A Semi-Analytical Model for the Hydraulic Resistance Due to Macro-Roughnesses of Varying Shapes and Densities

Abstract

:1. Introduction

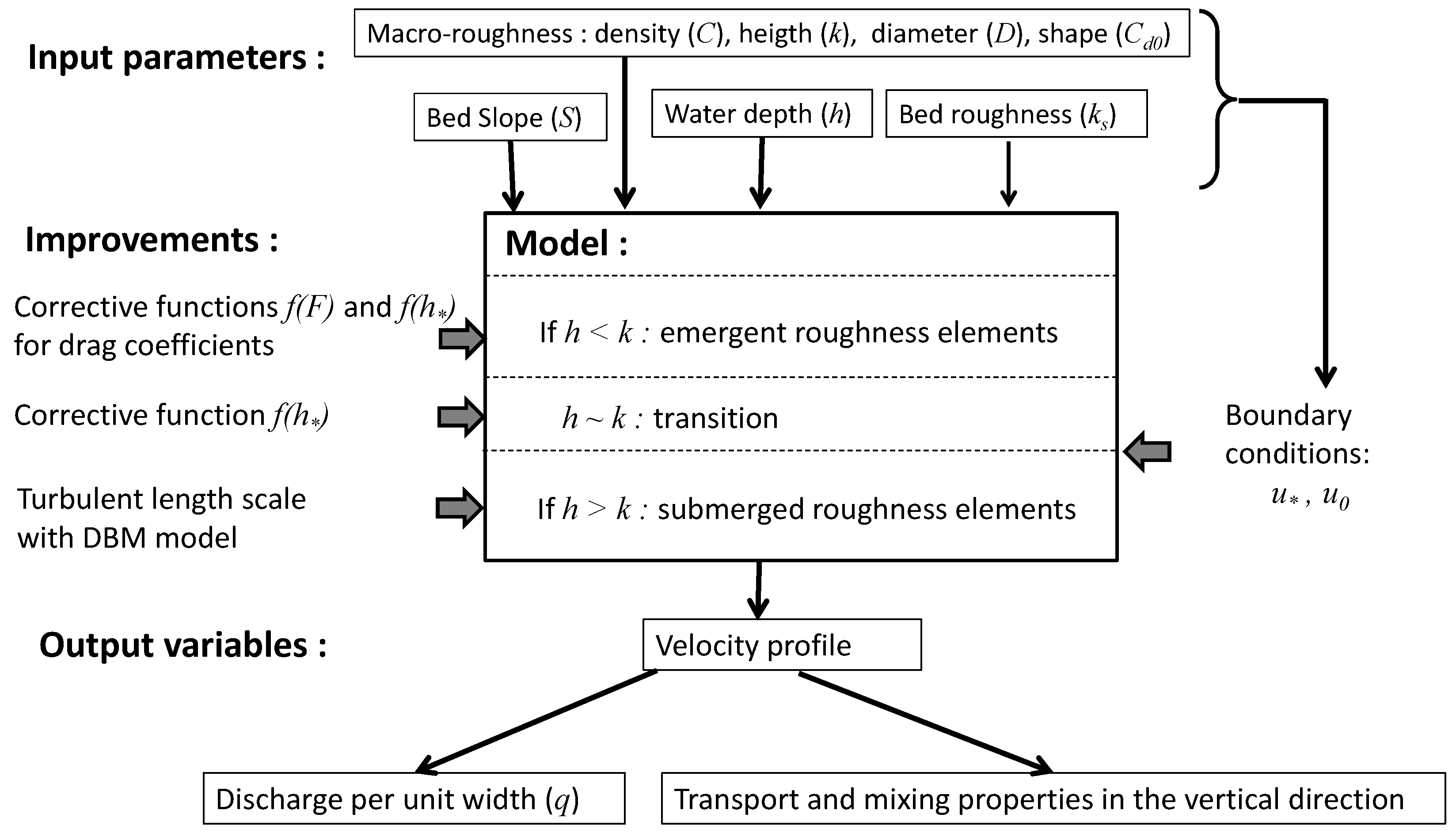

2. Material and Method

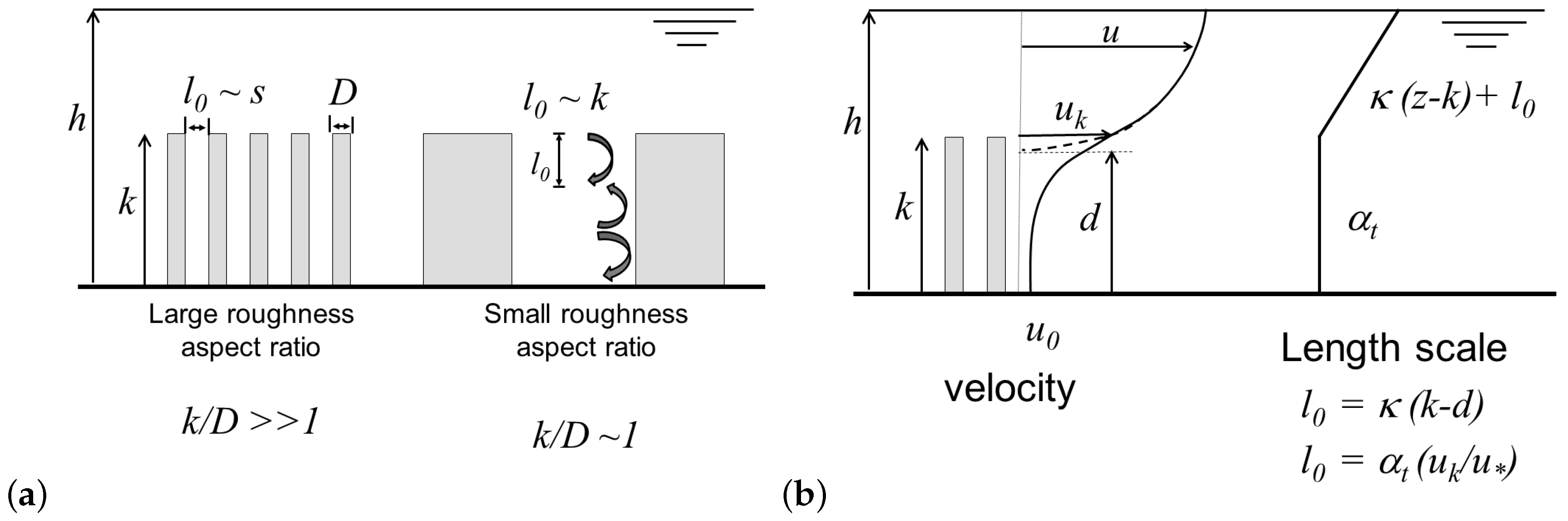

2.1. Bed and Model Description

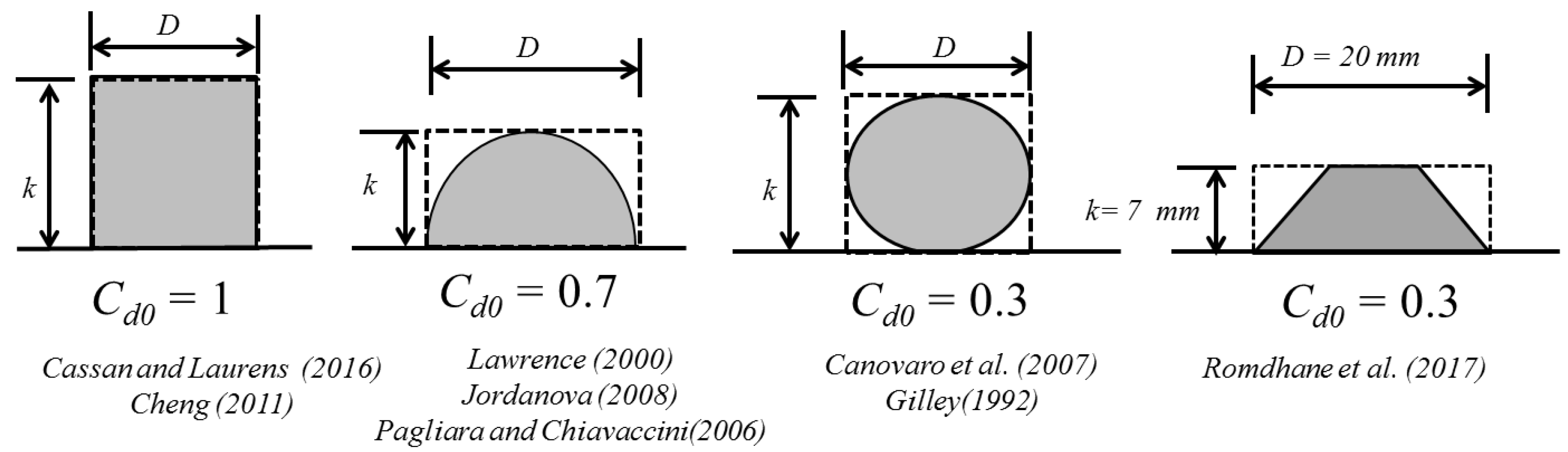

2.2. Emergent Roughness Elements

2.3. Submerged Roughness Elements

3. Results and Discussion

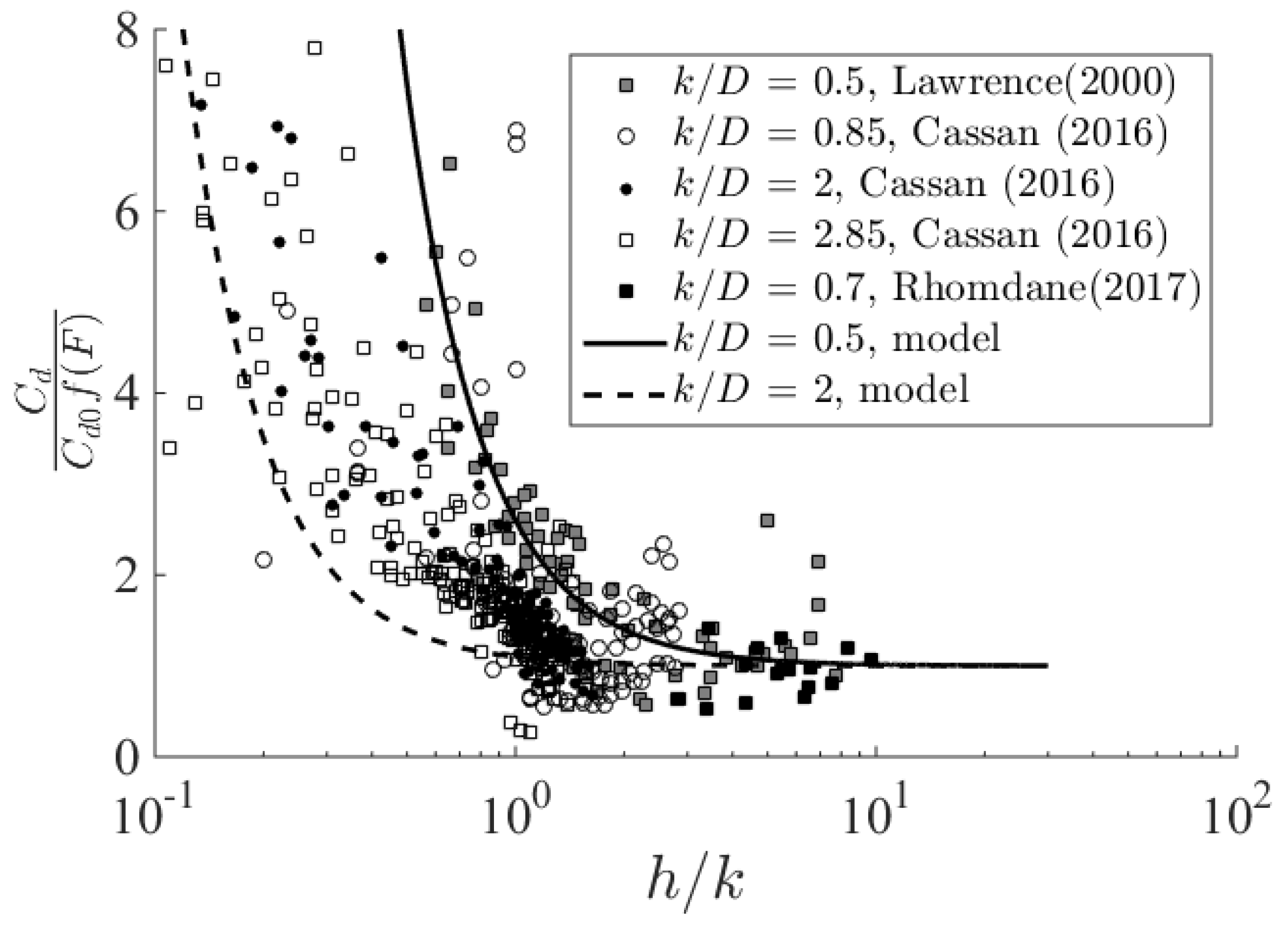

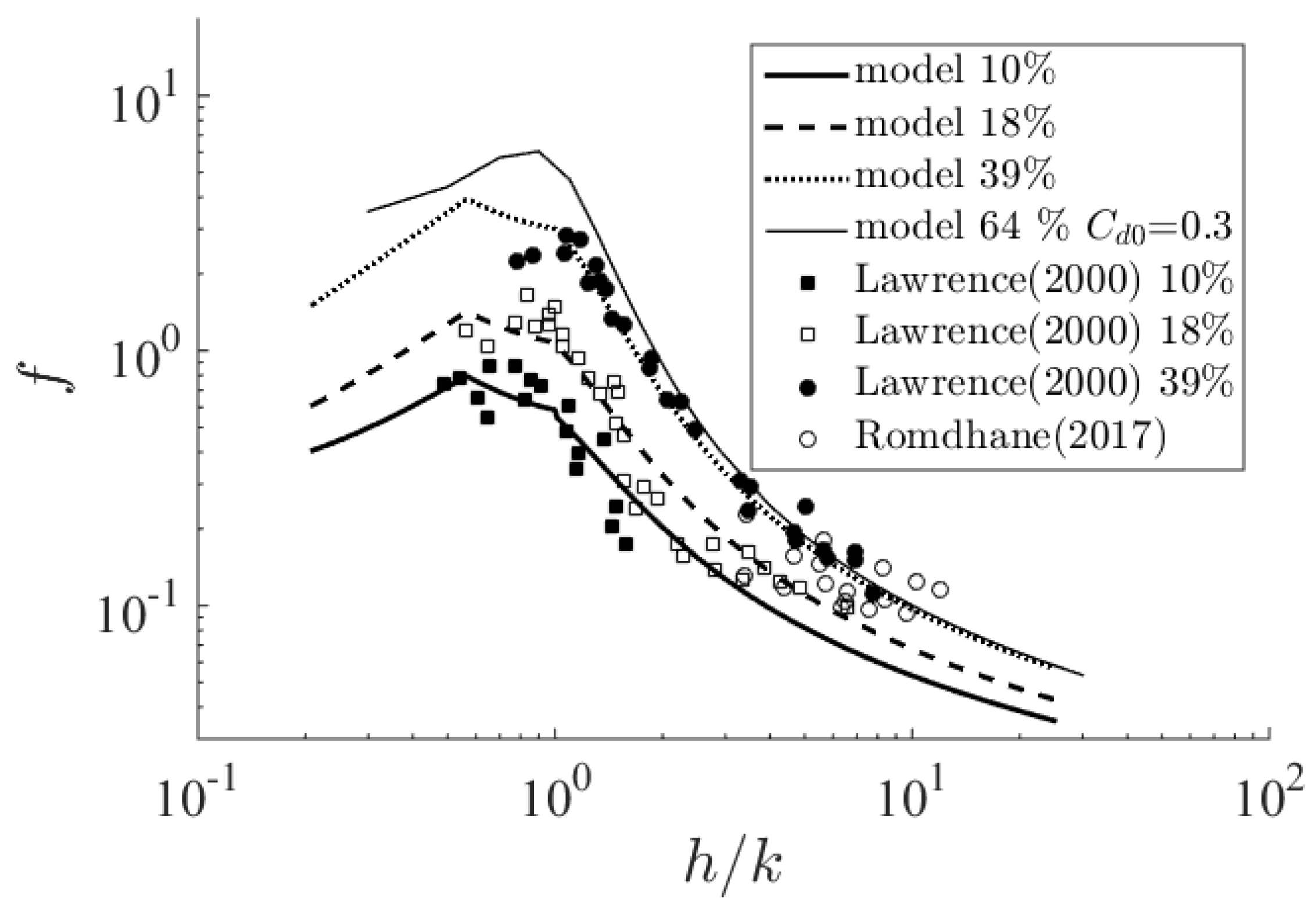

