Verification of Calculation Method Using Monte Carlo Method for Water Supply Demands of Office Building

Abstract

:1. Introduction

2. The Calculation Methods for Water Supply Demands

2.1. Conventional Water Load Calculation Methods

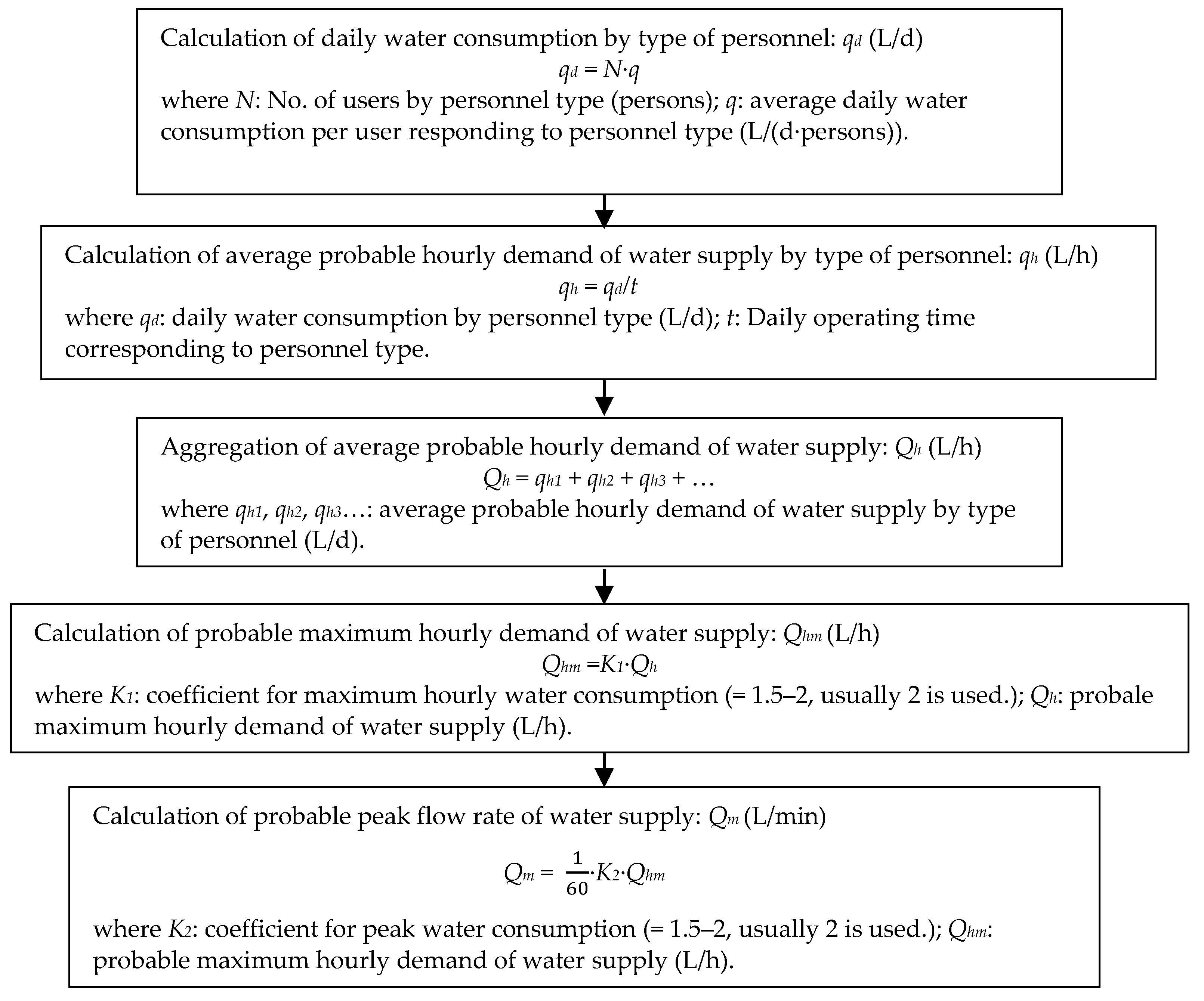

2.1.1. Facilities Design Criteria of Ministry of Land, Infrastructure, Transport and Tourism (MLIT)

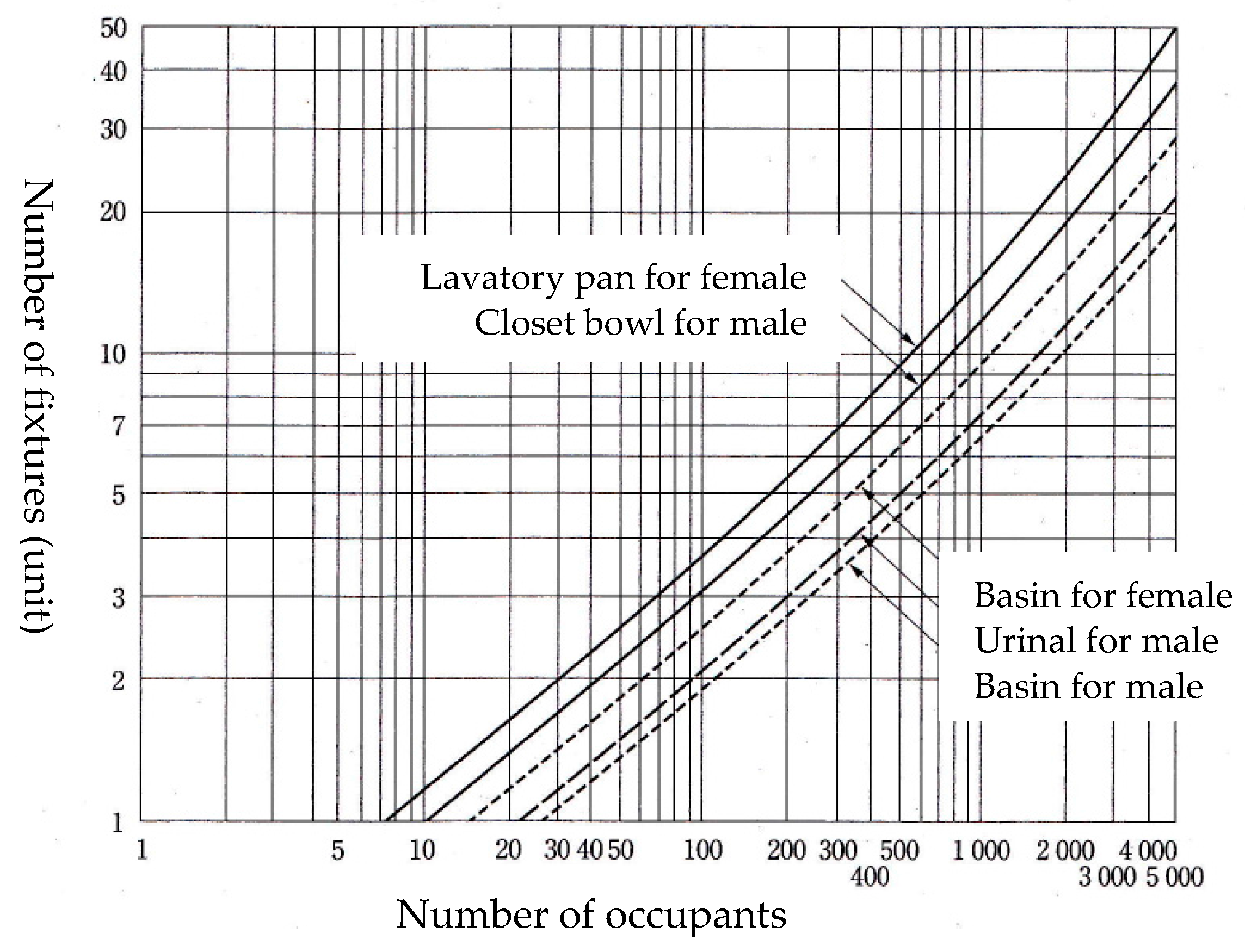

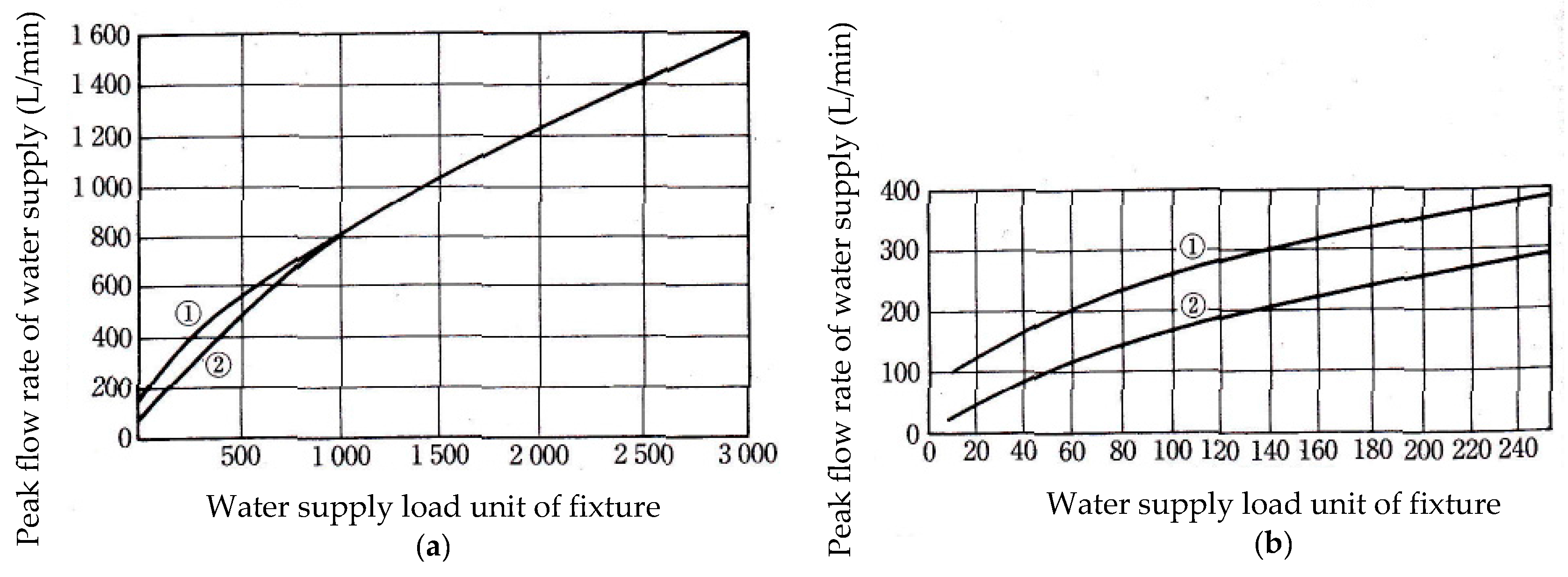

2.1.2. SHASE-S206

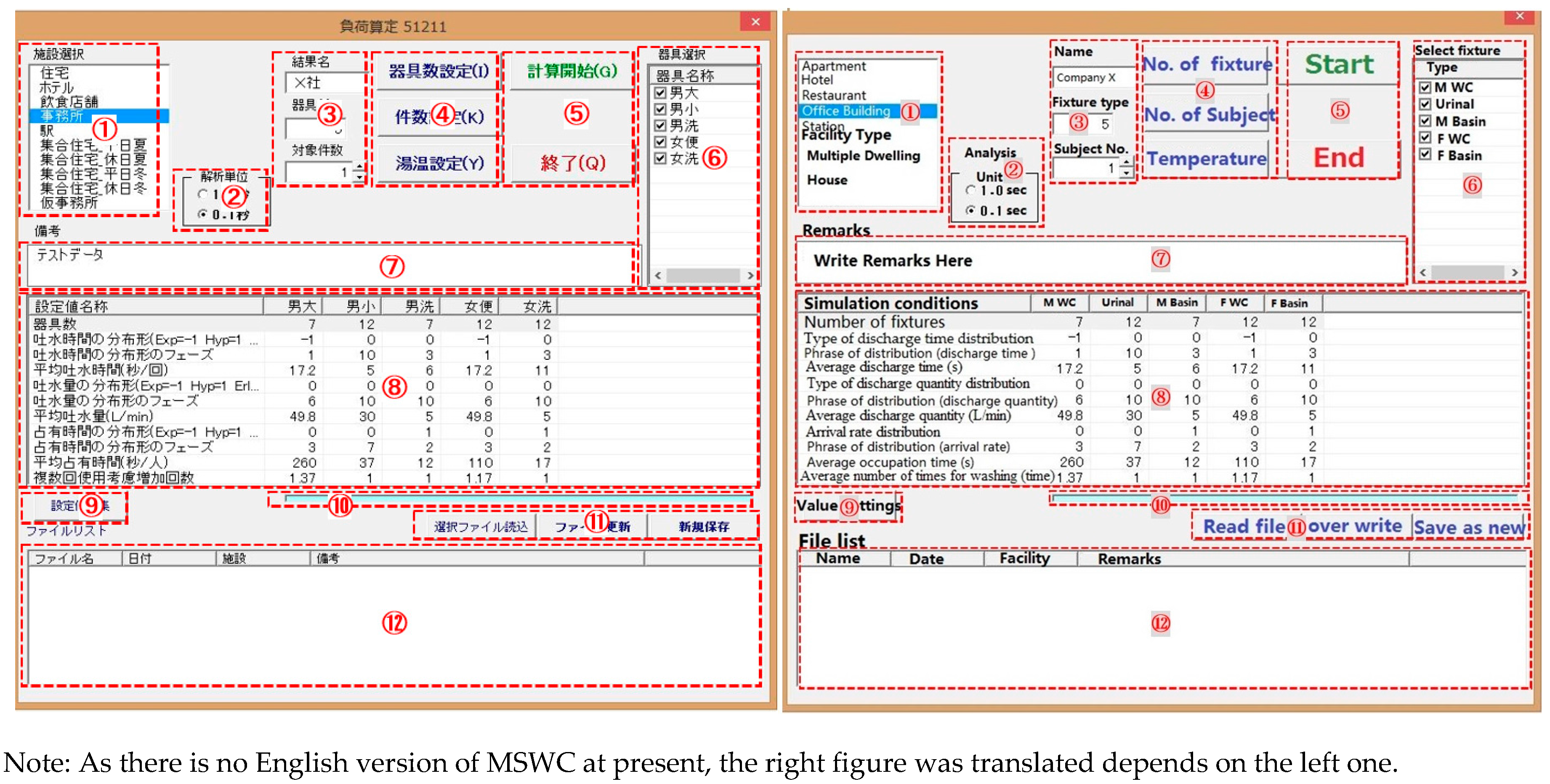

2.2. Water Load Calculation Method Using Murakawa’s Simulation for Water Consumption (MSWC)

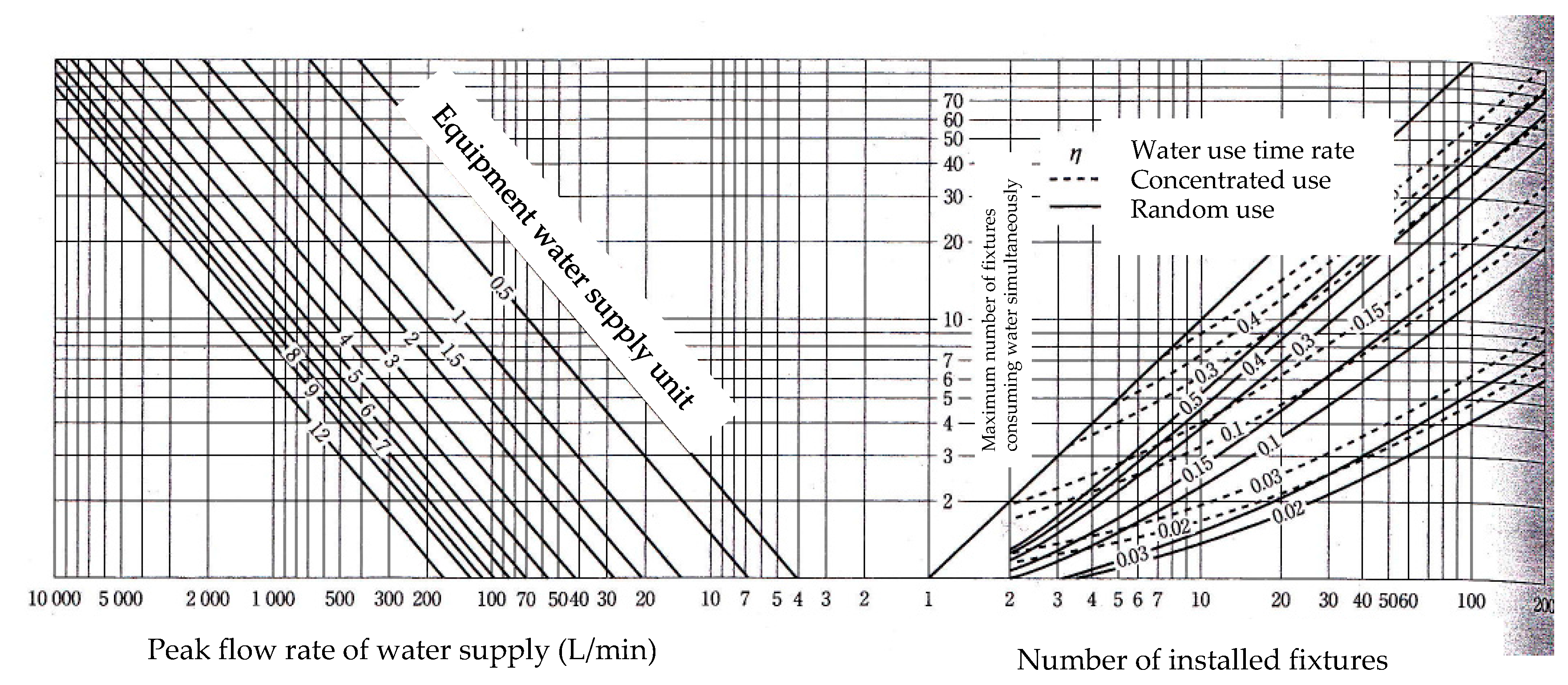

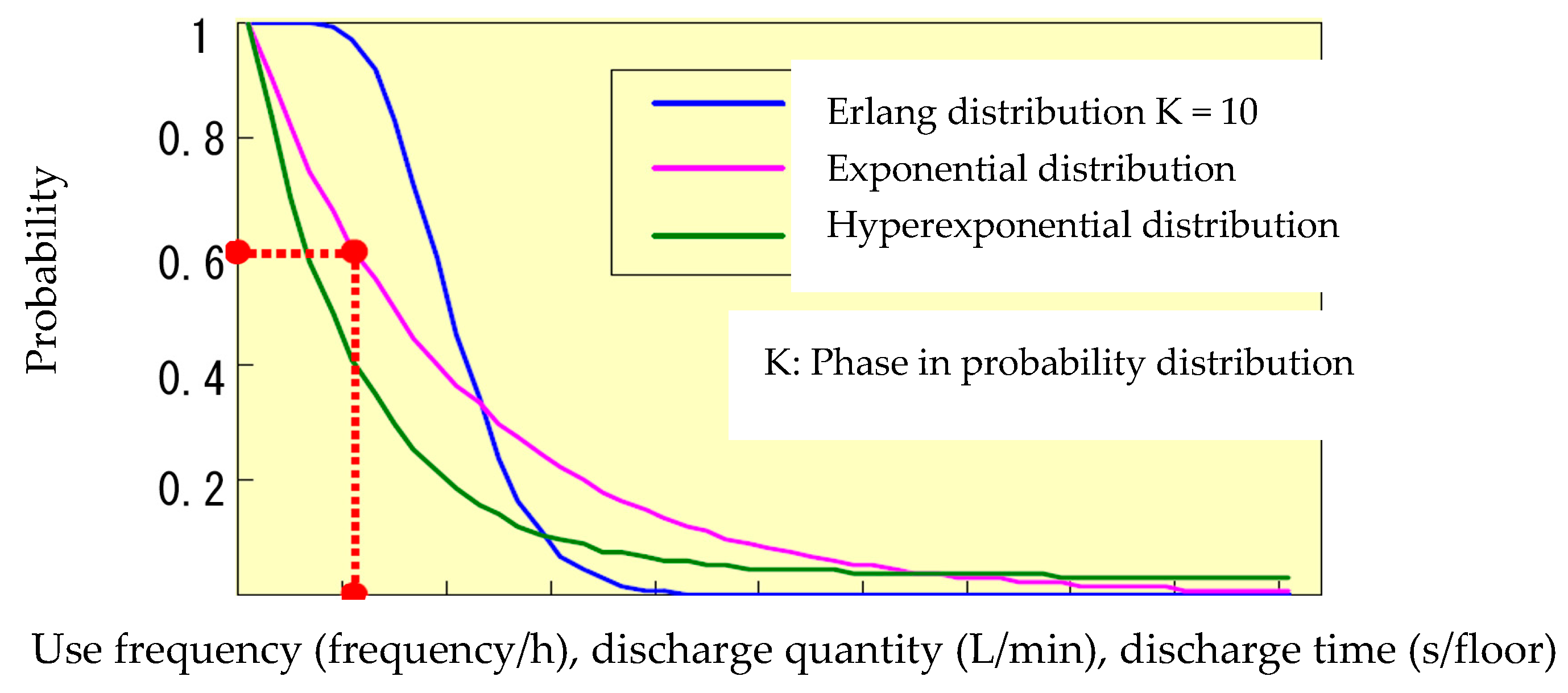

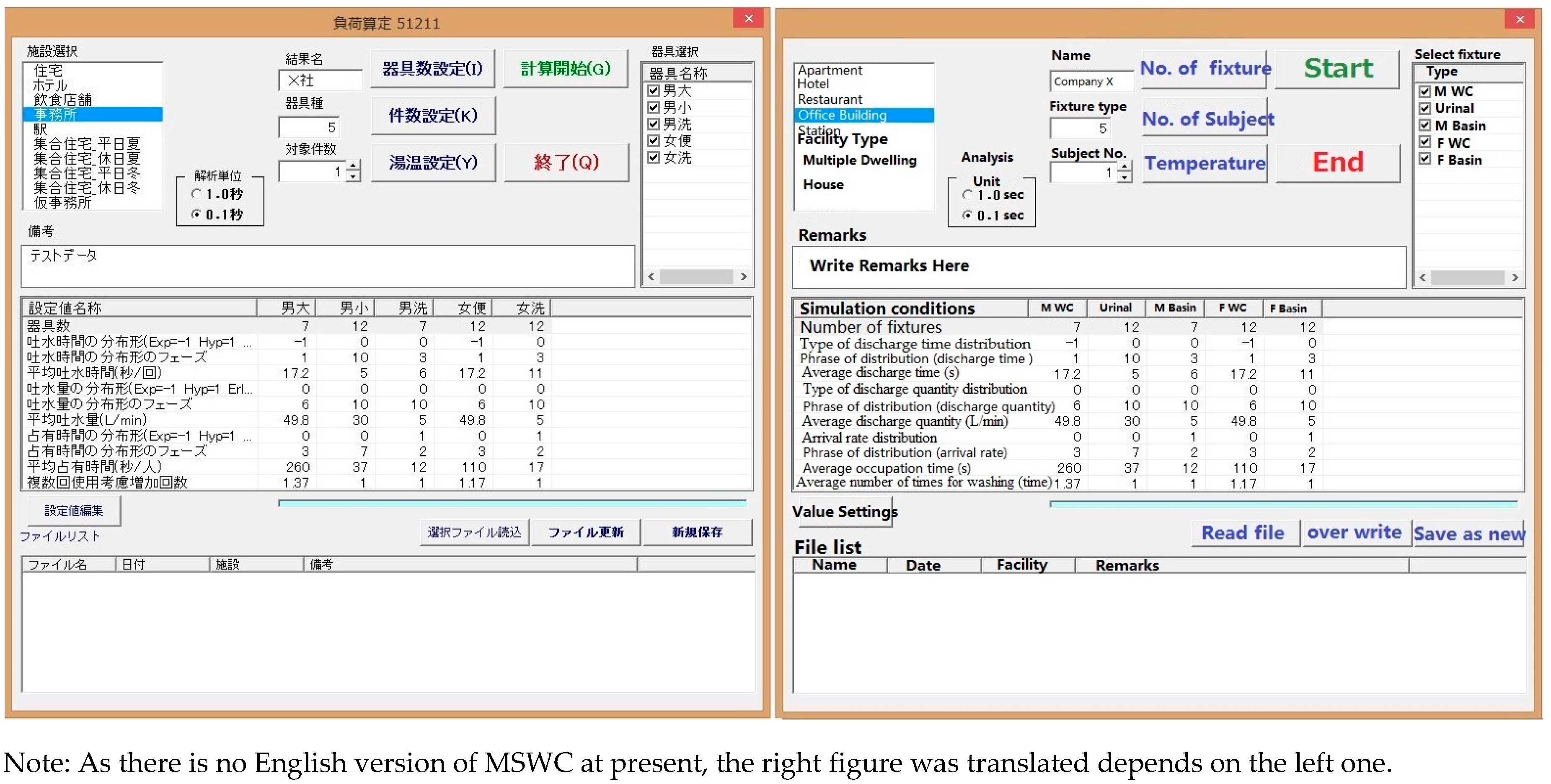

2.2.1. Outline of MSWC

2.2.2. Calculation Conditions of MSWC

3. Measurement

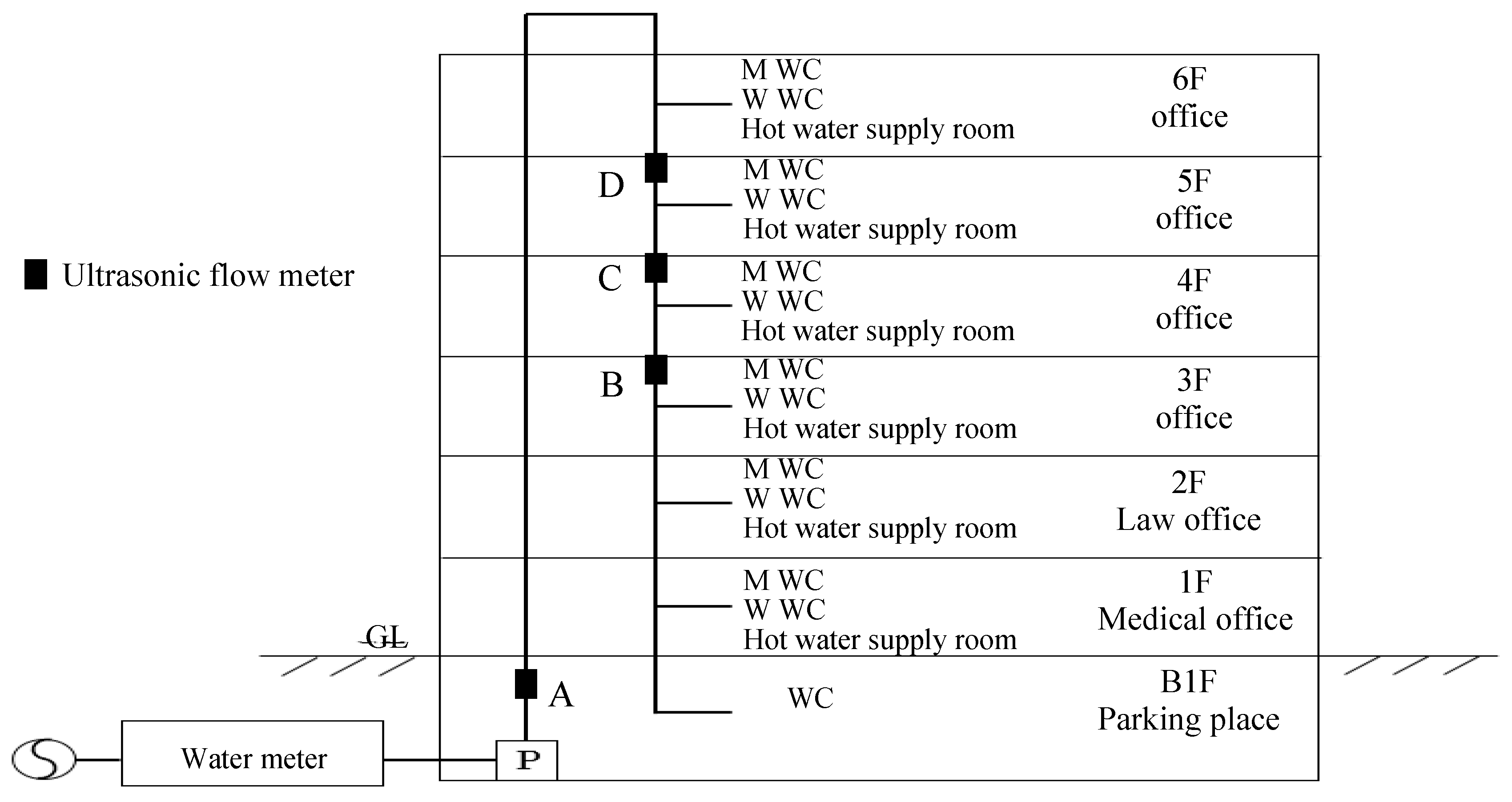

3.1. Measurement of the Water Consumption

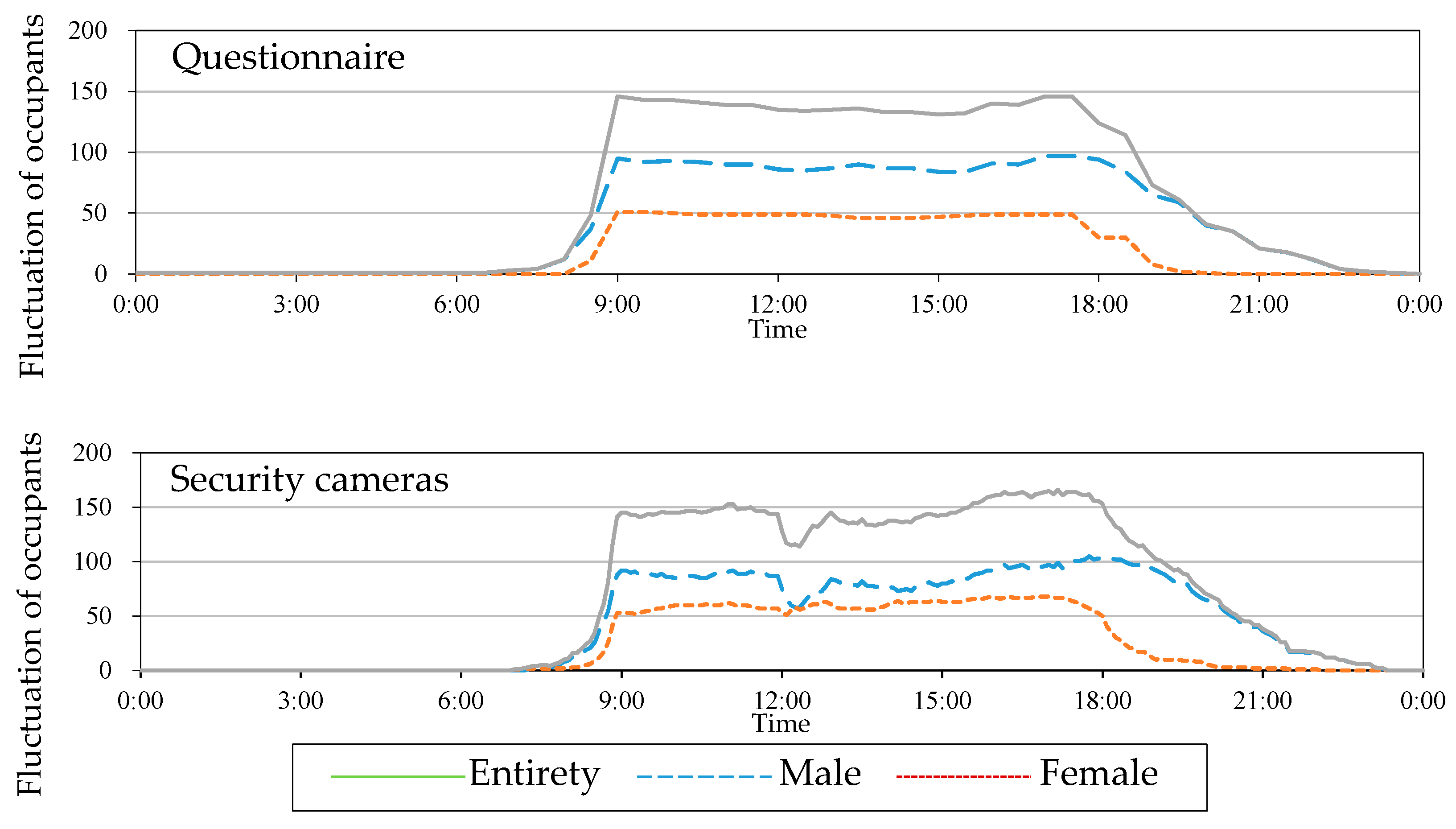

3.2. The Number of Occupants

3.3. Water Consumption Measurement

4. The Calculation of Water Load

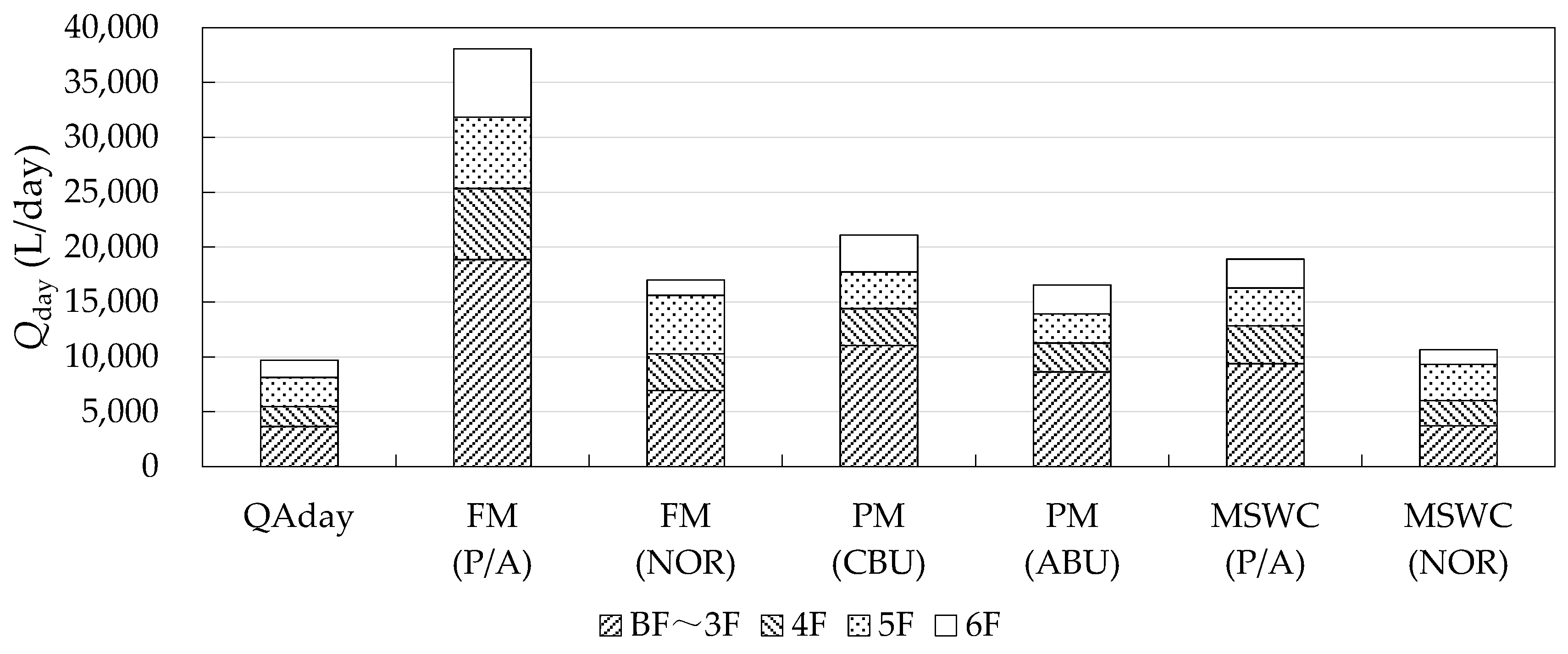

4.1. Conventional Water Load Calculation Method

4.2. Water Load Calculation Based on MSWC

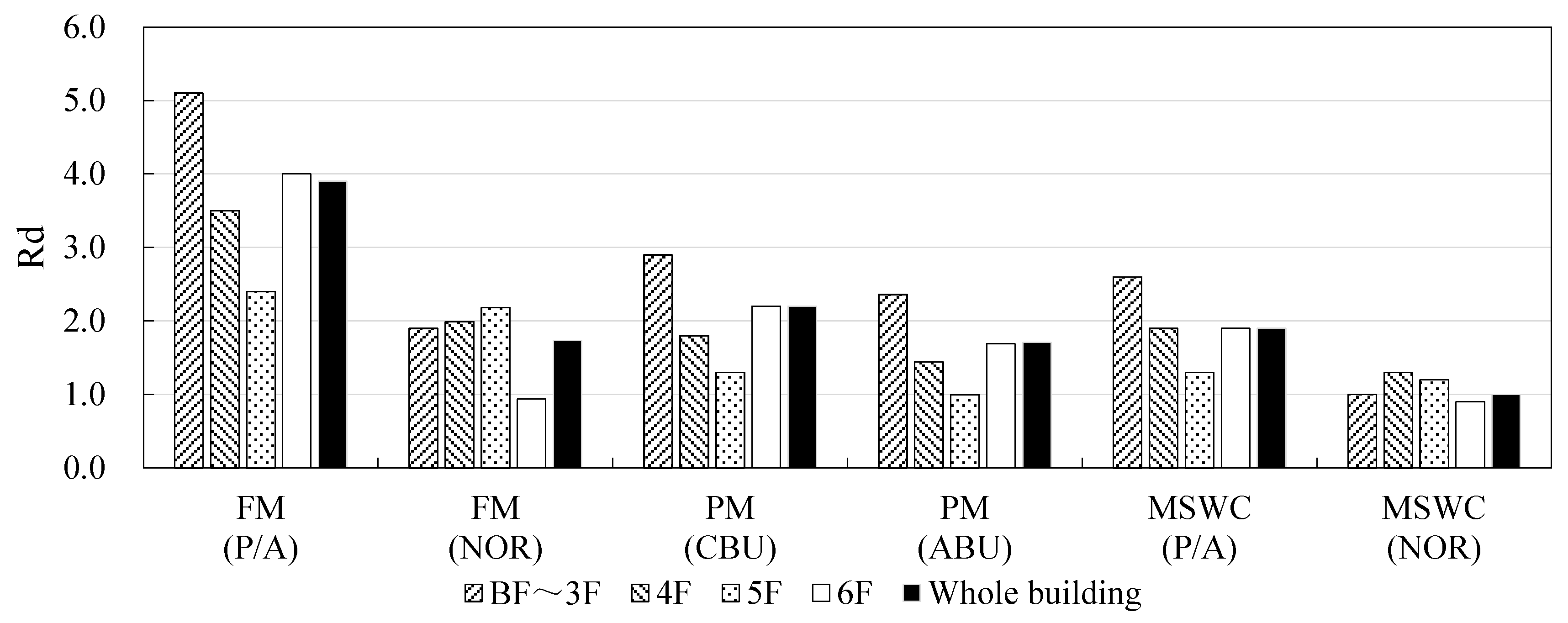

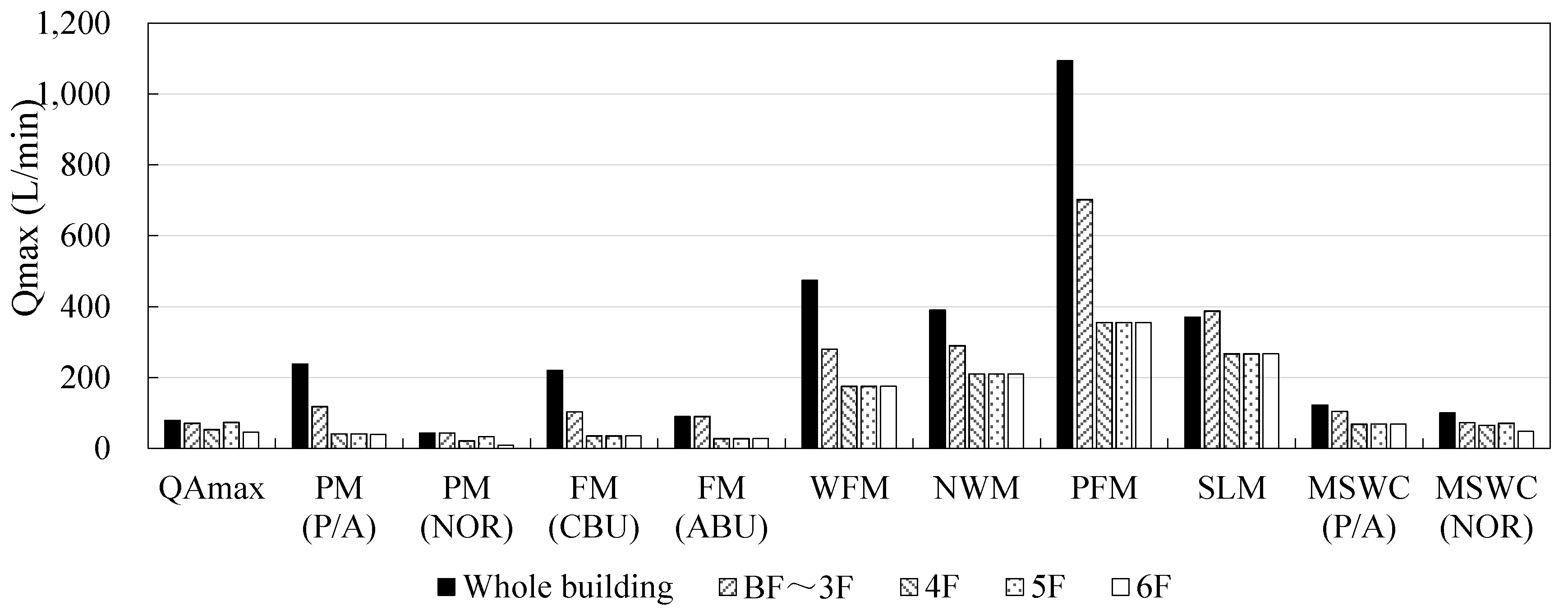

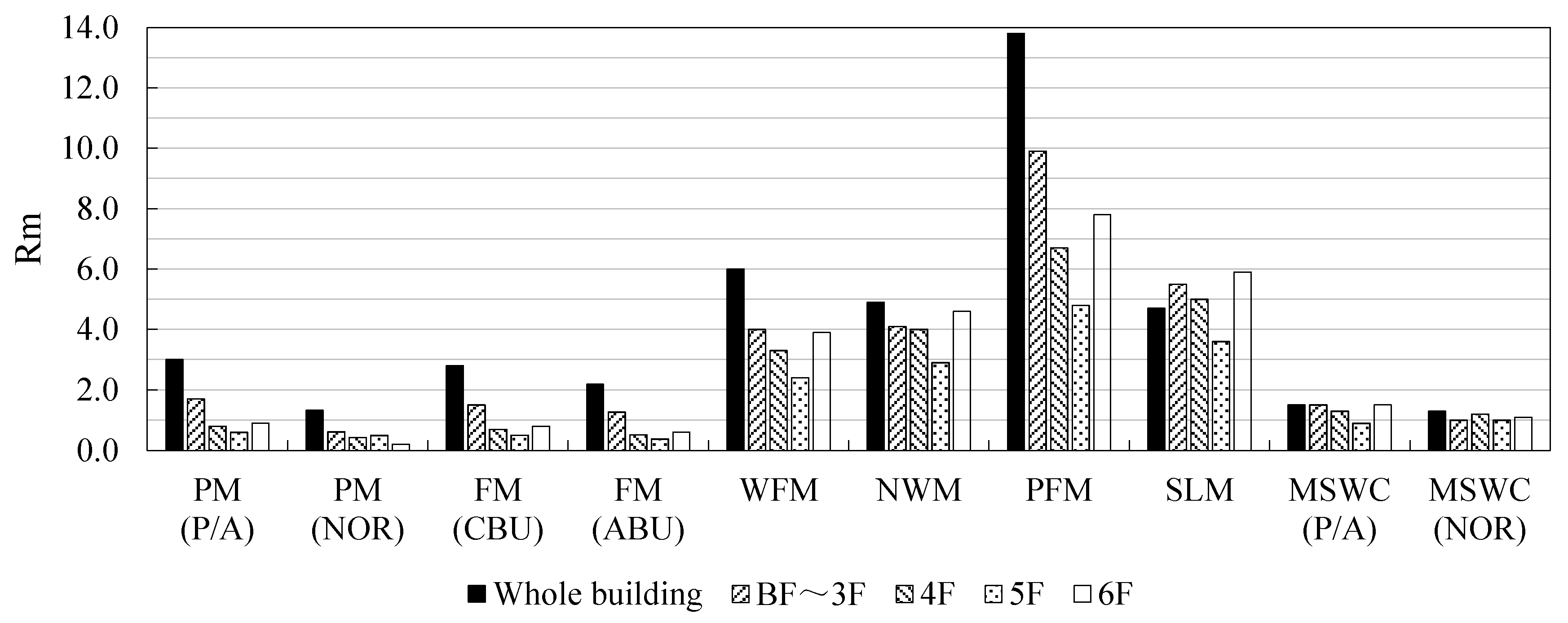

5. Comparison of Each Water Load Calculation Method

6. Conclusions

Author Contributions

Conflicts of Interest

References

