Impact of Coalbed Incidence Angle on Methane Enrichment Zone in Longwall Gob

Abstract

:1. Introduction

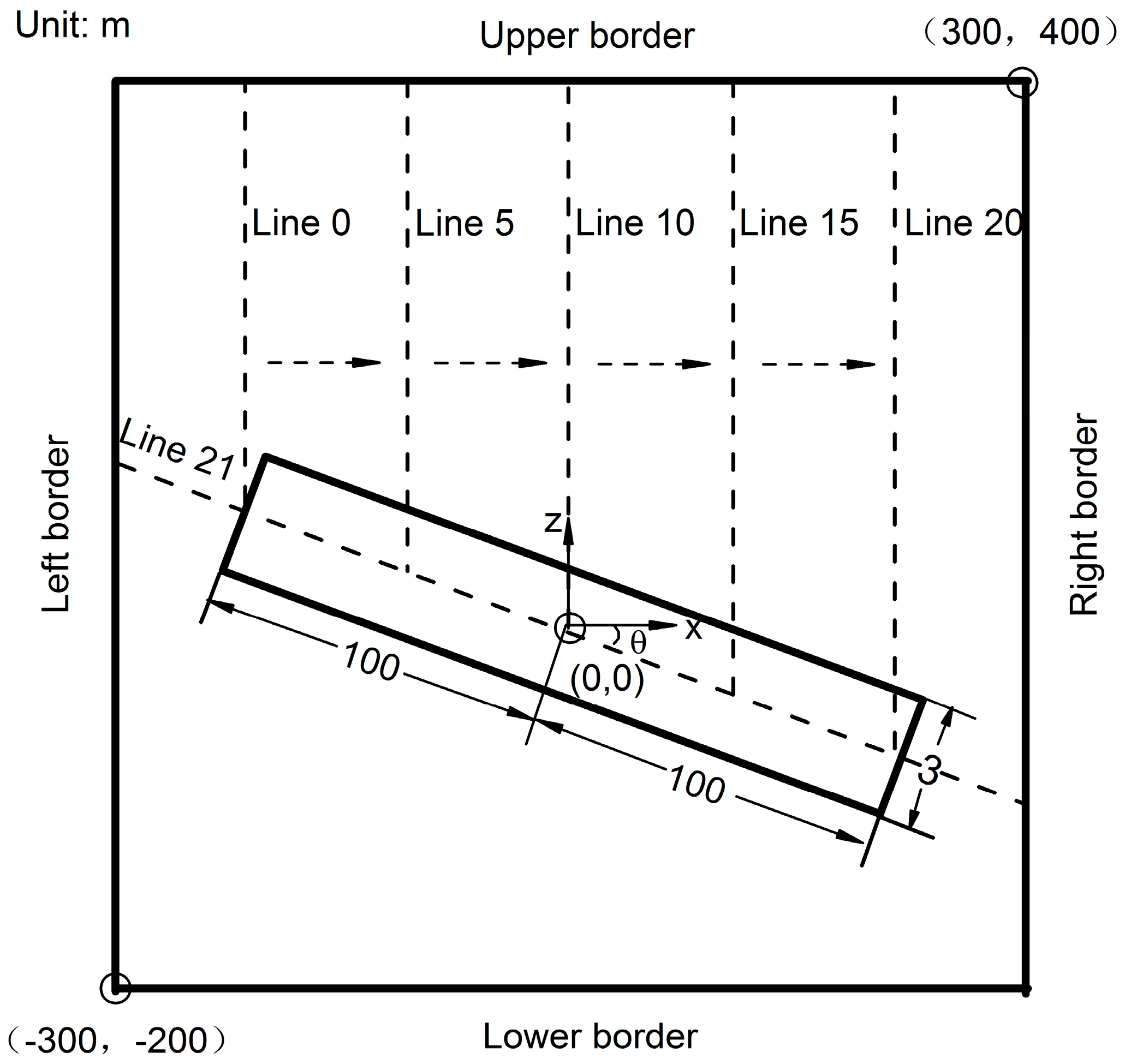

2. Numerical Modeling

