Laboratory Investigation of the Effect of Slenderness Effect on the Non-Darcy Groundwater Flow Characteristics in Bimsoils

Abstract

:1. Introduction

2. Experimental Methods

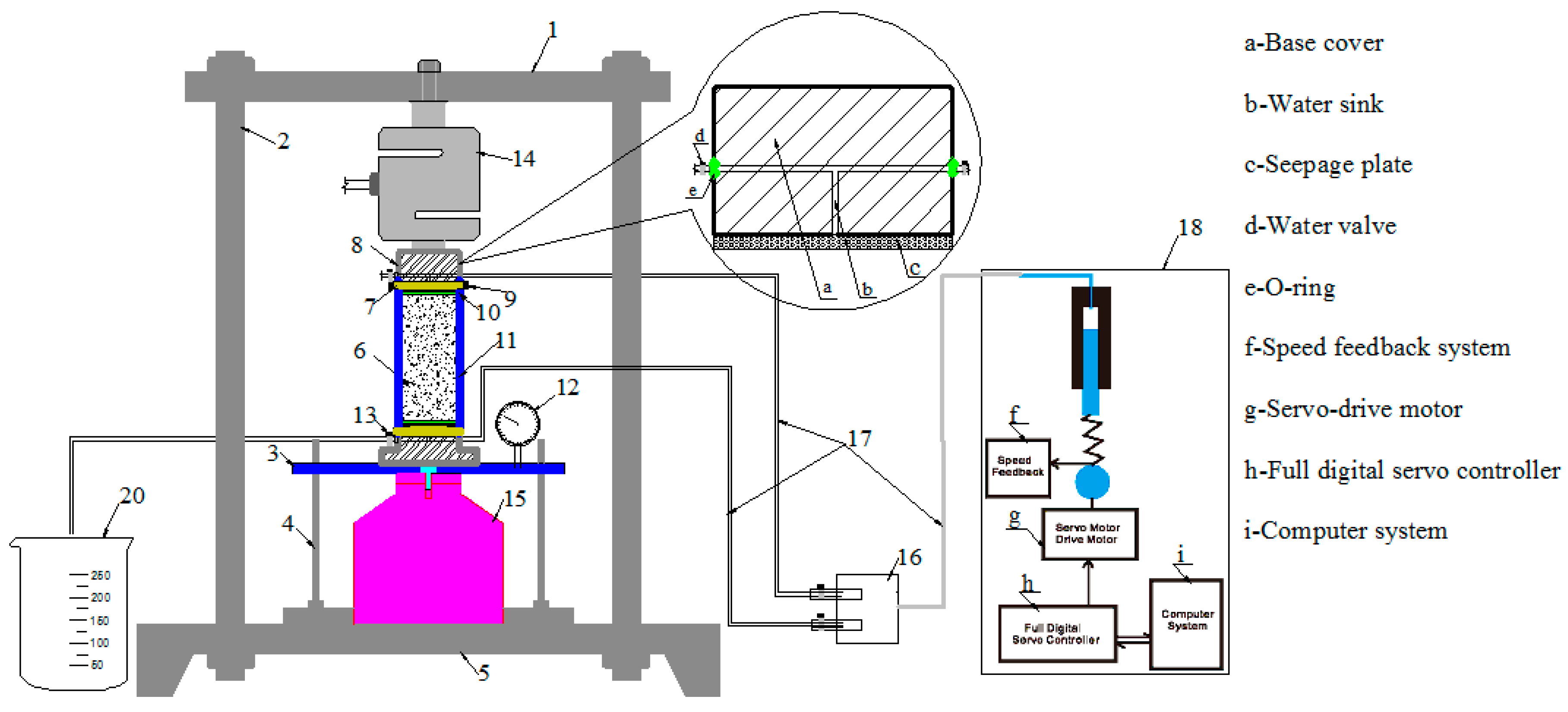

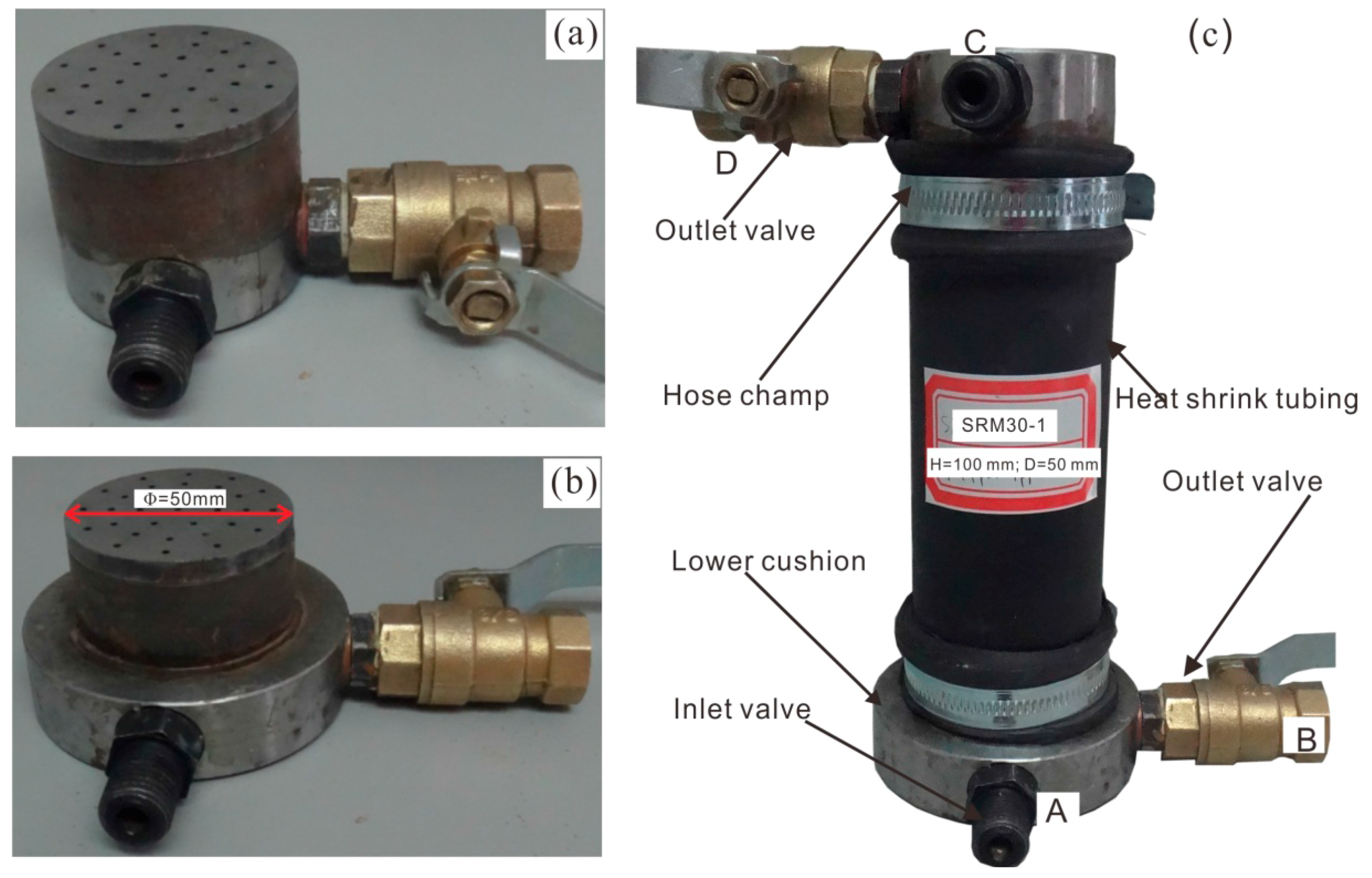

