Virtual Reference Feedback Tuning of Model-Free Control Algorithms for Servo Systems

Abstract

:1. Introduction

- -

- It is a widely applicable one-shot data-driven tuning technique that ensures the experiment-based optimal tuning of MFC algorithms.

- -

- -

- It can be easily generalized to other model-free control techniques.

- -

- The mixed MFC-VRFT approach is applied here to an MSS and is experimentally validated by real-time results.

- -

- Three different MFC structures are tuned in this paper using the new approach in order to investigate how the controller structure complexity influences the CS performance.

- -

- The VRFT-based iP, iPI, and iPID controllers are compared against three other model-based and model-free tuned controllers to support the further use of the new model-free tuning approach.

- (1)

- The performance of a CS with an iP controller optimally tuned by VRFT is compared with that of a CS with a model-based optimally tuned iP controller. Then the performance of the CSs with iP controllers is compared with that of a CS with an I controller, which is optimally tuned both in a model-based setting and using VRFT (i.e., in a data-driven model-free setting).

- (2)

- The same comparisons and controller tunings are carried out as in the experimental case study (1) but two iPI controllers and two PI controllers are involved.

- (3)

- The experimental case study (1) is applied, but two iPID controllers and two PID controllers are involved.

2. MFC, VRFT, and Mixed MFC-VRFT Approaches

2.1. Overview of MFC

2.2. Overview on Nonlinear VRFT

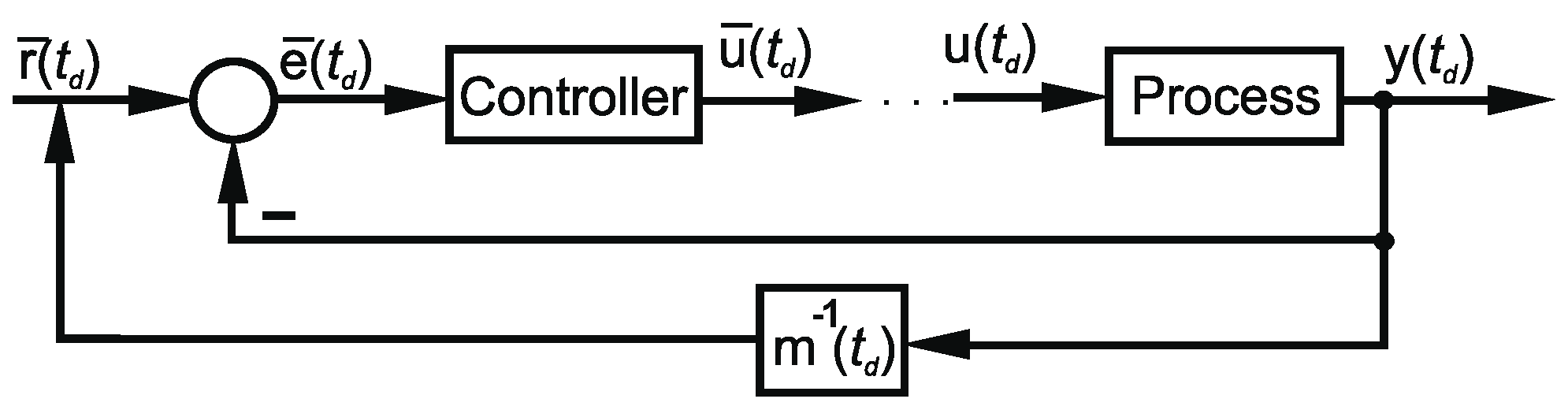

2.3. Mixed MFC-VRFT Approach

3. Experimental Results and Discussion

3.1. The Modular Servo System Equipment

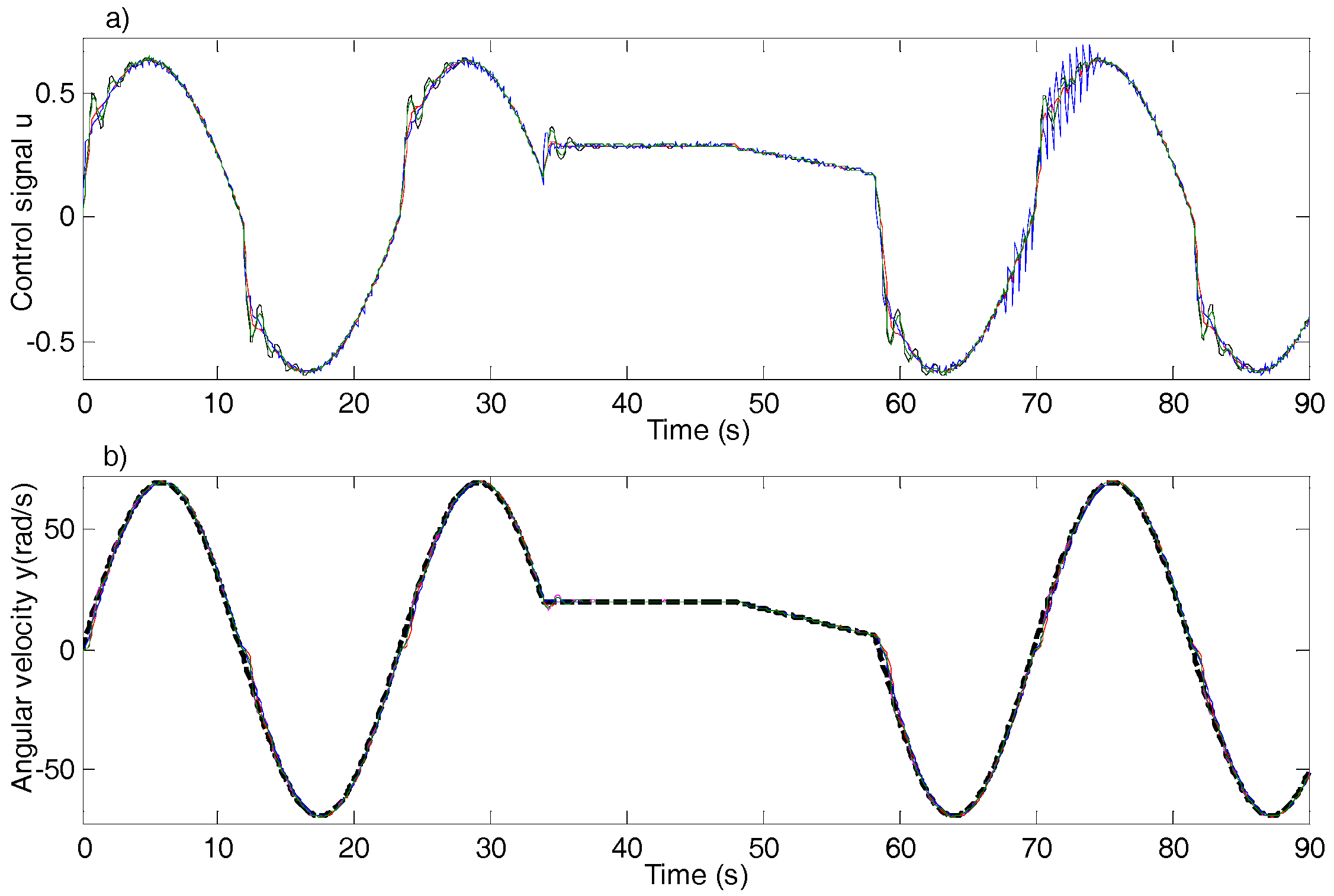

3.2. Experimental Validation

3.3. Discussion of Experimental Results

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Fliess, M.; Join, C. Model-free control. Int. J. Control 2013, 86, 2228–2252. [Google Scholar] [CrossRef] [Green Version]

- Carrillo, F.J.; Rotella, F. Some contributions to estimation for mode-free control. In Proceedings of the 17th IFAC Symposium on System Identification, Beijing, China, 19–21 October 2015; pp. 150–155. [Google Scholar]

- Ridha, T.M.; Moog, C.H. Model free control for type-1 diabetes: A fasting-phase study. In Proceedings of the 9th IFAC Symposium on Biological and Medical Systems, Berlin, Germany, 31 August–2 September 2015; pp. 76–81. [Google Scholar]

- Jama, M.A.; Noura, H.; Wahyudie, A.; Assi, A. Enhancing the performance of heaving wave energy converters using model-free control approach. Renew. Energy 2015, 83, 931–941. [Google Scholar] [CrossRef]

- D’Andrea-Novel, B.; Menhour, L.; Fliess, M.; Mounier, H. Some remarks on wheeled autonomous vehicles and the evolution of their control design. In Proceedings of the 9th IFAC Symposium on Intelligent Autonomous Vehicles, Leipzig, Germany, 29 June–1 July 2016; pp. 1–6. [Google Scholar]

