Copper Bioleaching in China: Review and Prospect

Abstract

:1. Introduction

2. Copper Bioleaching Development Process in China

2.1. Development and Status of Bioleaching around World

2.2. Major Characteristics of Copper Resources in China

- Jiangxi Copper Bases. Jiangxi Province has the richest copper resources and its reserves account for more than 34% of the total copper reserves in China. Some large-scale copper mines, like the Dexing Copper Mine, Yongping Copper Mine, Wushan Copper Mine, Chengmenshan Copper Mine, Dongxiang Copper Mine, and others have been established since 1978.

- Yunnan Copper Bases. Yunnan Province is the second-largest copper bases in China, including the Dongchuan Copper Mine, Yimen Copper Mine, Dayao Copper Mine, and Muding Copper Mine.

- Tongling Copper Bases. This base is located in Anhui Province and is the first copper base that produced about 10,000 t/a of copper in China, and includes the Tongguanshan Copper Mine, Dongguanshan Copper Mine, Shizishan Copper Mine, Xinqiao Copper Mine, and Fenghuangshan Copper Mine.

- Daye Copper Bases. Located in Hubei province can produce about 45,600 t electrolytic copper. The Tonglushan Copper Mine, Tongshankou Copper Mine, Xinye Copper Mine are included in this base.

- Zhongtiaoshan Copper Bases. Established in 1956, the base includes the Tongkuangyu Copper Mine, Bizhigou Copper Mine, and Hujiayu Copper Mine.

- Northeast Copper Bases. This base, located in Northeast region of China in Heilongjiang Province, Jilin Province, and Liaoning Province, has been developed since 1948. Some copper mines, like the Qingyuan Copper-Nickel Mine, Huatong Copper Mine, and Tianbao Copper Mine are established, producing 70,000 t/a electrolytic copper metals.

- Baiyin Copper Bases. This base located in Gansu province and can produce more than 60,000 t/a electrolytic copper metal, including the Zheyaoshan Copper Mine and Tongchanggou Copper Mine.

