Decoupling Water Consumption and Environmental Impact on Textile Industry by Using Water Footprint Method: A Case Study in China

Abstract

:1. Introduction

2. Study Object

3. Methodology and Data

3.1. Water Footprint

3.2. Decoupling Method

3.3. Water Footprint Decoupling Model

3.4. LMDI Method

3.5. Data

4. Results and Discussion

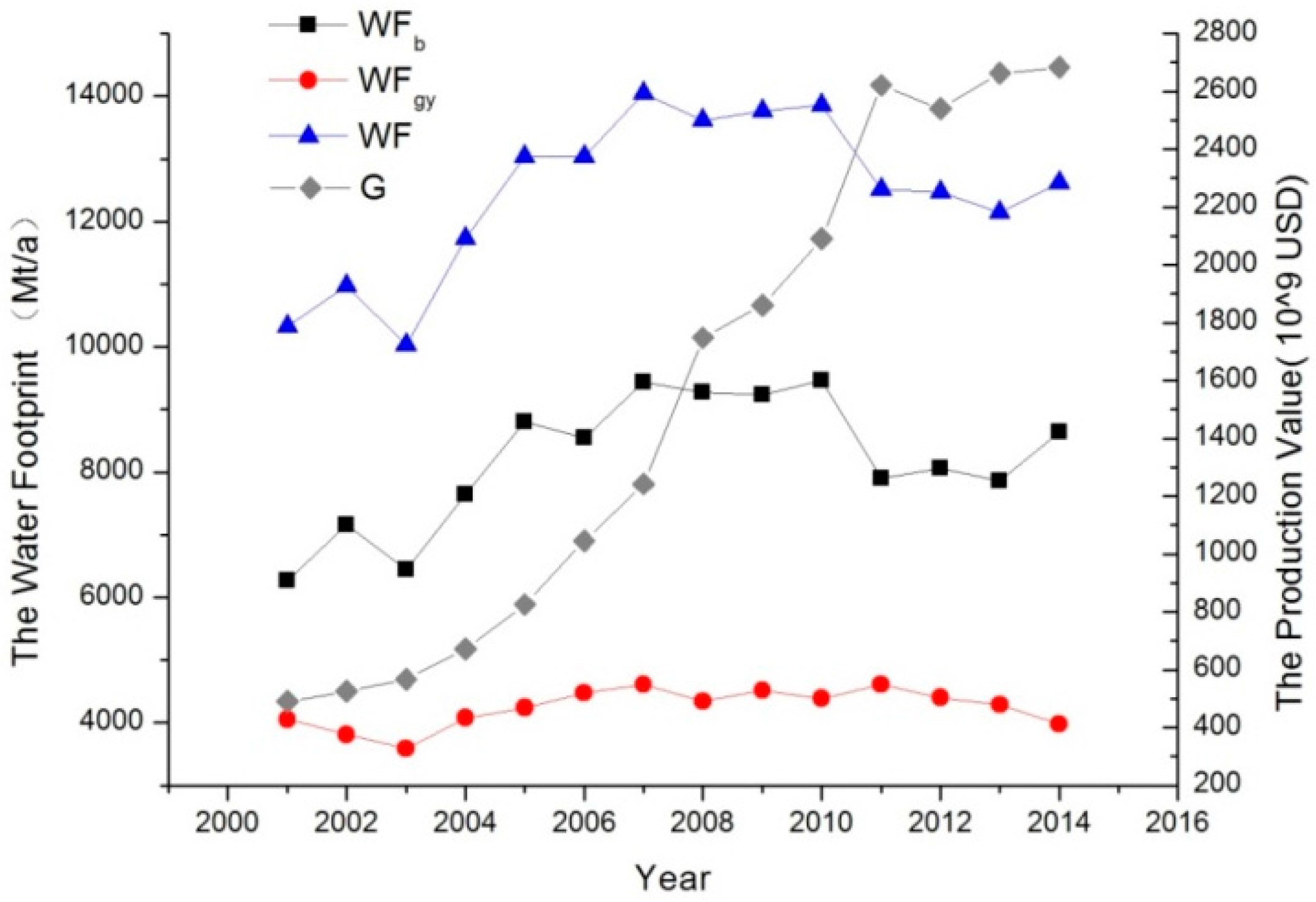