- Tebbani, S.; Titica, M.; Join, C.; Fliess, M.; Dumur, D. Model-based versus model-free control designs for improving microalgae growth in a closed photobioreactor: Some preliminary comparisons. In Proceedings of the 24th Mediterranean Conference on Control and Automation, Athens, Greece, 21–24 June 2016; pp. 1–6. [Google Scholar]

- Lafont, F.; Balmat, J.-F.; Pessel, N.; Fliess, M. A model-free control strategy for an experimental greenhouse with an application to fault accommodation. Comput. Electron. Agric. 2015, 110, 139–149. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, H.-M.; Yao, H.-Y. Model-free control of surface mounted PMSM drive system. In Proceedings of the 2016 IEEE International Conference on Industrial Technology, Taipei, Taiwan, 14–17 March 2016; pp. 175–180. [Google Scholar]

- Roman, R.-C.; Radac, M.-B.; Precup, R.-E. Multi-input-multi-output system experimental validation of model-free control and virtual reference feedback tuning techniques. IET Control Theory Appl. 2016, 10, 1395–1403. [Google Scholar] [CrossRef]

- Roman, R.-C.; Radac, M.-B.; Precup, R.-E. Mixed MFC-VRFT approach for multivariable aerodynamic system position control. In Proceedings of the 2016 IEEE International Conference on Systems, Man, and Cybernetics, Budapest, Hungary, 9–12 October 2016; pp. 2615–2620. [Google Scholar]

- Wang, H.-P.; Ye, X.-F.; Tian, Y.; Zheng, G.; Christov, N. Model-free-based terminal SMC of quadrotor attitude and position. IEEE Trans. Aerosp. Electron. Syst. 2016, 52, 2519–2528. [Google Scholar] [CrossRef]

- Precup, R.-E.; Radac, M.-B.; Roman, R.-C.; Petriu, E.M. Model-free sliding mode control of nonlinear systems: Algorithms and experiments. Inf. Sci. 2017, 381, 176–192. [Google Scholar] [CrossRef]

- Abouaïssa, H.; Fliess, M.; Join, C. On ramp metering: Towards a better understanding of ALINEA via model-free control. Int. J. Control 2017, 90, 1018–1026. [Google Scholar] [CrossRef] [Green Version]

- Han, J.Q. From PID to active disturbance rejection control. IEEE Trans. Ind. Electron. 2009, 56, 900–906. [Google Scholar] [CrossRef]

- Xia, Y.Q.; Pu, F.; Li, S.F.; Gao, Y. Lateral path tracking control of autonomous land vehicle based on ADRC and differential flatness. IEEE Trans. Ind. Electron. 2016, 63, 3091–3099. [Google Scholar] [CrossRef]

- Herbst, G. Practical active disturbance rejection control: Bumpless transfer, rate limitation, and incremental algorithm. IEEE Trans. Ind. Electron. 2016, 63, 1754–1762. [Google Scholar] [CrossRef]

- Hou, Z.S.; Jin, S. A novel data-driven control approach for a class of discrete-time nonlinear systems. IEEE Trans. Control Syst. Technol. 2011, 19, 1549–1558. [Google Scholar] [CrossRef]

- Hou, Z.S.; Zhu, Y.M. Controller-dynamic-linearization-based model free adaptive control for discrete-time nonlinear systems. IEEE Trans. Ind. Inform. 2013, 9, 2301–2309. [Google Scholar] [CrossRef]

- Pang, Z.-H.; Liu, G.-P.; Zhou, D.H.; Sun, D.H. Data-based predictive control for networked nonlinear systems with network-induced delay and packet dropout. IEEE Trans. Ind. Electron. 2016, 63, 1249–1257. [Google Scholar] [CrossRef]

- Campi, M.C.; Lecchini, A.; Savaresi, S.M. Virtual reference feedback tuning: A direct method for the design of feedback controllers. Automatica 2002, 38, 1337–1346. [Google Scholar] [CrossRef]

- Campestrini, L.; Eckhard, D.; Chía, L.A.; Boeira, E. Unbiased MIMO VRFT with application to process control. J. Proc. Control 2016, 39, 35–49. [Google Scholar] [CrossRef]

- Invernizzi, D.; Panizza, P.; Riccardi, F.; Formentin, S.; Lovera, M. Data-driven attitude control law of a variable-pitch quadrotor: A comparison study. IFAC PapersOnLine 2016, 49, 236–241. [Google Scholar] [CrossRef]

- Wang, Y.; Tang, X.-J. Attitude controller optimization for unmanned gyroplane using online virtual reference feedback control. In Proceedings of the 35th Chinese Control Conference, Chengdu, China, 27–29 July 2016; pp. 10754–10758. [Google Scholar]