2.1. Experimental Setup

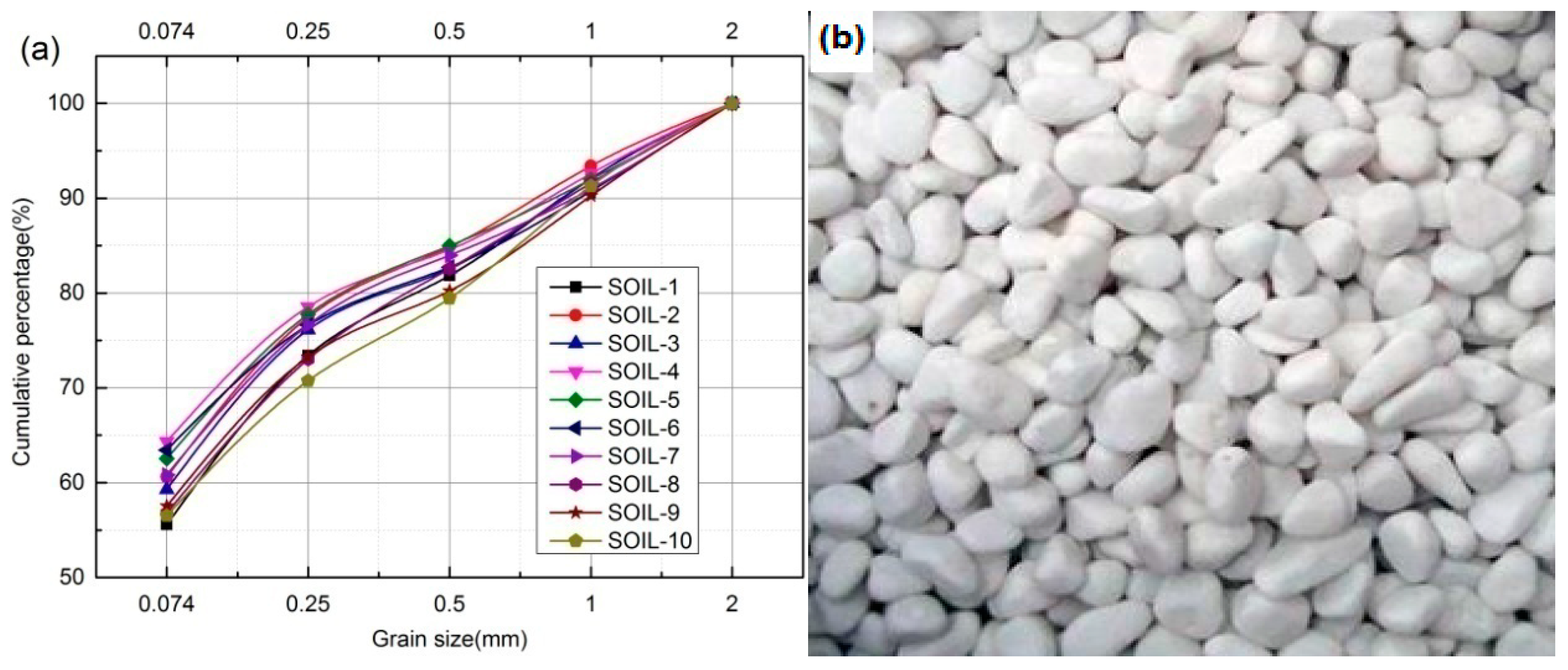

2.2. Material Properties

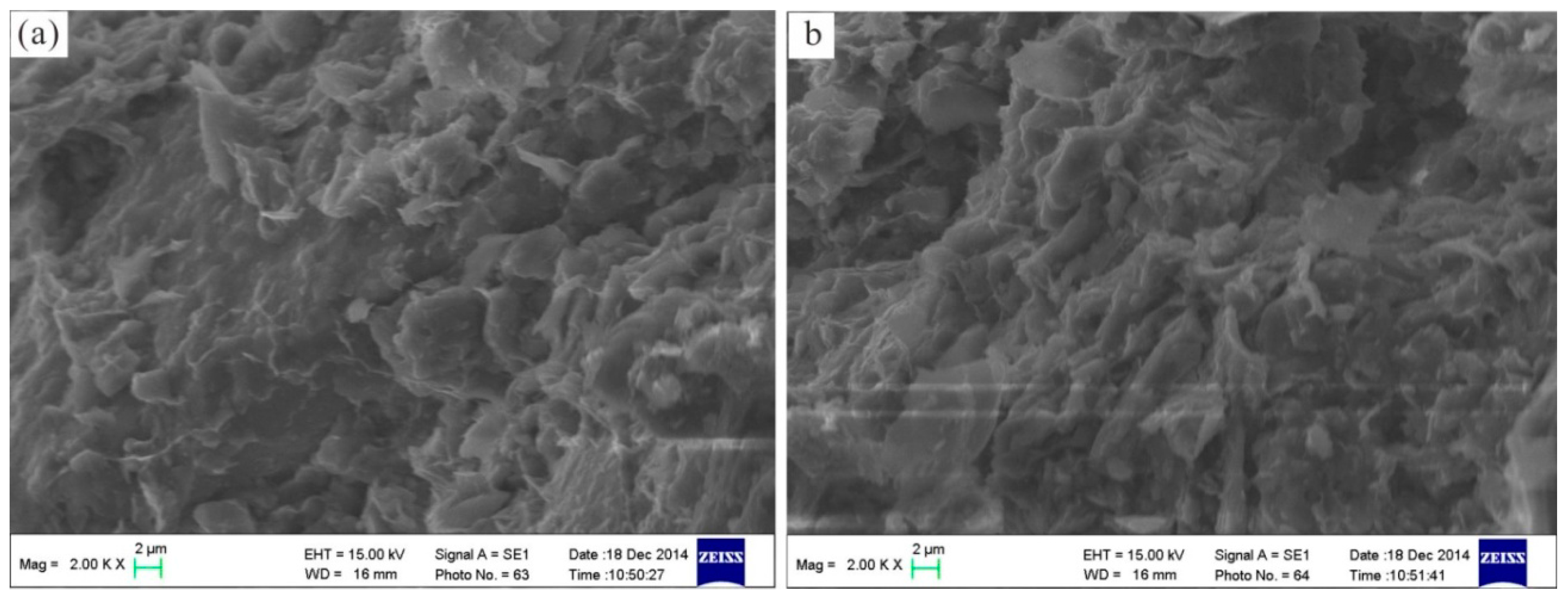

2.2.1. Soil Matrix

2.2.2. Rock Blocks

2.3. Remolded Sample Preparation

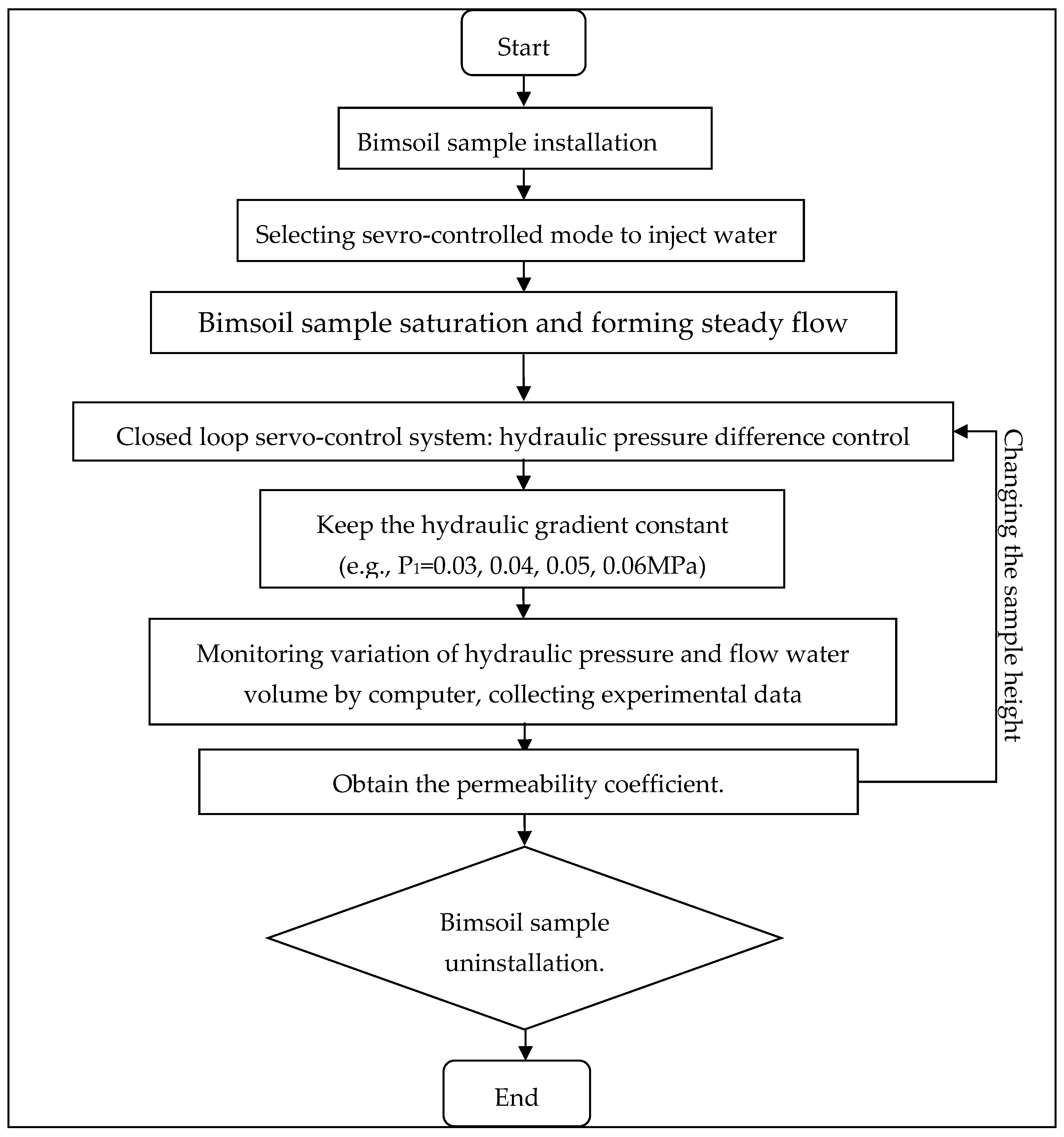