3. Results and Discussion

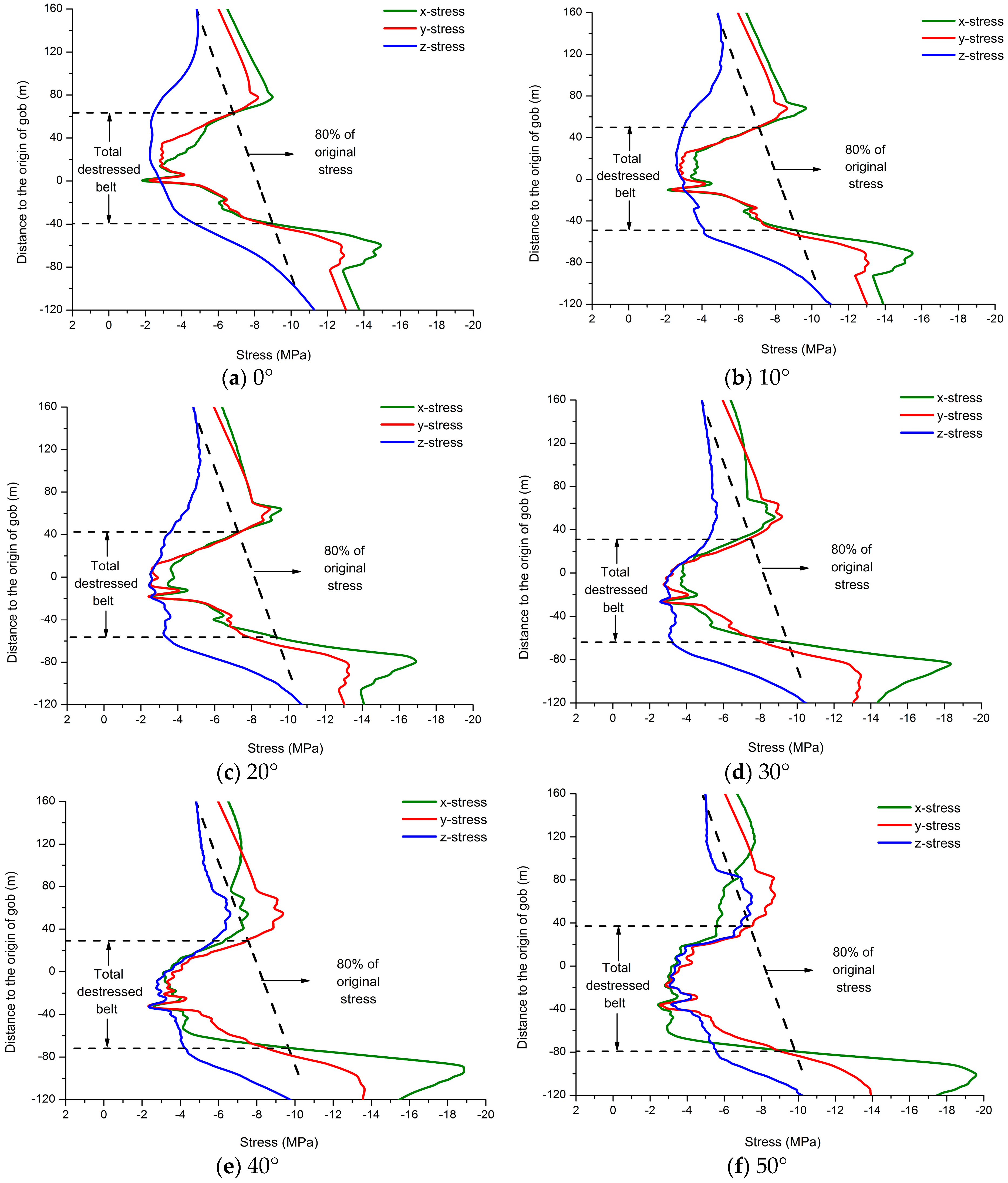

3.1. Stress Distribution

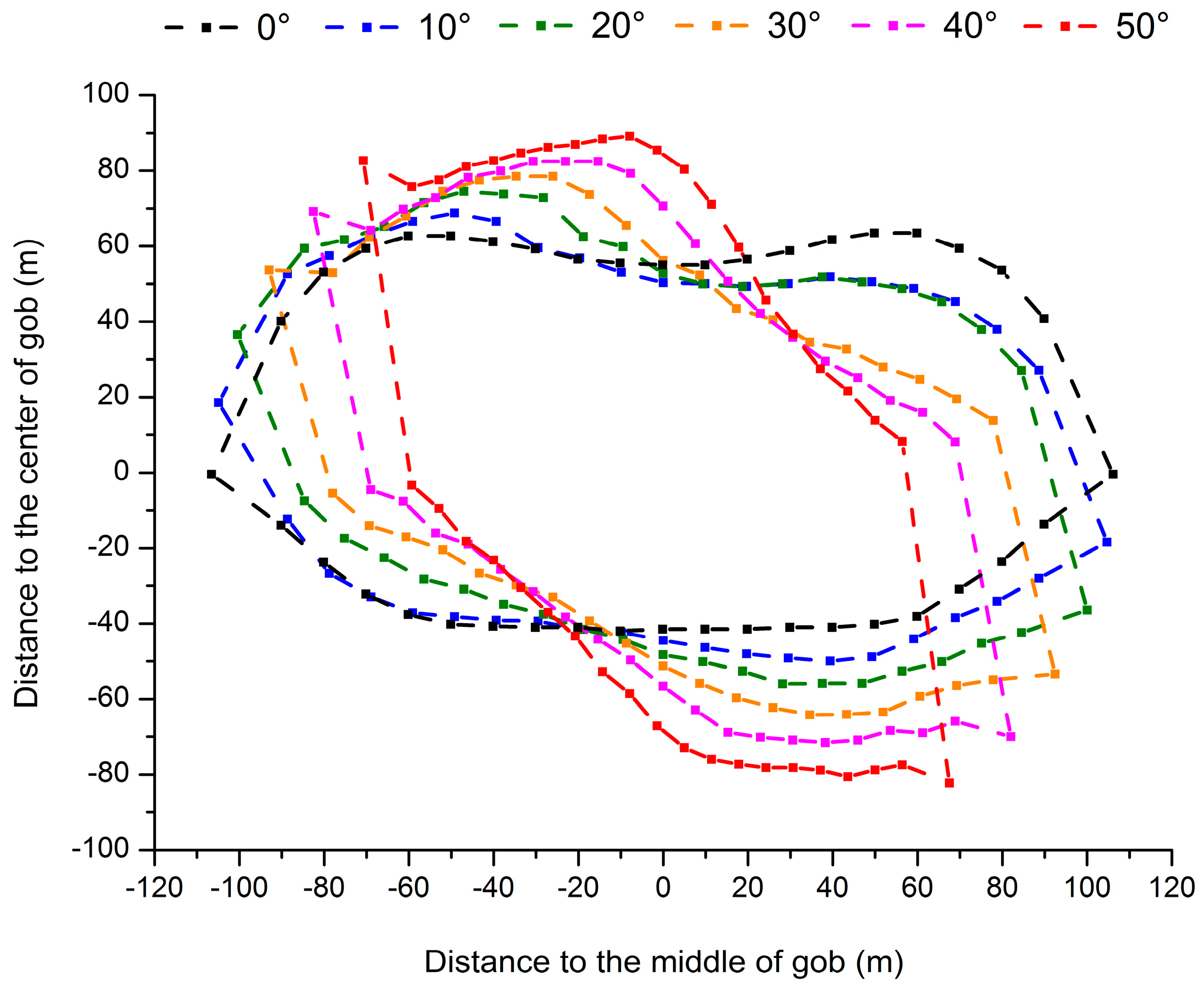

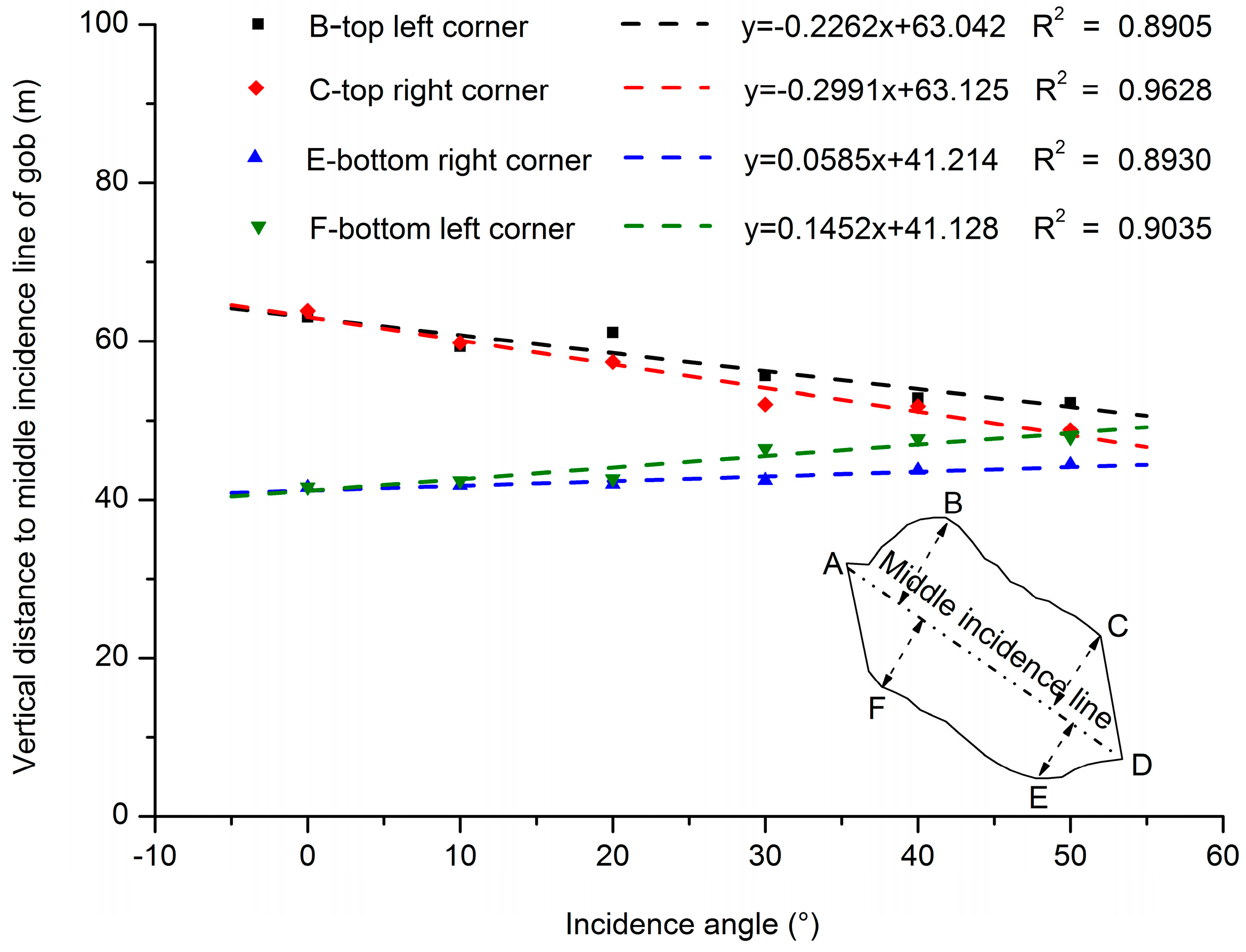

3.2. MEZ Division