2.3. History and Evolution of Copper Bioleaching in China

3. Status of Current Copper Bioleaching in China

3.1. Typical Application and Exploration Cases of Copper Bioleaching

3.2. Typical Commercial Cases of Copper Bioleaching in China

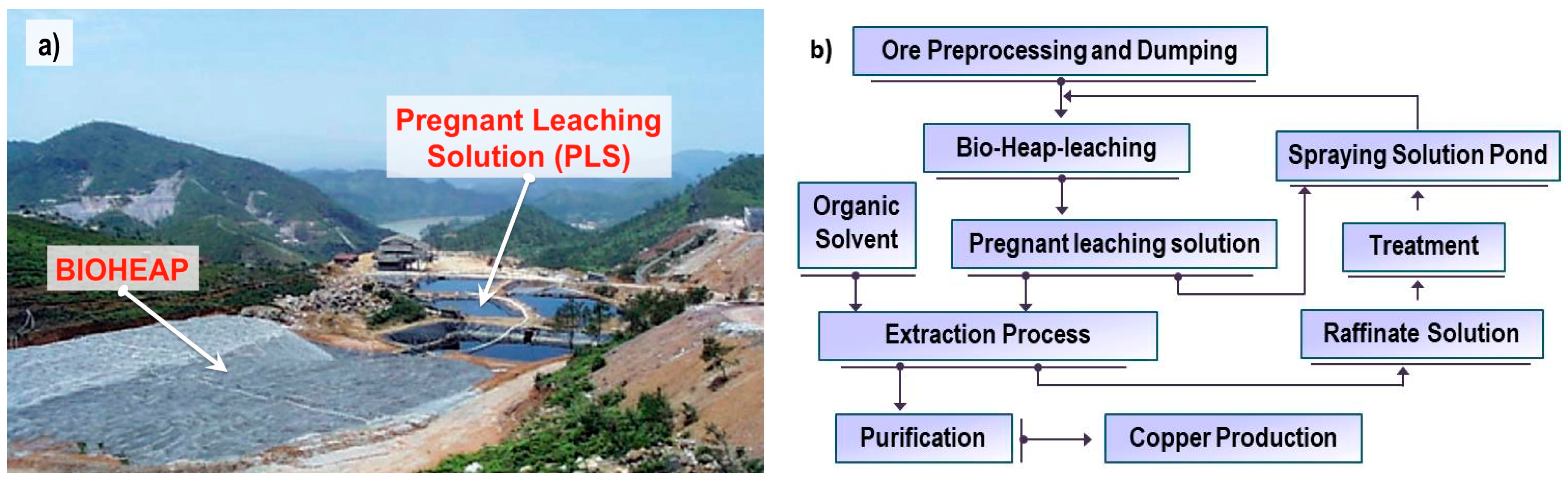

3.2.1. Zijinshan Copper Mine (ZCM)

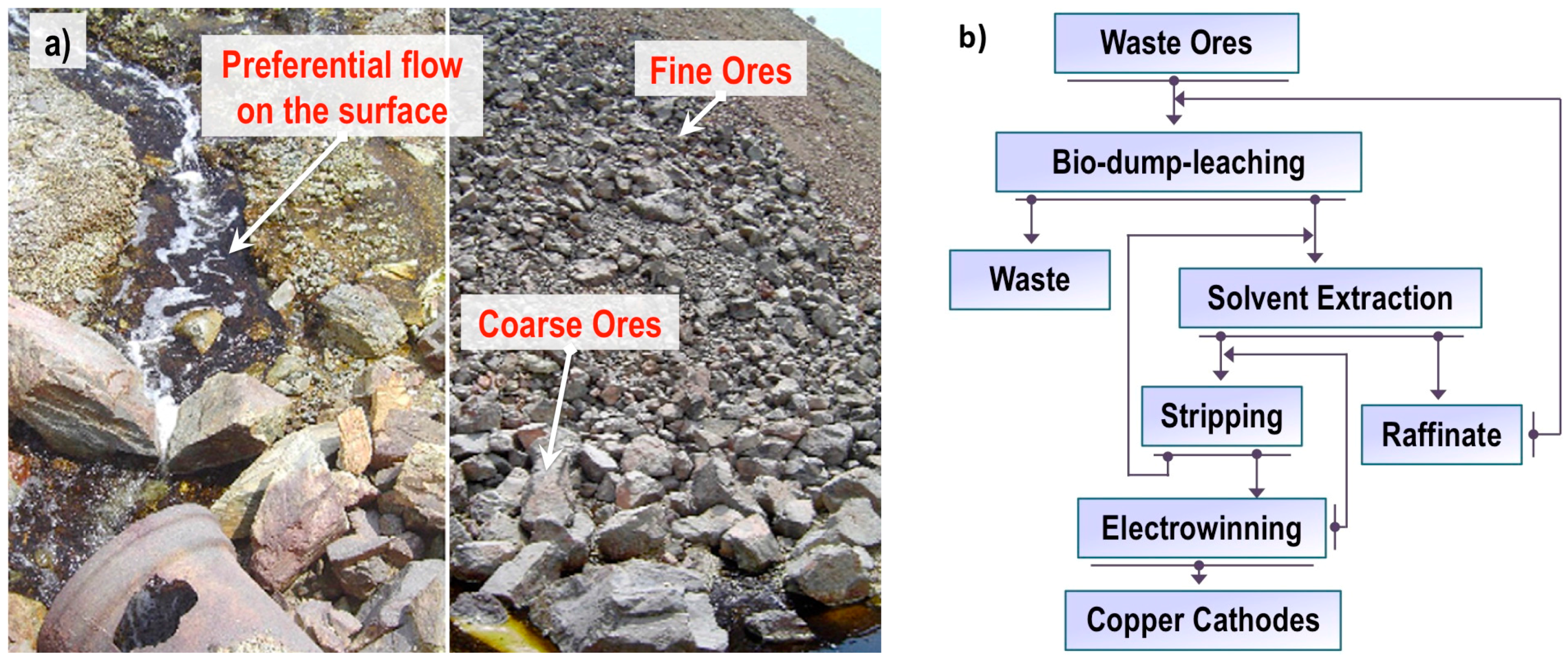

3.2.2. Dexing Copper Mine (DCM)

4. Recent Technical Progress of Copper Bioleaching

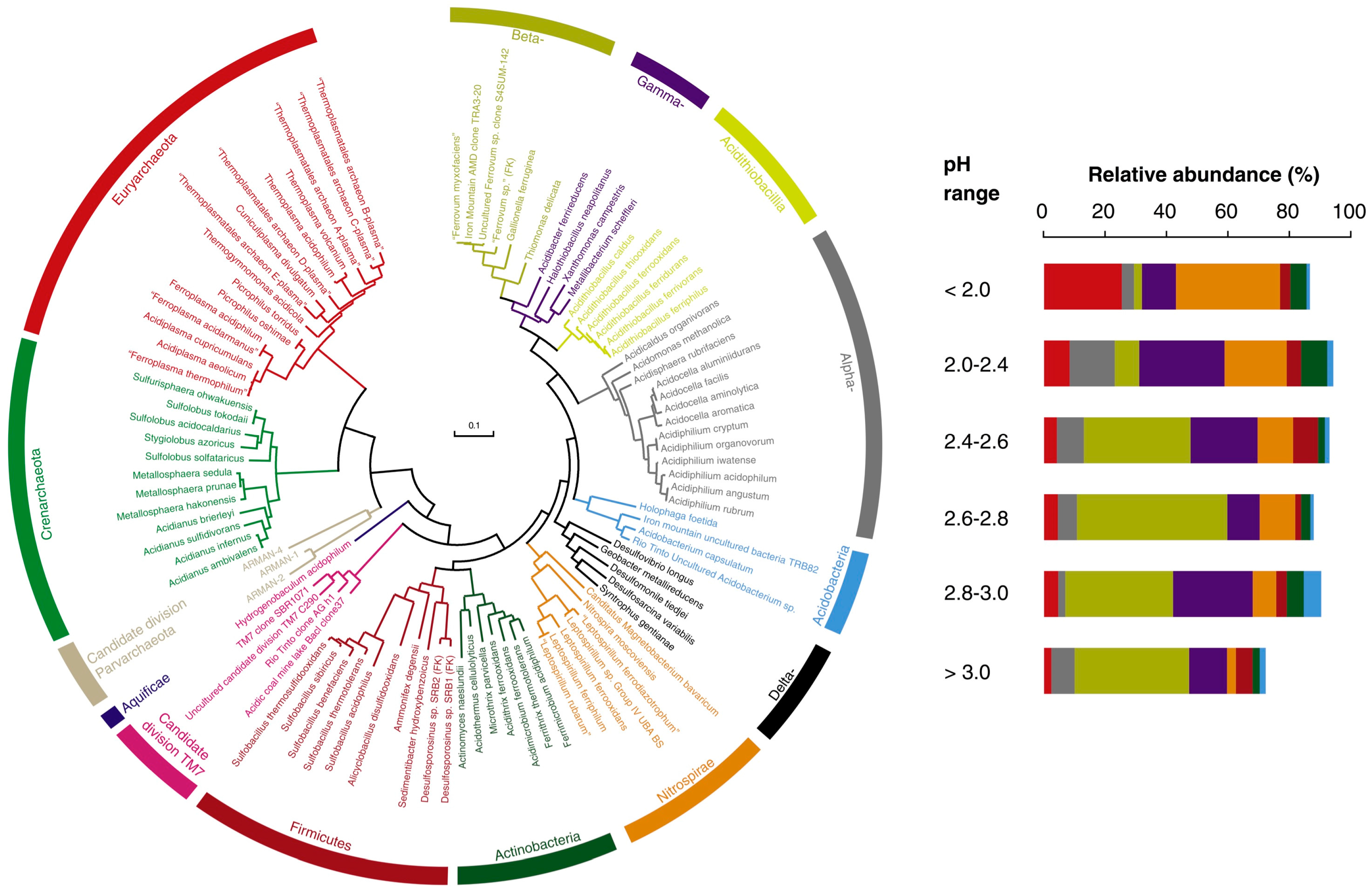

4.1. Isolation, Identification, and Enrichment of Bacteria

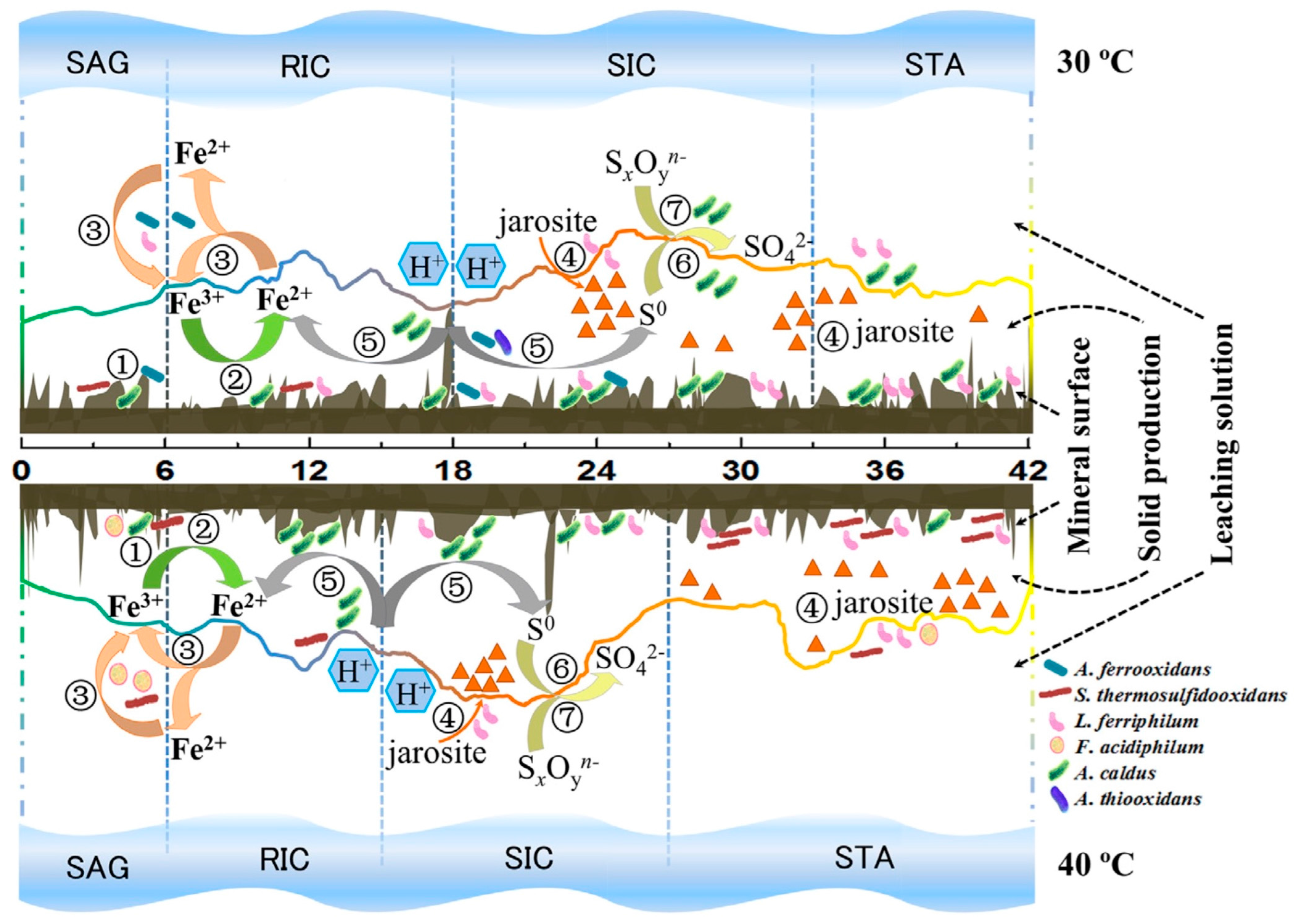

4.2. Bioleaching Mechanism and Interface Reaction

4.3. Multistage Percolation Behavior of Leaching Solution

4.4. Reconstruction and Characterization of Multiple Pore Structure

4.5. Multiphysics Coupled Model of Bioleaching Process

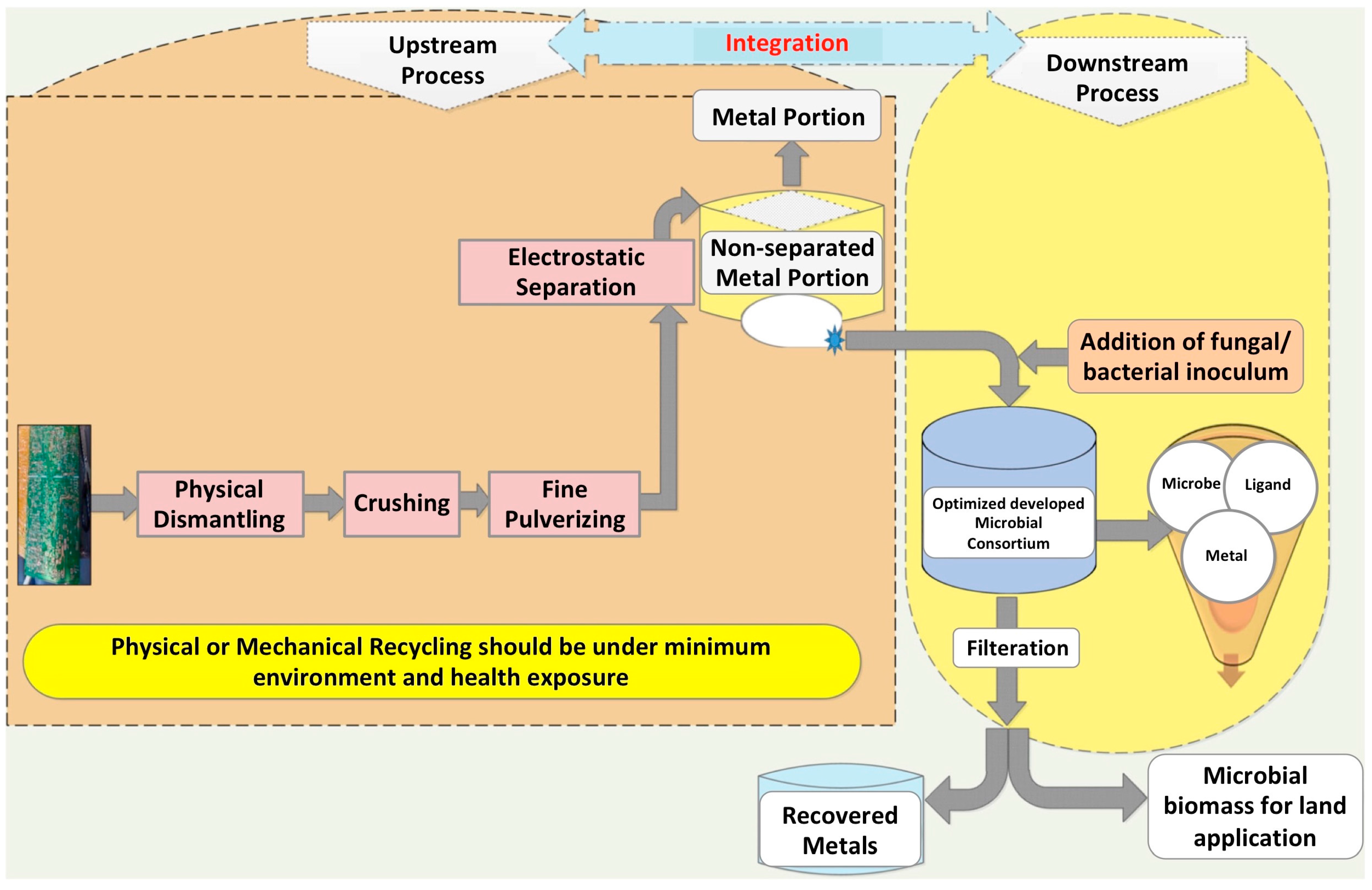

4.6. Enhanced Copper Bioleaching from Waste Printed Circuit Boards (WPCBs)

5. Future Opportunities and Challenges

5.1. Efficiency Improvement and Guarantee

- Enhanced bioleaching methods using external field energy, like enhanced aeration, permeability regulation, geothermal energy, underground pressure, etc.

- Target minerals activation pre-treatment insides ore and other enhanced minerals exposing technology.

- Bioleaching process control, like weakened passivation methods, especially for copper sulfide bioleaching.

5.2. Environmental Protection and Security

- Acid leaching solution is a serious hazard to surface runoff and groundwater, presenting risks such as depositing crop pollution, high cancer rates, and animal deformity.

- Exotic bacterium escaping from bioleaching industrial plants could be a momentous threat to native bio-diversity, even leading to crowning calamity of rare species.

- Ore dump and heap collapse threats under internal bioleaching mechanisma and external environmental factors such as rainstorms.

- Consummation of relevant environmental assessment (EIA) methods and regulations.

5.3. Application of Novel Technology and Methods

- New field energy, like solar thermal energy, wind energy, microwave treatment [251] is used to enhance bioleaching strength, obtaining a better extraction and decreasing environmental pollution.

- New visualization, intellectualization, and fluidization mining methods such as super-precise unperturbed scanning even deeper into the reaction interface, real-time 3D printing during bioleaching, unmanned in situ bioleaching.

- Metal recovery from solid waste like ore dumps WPCBs with surfactant based on bioleaching.

- New in situ copper bioleaching methods to explore mineral resources located in the deep earth.

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| AMD | Acid Mine Drainage |

| A.f | Acidthiobacillus ferrooxidans |

| AFM | Atomic Force Microscopy |

| CT | Computed Tomography |

| DCM | Dexing Copper Mine |

| EFM | Epifluorescence Microscope |

| EPS | Extracellular Polymeric Substances |

| FTIR | Fourier Transform Infrared |

| HPGR | High Pressure Grinding Rolls |

| ILS | Initial Leaching Solution |

| LBM | Lattice Boltzmann Model |

| MRI | Magnetic Resonance Imaging |

| NCNTs | Nitrogen-Doped Carbon Nanotubes |

| PIV | Particle Image Velocimetry |

| PLS | Pregnant Leaching Solution |

| T.f | Thiobacillus ferrooxidans |

| WEEE | Waste Electric and Electronic Equipment |

| WPCBs | Waste Printed Circuit Boards |

| WRD | Waste Rock Dump |

| ZCM | Zijinshan Copper Mine |

References

- Dunbar, W.S. Biotechnology and the mine of Tomorrow. Trends Biotechnol. 2017, 35, 79–89. [Google Scholar] [CrossRef] [PubMed]

- Panda, S.; Akcil, A.; Pradhan, N.; Deveci, H. Current scenario of chalcopyrite bioleaching: A review on the recent advances to its heap-leach technology. Bioresour. Technol. 2015, 196, 694–706. [Google Scholar] [CrossRef] [PubMed]

- Fang, X.; Shen, Y.; Zhao, J.; Bao, X.M.; Qu, Y.B. Status and prospect of lignocellulosic bioethanol production in China. Bioresour. Technol. 2010, 101, 4814–4819. [Google Scholar] [CrossRef] [PubMed]

- Rawlings, D.E.; Johnson, D.B. The microbiology of biomining: Development and optimization of mineral-oxidizing microbial consortia. Microbiology 2007, 153, 315–324. [Google Scholar] [CrossRef] [PubMed]

- Ehrlich, H.L.; Brierley, C.L. Microbial Mineral Recovery; McGraw Hill Book Co.: New York, NY, USA, 1990. [Google Scholar]

- Gentina, J.C.; Padilla, C.; Poirrier, P. Development of a culture strategy to produce a bacteriocin type substance utilizing a strain of Enterococcus mundtii. J. Biotechnol. 2010, 150, 414. [Google Scholar] [CrossRef]

- Acevedo, F.; Gentina, J.C.; Bustos, S. Bioleaching of minerals—A valid alternative for developing countries. J. Biotechnol. 1993, 31, 115–123. [Google Scholar] [CrossRef]

- Petersen, J. Heap leaching as a key technology for recovery of values from low-grade ores—A brief overview. Hydrometallurgy 2016, 165, 206–212. [Google Scholar] [CrossRef]

- Johnson, D.B. Biomining-biotechnologies for extracting and recovering metals from ores and waste materials. Curr. Opin. Biotechnol. 2014, 30, 24–31. [Google Scholar] [CrossRef] [PubMed]

- Watling, H.R. The bioleaching of sulphide minerals with emphasis on copper sulphides—A review. Hydrometallurgy 2006, 84, 81–102. [Google Scholar] [CrossRef]