4.1. Water Footprint of the Textile Industry

4.2. Analysis of Decoupling Models

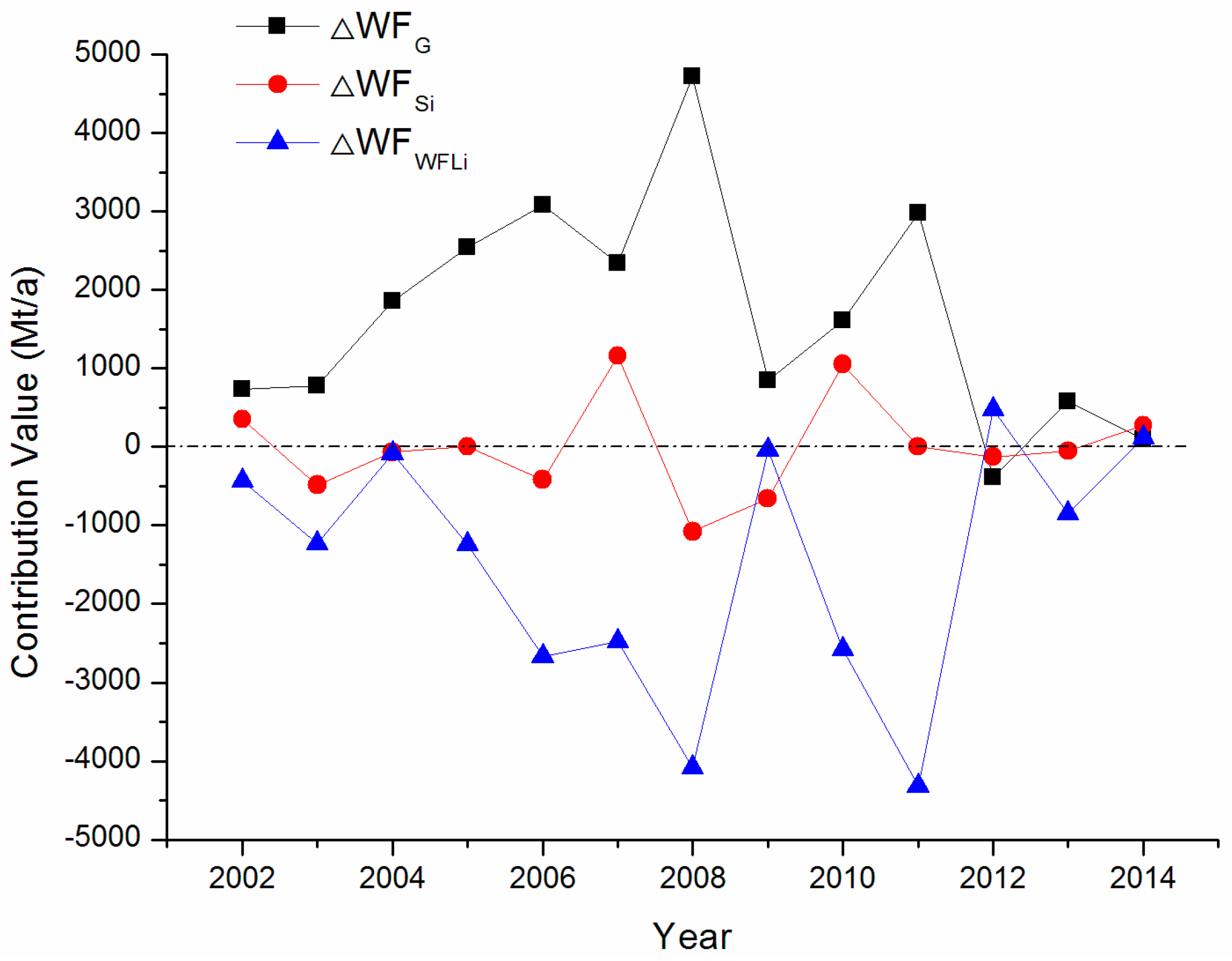

4.3. Decomposition Analysis

5. Conclusions

- (1)

- From 2001 to 2014, the WF of China’s textile industry generally followed an inverted “U” trend and rebounded in 2014. The trend can be divided into two stages: the rising (2001–2007) and decline phases (2008–2014).