2.4. Test Procedure

3. Experimental Results and Discussion

3.1. General Descriptions

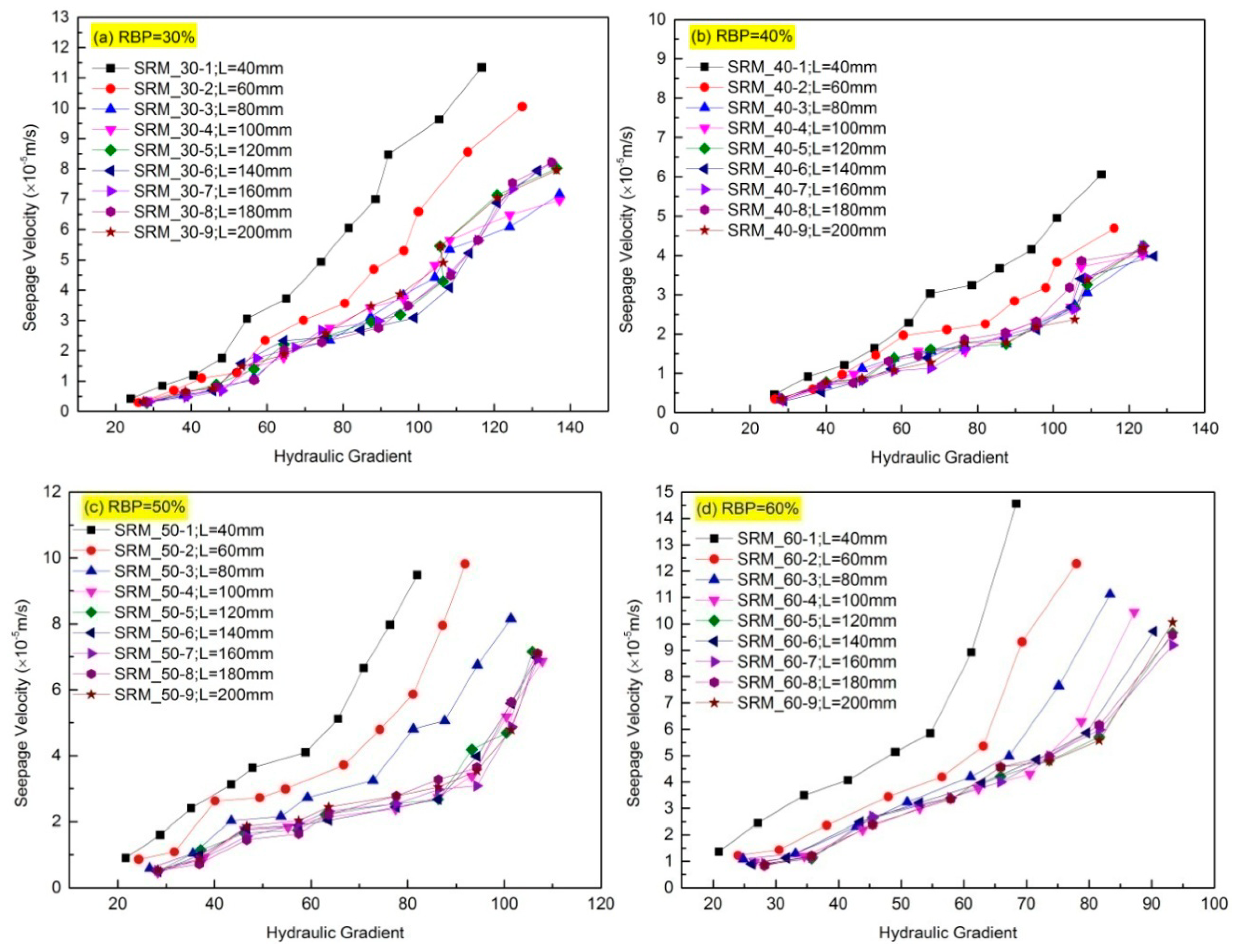

3.2. The Non-Darcy’s Flow of Bimsoils

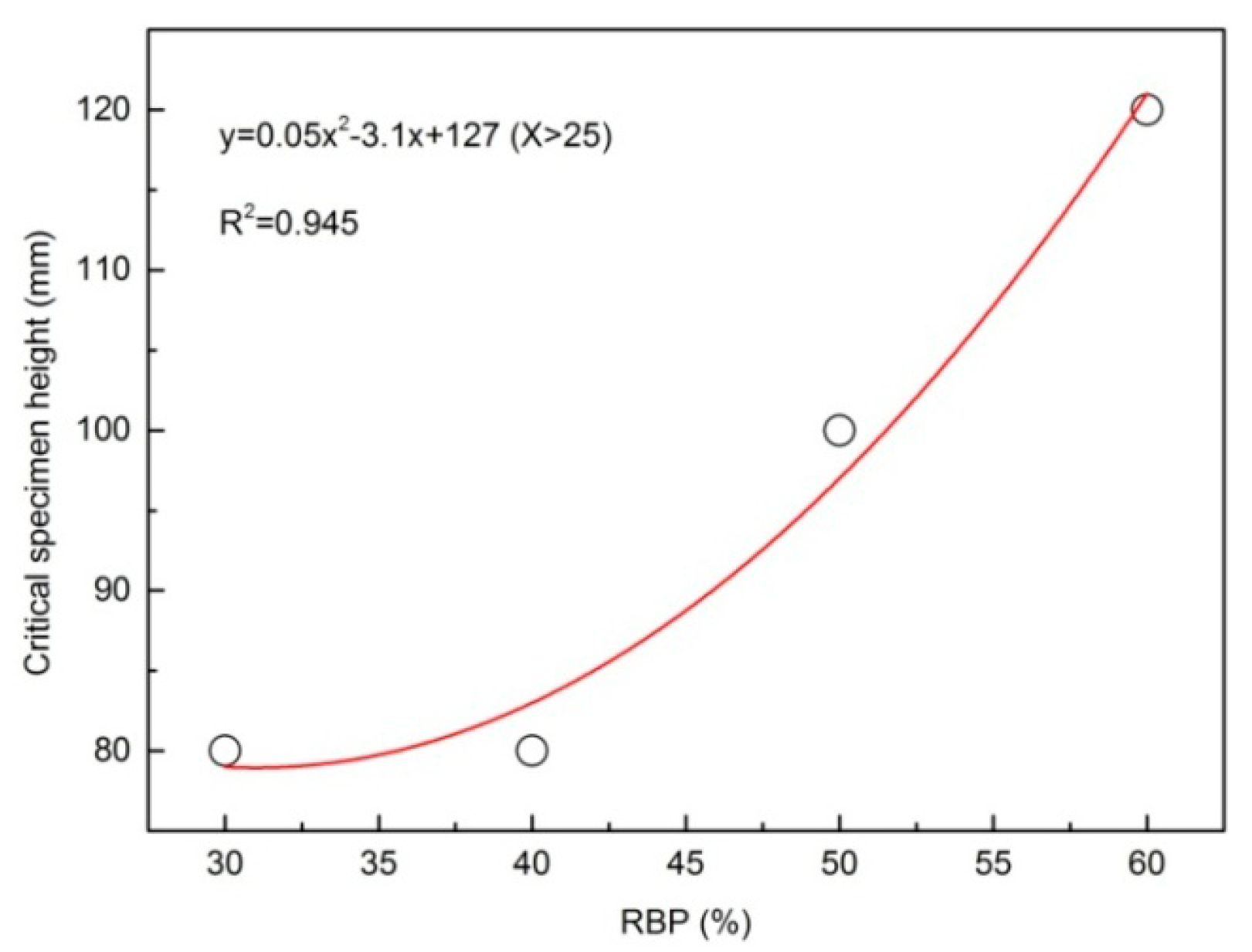

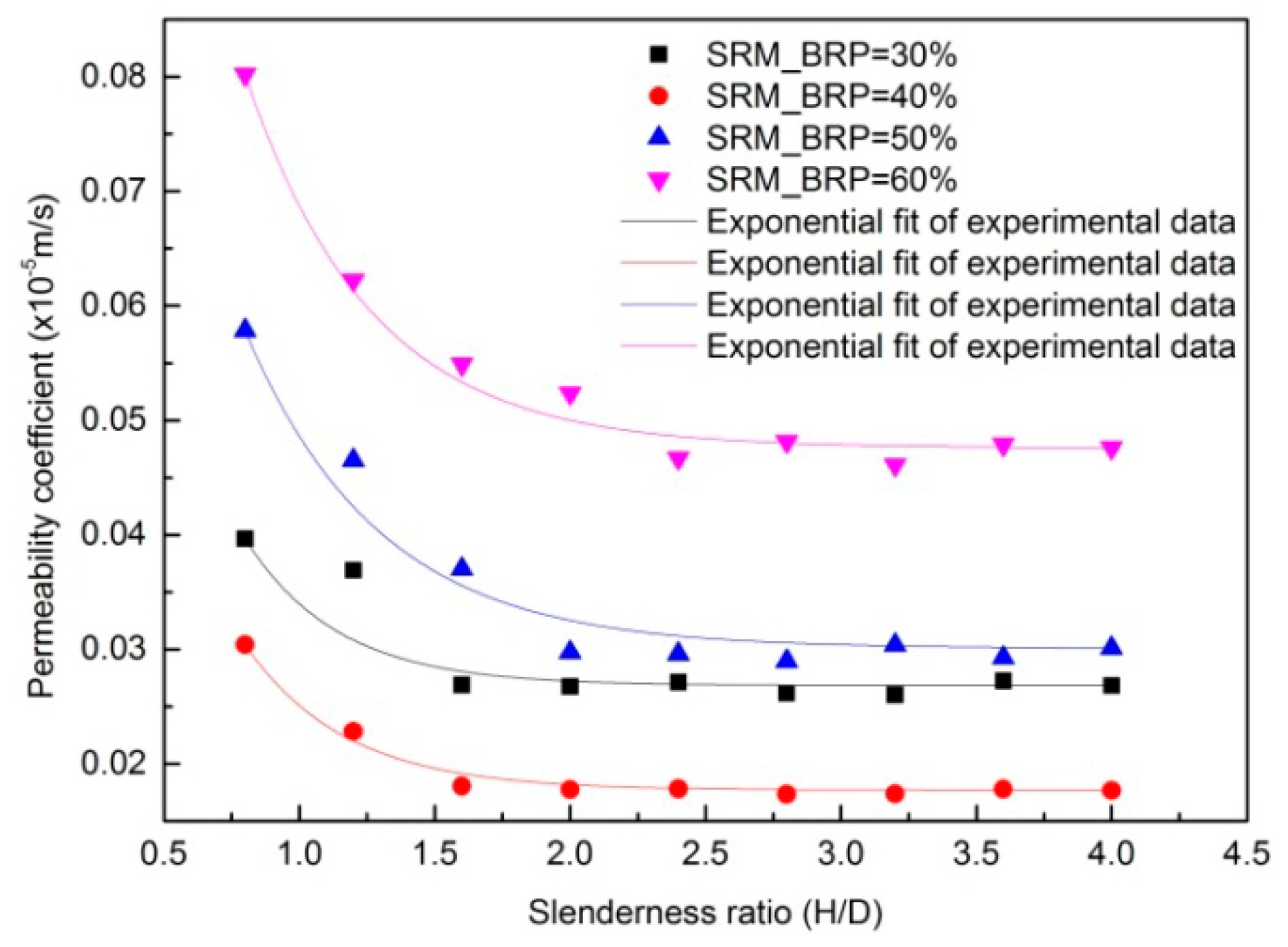

3.3. Slenderness Effect on Flow Characteristics

3.4. Discussions

4. Conclusions

- (1)

- Flow distance is a key factor influencing the non-Darcy flow characteristics of bimsoil. With the increase flow distance, the seepage field in bimsoil tends to stabilize, and the seepage velocity is prone to be a constant value at the same hydraulic gradient. The permeability of bimsoil is influenced by the soil matrix properties combined with rock blocks and rock–soil interfaces.

