Determination of Seismic Safety Zones during the Surface Mining Operation Development in the Case of the “Buvač” Open Pit

Abstract

:1. Introduction

2. Materials and Methods

- -

- monitoring of the existing state of constructions, infrastructural, and other objects’ conditions in the mine environment and at the mine;

- -

- the monitoring and recording of seismic shaking of the ground surface in blasting;

- -

- the maximum permitted explosive quantity by simultaneous ignition in specific conditions; and

- -

- optional determination of the optimal delay interval and possible alteration of other drilling and blasting parameters.

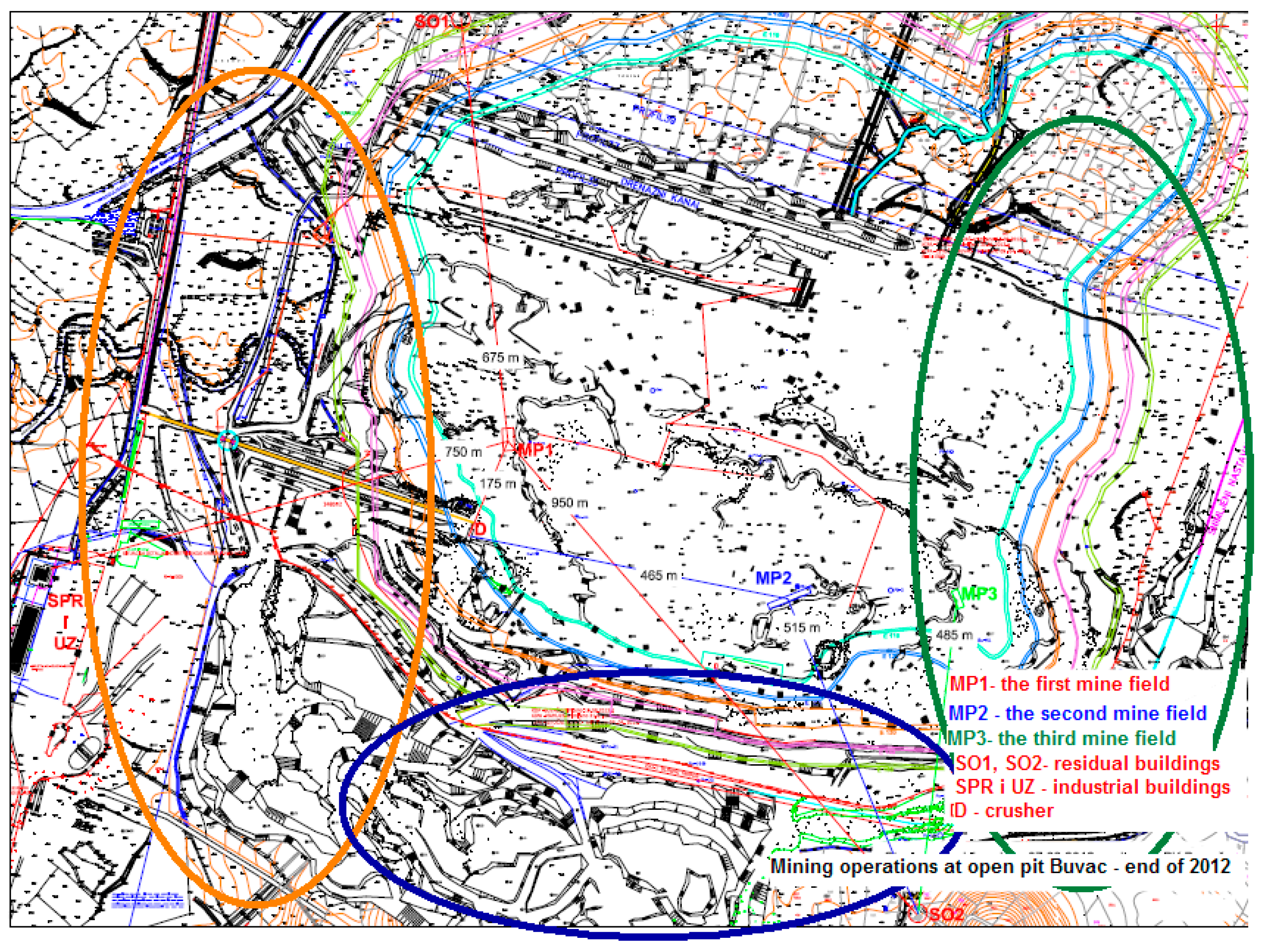

- Southwest zone on the pit (MP1-bench B120 west);

- Central south zone on the pit (MP2-bench B110 south); and

- Southeast zone on the pit (MP3-benchB120 east).

