1. Introduction

Usually, the main challenge in underground excavation stems from uncertainty concerning geological and geotechnical conditions, so these must be taken into consideration, at both the design and construction stages [

1]. The term “uncertainty”, as applied to the characteristics of the rock mass, is related to randomness, heterogeneity, and lack of knowledge of the real geotechnical conditions. To predict geotechnical behavior in unsampled locations and to assess the uncertainty associated with the spatial distribution of geological variables, geostatistical models are usually applied, enabling the simulation of geological properties in space and thus mapping of the quality of the rock mass as well as the associated uncertainty [

2,

3].

The heterogeneity of rock masses means that sometimes, even if more studies are carried out, it would not be possible in practice to know all of their features in detail. This is particularly true in linear excavations. It is difficult to spatially analyze and characterize the entire rock mass at different scales since, by itself, the scale effect is restrictive, as reported by several authors [

4,

5,

6] and also indirectly by Hoek [

7]. Furthermore, there are characteristics and phenomena that cannot be predicted or known, which often yield unforeseen situations during the construction process, especially in underground excavations. At this stage, the real features of the rock mass become accessible and it is necessary to deal with them.

This entails the need to adopt methodologies at the construction stage that review and adjust construction methods in order to deal with those particular problems, enabling subsequent advances to be planned so that the work to be done develops in a controlled manner, in terms of both safety and quality.

During the design of underground excavations, reconnaissance of the rock mass from the surface is hampered by the presence of vegetation and overburden, limiting the availability of direct data to occasional rock outcrops. It is thus always necessary to complement geological and geotechnical information with site investigation, which usually begins with the use of indirect methods, mainly geophysical techniques that require validation and calibration by direct methods, i.e., boreholes and in-situ tests. Nevertheless, both of the methods depend on the subjectivity of specialists’ interpretation, while direct methods provide only point information on the rock mass.

The rock mass at a given location is conditioned by its setting and its specific geological history, which are reflected in its intrinsic features. In a homogeneous rock mass, geological and geotechnical construction models are a valuable exercise; however, in the case of a heterogeneous mass, they can prove inappropriate and are often misleading. The pressures commonly arising from restrictions on the cost and time available for the study, and the need to include certain types of elements in the project, mean that sometimes documents are issued with a high degree of uncertainty. This problem led Dematteis [

8] to make recommendations for quantifying the reliability of geologic models used in designs of underground large excavations.

For underground excavations in rock masses, the characterization of the ground at each advance is usually performed by applying a geomechanical classification; frequently, this is done by assessing its rock mass rating (RMR) index, as developed by Bieniawski [

9], which is one of the most used classifications worldwide, as described by Castro-Fresno et al. [

10]. The RMR value is a quantification of rock mass quality for any civil or mining engineering works. Analysis of the variance of RMR value as the excavation advances evaluates changes in rock mass quality and indicates its heterogeneity. Although the geological environment is paramount, it is noteworthy that the according to Bieniawski’s [

9] classification does not take lithology into account, which makes the RMR values that were obtained in different geological settings comparable.

Estimation of the RMR index has been the subject of studies using numerical methods and adopting different methodologies. Barla et al. [

11] presented a case study to determine the variation of certain parameters of the rock mass, including RMR, in the area of the Masua mine (Italy), using kriging. These authors concluded that, when compared to the Monte Carlo simulation, kriging represented reality better. Subsequently, several studies appeared in the field of mining and civil engineering regarding the use of geostatistical simulation to evaluate spatial variation in RMR; they all concluded that it was suitable to quantify the spatial uncertainty of the RMR index. Some of them [

12,

13,

14,

15,

16,

17] initially estimated these values directly at geophysical surveyed locations and later compared them with real values measured from borehole data in order to establish an initial correlation; they then used them to predict rock mass quality outside the investigated areas, including at depth.

Using also information from geophysical surveys, You & Lee [

18] resorted to three-dimensional (3D) multiple indicator kriging to evaluate rock mass class in terms of the RMR index before and during tunneling for a road. The RMR values they observed in each 3–3.5 m advance of the excavation were compared to the estimated values, and they achieved acceptable results. To achieve several objectives, among which was predicting the quality of the rock mass along tunneling and at its face, as represented by RMR and Q [

19] values, Exadaktylos & Stavropoulou [

20] developed an optimization for estimating these indices using kriging in one-dimensional (1D), two-dimensional (2D), and 3D meshes, based on sampling and parameters that were obtained from a tunnel boring machine during drilling.