- Ministry of Land, Infrastructure, Transport and Tourism. Facilities Design Criteria; MLIT: Tokyo, Japan, 2006; pp. 447–454.

- The Society of Heating, Air-Conditioning and Sanitary Engineers of Japan; SHASE-S206-2009; SHASE: Tokyo, Japan, 2009.

- Murakawa, S. Study on the method for calculating water consumption and water uses in multi-story flats. In Proceedings of the 13th International Symposium of CIB W062, Tokyo, Japan, 9–10 April 1985; pp. 1–19. [Google Scholar]

- Wu, G.Z.; Sakaue, K.; Kojima, K.; Fujimura, K.; Murakawa, S.; Hayakawa, K. Examinations on Water Supply Load Calculation Methods of Office Building: Comparison between Conventional Design Methods and the Simulation Methods. In Proceedings of the 39th International Symposium of CIB W062, Nagano, Japan, 17–19 September 2013; pp. 529–540. [Google Scholar]

- Murakawa, S. Investigation of the Method of calculation of Water Consumption in the Designing of Building Equipments: Part 1 The Theory of Calculation and Analyses of the Use of Water in Multi-storey Flats. Transact. Archit. Inst. Jpn. 1976, 246, 71–80. (In Japanese) [Google Scholar]

- Murakawa, S. Investigation of the Method of calculation of Water Consumption in the Designing of Building Equipments: Part 4 Calculation of Water Load and Analysis of Simultaneous Uses. Transact. Archit. Inst. Jpn. 1976, 253, 103–112. (In Japanese) [Google Scholar]

- Holmberg, S. Computer dimensioning of water supply systems with use of continuous field measurements as input data. In Proceedings of the 15th International Symposium of CIB W062, Sao Paulo, Brazil, 14–18 September 1987. [Google Scholar]