- -

- Blasting monitoring in order to determine a mathematical model, meaning the functional dependence of parameters Q, explosive quantity; R, distance; v, vibration velocity; K, coefficient of the manner of blasting and the blasting environment; and n, coefficient of the fading of seismic waves on their spreading path in specific working conditions of the “Buvač” open pit. Although it is also possible to calculate the value of one of them if the determined values of the others with the known explosive quantity, Q, velocity, v, and the distance, R, are previously known.

- -

- Defining the procedure for calculating the allowed explosive quantities based on known distances between minefields and endangered objects, by using mathematical functions of dependence and rules of the spreading of the intensity of seismic activity (see Equation (2)).

- -

- Defining the procedure for calculating permissible safety distances based on the designed or planned quantities of explosives and the allowed vibration velocity rate of the ground according to the criteria, using the abovementioned Equation (2).

- -

- Verification of the calculation results through seismic monitoring (indicated in Chanpter 3.3).

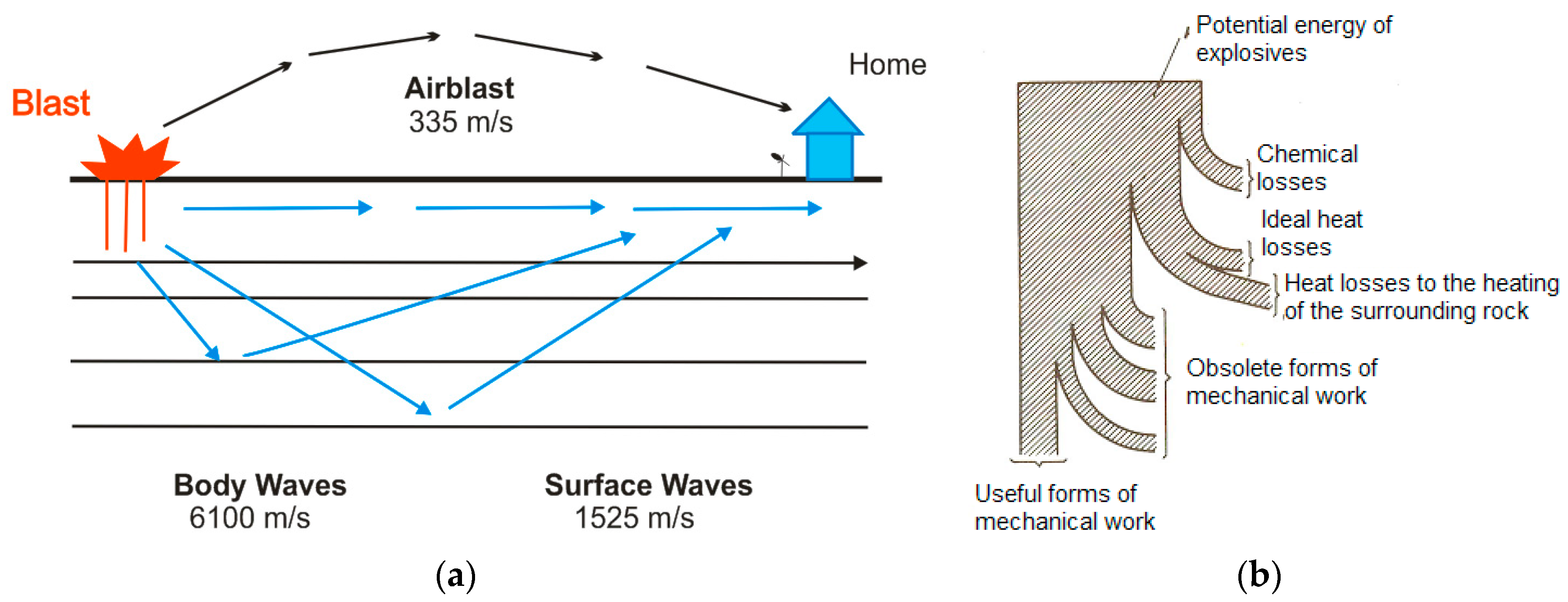

2.1. Seismic Shaking of the Ground Surface in Blasting

- -

- longitude (longitudinal)—l;

- -

- vertical—v and

- -

- transversal (transverse)—t.

