1. Introduction

Dealing with real world engineering problems often comes with facing multiple and conflicting objectives and requirements. Water distributions systems (WDS) are not exempt from this: while cost and hydraulic performance are usually conflicting objectives, several requirements related with environmental issues in water sources might be in conflict as well. Commonly, optimisation statements are defined in order to address the WDS design, management and/or control. Nevertheless, such problems become difficult since, besides their multi-objective conflicting nature, the optimisation problem might be non-linear (due to head-loss relationships for example) and/or discrete combinatorial (due to standardisation of pipe parameters) [

1,

2].

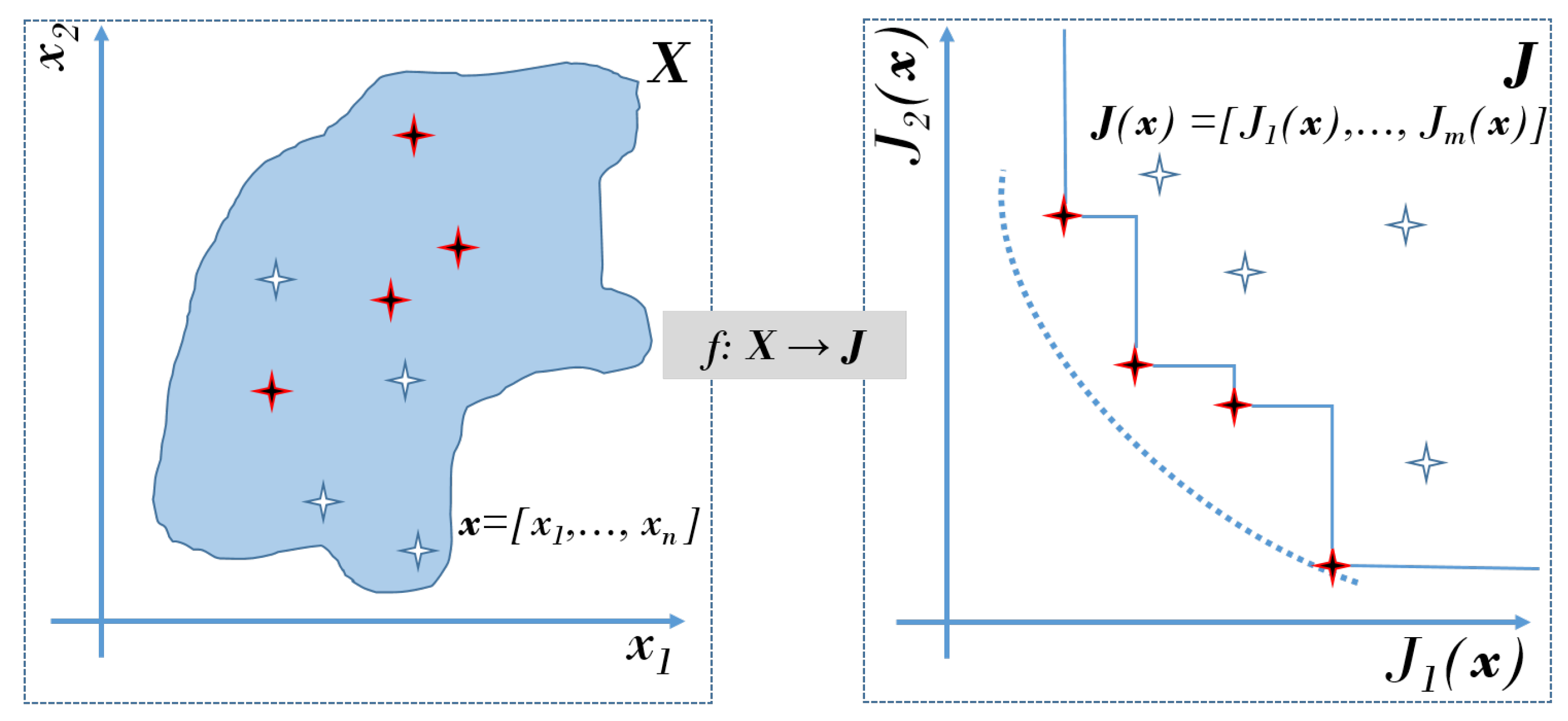

Multi-objective optimisation [

3] can handle such an issue, by means of a simultaneous optimisation of the design objectives. At the end of this process, a potential set of solutions, the Pareto front, is approximated. In this set of solutions, there is not a best solution, but a preferable solution. This means that several solutions are calculated, with different trade-offs between conflicting objectives and the engineer will select among them the most preferable for the problem at hand.

Given that several solutions are calculated, the designer must perform a decision making stage. In this stage, it is required to express somehow the preferences according to the trade-offs, in order to select the most suitable (preferable) solution for the problem at hand. This might not be a trivial task, since most of the times to interpret such trade-offs is not easy, given the multidimensional structure of the problem. Therefore, visualisation techniques [

4] and multi-criteria decision making methodologies are valuable and helpful for designers.

