Velocity Distribution and 3D Turbulence Characteristic Analysis for Flow over Water-Worked Rough Bed

Abstract

:1. Introduction

2. Experimental Description

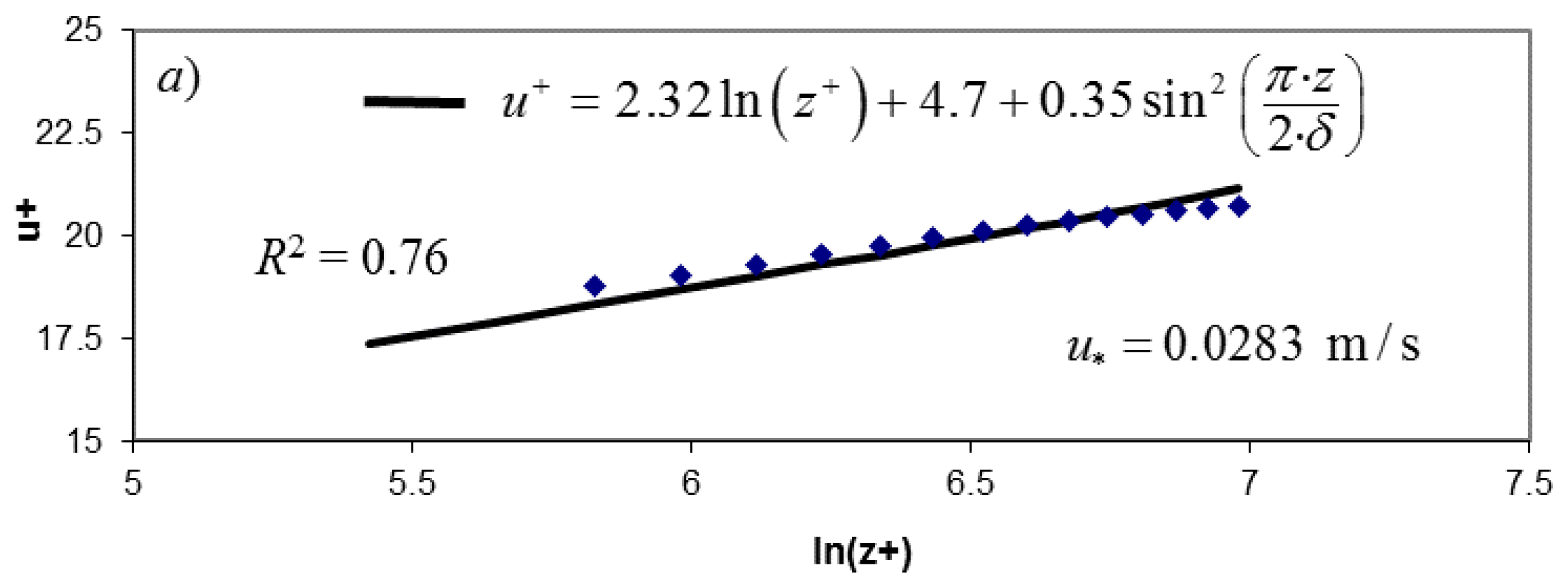

2.1. Friction Velocity

2.2. Experimental Instrumentations

2.3. Experimental Conditions

2.4. Rough and Water-Worked Beds Forming

3. Velocity Profile

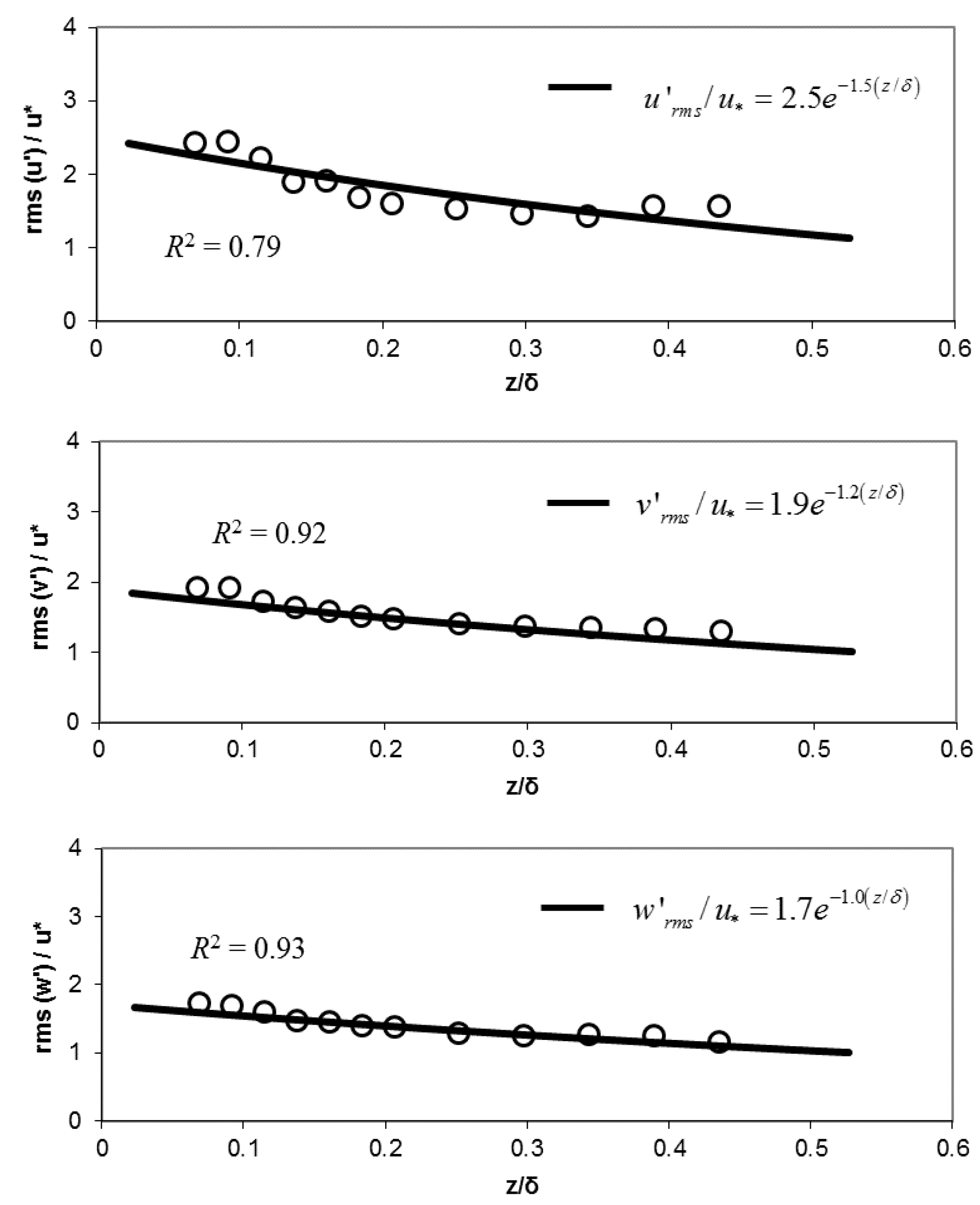

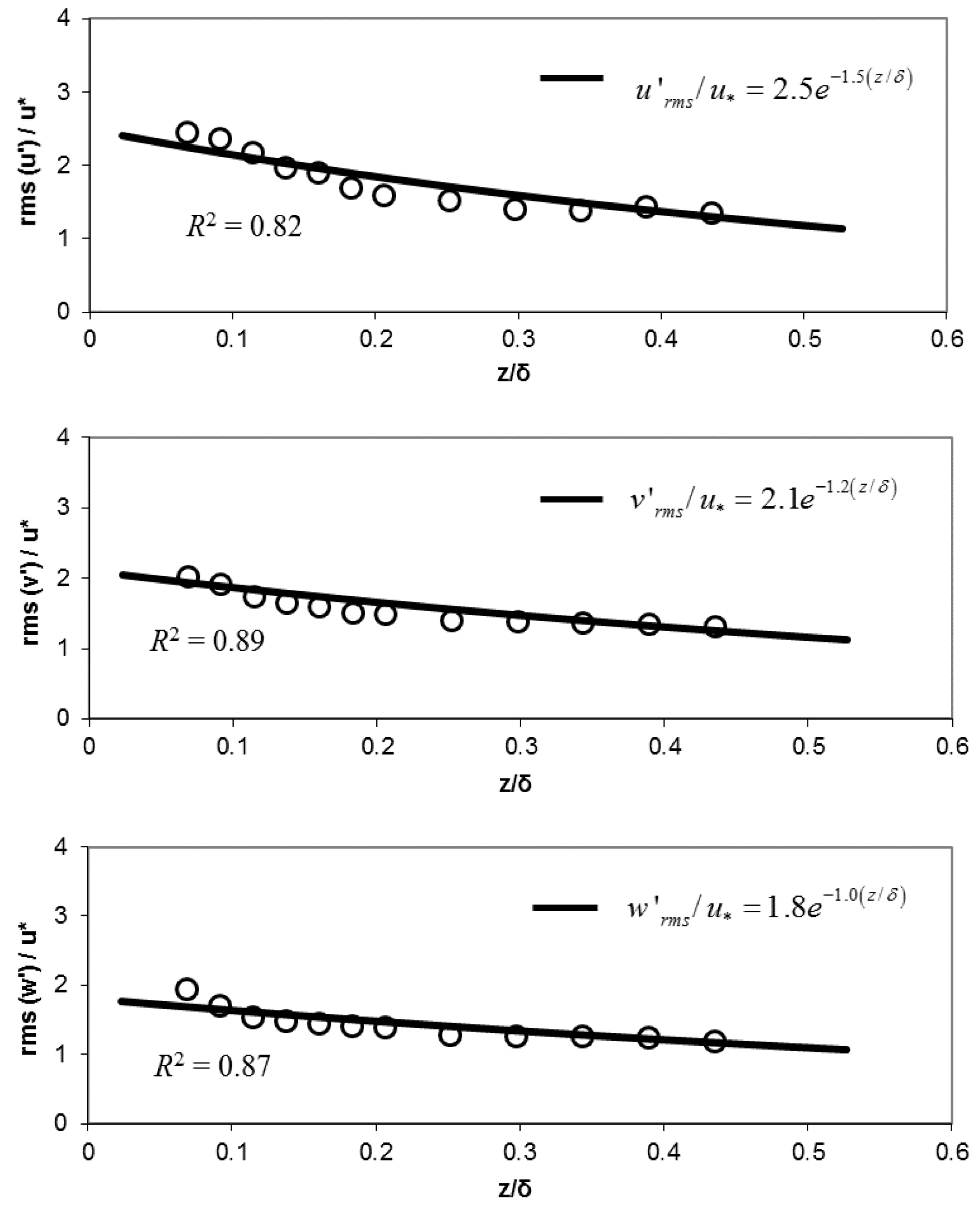