- s—size of the spatial displacement vector i, and

- sx, sy, sz—sizes of the displacement by space component x,y,z.

- v is the total vibration velocity rate of ground, (cm/s):

- vt—transverse vibration velocity rate (cm/s);

- vv—vertical velocity of vibration of the ground (cm/s);

- vl—longitudinal vibration rate of the ground (cm/s);

- K—coefficient of the manner of blasting and the environment where it is mined. The Coefficient is conditioned by ground characteristics, as well as blasting conditions, where the explosive amount is given by way of the volume. K is determined by terrain surveying [13];

- n—coefficient of seismic waves suppression on the expansion path, which is an exponent, conditioned by ground properties and mining conditions and determined by field measurements as well;

- Q—quantity of explosives (kg); and

- R—distance from the endangered facility/buildings (m).

- v1, v2—total vibration speed from object 1 or object 2; and

- ρ1, ρ2—the reduced explosive amounts.

2.2. Criteria of seismic safety

- -

- SN 640312—the Swiss standard [17] defines the allowed vibration frequency and the resultant ground vibration velocity, in relation to the type and quality of the building’s structure (buildings, infrastructure, etc.) and the underground structure (caverns, tunnels, caves, etc.). Based on the allowed rate of ground velocity of vibration, which, according to this standard, is 0.3–0.4 cm/s for industrial objects and 0.12–0.18 cm/s for residential buildings, the definition of the distance from endangered objects or by objects where the measurements were performed, and we can calculate maximum allowed quantity of explosives for simultaneous blasting.

- -

- DIN 4150 III—the German standard [18] categorizes objects/buildings by building condition and observed damages related to the allowed velocity of vibrations of the ground for certain object categories. Due to the allowed ground velocity of vibration rates for certain object categories it is the most rigorous standard and, therefore, it is safe to assess the seismic vulnerability of objects. This standard was used to define blasting areas and the allowed explosive quantities for construction sites located on the open pit mine—industrial buildings, the mobile crusher, and the closest residential buildings. Based on the allowed velocity of the vibration rate of the ground, which is 40 mm/s for industrial facilities and 15 mm/s for residential buildings, we can calculate the maximum allowed explosives quantity for simultaneous blasting through the definition of the distance from the objects that are endangered or where the measurements were performed.

- -

- WAC 296-52-67065/USBM RI8507—the American standard [19] for vibration control and damages that define maximum ground vibration/earthquake limits for population, public buildings, industrial zones, infrastructural facilities, temporary dams, pillars, docks, underground structures, and others.

- -

- GOST 6249-52—seismic scale for the ground shaking measuring due to blasting compiled by the Institute of the Earth Physics, Russian Academy of Sciences [20], wherein the ground velocity of vibration limits in relation to the level of the seismic action is defined, with descriptions of the effect of certain velocities on the environment—buildings and people. Based on the allowed ground velocity of vibration rate, according to this standard, it is 0.4–0.8 cm/s for buildings, and with the defined distance from endangered objects or where the measurements were performed, we can calculate the maximum allowed quantity of explosives for simultaneous blasting. GOST 6249-52 has not officially been used since 1995, but its norms and guidelines are incorporated in other standards and norms of the Russian Federation related to general rules and regulations for building materials, civil service classifications, construction techniques, calculation, and design standards.Therefore, it was used in this paper as a control-comparative norm and safety criterion.

2.3. Seismic Measurements in the Field as Verification of Calculated Parameters

2.4. Brief Description of the Omarska Deposit, the Exploitation System, and the Drilling and Blasting Parameters on the “Buvač” Open Pit

- -

- Shovel-truck system for direct excavation and transport of soft overburden (ST system);

- -

- Shovel-truck system for excavation and transport of “hard” overburden and waste (ST system); and

- -

- Shovel-truck-crusher-conveyor system for system for excavation and transport of iron ore (STCC).

3. Results

- -

- Southwest zone of the open pit—zone of industrial buildings on the west side of the mine where parameters and conditions of blasting are defined based on the closest possible minefields on that side;

- -

- Central south zone of the open pit—zone of residential buildings at the south side with analysis of the minefield effects closest to those objects; and

- -

- Southeast zone of open pit—zone of residential buildings on the south side with an analysis of the mine fields effects, which may be the nearest to the facilities.