- Gonçalves da Silva, G.R.; Campestrini, L.; Bazanella, A.S. Multivariable VRFT: An approach for systems with non-minimum phase transmission zeros. In Proceedings of the 2016 IEEE Conference on Control Applications, Buenos Aires, Argentina, 19–22 September 2016; pp. 1324–1329. [Google Scholar]

- Yamamoto, N.; Yubai, K.; Yashiro, D.; Komada, S. Direct design method of force controller based on input/output data. In Proceedings of the 2016 International Conference on Advanced Mechatronics Systems, Melbourne, Australia, 30 November–3 December 2016; pp. 126–131. [Google Scholar]

- Jeng, J.-C.; Yeh, C.-H. Coordinated control design for a PEMFC power system using adaptive VRFT method. J. Taiwan Inst. Chem. Eng. 2017, 73, 102–111. [Google Scholar] [CrossRef]

- Radac, M.-B.; Grad, R.-B.; Precup, R.-E.; Petriu, E.M.; Preitl, S.; Dragos, C.-A. Mixed virtual reference feedback tuning-iterative feedback tuning: Method and laboratory assessment. In Proceedings of the 2011 IEEE International Symposium on Industrial Electronics, Gdansk, Poland, 27–30 June 2011; pp. 649–654. [Google Scholar]

- Roman, R.-C.; Radac, M.-B.; Precup, R.-E.; Petriu, E.M. Data-driven model-free adaptive control tuned by virtual reference feedback tuning. Acta Polytech. Hung. 2016, 13, 83–96. [Google Scholar]

- Radac, M.-B.; Precup, R.-E.; Roman, R.-C. Model-free control performance improvement using virtual reference feedback tuning and reinforcement Q-learning. Int. J. Syst. Sci. 2017, 48, 1071–1083. [Google Scholar] [CrossRef]

- Campi, M.C.; Savaresi, S.M. Direct nonlinear control design: The Virtual Reference Feedback Tuning (VRFT) approach. IEEE Trans. Autom. Control 2006, 65, 14–27. [Google Scholar] [CrossRef]

- Yan, P.; Liu, D.; Wang, D.; Ma, H. Data-driven controller design for general MIMO nonlinear systems via virtual reference feedback tuning and neural networks. Neurocomputing 2016, 171, 815–825. [Google Scholar] [CrossRef]

- Inteco Ltd. Modular Servo System, User’s Manual; Inteco Ltd.: Krakow, Poland, 2006. [Google Scholar]

- Precup, R.-E.; David, R.-C.; Petriu, E.M. Grey wolf optimizer algorithm-based tuning of fuzzy control systems with reduced parametric sensitivity. IEEE Trans. Ind. Electron. 2017, 64, 527–534. [Google Scholar] [CrossRef]

- Precup, R.-E.; Angelov, P.; Costa, B.S.J.; Sayed-Mouchaweh, M. An overview on fault diagnosis and nature-inspired optimal control of industrial process applications. Comput. Ind. 2015, 74, 75–94. [Google Scholar] [CrossRef]

- Precup, R.-E.; Sabau, M.-C.; Petriu, E.M. Nature-inspired optimal tuning of input membership functions of Takagi-Sugeno-Kang fuzzy models for anti-lock braking systems. Appl. Soft Comput. 2015, 27, 575–589. [Google Scholar] [CrossRef]

- Del Toro, R.M.; Schmittdiel, M.C.; Haber-Guerra, R.-E.; Haber-Haber, R. System identification of the high performance drilling process for network-based control. In Proceedings of the 21st Biennial Conference on Mechanical Vibration and Noise, Las Vegas, NV, USA, 4–7 September 2007; pp. 827–834. [Google Scholar]

- Bošnak, M.; Matko, D.; Blažič, S. Quadrocopter hovering using position-estimation information from inertial sensors and a high-delay video system. J. Intell. Robot. Syst. 2012, 67, 43–60. [Google Scholar] [CrossRef]

- Wijayasekara, D.; Linda, O.; Manic, M.; Rieger, C. FN-DFE: Fuzzy-Neural Data Fusion Engine for enhanced resilient state-awareness of hybrid energy systems. IEEE Trans. Cybern. 2014, 44, 2065–2075. [Google Scholar] [CrossRef] [PubMed]

- Noroozi, N.; Khayatian, A.; Ahmadizadeh, S.; Karimi, H.R. On integral input-to-state stability for a feedback interconnection of parameterised discrete-time systems. Int. J. Syst. Sci. 2016, 47, 1598–1614. [Google Scholar] [CrossRef]