It is possible to use different decision making methodologies, such as TOPSIS [

5] (Technique for Order of Preference by Similarity to Ideal Solution), Physical Programming [

6], PROMETHEE [

7] (Preference Ranking Organisation METHod for Enrichment of Evaluations), among others. While it is usual to apply such methodologies in the decision making step, it is also possible to embed them into the optimisation process. For example, the Physical Programming method has been used before in order to evolve the population of a multi-objective evolutionary algorithm (MOEA) towards the pertinent region of the objective space [

8,

9]. With such approach, it is possible to use preference-information actively in the optimisation, improving the usability of the approximated Pareto front, as well as dealing with more than 3 design objectives effectively. In this paper some modifications are proposed, incorporating the TOPSIS and the PROMETHEE mechanism for the same purpose in a MOEA.

The remainder of this paper is as follows: in

Section 2 a review on multi-objective optimisation techniques for WDS is presented, identifying the necessity of preference handling techniques. In

Section 3 the TOPSIS and PROMETHEE methods are incorporated into a MOEA for preference handling and they are evaluated in

Section 4 with two MOPs. Finally, conclusions of this work are commented.

2. Review

A literature review on the optimisation of WDS is presented in [

2], where the authors bring together over two hundred journal publications from the past three decades. From those publications, the authors create a table with substantial information from over one hundred of them, from which seventeen papers focus on the use of a MOO approach. The first papers on MOO for WDS focused solely on the optimisation of operation and maintenance costs. Next, the optimisation of water quality became the main interest by some researchers. Nowadays, research on the subject focuses on finding the trade-off between cost and water quality. A review of each paper is presented below, followed by

Table 1, which resumes the MOO design characteristics of each publication. Background and definitions of the MOO process are presented in the

Appendix for interested readers.

A multi-objective hybrid approach of the Genetic Algorithm (GA) is introduced by [

10] to find the trade-off between the minimisation of: (a) energy; and (b) maintenance costs on a net with four pumps and one reservoir. One set of binary decision variables is used for this problem, which indicates the pump statuses for each hour on a twenty-four hours period. The recovery of the initial reservoir water level at the end of the simulation period is used as the equality constraint, while the minimum and maximum reservoir levels are set as inequality constraints.

A simplified system, composed of one source, five pumps and one elevated reservoir is the object of study by [

11], where strength Pareto evolutionary algorithm (SPEA), using one set of binary decision variables for the pump statuses, finds the trade-off between the minimisation of the: (a) pump operating costs; (b) number of pump switches; (c) difference between initial and final levels in the reservoir; and (d) maximum daily power peak. The problem contains four inequality constraints: (a) minimum reservoir water levels; (b) maximum reservoir water levels; (c) minimum pipeline pressure; and (d) maximum pipeline pressure. At the end of the paper, a two-dimensional Pareto front is presented.

A WDS from Belgium is optimised by [

12] using a multi-objective genetic algorithm (MOGA) with penalised tournament selection scheme, where two objectives are minimised: (a) the pump operating costs; and (b) the number of pump switches. Three sets of decision variables are defined: (a) the binary pump statuses; (b) the rotating speed of the pumps; and (c) the pressure loss coefficient for the control valve. The problem is composed of two sets of equality constraints: (a) the initial reservoir water level must be reached by the end of the optimisation; and (b) the consumer demands must be satisfied at any period of time. In addition, two sets of inequality constraints must be met: (a) the maximum; and (b) the minimum water levels for each reservoir. The authors plot a two-dimensional Pareto front, but do not choose a preferred solution.

A comparison of six MOO algorithms is performed by [

13] using the same WDS from [

11]. The compared algorithms are: SPEA, non-dominated sorting algorithm (NSGA), NSGA-II, controlled elitist non-dominated sorting genetic algorithm (CNSGA), niched Pareto genetic algorithm (NPGA), and MOGA. The MOP is designed with four objectives, the minimisation of: (a) pump operating costs; (b) number of pump switches; (c) difference between initial and final water levels in the reservoir; and (d) maximum daily power peak. Only one set of decision variables is used, the binary pump statuses, while four inequality constraints are used: (a) the minimum reservoir water levels; (b) the maximum reservoir water levels; (c) the minimum pipeline pressure; and (d) the maximum pipeline pressure. The algorithms are compared by six different metrics: (a) overall non-dominated vector generation; (b) overall non-dominated vector generation ratio; (c) error ratio; (d) generational distance; (e) maximum Pareto front error; and (f) spacing.

The simulation of a small WDS is optimised by [

14] using the second version of SPEA, the SPEA2. One set of decision variables, the binary pump status, is used to find the trade-off between two objectives, the minimisation of: (a) pump operating costs; and (b) number of pump switches. One equality constraint is used, the pressure at demand nodes, while three inequality constraints are used: (a) maximum tank water levels; (b) minimum tank water levels; and (c) tank volume deficit at the end of the simulation. The authors compare the Pareto fronts of four different methods for the initial population generation, using scatter plots and the attainment surfaces as the metric.