- Pradhan, N.; Nathsarma, K.C.; Rao, K.S.; Sukla, L.B.; Mishra, B.K. Heap bioleaching of chalcopyrite: A review. Miner. Eng. 2008, 21, 355–365. [Google Scholar] [CrossRef]

- Wang, Y.G.; Su, L.J.; Zhang, L.J.; Zeng, W.M.; Wu, J.Z.; Wan, L.L.; Qiu, G.Z.; Chen, X.H.; Zhou, H.B. Bioleaching of chalcopyrite by defined mixed moderately thermophilic consortium including a marine acidophilic halotolerant bacterium. Bioresour. Technol. 2012, 121, 348–354. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.C.; Pandey, B.D. Bio-processing of solid wastes and secondary resources for metal extraction—A review. Waste Manag. 2012, 32, 3–18. [Google Scholar] [CrossRef] [PubMed]

- Ndlovu, S. Biohydrometallurgy for sustainable development in the African minerals industry. Hydrometallurgy 2008, 91, 20–27. [Google Scholar] [CrossRef]

- Cloete, T.E.; Nel, L.H.; Theron, J. Biotechnology in South Africa. Trends Biotechnol. 2006, 24, 557–562. [Google Scholar] [CrossRef] [PubMed]

- Johnson, D.B. Biomining goes underground. Nat. Geosci. 2015, 8, 165–166. [Google Scholar] [CrossRef]

- Orell, A.; Navarro, C.A.; Arancibia, R.; Mobarec, J.C.; Jerez, C.A. Life in blue: Copper resistance mechanisms of bacteria and Archaea used in industrial biomining of minerals. Biotechnol. Adv. 2010, 28, 839–848. [Google Scholar] [CrossRef] [PubMed]

- Acevedo, F. Present and Future of bioleaching in developing countries. Electron. J. Biotechnol. 2002, 5, 52–56. [Google Scholar] [CrossRef]

- Huang, T.; Li, D. Presentation on mechanisms and applications of chalcopyrite and pyrite bioleaching in biohydrometallurgy—A presentation. Biotechnol. Rep. 2014, 4, 107–119. [Google Scholar]

- Shiers, D.W.; Collinson, D.M.; Watling, H.R. Life in heaps: A review of microbial responses to variable acidity in sulfide mineral bioleaching heaps for metal extraction. Res. Microbiol. 2016, 167, 576–586. [Google Scholar] [CrossRef] [PubMed]

- Rawlings, D.E.; Johnson, D.B. Biomining; Springer: Heidelberg, Germany, 2007. [Google Scholar]

- Cárdenas, J.P.; Quatrini, R.; Holmes, D.S. Genomic and metagenomic challenges and opportunities for bioleaching: A mini-review. Res. Microbiol. 2016, 167, 529–538. [Google Scholar] [CrossRef] [PubMed]

- Miao, X.X.; Gerke, K.M.; Sizonenko, T.O. A new way to parameterize hydraulic conductances of pore elements: A step towards creating pore-networks without pore shape simplifications. Adv. Water Resour. 2017, 105, 162–172. [Google Scholar] [CrossRef]

- Fagan, M.A.; Ngoma, I.E.; Chiume, R.A.; Minnaar, S.; Sederman, A.J.; Johns, M.L.; Harrison, S.T.L. MRI and gravimetric studies of hydrology in drip irrigated heaps and its effect on the propagation of bioleaching micro-organisms. Hydrometallurgy 2014, 150, 210–221. [Google Scholar] [CrossRef] [Green Version]

- Fagan, M.A.; Harrison, S.T.L.; Johns, M.L.; Sederman, A.J. Magnetic resonance imaging characterization of the influence of flowrate on liquid distribution in drip irrigated heap leaching. Hydrometallurgy 2015, 158, 157–164. [Google Scholar] [CrossRef]

- Fan, Y.; Jacob, K.V.; Freireich, B.; Lueptow, R.M. Segregation of granular materials in bounded heap flow: A review. Powder Technol. 2017, 312, 67–88. [Google Scholar] [CrossRef]

- Lin, C.L.; Videla, A.R.; Miller, J.D. Advanced three-dimensional multiphase flow simulation in porous media reconstructed from X-ray Microtomography using the He–Chen–Zhang Lattice Boltzmann Model. Flow Meas. Instrum. 2010, 21, 255–261. [Google Scholar] [CrossRef]

- Miller, J.D.; Lin, C.L.; Hupka, L.; Al-Wakeel, M.I. Liberation-limited grade/recovery curves from X-ray micro CT analysis of feed material for the evaluation of separation efficiency. Int. J. Miner. Process. 2009, 93, 48–53. [Google Scholar] [CrossRef]

- Dhawan, N.; Safarzadeh, M.S.; Miller, J.D.; Moats, M.S.; Rajamani, R.K.; Lin, C.L. Recent advances in the application of X-ray computed tomography in the analysis of heap leaching systems. Miner. Eng. 2012, 35, 75–86. [Google Scholar] [CrossRef]

- Nosrati, A.; Quast, K.; Xu, D.F.; Skinner, W.; Robinson, D.J. Agglomeration and column leaching behaviour of nickel laterite ores: Effect of ore mineralogy and particle size distribution. Hydrometallurgy 2014, 146, 29–39. [Google Scholar] [CrossRef]

- Quaicoe, I.; Nosrati, A.; Skinner, W.; Ad-Mensah, J. Agglomeration behaviour and product structure of clay and oxide minerals. Chem. Eng. Sci. 2013, 98, 40–50. [Google Scholar] [CrossRef]

- Lizama, H.M. Copper bioleaching behaviour in an aerated heap. Int. J. Miner. Process. 2001, 62, 257–269. [Google Scholar] [CrossRef]

- Bartlett, R.W.; Prisbrey, K.A. Convection and diffusion limited aeration during biooxidation of shallow ore heaps. Int. J. Miner. Process. 1996, 47, 75–91. [Google Scholar] [CrossRef]

- Ilankoon, I.M.S.K.; Neethling, S.J. Liquid spread mechanisms in packed beds and heaps. The separation of length and time scales due to particle porosity. Miner. Eng. 2016, 86, 130–139. [Google Scholar] [CrossRef]

- Chiume, R.; Minnaar, S.H.; Ngoma, I.E.; Bryan, C.G.; Harrison, S.T.L. Microbial colonisation in heaps for mineral bioleaching and the influence of irrigation rate. Miner. Eng. 2012, 39, 156–164. [Google Scholar] [CrossRef]

- Zhang, R.T.; Wei, D.Z.; Shen, Y.B.; Liu, W.G.; Lu, T.; Han, C. Catalytic effect of polyethylene glycol on sulfur oxidation in chalcopyrite bioleaching by Acidithiobacillus ferrooxidans. Miner. Eng. 2016, 95, 74–78. [Google Scholar] [CrossRef]

- Ai, C.M.; Wu, A.X.; Wang, Y.M.; Hou, C.L. Optimization and mechanism of surfactant accelerating leaching test. J. Cent. South Univ. (Engl. Ed.) 2016, 23, 1032–1039. [Google Scholar] [CrossRef]

- Muñoz, J.A.; Dreisinger, D.B.; Cooper, W.C.; Young, S.K. Silver-catalyzed bioleaching of low-grade copper ores: Part I: Shake flasks tests. Hydrometallurgy 2007, 88, 3–18. [Google Scholar] [CrossRef]

- Anjum, F.; Bhatti, H.N.; Ghauri, M.A. Enhanced bioleaching of metals from black shale using ultrasonics. Hydrometallurgy 2010, 100, 122–128. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, W.Y. Application of aerial image analysis for assessing particle size segregation in dump leaching. Hydrometallurgy 2017, 171, 99–105. [Google Scholar] [CrossRef]

- Rawlings, D.E.; Silver, S. Mining with Microbes. Nat. Biotechnol. 1995, 133, 17–19. [Google Scholar] [CrossRef]

- Anjum, F.; Shahid, M.; Akcil, A. Biohydrometallurgy techniques of low grade ores: A review on black shale. Hydrometallurgy 2012, 117–118, 1–12. [Google Scholar] [CrossRef]

- Ghosh, S.; Mohanty, S.; Akcil, A.; Sukla, L.B.; Das, A.P. A greener approach for resource recycling: Manganese bioleaching. Chemosphere 2016, 154, 628–639. [Google Scholar] [CrossRef] [PubMed]

- Colmer, A.R.; Temple, K.L.; Hinkle, M.E. An iron-oxidizing bacterium from the acid drainage of some bituminous coal mines. J. Bacteriol. 1950, 59, 317–328. [Google Scholar] [PubMed]

- Ehrlich, H.L. Past, Present and Future of Biohydrometallurgy. Hydrometallurgy 2001, 59, 127–134. [Google Scholar] [CrossRef]

- Brierley, J.A.; Brierley, C.J. Present and future commercial applications of biohydrometallurgy. Hydrometallurgy 2001, 59, 233–239. [Google Scholar] [CrossRef]

- Cowan, D.A. Biotechnology of the Archaea. Trends Biotechnol. 1992, 10, 315–323. [Google Scholar] [CrossRef]

- Tang, K.; Baskaran, V.; Nemati, M. Bacteria of the sulphur cycle: An overview of microbiology, biokinetics and their role in petroleum and mining industries. Biochem. Eng. J. 2009, 44, 73–94. [Google Scholar] [CrossRef]

- Silver, S.; Gupta, A. Mining for biogold. Nat. Biotechnol. 1998, 16, 485. [Google Scholar] [CrossRef]

- Moffat, A.S. Microbial mining boosts the environment, bottom line. Science 1994, 264, 778–779. [Google Scholar] [CrossRef] [PubMed]

- Brierley, J.A. A perspective on development in biohydrometallurgy. Hydrometallurgy 2008, 94, 2–7. [Google Scholar] [CrossRef]

- Latorre, M.; Cortés, M.P.; Travisany, D.; Genova, A.D.; Budinich, M.; Reyes-Jara, A.; Hodar, C.; Gonzalez, M.; Parada, P.; Bobadilla-Fazzini, R.A.; et al. The bioleaching potential of a bacterial consortium. Bioresour. Technol. 2016, 218, 659–666. [Google Scholar] [CrossRef] [PubMed]

- Mishra, D.; Kim, D.J.; Ahn, J.G.; Rhee, Y.H. Bioleaching: A Microbial Process of Metal Recovery. A Review. Met. Mater. Int. 2005, 11, 249–256. [Google Scholar] [CrossRef]

- Kelly, D. Metals and Micro-organisms. Trends Biotechnol. 1990, 8, 271–272. [Google Scholar] [CrossRef]

- Gericke, M.; Neale, J.W.; Staden, P.J.V. A Mintek perspective of the past 25 years in minerals bioleaching. J. South. Afr. Inst. Min. Metall. 2009, 109, 567–585. [Google Scholar]

- Ghorbani, J.; Franzidis, J.P.; Petersen, J. Heap Leaching Technology—Current State, Innovations, and Future Directions: A Review. Min. Process. Extr. Metall. Rev. 2016, 37, 73–119. [Google Scholar] [CrossRef] [Green Version]

- China Mineral Resources 2016; Ministry of Land and Resources People’s Republic of China; Geological Publishing House: Beijing, China, 2016.