- Gharbi, A.; Benrejeb, M.; Borne, P. A taboo search optimization of the control law of nonlinear systems with bounded uncertainties. Int. J. Comput. Communic. Control 2016, 11, 224–232. [Google Scholar] [CrossRef]

- Yin, S.; Shi, P.; Yang, H.Y. Adaptive fuzzy control of strict-feedback nonlinear time-delay systems with unmodeled dynamics. IEEE Trans. Cybern. 2016, 46, 1926–1938. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.J.; Li, H.Y.; Zhou, Q.; Lu, R.Q. Adaptive fuzzy control for nonstrict feedback systems with unmodeled dynamics and fuzzy dead zone via output feedback. IEEE Trans. Cybern. 2017, 47, 2400–2412. [Google Scholar] [CrossRef] [PubMed]

- Filip, F.G. Decision support and control for large-scale complex systems. Ann. Rev. Control 2008, 32, 61–70. [Google Scholar] [CrossRef]

- Vaščák, J. Adaptation of fuzzy cognitive maps by migration algorithms. Kybernetes 2012, 41, 429–443. [Google Scholar] [CrossRef]

- Maithripala, D.H.S.; Dayawansa, W.P.; Berg, J.M. Intrinsic observer-based stabilization for simple mechanical systems on Lie groups. SIAM J. Control Optim. 2015, 44, 1691–1711. [Google Scholar] [CrossRef]

- Solos, I.P.; Tassopoulos, I.X.; Beligiannis, G.N. Optimizing shift scheduling for tank trucks using an effective stochastic variable neighbourhood approach. Int. J. Artif. Intell. 2016, 14, 1–26. [Google Scholar]

- Ducic, N.; Cojbašic, Ž.; Radiša, R.; Slavkovic, R.; Milicevic, I. CAD/CAM design and genetic optimization of feeders for sand casting process. Facta Univ. Ser. Mech. Eng. 2016, 14, 147–158. [Google Scholar]

- Ali, M.Z.; Awad, N.H.; Duwairi, R.M. Multi-objective differential evolution algorithm with a new improved mutation strategy. Int. J. Artif. Intell. 2016, 14, 23–41. [Google Scholar]

- Cabrera-Guerrero, P.; Moltedo-Perfetti, A.; Cabrera, E.; Paredes, F. Comparing two heuristic local search algorithms for a complex routing problem. Stud. Inform. Control 2016, 25, 411–420. [Google Scholar] [CrossRef]

| Scenario | Average of | Variance of |

|---|---|---|

| VRFT-iP | 1.8832 | 0.0057 |

| iP | 1.8101 | 0.0042 |

| VRFT-I | 16.5884 | 2.8952 |

| I | 8.0407 | 0.1565 |

| Scenario | Average of | Variance of |

|---|---|---|

| VRFT-iPI | 2.4645 | 0.0151 |

| iPI | 1.5565 | 0.0033 |

| VRFT-PI | 2.0542 | 0.0071 |

| PI | 0.7675 | 0.0007 |

| Scenario | Average of | Variance of |

|---|---|---|

| VRFT-iPID | 2.2834 | 0.0062 |

| iPID | 1.4742 | 0.0102 |

| VRFT-PID | 2.0134 | 0.0107 |

| PID | 0.7636 | 0.0009 |

| Scenario | Characteristic Polynomials | Roots of the Characteristic Polynomials |

|---|---|---|

| VRFT-iP | ||

| iP | ||

| VRFT-iPI | ||

| iPI | ||

| VRFT-iPID | ||

| iPID |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roman, R.-C.; Radac, M.-B.; Precup, R.-E.; Petriu, E.M. Virtual Reference Feedback Tuning of Model-Free Control Algorithms for Servo Systems. Machines 2017, 5, 25. https://doi.org/10.3390/machines5040025

Roman R-C, Radac M-B, Precup R-E, Petriu EM. Virtual Reference Feedback Tuning of Model-Free Control Algorithms for Servo Systems. Machines. 2017; 5(4):25. https://doi.org/10.3390/machines5040025

Chicago/Turabian StyleRoman, Raul-Cristian, Mircea-Bogdan Radac, Radu-Emil Precup, and Emil M. Petriu. 2017. "Virtual Reference Feedback Tuning of Model-Free Control Algorithms for Servo Systems" Machines 5, no. 4: 25. https://doi.org/10.3390/machines5040025