A real-time pump scheduling framework is proposed by [

15], where optimisation is performed using a multialgorithm genetically adaptive method (AMALGAM). The framework is applied to a WDS from Brazil, and the MOP is composed of two objectives: (a) the minimisation of pump operating costs; and (b) maximisation of operational reliability. One set of decision variables, the binary pump status, is considered. Three sets of inequality constraints are used: (a) the minimum pressure at any network node; (b) the tank water levels at the end of the scheduling period; and (c) the maximum number of pump switches. In addition, one equality constraint, where the occurrence of simulation errors must be equal to zero, is considered. The authors present the resulting Pareto front on a two-dimensional scatter plot.

Seven different scenarios are optimised by [

16] using NSGA-II. Each scenario is composed of different emission factors and time horizons. The MOP is composed of one set of decision variables, the pump schedules, and two objectives, the minimisation of: (a) pump operating costs; and (b) greenhouse gas emissions associated with the use of electricity from fossil fuel sources. Two sets of inequality constraints are considered: (a) the minimum pressure at network nodes; and (b) minimum total volume of water pumped into each district metered area. The authors present the Pareto fronts on two-dimensional scatter plots, and the solutions selected for analysis are based on minimum values for both objectives.

The simulation of a real water utility network is subject to MOO by [

17] using NSGA-II, where the trade-off between two objectives: (a) the minimisation of the total disinfectant dose; and (b) the maximisation of the volumetric percentage of water supplied with disinfectant residuals, is found. Two decision variables are used in this optimisation: (a) the locations of booster disinfection stations; and (b) the disinfection injections schedules. In addition, three inequality constraints are used: (a) non-negative disinfectant doses; (b) lower bound on the value of the Objective (b); and (c) upper bound on disinfectant concentrations at monitoring nodes. An analysis of the Pareto front is made by the authors using scatter plots.

The Pareto front of a WDS is found by [

18] using NSGA-II. The MOP is elaborated with three objectives, the minimisation of: (a) the number of chlorine booster stations; (b) mean value of chlorine concentrations; and (c) mean value of instances not meeting quality requirements. In addition, two decision variables are used: (a) the presence of a booster stations at a network node; and (b) the chlorine concentrations at booster stations and treatment plants. In total, five inequality constraints are used in this problem: (a) the maximum number of booster stations; and (b) the minimum number of booster stations; (c) the maximum shlorine concentration and (d) the minimum chlorine concentrations; and (e) the minimum chlorine concentration at treatment plants. By the end of the paper, the authors present a scatter plot of the Objectives (b) and (c), which are grouped by the values of Objective (a).

A WDS from Poland is optimised by [

19] using a distributed MOGA, based on the island GA. The problem is composed of the same objectives and decision variables presented by [

18], but only uses the first four inequality constraints. The resulting Pareto front is presented by a two-dimension scatter plot of objectives (b) and (c) grouped by values of objective (a).

Two case studies are optimised by [

20] using NSGA-II, one hypothetical and one simulation of a WDS from Colombia. For both cases, the objectives are defined as the minimisation of: (a) the number of polluted nodes; and (b) the number of the operational interventions needed. Only one set of decision variables is used for this problem, the operational interventions on pumps, valves and switches. In total, three sets of constraints are used on this publication, two inequality constraints, where: (a) nodes pressures must be positive; and (b) technical operational capacity for interventions must be met, and one equality constraint, where network connectivity must be ensured. The resulting Pareto front is presented as a two-dimensional scatter plot.

The optimisation of a WDS is performed by [

21] using the optimised MOGA (OPTIMOGA). The MOP is composed of four inequality constraints: (a) the minimum pressure for sufficient pressure, expressed by the number of times which it is not satisfied; (b) the tank volume deficit at the end of the simulation; (c) the minimum tank levels, expressed as the times which it is not satisfied; and (d) the maximum tank levels. It is also composed of one equality constraint, the global mass balance in each tank (there is only one tank in the case study). One set of decision variables, the binary status of the pumps and gates, is used to minimise two objective functions. The first objective is an aggregate function of: (a) pump operating costs; and (b) water losses cost; and the second is the function of Inequality Constraints (a), (b) and (c). The authors present a table with the resulting Pareto front of the problem, and one solution is selected for being the only feasible solution.

Two multi-objective optimisation algorithms, based on the harmonic search algorithm (HSA), are developed by [

22] in order to solve a pump scheduling problem, the multi-objective HSA (MO-HSA) and the polyphonic HSA (Poly-HSA). The MO-HSA is used to optimise an operational pumping field from Paraguay, and the problem is composed by the minimisation of four objectives: (a) pump operating costs; (b) quantity of pumped water; (c) electric energy peak consumption; and (d) number of pump switches. The optimisation is executed two times, Once with Objectives (a), (b) and (c), and again with Objectives (a), (b), and (d). The problem is also composed of one set of decision variables, the binary pump status, and four sets of inequality constraints, used within a penalty mechanism. Such constraints are: (a) the minimum water levels in storage tanks; and (b) the maximum water level in storage tanks; and the (c) the minimum volume deficit in the storage tanks at the end of the scheduling period; and (d) the maximum volume deficit in the storage tanks at the end of the scheduling period. The authors present, for both runs, a three-dimensional scatter plot with the Pareto front.