- Chen, J.P.; Zhang, Y.; Wang, J.X.; Xiao, K.Y.; Lou, D.B.; Ding, J.H.; Yin, J.N.; Xiang, J. On present situation and potential analysis of copper resources in China. J. Geol. 2013, 37, 358–365. (In Chinese) [Google Scholar]

- Yang, S.R.; Xie, J.Y.; Qiu, G.Z.; Hu, Y.H. Research and application of bioleaching and biooxidation technologies in China. Miner. Eng. 2002, 15, 361–363. [Google Scholar]

- Zhu, X. Mining History in China; Geological Publishing House: Beijing, China, 2010. (In Chinese) [Google Scholar]

- Wu, A.X.; Yin, S.H.; Qin, W.Q.; Liu, J.S.; Qiu, G.Z. The effect of preferential flow on extraction and surface morphology of copper sulphides during heap leaching. Hydrometallurgy 2009, 95, 76–81. [Google Scholar] [CrossRef]

- Hu, K.J.; Wu, A.X.; Wang, H.J.; Wang, S.Y. A New Heterotrophic Strain for Bioleaching of Low Grade Complex Copper Ore. Minerals 2016, 6, 12. [Google Scholar] [CrossRef]

- Ruan, R.M.; Wen, J.K.; Chen, J.H. Bacterial heap-leaching: Practice in Zijinshan copper mine. Hydrometallurgy 2006, 83, 77–82. [Google Scholar]

- Wang, B.Y.; Cong, Z.F.; Dai, S.J. Current Developments and Prospects in Bioleaching of Copper Ores. Non-ferr. Min. Metall. 2008, 24, 28–31. (In Chinese) [Google Scholar]

- He, Z.G.; Xie, X.S.; Liu, J.; Qiu, G. Microbial diversity of mine water at Zhong Tiaoshan copper mine, China. J. Basic Microbiol. 2007, 47, 485–495. (In Chinese) [Google Scholar] [CrossRef] [PubMed]

- Lu, D.K.; Liu, D.X.; Wang, C.; Jiang, K.X.; Luo, Q.H. Research on underground leaching of low-grade copper ore in Zhongtiaoshan. Non-ferr. Smelt. 2001, 1, 17–19. [Google Scholar]

- Zhan, J.; Sun, Q.Y. Development of microbial properties and enzyme activities in copper mine wasteland during natural restoration. Catena 2014, 116, 86–94. [Google Scholar] [CrossRef]

- Qiu, G.Z.; Wan, M.X.; Qian, L.; Huang, Z.Y.; Liu, K.; Liu, X.D.; Shi, W.Y.; Yang, Y. Archaeal diversity in acid mine drainage from Dabaoshan Mine, China. J. Basic Microbiol. 2008, 48, 401–409. [Google Scholar] [CrossRef] [PubMed]

- Li, H.X.; Qiu, G.Z.; Hu, Y.H.; Liu, J.S.; Xu, J. Bacterial leaching of Dabaoshan Discarded Copper Ore. Kuangchan Zonghe Liyong 2000, 5, 31–34. (In Chinese) [Google Scholar]

- Hao, X.D.; Liang, Y.L.; Yin, H.Q.; Ma, L.Y.; Xiao, Y.H.; Liu, Y.Z.; Qiu, G.Z.; Liu, X.D. The effect of potential heap construction methods on column bioleaching of copper flotation tailings containing high levels of fines by mixed cultures. Miner. Eng. 2016, 98, 279–285. [Google Scholar] [CrossRef]

- Yang, H.X.; Zhou, A.D.; Xu, J.Z. Application of Biohydrometallurgy in Copper Indutriy. Non-ferr. Min. Metall. 2003, 19, 15–18. (In Chinese) [Google Scholar]

- Wu, Y.P. Study on Bioleaching of Yongping Low Grade Copper Sulfide Ore in Jiangxi by Mixed Cultures. Master’s Thesis, Jiangxi University of Science and Technology, Ganzhou Shi, China, 2011. (In Chinese). [Google Scholar]

- Wang, H.; Feng, C.Y.; Li, D.X.; Li, C.; Li, T.Z.; Liao, F.Z. Geology, geochronology and geochemistry of the Saishitang Cu deposit, East Kunlun Mountains, NW China: Constraints on ore genesis and tectonic setting. Ore Geol. Rev. 2016, 72, 43–59. [Google Scholar] [CrossRef]

- Li, J.J. Study on Bacteria Bioleaching and Adsorbent for Low Grade Copper Mine in Qinghai Saishitang; Southwest University of Science and Technology: Mianyang, China, 2012. (In Chinese) [Google Scholar]

- Dai, Z.M.; Yin, H.Q.; Zeng, X.X.; Liu, X.D. Comparison of Microbial Community of Acid Mine Drainage from Dongchuan Copper Pyrite. Xiandai Shengwuyixue Jinzhan 2007, 7, 1608–1611. (In Chinese) [Google Scholar]

- Feng, S.; Yang, H.; Wang, W. Improved chalcopyrite bioleaching by Acidithiobacillus sp. via direct step-wise regulation of microbial community structure. Bioresour. Technol. 2015, 192, 75–82. [Google Scholar] [CrossRef] [PubMed]

- Nakazawa, H.; Koizumi, M.; Sato, H. Bacterial Leaching of Copper-nickel Sulfide Ores from Jinchuan Mine, China. J. MMIJ 1992, 108, 731–735. [Google Scholar] [CrossRef]

- Banerjee, I.; Burrell, B.; Reed, C.; West, A.C.; Banta, S. Metals and minerals as a biotechnology feedstock: Engineering biomining microbiology for bioenergy applications. Curr. Opin. Biotechnol. 2017, 45, 144–155. [Google Scholar] [CrossRef] [PubMed]

- Jin, J.M. Experiment Study of Bacteria Enhanced Bioleaching Oxide Copper Mine. Master’s Thesis, Jiangxi University of Science and Technology, Ganzhou, China, 2009. (In Chinese). [Google Scholar]

- Li, J.L.; Li, D.C. The Practice of low grade primary chalcopyrite bacteria leaching technology. Copp. Eng. 2006, 2, 7–10. (In Chinese) [Google Scholar]

- He, Z.G.; Xiao, S.M.; Xie, X.H.; Hu, Y.H. Microbial diversity in acid mineral bioleaching systems of dongxiang copper mine and Yinshan lead-zinc mine. Extremophiles 2008, 12, 225–234. (In Chinese) [Google Scholar] [CrossRef] [PubMed]

- Wang, J. Research and Practice on Bioleaching of Low-Grade Complex Copper Sulfide. Ph.D. Thesis, Central South University, Changsha, China, 2011. (In Chinese). [Google Scholar]

- Zhen, S.J. Application Basis and Technology Research on the Bioleaching of Jinchuan Low Grade Nickel-Bearing Sufide Ore Containing High Magnesium. Ph.D. Thesis, Central South University, Changsha, China, 2010. (In Chinese). [Google Scholar]

- Zhen, S.J.; Qin, W.Q.; Yan, Z.Q.; Zhang, Y.S.; Wang, J.; Ren, L.Y. Bioleaching of low grade nickel sulfide minerals in column reactor. Trans. Nonferr. Met. Soc. China 2008, 18, 1480–1484. [Google Scholar] [CrossRef]

- Zhen, S.J.; Yan, Z.Q.; Zhang, Y.S.; Wang, J.; Campbell, M.; Qin, W.Q. Column bioleaching of a low grade nickel-bearing sulfide ore containing high magnesium as olivine, chlorite and antigorite. Hydrometallurgy 2009, 96, 337–341. [Google Scholar] [CrossRef]

- Liu, X.Y.; Chen, B.W.; Chen, J.H.; Zhang, M.J.; Wen, J.K.; Wang, D.Z.; Ruan, R.M. Spatial variation of microbial community structure in the Zijinshan commercial copper heap bioleaching plant. Miner. Eng. 2016, 94, 76–82. [Google Scholar] [CrossRef]

- Yuan, X.; Yuan, C.X.; Zhong, K.N.; Wei, Y.H. Microbes processing technology study for non-metallic minerals. China Non-Met. Min. Ind. Her. 2000, 4, 17–24. (In Chinese) [Google Scholar]

- Ruan, R.M.; Liu, X.Y.; Zou, G.; Chen, J.H.; Wen, J.K.; Wang, D.Z. Industrial practice of a distinct bioleaching system operated at low pH, high ferric concentration, elevated temperature and low redox potential for secondary copper sulfide. Hydrometallurgy 2011, 108, 130–135. [Google Scholar] [CrossRef]

- Ruan, R.M.; Zou, G.; Zhong, S.P.; Wu, Z.L.; Chan, B.; Wang, D.Z. Why Zijinshan copper bioheapleaching plant works efficiently at low microbial activity—Study on leaching kinetics of copper sulfides and its implications. Miner. Eng. 2013, 48, 36–43. [Google Scholar] [CrossRef]

- Liu, X.Y.; Chen, B.W.; Wen, J.K. Dominance of Acidithiobacillus at ore surface of Zijinshan commercial low-grade copper bioleaching heap. Trans. Nonferr. Met. Soc. China 2008, 18, 1506–1512. [Google Scholar] [CrossRef]

- Liu, X.Y.; Chen, B.W.; Wen, J.K.; Ruan, R.M. Leptospirillum, forms a minor portion of the population in Zijinshan commercial non-aeration copper bioleaching heap identified by 16S rRNA clone libraries and real-time PCR. Hydrometallurgy 2010, 104, 399–403. [Google Scholar]

- Sullivan, J.D. Chemistry of Leaching Covellite; TP 487; US Bureau of Mines: Washington, DC, USA, 1930.

- Sullivan, J.D. Chemistry of Leaching Chalcocite; TP 473; US Bureau of Mines: Washington, DC, USA, 1930.

- Wen, J.K.; Ruan, R.M.; Yao, G.C.; Song, Y.S. Acid equilibrium during bioleaching of alkaline low-grade copper sulfide ore. Rare Met. 2006, 25, 680–686. [Google Scholar] [CrossRef]

- Zhu, W.; Xia, J.L.; Yang, Y.; Nie, Z.Y.; Peng, A.A.; Liu, C.H.; Qiu, G.Z. Thermophilic archaeal community succession and function change associated with the leaching rate in bioleaching of chalcopyrite. Bioresour. Technol. 2013, 133, 405–413. [Google Scholar] [CrossRef] [PubMed]

- He, M.C.; Wang, Z.J.; Tang, H.X. Spatial and temporal patterns of acidity and heavy metals in predicting the potential for ecological impact on the Le An River polluted by acid mine drainage. Sci. Total Environ. 1997, 206, 67–77. [Google Scholar] [CrossRef]

- Liu, Q.M.; Yu, R.L.; Qiu, G.Z.; Feng, Z.; Chen, A.L.; Zhao, Z.W. Optimization of separation processing of copper and iron of dump bioleaching solution by Lix 984N in Dexing Copper Mine. Trans. Nonferr. Met. Soc. China 2008, 18, 1258–1261. [Google Scholar] [CrossRef]

- Yin, S.H.; Wu, A.X.; Wang, H.J.; Zhou, B. Challenges faced by Dexing Copper Mine—A case study of dump leaching in China. In Proceedings of the First International Seminar on the Management of Rock Dumps, Stockpiles and Heap Leach Pads, Perth, Australia, 5–6 March 2008; pp. 179–191. [Google Scholar]

- Liu, J.S.; Xia, H.B.; Wang, Z.H.; Hu, Y.H. Bacterial oxidation activity in heap leaching. J. Cent. South Univ. Technol. (Engl. Ed.) 2004, 11, 375–379. [Google Scholar] [CrossRef]

- Yin, S.H.; Wu, A.X.; Qiu, G.Z. Bioleaching of low-grade copper sulphides. Trans. Nonferr. Met. Soc. China 2008, 18, 707–713. [Google Scholar] [CrossRef]

- Wu, A.X.; Yin, S.H.; Yang, B.H.; Wang, J.; Qiu, G.Z. Study on preferential flow in dump leaching of low-grade ores. Hydrometallurgy 2007, 87, 124–132. [Google Scholar] [CrossRef]

- Wu, A.X.; Yin, S.H.; Wang, H.J.; Qin, W.Q.; Qiu, G.Z. Technological assessment of a mining-waste dump at the Dexing copper mine, China, for possible conversion to an in situ bioleaching operation. Bioresour. Technol. 2009, 100, 1931–1936. [Google Scholar] [CrossRef] [PubMed]

- Zhuang, W.Q.; Fitts, J.P.; Ajo-Franklin, C.M.; Maes, S.; Alvarez-Cohen, L.; Hennebel, T. Recovery of critical metals using biometallurgy. Curr. Opin. Biotechnol. 2015, 33, 327–335. [Google Scholar] [CrossRef] [PubMed]

- Wackett, L.P.; Bruce, N.C. Environmental biotechnology: Towards sustainability. Curr. Opin. Biotechnol. 2000, 11, 229–231. [Google Scholar] [CrossRef]

- He, Z.L.; Nostrand, J.D.V.; Zhou, J.Z. Applications of functional gene microarrays for profiling microbial communities. Curr. Opin. Biotechnol. 2012, 23, 460–466. [Google Scholar] [CrossRef] [PubMed]

- Tuovinen, O.H.; Fry, I.J. Bioleaching and mineral biotechnology. Curr. Opin. Biotechnol. 1993, 4, 344–355. [Google Scholar] [CrossRef]

- Johnson, D.B. Importance of microbial ecology in the development of new mineral technologies. Hydrometallurgy 2001, 59, 147–157. [Google Scholar] [CrossRef]