- Yamane, Y.; Murakawa, S.; Takata, H.; Sakamoto, K. Analysis on The Water Usage in Office Buildings: A study on the calculating method for cold and hot water supply demands based on the analysis of water usage in the time series (Part 2). J. Environ. Eng. Trans. AIJ 2005, 70, 65–72. (In Japanese) [Google Scholar] [CrossRef]

- Blokker, E.J.M.; Pieter-Quirijns, E.J.; Vreeburg, J.H.G.; van Dijk, J.C. Simulating nonresidential water demand with a stochastic end-use model. J. Water Res. Plan. Manag. 2011, 137, 511–520. [Google Scholar] [CrossRef]

- Wong, L.T.; Mui, K.W.; Zhou, Y. Energy Efficiency Evaluation for the Water Supply Systems in Tall Buildings. Available online: http://journals.sagepub.com/doi/abs/10.1177/0143624417699857?journalCode=bsea& (accessed on 23 May 2017).

- Murakawa, S.; Takata, H. Development of the calculating method for cold and hot water consumption based on the fixture usage in the time series through a day: A case study of apartment houses. In Proceedings of the International Symposium of CIB/W62 on Water Supply and Drainage for Buildings, Iasi, Romania, 18–19 September 2002; pp. 1–13. [Google Scholar]

- Murakawa, S.; Hiroshi, T. Development of the calculating method for the loads of clod and hot water consumption in the apartment houses. In Proceedings of the International Symposium of CIB/W62 on Water Supply and Drainage for Buildings, Ankara, Turkey, 11–12 September 2003; pp. 281–295. [Google Scholar]