Two optimisation problems, one related to chlorine concentrations, and another related to water age, are solved by [

23] using SPEA2. In total, four objectives are defined for the MOP, the minimisation of: (a) pump operating costs; (b) disinfectant concentrations at monitoring nodes; (c) water age for demand nodes; and (d) cost of tanks. The first optimisation model includes Objectives (a), (b) and (c), while the second model includes Objectives (a), (c) and (d). Three sets of decision variables are used for this problem: (a) the pump speeds; (b) the disinfectant concentrations at treatment plants; and (c) tank diameters. One equality constraint, the pressure at nodes, and three inequality constraints: (a) the minimum volume deficit at the end of the simulation; (b) the maximum volume surplus at the end of the simulation; and (c) the minimum amount of stored water at any time, are used in both optimisation models. The resulting Pareto fronts are presented on three-dimensional scatter plots, and three solutions are selected for each Pareto, one “balanced” solution, which is the closest an Utopian solution, and the other two are related to minimal values for Objectives (a) and (b).

The optimisation of two systems is performed in [

24] using SPEA2 and the MOP defined in [

23], but only the first two objectives and decision variables are used. The authors present a two-dimensional scatter plot for both examples, and a single “balanced” solution is selected on the MCDM stage, but no metrics were specified.

A total of fourteen different scenarios are optimised by [

25] using NSGA-II. All scenarios are defined as a MOP with two objectives, the minimisation of: (a) pump operating costs; and (b) deviations of the actual constituent concentrations from the required values. For such problems, one set of decision variables, the binary pump status, are defined. Furthermore four sets of inequality constraints are considered: (a) the minimum pressure at customer nodes; (b) the minimum water level in the storage tanks; (c) the maximum water level in the storage tanks; and (d) the volume deficit in the storage tanks at the end of the scheduling period. The resulting Pareto front for all scenarios are presented on a two dimensional scatter plot and, for comparison with results from the literature, one “balanced” solution is selected for analysis, but no metrics were specified.

Six different scenarios based on a network with ninety-four nodes are optimised by [

26] using NSGA-II. All scenarios are defined as a MOP with three objectives, the minimisation of: (a) pump operating costs; (b) the turbidity deviations from the allowed values; and (c) deviations of the actual constituent concentrations from the required values. Decision variables and constraints are defined as in [

25]. The resulting Pareto fronts for all scenarios are presented on a three-dimensional scatter plot and three different two-dimensional scatter plots, for each two objectives combination, and two solutions were selected from two different scenarios for comparison purposes. No specific metrics were indicated for such selections.

In

Table 1 a summary of such papers is shown. It is interesting to note that the vast majority of papers are focusing on MOPs with two or three design objectives. A possible reason for this might be the difficulties to perform a MCDM and to visualise the Pareto front approximation. For this reason, the idea of stating more than three design objectives for WDS is exploited in this paper, using different preference mechanisms to evolve towards the pertinent region of the Pareto front.

3. Proposal and Experiment Description

As it has been noticed before, tendencies regarding the number of design objectives for MOPs is to state two or three. One of the circumstances leading to this might be that any MOP with more than three design objectives is said to be a many-objectives MOP problem. In such an instance, mechanisms for diversity and convergence are in conflict. Therefore, additional mechanisms are often required in order to guarantee a suitable performance of the Pareto front approximation process. One of such mechanisms is the inclusion of preferences [

27].

As it has been commented in the introduction, a MOEA using Physical Programming as preference handling mechanism, the sp-MODEII (Multi-Objective Differential Evolution with Spherical Pruning, version II) (Toolbox available at

https://www.mathworks.com/matlabcentral/fileexchange/47035) has been proposed before [

8,

9]. The sp-MODEII is an evolutionary algorithm for multi-objective optimisation. Its main characteristics are:

It uses Differential Evolution (DE) algorithm [

28,

29,

30] to produce its offspring at each generation. It is used given its convergence properties and simplicity for MOO [

31].

It uses spherical pruning [

32] in order to promote diversity in the approximated Pareto front. Basically, the objective space is partitioned using spherical coordinates, and one solution is selected in each spherical sector, avoiding overcrowding areas.

It uses physical programming (PP) [

6] for pertinency improvement and as a mechanism for many-objectives optimisation. It states such preferences in aspiration levels in a matrix M as depicted in

Table 2. This PP index is used as an additional mechanism to prune solutions, according to the preference index, in order to get a manageable size of the Pareto front approximation.

Nevertheless, in spite of its usefulness, different mechanisms might substitute the Physical Programming approach requiring less information from the designer. For this reason, we modify such an algorithm with two additional mechanisms for pertinency improvement (Available at:

https://www.mathworks.com/matlabcentral/fileexchange/65145). The first of them the TOPSIS mechanism [

5], and the second the PROMETHEE II [

7] method. That is, the original pruning mechanism using Physical Programming is modified. While the TOPSIS mechanism just require as input the Pareto front approximation, the PROMETHEE II method require information about (in) significant differences for each design objective (See

Table 3). The idea is to evaluate and compare different preference information methods working actively in the MOO process. Among the TOPSIS, PROMETHEE II and PP methods, the former requires the less information, while the latter the most. Comparison of input required for each mechanism is depicted in

Table 4.