The possibility of variations in ground quality during tunneling and how to predict them for each tunnel advance was studied by Santos et al. [

21], using mathematical methods to estimate them, including linear regression, kriging, and neural networks. The values obtained by these different methods of estimation were compared with the actual values observed in hydraulic tunneling by drilling and blasting (D&B), showing high correlation and few errors. A similar study was performed by Kaewkongkaew et al. [

22] to assess the limitations and advantages of using geostatistics to estimate rock mass quality along tunnel alignments in two projects in Thailand, in particular, ordinary kriging, during the design stage. In the case of the more heterogeneous tunnel, ordinary kriging did not work well and there was a large difference between the estimated and actual values, unlike the more homogeneous alignment, for which the estimation worked reasonably well.

In an application to a mine in Chile, Egaña, and Ortiz [

23] studied the advantages of applying geostatistical simulation to estimate RMR and to assess the uncertainty related to changing rock mass quality. The methodology showed significantly increased quality of estimation as compared to more standard techniques based on sampled data. Yi et al. [

24] presented a methodology to estimate RMR more accurately for mining drifts and redevelopment, using information from electric resistivity tomography, boreholes, and RMR values available from nearby excavations as input for kriging. They found that in 73% of cases, the estimated RMR values were assigned to the correct RMR class if two correction methods were used to supplement indicator kriging to resolve the influence of existing drifts and distortions in drilling log results. Recently, Vatcher et al. [

25] conducted a study to address the difficulty of characterizing a heterogeneous and complex rock mass, such as those found in major mining environments like the Kiirunavaara Mine in Sweden. They developed a methodology based on classical statistics, geostatistics, and an extension of previous quantitative structural domaining work and revealed correlations between modeled behavior and the structure. These relationships have enabled the development of geomechanical models of rock mass behavior in the mine and highlight places where supplementary data collection could add the most value. They conclude that the differentiated methodology applied is useful in the characterization of complex rock masses.

Finally, other numerical methods have been used. To identify parameters that are relevant to the calculation of RMR and possibly to predict its values, Miranda [

26] and Miranda & Sousa [

27] used multivariate regression and neural networks, respectively, developing models for rock masses. With the same purpose, Jalalifar et al. [

28] resorted to fuzzy inference and multivariate regression applied to the parameters on which this index is based, having selected the equation that had the best fit using a linear model and logarithmic, exponential, and inverse function analysis. The results showed that discontinuity conditions were the most important parameter in determining RMR, and, of the two methodologies that were used, fuzzy inference performed better than regression modeling.

According to Pinheiro et al. [

29], geostatistics enables rock mass properties to be predicted, their heterogeneity to be mapped at different scales, and their uncertainty to be quantified. They adopted two approaches based on RMR values. The first approach was the direct simulation of RMR values, based on a Gaussian spatial random field model, while the second used the truncated Gaussian model to separately simulate the individual parameters that constitute RMR, which are subsequently added to obtain the final RMR value. They concluded that both approaches are valid, but the second provides more accurate results.

In this paper, in the context of the development of underground excavations by D&B, the RMR values for the next excavation faces are estimated based on an extensive database of case studies using an innovative probability calculation methodology that has never previously been employed by other researchers. The estimation is also used to predict the rock mass quality beyond the excavation face, based on results of previous excavation advances, for which estimates are made, which has also never been used so comprehensively at this scale. To have a rock mass quality change of scenario in the subsequent excavation advances, the goal of this study is to determine the probable RMR values as the excavation progresses, based on the RMR value observed at the last excavation advance. The following sections present the methodology, case studies analyzed, and a discussion of the results. It is concluded that, up to about 20 m ahead of the current face, the quality of the rock mass for the next advances is close to the quality observed in the present face, and that, with an increasing distance, there is a greater deviation of RMR with respect to the quality observed at the current face.

2. Methodology

D&B methods are usually preferred in mining drifts as well as in short tunneling and very high strength or heterogeneous rock masses, since they enable flexible sequential advances to be made by cyclic procedures, which are generally drilling, explosive charging, blasting, ventilation, debris removal, unstable material scaling, and reinforcement of the ground when necessary.

In many cases, the need to support the rock mass during mining or construction works is specified according to geotechnical zoning and is implemented in the project specifications. For such a framework it is necessary to characterize the geomechanical behavior of the exposed rock mass and, as mentioned above, one of the most widely used ways to achieve this is to estimate its RMR index [

9]. Calculation of these ratings for each excavation advance produces a representative numerical value for rock mass quality, enabling variation in its quality along the drift/tunnel to be analyzed.

In order to identify the contribution of the several RMR parameters (strength of intact material, drill core quality—RQD, discontinuities spacing, conditions of discontinuities, groundwater, and discontinuities orientation) to rock mass quality index, a previous multivariate data analysis (factorial analysis in [

30]) was completed, demonstrating that the join conditions seemed to be mainly responsible for the rock mass heterogeneity detection and quality evaluation.