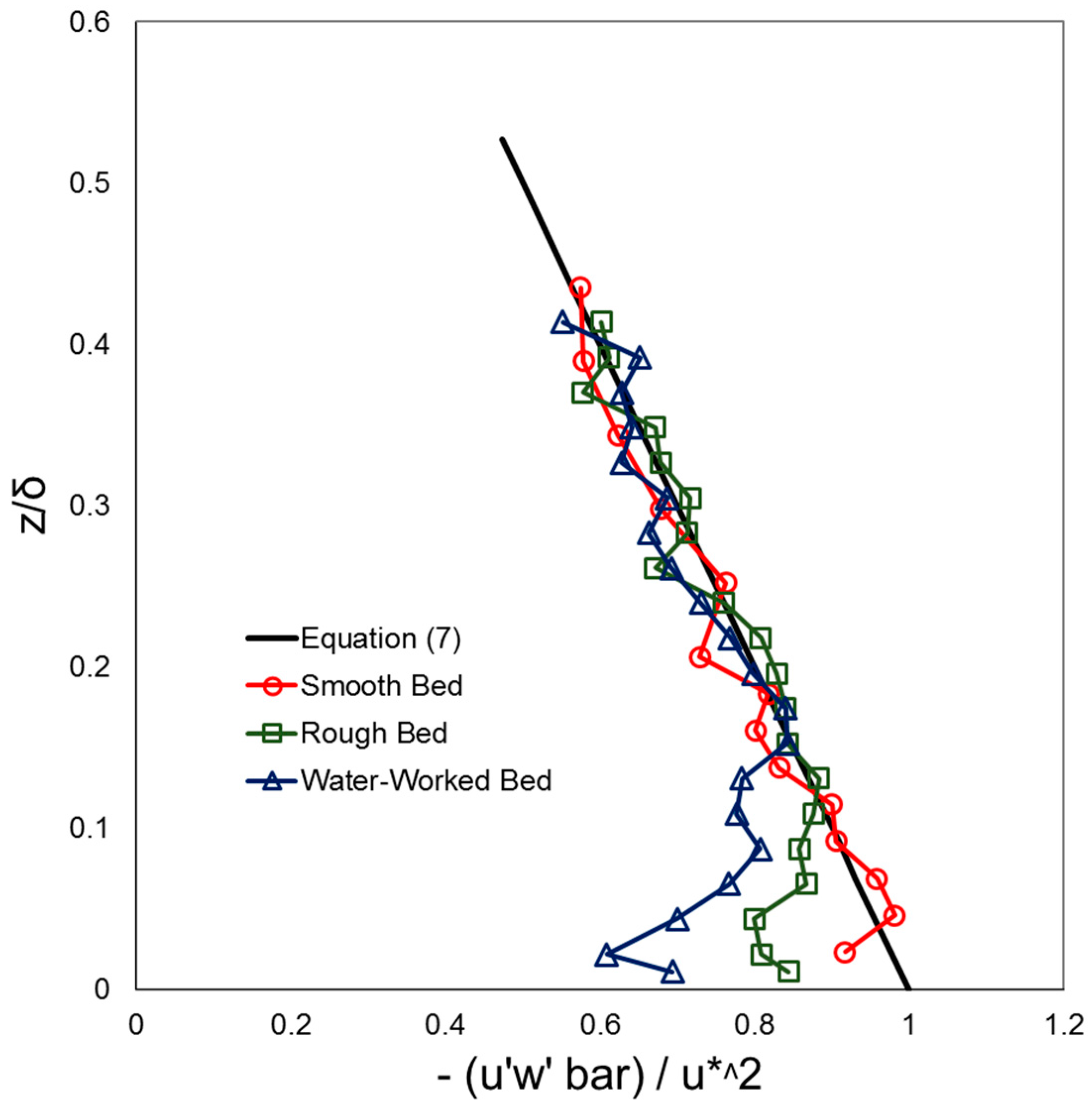

4. Turbulence Characteristics

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclatures

| Br | log law integration constant |

| d | sediment diameter/grain size |

| Fr | Froude number |

| g | gravitational acceleration |

| ks | Nikuradse roughness |

| P | pressure |

| R | hydraulic radius |

| So | channel slope |

| u* | friction velocity |

| u’ | fluctuation of streamwise velocity |

| v’ | fluctuation of lateral velocity |

| w’ | fluctuation of vertical velocity |

| x | longitudinal distance |

| y | lateral distance |

| z | vertical distance |

| zo | reference zero-plane displacement level |

| β | pressure gradient parameter |

| δ | water flow depth |

| κ | von Karman constant |

| ν | kinematic viscosity |

| П | wake parameter |

| ρ | water density |

| τo | bed shear stress |

References

- Cooper, J.R.; Tait, S.J. Examining the physical components of boundary shear stress for water-worked gravel deposits. Earth Surf. Process. Landf. 2010, 35, 1240–1246. [Google Scholar] [CrossRef]

- Cooper, J.R.; Tait, S.J. Spatial representative velocity measurement over water-worked gravel beds. Water Resour. Res. 2010, 46, 1–15. [Google Scholar] [CrossRef]