- Johnson, D.B. Biodiversity and ecology of acidophilic microorganisms. FEMS Microbiol. Ecol. 1998, 27, 307–317. [Google Scholar] [CrossRef]

- Luo, Y.J.; Liu, Y.D.; Zhang, C.G.; Luo, H.L.; Guan, H.; Liao, H.H.; Qiu, G.Z.; Liu, X.D. Insights into Two High Homogenous Genes Involved in Copper Homeostasis in Acidithiobacillus ferrooxidans. Curr. Microbiol. 2008, 57, 274–280. [Google Scholar] [CrossRef] [PubMed]

- Yin, H.Q.; Cao, L.H.; Qiu, G.Z.; Wang, D.Z.; Kellogg, L.; Zhou, J.Z.; Liu, X.X.; Dai, Z.M.; Ding, J.N.; Liu, X.D. Bacterial diversity based on 16S rRNA and gyrB genes at Yinshan mine, China. Syst. Appl. Microbiol. 2008, 31, 302–311. [Google Scholar] [CrossRef] [PubMed]

- Gao, J.; Zhang, C.G.; Wu, X.L.; Wang, H.H.; Qiu, G.Z. Isolation and identification of a strain of Leptospirillum ferriphilum from an extreme acid mine drainage site. Ann. Microbiol. 2007, 57, 171–176. [Google Scholar] [CrossRef]

- Xie, X.; Xiao, S.; He, Z.; Liu, J.; Qiu, G.Z. Microbial populations in acid mineral bioleaching systems of Tong Shankou Copper Mine, China. J. Appl. Microbiol. 2007, 103, 1227–1238. [Google Scholar] [CrossRef] [PubMed]

- Urbieta, M.S.; Donati, E.R.; Chan, K.G.; Shahar, S.; Sin, L.L.; Goh, K.M. Thermophiles in the genomic era: Biodiversity, science, and applications. Biotechnol. Adv. 2015, 33, 633–647. [Google Scholar] [CrossRef] [PubMed]

- Qiu, G.Z.; Liu, X.D.; Zhou, H.B. Microbial community structure and function in sulfide ore bioleaching systems. Trans. Nonferr. Met. Soc. China 2008, 18, 1295–1301. [Google Scholar] [CrossRef]

- Zhao, H.B.; Wang, J.; Yang, C.R.; Hu, M.H.; Gan, X.W.; Tao, L.; Qin, W.Q.; Qiu, G.Z. Effect of redox potential on bioleaching of chalcopyrite by moderately thermophilic bacteria: An emphasis on solution compositions. Hydrometallurgy 2015, 151, 141–150. [Google Scholar] [CrossRef]

- Hu, Q.; Guo, X.; Liang, Y.L.; Hao, X.D.; Ma, L.Y.; Yin, H.Q.; Liu, X.D. Comparative metagenomics reveals microbial community differentiation in a biological heap leaching system. Res. Microbiol. 2015, 166, 525–534. [Google Scholar] [CrossRef] [PubMed]

- Qin, W.Q.; Yang, C.R.; Lai, S.S.; Wang, J.; Liu, K.; Zhang, B. Bioleaching of chalcopyrite by moderately thermophilic microorganisms. Bioresour. Technol. 2013, 129, 200–208. [Google Scholar] [CrossRef] [PubMed]

- Jia, Y.; Sun, H.Y.; Chen, D.F.; Gao, H.S.; Ruan, R.M. Characterization of microbial community in industrial bioleaching heap of copper sulfide ore at Monywa mine, Myanmar. Hydrometallurgy 2016, 164, 355–361. [Google Scholar] [CrossRef]

- Ma, L.Y.; Wang, X.J.; Feng, X.; Liang, Y.L.; Xiao, Y.H.; Hao, X.D.; Yin, H.Q.; Liu, H.W.; Liu, X.D. Co-culture microorganisms with different initial proportions reveal the mechanism of chalcopyrite bioleaching coupling with microbial community succession. Bioresour. Technol. 2017, 223, 121–130. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Gan, X.W.; Zhao, H.B.; Hu, M.H.; Qin, W.Q.; Qiu, G.Z. Dissolution and passivation mechanisms of chalcopyrite during bioleaching: DFT calculation, XPS and electrochemistry analysis. Miner. Eng. 2016, 98, 264–278. [Google Scholar] [CrossRef]

- Li, S.Z.; Zhong, H.; Hu, Y.H.; Zhao, J.C.; He, Z.G.; Gu, G.H. Bioleaching of a low-grade nickel–copper sulfide by mixture of four thermophiles. Bioresour. Technol. 2014, 153, 300–306. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Diao, M.X.; Liu, K.; Qian, L.; Qiu, G.Z. Column bioleaching of low-grade copper ore by Acidithiobacillus ferrooxidans in pure and mixed cultures with a heterotrophic acidophile Acidiphilium sp. Hydrometallurgy 2013, 131–132, 93–98. [Google Scholar] [CrossRef]

- Zhang, Y.S.; Qin, W.Q.; Wang, J.; Zhen, S.J.; Yang, C.R.; Zhang, J.W.; Lai, S.S.; Qiu, G.Z. Bioleaching of chalcopyrite by pure and mixed culture. Trans. Nonferr. Met. Soc. China 2008, 18, 1491–1496. [Google Scholar] [CrossRef]

- Liu, C.Q.; Plumb, J.; Hendry, P. Rapid specific detection and quantification of bacteria and archaea involved in mineral sulfide bioleaching using real-time PCR. Biotechnol. Bioeng. 2006, 94, 330–336. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; She, S.Y.; Dong, W.L.; Niu, J.J.; Xiao, Y.H.; Liang, Y.L.; Liu, X.D.; Zhang, X.X.; Fan, F.L.; Yin, H.Q. Comparative genomics unravels metabolic differences at the species and/or strain level and extremely acidic environmental adaptation of ten bacteria belonging to the genus Acidithiobacillus. Syst. Appl. Microbiol. 2016, 39, 493–502. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Niu, J.J.; Liang, Y.L.; Liu, X.D.; Yin, H.Q. Metagenome-scale analysis yields insights into the structure and function of microbial communities in a copper bioleaching heap. BMC Gentics 2016, 17, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.L.; Yang, F.C.; Huang, C.H.; Fang, H.W.; Cheng, Y.C. Sensitivity analysis of the semiempirical model for the growth of the indigenous Acidithiobacillus thiooxidans. Chem. Eng. J. 2007, 129, 105–112. [Google Scholar] [CrossRef]

- Dong, Y.B.; Lin, H.; Wang, H.; Mo, X.L.; Fu, K.B.; Wen, H.W. Effects of ultraviolet irradiation on bacteria mutation and bioleaching of low-grade copper tailings. Miner. Eng. 2011, 24, 870–875. [Google Scholar] [CrossRef]

- Xu, A.L.; Xia, J.L.; Zhang, S.; Yang, Y.; Nie, Z.Y.; Qiu, G.Z. Bioleaching of chalcopyrite by UV-induced mutagenized Acidiphilium cryptum and Acidithiobacillus ferrooxidans. Trans. Nonferr. Met. Soc. China 2010, 20, 315–321. [Google Scholar] [CrossRef]

- Meng, C.; Shi, X.A.; Liu, H.; Chen, J.F.; Guo, Y.H. UV induced mutations in Acidianus brierleyi growing in a continuous stirred tank reactor generated a strain with improved bioleaching capabilities. Enzyme Microb. Technol. 2007, 40, 1136–1140. [Google Scholar] [CrossRef]

- Tanda, B.C.; Eksteen, J.J.; Oraby, E.A. An investigation into the leaching behaviour of copper oxide minerals in aqueous alkaline glycine solutions. Hydrometallurgy 2017, 167, 153–162. [Google Scholar] [CrossRef]

- Willscher, S.; Bosecker, K. Studies on the leaching behaviour of heterotrophic microorganisms isolated from an alkaline slag dump. Hydrometallurgy 2003, 71, 257–264. [Google Scholar] [CrossRef]

- Deng, S.; Gu, G.H.; Wu, Z.T.; Xu, X.Y. Bioleaching of arsenopyrite by mixed cultures of iron-oxidizing and sulfur-oxidizing microorganisms. Chemosphere 2017, 185, 403. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.X.; Huang, L.N.; Garcia, C.M.; Kuang, J.L.; Hua, Z.S.; Liu, J.; Shu, W.S. Microbial communities, processes and functions in acid mine drainage ecosystems. Curr. Opin. Biotechnol. 2016, 38, 150–158. [Google Scholar] [CrossRef] [PubMed]

- Rawlings, D.E.; Tributsch, H.; Hansford, G.S. Reasons why Leptospirillum-like species rather than Thiobacillus ferrooxidans are the dominant iron-oxidizing bacteria in many commercial processes for the biooxidation of pyrite and related ores. Microbiology 1999, 145, 5–13. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.F.; Yang, C.R.; Qin, W.Q.; Jiao, F.; Wang, J.; Zhang, Y.S. Sulfur composition on surface of chalcopyrite during its bioleaching at 50 °C. Trans. Nonferr. Met. Soc. China 2015, 12, 4110–4118. [Google Scholar] [CrossRef]

- Gu, G.H.; Sun, X.J.; Hu, K.T.; Li, J.H.; Qiu, G.Z. Electrochemical oxidation behavior of pyrite bioleaching by Acidthiobacillus ferrooxidans. Trans. Nonferr. Met. Soc. China, 2012, 5, 1250–1254. [Google Scholar] [CrossRef]

- Zeng, W.M.; Tan, S.; Chen, M.; Qiu, G.Z. Detection and analysis of attached microorganisms on the mineral surface during bioleaching of pure chalcopyrite with moderate thermophiles. Hydrometallurgy 2011, 1–2, 46–50. [Google Scholar] [CrossRef]

- Zeng, W.M.; Qiu, G.Z.; Zhou, H.Z.; Peng, J.H.; Chen, M.; Tan, S.N.; Chao, W.L.; Liu, X.D.; Zhang, Y.S. Community structure and dynamics of the free and attached microorganisms. Bioresour. Technol. 2010, 101, 7068–7075. [Google Scholar] [CrossRef] [PubMed]

- Dong, Y.B.; Lin, H.; Xu, X.F.; Zhang, Y.; Gao, Y.J.; Zhou, S.S. Comparative study on the bioleaching, biosorption and passivation of copper sulfide minerals. Int. Biodeterior. Biodegrad. 2013, 84, 29–34. [Google Scholar] [CrossRef]

- Liu, C.H.; Nie, Z.Y.; Xia, J.L.; Zhu, H.R.; Yang, Y.; Zhao, C.H.; Zheng, L.; Zhao, Y.D. Investigation of copper, iron and sulfur speciation during bioleaching of chalcopyrite by moderate thermophile Sulfobacillus thermosulfidooxidans. Int. J. Miner. Process. 2015, 137, 1–8. [Google Scholar] [CrossRef]

- He, Z.G.; Yang, Y.P.; Zhou, S.; Hu, Y.H.; Zhong, H. Effect of pyrite, elemental sulfur and ferrous ions on EPS production by metal sulfide bioleaching microbes. Trans. Nonferr. Met. Soc. China 2014, 24, 1171–1178. [Google Scholar] [CrossRef]

- Fu, K.B.; Lin, H.; Cheng, H.; Mo, X.L.; Dong, Y.B. Bioleaching of djurleite using Acidithiobacillus ferrooxidans. Miner. Eng. 2013, 40, 38–41. [Google Scholar] [CrossRef]

- Yang, H.Y.; Liu, W.; Chen, G.B.; Liu, Y.Y.; Tong, L.L.; Jin, Z.N.; Liu, Z.L. Function of microorganism and reaction pathway for carrollite dissolution during bioleaching. Trans. Nonferr. Met. Soc. China 2015, 25, 2718–2754. [Google Scholar] [CrossRef]

- Zhao, H.B.; Wang, J.; Hu, M.H.; Qin, W.Q.; Zhang, Y.S.; Qiu, G.Z. Synergistic bioleaching of chalcopyrite and bornite in the presence of Acidithiobacillus ferrooxidans. Bioresour. Technol. 2013, 149, 71–76. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.B.; Huang, X.T.; Wang, J.; Li, Y.N.; Liao, R.; Wang, X.X.; Qiu, X.; Xiong, Y.M.; Qin, W.Q.; Qiu, G.Z. Comparison of bioleaching and dissolution process of p-type and n-type chalcopyrite. Miner. Eng. 2017, 109, 153–161. [Google Scholar] [CrossRef]