Using the RMR values that were obtained at each excavation face during the opening of several tunnels in different geological settings, as described below for each of the case studies, for a given RMR value at the actual excavation face (

n), the RMR values that will succeed it in the following excavation advances are estimated. For the estimation of rock mass properties, a maximum distance of 20 m ahead the current front was considered based on the spatial correlation between the variables used for RMR determinations, calculated by variography [

30]. It was also considered that such distance was sufficient to allow for an opportune crew, equipment, and materials mobilization for the excavation front.

The probabilities of RMR values in next five advancing faces (n + 1, ..., n + 5) are calculated, each assuming an average advance of 4 m for each excavation and thus corresponding to distances of approximately 4 m, 8 m, 12 m, 16 m, and 20 m ahead of the current face.

Specifically, based on data from six underground excavations in Portugal (for hydraulic circuits) that have been concluded, the following procedures are performed:

for each RMR value observed at the current excavation face (n), RMR values are estimated for the next five advances (n + 1, ..., n + 5);

with these RMR values recorded for subsequent advances, the sample mean and standard deviation are calculated;

Results for each RMR value (n) at the face and for each of the following excavation advances (n + 1, ..., n + 5) are computed to assess all the inherent probability functions, assuming a normal distribution;

for each of these probability functions, the probability of occurrence of each RMR value on a scale of 1–100 for subsequent advances (n + 1, ..., n + 5) is calculated; and,

the resulting probabilities are presented as percentages in graphical form as a probability map of each RMR value of the current face (n) and the associated probabilities of all the RMR values occurring for the next advances (n + 1, ..., n + 5) are presented.

Specifically, with data on RMR values being available for more than 6300 excavation faces and for each of these RMR values at the current face (

n), the probability of each of the 1–100 RMR values occurring for the following five excavation advances is calculated, as outlined in

Figure 1.

The RMR values occurring in the following excavation advances are calculated using commercially available software to obtain the sample mean and standard deviation, as well as the probability function, assuming that a normal distribution is the one that best represents the sample.

The resulting probabilities for each of the RMR values are arranged in a graphic, using interpolation (point kriging), representing the probability of occurrence of all RMR values throughout the entire range (1–100).

Given the quality of a rock mass in an underground excavation face summarized by its RMR value, with this methodology it is possible, by carefully analyzing the graphics made available in this paper, to estimate the RMR values for the five next advances over the whole RMR scale (1–100), as well as the values that are most and least likely to occur, if there are no geological changes ahead of the excavation front.