- Coleman, S.E.; Nikora, V.I.; Schlicke, T. Spatially-averaged oscillatory flow over a rough bed. Acta Geophys. 2008, 56, 698–733. [Google Scholar] [CrossRef] [Green Version]

- Qin, J.; Ng, S.L. Estimation of effective roughness for water-worked gravel surfaces. J. Hydraul. Eng. 2012, 138, 923–934. [Google Scholar] [CrossRef]

- Pu, J.H.; Shao, S.; Huang, Y. Numerical and experimental turbulence studies on shallow open channel flows. J. Hydrol. Environ. Res. 2014, 8, 9–19. [Google Scholar] [CrossRef]

- Nezu, I.; Rodi, W. Open-channel flow measurements with a laser Doppler anemometer. J. Hydraul. Eng. 1986, 112, 335–355. [Google Scholar] [CrossRef]

- Nezu, I.; Nakagawa, H. Turbulent Open-Channel Flows; IAHR Monograph Series: Rotterdam, The Netherlands, 1993. [Google Scholar]

- Nezu, I.; Azuma, R. Turbulence characteristics and interaction between particles and fluid in particle-laden open channel flows. J. Hydraul. Eng. 2004, 130, 988–1001. [Google Scholar] [CrossRef]

- Coles, D. The law of the wake in the turbulent boundary layer. J. Fluid Mech. 1956, 1, 191–226. [Google Scholar] [CrossRef]

- Keulegan, G.H. Laws of turbulent flow in open channels. J. Res. Nat. Bur. Stand. 1938, 21, 707–741. [Google Scholar] [CrossRef]

- Biron, P.M.; Robson, C.; Lapointe, M.F.; Gaskin, S.J. Comparing different methods of bed shear stress estimates in simple and complex flow fields. Earth Surf. Process. Landf. 2004, 29, 1403–1415. [Google Scholar] [CrossRef]

- Song, T.; Chiew, Y.M. Turbulence measurement in nonuniform open-channel flow using acoustics Doppler velocimeter (ADV). J. Eng. Mech. 2001, 127, 219–232. [Google Scholar] [CrossRef]

- Dey, S.; Raikar, R.V. Characteristics of loose rough boundary streams at near-threshold. J. Hydraul. Eng. 2007, 133, 288–304. [Google Scholar] [CrossRef]

- Yu, G.; Tan, S.K. Errors in bed shear stress as estimated from vertical velocity profile. J. Irrig. Drain. Eng. 2006, 132, 490–497. [Google Scholar] [CrossRef]

- Pu, J.H. Turbulence modelling of shallow water flows using Kolmogorov approach. Comput. Fluids 2015, 115, 66–74. [Google Scholar] [CrossRef]

- Pu, J.H.; Shao, S. Non-uniform open channel flows study using three-dimensional turbulence measurements. In Proceedings of the 35th International IAHR World Congress, Chengdu, China, 8–13 September 2013; Article A10326. pp. 1–10. [Google Scholar]

- Blanckaert, K.; Lemmin, U. Means of noise reduction in acoustic turbulence measurements. J. Hydraul. Res. 2006, 44, 1–15. [Google Scholar] [CrossRef]

- Van Rijn, L.C. Sediment transport. Part I: Bed load transport. J. Hydraul. Eng. 1984, 110, 1431–1456. [Google Scholar] [CrossRef]

- Cardoso, A.H.; Graf, W.H.; Gust, G. Uniform flow in a smooth open channel. J. Hydraul. Res. 1989, 27, 603–616. [Google Scholar] [CrossRef]

- Song, T.; Graf, W.H.; Lemmin, U. Uniform flow in open channels with movable gravel bed. J. Hydraul. Res. 1994, 32, 149–173. [Google Scholar] [CrossRef]

- Auel, C.; Albayrak, I.; Boes, R.M. Turbulence characteristics in supercritical open channel flows: Effects of Froude number and aspect ratio. J. Hydraul. Eng. 2014, 140, 04014004. [Google Scholar] [CrossRef]

- Mellor, G.L.; Gibson, D.M. Equilibrium turbulent boundary layers. J. Fluid Mech. 1966, 24, 225–253. [Google Scholar] [CrossRef]