- Zhang, L.J.; Mao, F.; Li, K.; Wang, Y.G.; Chen, X.H.; Zhou, H.B. Enhancement in copper extraction from chalcopyrite by re-inoculation of different acidophilic, moderately thermophilic microorganisms. Hydrometallurgy 2015, 156, 142–151. [Google Scholar] [CrossRef]

- Zhang, L.J.; Wu, J.Z.; Wang, Y.G.; Wan, L.L.; Mao, F.; Zhang, W.; Chen, X.H.; Zhou, H.B. Influence of bioaugmentation with Ferroplasma thermophilum on chalcopyrite bioleaching and microbial community structure. Hydrometallurgy 2014, 146, 15–23. [Google Scholar] [CrossRef]

- Zhou, S.; Gan, M.; Zhu, J.Y.; Li, Q.; Jie, S.Q.; Yang, B.J.; Liu, X.D. Catalytic effect of light illumination on bioleaching of chalcopyrite. Bioresour. Technol. 2015, 182, 345–352. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.Y.; Wang, Q.F.; Zhou, S.; Li, Q.; Gan, M.; Jiang, H.; Qin, W.Q.; Liu, X.D.; Hu, Y.H.; Qiu, G.Z. Insights into the relation between adhesion force and chalcopyrite-bioleaching by Acidithiobacillus ferrooxidans. Colloids Surf. B 2015, 126, 351–357. [Google Scholar] [CrossRef] [PubMed]

- Diao, M.X.; Taran, E.; Mahler, S.; Nguyen, A.V. A concise review of nanoscopic aspects of bioleaching bacteria–mineral interactions. Adv. Colloid Interface Sci. 2014, 212, 45–63. [Google Scholar] [CrossRef] [PubMed]

- Yu, Z.J.; Yu, R.L.; Liu, A.J.; Liu, J.; Zeng, W.M.; Liu, X.D.; Qiu, G.Z. Effect of pH values on extracellular protein and polysaccharide secretions of Acidithiobacillus ferrooxidans during chalcopyrite bioleaching. Trans. Nonferr. Met. Soc. China 2017, 27, 406–412. [Google Scholar] [CrossRef]

- Peng, T.J.; Zhou, D.; Liu, X.D.; Yu, R.L.; Jiang, T.; Gu, G.H.; Chen, M.; Qiu, G.Z.; Zeng, W.M. Enrichment of ferric iron on mineral surface during bioleaching of chalcopyrite. Trans. Nonferr. Met. Soc. China 2016, 26, 544–550. [Google Scholar] [CrossRef]

- Yang, H.L.; Feng, S.S.; Xin, Y.; Wang, W. Community dynamics of attached and free cells and the effects of attached cells on chalcopyrite bioleaching by Acidithiobacillus sp. Bioresour. Technol. 2014, 154, 185–191. [Google Scholar] [CrossRef] [PubMed]

- Yu, R.L.; Shi, L.J.; Gu, G.H.; Zhou, D.; You, L.; Chen, M.; Qiu, G.Z.; Zeng, W.M. The shift of microbial community under the adjustment of initial and processing pH during bioleaching of chalcopyrite concentrate by moderate thermophiles. Bioresour. Technol. 2014, 162, 300–307. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Yin, H.Q.; Zeng, W.M.; Liang, Y.L.; Liu, Y.; Baba, N.; Qiu, G.Z.; Shen, L.; Fu, X.; Liu, X.D. The effect of the introduction of exogenous strain Acidithiobacillus thiooxidans A01 on functional gene expression, structure and function of indigenous consortium during pyrite bioleaching. Bioresour. Technol. 2011, 102, 8092–8098. [Google Scholar] [CrossRef] [PubMed]

- Li, R.R.; Yang, Y.S.; Pan, J.X.; Pereira, G.G.; Taylor, J.A.; Clennell, B.; Zou, C.N. Lattice Boltzmann modeling of permeability in porous materials with partially percolating voxels. Phys. Rev. E 2014, 90, 1–10. [Google Scholar] [CrossRef] [PubMed]

- He, Z.G.; Gao, F.L.; Zhong, H.; Hu, Y.H. Effects of L-cysteine on Ni–Cu sulfide and marmatite bioleaching by Acidithiobacillus caldus. Bioresour. Technol. 2009, 100, 1383–1387. [Google Scholar] [CrossRef] [PubMed]

- He, Z.G.; Hu, Y.T.; Yin, Z.; Hu, Y.H.; Zhong, H. Microbial Diversity of Chromium-Contaminated Soils and Characterization of Six Chromium-Removing Bacteria. Environ. Manag. 2016, 57, 1319–1328. [Google Scholar] [CrossRef] [PubMed]

- Jing, R.; Kjellerup, B.V. Biogeochemical cycling of metals impacting by microbial mobilization and immobilization. J. Environ. Sci. 2017, 4, 35. [Google Scholar] [CrossRef]

- Dong, Y.B.; Lin, H.; Zhou, S.S.; Xu, X.F.; Zhang, Y. Effects of quartz addition on chalcopyrite bioleaching in shaking flasks. Miner. Eng. 2013, 46–47, 177–179. [Google Scholar] [CrossRef]

- Pan, H.D.; Yang, H.Y.; Tong, L.L.; Zhong, C.B.; Zhao, Y.S. Control method of chalcopyrite passivation in bioleaching. Trans. Nonferr. Met. Soc. China 2012, 22, 2255–2260. [Google Scholar] [CrossRef]

- Jiang, J.; Lawson, F. Reaction mechanism for the formation of ammonium jarosite. Hydrometallurgy 2006, 82, 195–198. [Google Scholar] [CrossRef]

- Feng, S.S.; Yang, H.L.; Zhan, X.; Wang, W. Novel integration strategy for enhancing chalcopyrite bioleaching by Acidithiobacillus sp. in a 7-L fermenter. Bioresour. Technol. 2014, 161, 371–378. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Bellenberg, S.; Castro, L.; Neu, T.R.; Sand, W.; Vera, M. Colonization and biofilm formation of the extremely acidophilic archaeon Ferroplasma acidiphilum. Hydrometallurgy 2014, 150, 245–252. [Google Scholar] [CrossRef]

- Wang, J.; Tao, L.; Zhao, H.B.; Hu, M.H.; Zheng, X.H.; Peng, H.; Gan, X.W.; Xiao, W.; Cao, P.; Qin, W.Q.; et al. Cooperative effect of chalcopyrite and bornite interactions during bioleaching by mixed moderately thermophilic culture. Miner. Eng. 2016, 95, 116–123. [Google Scholar] [CrossRef]

- Li, Q.; Sand, W. Mechanical and chemical studies on EPS from Sulfobacillus thermosulfidooxidans: From planktonic to biofilm cells. Colloids Surf. B 2017, 153, 34–40. [Google Scholar] [CrossRef] [PubMed]

- Niu, Y.S.; Sun, F.Y.; Xu, Y.H.; Cong, Z.C.; Wang, E.K. Applications of electrochemical techniques in mineral analysis. Talanta 2014, 127, 211–218. [Google Scholar] [CrossRef] [PubMed]

- Li, H.X.; Li, C.; Zhang, Z.Q. Decomposition mechanism of pentlandite during eletrochamical bio-oxidation process. Trans. Nonferr. Met. Soc. China 2012, 22, 731–739. [Google Scholar] [CrossRef]

- Ma, L.Y.; Wang, X.J.; Tao, J.M.; Feng, X.; Zou, K.; Xiao, Y.H.; Liang, Y.L.; Yin, H.Q.; Liu, X.D. Bioleaching of the mixed oxide-copper sulfide ore by artificial indigenous and exogenous microbial community. Hydrometallurgy 2017, 169, 41–46. [Google Scholar] [CrossRef]

- Cariaga, E.; Concha, F.; Sepúlveda, M. Flow through porous media with applications to heap leaching of copper ores. Chem. Eng. J. 2005, 111, 151–165. [Google Scholar] [CrossRef]

- Yin, S.H.; Wu, A.X.; Su, Y.D.; Zhang, J. Experimental study on preferential solution flow during dump leaching of low-grade ores. J. Cent. South Univ. (Engl. Ed.) 2007, 14, 584–588. [Google Scholar] [CrossRef]

- Mcbride, D.; Ilankoon, I.M.S.K.; Neehling, S.J.; Gebhardt, J.E.; Cross, M. Preferential flow behaviour in unsaturated packed beds and heaps: Incorporating into a CFD model. Hydrometallurgy 2017, 171, 402–411. [Google Scholar] [CrossRef]

- Wu, A.X.; Yin, S.H.; Liu, J.Z.; Yang, B.H. Formative mechanism of preferential solution flow during dump leaching. J. Cent. South Univ. (Engl. Ed.) 2006, 13, 590–594. [Google Scholar] [CrossRef]

- Wang, H.J.; Wu, A.X.; Su, Y.D.; Yang, B.H.; Zhang, J. Seepage anisotropy of heterogeneous body. J. China Univ. Min. Technol. (Engl. Ed.) 2007, 17, 572–577. [Google Scholar] [CrossRef]

- Yin, S.H.; Wang, L.M.; Chen, X.; Wu, A.X. Effect of ore size and heap porosity on capillary process inside leaching heap. Trans. Nonferr. Met. Soc. China 2016, 26, 835–841. [Google Scholar] [CrossRef]

- Liu, J.Z.; Jiang, Z.Y.; Wu, A.X. The existence of periodic solutions for a class of nonlinear functional differential equations. Appl. Math. 2008, 53, 97–103. [Google Scholar] [CrossRef]

- Liu, J.Z.; Wu, A.X.; Yang, B.H.; Jiang, H.C. Dynamic experiment and numerical simulation of solute transmission in heap leaching processing. J. Cent. South Univ. Technol. (Engl. Ed.) 2007, 14, 838–841. [Google Scholar] [CrossRef]

- Miao, X.X.; Narsilio, G.A.; Wu, A.X.; Yang, B.H. A 3D dual pore-system leaching model. Part 1: Study on fluid flow. Hydrometallurgy 2017, 167, 173–182. [Google Scholar] [CrossRef]

- Liu, W.Y.; Hashemzadeh, M. Solution flow behavior in response to key operating parameters in heap leaching. Hydrometallurgy 2017, 169, 183–191. [Google Scholar] [CrossRef]

- Yin, S.H.; Wang, L.M.; Xie, F.F.; Chen, X.; Pan, C.Y.; Ai, C.M. Effect of heap structure on column leaching of secondary copper sulfide. Chin. J. Nonferr. Met. 2017, 27, 2340–2348. (In Chinese) [Google Scholar]

- Yin, S.H.; Wang, L.M.; Pan, C.Y.; Chen, X.; Xie, F.F. Fluid flowing characteristics in ore granular with fine interlayers existed. Chin. J. Nonferr. Met. 2017, 27, 574–581. (In Chinese) [Google Scholar]

- Wu, A.X.; Xi, Y.; Yang, B.H.; Chen, X.S.; Jiang, H.C. Study on grey forecasting model of copper extraction rate with bioleaching of primary sulfide ore. Acta Metall. Sin. (Engl. Lett.) 2007, 20, 117–128. [Google Scholar] [CrossRef]

- Miao, X.X.; Wu, A.X.; Yang, B.H.; Liu, J.Z.; Yin, S.H.; Wang, H.J. Unsaturated flow and solute transport in a porous column using spherical ore particles. Int. J. Miner. Metall. Mater. 2014, 21, 113–121. [Google Scholar] [CrossRef]

- Dhawan, N.; Safarzadeh, M.S.; Miller, J.D.; Moats, M.S.; Rajamani, R.K. Crushed ore agglomeration and its control for heap leach operations. Miner. Eng. 2013, 41, 53–70. [Google Scholar] [CrossRef]

- Ghorbani, Y.; Mainza, A.N.; Petersen, J.; Becker, M.; Franzidis, J.P.; Kalala, J.T. Investigation of particles with high crack density produced by HPGR and its effect on the redistribution of the particle size fraction in heaps. Miner. Eng. 2013, 43, 44–51. [Google Scholar] [CrossRef] [Green Version]