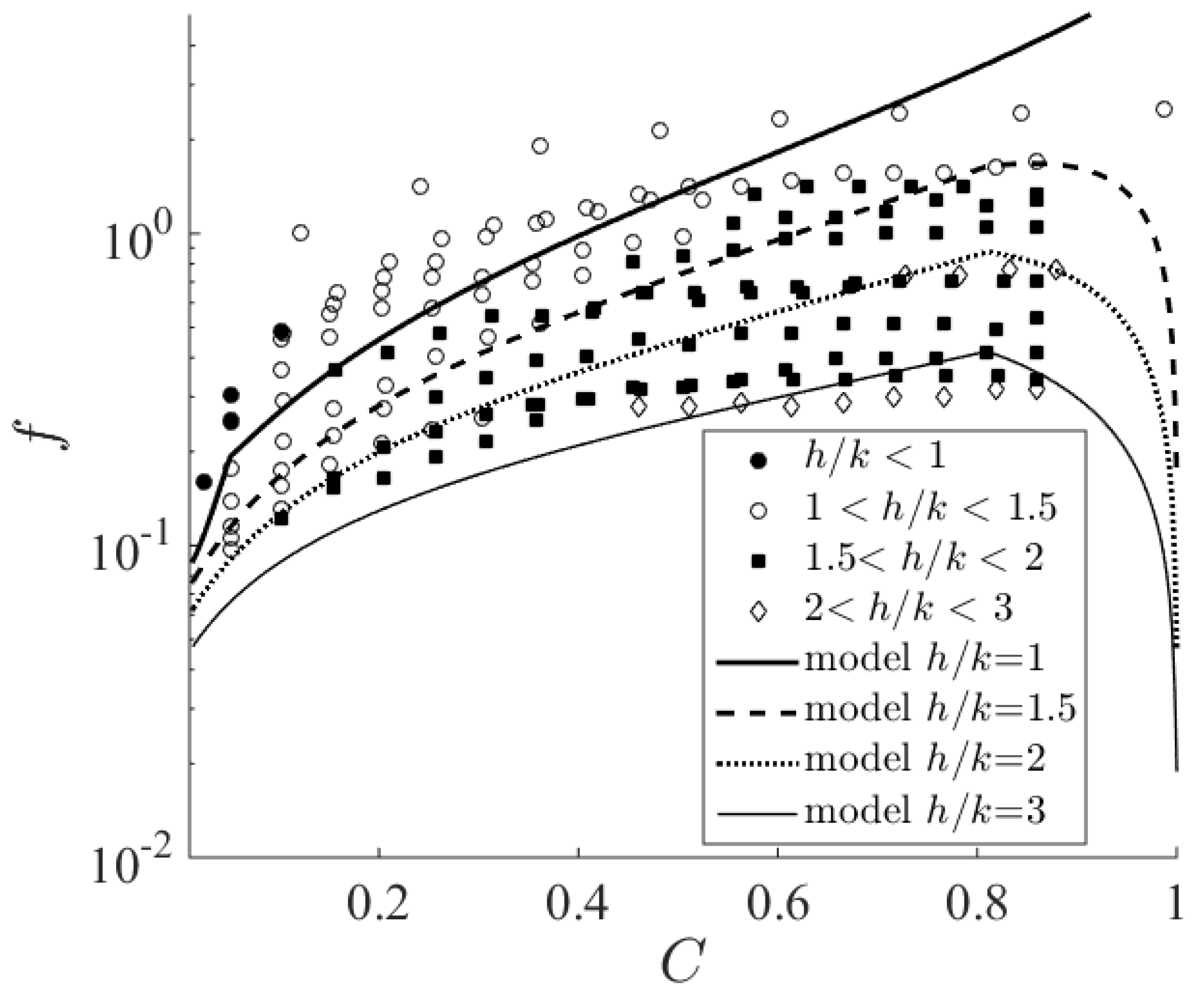

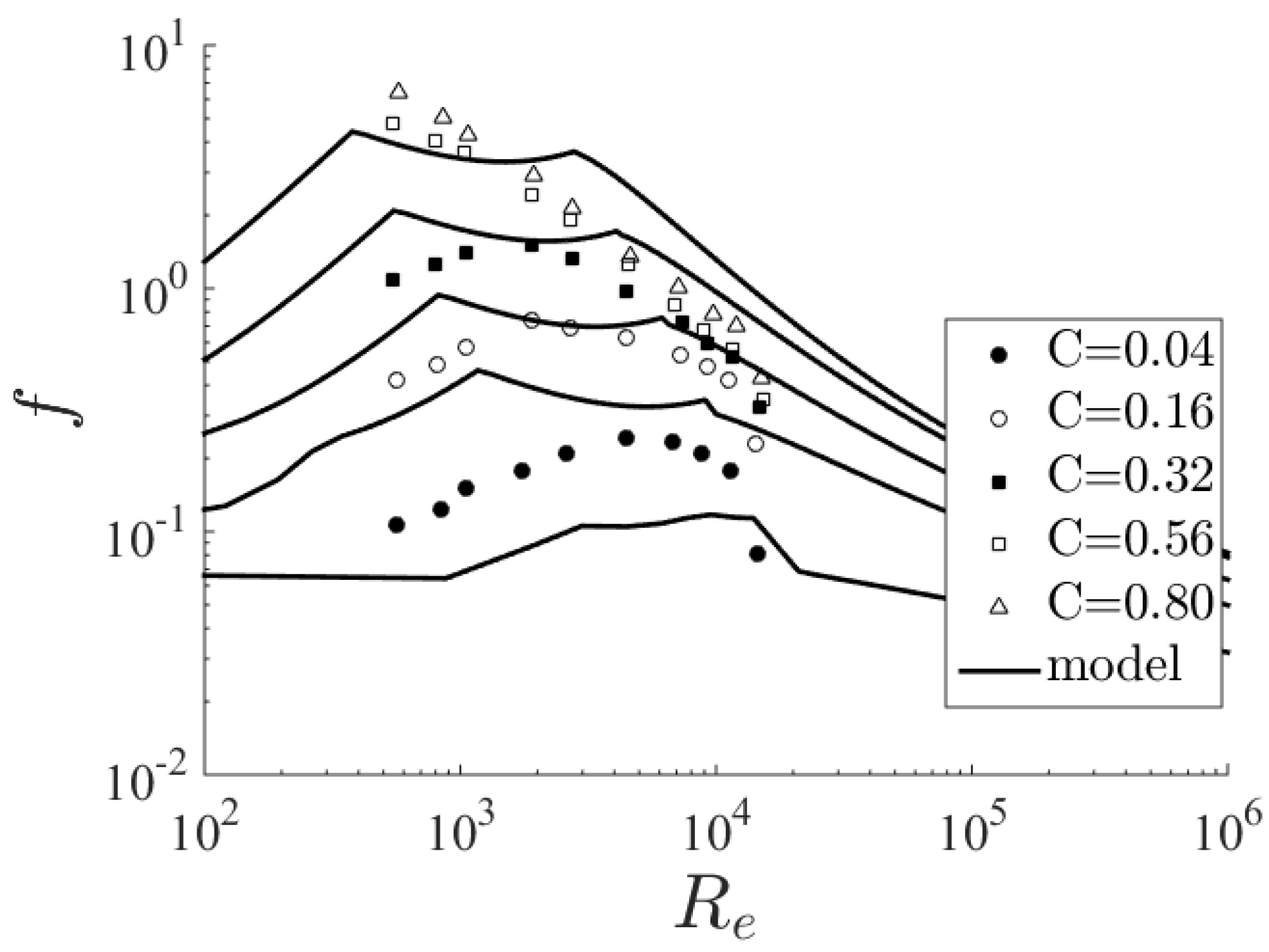

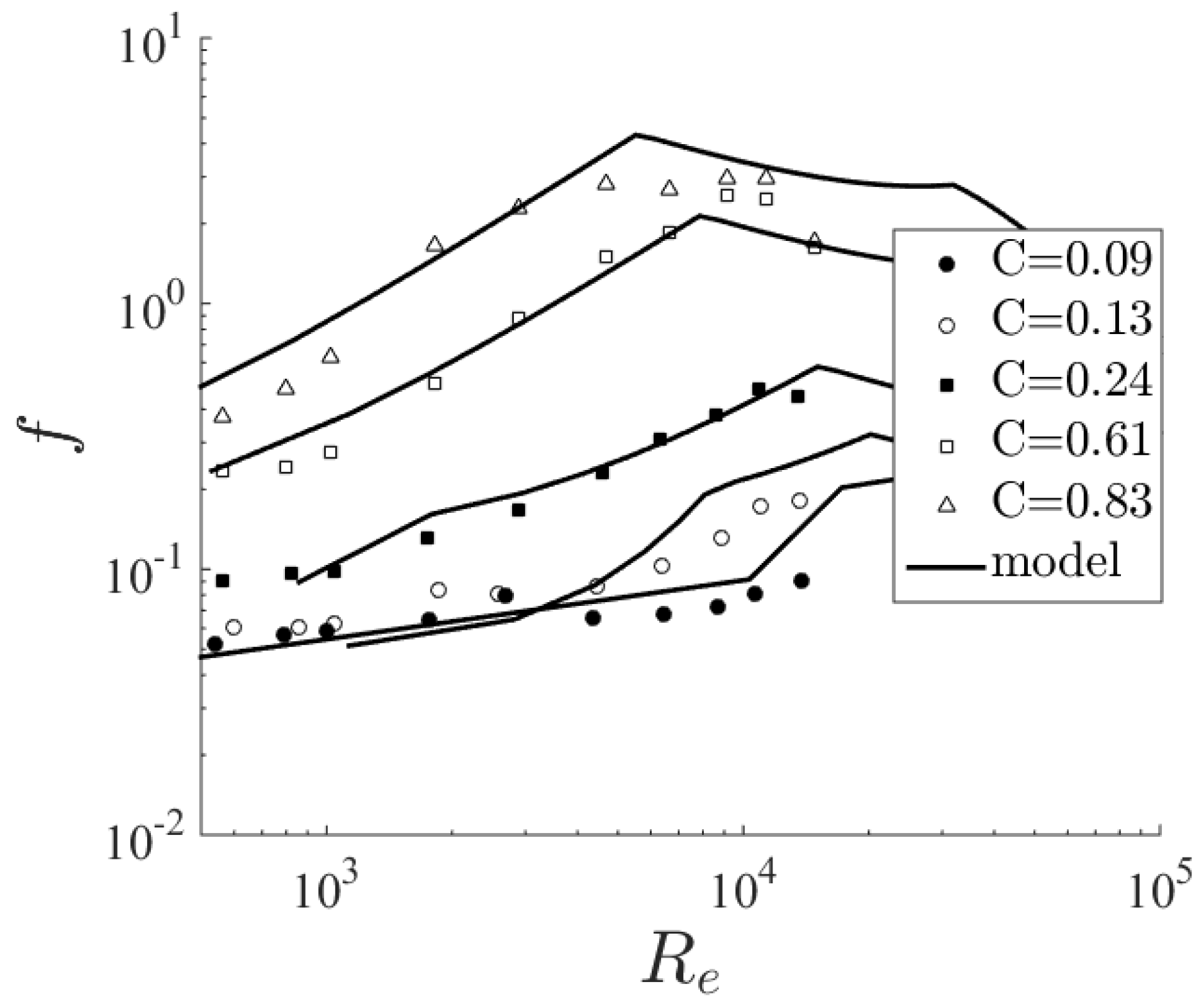

3.1. Calibration of Drag Coefficients

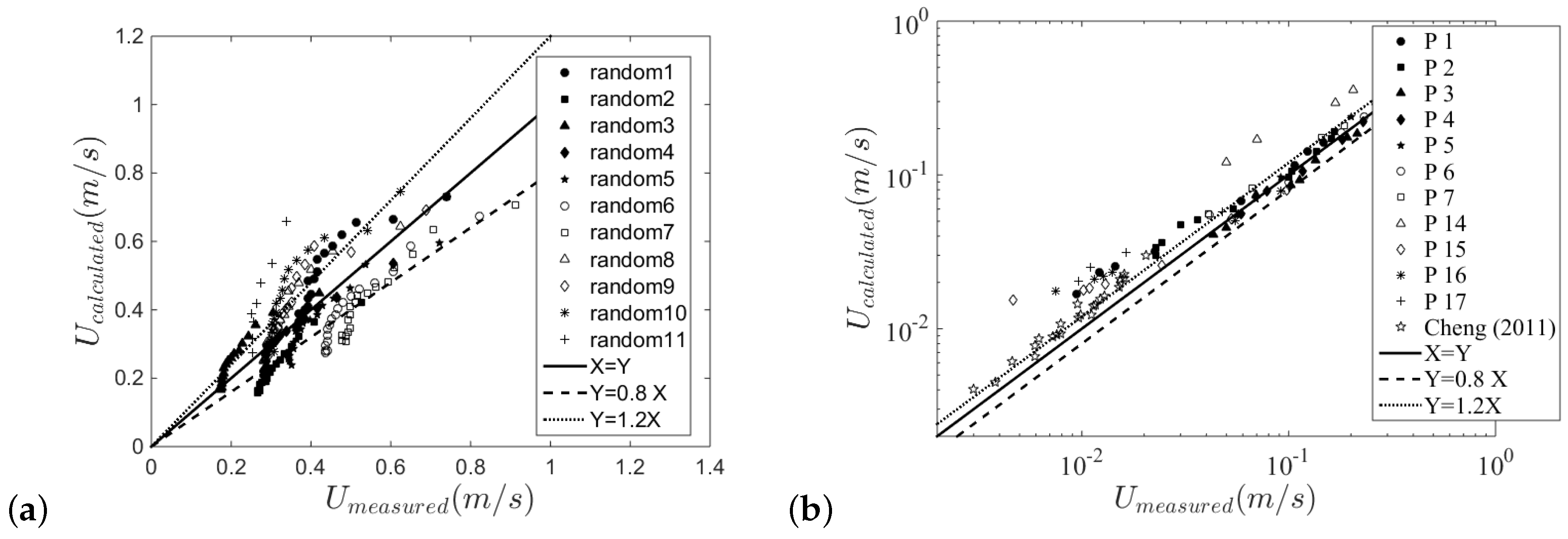

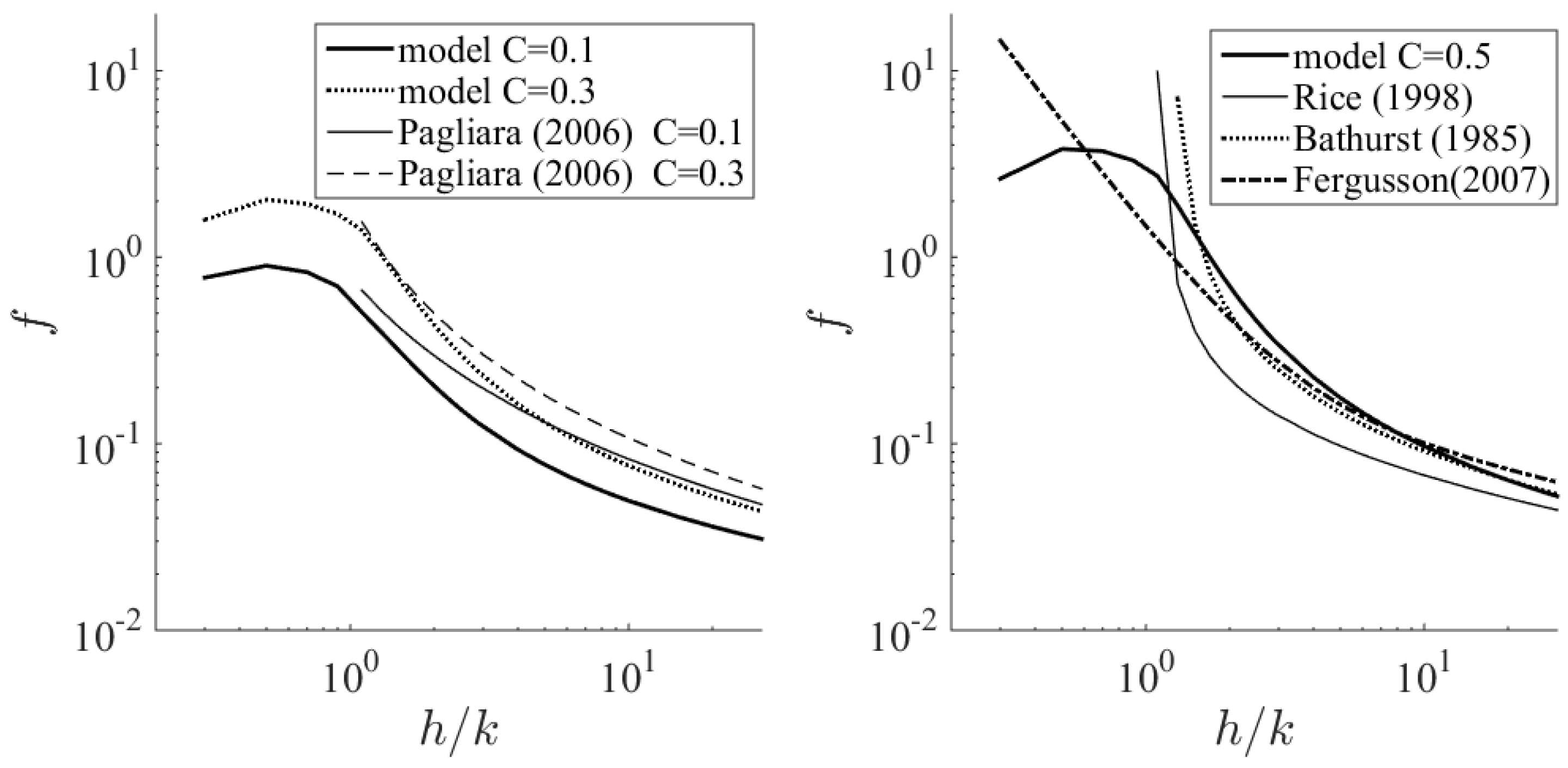

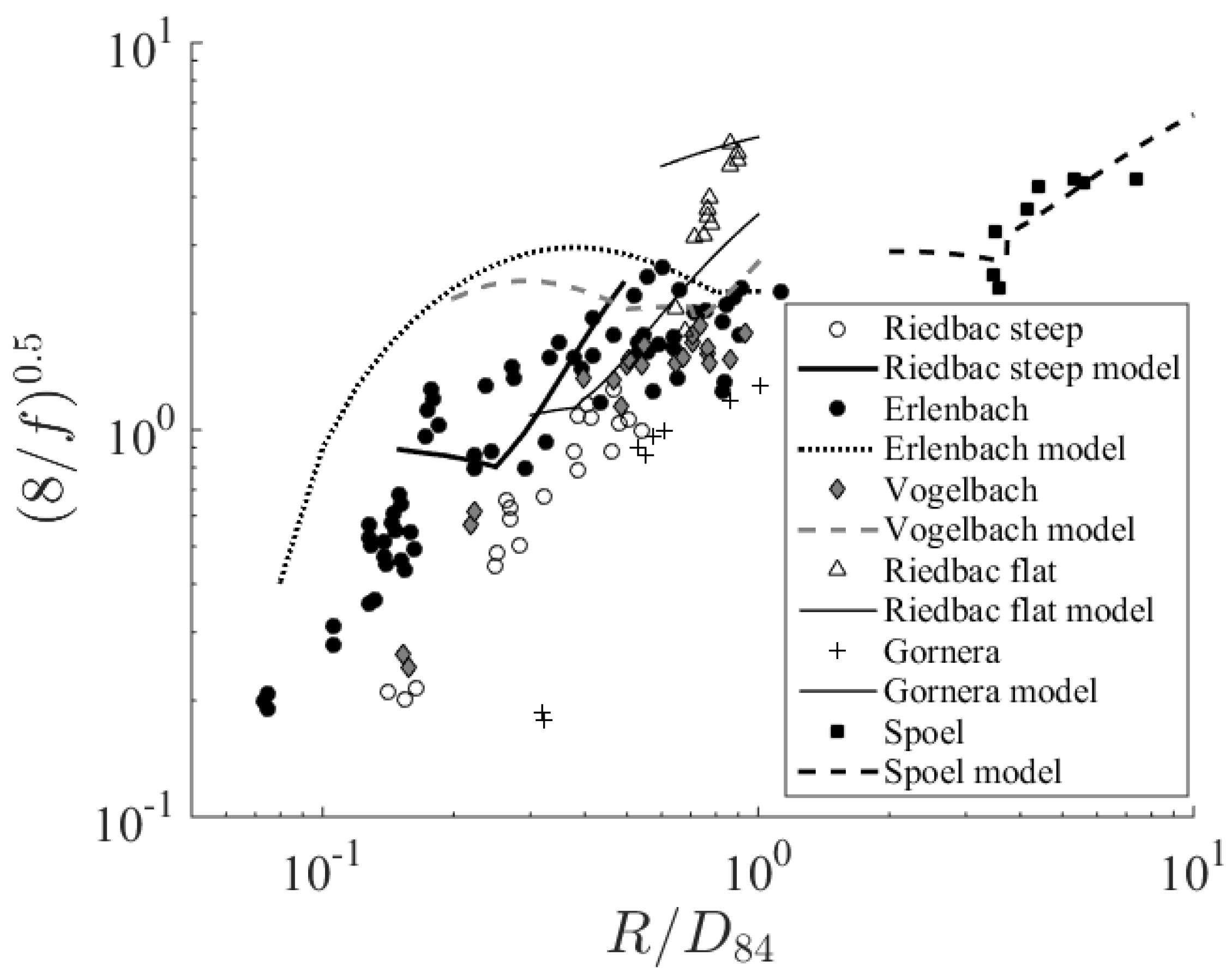

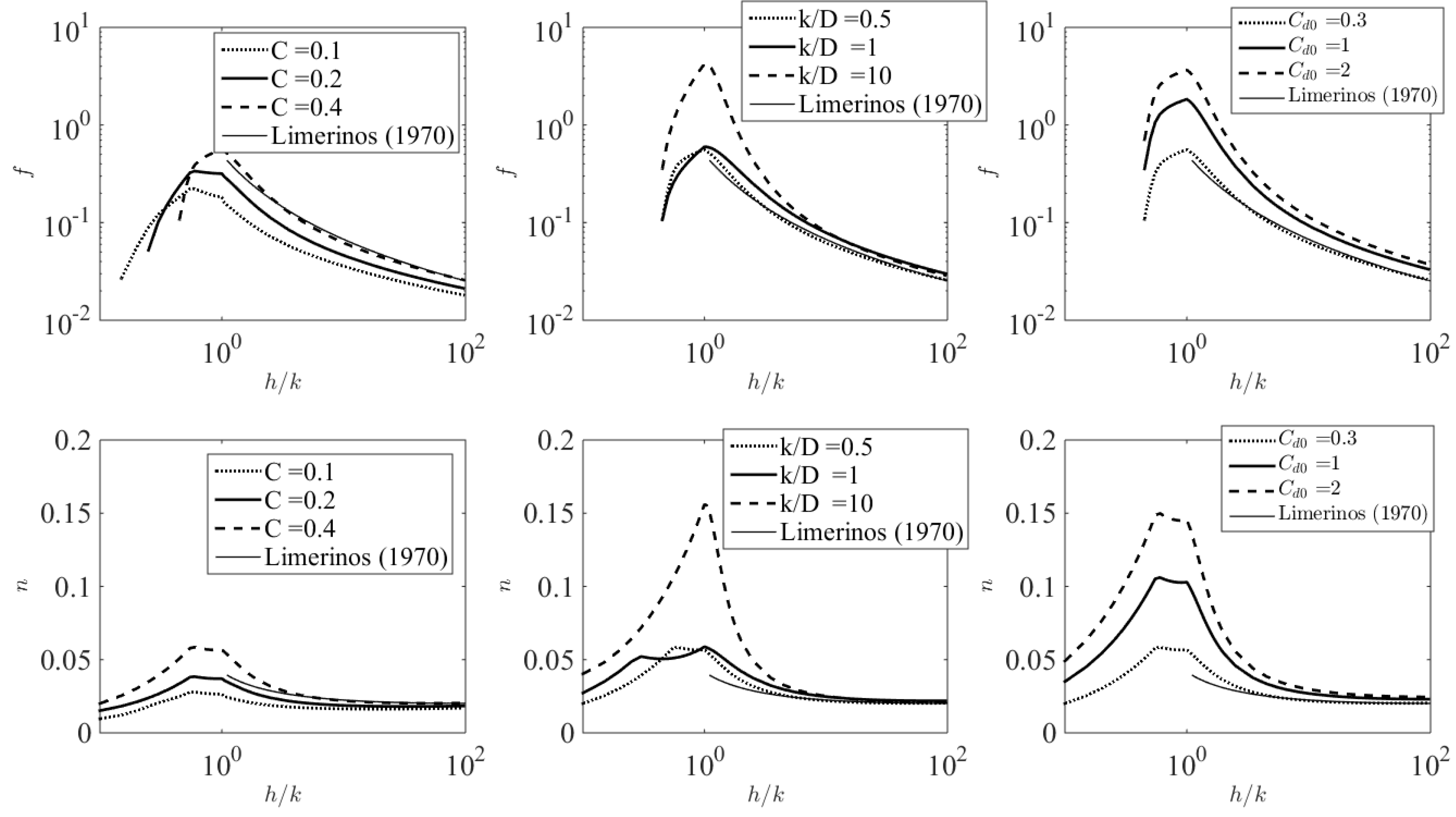

3.2. Validation of Friction Coefficients for River Flows

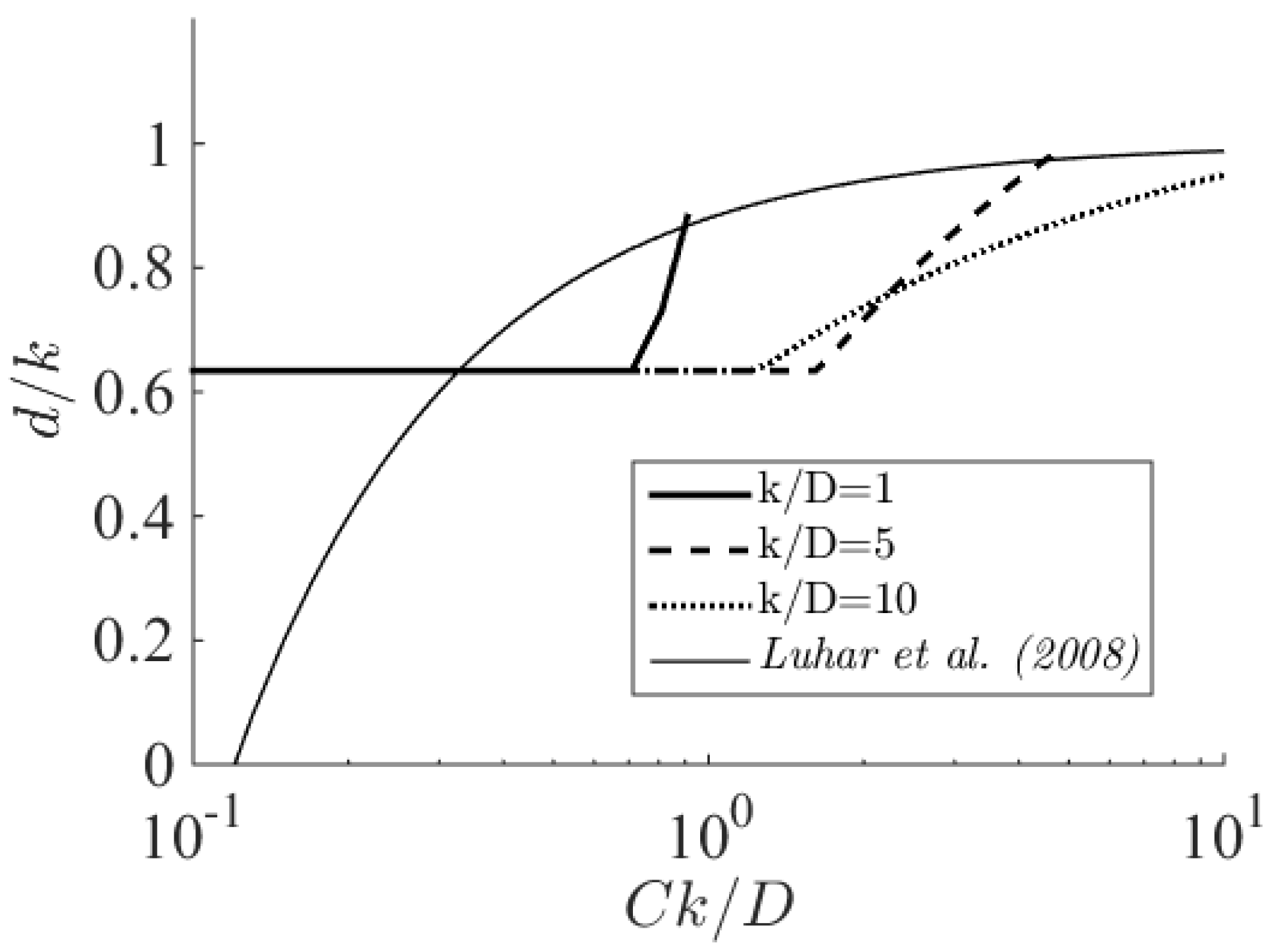

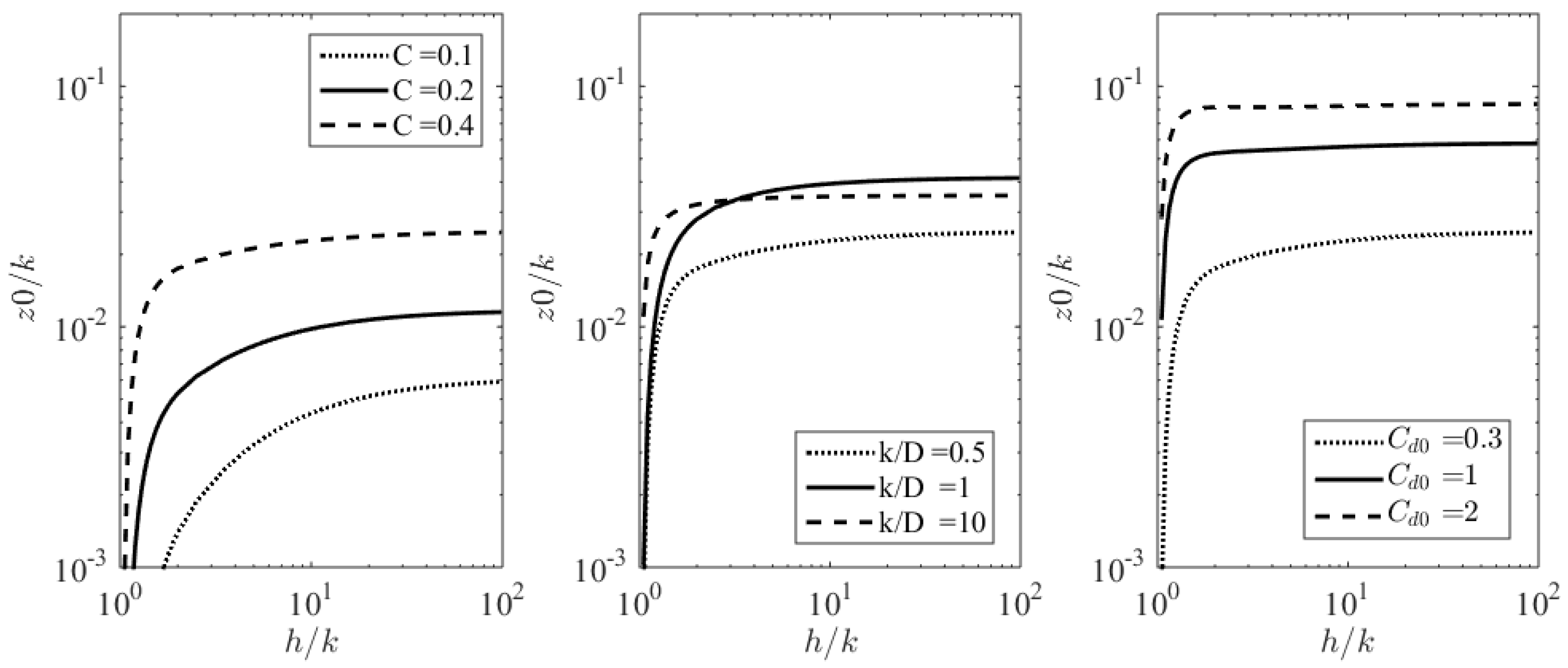