3.1. Determination of the Allowed Explosives Quantity

- -

- designed drilling and blasting parameters:Qhole = 156 kg/holeQmax = 4000 kg

- -

- The determined distances by graphical maps:Distance of the nearest minefield in the southwestern zone from an industrial facility—crusher (MP1): 175 mDistance of the nearest minefield in the southwestern zone from residential object SO1 (MP1): 675 mDistance of the nearest minefield in the southwestern zone from residential object SO2 (MP1): 950 mDistance of the nearest minefield in the southwestern zone of industrial facilities—building SPR and administrative building UZ (MP1): 750 mDistance of the nearest minefield in the central southern zone from an industrial facility—crusher (MP2): 465 mDistance of the nearest minefield in the central southern zone from residential object SO2 (MP2): 515 mDistance of the nearest minefield in the south-eastern zone from residential object SO3 (MP3): 485 m

3.2. Determination of Safety Distances in Relation to a Defined Quantity of Explosives

- -

- In the southwestern zone, according to used/designed explosive quantities, the endangered object is a crusher according to all standards of safety criteria, and residential buildings according to DIN 4150 III standard.

- -

- In the central southern zone, according to used/designed explosive quantities, endangered facilities are residential buildings according to the standards DIN 4150 III and SN 640312. The industrial facility (crusher) is not compromised based on any criteria.

- -

- In the southeastern zone, according to used/designed explosive quantities, residential buildings are endangered based on the standards DIN 4150 III and SN 640312.

3.3. Measuring of Ground Vibrations—Monitoring of Negative Seismic Impacts by Drilling and Blasting

4. Discussion

- -

- Residential buildings are endangered if the blasting is carried out in field MP1 by the designed parameters according to the standards and allowed ground vibrations of DIN 4150 III, SN 640312, and USBM RI8507. It is necessary to additionally delay and split the explosive charge in drill holes.

- -

- According to the other defined distances in other analysed blasting zones (MP2 and MP3), the objects are not endangered, so even delaying can be placed on two or more drill holes.

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Office of Surface Mining Reclamation and Enforcement. OSM Blasting Training Modules. 2004. Available online: https://www.osmre.gov/resources/blasting/btm/Module8.pdf (accessed on 14 May 2017).

- Purtić, N. Seizmičko Dejstvo Eksplozije” u Udžbeniku “Bušenje i Miniranje, 1st ed.; (Seismic Action of the Explosion. Drilling and blasting, 1st ed.); Faculty of Mining and Geology: Belgrade, Serbia, 1991; pp. 234–243. [Google Scholar]

- Zhong, G.; Li, J.; Zhao, K. Structural safety criteria for blasting vibration based on wavelet packet energy spectra. Min. Sci. Technol. 2011, 21, 35–40. [Google Scholar] [CrossRef]

- Stagg, M.S.; Siskind, D.E. Effects of Blast Vibration on Construction Material Cracking in Residential Structures; Bureau of Mines Technology Transfer Seminar: Chicago, MI, USA, 1987; p. 43.

- Siskind, D.E.; Stagg, M.S. Blast Vibration Measurements Near Structures; Bureau of Mines Technology Transfer Seminar: Chicago, MI, USA, 1987; pp. 46–50.

- Hustrulid, W.A. Blasting Principles for Open Pit Mining, 1st ed.; CRC Press: Rotterdam, The Netherlands, 1999; Volume 2. [Google Scholar]

- Malbašić, V.; Stojanović, L. Determination of Seismic Safety Zones during the Surface Mining Operation Development in the Case of Open Pit “Buvač”. In Proceedings of the 6th International Symposium MEP 17, Vrdnik, Serbia, 21–24 June 2017; pp. 138–144. [Google Scholar]

- Körmendi, A.; Bodoky, T.; Hrmann, L.; Dianiska, L.; Kālman, T. Seismic Measurements for Safety in Mines. In Proceedings of the 45th Meeting of the EAEG, Oslo, Norway, 14–17 June 1983. [Google Scholar]

- Maxwell, S.C.; Young, R.P. Seismic imaging of blast damage. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1993, 30, 1435–1440. [Google Scholar] [CrossRef]

- Malbašić, V.; Čelebić, M. Determination of Safety Zones by Drilling and Blasting to Maximal Possible Structure Protection on Quarry, Ljubačevo Near Banja Luka Sample; Archives for Technical Science: Bijeljina, Republica Srpska, 2011; pp. 119–132.