- Anwar, H.O.; Atkins, R. Turbulence measurements in simulated tidal flow. J. Hydraul. Div. 1980, 106, 1273–1289. [Google Scholar]

- Kironoto, B.A.; Graf, W.H. Turbulence characteristics in rough uniform open-channel flow. Proc. Inst. Civ. Eng.-Water Marit. Eng. 1994, 106, 333–344. [Google Scholar] [CrossRef]

- Kirkgoz, M.S. Turbulent velocity profiles for smooth and rough open channel flow. J. Hydraul. Eng. 1989, 115, 1543–1561. [Google Scholar] [CrossRef]

- Steffer, P.M.; Rajaratnam, N.; Peterson, A.W. LDA measurements in open channel. J. Hydraul. Eng. 1985, 111, 119–130. [Google Scholar] [CrossRef]

- Pu, J.H. Universal velocity distribution for smooth and rough open channel flows. J. Appl. Fluid Mech. 2013, 6, 413–423. [Google Scholar]

- Nezu, I. Turbulent Structure in Open Channel Flows. Ph.D. Thesis, Kyoto University, Kyoto, Japan, 1 July 1977. (In Japanese). [Google Scholar]

- Papanicolaou, A.N.; Hilldale, R. Turbulence characteristics in gradual channel transition. J. Hydraul. Eng. 2002, 128, 948–960. [Google Scholar] [CrossRef]

| Test No. | Q (L/s) | U (m/s) | δ (m) | Fr (-) | u* (m/s) | Bed Condition | Flow Feature |

|---|---|---|---|---|---|---|---|

| 1 | 40.5 | 0.667 | 0.135 | 0.579 | 0.0283 | Smooth | Uniform |

| 2 | 40.5 | 0.687 | 0.131 | 0.606 | 0.0536 | Rough | Uniform |

| 3 | 40.5 | 0.687 | 0.131 | 0.606 | 0.0598 | Water-Worked | Uniform |

| Sources | D1 | D2 | D3 | λ1 | λ2 | λ3 | Bed Condition(s) |

|---|---|---|---|---|---|---|---|

| Present Study | 2.50 | 1.60 | 1.50 | 1.50 | 1.00 | 0.60 | Smooth |

| Present Study | 2.50 | 1.90 | 1.70 | 1.50 | 1.20 | 1.00 | Rough |

| Present Study | 2.50 | 2.10 | 1.80 | 1.50 | 1.20 | 1.00 | Water-Worked |

| Cardoso et al. [19] | 2.28 | - | - | 1.08 | - | - | Smooth |

| Dey and Raikar [13] | 2.07 | - | 1.17 | 0.95 | - | 0.69 | Rough |

| Kironoto and Graf [24] | 2.04 | - | 1.14 | 0.97 | - | 0.76 | Rough |

| Nezu and Azuma [8] | 2.30 | - | 1.27 | 1.00 | - | 1.00 | Smooth & Rough |

| Nezu and Nakagawa [7] | 2.30 | 1.63 | 1.27 | 1.00 | 1.00 | 1.00 | Smooth & Rough |

| Nezu and Rodi [6] | 2.26 | - | 1.23 | 0.88 | - | 0.67 | Smooth & Rough |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pu, J.H.; Wei, J.; Huang, Y. Velocity Distribution and 3D Turbulence Characteristic Analysis for Flow over Water-Worked Rough Bed. Water 2017, 9, 668. https://doi.org/10.3390/w9090668

Pu JH, Wei J, Huang Y. Velocity Distribution and 3D Turbulence Characteristic Analysis for Flow over Water-Worked Rough Bed. Water. 2017; 9(9):668. https://doi.org/10.3390/w9090668

Chicago/Turabian StylePu, Jaan Hui, Jiahua Wei, and Yuefei Huang. 2017. "Velocity Distribution and 3D Turbulence Characteristic Analysis for Flow over Water-Worked Rough Bed" Water 9, no. 9: 668. https://doi.org/10.3390/w9090668