. O Ευφυής Μηχανικός (Archimedes. The Intelligent Engineer); Aelos: Athens, Greece, 1995. (In Greek) [Google Scholar]

- Stamatis, E. Άπαντα του Αρχιμήδη—Τόμος Α΄ (Complete Works of Archimedes—Volume A΄; Technical Chamber of Greece: Athens, Greece, 1964. (In Greek) [Google Scholar]

- Dijksterhuis, E.J. Archimedes; Dikshoorn, C., Translator; Princeton University Press: Princeton, NJ, USA, 1987; p. 457. [Google Scholar]

- Lazos, C.D. Engineering and Technology in Ancient Greece; Aeolus: Athens, Greece, 1993; p. 128. (In Greek) [Google Scholar]

- Ηumphrey, J.W.; Oleson, J.P.; Sherwood, A.N. Greek and Roman Technology: A Sourcebook: Annotated Translations of Greek and Latin Texts and Documents; Taylor & Francis e-Library: London, UK; New York, NY, USA, 2003; p. 623. [Google Scholar]

- Kotsanas, K. Ancient Hellenic Technology—The Inventions of the Ancient Hellenes: Research, Study and Construction; K. Kotsanas Publ.: Pyrgos, Greece, 2013; p. 160. [Google Scholar]

- Koutsoyiannis, D.; Angelakis, A.N. Hydrologic and Hydraulic Science and Technology in Ancient Greece; Encyclopedia of Water Science; Stewart, B.A., Howell, T., Eds.; Marcel Dekker Inc.: New York, NY, USA, 2003; pp. 415–417. [Google Scholar]

- Drachmann, A.G. Ktesibios, Philon and Heron: A Study in Ancient Pneumatics; E. Munksgaard: Copenhagen, Denmark, 1948; p. 197. [Google Scholar]

- Valavanis, K.P.; Vachtsevanos, G.J.; Antsaklis, P.J. Technology and Autonomous Mechanisms in the Mediterranean: From Ancient Greece to Byzantium. In Proceedings of the European Control Conference, Kos, Greece, 2–5 July 2007; pp. 263–270.

- Hurst, K.S. Engineering Design Principles; John Wiley & Sons: New York, NY, USA, 1999; p. 172. [Google Scholar]

- Angelakis, A.N. Personal archives.

- Wikipedia: The Free Encyclopedia. Available online: http://en.wikipedia.org/wiki/Water_organ (accessed on 27 April 2014).

- Heron of Alexandria. Pneumatika. In Herons von Alexandria Druckwerke und Automatentheater, Book II; Wilhelm, S., Translator; B.G. Teubner: Leipzig, Germany, 1889; Chapter XL; pp. 228–232, (In Greek and German). [Google Scholar]

- Tassios, T. A Potential Steam-Powered Force Pump in Hellenistic Times (ca. 330–67 BC); Newsletter of IWA SG on Water & Wastewater in Ancient Civilizations (WWAC); International Water Association: London, UK, 2015; p. 4, in press. [Google Scholar]

- Encyclopedia Britannica. Available online: http://www.britannica.com (accessed on 15 May 2015).

- Needham, J. Science and Civilization in China: Volume 4, Physics and Physical Technology, Part 2, Mechanical Engineering; Caves Books, Ltd.: Taipei, Taiwan, 1986. [Google Scholar]

- Baichun, Z. Ancient Chinese windmill. In International Symposium on History of Machine and Mechanism; Springer: Berlin Heidelberg, Germany, 2009; pp. 203–214. [Google Scholar]

- Dodge, D.M. Illustrated History of Wind Power Development. Part 1-Early History through 1875–2006. Available online: http://telosnet.com/wind/early.html (accessed on 27 April 2014).