3. Case Studies

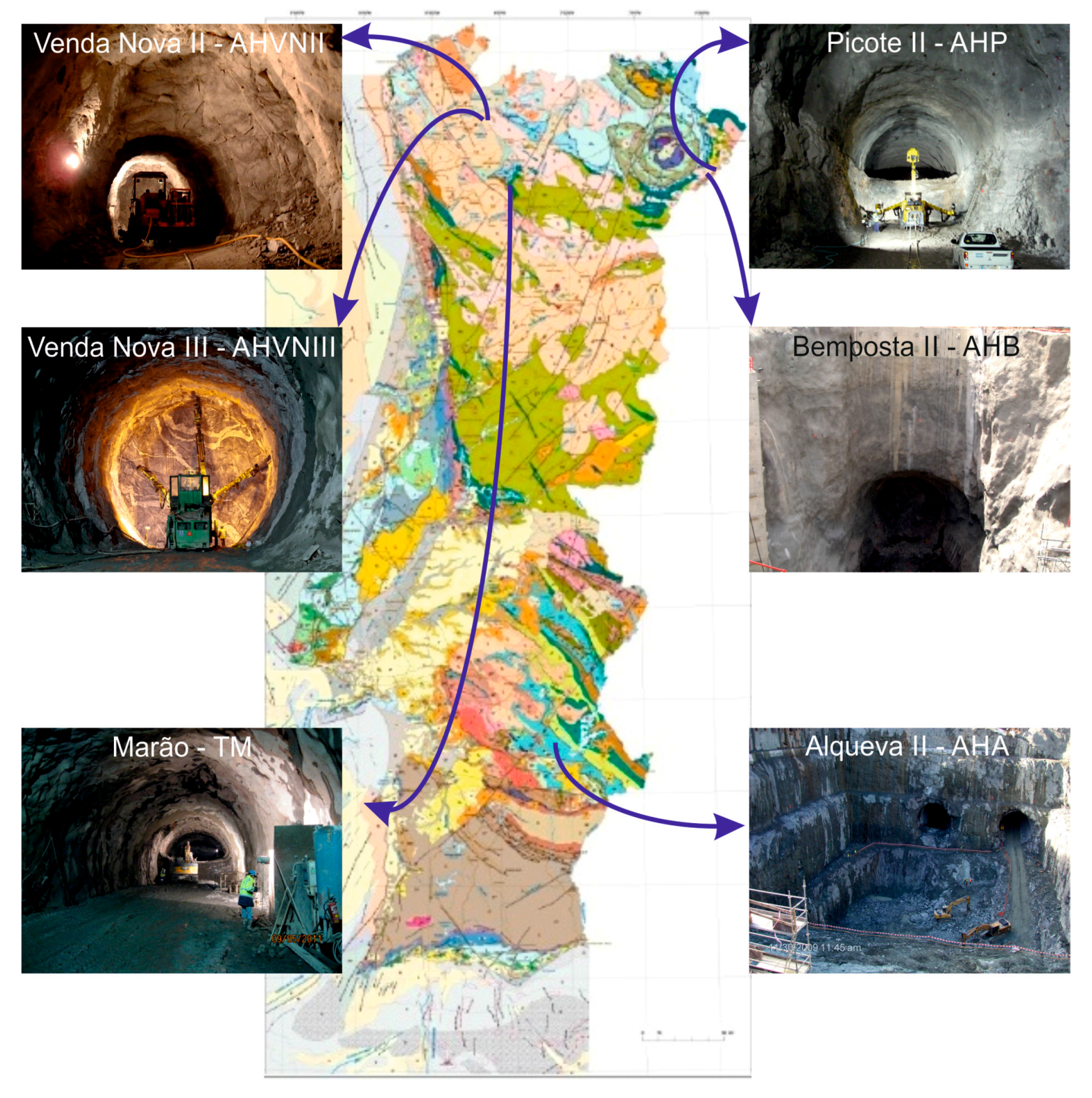

In recent decades, some Portuguese institutions have undertaken the construction of several underground works of considerable size and importance, such as new motorway tunnels that are the longest in the Iberian Peninsula and hydraulic circuits for hydroelectric power stations. Six of these works have been selected as case studies for this study (

Figure 2).

Major hydropower plants in Portugal are normally associated with concrete arch dams, inserted into good quality rock masses, which are located below overburdens a few hundred meters in depth.

According to Sousa [

31], Venda Nova was the first major underground hydroelectric project in Portugal, dating back to 1927. The developments of Picote and Bemposta began operation in 1957 and 1964, respectively. These are among the projects that were designed to have a power booster function, which were completed in this century.

Power booster facilities are located in the vicinity of the original hydroelectric plants, so there was already knowledge of the sites’ geological settings and of the rock mass behavior before the design stage of the hydraulic circuits. During this power boost phase, all of the tunnels/galleries were excavated using explosives (D&B) and a methodology based on the New Austrian Tunneling Method (NATM).

Thus, for the purposes of this study, the cases of the Venda Nova II (AHVNII) and Venda Nova III (AHVNIII) hydropower plants were selected, because they were both constructed predominantly in granite rock masses, containing pre-, post-, and syntectonic stages granites, which also include some Paleozoic formations with weathered and metamorphic rocks [

32]—

Figure 3.

As for previous hydraulic circuits, Picote II (AHP) is also built into granite. According to Pereira et al. [

33], this was formed during the Variscan orogeny and is described as porphyritic, two-mica medium grain granite (Picote, Bemposta)—

Figure 4.

The Bemposta II (AHB) hydraulic circuits are excavated in metasedimentary rocks that present a high degree of metamorphism. Their foliation does not act as important structural element in the stability of the underground excavations, i.e., the behavior of the rock mass is similar to that of granite. According to Pereira et al. [

33], these hydraulic circuits are located in native Variscan ground, consisting of a paragneiss complex, gneissic granites, and migmatites, also referred to as “nodular granite of Tourém, Miranda do Douro, Sendim, and the Bemposta Dam”—

Figure 4.