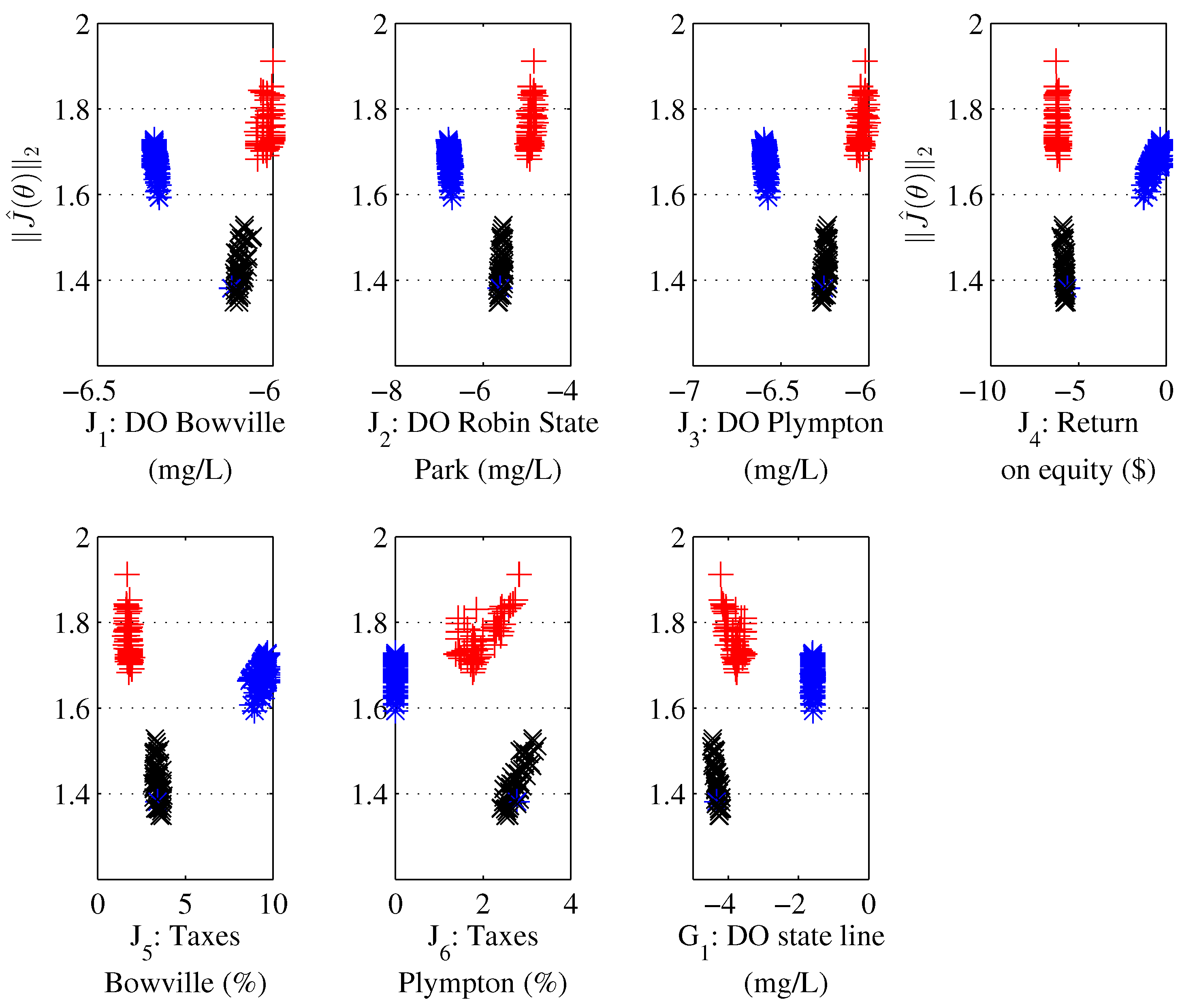

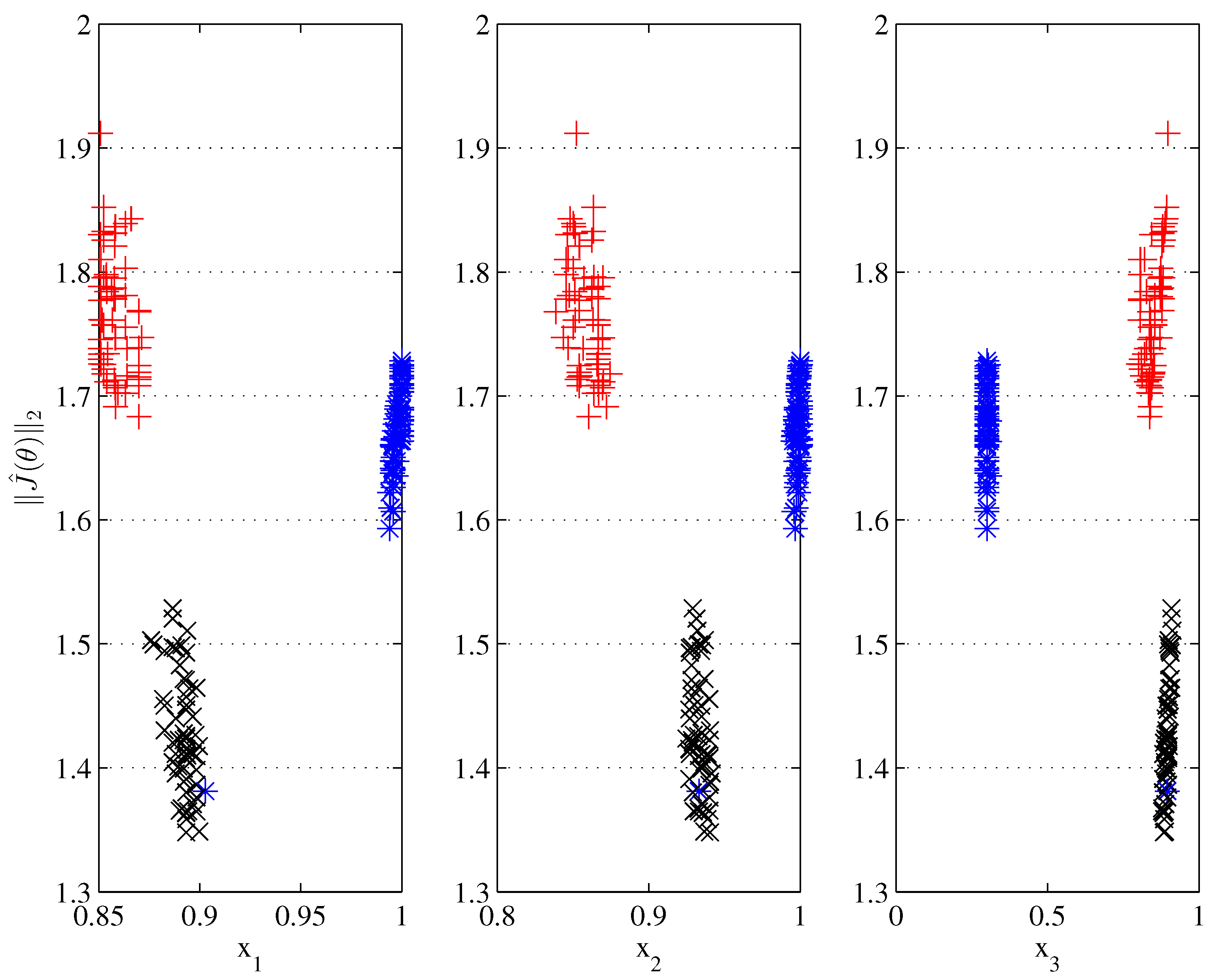

It uses as many subplots as design objectives to depict trade-off information.

Solutions are synchronised by the vertical axis, while the horizontal axis keeps their original units. That is, no normalisation deforming the units scale is used.

Trade-off relationships might be propagated to design variables by synchronising the same vertical axis.