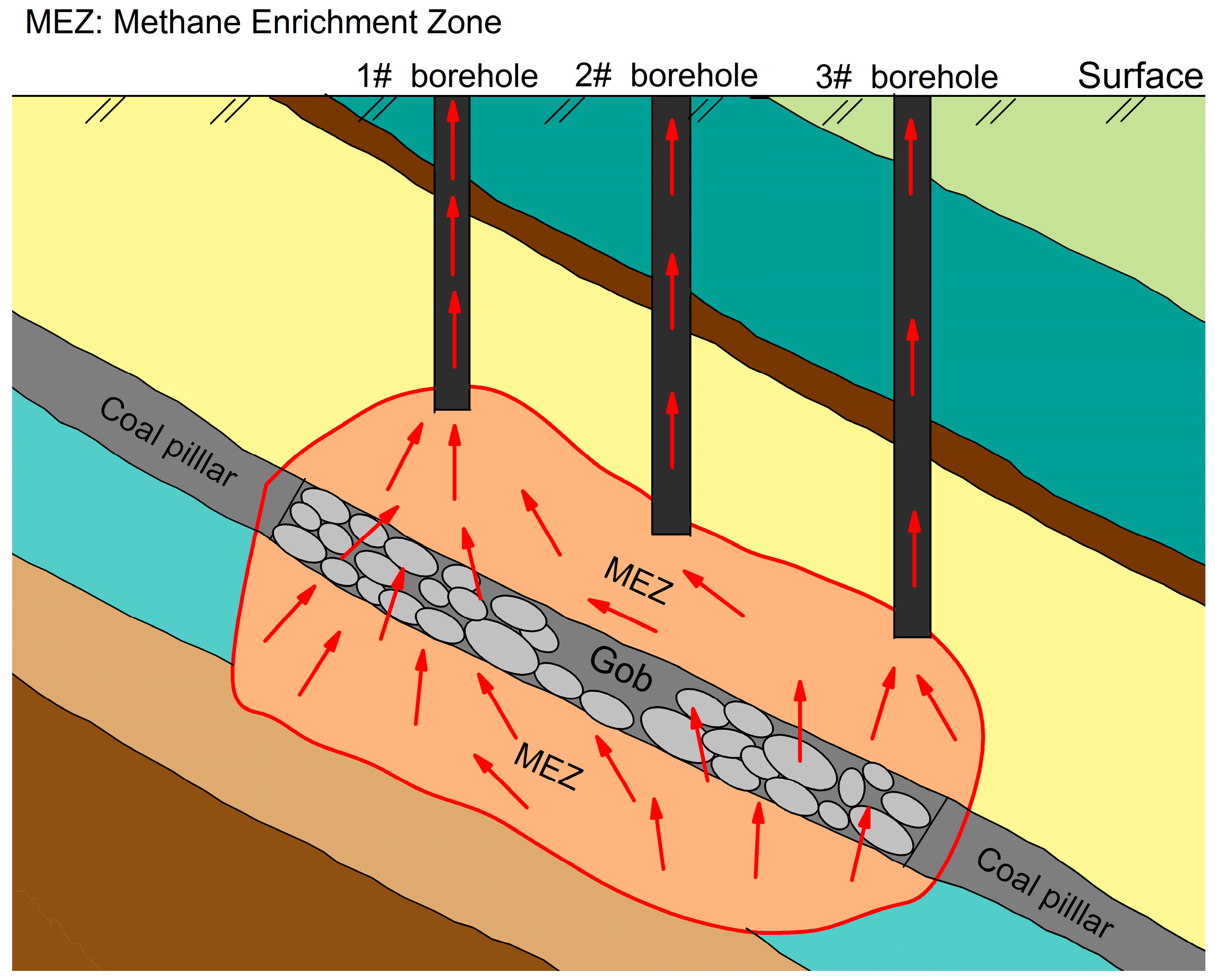

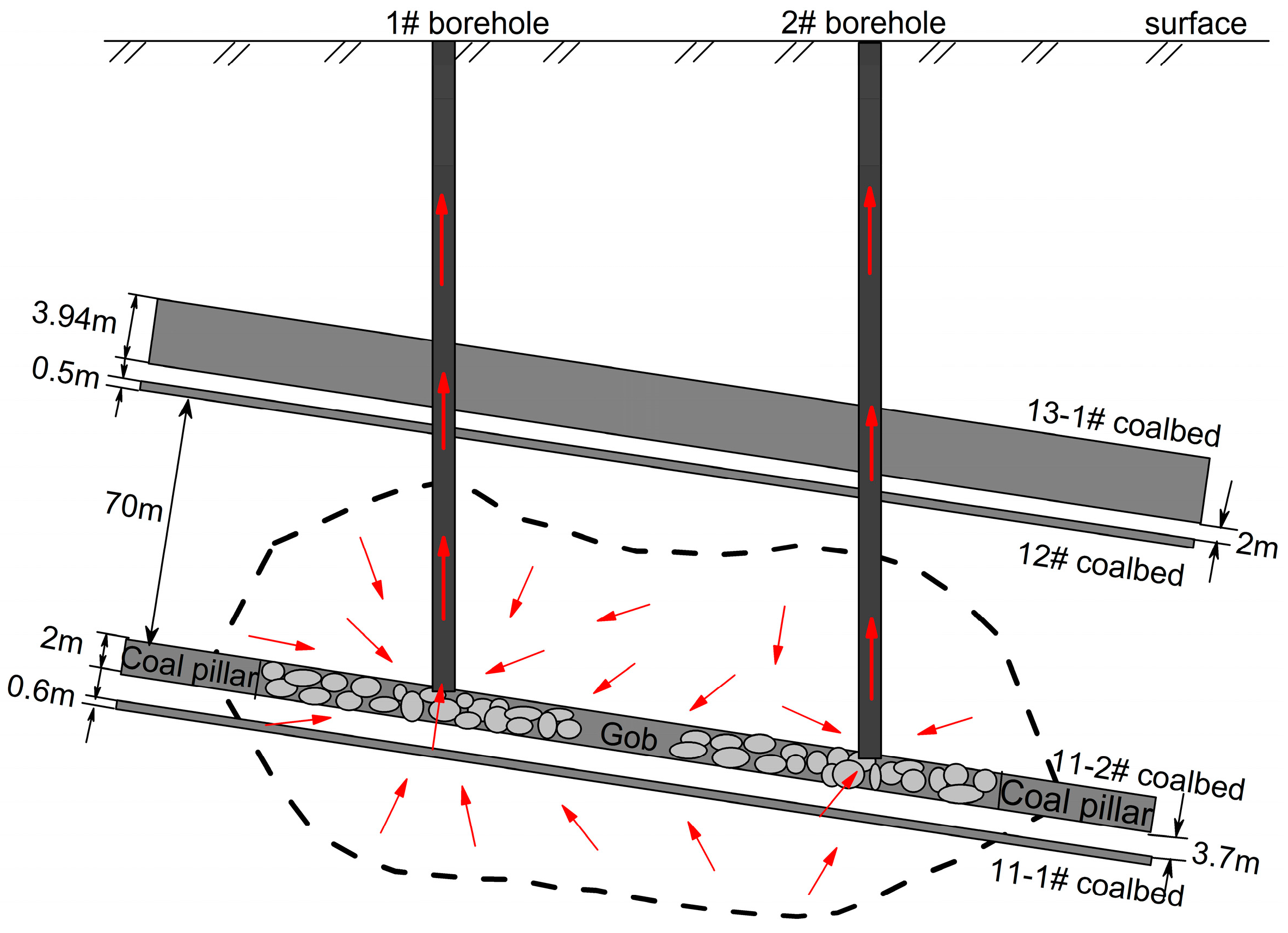

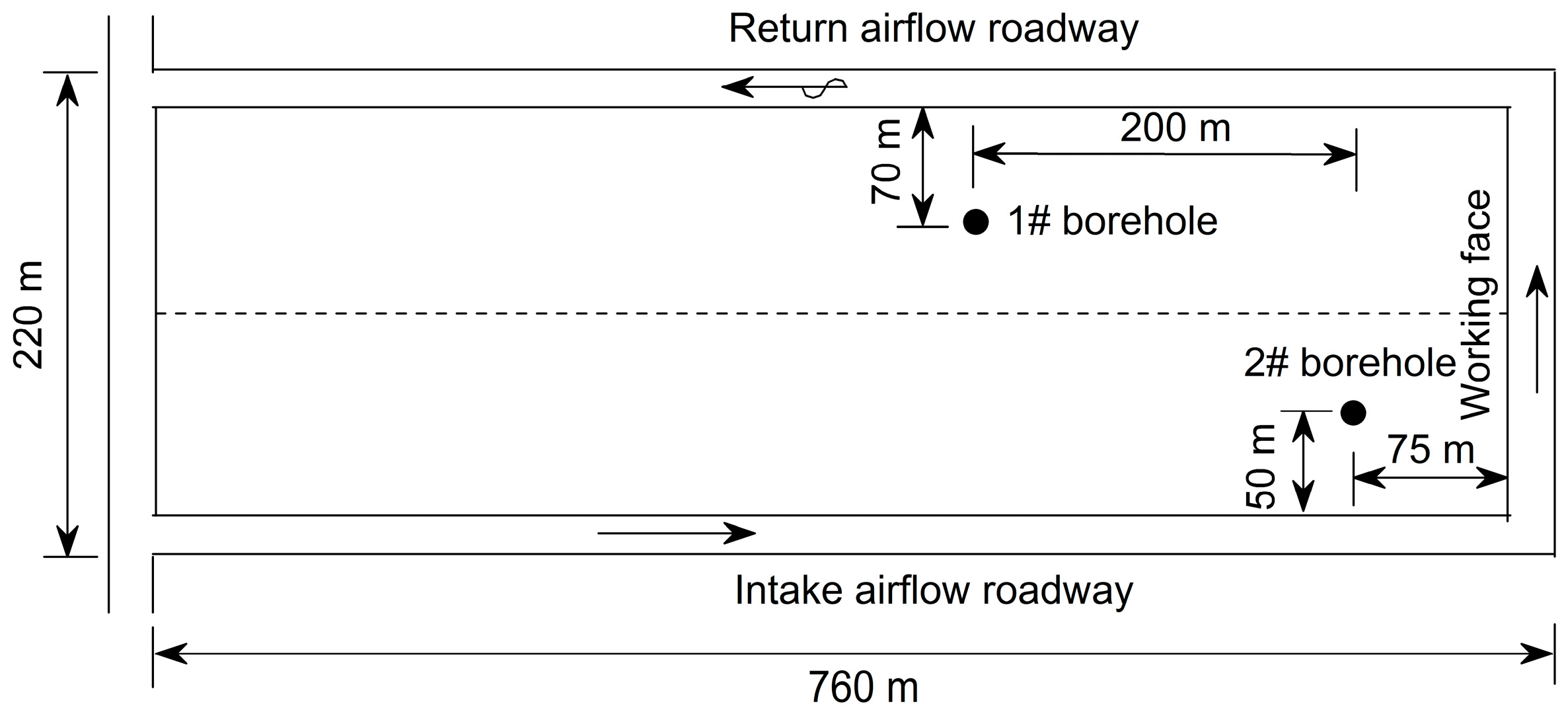

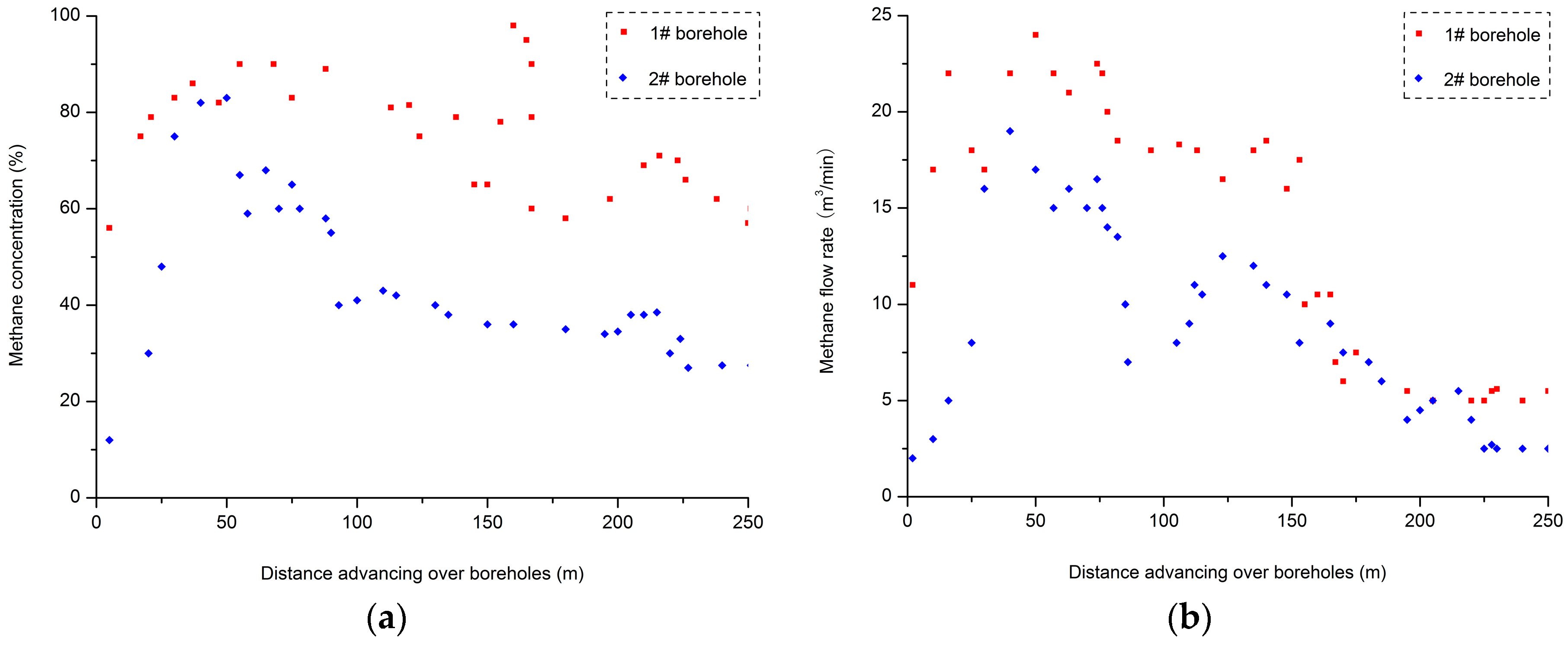

4. Field Application