- (2)

- In 2002–2014, China’s textile industry’s overall WF showed good decoupling between economic growth, with five years strong decoupling (2003, 2006, 2008, 2011, and 2013) and four years of weak decoupling (2005, 2007, 2009, and 2010). The decoupling trend as a whole is good, but the development of the textile industry is not completely independent of the WF. The government and textile enterprises should pay great attention to water-saving and waste water reduction in order to prevent reversal of the trend of decoupling.

- (3)

- The main factors affecting the decoupling of WF and economic growth in China’s textile industry are industry scale and technical level. The influence of industry structure is not evident. Industry scale factor is the primary factor that causes WF growth; technical level is the biggest contributor in the suppression of WF growth.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Organization for Economic Co-operation and Development (OECD). Indicators to Measure Decoupling of Environmental Pressure from Economic Growth; OECD Publishing: Paris, France, 2002. [Google Scholar]

- Organization for Economic Co-operation and Development. Decoupling: A Conceptual Overview; OECD Publishing: Paris, France, 2001. [Google Scholar]

- Fischer-Kowalski, M.; Swilling, M.; von Weizsäcker, E.U.; Ren, Y.; Moriguchi, Y.; Crane, W.; Krausmann, F.; Eisenmenger, N.; Giljum, S.; Hennicke, P.; et al. Decoupling Natural Resource Use and Environmental Impacts from Economic Growth. A Report of the Working Group on Decoupling to the International Resource Panel. Available online: http://www.unep.org/resourcepanel/decoupling/files/pdf/decoupling_report_english.pdf (accessed on 15 November 2016).

- Larson, E.D.; Ross, M.H.; Williams, R.H. Beyond the era of materials. Sci. Am. 1986, 254, 34–41. [Google Scholar] [CrossRef]

- Selden, T.M.; Song, D. Environmental quality and development: Is there a Kuznets Curve for air pollution emissions. J. Environ. Econ. Manag. 1994, 2, 147–162. [Google Scholar] [CrossRef]

- Vehmas, J.; Kaivo-Oja, J.; Luukkanen, J.; Malaska, P. Environmental taxes on fuels and electricity—Some experiences from the Nordic countries. Energy Policy 1999, 27, 343–355. [Google Scholar] [CrossRef]

- Ayres, R.U.; Ayres, L.W.; Warr, B. Exergy, power and work in the US economy, 1900–1998. Energy 2003, 28, 219–273. [Google Scholar] [CrossRef]

- Arouri, M.E.H.; Youssef, A.B.; M’Henni, H.; Rault, C. Energy consumption, economic growth and CO2 emissions in Middle East and North African countries. Energy Policy 2012, 45, 342–349. [Google Scholar] [CrossRef] [Green Version]

- Tapio, P.; Banister, D.; Luukkanen, J.; Vehmas, J.; Willamo, R. Energy and transport in comparison: Immaterialisation, dematerialisation and decarbonisation in the EU15 between 1970 and 2000. Energy Policy 2007, 35, 433–451. [Google Scholar] [CrossRef]

- Wu, H.; Gu, S.; Zhou, H.; Wang, X.; Dong, D.; Hu, Y. Relationship between energy consumption-carbon emissions and economic growth in Hebei province. Resour. Sci. 2011, 33, 1897–1905. [Google Scholar]

- Zhu, H.; Li, W.; Yu, J.; Sun, W.; Yao, X. An Analysis of Decoupling Relationships of Water Uses and Economic Development in the Two Provinces of Yunnan and Guizhou during the First Ten Years of Implementing the Great Western Development Strategy. Procedia Environ. Sci. 2013, 18, 864–870. [Google Scholar] [CrossRef]

- Lei, Y.T.; Su, L. Decoupling Relationship between Industrial Water Use and Economic Development in Guangdong Province. Water Conserv. Sci. Technol. Econ. 2015, 21, 1–4. (In Chinese) [Google Scholar]

- Gilmont, M. Decoupling Dependence on Natural Water: Reflexivity in the Regulation and Allocation of Water in Israel. Water Policy 2014, 16, 79–101. [Google Scholar] [CrossRef]