- Takahashi, D.; Murakawa, S.; Nishina, D.; Takada, H. Development of the calculating method of cold and hot water consumption based on the fixture usage in the time series through a day (Part 4) Analysis on the loads of water supply demands in the restaurants of a complex commercial building. In Summaries of Technical Papers of Annual Meeting; Architectural Institute of Japan: Tokyo, Japan, 2004; Volume D-1. [Google Scholar]

- Takata, H.; Murakawa, S.; Nishina, D.; Tanaka, A. An Analysis on the Loads of Hot Water Consumption of Guest Rooms in a Hotel. In Proceedings of the International Symposium of CIB/W62 on Water Supply and Drainage for Buildings, Brussels, Belgium, 14–16 September 2005; pp. 1–9. [Google Scholar]

- Wu, G.Z.; Sakaue, K.; Hayakawa, K.; Murakawa, S. Comparison between the traditional methods and the simulation method in water supply load calculation methods for office building. In Proceedings of the 40th International Symposium of CIB W062, Sao Paulo, Brazil, 8–10 September 2014; pp. 35–44. [Google Scholar]

- Wu, G.Z.; Sakaue, K.; Hayakawa, K.; Murakawa, S.; Inada, Y. Verification of calculating method using the Monte Carlo method for water supply demands: The water consumption of mixed-use building for rent. In Proceedings of the 41th International Symposium of CIB W062, Beijing, China, 17–20 August 2015; pp. 306–318. [Google Scholar]