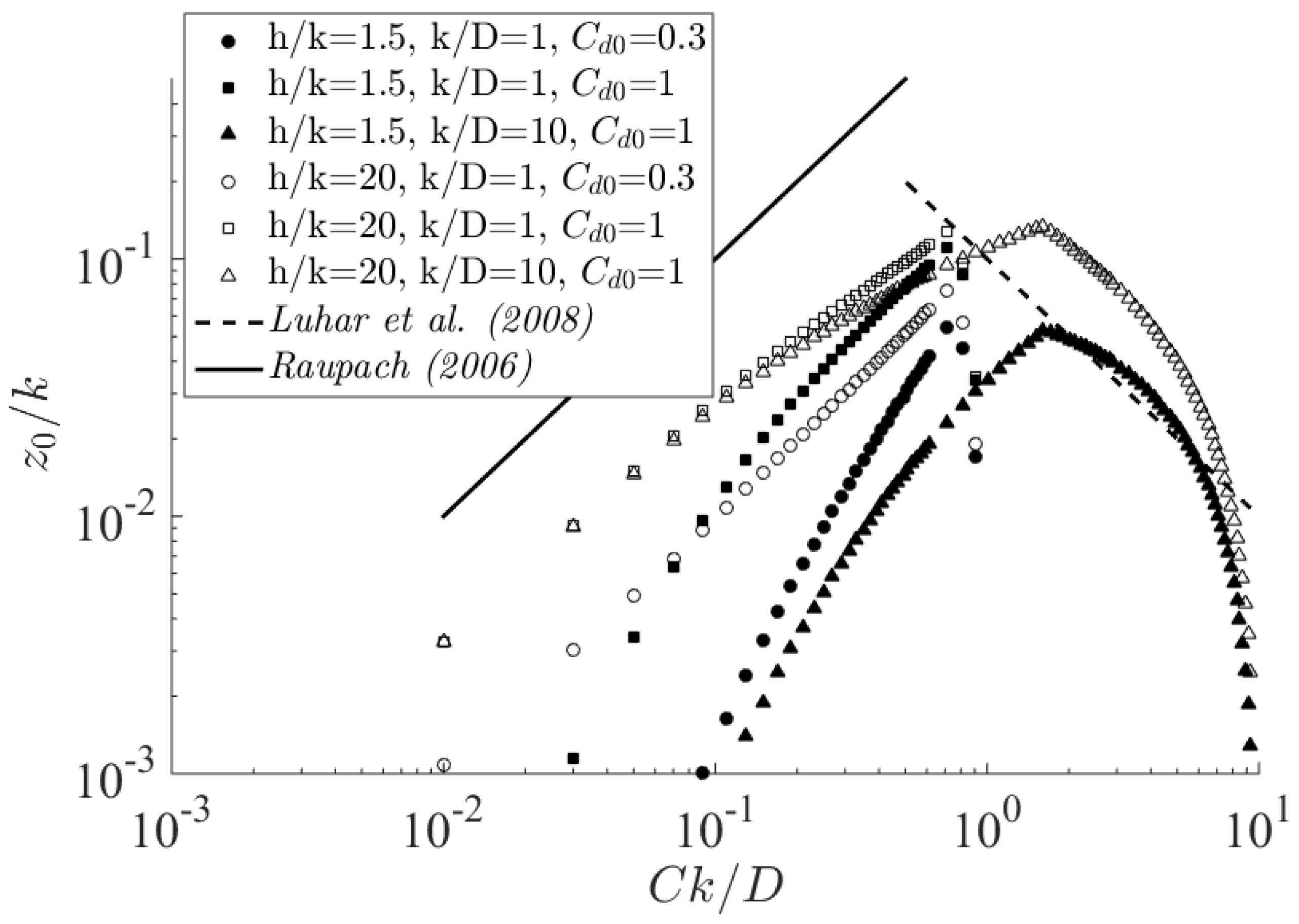

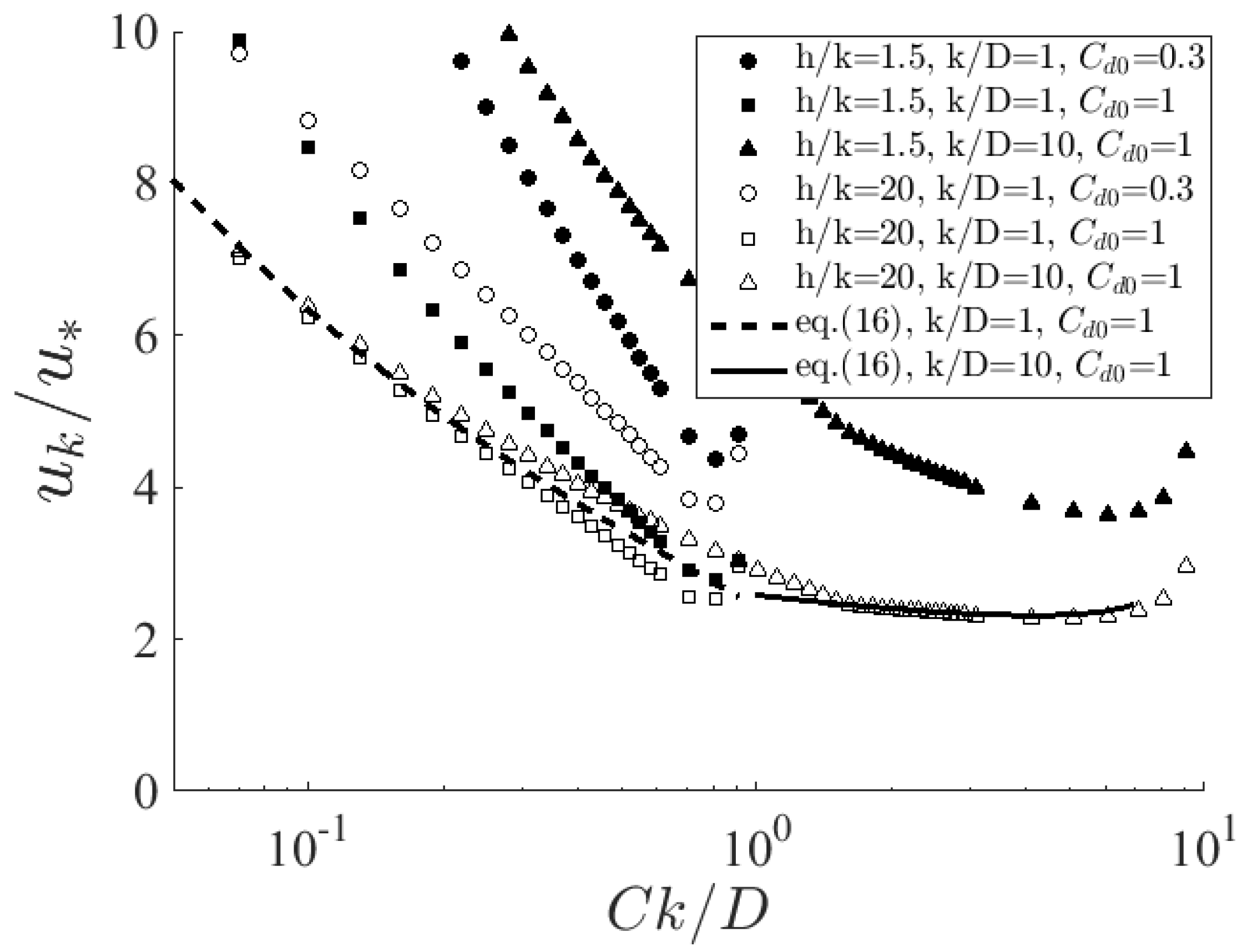

3.3. Log Law Parameters

3.4. Implication for Engineering Practice

4. Conclusions

- The friction for emergent or submerged roughness elements to be obtained in a continuous sense, which can arise when modeling obstacles in a main channel that are steeply sloping or very cluttered.

- The inclusion of the shape factor for blocks. Indeed, not taking it into account can lead to serious errors when