- Wu, D.; Wang, Y.H. Evaluation and prospect on the decoupling trend of economic development and water environment pressure in China. Resour. Environ. Yangtze Basin 2013, 22, 1103–1109. (In Chinese) [Google Scholar]

- Caneghem, J.V. Eco-efficiency trends of the Flemish industry: Decoupling of environmental impact from economic growth. J. Clean. Prod. 2010, 18, 1349–1357. [Google Scholar] [CrossRef]

- Conrad, E.; Cassar, L.F. Decoupling Economic Growth and Environmental Degradation: Reviewing Progress to Date in the Small Island State of Malta. Sustainability 2014, 6, 6729–6750. [Google Scholar] [CrossRef]

- Chen, Q.; Li, J.M.; Management, S.O. Analysis on the decoupling relationship between marine environmental stress and marine economic growth in China. Mar. Environ. Sci. 2015, 34, 827–833. (In Chinese) [Google Scholar]

- Li, X.K.; Wei, J. Decoupling between Environmental Pressure and Economic Growth in Chongqing Metropolitan Area. J. Nat. Resour. 2010, 25, 139–147. (In Chinese) [Google Scholar]

- Gai, M.; Hu, H.A.; Ke, L.N. Decoupling Analysis between Economic Development and Resources and Environmental of the Yangtze River Delta. J. Nat. Resour. 2013, 28, 185–198. (In Chinese) [Google Scholar]

- Wang, L.L.; Ding, X.M.; Wu, X.Y. Blue and grey water footprint of textile industry in China. Water Sci. Technol. 2013, 11, 2485–2490. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Yang, Q.S. Decoupling agricultural water consumption and environmental impact from crop production based on the water footprint method: A case study of the Heilongjiang land reclamation area, China. Ecol. Indic. 2014, 43, 29–35. [Google Scholar]

- Gilmont, M. Water resource decoupling in the MENA through food trade as a mechanism for circumventing national water scarcity. Food Secur. 2015, 7, 1–19. [Google Scholar] [CrossRef]

- Pan, A.; Chen, L. Decoupling and Water Footprint Analysis of the Coordinate Development between Water Utilization and the Economy in Hubei. Resour. Sci. 2014, 36, 328–333. (In Chinese) [Google Scholar]

- National Bureau of Statistics of the People’s Republic of China. China Industry Economy Statistical Yearbook; China Statistics Press: Beijing, China, 2015. (In Chinese)

- Peng, Y. Study on the Upgrading of China’s Textile Industry Competitiveness. Dissertation, Shanghai Academy of Social Sciences, Shanghai, China, 2010. [Google Scholar]

- World Trade Organization. International Trade and Market Access Data. 2001–2014. Available online: https://www.wto.org/english/res_e/statis_e/statis_bis_e.htm?solution=WTO&path=/Dashboards/MAPS&file=Map.wcdf&bookmarkState={%22impl%22:%22client%22,%22params%22:{%22langParam%22:%22en%22}} (accessed on 17 September 2016).

- The State Development Research Center. Total Value of Import and Export of Textiles and Garments. 2002–2015. Available online: http://d.drcnet.com.cn/eDRCnet.common.web/docview.aspx?version=data&docId=4441142&leafId=17357&chnId=4522 (accessed on 17 September 2016). (In Chinese)

- Global Textile Network. Available online: http://www.tnc.com.cn/info/c-013003-d-228148.html (accessed on 15 November 2016). (In Chinese)

- Ministry of Industry and Information Technology Regulations of China. The 13th Five-Year Planning of Textile Industry. 2016. Available online: http://www.miit.gov.cn/n1146295/n1652930/n3757019/c5267251/content.html (accessed on 14 November 2016). (In Chinese) [Google Scholar]

- Boulay, A.M.; Hoekstra, A.Y.; Vionnet, S. Complementarities of water-focused life cycle assessment and water footprint assessment. Environ. Sci. Technol. 2013, 47, 1926–11927. [Google Scholar] [CrossRef] [PubMed]

- Hoekstra, A.Y. Virtual Water Trade: Proceedings of the International Expert Meeting on Virtual Water Trade; Value of Water Research Report Series; IHE Delft: Delft, The Netherlands, 2003; Volume 2, pp. 13–23. [Google Scholar]

