Evaluation of Power Ultrasonic Effects on Algae Cells at a Small Pilot Scale

Abstract

:1. Introduction

2. Material and Methods

2.1. Algae and Culture Conditions

2.2. Ultrasonic Equipment

2.2.1. Dual Frequency Reactor (Advanced Sonic Processing Systems, USA)

2.2.2. Sonolator (Sonic Corporation, Stanford, CA, USA)

2.3. Ultrasonic Treatment

2.3.1. Sonication of Algae Using 16 and 20 kHz Dual Frequency Reactor (DFR)

2.3.2. Sonication of Algae Using the Sonolator for 5 h

2.3.3. Measurement of the Effect of Cavitation on Algae Suspensions

3. Results and Discussion

3.1. Sonication of Algae Using the Dual Frequency Reactor (DFR)

3.1.1. Batch Mode

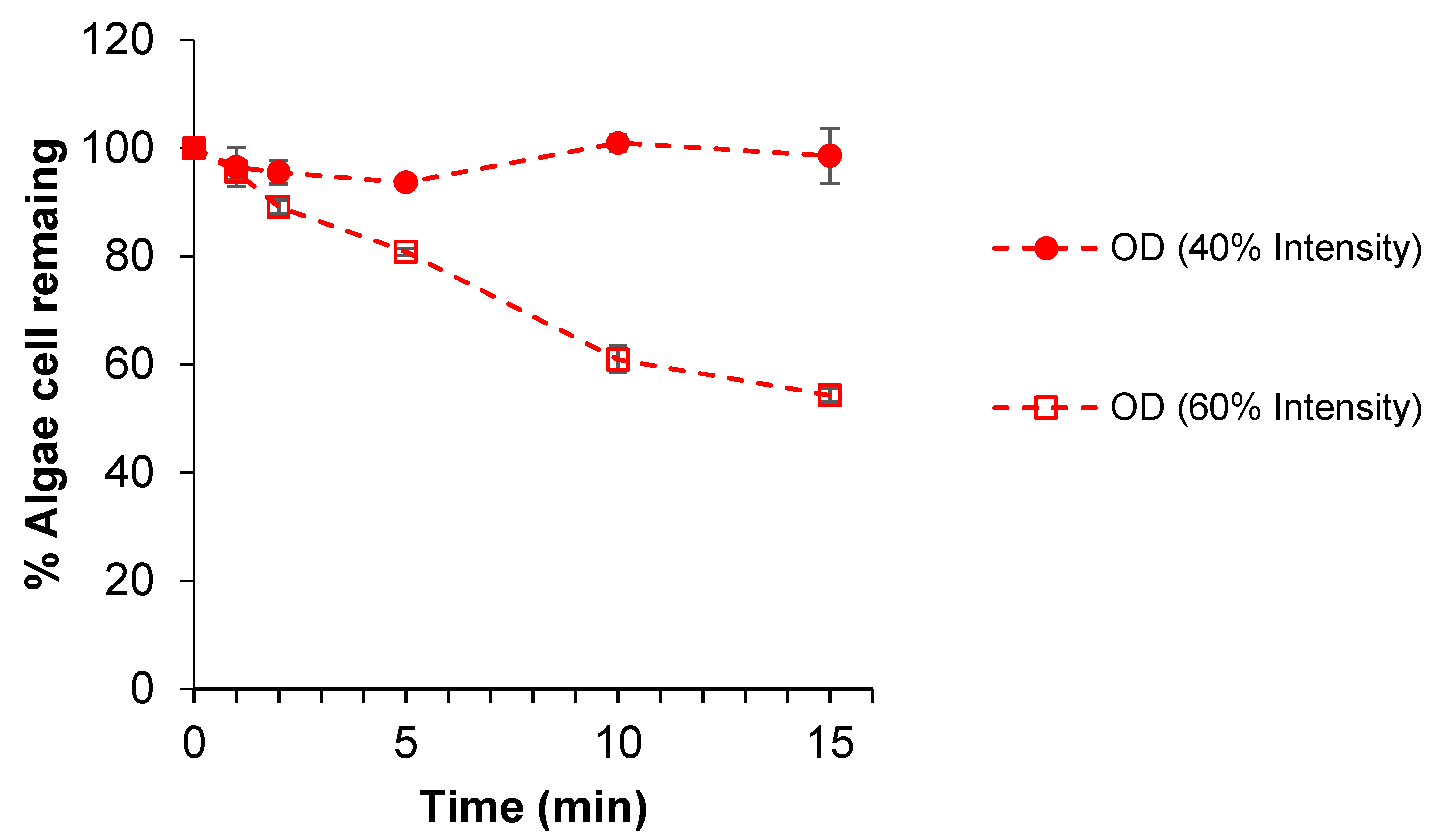

3.1.2. Recirculating Mode

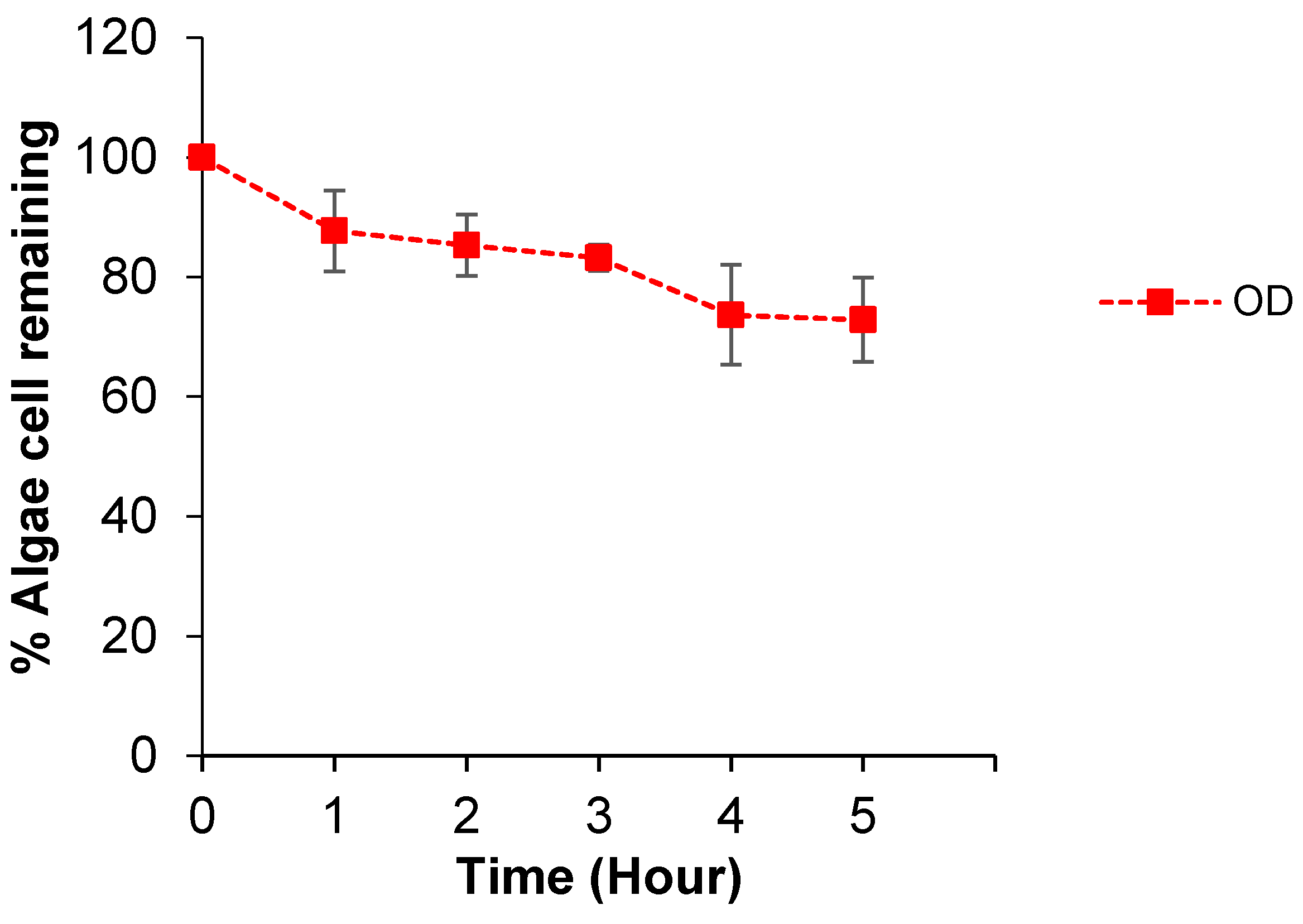

3.2. Sonication of Algae (5 L) Using the Sonolator in Recycling Mode for 5 h

4. Conclusions

Supplementary Materials

Author Contributions

Conflicts of Interest

References

- National Rivers Authority (NRA). Toxic Blue-Green Algae: The Report by the National Rivers Authority; National Rivers Authority: London, UK, 1990.

- World Health Organization. Algae Toxins: Microcystin-LR in Drinking-Water; WHO: Geneva, Switzerland, 2003. [Google Scholar]

- Chorus, I.; Cavalieri, M. Algae and Toxic Algae in Water: A Guide to Their Public Health Consequences, Monitoring and Management; Bartram, J., Rees, G., Eds.; WHO: Geneva, Switzerland, 2000. [Google Scholar]

- Anderson, D.M. Approaches to monitoring, control and management of harmful algal blooms (HABs). Ocean Coast. Manag. 2009, 52, 342–347. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Joyce, E.M.; Mason, T.J. The effect of ultrasound on algae. Harmful Algae 2011, 10, 738–743. [Google Scholar] [CrossRef]

- Joyce, E.; Wu, X.; Mason, T.J. Effect of ultrasonic frequency and power on algae suspensions. J. Environ. Sci. Health A 2010, 45, 863–866. [Google Scholar] [CrossRef] [PubMed]