modeling emergent obstacles. In the proposed model, both rocky blocks and vegetation (large ) can be represented as, for example, plantations of trees in a floodplain or overland flows for hillslope hydrology.

- The inclusion of the concentration of obstacles that can be determined in the field or by remote sensing.

- A continuous trend towards “rough bed” formulae when there is a high degree of submergence.

- A calibration parameter to be provided that depends only on the shape of the obstacle.

Author Contributions

Conflicts of Interest

References

- Pagliara, S.; Chiavaccini, P. Flow resistance of rock chutes with protruding boulders. J. Hydraul. Eng. 2006, 132, 545–552. [Google Scholar] [CrossRef]

- Klopstra, D.; Barneveld, H.; van Noortwijk, J.; van Velzen, E. Analytical model for hydraulic resistance of submerged vegetation. In Proceedings of the 27th IAHR Congress, San Francisco, CA, USA, 10–15 August 1997; pp. 775–780. [Google Scholar]

- Nepf, H.M. Drag, turbulence, and diffusion in flow through emergent vegetation. Water Resour. Res. 1999, 35, 479–489. [Google Scholar] [CrossRef]

- Chow, V.T. Open-Channel Hydraulics; McGraw-Hill: New York, NY, USA, 1995. [Google Scholar]

- Bathurst, J. Flow resistance estimation in mountain rivers. J. Hydraul. Eng. ASCE 1985, 111, 625–641. [Google Scholar] [CrossRef]

- Katul, G.G.; Poggi, D.; Ridolfi, L. A flow resistance model for assessing the impact of vegetation on flood routing mechanics. Water Resour. Res. 2011, 47, W08533. [Google Scholar] [CrossRef]

- Rice, C.E.; Kadavy, K.C.; Robinson, K.M. Roughness of loose rock riprap on steep slopes. J. Hydraul. Eng.-ASCE 1998, 124, 179–185. [Google Scholar] [CrossRef]

- Calomino, F.; Tafarojnoruz, A.; De Marchis, M.; Gaudio, R.; Napoli, E. Experimental and numerical study on the flow field and friction factor in a pressurized corrugated pipe. J. Hydraul. Eng. 2015, 141, 04015027. [Google Scholar] [CrossRef]