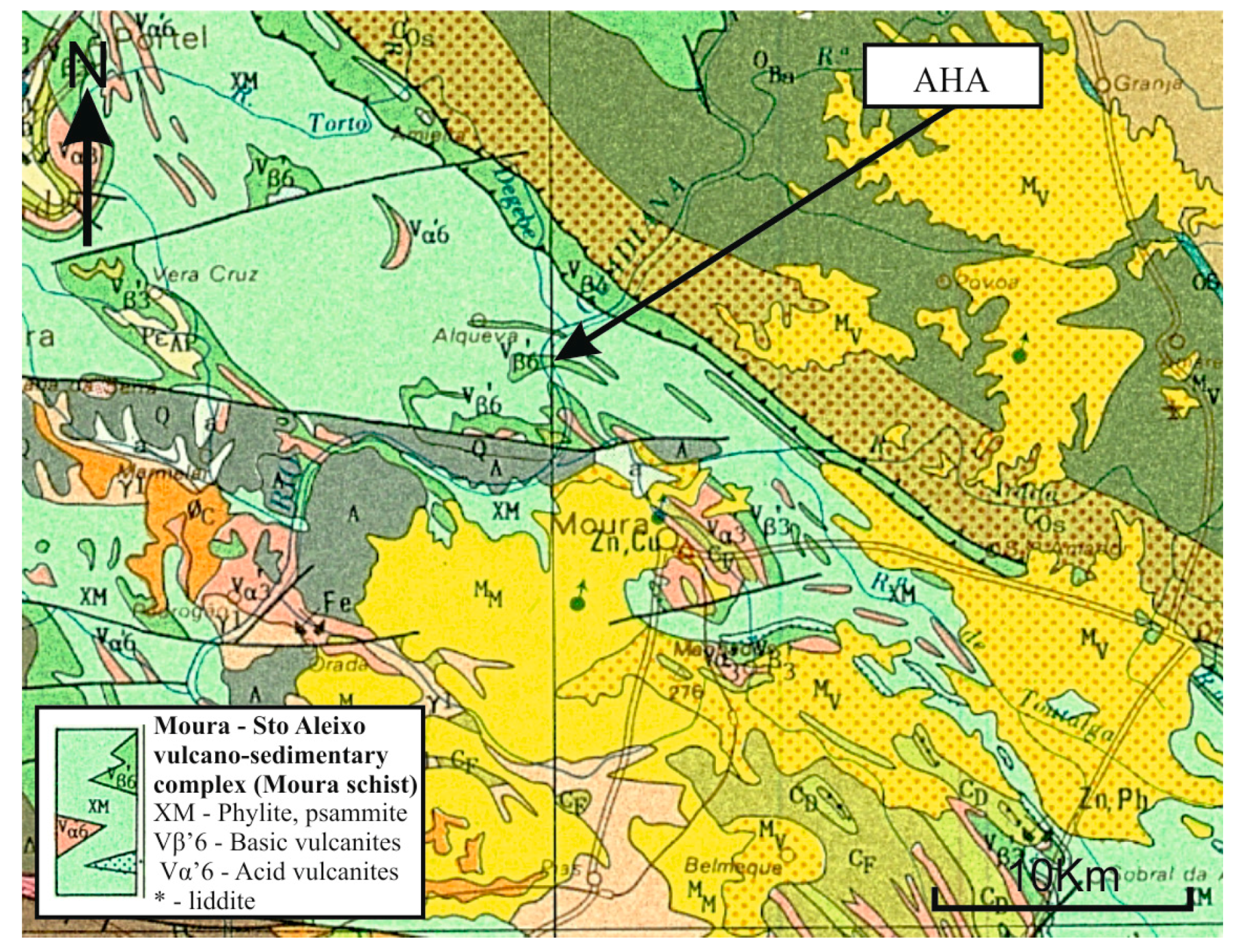

The Alqueva II (AHA) power booster is also built across a metasedimentary rock mass, but it differs from the previous one since this site has azoic, green foliated crystalline rocks [

35], presently designated as the “volcano-sedimentary complex of Moura-Santo Aleixo” [

36]. In this case, the foliation is marked and is a significant structural element of the rock mass, sometimes running as its main joint set—

Figure 5.

Finally, the methodology was also applied to the Marão tunneling (TM), which has a different purpose from the previous cases: it is a part of the A4 Amarante—Vila Real freeway. The geological setting where it was excavated is unusual, since the metasedimentary rock mass includes several geological formations, encompassing different lithologies, such as shale, psammite, quartzite, and volcano-sedimentary rocks [

38,

39], among others, some of which are affected by contact metamorphism that gives them characteristics closer to those of hornfels [

40]—

Figure 6.

The analysis presented is limited to available data on underground excavations of the main hydraulic circuits, as well as auxiliary galleries and all excavation sections designated as current; they thus exclude portals, intersections with other galleries/tunnels, and excerpts in the vicinity of larger structures, such as underground plants and transformers or sluice chambers.

Table 1 presents a summary of the features of each of the underground linear structures analyzed. All of the rock masses had three main joint sets.