- Atchley, A.A.; Crum, L.A. Acoustic cavitation and bubble dynamics. In Ultrasound: Its Chemical, Physical, and Biological Effects; Suslick, K.S., Ed.; Wiley-VCH: New York, NY, USA, 1988. [Google Scholar]

- Mason, T.J.; Lorimer, J.P. Sonochemistry: Theory, Application and Uses of Ultrasound in Chemistry; Ellis Horwood: Chichester, UK, 1988. [Google Scholar]

- Frizzell, L.A. Biological effect of acoustic cavitation. In Ultrasound: Its Chemical, Physical and Biological Effects; Suslick, K.S., Ed.; VCH: New York, NY, USA, 1988; pp. 287–290. [Google Scholar]

- Wu, X.; Joyce, E.; Timothy, J.M. Evaluation of ultrasonic effects on Microcystis aeruginosa using different ultrasonic parameters (frequencies and intensities) and mechanism studies using flow cytometry. Water Res. 2012, 46, 2851–2858. [Google Scholar] [CrossRef] [PubMed]

- Hulsmans, A.; Joris, K.; Lambert, N.; Rediers, H.; Declerck, P.; Delaeft, Y.; Ollevier, F.; Liers, S. Evaluation of process parameters of ultrasonic treatment of bacterial suspensions in a pilot scale water disinfection system. Ultrason. Sonochem. 2010, 17, 1004–1009. [Google Scholar] [CrossRef] [PubMed]

- Declerck, P.; Vanysacker, L.; Hulsmans, A.; Lambert, N.; Liers, S. Evaluation of power ultrasound for disinfection of both Legionella pneumophila and its environmental host Acanthamoeba castellanii. Water Res. 2010, 44, 703–710. [Google Scholar] [CrossRef] [PubMed]

- Joyce, E.; Phull, S.S.; Lorimer, J.P.; Mason, T.J. The development and evaluation of ultrasound for the treatment of bacterial suspensions. A study of frequency, power and sonication time on cultured Bacillus species. Ultrason. Sonochem. 2008, 10, 315–318. [Google Scholar] [CrossRef]

- Lee, T.; Nakano, K.; Matsumura, M. A new method for the rapid evaluation of gas vacuoles regeneration and viability of algae by flow cytometry. Biotechnol. Lett. 2010, 22, 833–1838. [Google Scholar]

- Thoma, G.; Gleason, M. Sonochemical treatment of benzene/toluene contaminated wastewater. Environ. Prog. 1998, 17, 154–160. [Google Scholar] [CrossRef]

- Xu, Y.; Yang, J.; Wang, Y.; Liu, F.; Jia, J. The effects of jet cavitation on the growth of Microcystis aeruginosa. Environ. Sci. Health A 2006, 41, 2345–2358. [Google Scholar] [CrossRef] [PubMed]

- Gogate, P.R.; Pandit, A.B. A review and assessment of hydrodynamic cavitation as a technology for the future. Ultrason. Sonochem. 2005, 12, 21–27. [Google Scholar] [CrossRef] [PubMed]

- Mason, T.J.; Lorimer, J.P. Applied Sonochemistry: Uses of Power Ultrasound in Chemistry and Processing; Wiley: Weinheim, Germany, 2002. [Google Scholar]

- Mason, T.J.; Peters, D. Practical Sonochemistry: Power Ultrasound Uses and Applications; Woodhead Publishing: Sawston, UK, 2002. [Google Scholar]

- Vinatoru, M.; Mason, T.J. Comments on the use of loop reactors in sonochemical processes. Ultrason. Sonochem. 2017, 39, 240–242. [Google Scholar] [CrossRef]

| Ultrasonic Treatment | Intensity | Volume (Litre) | Residence Time (Minutes) | % Cell Remaining (OD) |

|---|---|---|---|---|

| 20 kHz Probe [10] | 0.0403 | 0.2 | 30 | 50.82 |

| DFR (Static, 40% power setting) | 0.0177 | 1 | 10 | 92 |

| DFR (Static, 60% power setting) | 0.0256 | 1 | 10 | 39.17 |

| DFR (Recirculating, 40% power 15 min) | - | 3.5 | 4.29 | 98.60 |

| DFR (Recirculating, 60% power 15 min) | - | 3.5 | 4.29 | 54.31 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, X.; Mason, T.J. Evaluation of Power Ultrasonic Effects on Algae Cells at a Small Pilot Scale. Water 2017, 9, 470. https://doi.org/10.3390/w9070470

Wu X, Mason TJ. Evaluation of Power Ultrasonic Effects on Algae Cells at a Small Pilot Scale. Water. 2017; 9(7):470. https://doi.org/10.3390/w9070470

Chicago/Turabian StyleWu, Xiaoge, and Timothy J. Mason. 2017. "Evaluation of Power Ultrasonic Effects on Algae Cells at a Small Pilot Scale" Water 9, no. 7: 470. https://doi.org/10.3390/w9070470