5. Conclusions

- (1)

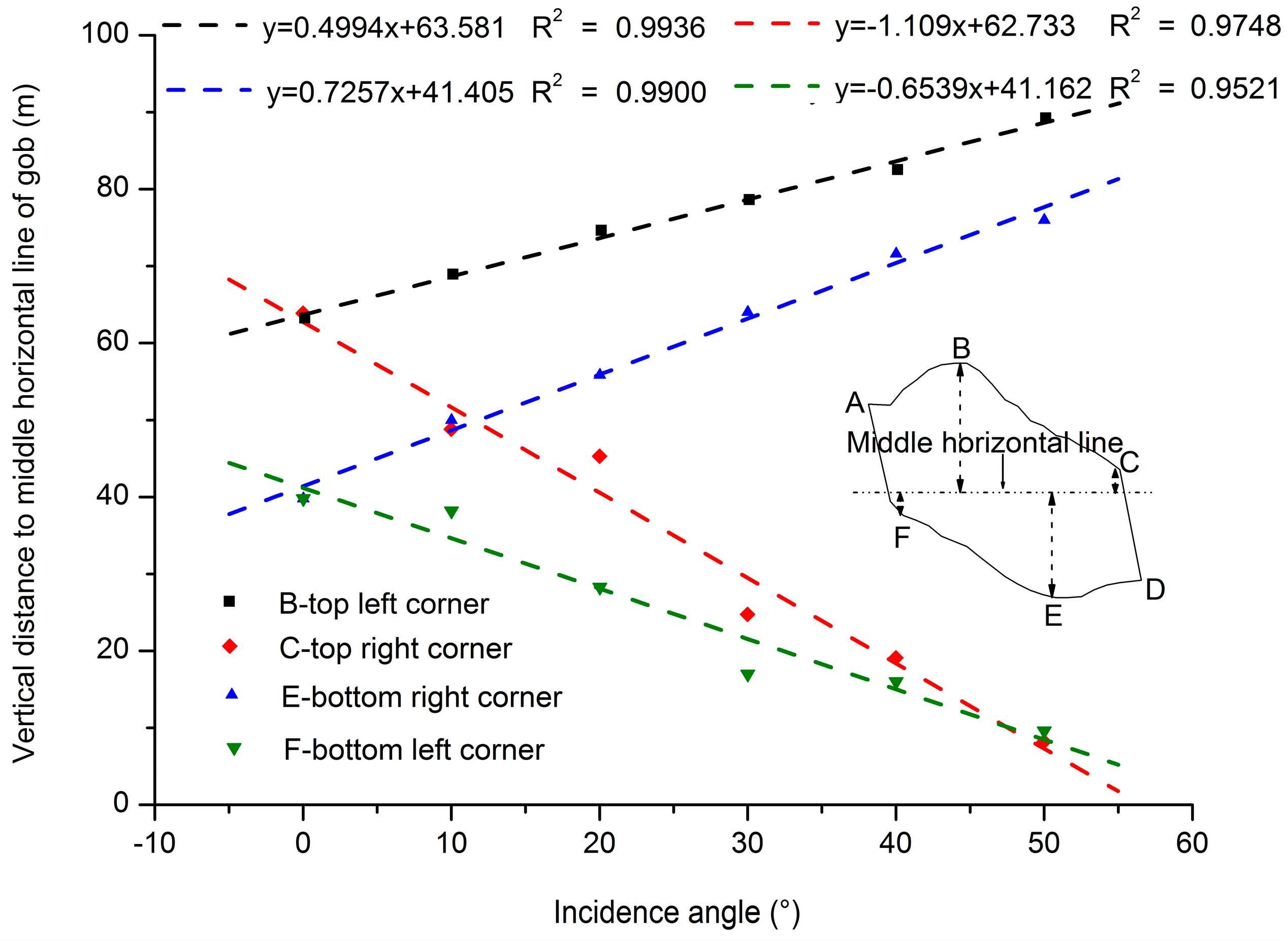

- The MEZ around mined coalbeds with incidence angles ranging from 0° to 50° consistently exhibit a “hexagon” shape, and rotate in a clockwise direction as the coalbed angle increases. Three-dimensional stresses in the MEZ are low enough to make good flow channels for methane to flow freely.