4. Results and Discussion

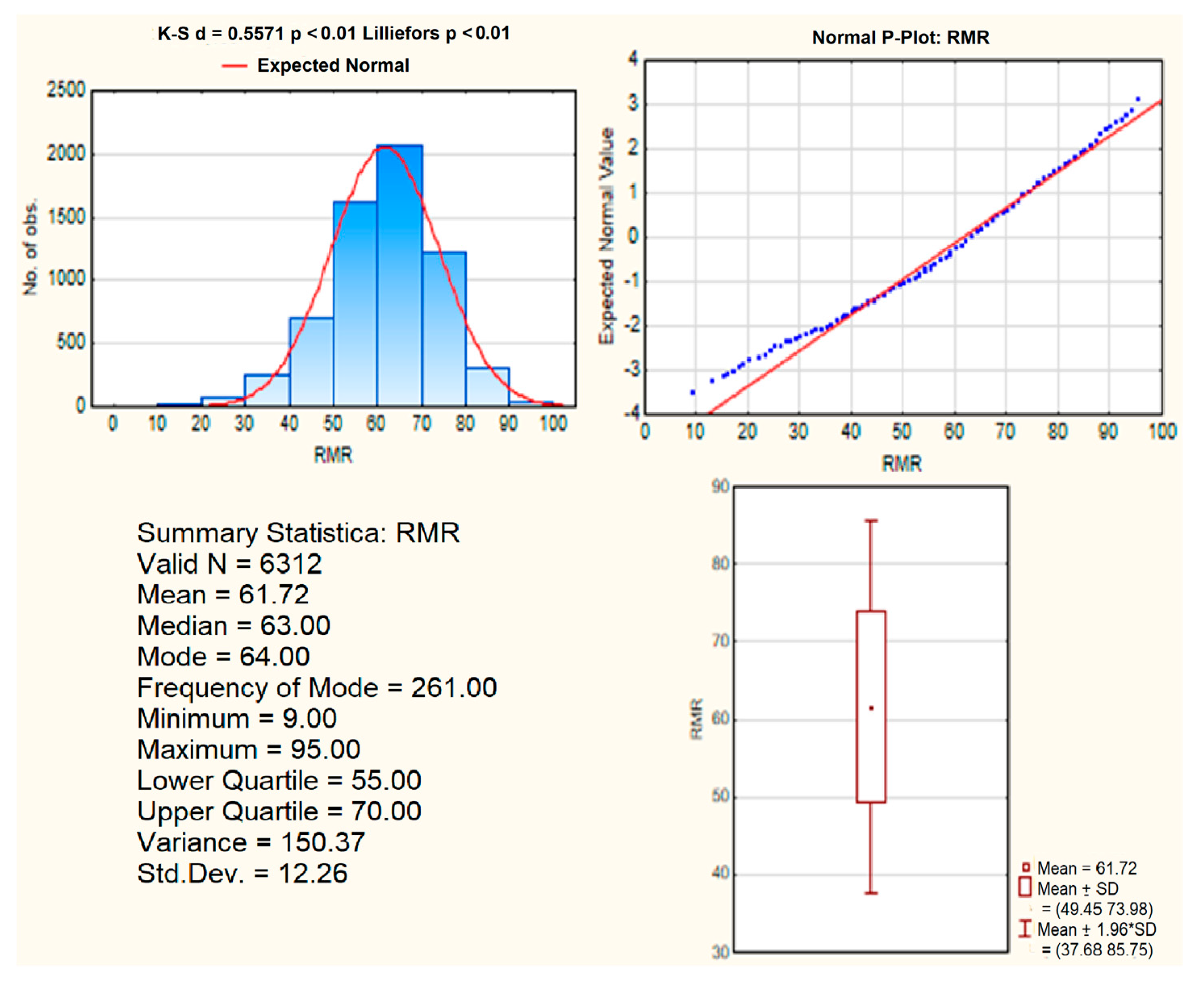

When considering the collated results of RMR values obtained from all of the excavation faces (

Figure 7), it can be concluded that underground excavations of rock masses with at least three joint sets are expected to have an average RMR close to 62, ranging between 9 and 95, the most frequent values recorded being between 60 and 70. The normality of RMR values distribution along the excavation axis is checked by P-Plot and Kolgomorov-Smirnov tests—

Figure 7.

It is noticed that the real RMR values are slightly higher than expected normal ones, in particular for RMR above 60, as stressed out by the fact that the median and the mode of RMR values are slightly higher than the mean. These results also demonstrate that the rock masses observed beyond portals are of good to vary good quality (RMR = 63 for P50).

The same figure also shows that, for the calculation of RMR probabilities for subsequent excavation advances, the number of RMR values of the rock mass within the range of 40–80 is greater than those of poor (RMR < 40) or good/excellent (RMR > 80) quality rock, which provides greater statistical, and therefore probabilistic, significance for the outputs in the central range.