- (2)

- The permeability coefficient of bimsoil samples with different slenderness ratios is different. The value of the permeability coefficient decreases with the increase of flow distance. At the same sample diameter, the critical height varies for samples with different RBP, and its value increases with increasing RBP. The permeability coefficient varies in a monotonously decreasing nonlinear correlation with the sample slenderness. The slenderness effect for high RBP scenario is much more obvious.

- (3)

- The degree of non-Darcy flow in bimsoil decreases with the increase of sample height. The flow path is prone to be along the channel with the least tortuosity, and a more slender sample can provide more possible flow paths along the flow direction.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Coli, N.; Berry, P.; Boldini, D. In situ non-conventional shear tests for the mechanical characterisation of a bimrock. Int. J. Rock Mech. Min. 2011, 48, 95–102. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X. Experimental study on cracking damage characteristics of a soil and rock mixture by UPV testing. Bull. Eng. Geol. Environ. 2015, 74, 775–788. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Wu, Y.F.; Lin, C.; Zhang, B. Experimental study on meso-damage cracking characteristics of RSA by CT test. Environ. Earth Sci. 2015, 73, 5545–5558. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Zheng, B.; Zhang, B.; Wang, J.B. Real-time ultrasonic experiments and mechanical properties of soil and rock mixture during triaxial deformation. Géotech. Lett. 2015, 5, 281–286. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Zheng, B.; Zhang, Y.X.; Li, G.F. Experimental study on the non-Darcy flow characteristics of soil–rock mixture. Environ. Earth Sci. 2016, 75, 1–18. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Zheng, B.; Li, S.D.; Duan, Y.T. A laboratory study of the effect of confining pressure on permeable property in soil-rock mixture. Environ. Earth Sci. 2016, 75, 1–16. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Zheng, B.; Ma, C.F. An Experimental Investigation of the Flow–Stress Coupling Characteristics of Soil–Rock Mixture Under Compression. Transp. Porous Med. 2016, 112, 429–450. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Zheng, B.; He, J.M.; Li, S.D. Macro–meso failure mechanism of soil–rock mixture at medium strain rates. Géotech. Lett. 2016, 6, 28–33. [Google Scholar] [CrossRef]

- Zhang, S.; Tang, H.M.; Zhan, H.B.; Lei, G.P.; Cheng, H. Investigation of scale effect of numerical unconfined compression strengths of virtual colluvial–deluvial soil–rock mixture. Int. J. Rock Mech. Min. 2015, 77, 208–219. [Google Scholar] [CrossRef]

- Lindquist, E.S. The Strength and Deformation Properties of Melange. Ph.D. Thesis, Department of Civil Engineering, University of California, Berkeley, CA, USA, June 1994. [Google Scholar]

- Goodman, R.E.; Ahlgren, C.S. Evaluating safety of concrete gravity dam on weak rock. J. Geotech. Geoenviron. Eng. 2000, 126, 429–442. [Google Scholar] [CrossRef]

- Medley, E.; Lindquist, E.S. The engineering significance of the scale-independence of some Franciscan Melanges in California, USA. In Proceedings of the 35th US Rock Mechanics Symposium, Reno, NV, USA, 5–7 June 1995; Daemen, J.K., Schultz, R.A., Eds.; Balkema: Rotterdam, The Netherlands, 1995; pp. 907–914. [Google Scholar]

- Medley, E.W. Systematic characterization of mélange bimrocks and other chaotic soil/rock mixtures. Felsbau-Rock Soil Eng. 1999, 17, 152–162. [Google Scholar]

- Medley, E.W. Observations on tortuous failure surfaces in Bimrocks. Felsbau Rock Soil Eng. 2004, 5, 35–43. [Google Scholar]

- Medley, E.W.; Wakabayashi, J. Geological characterization of mélange for practitioners. Felsbau Rock Soil Eng. J. Eng. Geol. Geomech. Tunn. 2004, 2, 10–18. [Google Scholar]

- Sonmez, H.; Kasapoglu, K.E.; Coskun, A.; Tunusluoglu, C.; Medley, E.W.; Zimmerman, R.W. A conceptional empirical approach for the overall strength of unwelded bimrocks. In Rock Engineering in Difficult Ground Conditions, Karst and Soft Rock, Proceeding of the International Society Rock Mechanics Regional Symposium, Dubrovnik, Croatia, 29–31 October 2009; CRC Press: Leiden, The Netherlands, 2009; pp. 29–31. [Google Scholar]

- Coli, N.; Boldin, I.D.; Bandini, A.; Lopes, D.S. Modeling of complex geological rock mixtures under triaxial testing conditions. In Proceedings of the International Symposium on Rock Engineering & Technology for Sustainable Underground Construction (Eurock), Stockholm, Sweden, 28–30 May 2012. [Google Scholar]

- Kahraman, S.; Alber, M. Estimating unconned compressive strength and elastic modulus of a fault breccias mixture of weak block sand strong matrix. Int. J. Rock Mech. Min. Sci. 2006, 43, 1277–1287. [Google Scholar] [CrossRef]

- Kahraman, S.; Albe, R.M. Triaxial strength of a fault breccias of weak rocks in a strong matrix. Bull. Eng. Geol. Environ. 2008, 67, 435–441. [Google Scholar] [CrossRef]

- Afifipour, M.; Moarefvand, P. Failure patterns of geomaterials with block-in-matrix texture: Experimental and numerical evaluation. Arab. J. Geosci. 2014, 7, 2781–2792. [Google Scholar] [CrossRef]