- Gu, Y.F.; Xu, J.; Wang, H.T.; Li, F.T. Industrial Water Footprint Assessment: Methodologies in Need of Improvement. Environ. Sci. Technol. 2014, 5, 6531–6532. [Google Scholar] [CrossRef] [PubMed]

- Egan, M. The Water Footprint Assessment Manual. Setting the Global Standard. Soc. Environ. Account. J. 2011, 31, 181–182. [Google Scholar] [CrossRef]

- Ma, J.; Peng, J. Research Process on Water Footprint. Acta Econ. Sin. 2013, 33, 5458–5466. [Google Scholar]

- Manzardo, A.; Mazzi, A.; Loss, A.; Butler, M.; Williamson, A.; Scipioni, A. Lessons learned from the application of different water footprint approaches to compare different food packaging alternatives. J. Clean. Prod. 2015, 112, 4657–4666. [Google Scholar] [CrossRef]

- Hoekstra, A.Y.; Chapagain, A.K.; Aldaya, M.M.; Mekonnen, M.M. The Water Footprint Assessment Manual: Setting the Global Standard; Earthscan: London, UK, 2011. [Google Scholar]

- Kounina, A.; Margni, M.; Bayart, J.-B.; Boulay, A.-M.; Berger, M.; Bulle, C.; Frischknecht, R.; Koehler, A.; Milà i Canals, L.; Motoshita, M.; et al. Review of methods addressing freshwater use in life cycle inventory and impact assessment. Int. J. Life Cycle Assess. 2013, 18, 707–721. [Google Scholar] [CrossRef]

- Ene, S.A.; Teodosiu, C.; Robu, B.; Volf, I. Water footprint assessment in the winemaking industry: A case study for a Romanian medium size production plant. J. Clean. Prod. 2013, 43, 122–135. [Google Scholar] [CrossRef]

- Herath, I.; Green, S.; Singh, R.; Horne, D.; Zijpp, S.V.D.; Clothier, B. Water foot printing of agricultural products: A hydrological assessment for the water footprint of New Zealand’s wines. J. Clean. Prod. 2013, 41, 232–243. [Google Scholar] [CrossRef]

- Gu, Y.F.; Xu, J.; Keller, A.A.; Yuan, D.Z.; Li, Y.; Zhang, B.; Weng, Q.T.; Zhang, N.L.; Ping, D.; Wang, H.T.; et al. Calculation of water footprint of the iron and steel industry: A case study in Eastern China. J. Clean. Prod. 2015, 92, 274–281. [Google Scholar] [CrossRef]

- Hoekstra, A.Y.; Mekonnen, M.M. The water footprint of humanity. Proc. Natl. Acad. Sci. USA 2012, 109, 3232–3237. [Google Scholar] [CrossRef] [PubMed]

- Chapagain, A.K.; Hoekstra, A.Y. The blue, green and grey water footprint of rice from production and consumption perspectives. Ecol. Econ. 2011, 70, 749–758. [Google Scholar] [CrossRef]

- Mekonnen, M.M.; Hoekstra, A.Y. A Global Assessment of the Water Footprint of Farm Animal Products. Ecosystems 2012, 15, 401–415. [Google Scholar] [CrossRef]

- Mekonnen, M.M.; Hoekstra, A.Y.; Becht, R. Mitigating the Water Footprint of Export Cut Flowers from the Lake Naivasha Basin, Kenya. Water Resour. Manag. 2012, 26, 3725–3742. [Google Scholar] [CrossRef]

- Wang, X.M.; Huang, K.; Yang, S.S. Temporal Variability and Influencing Factors of Sectorial Water Footprint in China. J. Nat. Resour. 2014, 29, 2114–2126. [Google Scholar]

- Mekonnen, M.M.; Hoekstra, A.Y. A global and high-resolution assessment of the green, blue and grey water footprint of wheat. Hydrol. Earth Syst. Sci. 2010, 14, 1259–1276. [Google Scholar] [CrossRef] [Green Version]

- Tapio, P. Towards a theory of decoupling: Degrees of decoupling in the EU and case of road traffic in Finland between 1970 and 2001. Trans. Policy 2005, 12, 137–151. [Google Scholar] [CrossRef]