- Kopp, J.W. Initiation Timing Influence on Ground Vibration and Airblast; Bureau of Mines Technology Transfer Seminar: Chicago, MI, USA, 1987; pp. 51–59.

- Yu, S. Safety of Ground Motion in Engineering Blasting. 1995. Available online: http://en.cnki.com.cn/Article_en/CJFDTotal-GCBP502.012.htm (accessed on 23 November 2017).

- Lutovac, S.; Medenica, D.; Glušcevic, B.; Tokalic, R.; Beljic, C. Some models for determination of parameters of the soil oscillation law during blasting operations. Energies 2016, 9, 617. [Google Scholar] [CrossRef]

- Arsenović, Ž. Study on the Negative Environmental Effects of Blasting Technology on Open Pit “Dubokipotok-Bijela Rijeka” and Negative Efectson Buildings in Gravitational Urbanism Zones of the Settlement Duboki potok and Bjelave at the Quarry Exploitation Field; CTU Ipkin: Bijeljina, Republica Srpska, 2009; pp. 15–18. [Google Scholar]

- Ebrahimi, F.F.; Mokammad, F.; Hamid, A.M. Simultaneous investigation of blast induced ground vibration and airblast effects on safety level of structures and human in surface blasting. Int. J. Min. Sci. Technol. 2014, 24, 663–669. [Google Scholar]

- Phifer, M.; Hem, P. Blasting, TechnoMine-Mining Technologies. March 2012. Available online: http://technology.infomine.com/reviews/Blasting (accessed on 12 December 2017).

- SN 640312. Auszug Norm Gebäudeschäden Durch Vibrationen. Available online: https://infostore.saiglobal.com/en-au/Standards/SN-640312-2013-1723806/ (accessed on 12 March 2017).

- DIN 4150 III. Structural Vibration—Effects of Vibration on Structures. Available online: https://infostore.saiglobal.com/en-gb/Standards/DIN-4150-3-1999-02--515801/ (accessed on 20 April 2017).

- WAC 296-52-67065/USBM RI8507. Vibration and Damage Control. Available online: https://app.leg.wa.gov/wac/default.aspx?cite=296-52-67065 (accessed on 10 March 2017).

- GOST 6249-52—Scale for Determining the Strength of the Earthquake in the Range from 6 to 9 Points (Scale for Determining the Strength of the Earthquake in the Range from 6 to 9 Points). Available online: http://internet-law.ru/gosts/gost/46361/ (accessed on 10 February 2017). (In Russian).

- Malbašić, V. At All Main Mining Project for Exploitation of Deposit "Omarska" Locality "Buvač”; Institute of mining Prijedor and Faculty of Mining and Geology Belgrade: Belgrade, Serbia, 2007.

- Jovanović, N. Definisanje Sigurnosnih Zona Pri Miniranju na PK Buvač; Graduated work Faculty of mining Prijedor University Banja Luka: Belgrade, Serbia, 2012. [Google Scholar]

- Documentation-logs of Mining and Seismic Measurements on Open Pit Buvač Made by Employees in AMP; ArcelorMittal Rudnici: Prijedor, Bosnia and Herzegovina, 2013.

| Drilling and Blasting Parameters | The Unit of Measure | Blasting with a 150–170 mm Hole Diameter of, Bench Height H = 10 m | |||

|---|---|---|---|---|---|

| Main Loading | kg | AN-FO | Emulsion | Plastic Explosives | Plastic Explosives |

| Support Loading | kg | Emulsion | AN-FO | AN-FO | Powder Explosive |

| W | m | 5.50 | 5.00 | 5.50 | 5.50 |

| a | m | 5.50 | 5.50 | 6.00 | 5.60 |

| b | m | 5.50 | 5.50 | 5.50 | 5.50 |

| m | 1.00 | 1.10 | 1.10 | 1.10 | |

| Ldrill hole | m | 11.40 | 11.50 | 11.65 | 11.65 |

| Lpitting | m | 1.40 | 1.50 | 1.65 | 1.65 |

| Lmain load. | m | 7.40 | 4.03 | 4.22 | 4.28 |

| Lsupp.load. | m | - | 3.47 | 3.43 | 3.39 |

| Lcork | m | 4.00 | 4.00 | 4.00 | 4.00 |

| Qmain | kg | 138.00 | 72.00 | 81.25 | 82.37 |

| Qsupp. | kg | 18.00 | 45.00 | 44.18 | 55.42 |

| Qtotal | kg | 156.00 | 117.00 | 125.43 | 137.79 |

| Delay | ms | 40 | 40 | 40 | 40 |

| Quantity | t | 726 | 660 | 792 | 792 |

| q | kg/t | 0.215 | 0.177 | 0.160 | 0.174 |

| Capacity | t/m | 63.68 | 57.40 | 67.68 | 67.68 |

| Standard Calculated Explosive Quantity, kg | Distance | Qhole, kg Q field | ||||||