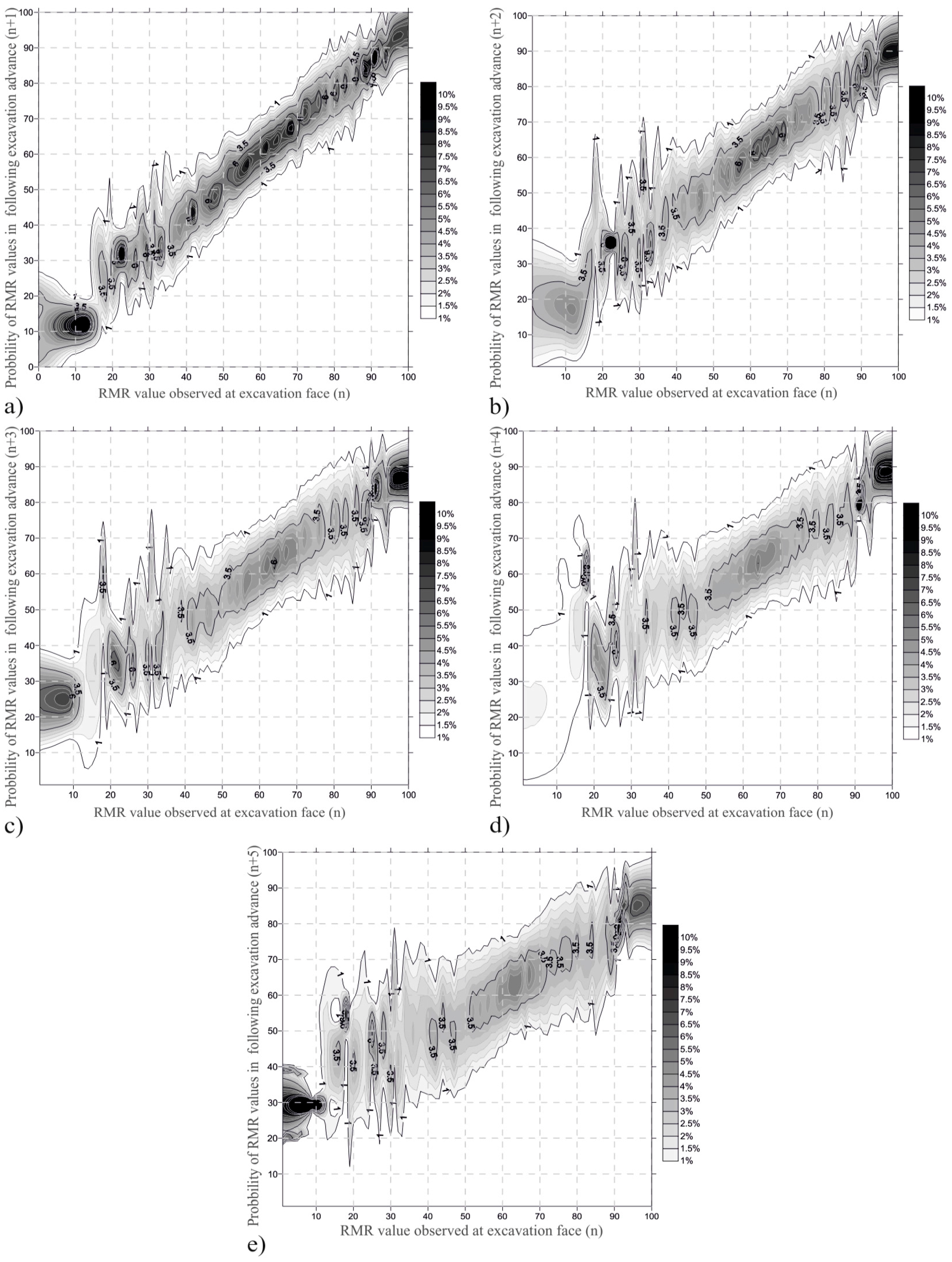

Figure 8 specifies the RMR results recorded for the following face advances (

n + 1, ...,

n + 5) after checking the RMR of any given value at the current face (

n) of the underground excavation.

Taking into account the database of the case studies, at an excavation face with any given recorded value of RMR, the probability can be calculated of each RMR occurring for the next advance, which corresponds to advancing the excavation face by a distance of approximately 4 m (

Figure 8a).

Figure 9 shows that, whatever the RMR value at this excavation face (

n), for the next advance (

n + 1), the highest probability is of obtaining a similar RMR value to this one, for a standard deviation of 6.3.

Using the same methodology, for each RMR value at the observed excavation face (

n), the probability is calculated of each of the RMR values occurring for the second traverse (

n + 2) ahead, corresponding to an accumulated distance of approximately 8 m (

Figure 8b). Similarly, the RMR value most likely to occur in the second excavation advance from the current front is similar to that observed at the current face (

n), but the standard deviation is now 8.3.

Calculating the probability of an RMR value occurring by the methodology presented above, for the third following advance (

n + 3), corresponding to a distance of approximately 12 m ahead of the current excavation face (

n), a different set of values is obtained. If the RMR value at the current face (

n) is greater than 60, then the RMR value most likely to occur at the third forward front (

n + 3) is less than that observed at the current face (

n); if the current RMR is less than 40, then the RMR most likely to occur in the third advance is slightly higher than that at the current face. If the value is in the middle range (40 < RMR < 60), the most probable value for the third face advance is similar to those observed (

Figure 8c). At this distance from the current excavation face, the standard deviation is 9.4.