- Lucas, A. Wind, Water, Work: Ancient and Medieval Milling Technology; Brill Publishers: Leiden, The Netherlands, 2006; p. 460. [Google Scholar]

- Sathyajith, M. Wind Energy: Fundamentals, Resource Analysis and Economics; Springer: Berlin Heidelberg, Germany, 2006; p. 246. [Google Scholar]

- Kyriakopoulos, G. Water Pumping Mechanisms in Ancient World. Master’s Thesis, National Technological Uniersity of Athens, Athens, Greece, June 2015. [Google Scholar]

- White, L., Jr. Medieval Technology and Social Change; Oxford University Press: Oxford, UK, 1979; p. 194. [Google Scholar]

- Rosen, W.A. The Most Powerful Idea in the World: A Story of Steam, Industry and Invention; Random House: New York, NY, USA, 2010; p. 400. [Google Scholar]

- Edgerton, S.Y. Brunelleschi’s mirror, Alberti’s window, and Galileo’s perspective tube. História Ciências Saúde-Manguinhos 2006, 13, 151–179. [Google Scholar] [CrossRef]

- Al-Jazari (1136–1206). Available online: http://everythingnice.wordpress.com/tag/al-jazari/ (accessed on 27 April 2014).

- Madey, T.E. Early applications of vacuum, from Aristotle to Langmuir. J. Vac. Sci. Technol. 1984, 2, 110–117. [Google Scholar] [CrossRef]

- The Art & Science of Water. Available online: https://www.saudiaramcoworld.com/issue/200603/the.art.and.science.of.water.htm (accessed on 27 April 2014).

- De Vedia, E.; de Cieza de León, P. (1553) La crónica del Perú: Historiadores Primitivos de Indias, Tomo Segundo; de Vedia, E., Ed.; Imprenta y Estereotipía de M. Rivadeneyra: Madrid, Spain, 1853. [Google Scholar]

- Rydén, S. Was the pump known in pre-Columbian South America? Am. Anthropol. 1955, 57, 619–620. [Google Scholar] [CrossRef]

- Sava Pump. Water Pump History. Available online: http://www.savapump.com/water-pump-history (accessed on 22 September 2013).

- Koenig, A. Western books on hydraulics in the historic Beitang library of the Jesuits in Beijing, China (1583–1773). In Proceedings of the 1st IWA Regional Symposium on Water, Wastewater, and Environment: Traditions and Culture, Patras, Greece, 22–25 March 2014; pp. 251–264.

- Koutsoyiannis, D.; Patrikiou, A. Water control in Ancient Greek cities. In Water and Urbanization; Ostigard, T., Ed.; B. Tauris: London, UK, 2013; pp. 130–148. [Google Scholar]

- Dixit, A. Basic Water Science. Nepal Water Conservation Foundation, Kathmandu, Nepal, 2002. Available online: http://www.nwcf.org.np/ (accessed on 12 January 2015).

- Ibrahim, G.A.; Che haron, C.H.; Azhari, C.H. Traditional Water Wheels as a Renewable Rural Energy. Online J. Power Energy Eng. 2010, 1, 62–66. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yannopoulos, S.I.; Lyberatos, G.; Theodossiou, N.; Li, W.; Valipour, M.; Tamburrino, A.; Angelakis, A.N. Evolution of Water Lifting Devices (Pumps) over the Centuries Worldwide. Water 2015, 7, 5031-5060. https://doi.org/10.3390/w7095031

Yannopoulos SI, Lyberatos G, Theodossiou N, Li W, Valipour M, Tamburrino A, Angelakis AN. Evolution of Water Lifting Devices (Pumps) over the Centuries Worldwide. Water. 2015; 7(9):5031-5060. https://doi.org/10.3390/w7095031

Chicago/Turabian StyleYannopoulos, Stavros I., Gerasimos Lyberatos, Nicolaos Theodossiou, Wang Li, Mohammad Valipour, Aldo Tamburrino, and Andreas N. Angelakis. 2015. "Evolution of Water Lifting Devices (Pumps) over the Centuries Worldwide" Water 7, no. 9: 5031-5060. https://doi.org/10.3390/w7095031