|---|---|---|---|---|---|---|---|---|

| MP1 | MP2 | MP3 | ||||||

| 175 | 675 | 750 | 950 | 465 | 515 | 485 | 117–156 4000 | |

| SN 640312 industrial buildings | 272 | 15,625 | 21,433 | 43,560 | 7095 | 9638 | 117–156 4000 | |

| SN 640312 residential buildings | 84 | 4805 | 6592 | 13,2396 | 2155 | 2928 | 2079 | 117–156 4000 |

| DIN 4150 III industrial buildings | 237 | 7095 | 117–156 4000 | |||||

| DIN 4150 III residential buildings | 63 | 3610 | 4593 | 10,064 | 1695 | 2303 | 1596 | 117–156 4000 |

| USBM RI8507 | 47.5 | 706 | 872 | 1398 | 335 | 411 | 365 | 117–156 4000 |

| GOST 6249-52 | 781 | 44,838 | 61,507 | 12,500 | 20,465 | 27,082 | 19,562 | 117–156 4000 |

| Buildings | GOST 6249-52 | SN 640312 | DIN 4150 III | USBM RI8507 | ||||

|---|---|---|---|---|---|---|---|---|

| Lmeas | Lcalc | Lmeas | Lcalc | Lmeas | Lcalc | Lmeas | Lcalcul | |

| MP1 | ||||||||

| Industrial buildings and crusher | 175 | 302 | 175 | 429 | 175 | 429 | 175 | 1606 |

| Residential buildings | 675 | 302 | 675 | 635 | 675 | 698 | 675 | 1606 |

| 950 | 302 | 950 | 635 | 950 | 698 | 950 | 1606 | |

| Administrative building and workshop | 750 | 302 | 750 | 635 | 750 | 429 | 750 | 1606 |

| MP2 | ||||||||

| Industrial buildings and crusher | 465 | 270 | 465 | 384 | 465 | 384 | 465 | 1606 |

| Residential buildings | 515 | 270 | 515 | 571 | 515 | 619 | 515 | 1606 |

| MP3 | ||||||||

| Residential buildings | 485 | 286 | 485 | 603 | 485 | 619 | 485 | 1606 |

| Bench | Date | Explosive Quantity (kg) | Distance (m) | PPV Transversal (mm/s) | PPV Vertical (mm/s) | PPV Longitude (mm/s) | Peak Vector Sum (mm/s) |

|---|---|---|---|---|---|---|---|

| East 130 | 06.10.2013. | Qexp = 891 Qsim = 224–334 | Blasting field to residential building SO1 510 | 0.889 | 0.0635 | 0.318 | 0.889 |

| West 130 | 10.10.2013. | Qexp = 1479 Qsim = 224–672 | Blasting field to residential building SO1 740 | 0.445 | 0.0635 | 1.08 | 1.11 |

| East 130 | 26.10.2013. | Qexp = 912 Qsim = 224–344 | Blasting field to residential building SO1 530 | 0.318 | 0.0635 | 0.762 | 0.826 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malbasic, V.; Stojanovic, L. Determination of Seismic Safety Zones during the Surface Mining Operation Development in the Case of the “Buvač” Open Pit. Minerals 2018, 8, 71. https://doi.org/10.3390/min8020071

Malbasic V, Stojanovic L. Determination of Seismic Safety Zones during the Surface Mining Operation Development in the Case of the “Buvač” Open Pit. Minerals. 2018; 8(2):71. https://doi.org/10.3390/min8020071

Chicago/Turabian StyleMalbasic, Vladimir, and Lazar Stojanovic. 2018. "Determination of Seismic Safety Zones during the Surface Mining Operation Development in the Case of the “Buvač” Open Pit" Minerals 8, no. 2: 71. https://doi.org/10.3390/min8020071