- Sakamoto, K.; Murakawa, S.; Takada, H.; Toyosada, K.; Yoshikawa, H. Development of the calculating method for the loads of water consumption in office buildings: Dynamic estimation for the loads of water demands for design of water supply system. Archit. Inst. Jpn. 2016, 39, 475–478. (In Japanese) [Google Scholar]

- Kurisu, S.; Sakaue, K.; Murakawa, S.; Wu, G.Z.; Fujimura, K. Verification of calculation method using Monte Carlo method for water supply demands: The water consumption of an office building. In Proceedings of the 42th International Symposium of CIB W062, Kosice, Slovakia, 29 August–1 September 2016; pp. 306–318. [Google Scholar]

- Okada, K. Some Problems on the Probability of Simultaneous Usage of Building Equipments (Scientefic Basis of Planning Building). Archit. Inst. Jpn. 1957, 57, 65–68. (In Japanese) [Google Scholar]

- Kanasaki, T.; Murakawa, S. Fundamental Study on the Appropriate Number of scale of Plumbing Fixture: Part 5 The Number of Appropriate Fixtures at Office Building. Archit. Inst. Jpn. 1983, 151. (In Japanese) [Google Scholar]

- Murakawa, S.; Yamate, T. Investigation of Calculating Method for Flow Rates Design and Water Uses in Multi-storey Flats. Soc. Heat. Air-Cond. Sanit. Eng. Jpn. 1982, 20, 11–27. [Google Scholar]

- Murakawa, S. New Design Method of plumbing and drainage systems of Revenue House. Jpn. Soc. Plumb. Eng. 1990, 7, 23–26. (In Japanese) [Google Scholar]

- Hunter, R.B. Building Materials and Structures Report No.65; U.S. Department of Commerce: Washington, DC, USA, 1940.