The probabilities of the occurrence of each of the RMR values, when considering the RMR value of the current face (

n), for the fourth following excavation advance (

n + 4), which corresponds to a distance of about 16 m, are summarized in

Figure 8d. Calculation of the probabilities for this situation shows that, for current high values (RMR > 70), the most likely value for that distance forward is lower than that recorded at the current face (

n), and conversely for lower values (RMR < 40) of the RMR index; at the middle of the RMR range (40 < RMR < 70), the most probable values are similar to those observed at the current excavation face. In this situation, the standard deviation is 10.4.

Figure 8e lists the probabilities for occurrence of RMR values at the fifth excavation face (

n + 5) forward from the current one (

n), which amounts to a distance of approximately 20 m. At this distance, if the RMR value observed at the excavation face (

n) is less than 40, then it is most likely that the rock mass in this advance (

n + 5) will reveal a higher quality; in the case of the RMR value at the current face (

n) being in the range 40 < RMR < 70, the most likely new value at approximately 20 m ahead will be similar to that observed in this face (

n); if the RMR value at the current face (

n) is higher (RMR > 70), it is most likely that the rock mass in the fifth advance forward will present a lower RMR than that currently observed. Calculating the average standard deviation for this situation results in a value of 10.7.

As the RMR values that are available from the case studies are limited to the range of 9 to 95, there are no data available either above or below this range that can be used to calculate the corresponding probabilities, so the figures below are the result of interpolation by ordinary kriging. Analyzing the probability graphics in

Figure 9, it appears that the dispersion of probability around the most likely value is similar across the middle range of RMR values, but for values of less than 40 or above 80 the dispersion increases; however, as indicated in

Figure 9, the statistical significance of these classes as a whole is little more than 10%.

As the distance to the next front to be estimated increases and if the current RMR value is below 40, there is a tendency for the most probable RMR values to be higher than that observed at the current face. Conversely, for RMR values above 80, there is a tendency for the most probable values in the farthest advances of the excavation front to be lower than the current one.

The standard deviation of RMR values observed in the following excavation faces (n + 1, ..., n + 5) increases with distance, indicating a higher dispersion of values relative to that observed in the current front, i.e., the probability of occurrence for the estimated RMR value will most likely decrease with distance, which in practice means that it is less likely to correctly evaluate the rock mass quality ahead.

5. Conclusions

The ability to predict and anticipate the quality variation of the rock mass is fundamental to the success of underground excavation and it may constitute one of its highest risks.

This study analyzed the most likely scenarios for changes in the quality of the rock mass to be excavated in the next five advances of 4 m each of the underground excavation face beyond the portals. Prediction of RMR values for the next excavation front is based on the spatial correlation of the RMR values observed at more than 6300 excavation faces in granite or metasedimentary rocks. This is done after assessing the quality of the rock mass at the current excavation front, as summarized by its RMR value, and by carefully analyzing the graphics in

Figure 9. These graphics enable the RMR values for the five next advances to be estimated over the whole RMR scale (1–100), as well as the values that are most and least likely to occur, if there are no geological changes ahead.

Using a more limited analysis of RMR values, it is possible to determine a range of values that are most likely to occur in the next excavation advances, knowing the RMR value at the current front. It is concluded that, generally, for an average to good quality rock mass at the current face, the quality for the next advances is similar to quality observed, but with increasing distance, there is a greater deviation of RMR with respect to the quality recorded at the current front. As distance to the next front to be estimated increases, if the rock mass quality is poor—very poor (RMR < 40) or conversely if is higher (RMR > 70), it is most likely that the distant face will reveal a higher/lower quality, respectively, than that currently observed. The probability of occurrence for the estimated RMR value will most likely decrease with distance, which in practice means that it is less likely to correctly evaluate the rock mass quality ahead.

It is possible to conclude that the values of quality do not depend by itself on the lithology, but rather on the structural characteristics of rock mass to be analyzed. Therefore, the results presented before may be apply to any geological and mining situation around the excavations, regardless its lithology

It should be noticed that for the estimation of abrupt changes in the ground characteristics, co-regionalization mathematical models may be used (Almeida, 2010 [

3]). These models require the incorporation of additional secondary data (soft data, such as the occurrence of fault planes or field propagation of seismic waves), highly correlated with the primary data, used as indicator for the properties to be estimated.

This methodology can be integrated into geotechnical risk management during the underground excavation of rock masses for mining drifts or tunneling, in order to predict the range of rock mass quality scenarios for the next advances, enabling faster development or the adoption of measures to mitigate the potential risk of heterogeneity of the rock mass.

Nevertheless, this is a statistical and probabilistic study, which is limited to the available information used, and any additional data will tend to reduce the variability and therefore it may be continued and updated with data from other types of rock masses.