5. Conclusions

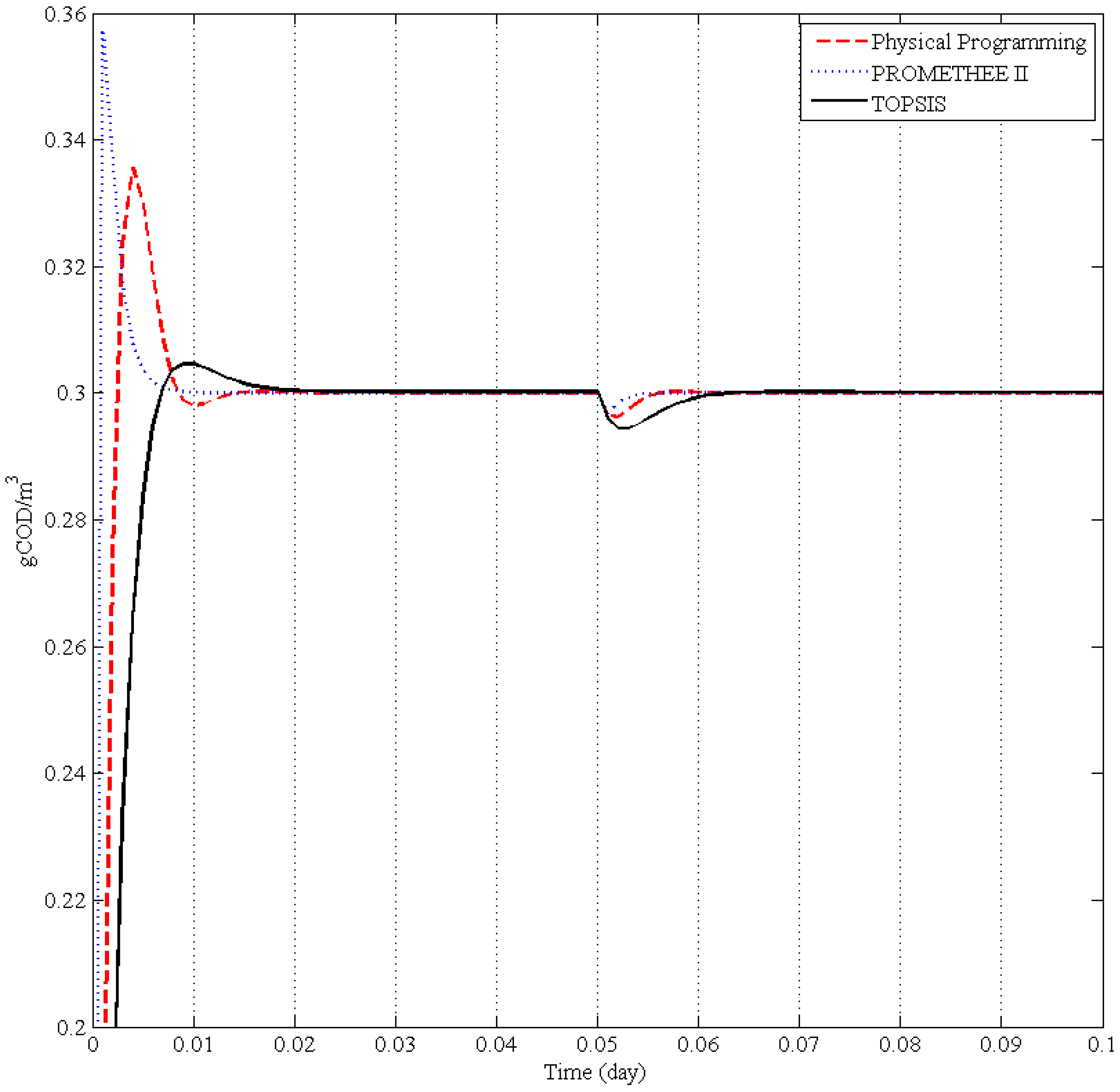

In this paper, we incorporated two additional mechanisms to handle designers’ preferences in multi-objective optimisation in the sp-MODEII algorithm. Such mechanisms are based on the TOPSIS and PROMETHEE methods, usually employed for multi-criteria analysis and decision making.