- Medley, E.W. Uncertainty in estimates of block volumetric proportions in melange bimrock. In Proceedings of the International Symposium, 22nd Engineering Geology and the Environment, Athens, Greece, 23–27 June 1997; Marinos, P.G., Koukis, G.C., Tsiambaos, G.C., Stournaras, G.C., Eds.; Balkema: Rotterdam, The Netherlands, 1997; pp. 267–272. [Google Scholar]

- Li, X.; Liao, Q.L.; He, J.M. In-situ tests and astochastic structural model of rock and soil aggregate in the three Gorges Reservoir Area, China. Int. J. Rock Mech. Min. Sci. 2004, 41, 702–727. [Google Scholar] [CrossRef]

- Akram, M.S. Physical and Numerical Investigation of Conglomeratic Rocks. Ph.D. Thesis, University of New South Wales, Sydney, Australia, June 2010. [Google Scholar]

- Bagnold, R.A.; Barndorff-Nielsen, O. The pattern of natural size distribution. Sedimentology 1980, 27, 199–207. [Google Scholar] [CrossRef]

- Xu, W.J.; Wang, Y.G. Meso-structural permeability of S-RM based on numerical tests. Chin. J. Geotech. Eng. 2010, 32, 543–550. (In Chinese) [Google Scholar]

- Shelley, T.L.; Daniel, D.E. Effect of gravel on hydraulic conductivity of compacted soil liners. J. Geotech. Eng. ASCE 1993, 119, 54–68. [Google Scholar] [CrossRef]

- Shafiee, A. Permeability of compacted granule-clay mixtures. Eng. Geol. 2008, 97, 199–208. [Google Scholar] [CrossRef]

- Vallejo, L.E.; Zhou, Y. The mechanical properties of simulated soil–rock mixtures. In Proceedings of the 13th International Conference on Soil Mechanics and Foundation Engineering, New Delhi, India, 5–10 January 1994; pp. 365–368. [Google Scholar]

- Gutierrez, J.J.; Vallejo, L.E. Laboratory Experiments on the Hydraulic Conductivity of Sands with Dispersed Rock Particles. Geotech. Geol. Eng. 2013, 31, 1405–1410. [Google Scholar] [CrossRef]

- Chen, X.B.; Li, Z.Y.; Zhang, J.S. Effect of granite gravel content on improved granular mixtures as railway subgrade fillings. J. Cent. South Univ. 2014, 21, 3361–3369. (In Chinese) [Google Scholar] [CrossRef]

- Chen, Z.H.; Chen, S.J.; Chen, J.; Sheng, Q.; Yan, H.; Hu, W. In-situ Double-Ring Infiltration Test of Soil-Rock Mixture. J. Yangtze River Sci. Res. Inst. 2012, 29, 52–56. (In Chinese) [Google Scholar]

- Gao, Q.; Liu, Z.H.; Li, X.; Li, J.H. Permeability Characteristics of Rock and Soil Aggregate of Backfilling Open-Pit And Particle Element Numerical Analysis. Chin. J. Rock Mech. Eng. 2009, 28, 2342–2348. (In Chinese) [Google Scholar]

- Wu, J.H.; Chen, J.H.; Lu, C.W. Investigation of the Hsien-du-Shan rock avalanche caused by typhoon Morakot in 2009 at Kaohsiung county, Taiwan. Int. J. Rock Mech. Min. 2013, 60, 148–159. [Google Scholar] [CrossRef]

- Liao, Q.L. Geological Origin and Structure Model of Rock and Soil Aggregate and Study on Its Mechanical and MH Coupled Properties. Ph.D. Thesis, Institute of Geology and Geophysics, Chinese Academy of Science, Beijing, China, July 2004. (In Chinese). [Google Scholar]

- British Standard Methods of Test for Soils for Civil Engineering Purposes-Part 1: General Requirements and Sample Preparation; BS1377-1; BSI: London, UK, 1990.

- Standard for Soil Test Method, GB/T 50123-1999; Ministry of Water Resources of the People’s Republic of China: Beijing, China, 1999.

- Donaghe, R.T.; Torrey, V.H. Proposed New Standard Test Method For Laboratory Compaction Testing of Soil-Rock Mixtures Using Standard Effort. Geotech. Test. J. 1994, 3, 387–392. [Google Scholar]

- Rücknagel, J.; Götze, P.; Hofmann, B.; Christen, O.; Marschall, K. The influence of soil gravel content on compaction behaviour and pre-compression stress. Geoderma 2013, 209–210, 226–232. [Google Scholar] [CrossRef]

- Forchheimer, P. Wasserbewegung durch Boden. Zeitz. Ver. Dtsch Ing. 1901, 45, 1782–1788. [Google Scholar]