- Ang, B.W. Decomposition analysis for policy making in energy: Which is the preferred method. Energy Policy 2004, 32, 1131–1139. [Google Scholar] [CrossRef]

- Sheinbaum-Pardo, C.; Ozawa, L.; Castillo, D. Using logarithmic mean Divisia index to analyze changes in energy use and carbon dioxide emissions in Mexico’s iron and steel industry. Energy Econ. 2010, 32, 1337–1344. [Google Scholar] [CrossRef]

- Sheinbaum-Pardo, C.; Mora-Pérez, S.; Robles-Morales, G. Decomposition of energy consumption and CO2 emissions in Mexican manufacturing industries: Trends between 1990 and 2008. Energy Sustain. Dev. 2012, 16, 57–67. [Google Scholar] [CrossRef]

- Ang, B.W.; Liu, F.L. A new energy decomposition method: Perfect in decomposition and consistent in aggregation. Energy 2001, 26, 537–548. [Google Scholar] [CrossRef]

- Ang, B.W.; Zhang, F.Q.; Choi, K.H. Factorizing changes in energy and environmental indicators through decomposition. Energy 1998, 23, 489–495. [Google Scholar] [CrossRef]

- Pfister, S.; Ridoutt, B.G. Water Footprint: Pitfalls on common ground. Environ. Sci. Technol. 2014, 48, 4. [Google Scholar] [CrossRef] [PubMed]

- National Bureau of Statistics of the People’s Republic of China. China’s National Economic Industry Classification Standard (GB/T4754-2011). 2011. Available online: http://www.mca.gov.cn/article/sj/tjbz/b/201507/20150700854769.shtml (accessed on 29 October 2016). (In Chinese) [Google Scholar]

- Ministry of Environmental Protection of China. Water Pollutant Discharge Standard (GB13458-2013). 2013. Available online: http://kjs.mep.gov.cn/hjbhbz/bzwb/shjbh/swrwpfbz/201303/t20130325_249814.htm (accessed on 29 October 2016). (In Chinese) [Google Scholar]

- Standing Committee of the National People’s Congress of the People’s Republic of China. Water Law of the People’s Republic of China. 2002. Available online: http://www.gov.cn/ziliao/flfg/2005-08/31/content_27875.htm (accessed on 29 October 2016). (In Chinese) [Google Scholar]

- Standing Committee of the National People’s Congress of the People’s Republic of China. Water Pollution Prevention and Control Law of the People’s Republic of China. 2008. Available online: http://www.gov.cn/flfg/2008-02/28/content_905050.htm (accessed on 8 September 2016). (In Chinese) [Google Scholar]

- Ministry of Industry and Information Technology of China. Ministry of Industry and Information Technology (MIIT)’s Opinions on Further Strengthening Industrial Water Saving Work. 2010. Available online: http://www.miit.gov.cn/n1146295/n1652858/n1652930/n3757016/c3760234/content.html (accessed on 16 November 2016). (In Chinese) [Google Scholar]

- The State Council of the People’s Republic of China. State Council on the Implementation of the Most Stringent Water Management System. 2012. Available online: http://www.gov.cn/zwgk/2012-02/16/content_2067664.htm (accessed on 8 September 2016). (In Chinese) [Google Scholar]

- Ministry of Environmental Protection of China. Discharge Standard of Water Pollutant for Dyeing and Finishing of Textile Industry (GB 4287-2012). 2012. Available online: http://kjs.mep.gov.cn/hjbhbz/bzwb/shjbh/swrwpfbz/201211/t20121109_241788.htm (accessed on 8 September 2016). (In Chinese) [Google Scholar]

| Status | Elastic Values | |

|---|---|---|

| Negative decoupling | Expansive negative decoupling | ∆VOL > 0, ∆G > 0, D ∈ (1.2, +∞) |