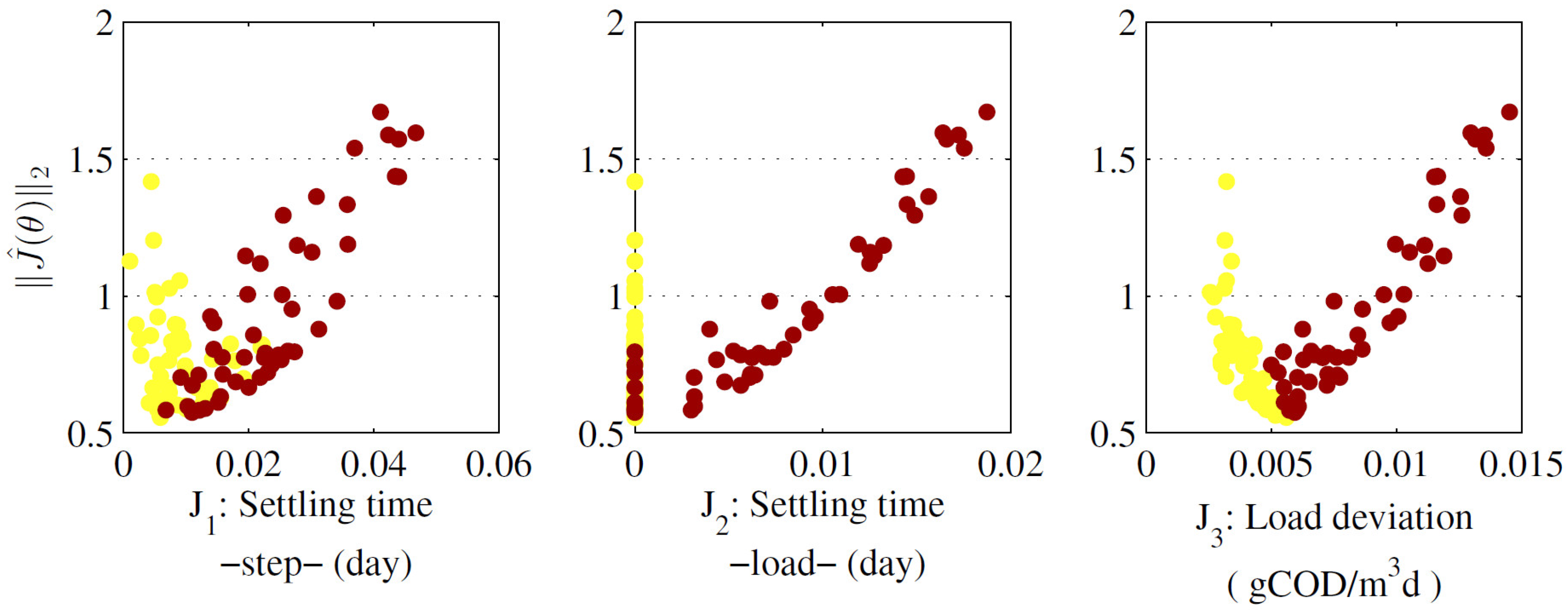

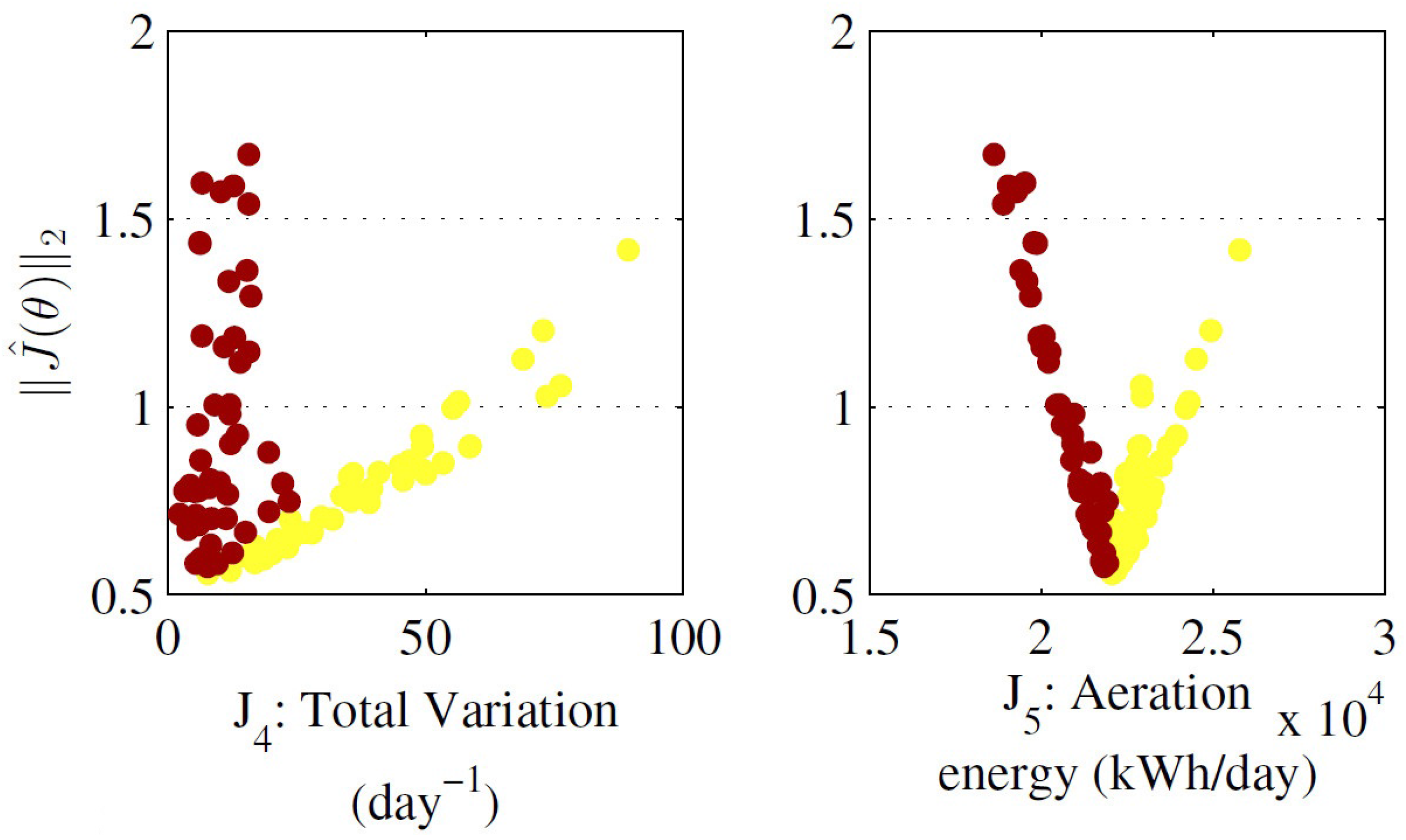

A comparison to handle designers’ preferences on two benchmarks dealing with water distribution systems was performed. On the one hand, it was shown that an analysis in such m-dimensional spaces with more than three design objectives is possible via specialised visualisation tool (Level Diagrams). On the other hand, the structural differences between different approaches to approximate a pertinent region of the Pareto front was also analysed.

In the latter case, the capacity to approximate a compact set focusing in the region of interest of the decision maker is evaluated. It was shown that the main structural difference among approaches (TOPSIS, PROMETHEE II, and Physical Programming) is the closeness of their clusters to an ideal solution, defined by the Pareto front approximation itself.

Further work will focus on using additional mechanisms to handle such preferences actively in the optimisation stage. Besides, merging two or more mechanisms might be an interesting idea to explore, in order to exploit synergies between different approaches.