| Index | Soil Matrix | Rock Block |

|---|---|---|

| Bulk density (g/cm3) | 1.64 | 2.53 |

| Dryweight density (g/cm3) | 2.06 | / |

| Optimum water content (%) | 9.5 | / |

| Specific gravity (GS) | 2.73 | / |

| Effective particle size, D10 (mm) | 0.01 | / |

| Coefficient of uniformity, Cu | 4.2 | / |

| Coefficient of curvature, Cc | 1.32 | / |

| Liquid limit (%) | 64 | / |

| plastic limit (%) | 36 | / |

| plasticity index | 28 | / |

| liquidity index | 0.121 | / |

| Wet compressive strength (MPa) | 0.57 | 43.21 |

| Dry compressive strength (MPa) | 2.27 | 80.75 |

| Mineral | Soil Matrix 1 | Soil Matrix 2 |

|---|---|---|

| Montmorillonite | 61.52 | 63.28 |

| Kaolinite | 26.73 | 24.66 |

| Illite | 6.25 | 6.58 |

| chlorite | 5.5 | 5.48 |

| Specimen No. | −J = −aV + bV2 (Equation (4)) | K (×10−5 m/s) | R2 | |

|---|---|---|---|---|

| a | b | |||

| Bimsoil_30-1(H = 40 mm) | 25.4676 | 57.28886 | 0.03966 | 0.975 |

| Bimsoil_30-1(H = 60 mm) | 27.3673 | 46.06427 | 0.03691 | 0.977 |

| Bimsoil_30-1(H = 80 mm) | 37.5564 | 36.6585 | 0.02689 | 0.990 |

| Bimsoil_30-1(H = 100 mm) | 37.7689 | 25.86399 | 0.02674 | 0.977 |

| Bimsoil_30-1(H = 120 mm) | 37.2458 | 25.04659 | 0.02712 | 0.980 |

| Bimsoil_30-1(H = 140 mm) | 38.612 | 26.41917 | 0.02616 | 0.981 |

| Bimsoil_30-1(H = 160 mm) | 38.827 | 27.59595 | 0.02601 | 0.979 |

| Bimsoil_30-1(H = 180 mm) | 37.0617 | 27.39719 | 0.02725 | 0.980 |

| Bimsoil_30-1(H = 200 mm) | 37.6457 | 26.13581 | 0.02683 | 0.976 |

| Specimen No. | −J = −aV + bV2 (Equation (4)) | K (×10−5 m/s) | R2 | |

|---|---|---|---|---|

| a | b | |||

| Bimsoil_40-1(H = 40 mm) | 33.21934 | 79.41739 | 0.0304 | 0.991 |

| Bimsoil_40-1(H = 60 mm) | 44.2489 | 54.85734 | 0.02283 | 0.957 |

| Bimsoil_40-1(H = 80 mm) | 55.9207 | 46.08953 | 0.01806 | 0.978 |

| Bimsoil_40-1(H = 100 mm) | 56.86151 | 38.04205 | 0.01776 | 0.986 |

| Bimsoil_40-1(H = 120 mm) | 56.6892 | 29.67069 | 0.01782 | 0.976 |

| Bimsoil_40-1(H = 140 mm) | 58.2059 | 30.95381 | 0.01735 | 0.990 |

| Bimsoil_40-1(H = 160 mm) | 58.0889 | 30.68529 | 0.01739 | 0.989 |

| Bimsoil_40-1(H = 180 mm) | 56.72037 | 30.81588 | 0.01781 | 0.957 |

| Bimsoil_40-1(H = 200 mm) | 57.1004 | 28.84796 | 0.01769 | 0.977 |

| Specimen No. | −J = −aV + bV2 (Equation (4)) | K (×10−5 m/s) | R2 | |

|---|---|---|---|---|

| a | b | |||

| Bimsoil_50-1(H = 40 mm) | 17.45548 | 48.85914 | 0.05786 | 0.996 |

| Bimsoil_50-2(H = 60 mm) | 21.70822 | 36.53996 | 0.04653 | 0.992 |

| Bimsoil_50-3(H = 80 mm) | 27.27899 | 25.15432 | 0.03702 | 0.991 |

| Bimsoil_50-4(H = 100 mm) | 33.96639 | 27.1969 | 0.02974 | 0.991 |

| Bimsoil_50-5(H = 120 mm) | 34.12356 | 26.77677 | 0.0296 | 0.992 |

| Bimsoil_50-6(H = 140 mm) | 34.85317 | 26.23295 | 0.02898 | 0.990 |

| Bimsoil_50-7(H = 160 mm) | 33.23728 | 27.15362 | 0.03039 | 0.992 |

| Bimsoil_50-8(H = 180 mm) | 34.50031 | 26.9832 | 0.02928 | 0.992 |

| Bimsoil_50-9(H = 200 mm) | 33.54192 | 26.56346 | 0.03011 | 0.993 |

| Specimen No. | −J = −aV + bV2 (Equation (4)) | K (×10−5 m/s) | R2 | |

|---|---|---|---|---|

| a | b | |||

| Bimsoil_60-1(H = 40 mm) | 12.5917 | 30.10298 | 0.08021 | 0.997 |

| Bimsoil_60-2(H = 60 mm) | 16.2290 | 22.59943 | 0.06223 | 0.993 |

| Bimsoil_60-3(H = 80 mm) | 18.3969 | 17.88247 | 0.0549 | 0.988 |

| Bimsoil_60-4(H = 100 mm) | 19.2867 | 17.64004 | 0.05237 | 0.990 |

| Bimsoil_60-5(H = 120 mm) | 21.6305 | 17.5256 | 0.04669 | 0.987 |

| Bimsoil_60-6(H = 140 mm) | 20.9707 | 17.21499 | 0.04816 | 0.989 |

| Bimsoil_60-7(H = 160 mm) | 21.9001 | 16.46893 | 0.04612 | 0.988 |

| RBP (%) | Regression Function of Permeability Coefficient (k × 10−5) | R2 |

|---|---|---|

| 30 | K = 0.02683 + 0.13314e−2.92448(H/D) | 0.8455 |

| 40 | K = 0.01769 + 0.11061e−2.70369(H/D) | 0.9831 |

| 50 | K = 0.03007 + 0.14022e−2.02304(H/D) | 0.9663 |

| 60 | K = 0.04756 + 0.18436e−2.16395(H/D) | 0.9862 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Li, C.; Wei, X.; Hou, Z. Laboratory Investigation of the Effect of Slenderness Effect on the Non-Darcy Groundwater Flow Characteristics in Bimsoils. Water 2017, 9, 676. https://doi.org/10.3390/w9090676

Wang Y, Li C, Wei X, Hou Z. Laboratory Investigation of the Effect of Slenderness Effect on the Non-Darcy Groundwater Flow Characteristics in Bimsoils. Water. 2017; 9(9):676. https://doi.org/10.3390/w9090676

Chicago/Turabian StyleWang, Yu, Changhong Li, Xiaoming Wei, and Zhiqiang Hou. 2017. "Laboratory Investigation of the Effect of Slenderness Effect on the Non-Darcy Groundwater Flow Characteristics in Bimsoils" Water 9, no. 9: 676. https://doi.org/10.3390/w9090676