- (2)

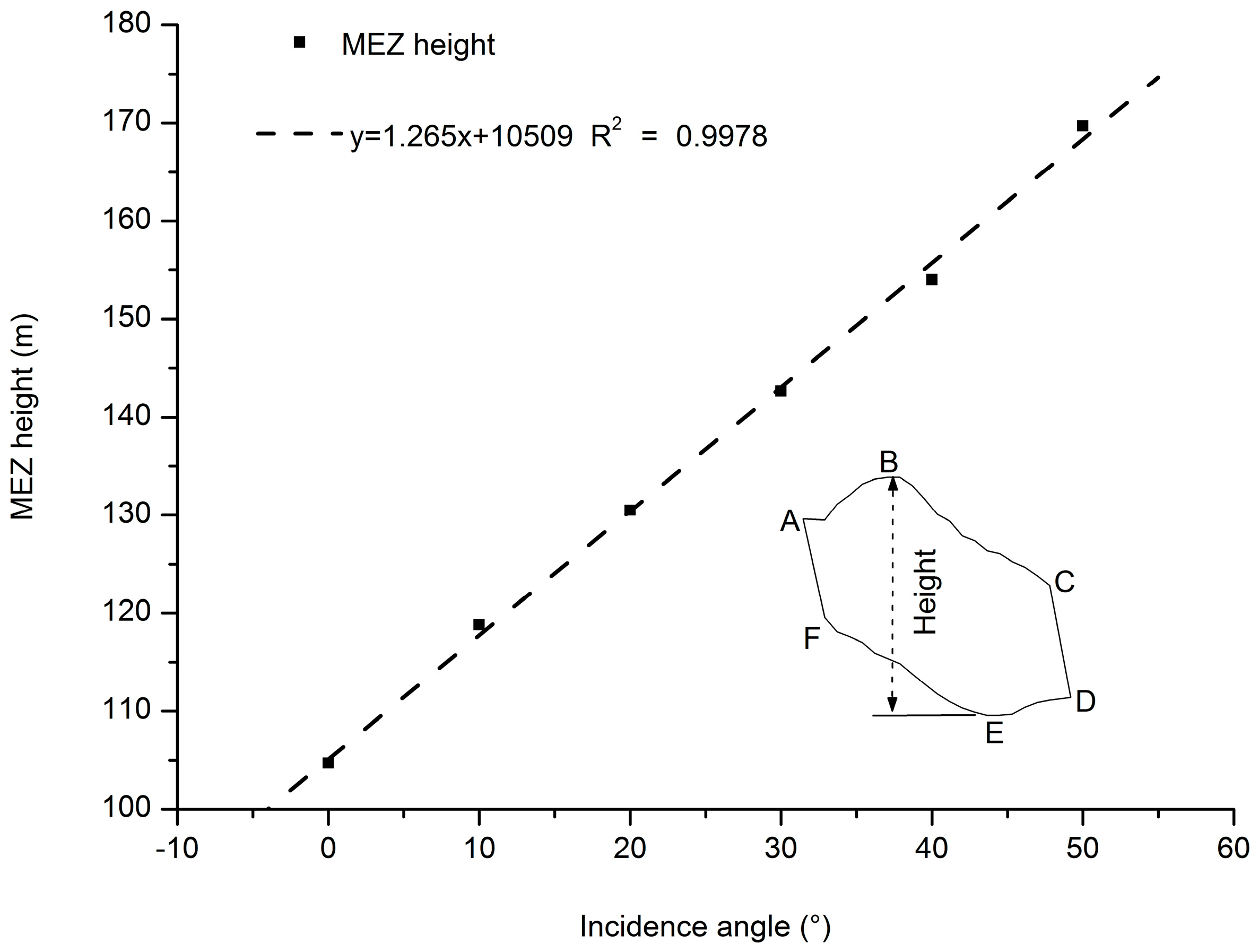

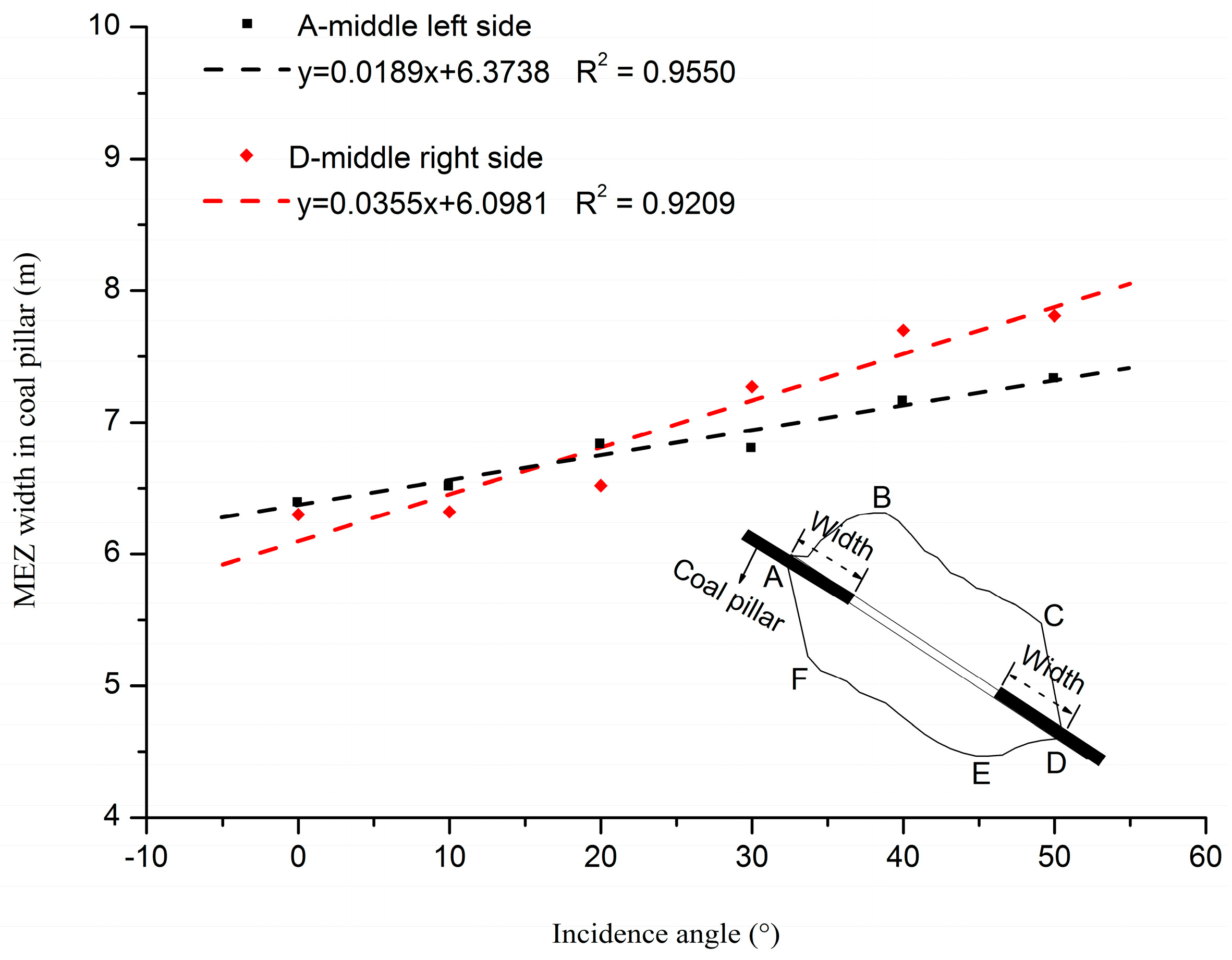

- The MEZ range above the mined seam is larger than that below the mined seam for different coalbed angles. The effect of coal seam angle on the MEZ distribution range is minimal. As the coal seam angle increases, the MEZ range in the roof decreases, whereas the MEZ range in the floor increases. The MEZ widths in the upper and lower coal pillars of gobs increase as the coalbed angle increases, and the MEZ width in lower pillar increases faster.

- (3)

- The coalbed angle has a significant impact on the MEZ height. The MEZ height increases as the coal seam angle increases. As the MEZ height increases, the methane concentration of the corresponding height increases exponentially. A field test conducted in the Pansan mine in China confirms this. The results indicate that a higher methane concentration and flow rate can be achieved by arranging a surface vertical borehole at a relatively higher position in the MEZ.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yuan, L. Theory and practice of integrated pillar-less coal production and methane extraction in multi-seam of low permeability. Eng. Sci. 2009, 11, 72–80. [Google Scholar]

- Wang, L.; Cheng, Y.P. Drainage and utilization of Chinese coal mine methane with a coal-methane co-exploitation model: Analysis and projections. Resour. Policy 2012, 37, 315–321. [Google Scholar] [CrossRef]

- Majdi, A.; Hassani, F.P.; Nasiri, M.Y. Prediction of the height of destressed zone above the mined panel roof in longwall coal mining. Int. J. Coal Geol. 2012, 98, 62–72. [Google Scholar] [CrossRef]

- Hu, S.Y.; Li, Z.; Feng, G.R.; Xu, G.; Xia, T.Q.; Jiang, H.N.; Zhang, Y.T.; Cheng, J.W.; Gao, Q.; Wang, Z.; et al. Changes on methane concentration after CO2 injection in a longwall gob: A case study. J. Nat. Gas Sci. Eng. 2016, 29, 550–558. [Google Scholar] [CrossRef]

- Karacan, C.Ö. Analysis of gob gas venthole production performances for strata gas control in longwall mining. Int. J. Rock Mech. Min. Sci. 2015, 79, 9–18. [Google Scholar] [CrossRef]

- Saghafi, A.; Pinetown, K.L. A new method to determine the depth of the de-stressed gas-emitting zone in the underburden of a longwall coal mine. Int. J. Coal Geol. 2015, 152, 156–164. [Google Scholar] [CrossRef]

- Karacan, C.Ö. Forecasting gob gas venthole production performances using intelligent computing methods for optimum methane control in longwall coal mines. Int. J. Coal Geol. 2009, 79, 131–144. [Google Scholar] [CrossRef]