- Takada, H. Analysis on the Uses and Cold-Hot Water Consumption of Toilet and Hot-Water Service Room in the Office Building: Part 1 Using frequency of sanitary fixtures. Archit. Inst. Jpn. 2003, 26, 533–536. (In Japanese) [Google Scholar]

- Takada, H.; Murakawa, S.; Nishina, D.; Sakamoto, K.; Yamaoka, M.; Yamane, Y. A Study on the Cold and Hot Water Consumption based on the Time Series Analysis: Part 2 The Usage of Fixtures in the Office Building’s Toilets. In Summaries of Technical Papers of Annual Meeting; Architectural Institute of Japan: Tokyo, Japan, 2003; pp. 455–456. (In Japanese) [Google Scholar]

- Yamane, Y.; Murakawa, S.; Nishina, D.; Sakamoto, K.; Yamaoka, M.; Takada, H. A Study on the Cold and Hot Water Consumption based on the Time Series Analysis: Part 3 Analysis on the Cold-Hot Water Demands in the Office Building’s Toilets. In Summaries of Technical Papers of Annual Meeting; Architectural Institute of Japan: Tokyo, Japan, 2003; pp. 457–458. (In Japanese) [Google Scholar]

- Takada, H.; Murakawa, S.; Nishina, D.; Yamane, Y. A Study on the Cold and Hot Water Consumption based on the Time Series Analysis: Part 6 Cold Water Demands in the Office Building’s Toilets. In Summaries of Technical Papers of Annual Meeting; Architectural Institute of Japan: Tokyo, Japan, 2004; pp. 559–560. (In Japanese) [Google Scholar]

- Sakamoto, K.; Murakawa, S.; Koshikawa, Y.; Takada, H.; Yamane, Y. Development of the Calculating Method of Cold and Hot Water Consumption based on the Fixture Usage in the Time Series through a Day: Part 5 Analysis on the Loads of Water Supply Demands in the Office Buildings. In Summaries of Technical Papers of Annual Meeting; Architectural Institute of Japan: Tokyo, Japan, 2005; pp. 416–451. (In Japanese) [Google Scholar]

- Yamane, Y.; Murakawa, S.; Nishina, D.; Takada, H.; Nagae, M. Analysis on the Uses and Cold-Hot Water Consumption of Toilet and Hot-Water Service Room in the Office Building: Part 3 The usage in hot-water service room and basin. Archit. Inst. Jpn. 2004, 27, 533–536. (In Japanese) [Google Scholar]

- Takada, H.; Murakawa, S.; Yamane, Y.; Sakamoto, K. Analysis on The Water Usage in Office Buildings: A study on the calculating method for cold and hot water supply demands based on the analysis of water usage in the time series (Part 3). J. Environ. Eng. Trans. AIJ 2005, 71, 51–58. (In Japanese) [Google Scholar] [CrossRef]

- Koshikawa, Y. Analysis of the Adult’s Uses and Consciousness of Lavatories. Soc. Heat. Air-Cond. Sanit. Eng. Jpn. 1997, 65, 41–52. (In Japanese) [Google Scholar]

- Wu, G.Z.; Sakaue, K.; Fujimura, K.; Murakawa, K.; Kojima, K.; Hayakawa, K. Examinations on Water Supply Load Calculation Methods of Office Building: Comparison between Traditional Design Methods and the Simulation Tool. Tech. Pap. Annu. Meet. Soc. Heat. Air-Cond. Sanit. Eng. Jpn. 2013, 1, 1–4. (In Japanese) [Google Scholar]

| Calculation Method | Abbr. | Possible Calculated Water Supply Demand | |

|---|---|---|---|

| Facilities design criteria of MLIT [1] | Calculation method based on personnel | PM | Qday |

| Calculation method based on sanitary fixture | FM | Qmax | |

| SHASE-S 206 [2] | Calculation method based on Water use time rate and Fixture unit for water supply | WFM | Qmax |

| Method based on newer water supply demand unit | NWM | ||

| prediction of fixture usage | PFM | ||

| Method based on water supply load unit of fixture | SLM | ||

| Intended Use | User Type | Calculation Base for A User *1 | Daily Water Consumption Per Person (L/d·Person) | Average Daily Consumption Time (h) | Remarks |

| Office | Worker | 0.1–0.2 person/m2 (Depending of office space) *2 | 80–100 | 8 | Water consumption in workers‘ cafeteria is calculated separately. 20–30 L/(person·meal) |

| Fixture | Faucet | Flow Rate of Each Plumbing Fixture and Faucet | Remarks | Water Supply Load Unit of Fixture * | |||

|---|---|---|---|---|---|---|---|

| Water Consumption Per Use q (L) | Usage Frequency Per Hour (Frequency) | Peak Flow Rate qp (L/min) | Public Use | Private Use | |||

| Western style toilet | Flush valve | 10–10.5 | 6–12 | 80–150 | 70 | 10 | 6 |

| Flushing water tank | 8–10.5 | 6–12 | 10 | - | 5 | 3 | |

| Urinal | - | 2–4 | 12–20 | 20–25 | 70 | 5 | - |

| Basin | - | 10 | 6–12 | 10 | - | 2 | 1 |

| Method | Application | Characteristics in Use | Concept and Flow of Calculation | Source |

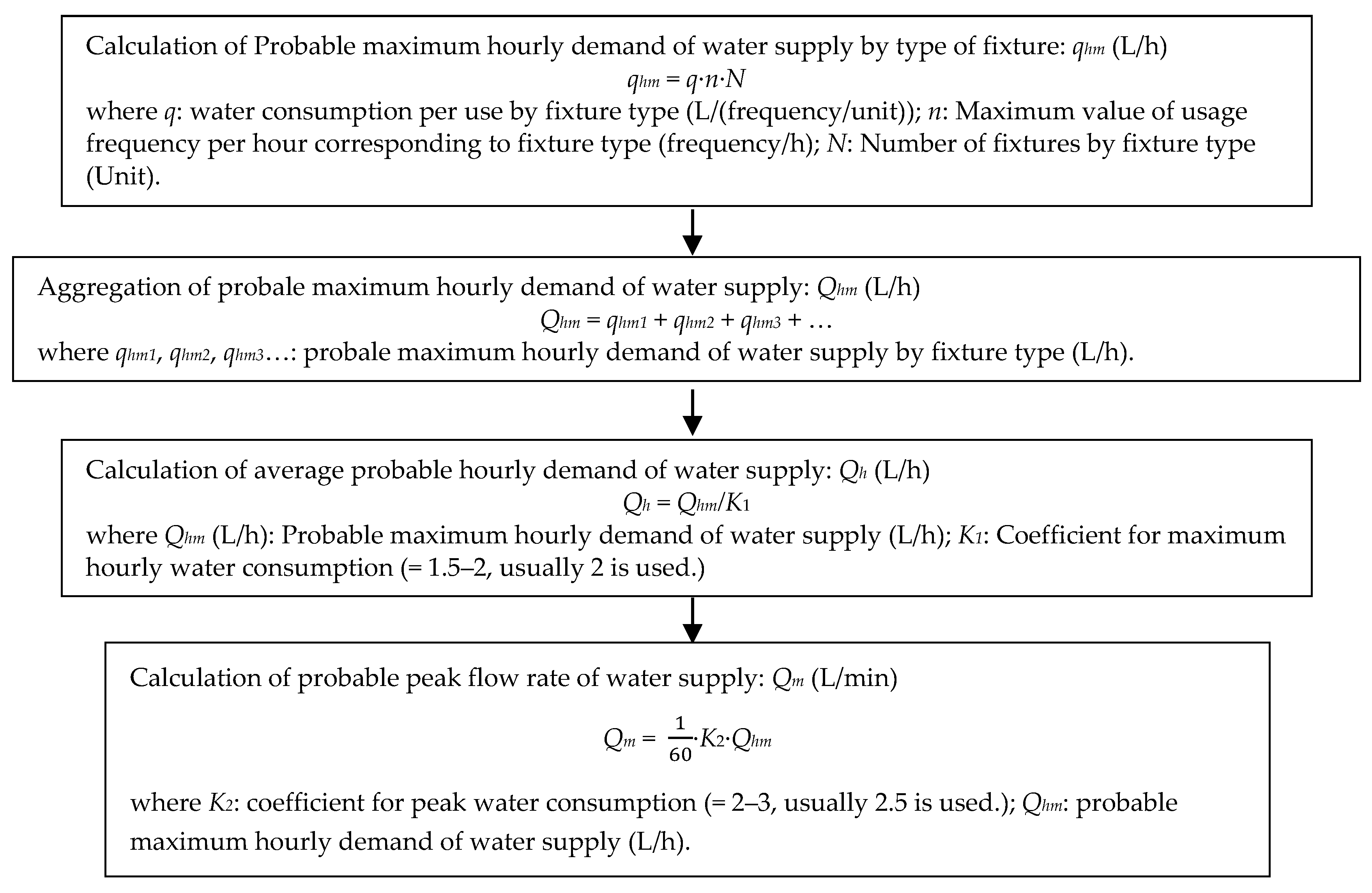

| Method 1: Calculation method based on water use time rate and fixture unit for water supply | Applicable for various purposes | [Advantages] - Data has been accumulated over many years in this calculation method, which has been, as the result, used for a long time. - Architects can have many options for their judgement and can calculate pipe diameters based on actual situation. - Fixed options are established for the case where a number of users is not sufficient for a number of fixtures. [Disadvantages] - The calculation method requires complex calculation. - Many provision values are used for calculation of water use time rate η. - When combining a different type of fixtures, it is required to consider to halve the addition coefficient. - Adjustment data can be used only for closet bowls, urinals and basins, and adjustment methods for other fixtures are unclear. | (1) Reduction in number of installed fixtures → Maximum number of fixtures used simultaneously Theoretical formula: (2) Maximum number of fixtures used simultaneously and water supply unit of each fixture → peak flow rate of water supply (water consumption in simultaneous fixture use) Theoretical formula: * Standard water pressure:100 kPa, aperture: 90°–120° (3) Adjustment in number of fixtures (in case of random use) In case where fixtures are installed horizontally in 2 or more places or vertically on 2 or more floors (4) Combination of different types of fixtures Peak flow rate of fixtures + 1/2 of total flow rate of others * Simple projection (Random use and concentrated use) | Approximation by Mitsumasa Okada