- Kodali, P.; Dhawan, N.; Depci, T.; Lin, C.L.; Miller, J.D. Particle damage and exposure analysis in HPGR crushing of selected copper ores for column leaching. Miner. Eng. 2011b, 24, 1478–1487. [Google Scholar] [CrossRef]

- Miller, J.D.; Lin, C.L.; Garcia, C.; Arias, H. Ultimate recovery in heap leaching operations as established from mineral exposure analysis by X-ray microtomography. Int. J. Miner. Process. 2003, 72, 331–340. [Google Scholar] [CrossRef]

- Fagan, M.A.; Sederman, A.J.; Harrison, S.T.L.; John, M.L. Phase distribution identification in the column leaching of low grade ores using MRI. Miner. Eng. 2013, 48, 94–99. [Google Scholar] [CrossRef] [Green Version]

- Fagan, M.A.; Cilliers, J.J.; Sederman, A.J.; Harrison, S.T.L. Spatial variations in leaching of a low-grade, low-porosity chalcopyrite ore identified using X-ray μCT. Miner. Eng. 2017, 105, 63–68. [Google Scholar] [CrossRef]

- Lin, Q.; Barker, D.; Dobson, K.; Lee, P.; Neethling, S. Modelling particle scale leach kinetics based on X-ray computed micro-tomography images. Hydrometallurgy 2016, 162, 25–36. [Google Scholar] [CrossRef] [Green Version]

- Lin, Q. Use of X-ray Computed Microtomography to Measure the Leaching Behaviour of Metal Sulphide Ores. Ph.D. Thesis, Imperial College London, London, UK, 2015. [Google Scholar]

- Lin, Q.; Neethling, S.J.; Courtois, L.; Dobson, K.J.; Lee, P.D. Multi-scale quantification of leaching performance using X-ray tomography. Hydrometallurgy 2016, 164, 265–277. [Google Scholar] [CrossRef]

- Li, W.Z.; Zhou, X.; Dong, B.; Sun, T. A thermal LBM model for studying complex flow and heat transfer problems in body-fitted coordinates. Int. J. Therm. Sci. 2015, 98, 266–276. [Google Scholar] [CrossRef]

- Yang, B.H.; Wu, A.X.; Miao, X.X.; Liu, J.Z. 3D characterization and analysis of pore structure of packed ore particle beds based on computed tomography images. Trans. Nonferr. Met. Soc. China 2014, 24, 833–838. [Google Scholar] [CrossRef]

- Yang, B.H.; Wu, A.X.; Wang, C.L.; Niu, W.X.; Liu, J.Z. Three-dimensional simulation of pore scale fluid flow in granular ore media with realistic geometry. Trans. Nonferr. Met. Soc. China 2012, 22, 3081–3086. [Google Scholar] [CrossRef]

- Yang, B.H.; Wu, A.X.; Jiang, H.C. Evolvement of permeability of ore granular media during heap leaching based on image analysis. Trans. Nonferr. Met. Soc. China 2008, 18, 426–431. [Google Scholar] [CrossRef]

- Wu, A.X.; Yang, B.H.; Zhou, X. Fractal analysis of granular ore media based on computed tomography image processing. Trans. Nonferr. Met. Soc. China 2008, 18, 1523–1528. [Google Scholar] [CrossRef]

- Petersen, J.; Minnaar, S.H.; Plesis, C.A.D. Carbon dioxide and oxygen consumption during the bioleaching of a copper ore in a large isothermal column. Hydrometallurgy 2010, 104, 356–362. [Google Scholar] [CrossRef]

- Robertson, S. Development of an integrated heap leach solution flow and mineral leaching model. Hydrometallurgy 2007, 169, 79–88. [Google Scholar] [CrossRef]

- Yang, B.H.; Wu, A.X.; Yin, S.H. Simulation of pore scale fluid flow of granular ore media in heap leaching based on realistic model. J. Cent. South Univ. Technol. (Engl. Ed.) 2011, 18, 848–853. [Google Scholar] [CrossRef]

- Yin, S.H.; Wu, A.X.; Wang, S.Y.; Wang, H.J. Simulation of solute transportation within porous particles during the bioleaching process. Int. J. Miner. Metall. Mater. 2010, 17, 389–396. [Google Scholar] [CrossRef]

- Song, J.; Lin, J.Q.; Gao, L.; Lin, J.Q.; Qu, Y.B. Modelling and simulation of enargite bioleaching. J. Chem. Eng. 2008, 16, 785–790. [Google Scholar]

- He, Z.G.; Zhao, J.C.; Gao, F.L.; Hu, Y.H.; Qiu, G.Z. Monitoring bacterial community shifts in bioleaching of Ni-Cu sulfide. Bioresour. Technol. 2010, 101, 8287–8293. [Google Scholar] [CrossRef] [PubMed]

- Leathy, M.J.; Schwarz, M.P.; Davidson, M.R. An air sparging CFD model for heap bioleaching of chalcocite. Appl. Math. Model. 2006, 30, 1428–1444. [Google Scholar] [CrossRef]

- Jin, B.J.; Yang, X.W.; Shen, Q.F. Kinetics of copper dissolution during pressure oxidative leaching of lead-containing copper matte. Hydrometallurgy 2009, 99, 119–123. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, Y.; Deng, T.; Wang, K. Kinetic modeling for the bacterial leaching of chalcopyrite catalyzed by silver ions. Miner. Eng. 2004, 17, 943–947. [Google Scholar] [CrossRef]

- Zhou, L.; Xu, Z. Response to waste electrical and electronic equipment in China: Legislation, recycling system, and advanced integrated process. Environ. Sci. Technol. 2012, 46, 4713–4724. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Li, J.H.; Liu, L.L. Current status and future perspective of recycling copper by hydrometallurgy from waste printed circuit boards. Procedia Environ. Sci. 2016, 31, 162–170. [Google Scholar] [CrossRef]

- Zhang, L.G.; Xu, Z.M. A review of current progress of recycling technologies for metals from waste electrical and electronic equipment. J. Clean. Prod. 2016, 127, 19–36. [Google Scholar] [CrossRef]

- Lu, Y.; Xu, Z.M. Precious metals recovery from waste printed circuit boards: A review for current status and perspective. Resour. Conserv. Recycl. 2016, 113, 28–39. [Google Scholar] [CrossRef]

- Liang, G.B.; Tang, J.H.; Liu, W.P.; Zhou, Q.F. Optimizing mixed culture of two acidophiles to improve copper recovery from printed circuit boards(PCBs). J. Hazard. Mater. 2013, 250, 238–245. [Google Scholar] [CrossRef] [PubMed]

- Cui, J.R.; Zhang, L.F. Metallurgical recovery of metals from electronic waste: A review. J. Hazard. Mater. 2008, 158, 228–256. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.H.; Zheng, Y.; Yan, W.F.; Chen, L.X.; Mahadevan, G.D.; Zhao, F. Enhanced bioleaching efficiency of metals from E-wastes driven by biochar. J. Hazard. Mater. 2016, 320, 393–400. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Yang, Y.K.; Liu, C.Q.; Dong, F.Q.; Liu, B.J. Column bioleaching copper and its kinetics of waste printed circuit boards (WPCBs) by Acidithiobacillus ferrooxidans. Chemosphere 2015, 141, 162–168. [Google Scholar] [CrossRef] [PubMed]

- Zhu, N.W.; Xiang, Y.; Zhang, T.; Wu, P.X.; Dang, Z.; Li, P.; Wu, J.H. Bioleaching of metal concentrates of waste printed circuit boards by mixed culture of acidophilic bacteria. J. Hazard. Mater. 2011, 192, 614–619. [Google Scholar] [CrossRef] [PubMed]

- Cao, K.; Li, D.X.; Yang, Y.M. The research of leaching copper from printed circuit boards in microbial metabolic under the action of electric field. North. Environ. 2012, 25, 49–53. [Google Scholar]

- Yang, Y.K.; Chen, S.; Li, S.C.; Liu, B.J. Bioleaching waste printed circuit boards by Acidithiobacillus ferrooxidans and its kinetics aspect. J. Biotechnol. 2014, 173, 24–30. [Google Scholar] [CrossRef] [PubMed]

- Yang, T.; Xu, Z.; Wen, J.K.; Yang, L.M. Factors influencing bioleaching copper from waste printed circuit boards by Acidithiobacillus ferrooxidans. Hydrometallurgy 2009, 97, 29–32. [Google Scholar] [CrossRef]

- Gu, W.H.; Bai, J.F.; Dong, B.; Zhuang, X.N.; Zhao, J.; Zhang, C.L.; Wang, J.W.; Shih, K.M. Enhanced bioleaching efficiency of copper from waste printed circuit board driven by nitrogen-doped carbon nanotubes modified electrode. Chem. Eng. J. 2017, 324, 122–129. [Google Scholar] [CrossRef]

- Gu, W.H.; Bai, J.F.; Dong, B.; Dong, B.; Zhuang, X.N.; Shih, K.M. Catalytic effect of graphene in bioleaching copper from waste printed circuit boards by Acidithiobacillus ferrooxidans. Hydrometallurgy 2017, 171, 172–178. [Google Scholar] [CrossRef]

- Liang, G.B.; Mo, Y.W.; Zhou, Q.F. Novel strategies of bioleaching metals from printed circuit boards (PCBs) in mixed cultivation of two acidophiles. Enzyme Microb. Technol. 2010, 47, 322–326. [Google Scholar] [CrossRef]

- Valix, M. Bioleaching of Electronic Waste: Milestones and Challenges. In Current Developments in Biotechnology and Bioengineering; Wong, J.W.C., Tyagi, R.D., Pandey, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 407–422. [Google Scholar] [CrossRef]

- Bhat, V.; Rao, P.; Patil, Y. Development of an Integrated Model to Recover Precious Metals from Electronic Scrap—A Novel Strategy for E-Waste Management. Procedia Soc. Behav. Sci. 2012, 37, 397–406. [Google Scholar] [CrossRef]

- Awasthi, A.K.; Zeng, X.L.; Li, J.H. Integrated bioleaching of copper metal from waste printed circuit board—A comprehensive review of approaches and challenges. Environ. Sci. Pollut. Res. 2016, 23, 21141–21156. [Google Scholar] [CrossRef] [PubMed]

- Tripathi, V.; Edrisi, S.A.; Chen, B.; Gupta, V.K.; Vilu, R.; Gathergood, N.; Abhilash, P.C. Biotechnologyical Advances for restoring degraded land for sustainable development. Trends Biotechnol. 2017, 35, 847–859. [Google Scholar] [CrossRef] [PubMed]

- Dubiński, J. Sustainable Development of Mining Mineral Resources. J. Sustain. Min. 2013, 12, 1–6. [Google Scholar] [CrossRef]

- Ghose, A.K. Technology vision 2050 for sustainable mining. Procedia Earth Planet. Sci. 2009, 1, 2–6. [Google Scholar] [CrossRef]

- Gentina, J.C.; Acevedo, F. Microbial ore leaching in developing countries. Trends Biotechnol. 1985, 3, 86–89. [Google Scholar] [CrossRef]

- Torma, A.E. Biotechnology applied to mining of metals. Biotechnol. Adv. 1983, 1, 73–80. [Google Scholar] [CrossRef]

- Belliveau, B.H.; Starodub, M.E.; Cotter, C.; Trevors, J.T. Metal resistance and accumulation in bacteria. Biotechnol. Adv. 1987, 5, 101–127. [Google Scholar] [CrossRef]

- Rawlings, D.E. Heavy metal mining using microbes. Annu. Rev. Microbiol. 2002, 56, 65–91. [Google Scholar] [CrossRef] [PubMed]

- Brierley, C.L.; Brierley, J.A. Progress in bioleaching: Part B: Application of microbial processes by the minerals industries. Appl. Microbiol. Biotechnol. 2013, 97, 7543–7552. [Google Scholar] [CrossRef] [PubMed]

- Sairinen, R.; Tiainen, H.; Mononen, T. Talvivaara mine and water pollution: An analysis of mining conflict in Finland. Extr. Ind. Soc. 2017, 4, 640–651. [Google Scholar] [CrossRef]

- Zechendorf, B. Sustainable development: How can biotechnology contribute? Trends Biotechnol. 1999, 17, 219–225. [Google Scholar] [CrossRef]

- Wang, X.H.; Muller, W.E.G. Marine biominerals: Perspectives and challenges for polymetallic nodules and crusts. Trends Biotechnol. 2009, 27, 375–383. [Google Scholar] [CrossRef] [PubMed]