- Lopez, F.; Garcia, M. Mean flow and turbulence structure of open-channel flow through non-emergent vegetation. J. Hydraul. Eng. 2001, 127, 392–402. [Google Scholar] [CrossRef]

- Nikora, N.; Nikora, V.; ODonoghue, T. Velocity profiles in vegetated open-channel flows: Combined effects of multiple mechanisms. J. Hydraul. Eng. 2013, 139, 1021–1032. [Google Scholar] [CrossRef]

- Huthoff, F.; Augustijn, D.C.M.; Hulscher, S.J. Analytical solution of the depth-averaged flow velocity in case of submerged rigid cylindrical vegetation. Water Resour. Res. 2007, 43. [Google Scholar] [CrossRef]

- Konings, A.G.; Katul, G.G.; Thompson, S.E. A phenomenological model for the flow resistance over submerged vegetation. Water Resour. Res. 2012, 48, W02522. [Google Scholar] [CrossRef]

- Meijer, D.G.; Van Velzen, E. Prototype scale flume experiments on hydraulic roughness of submerged vegetation. In Proceedings of the 28th International IAHR Conference, Graz, Austria, 22–27 August 1999. [Google Scholar]

- Defina, A.; Bixio, A. Mean flow and turbulence in vegetated open channel flow. Water Ressour. Res. 2005, 41, 1–12. [Google Scholar] [CrossRef]

- Huai, W.; Zeng, Y.; Xu, Z.; Yang, Z. Three-layer model for vertical velocity distribution in open channel flow with submerged rigid vegetation. Adv. Water Res. 2009, 32, 487–492. [Google Scholar] [CrossRef]

- Poggi, D.; Krug, C.; Katul, G.G. Hydraulic resistance of submerged rigid vegetation derived from first-order closure models. Water Resour. Res. 2009, 45, W10442. [Google Scholar] [CrossRef]

- Cassan, L.; Laurens, P. Design of emergent and submerged rock-ramp fish passes. Knowl. Manag. Aquat. Ecosyst. 2016, 417, 45. [Google Scholar] [CrossRef]

- Canovaro, F.; Paris, E.; Solari, L. Effects of macro-scale bed roughness geometry on flow resistance. Water Resour. Res. 2007, 43, W10414. [Google Scholar] [CrossRef]

- Nitsche, M. Macro-Roughness, Flow Resistance and Sediment Transport in Steep Mountain Streams. Ph.D. Thesis, ETH Zurich, Zurich, Switzerland, 2012. [Google Scholar]

- Lawrence, D.S. Hydraulic resistance in overland flow during partial and marginal surface inundation: Experimental observations and modeling. Water Resour. Res. 2000, 36, 2381–2393. [Google Scholar] [CrossRef]

- Cheng, N. Representative roughness height of submerged vegetation. Water Resour. Res. 2011, 47, W08517. [Google Scholar] [CrossRef]

- Jordanova, A. Low Flow Hydraulics in Rivers for Environmental Applications in South Africa. Ph.D. Thesis, University of the Witwatersrand, Johannesburg, South Africa, 2008. [Google Scholar]

- Gilley, E.; Kottwitz, E.; Wieman, G. Darcy-weisbach roughness coefficients for gravel and cobble surfaces. J. Irrig. Drain. Eng. 1992, 118, 104–112. [Google Scholar] [CrossRef]

- Romdhane, H.; Soualmia, A.; Cassan, L.; Masbernat, L. Evolution of flow velocities in a rectangular channel with homogeneous bed roughness. Int. J. Eng. Res. 2017, 6, 120–128. [Google Scholar]

- Ferguson, R. Flow resistance equations for gravel- and boulder-bed streams. Water Resour. Res. 2007, 43, W05427. [Google Scholar] [CrossRef]

- Cassan, L.; Tien, T.; Courret, D.; Laurens, P.; Dartus, D. Hydraulic resistance of emergent macroroughness at large froude numbers: Design of nature-like fishpasses. J. Hydraul. Eng. 2014, 140, 04014043. [Google Scholar] [CrossRef]

- Ducrocq, T.; Cassan, L.; Chorda, J.; Roux, H. Flow and drag force around a free surface piercing cylinder for environmental applications. Environ. Fluid Mech. 2017, 17, 629–645. [Google Scholar] [CrossRef]

- Tran, T.D.; Chorda, J.; Laurens, P.; Cassan, L. Modelling nature-like fishway flow around unsubmerged obstacles using a 2d shallow water model. Environ. Fluid Mech. 2016, 16, 413–428. [Google Scholar] [CrossRef] [Green Version]

- Sadeque, M.; Rajaratnam, N.; Loewen, M. Flow around Cylinders in Open Channels. J. Eng. Mech. 2009, 134, 60–71. [Google Scholar] [CrossRef]

- Baki, A.; Zhu, D.; Rajaratnam, N. Flow Simulation in a Rock-Ramp Fish Pass. J. Hydraul. Eng. ASCE 2016, 142. [Google Scholar] [CrossRef]

- Luhar, M.; Rominger, J.; Nepf, H. Interaction between flow, transport and vegetation spatial structure. Environ. Fluid Mech. 2008, 8, 423–439. [Google Scholar] [CrossRef]

- Cheng, H.; Hayden, P.; Robins, A.; Castro, I. Flow over cube arrays of different packing densities. J. Wind Eng. Ind. Aerodyn. 2007, 95, 715–740. [Google Scholar] [CrossRef]

- Dodaro, G.; Tafarojnoruz, A.; Sciortino, G.; Adduce, C.; Calomino, F.; Gaudio, R. Modified Einstein sediment transport method to simulate the local Scour evolution downstream of a rigid bed. J. Hydraul. Eng. ASCE 2016, 142. [Google Scholar] [CrossRef]

- Nikuradse, J. Laws of Flow in Rough Pipes; National Advisory Committee for Aeronautics: Washington, DC, USA, 1933. [Google Scholar]

- Raupach, M.R.; Antonia, R.A.; Rajagopalan, S. Rough-wall turbulent boundary layers. Appl. Mech. Rev. 1991, 44, 1–25. [Google Scholar]

- Raupach, M.R.; Hughes, D.E.; Cleuch, H.A. Momentum absorption in rough-wall boundary layers with sparse roughness elements in ramdom and clustered distributions. Bound.-Lay. Meteorol. 2006, 120, 201–218. [Google Scholar]

- Limerinos, J. Determination of the Manning Coefficient from Measured Bed Roughness in Natural Channels; U.S. Geoeological Survey: Tacoma, WA, USA, 1970.

| D (mm) | k (mm) | C | Shape | |

|---|---|---|---|---|

| [17] | 35 | 30–100 | 0.08–0.2 | cylinder |

| [24] | 20 | 7 | 0.41 | truncated cone |

| [1] | 38 | 19 | 0–0.38 | hemisphere |

| [20] | 20 | 10 | 0.078/0.14/0.30 | hemisphere |

| [18] | 38–76 | 26–57 | 0–0.9 | pebbles |

| [21] | 3.2–8.3 | 100 | 0.05–0.15 | cylinder |

| [22] | 46–108 | 23–54 | 0.06–0.82 | hemisphere |

| [23] | (25.4–38.1) | (25.4–38.1) | 0.04–0.8 | gravels |

| [23] | (127–250) | (127–250) | 0.09–0.83 | cobbles |

| [19] | (620–830) | (220–410) | 0.05–0.37 | rocks |

| h/k | S(%) | C | ||

|---|---|---|---|---|

| [7] | 0.4–2 | 2.5–22 | rock ramp | |

| [5] | 0.5–6 | 0.5–3 | rock ramp | |

| [1] | 1–4 | 2.4–8.8 | 0–0.38 | |

| [25] | 0.1-30 | / | various |

| u (m s) | Parameters | |

|---|---|---|

| Upper layer | ||

| Lower layer | ||

| = |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cassan, L.; Roux, H.; Garambois, P.-A. A Semi-Analytical Model for the Hydraulic Resistance Due to Macro-Roughnesses of Varying Shapes and Densities. Water 2017, 9, 637. https://doi.org/10.3390/w9090637

Cassan L, Roux H, Garambois P-A. A Semi-Analytical Model for the Hydraulic Resistance Due to Macro-Roughnesses of Varying Shapes and Densities. Water. 2017; 9(9):637. https://doi.org/10.3390/w9090637

Chicago/Turabian StyleCassan, Ludovic, Hélène Roux, and Pierre-André Garambois. 2017. "A Semi-Analytical Model for the Hydraulic Resistance Due to Macro-Roughnesses of Varying Shapes and Densities" Water 9, no. 9: 637. https://doi.org/10.3390/w9090637