Water use time = 0.5 (provisional) [19]. Table of water supply unit of fixture (Table 5). Saburo Murakawa: 10-h average Poisson distribution on assumption of use in an office with reject rate: 0.001 [20] |

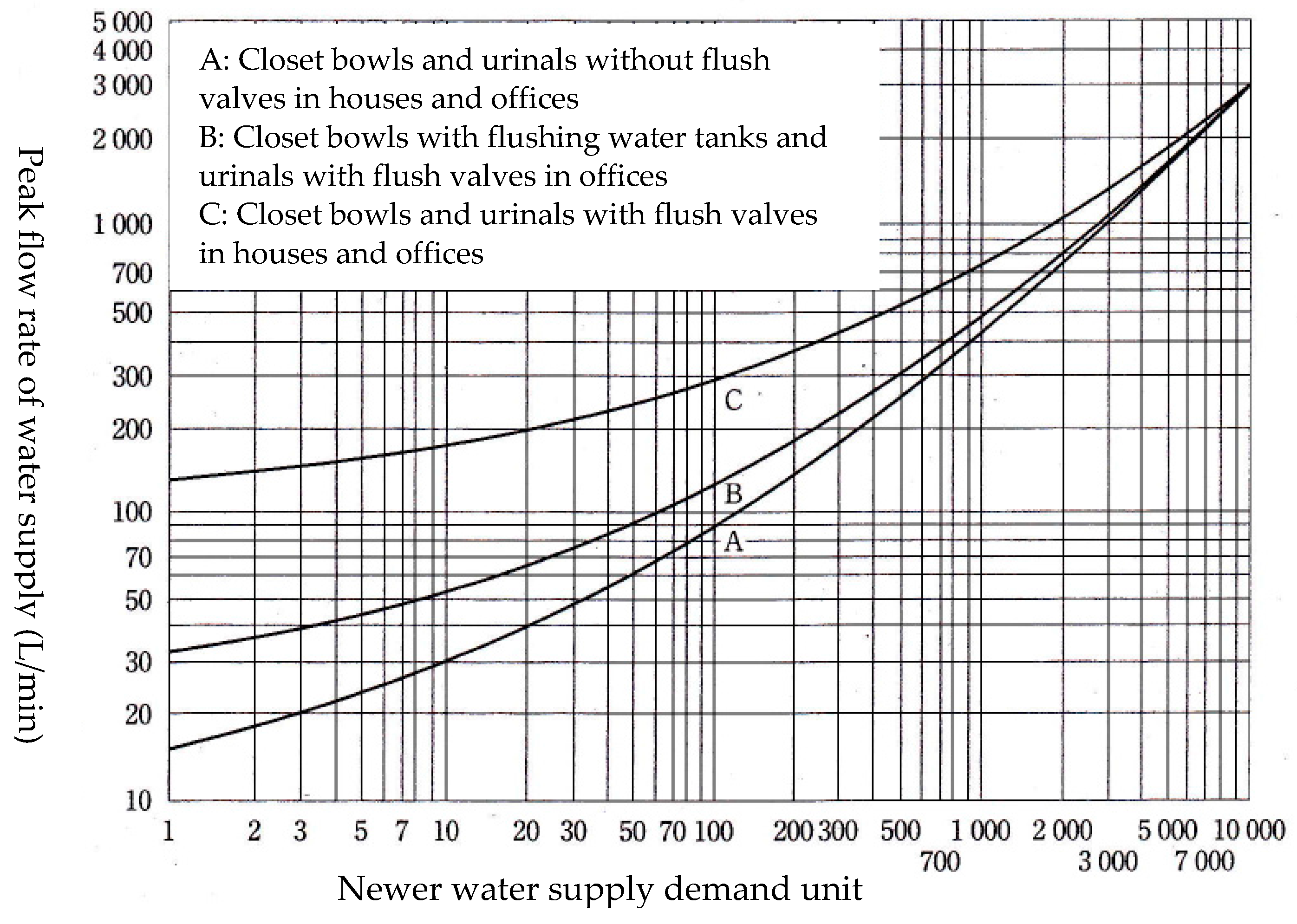

| Method 2: Method based on newer water supply demand unit | Applicable only for houses, multi-family housings and offices | [Advantages] - Data has been accumulated over many years in this calculation method, which has been, as the result, used for a long time. - Calculation is simple and easy. [Disadvantages] - Applicable only for houses, multi-family housings and offices - If a house or office is also used for other application, calculation cannot be made. - If a flush valve and flushing water tank coexist, calculation cannot be made. | (1) Distribution of frequency of simultaneous water consumption: closely related to Poisson distribution or binomial distribution

(2) Calculation of newer water supply demand unit by using a basin (house) as a base (3) Newer water supply demand unit → Peak flow rate of water supply (by using diagram) (Whether or not there is a flush valve in a house or office is selected.) | Table of newer water supply demand unit (Table 8) [21,22] |

| Method 3: Calculation method based on fixture usage | Applicable at architect’s own discretion, when a small number of fixtures are used or when regularity exists in use of fixtures or water consumption | [Advantages] - Calculation is simple and easy. - For example, this method is applicable for and effective in the following cases: (1) There are some parts that are used in different time zones in a building, such as a laboratory, room for a cooking class, and students’ toilets in a school. (2) There is a place where time of use is concentrated, such as a shower room in a school. [Disadvantages] - Applicable only when only a small number of fixtures is used. | (1) Number of fixtures (closet bowls) (flush valve) (general fixtures) → Rate of simultaneous use of fixture

(2) Rate of simultaneous use of the fixture x Peak flow rate of water supply of each fixture → Peak flow rate of water supply | Quantity consumption and peak flow rate of water supply of each plumbing fixture and faucet (Table 10) |

| Method 4: method based on water supply load unit of fixture | Applicable for various purposes | [Advantages] - Calculation is simple and easy. Therefore, this method is effective for calculation of the place where time of use is concentrated. [Disadvantages] - If water supply load unit of fixture is 10 or fewer (too few fixtures) or 3000 or more (too many fixtures), calculation cannot be made (any diagram cannot be prepared). - If a flush valve and flushing water tank coexist, the method calculation is unclear. - Any consideration is not made to a decrease in the calculation result in the case where the ratio of users to the number of fixtures is low. - Its safety factor is too high. | (1) Sum of water supply load unit of fixture of each fixture (public use/private use)

(2) Sum of water supply load unit of fixture → Peak flow rate of water supply | Hunter (US)

Table of water supply unit of fixture Diagram of the water supply load unit of fixture and peak flow rate of water supply (Hunter Curve) [23] |

| Fixture | Water Supply System | Connection Diameter (A) | Fixture Unit for Water Supply | Drain Cock Unit for Water Supply | Water Use Time η |

|---|---|---|---|---|---|

| Closet bowl | Siphon-type flush valve/male | 25 | 9 | - | 0.03 (10/300) |

| Siphon-type with flush valve/female | 25 | 9 | - | 0.15 (15/100) with sound imitating device: 0.1 (10/100) | |

| Washing-type flush valve/male | 25 | 6 | - | 0.03 (10/300) | |

| Washing-type flush valve/female | 25 | 6 | - | 0.15 (15/100) with sound imitating device: 0.1 (10/100) | |

| Flushing water tank/male | 13 | 1 | - | 0.15 (15/100) | |

| Flushing water tank/female | 13 | 1 | - | 0.5 (50/100) | |

| Tank-less type/male/6 L | 13 | 1.4 | - | 0.08 (22/300) | |

| Tank-less type/female/6 L | 13 | 1.4 | - | 0.33 (33/100) with sound imitating device: 0.22 (22/100) | |

| Tank-less type/male/8 L | 13 | 1.4 | - | 0.09 (27/300) | |

| Tank-less type/female/8 L | 13 | 1.4 | - | 0.41 (41/100) with sound imitating device: 0.27 (27/100) | |

| Urinal | Flush valve | 13 | 2 | - | 0.3 (13/40) |

| Flushing water tank | 13 | 0.5 | - | 1.0 (continuous flow) | |

| Basin | Lavatory faucet for water saving washing | 13 | 1 | 0.5 | 0.5 |

| Mixed use for water pouring washing | 13 | 1 | 0.5 | 0.5 | |

| Automatic faucet with continuous flow valve | 13 | 0.2 | - | 0.5 | |

| Automatic faucet without continuous flow valve | 13 | 0.5 | - | 0.5 |

| No. of Fixtures c | 1 | 2 | 3 | 4 | 5 | 7 | 10 | 15 | 20 | 50 | 100 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Usage rate ρ | 0.01 | 0.07 | 0.13 | 0.20 | 0.26 | 0.33 | 0.42 | 0.50 | 0.55 | 0.65 | 0.70 |

| Approximation of usage rate (reference) ρ = 0.1684Ln(c) − 0.0087 | 0 (a) | 0.108 | 0.176 | 0.225 | 0.262 | 0.319 | 0.379 | 0.447 | 0.496 | 0.65 | 0.767 |