- McHale, A.P.; McHale, S. Microbial biosorption of metals: Potential in the treatment of metal pollution. Biotechnol. Adv. 1994, 12, 647–652. [Google Scholar] [CrossRef]

- Rawlings, D.E.; Dew, D.; Plessis, C.D. Biomineralization of metal-containing ores and concentrates. Trends Biotechnol. 2003, 21, 38–44. [Google Scholar] [CrossRef]

- Chen, L.X.; Huang, L.N.; Méndez-García, C.; Kuang, J.L.; Hua, Z.S.; Liu, J.; Shu, W.S. Microbial communities, processes and functions in acid mine drainage ecosystems. Curr. Opin. Biotechnol. 2016, 38, 150–158. [Google Scholar] [CrossRef] [PubMed]

- Mergeay, M. Towards an understanding of the genetics of bacterial metal resistance. Trends Biotechnol. 1991, 9, 17–24. [Google Scholar] [CrossRef]

- Herbert, R.A. A perspective on the biotechnological potential of extremophiles. Trends Biotechnol. 1992, 10, 395–402. [Google Scholar] [CrossRef]

- Podar, M.; Reysenbach, A.L. New opportunities revealed by biotechnological explorations of extremophiles. Curr. Opin. Biotechnol. 2006, 17, 250–255. [Google Scholar] [CrossRef] [PubMed]

- Pathak, A.; Morrison, L.; Healy, M.G. Catalytic potential of selected metal ions for bioleaching, and potential techno-economic and environmental issues: A critical review. Bioresour. Technol. 2017, 229, 211–221. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.J.; Chen, B.W.; Wang, N.; Chen, J.H.; Zou, L.C.; Liu, X.Y.; Wang, Z.N.; Wen, J.K.; Liu, W.Y. Effects of heap-bioleaching plant on microbial community of the nearby river. Int. Biodeterior. Biodegrad. 2016. [Google Scholar] [CrossRef]

- Haque, N.; Norgate, T. The greenhouse gas footprint of in-situ leaching of uranium, gold and copper in Australia. J. Clean. Prod. 2014, 84, 382–390. [Google Scholar] [CrossRef]

- Gadd, G.M.; White, C. Microbial treatment of metal pollution—A working biotechnology? Trends Biotechnol. 1993, 11, 353–359. [Google Scholar] [CrossRef]

- Liu, S.H.; Zeng, G.M.; Niu, Q.Y.; Zhou, L.; Jiang, L.H.; Tan, X.F.; Xu, P.; Zhang, C.; Cheng, M. Bioremediation mechanisms of combined pollution of PAHs and heavy metals by bacteria and fungi: A mini review. Bioresour. Technol. 2017, 224, 25–33. [Google Scholar] [CrossRef] [PubMed]

- Li, W.W.; Yu, H.Q. Electro-assisted groundwater bioremediation: Fundamentals, challenges and future perspectives. Bioresour. Technol. 2015, 196, 677–684. [Google Scholar] [CrossRef] [PubMed]

- Murray, C.; Platzer, W.; Petersen, J. Potential for solar thermal energy in the heap bioleaching of chalcopyrite in Chilean copper mining. Miner. Eng. 2017, 100, 75–82. [Google Scholar] [CrossRef]

- Cuevas, F.; Murray, C.; Platzer, W.; Heimsath, A. Large Scale Solar Plants Integration in Electro-winning Copper Recuperation Process. Energy Procedia 2015, 70, 605–614. [Google Scholar] [CrossRef]

- Charikinya, E.; Bradshaw, S.M. An experimental study of the effect of microwave treatment on long term bioleaching of coarse, massive zinc sulphide ore particles. Hydrometallurgy 2017, 173, 106–114. [Google Scholar] [CrossRef]

- Van Zyl, D.; Bronson, B. Geotechnical and Environmental Aspects of Heap Leach Design, Operation and Closure; Bendigo: Bendigo, Australia, 1994; pp. 27–29. [Google Scholar]

- Thiela, R.; Smith, M.E. State of the practice review of heap leach pad design issues-Technical Note. Geotext. Geomembr. 2004, 22, 555–568. [Google Scholar] [CrossRef]

- Domic, E. Thin layer leaching practice: Cost of operation and process requirements. J. Met. 1984, 36, 48–53. [Google Scholar] [CrossRef]

- Hoque, M.E.; Philip, O.J. Biotechnological recovery of heavy metals from secondary sources—An overview. Mater. Sci. Eng. C 2011, 31, 57–66. [Google Scholar] [CrossRef]

- Brierley, C.L. How will biomining be applied in future? Trans. Nonferr. Met. Soc. China 2008, 18, 1302–1310. [Google Scholar] [CrossRef]

- Klas, M.; Tsafnat, N.; Dennerley, J.; Beckmann, S.; Manefield, M. Biomining and methanogenesis for resource extraction from asteroids. Space Policy 2015, 34, 18–22. [Google Scholar] [CrossRef]

- Nancharaiah, Y.V.; Mohan, S.V.; Lens, P.N.L. Biological and Bioelectrochemical Recovery of Critical and Scarce Metals. Trends Biotechnol. 2016, 34, 137–155. [Google Scholar] [CrossRef] [PubMed]

| Typical Mine | Location | Features | Minerals | References |

|---|---|---|---|---|

| Dexing Copper Mine | Dexing, Jiangxi Province | Biodump leaching; extraction rate 30%; >2000 t/a; built in 1965; started to use bioleaching in 1979; built bioleaching factory in 1997 | Cu 0.30%; 0.45% primary copper sulfide, 0.028% secondary | [61] |

| Yangla Copper Mine | Diqing County, Yunnan Province | Alkaline bioleaching of low-grade oxide copper ores by Providencia sp. JAT-1; initial pH 8 and 30 °C; Cu extraction rate is 54.5% after 156 h | Copper oxide ore (Cu 1.01%, malachite 0.36%, chrysocolla 0.29%, chalcopyrite 0.29%) | [62] |

| Zijinshan Mine | Shanghang City, Fujian Province | bioheap leaching using Solvent extraction/Electro-Winning(SX-EW) technology; Around 20,000 t/a; Bioheap leaching factory was built in 2006 | Cu 0.38%; low-grade copper sulfide ore (digenite and covellite) | [63] |

| Guanfang Copper Mine | Lincang County, Yunnan Province | Bioheap leaching factory of primary copper sulfide and secondary coppe sulfide was built in 2003 | Cu 0.9% (mainly secondary copper sulfide) | [64] |

| Zhongtiaoshan Copper Mine | Yuncheng City, Shanxi Province | In situ leaching; underground; bioleaching and acid leaching (extraction electrowinning process); >500 t/a in 2000 | Cu 0.65%, SiO2 68.44%; secondary copper sulfide 59.1%, free oxide copper 37.4% | [65,66] |

| Tongguanshan Copper Mine | Tongling City, Anhui Province | Underground bioleaching since 1965; Cu recovery reached 95% in 1980; discontinued production in 2003; Bioleaching tests from 1972 to 1980; | Cu 0.9% | [67] |

| Dabaoshan Copper Mine | Qujiang County, Guangdong, Province | Biodump leaching by T.f obtained from Dabaoshan mining region | Cu 1.06%, Fe 26.8%; primary and secondary copper sulfide occupied 90% of Cu | [68,69] |

| Yulong Copper Mine | Jiangda County, Tibet Autonomous Region | Bioheap leaching of oxide and copper sulfide minerals; High altitude (4569–5118 m) of Tibet; Bioleaching SX-EW technology, realizing >80% copper extraction rate of sulfide ores | Cu 2.75%; secondary copper sulfide 28.95%, primary copper sulfides 35% | [70] |

| Asele Copper Mine | Habahe County, Xinjiang Autonomous Region | Cu recovery reached 80%; Formal operation of bioleaching industrial plant used since July 2004 | Cu 2.43% | [71] |

| Yongping Copper Mine | Shangrao City, Jiangxi Province | Second-largest open copper pit in China; formal operation from October 1984; recycle low grade oresand wastes by bioleaching since the 1990s | Cu 0.32%; primary copper sulfide (65.6%) and secondary copper sulfide (16.3%) | [72] |

| Saishitang Copper Mine | Hainan Tibetan Autonomous Prefecture, Qinghai Province | High altitude (3450 m); located in Qinghai–Tibet Plateau; bioleaching experiment and plant under extremely high and cold environment | Cu 0.83%; copper sulfide ore and oxide copper ores | [73,74] |

| Dongchuan Copper Mine | Dongchuan City, Yunnan Province | Built in the 1960s, performed copper bioleaching experiments with the whole plants successfully | Cu 0.9–1.5%; 33% sulfide ore (bornite, chalcocite, chalcopyrite); 41% oxide ores | [75] |

| Dongguashan Copper Mine | Tongling City, Anhui Province | Bioleaching experiments of low-grade chalcopyrite sample by Acidithiobacillus ferrooxidans and Acidithiobacillus thiooxidans | Cu 0.94–1.06% (chalcopyrite mainly), leaching bacteria is A.f (CUMT-1 & ZJJN-3) | [76] |

| Jinchuan Copper-Nickel Mine | Jinchang City, Gansu Province | Mainly nickel (Top two in the world); operated from 2006 to 2009; coupled multi-metals included nickel, copper and cobalt; good leachability: copper extraction rate reaches 93.48% after 40 days | Cu 0.44%; primary copper sulfide 69.8%, free oxide copper 20.6% and secondary copper sulfide 8% | [77,78] |

| Dongxiang Copper Mine | Fuzhou City, Jiangxi Province | In situ bioleaching of low-grade primary chalcopyrite after underground blasting and crushing, high sulfur ores | Cu 1.34% (chalcopyrite 1.01%, chalcocite 0.33%), pyrite 11.48%, Fe 30.05% | [79,80] |

| Yunfu Ni-Cu sulfide Mine | Meizhou City, Jiangxi Province | Combined bacteria: Betaproteobacteria 47.75%, phylum Nitrospira 0.9%, Gammaproteobacteria 37.84%, Alphaproteobacteria 13.51% | First FeS2 mine in China | [81] |

| Sarake Copper Mine | Wuqian, Xinjiang Autonomous Region | Based on experimental plant experiments, extraction rates reached 93.77% after 155 days, applied heaps bioleaching | Cu 1.34%; secondary copper sulfide (chalcocite, digenite and chalcopyrite mainly) | [82] |

| Zhongwei Copper Mine | Ningxia Hui Autonomous Region | Based on experimental plant experiments, extraction rate reaches 83.03% after 315 days; Existed amount of CaSO4 | Cu 0.32%; secondary copper sulfide 59.38% and primary copper sulfide 37.5% | |

| Duobaoshan Copper Mine | Nenjiang County, Heilongjiang Province | Cu extraction rate just 15.5% after 326 days and CaSO4 passivation disturbed results obviously | Cu 0.51%; primary copper sulfide 0.38% (chalcopyrite mainly) | |

| Daye Copper Mine | Daye City, Hubei Province | Low-grade, biodump leaching, high-oxide, high-clay; copper extraction rate can reach 83.97% after 80 days | Cu 0.35%; copper sulfide 32.3%, free oxide copper 26.3%, silicate copper 22% | |

| Hami Copper-Nickel Mine | Hami, Xinjiang Autonomous Region | Low grade sulfide ores containing high magnesium; nickel and copper bioleaching; extraction rate: Cu 32.6%, Ni 84.6% | Sufide ores 3–8% (pyrrhotite, nickel pyrite, chalcopyrite mainly) | [83,84,85] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, S.; Wang, L.; Kabwe, E.; Chen, X.; Yan, R.; An, K.; Zhang, L.; Wu, A. Copper Bioleaching in China: Review and Prospect. Minerals 2018, 8, 32. https://doi.org/10.3390/min8020032

Yin S, Wang L, Kabwe E, Chen X, Yan R, An K, Zhang L, Wu A. Copper Bioleaching in China: Review and Prospect. Minerals. 2018; 8(2):32. https://doi.org/10.3390/min8020032

Chicago/Turabian StyleYin, Shenghua, Leiming Wang, Eugie Kabwe, Xun Chen, Rongfu Yan, Kai An, Lei Zhang, and Aixiang Wu. 2018. "Copper Bioleaching in China: Review and Prospect" Minerals 8, no. 2: 32. https://doi.org/10.3390/min8020032