- Zhai, C.; Xiang, X.W.; Zou, Q.L.; Yu, X.; Xu, Y.M. Influence factors analysis of a flexible gel sealing material for coal-bed methane drainage boreholes. Environ. Earth Sci. 2016, 75, 151. [Google Scholar] [CrossRef]

- Qu, Q.D.; Guo, H.; Loney, M. Analysis of longwall goaf gas drainage trials with surface directional boreholes. Int. J. Coal Geol. 2016, 156, 59–73. [Google Scholar] [CrossRef]

- Karacan, C.Ö.; Ruiz, F.A.; Cotè, M.; Phipps, S. Coal mine methane: A review of capture and utilization practices with benefits to mining safety and to greenhouse gas reduction. Int. J. Coal Geol. 2011, 86, 121–156. [Google Scholar] [CrossRef]

- Qin, Z.Y.; Yuan, L.; Guo, H.; Qu, Q.D. Investigation of longwall goaf gas flows and borehole drainage performance by CFD simulation. Int. J. Coal Geol. 2015, 150–151, 51–63. [Google Scholar] [CrossRef]

- Flügge, G. Die anwendung der trogtheorie auf den raum der zusatzausgasung. Glückauf Forsch. 1971, 32, 122–129. [Google Scholar]

- Singh, R.P.; Yadav, R.N. Prediction of subsidence due to coal mining in Raniganj coalfield, West Bengal, India. Eng. Geol. 1995, 39, 103–111. [Google Scholar] [CrossRef]

- Palchik, V. Localization of mining-induced horizontal fractures along rock layer interfaces in overburden: Field measurements and prediction. Environ. Geol. 2005, 48, 68–80. [Google Scholar] [CrossRef]

- Miao, X.X.; Cui, X.M.; Wang, J.A.; Xu, J.L. The height of fractured water-conducting zone in undermined rock strata. Eng. Geol. 2011, 120, 32–39. [Google Scholar] [CrossRef]

- Guo, H.; Yuan, L.; Shen, B.; Qu, Q.; Xue, J. Mining-induced strata stress changes, fractures and gas flow dynamics in multi-seam longwall mining. Int. J. Rock Mech. Min. Sci. 2012, 54, 129–139. [Google Scholar] [CrossRef]

- Gao, F.Q.; Stead, D.; Coggan, J. Evaluation of coal longwall caving characteristics using an innovative UDEC Trigon approach. Comput. Geotech. 2014, 55, 448–460. [Google Scholar] [CrossRef] [Green Version]

- Qu, Q.D.; Xu, J.L.; Wu, R.L.; Qin, W.; Hu, G.Z. Three-zone characterization of coupled strata and gas behaviour in multi-seam mining. Int. J. Rock Mech. Min. Sci. 2015, 78, 91–98. [Google Scholar]

- Wang, S.F.; Li, X.B.; Wang, D.M. Void fraction distribution in overburden disturbed by longwall mining of coal. Environ. Earth Sci. 2016, 75, 151. [Google Scholar] [CrossRef]