| k | 0.1 | 0.05 | 0.02 | 0.01 | 0.005 | 0.002 | 0.001 | 0.0001 |

|---|---|---|---|---|---|---|---|---|

| b | 1.28 | 1.64 | 2.05 | 2.33 | 2.58 | 2.88 | 3.09 | 4.26 |

| Δ | 0.6 | 0.8 | 0.9 | 1.0 | 1.11 | 1.3 | 1.4 | 1.7 |

| Sex | Fixture | Newer Water Supply Demand Unit | Remarks |

|---|---|---|---|

| Male | Closet bowl | 5 | Flush valve type |

| Closet bowl | 3.5 | Tank type | |

| Urinal | 3 | Flush valve type (including automatic flush valve with sensor) | |

| Basin | 1.5 | - | |

| Female | Lavatory pan | 8 | Flush valve type |

| Lavatory pan | 5 | Tank type | |

| Basin | 1.5 | - |

| No. of Fixtures c | 1 | 2 | 4 | 8 | 12 | 16 | 24 | 32 | 40 | 50 | 70 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Closet Bowl (Flush Valve) | 100 | 50 | 50 | 40 | 30 | 27 | 23 | 19 | 17 | 15 | 12 |

| General Fixture | 100 | 100 | 70 | 55 | 48 | 45 | 42 | 40 | 39 | 38 | 35 |

| Fixture | Quantity Consumption Per Use (L) | Peak Flow Rate of Water Supply (L/min) | Remarks |

|---|---|---|---|

| Closet bowl with flush valve | 6–13 | 105 | It is assumed that users wash the fixture once per use. In public toilets, males wash the fixture about 1.5 times per use, and fames wash it about 2.0 times per use. |

| Closet bowl coupled with low tank | 6–10 | 10 | |

| Closet bowl with low tank on the flat wall | 8–11 | 10 | |

| Closet bowl with low tank on corner | 8–11 | 10 | |

| Closet bowl integrated with low tank (single unit type) | 16 | 10 | |

| Closet bowl without tank | 6–8 | 20 | |

| Closet bowl without tank (small tank included) | 5–5.5 | 10–13 | |

| Urinal with flush valve | 4–6 | 30 | The required flow rate for a plunge bath is calculated based on the time spent to fill the bath tab with water. |

| Urinal with automatic Flushing water tank | 4–6 | 8–13 | |

| Basin | 10 | 10 |

| Fixture | Faucet | Water Supply Load Unit of Fixture | |

|---|---|---|---|

| Public Use | Private Use | ||

| Closet bowls | Flush valve | 10 | 6 |

| Closet bowls | Flushing water tank | 5 | 3 |

| Urinal | Flush valve | 5 | - |

| Urinal | Flushing water tank | 3 | - |

| Basin | Faucet | 2 | 1 |

| Simulation Model | Male | Female | ||||

|---|---|---|---|---|---|---|

| Closet Bowl | Urinal | Basin | Lavatory Pan | Basin | ||

| Arrival-to-fixture model Fixture occupation time model | Arrival rate by time (person/min) | To be set by fixture and time zone | ||||

| Arrival rate distribution | Poisson distribution | |||||

| No. of fixtures to be set (unit) | To be set based on the subject building | |||||

| Average occupation time (s) | 260 | 37 | 12 | 110 | 17 | |

| Discharge quantity model | Type of occupation time distribution | Erl.3 | Erl.7 | Hyp.2 | Erl.3 | Hyp2 |

| Average discharge time (s) | 17.2 | 5 | 6 | 17.2 | 11 | |

| Fixture operation model | Type of discharge time distribution | Exp. | Exp.10 | Erl.3 | Exp. | Erl.3 |

| Average discharge quantity (L/min) | 49.8 | 30 | 5 | 49.8 | 5 | |

| Type of discharge quantity distribution | Erl.6 | Erl.10 | Erl.10 | Erl.6 | Erl.10 | |

| Average number of times for washing (time) | 1.37 | 1 | 1 | 1.17 | 1 | |

| Subject number (No. of users, tenants and rooms) | To be entered based on the subject building | |||||

| Period | Classification | Whole Building | 6F | 5F | 4F | B1F~3F |

|---|---|---|---|---|---|---|

| 8/5 (Wed.) | Qday (L/day) | 9361 | 1434 | 2357 | 2017 | 3552 |

| Qmax (L/min) | 86.7 | 28.6 | 66.2 | 85.3 | 69.5 | |

| 8/6 (Thu.) | Qday (L/day) | 9701 | 1558 | 2649 | 1827 | 3667 |

| Qmax (L/min) | 79.0 | 45.4 | 73.3 | 52.9 | 70.7 | |

| 11/12 (Thu.) | Qday (L/day) | 9493 | 1574 | 2438 | 2182 | 3298 |

| Qmax (L/min) | 67.1 | 38.1 | 58.4 | 53.7 | 67.1 | |

| Ave. | Qday (L/day) | 9518 | 1522 | 2481 | 2009 | 3506 |

| Qmax (L/min) | 77.6 | 37.4 | 66.0 | 64.0 | 69.1 |

| Floor | Tenants | Aug. | Nov. | ||

|---|---|---|---|---|---|

| Male | Female | Male | Female | ||

| 6F | Office | 20 | 6 | 22 | 4 |

| 5F | 53 | 19 | 55 | 19 | |

| 4F | 38 | 14 | 36 | 14 | |

| 3F | 53 | 10 | 51 | 12 | |

| 1–2F | Law office Medical office | 17 | 7 | 17 | 7 |

| Entirety | - | 181 | 56 | 181 | 56 |

| Period | Questionnaire | Security Camera | ||

|---|---|---|---|---|

| Male | Female | Male | Female | |

| 8/5 (Wed.) | 136 | 52 | - | - |

| 8/6 (Thu.) | 142 | 52 | - | - |

| 8/7 (Fri.) | 134 | 53 | - | - |

| Aug. (Ave.) | 137 | 52 | - | - |

| 11/11 (Wed.) | 112 | 52 | 111 | 61 |

| 11/12 (Thu.) | 97 | 51 | 105 | 68 |

| 11/13 (Fri.) | 103 | 50 | 96 | 66 |

| Nov. (Ave.) | 104 | 51 | 104 | 65 |

| Count | Water Supply Discharge Time (s) | Water Supply Discharge (L) | Average Water Supply Discharge Volume (L/min) |

|---|---|---|---|

| 1st | 17 | 13.8 | 48.5 |

| 2nd | 20 | 14.1 | 42.4 |

| 3rd | 16 | 14.4 | 54.0 |

| 4th | 15 | 14.4 | 57.5 |

| 5th | 18 | 14.0 | 46.7 |

| Ave. | 17.2 | 14.1 | 49.8 |

| Water Consumption | MLIT | SHASE-S206 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| PM | FM | WFM | NWM | PFM | SLM | ||||

| P/A | NOR | CBU | ABU | ||||||

| Whole building | Qday (L/day) | 38,080 | 16,800 | 21,120 | 16,554 | - | - | - | - |

| Qmax (L/min) | 238 | 105 | 220 | 172 | 474 | 390 | 1094 | 370 | |

| B1F~3F | Qday (L/day) | 18,880 | 6960 | 11,040 | 8650 | - | - | - | - |

| Qmax (L/min) | 118 | 43.6 | 103 | 90.0 | 280 | 290 | 702 | 380 | |

| 4F | Qday (L/day) | 6480 | 3331 | 3360 | 2635 | - | - | - | - |

| Qmax (L/min) | 41 | 20.8 | 35 | 27.4 | 175 | 210 | 355 | 257 | |

| 5F | Qday (L/day) | 6480 | 5330 | 3360 | 2635 | - | - | - | - |

| Qmax (L/min) | 41 | 33.3 | 35 | 27.4 | 175 | 210 | 355 | 257 | |

| 6F | Qday (L/day) | 6240 | 1396 | 3360 | 2635 | - | - | - | - |

| Qmax (L/min) | 39 | 8.7 | 35 | 27.4 | 175 | 210 | 355 | 267 | |

| Fixture | Men’s WC | Men’s Urinal | Men’s Wash Basin | Women’s WC | Women’s Wash Basin |

|---|---|---|---|---|---|

| No. of Fixture | To be Set Based on the Subject Building | ||||

| Distribution diagram phase of average water supply discharge time | 1 | 10 | 3 | 1 | 3 |

| Average water supply discharge time (s/use) | 17.2 | 5 | 6 | 17.2 | 11 |

| Distribution form phase of average water supply discharge volume | 6 | 10 | 10 | 6 | 10 |

| Average water supply discharge volume (L/min) | 49.8 | 30 | 5 | 49.8 | 5 |

| Distribution form phase of occupancy time | 3 | 7 | 2 | 3 | 2 |

| Average occupancy time (s/person) | 260 | 37 | 12 | 110 | 17 |

| Increase of usage with multiple use taken into account | 1.37 | 1 | 1 | 1.17 | 1 |

| No. of People, House, Room | To be Set Based on the Subject Building | ||||

| Fixture usage rate (Ratio of water to hot water) | 1 | 1 | 1 | 1 | 1 |

| Water Consumption | P/A | NOR | |

|---|---|---|---|

| Whole building | Qday (L/day) | 18,382 | 9669 |

| Qmax (L/min) | 122.3 | 100.3 | |

| B1F~3F | Qday (L/day) | 9402 | 3740 |

| Qmax (L/min) | 104.5 | 72.9 | |

| 4F | Qday (L/day) | 3436 | 2298 |

| Qmax (L/min) | 68.4 | 65.0 | |

| 5F | Qday (L/day) | 3450 | 3299 |

| Qmax (L/min) | 68.8 | 70.8 | |

| 6F | Qday (L/day) | 3001 | 1336 |

| Qmax (L/min) | 68.5 | 48.1 | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, G.-Z.; Sakaue, K.; Murakawa, S. Verification of Calculation Method Using Monte Carlo Method for Water Supply Demands of Office Building. Water 2017, 9, 376. https://doi.org/10.3390/w9060376

Wu G-Z, Sakaue K, Murakawa S. Verification of Calculation Method Using Monte Carlo Method for Water Supply Demands of Office Building. Water. 2017; 9(6):376. https://doi.org/10.3390/w9060376

Chicago/Turabian StyleWu, Guang-Zheng, Kyosuke Sakaue, and Saburo Murakawa. 2017. "Verification of Calculation Method Using Monte Carlo Method for Water Supply Demands of Office Building" Water 9, no. 6: 376. https://doi.org/10.3390/w9060376