| Strong negative decoupling | ∆VOL > 0, ∆G < 0, D ∈ (−∞, 0) | |

| Weak negative decoupling | ∆VOL < 0, ∆G < 0, D ∈ [0, 0.8) | |

| Decoupling | Weak decoupling | ∆VOL > 0, ∆G > 0, D ∈ [0, 0.8) |

| Strong decoupling | ∆VOL < 0, ∆G > 0, D ∈ (−∞, 0) | |

| Recessive decoupling | ∆VOL < 0, ∆G < 0, D ∈ (1.2, +∞) | |

| Coupling | Expansive coupling | ∆VOL > 0, ∆G > 0, D ∈ [0.8, 1.2] |

| Recessive coupling | ∆VOL < 0, ∆G < 0, D ∈ [0.8, 1.2] | |

| Sub-Sectors | The Name in China’s Statistical Yearbook | |

|---|---|---|

| Textile Industry | Textile industry | Textile industry |

| Garment Industry | Clothing and other fiber products manufacturing; textile and garment, shoes, hats manufacturing; textile and garment, apparel industry | |

| Chemical fiber industry | Chemical fiber industry |

| Limits of Pollutant Species | Limits |

|---|---|

| pH | 6–9 |

| CODCr | 100 |

| BOD5 | 25 |

| Suspended matter | 60 |

| Chroma | 70 |

| Aniline | 1.0 |

| Total nitrogen | 20 |

| Total phosphorus | 1.0 |

| ClO2 | 0.5 |

| Organic halogen | 15 |

| Sulfide | 1.0 |

| Ammonia nitrogen | 12 |

| Hexavalent chromium | 0.5 |

| Year | %∆G | %∆WF | DG-WF | Degrees of Decoupling/Coupling |

|---|---|---|---|---|

| 2002 | 7.15% | 6.29% | 0.88 | Expansive coupling |

| 2003 | 7.66% | −8.61% | −1.12 | Strong decoupling |

| 2004 | 18.67% | 16.93% | 0.91 | Expansive coupling |

| 2005 | 22.86% | 11.18% | 0.49 | Weak decoupling |

| 2006 | 26.64% | −0.08% | −0.003 | Strong decoupling |

| 2007 | 18.85% | 7.79% | 0.41 | Weak decoupling |

| 2008 | 40.73% | −3.09% | −0.08 | Strong decoupling |

| 2009 | 6.38% | 1.09% | 0.17 | Weak decoupling |

| 2010 | 12.40% | 0.68% | 0.05 | Weak decoupling |

| 2011 | 25.39% | −9.71% | −0.38 | Strong decoupling |

| 2012 | −3.09% | −0.35% | 0.11 | Weak negative decoupling |

| 2013 | 4.84% | −2.58% | −0.53 | Strong decoupling |

| 2014 | 0.75% | 3.96% | 5.27 | Expansive negative decoupling |

| Year | ∆WFG (Mt/a) | ∆WFSi (Mt/a) | ∆WFIi (Mt/a) |

|---|---|---|---|

| 2002 | 734.88 | 351.72 | −437.15 |

| 2003 | 773.93 | −485.78 | −1233.45 |

| 2004 | 1856.60 | −67.75 | −90.99 |

| 2005 | 2546.43 | 5.16 | −1239.96 |

| 2006 | 3077.94 | −419.49 | −2668.28 |

| 2007 | 2336.59 | 1158.26 | −2479.61 |

| 2008 | 4724.20 | −1076.68 | −4081.96 |

| 2009 | 845.91 | −657.46 | −40.77 |

| 2010 | 1613.06 | 1053.40 | −2573.08 |

| 2011 | 2976.76 | 2.10 | −4323.21 |

| 2012 | −391.61 | −126.59 | 475.01 |

| 2013 | 581.83 | −50.48 | −852.59 |

| 2014 | 92.63 | 273.81 | 113.95 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Lu, L.; Tan, Y.; Wang, L.; Shen, M. Decoupling Water Consumption and Environmental Impact on Textile Industry by Using Water Footprint Method: A Case Study in China. Water 2017, 9, 124. https://doi.org/10.3390/w9020124

Li Y, Lu L, Tan Y, Wang L, Shen M. Decoupling Water Consumption and Environmental Impact on Textile Industry by Using Water Footprint Method: A Case Study in China. Water. 2017; 9(2):124. https://doi.org/10.3390/w9020124

Chicago/Turabian StyleLi, Yi, Linyi Lu, Yingxi Tan, Laili Wang, and Manhong Shen. 2017. "Decoupling Water Consumption and Environmental Impact on Textile Industry by Using Water Footprint Method: A Case Study in China" Water 9, no. 2: 124. https://doi.org/10.3390/w9020124