- Jing, L. A review of techniques advances and outstanding issues in numerical modeling for rock mechanics and rock engineering. Int. J. Rock Mech. Min. Sci. 2003, 40, 283–353. [Google Scholar] [CrossRef]

- Yasitli, N.E.; Unver, B. 3D numerical modeling of longwall mining with top-coal caving. Int. J. Rock Mech. Min. Sci. 2005, 42, 219–235. [Google Scholar] [CrossRef]

- Whittles, D.N.; Lowndes, I.S.; Kingman, S.W.; Yates, C.; Jobling, S. Influence of geotechnical factors on gas flow experienced in a UK longwall coal mine panel. Int. J. Rock Mech. Min. Sci. 2006, 43, 369–387. [Google Scholar] [CrossRef]

- Chen, J.H.; Wang, T.; Zhou, Y.; Zhu, Y.L.; Wang, X.X. Failure modes of the surface venthole casing during longwall coal extraction: A case study. Int. J. Coal Geol. 2012, 90–91, 135–148. [Google Scholar] [CrossRef]

- Yang, W.; Lin, B.Q.; Qu, Y.A.; Zhao, S.; Zhai, C.; Jia, L.L.; Zhao, W.Q. Mechanism of strata deformation under protective seam and its application for relieved methane control. Int. J. Coal Geol. 2011, 85, 300–306. [Google Scholar] [CrossRef]

- Yang, W.; Lin, B.Q.; Yan, Q.; Zhai, C. Stress redistribution of longwall mining stope and gas control of multi-layer coal seams. Int. J. Rock Mech. Min. Sci. 2014, 72, 8–15. [Google Scholar] [CrossRef]

- Corthésy, R.; Leite, M.H. A strain-softening numerical model of core discing and damage. Int. J. Rock Mech. Min. Sci. 2008, 45, 329–350. [Google Scholar] [CrossRef]

- Yang, W.; Lin, B.Q.; Zhai, C.; Li, X.Z.; An, S. How in situ stresses and the driving cycle footage affect the gas outburst risk of driving coal mine roadway. Tunn. Undergr. Space Technol. 2012, 31, 139–148. [Google Scholar] [CrossRef]

- Wang, J.-A.; Park, H.D. Fluid permeability of sedimentary rocks in a complete stress-strain process. Eng. Geol. 2002, 63, 291–300. [Google Scholar] [CrossRef]

- Yang, T.H.; Liu, J.; Zhu, W.C.; Elsworth, D.; Tham, L.G.; Tang, C.A. A coupled flow-stress-damage model for groundwater outbursts from an underlying aquifer into mining excavations. Rock Mech. Rock Eng. 2007, 44, 87–97. [Google Scholar] [CrossRef]

- Wang, S.G.; Elsworth, D.; Liu, J.S. Permeability evolution during progressive deformation of intact coal and implications for instability in underground coal seams. Rock Mech. Rock Eng. 2013, 58, 34–45. [Google Scholar] [CrossRef]

- Hu, S.Y.; Zhou, F.B.; Liu, Y.K.; Xia, T.Q. Effective Stress and Permeability Redistributions Induced by Successive Roadway and Borehole Excavations. Rock Mech. Rock Eng. 2015, 48, 319–332. [Google Scholar] [CrossRef]

- Li, S.G.; Lin, H.F.; Zhao, P.X.; Xiao, P.; Pan, H.Y. Dynamic evolution of mining fissure elliptic paraboloid zone and extraction coal and gas. J. China Coal Soc. 2014, 39, 1455–1462. [Google Scholar]

- Yuan, L.; Guo, H.; Li, P.; Liang, Y.P.; Liao, B.C. Theory and technology of goaf gas drainage with large diameter surface boreholes. J. China Coal Soc. 2013, 38, 1–8. [Google Scholar]

- Liang, Y.P. Practice of methane drainage by surface well drilling in Huainan mining area. J. Min. Saf. Eng. 2007, 24, 409–413. [Google Scholar]

- Liu, Y.K.; Zhou, F.B.; Liu, L.; Liu, C.; Hu, S.Y. An experimental and numerical investigation on the deformation of overlying coal seams above double-seam extraction for controlling coal mine methane emissions. Int. J. Coal Geol. 2011, 87, 139–149. [Google Scholar]

| Plastic Shear Strain | 0 | 0.01 | 0.05 | 0.1 | 0.5 | 1 | |

| Coal | Cohesion (MPa) | 1.5 | 1.3 | 1.1 | 0.8 | 0.7 | 0.7 |

| Friction angle (°) | 25.0 | 22.0 | 20.0 | 17.0 | 14.0 | 14.0 | |

| Tensile strength (MPa) | 1.5 | 1.3 | 1.1 | 0.8 | 0.7 | 0.7 | |

| Dilation angle (°) | 16.0 | 13.0 | 10.0 | 8.0 | 7.0 | 7.0 | |

| Roof and floor | Cohesion (MPa) | 3.8 | 2.6 | 2.2 | 1.9 | 1.8 | 1.8 |

| Friction angle (°) | 35.0 | 31.0 | 28.0 | 25.0 | 22.0 | 22.0 | |

| Tensile strength (MPa) | 4.0 | 2.6 | 2.2 | 1.9 | 1.8 | 1.8 | |

| Dilation angle (°) | 16.0 | 13.0 | 10.0 | 8.0 | 7.0 | 7.0 | |

| Lithology | Density (kg/m3) | Bulk Modulus (GPa) | Shear Modulus (GPa) |

|---|---|---|---|

| Coal | 1450 | 3.0 | 1.0 |

| Roof and floor | 2700 | 14.4 | 9.0 |

| Angle (°) | Node | Unit |

|---|---|---|

| 0 | 1,315,440 | 1,278,800 |

| 10 | 1,331,883 | 1,293,040 |

| 20 | 1,351,647 | 1,311,120 |

| 30 | 1,369,224 | 1,327,520 |

| 40 | 1,371,330 | 1,329,520 |

| 50 | 1,355,049 | 1,313,440 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, S.; Zhang, A.; Feng, G.; Guan, S.; Guo, X.; Li, C.; Xu, G. Impact of Coalbed Incidence Angle on Methane Enrichment Zone in Longwall Gob. Minerals 2017, 7, 166. https://doi.org/10.3390/min7090166

Hu S, Zhang A, Feng G, Guan S, Guo X, Li C, Xu G. Impact of Coalbed Incidence Angle on Methane Enrichment Zone in Longwall Gob. Minerals. 2017; 7(9):166. https://doi.org/10.3390/min7090166

Chicago/Turabian StyleHu, Shengyong, Ao Zhang, Guorui Feng, Shuwen Guan, Xiangqian Guo, Chao Li, and Guang Xu. 2017. "Impact of Coalbed Incidence Angle on Methane Enrichment Zone in Longwall Gob" Minerals 7, no. 9: 166. https://doi.org/10.3390/min7090166