Tribofilms Forming in Oil-Lubricated Contacts

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Steel Disk (56NiCrMoV7) versus Steel Pin (C86)

2.1.2. Aluminum Disk (AlSi9Cu3) versus Steel Pin (100Cr6)

2.2. Methods

2.2.1. Tribometry

2.2.2. Structural Analysis

2.2.3. Chemical Analysis

2.2.4. Shear Analysis

3. Results

3.1. Friction and Wear Analysis

3.2. Microstructural Analysis

3.3. Chemical Analysis

3.4. Shear Analysis (Al Disk Only)

4. Discussion

5. Conclusions

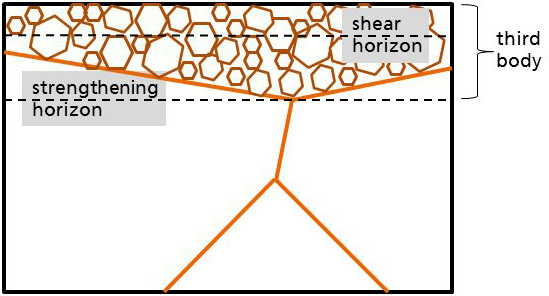

- The third body is a tribofilm that is formed underneath the surface and extends into both friction bodies.

- The third body shows a dinstinctively altered topography, microstructure and chemical composition than the base materials.

- The third body possesses a substructure. The accomodation of shear takes place close to the inner surface and is characterized by the depth of intermixed CH groups.

- The depth of introduced oxygen depends on heat generation in the contact and the ability of the materials to grow a dense oxide.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Dienwiebel, M.; Poehlmann, K. Nanoscale Evolution of Sliding Metal Surfaces During Running-in. Tribol. Lett. 2007, 27, 255–260. [Google Scholar] [CrossRef]

- Reichelt, M.; Gunst, U.; Wolf, T.; Mayer, J.; Arlinghaus, H.; Gold, P. Nanoindentation, TEM and ToF-SIMS studies of the tribological layer system of cylindrical roller thrust bearings lubricated with different oil additive formulations. Wear 2010, 268, 1205–1213. [Google Scholar] [CrossRef]

- Scherge, M.; Shakhvorostov, D.; Poehlmann, K. Fundamental wear mechanism of metals. Wear 2003, 255, 395–400. [Google Scholar] [CrossRef]

- Godet, M. The third-body approach: A mechanical view of wear. Wear 1984, 100, 437–452. [Google Scholar] [CrossRef]

- Rigney, D.A.; Karthikeyan, S. The Evolution of Tribomaterial During Sliding: A Brief Introduction. Tribol. Lett. 2010, 39, 3–7. [Google Scholar] [CrossRef]

- Rigney, D. Transfer, mixing and associated chemical and mechanical processes during the sliding of ductile materials. Wear 2000, 245, 1–9. [Google Scholar] [CrossRef]

- Fischer, A. Subsurface microstructural alterations during sliding wear of biomedical metals. Modelling and experimental results. Comput. Mater. Sci. 2009, 46, 586–590. [Google Scholar] [CrossRef]

- Scherge, M.; Linsler, D.; Schlarb, T. The running-in corridor of lubricated metal-metal contacts. Wear 2015, 342, 60–64. [Google Scholar] [CrossRef]

- Rogers, H. Adiabatic plastic deformation. Ann. Rev. Mater. Sci. 1979, 9, 283–311. [Google Scholar] [CrossRef]

- Lasagni, F.; Lasagni, A.; Marks, E.; Holzapfel, C.; Muecklich, F.; Degischer, H. Three-dimensional characterization of as-cast and solution-treated AlSi12(Sr) alloys by high-resolution FIB tomography. Acta Mater. 2007, 55, 3875–3882. [Google Scholar] [CrossRef]

- Timpel, M.; Wanderka, N.; Schlesiger, R.; Yamamoto, T.; Isheim, D.; Schmitz, G.; Matsumura, S.; Banhart, J. SrAlSi co-segregated regions in eutectic Si phase of Sr-modified Al-10Si alloy. Ultramicroscopy 2013, 132, 216–221. [Google Scholar] [CrossRef] [PubMed]

- Scherge, M.; Poehlmann, K.; Gerve, A. Wear measurement using radionuclide-technique (RNT). Wear 2003, 254, 801–817. [Google Scholar] [CrossRef]

- Linsler, D.; Schlarb, T.; Weingaertner, T.; Scherge, M. Influence of subsurface microstructure on the running-in of an AlSi alloy. Wear 2015, 332, 926–931. [Google Scholar] [CrossRef]

- Brink, A.; Lichtenberg, K.; Scherge, M. Influencing the tibological performance by different initial microstructures and adjusting stressing levels during the running-in. Wear 2016. submitted. [Google Scholar]

- Shakhvorostov, D.; Poehlmann, K.; Scherge, M. An energetic approach to friction, wear and temperature. Wear 2004, 257, 124–130. [Google Scholar] [CrossRef]

- Fischer, A.; Weiss, S.; Wimmer, M. The tribological difference between biomedical steels and CoCrMo-alloys. J. Mech. Behav. Biomed. Mater. 2012, 9, 50–62. [Google Scholar] [CrossRef] [PubMed]

- Quinn, T.; Rowson, D.; Sullivan, J. Application of the oxidational theory of mild wear to the sliding wear of low alloy steel. Wear 1980, 65, 1–20. [Google Scholar] [CrossRef]

- Kuhlmann-Wilsdorf, D. Demystifying Flash Temperatures I. Analytical Expressions Based on a Simple Model. Mater. Sci. Eng. 1987, 93, 107–117. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | P | S | Cr | Ni | Mo | V |

|---|---|---|---|---|---|---|---|---|---|

| Conc. in wt% | 0.5–0.6 | 0.1–0.4 | 0.65–0.95 | <0.03 | <0.03 | 0.1–1.2 | 1.5–1.8 | 0.45–0.55 | 0.07–0.12 |

| Element | Si | Cu | Fe | Zn | Mg | Mn, Pb, Ti | Sr | Al |

|---|---|---|---|---|---|---|---|---|

| Conc. in wt% | 10.6 | 2.5 | 0.9 | 0.8 | 0.2 | <0.2 | 200 ppm | balance |

| Steel Disk | Pin | Al Disk | Pin | |

|---|---|---|---|---|

| material | 56NiCrMoV7 | C86 | AlSi9Cu3 | N/A 100Cr6 |

| microhardness | 7–8 GPa | N/A | 2.5–3 GPa | N/A |

| austenitizing temperature | 850 C | N/A | N/A | N/A |

| annealing temperature | 630 C | N/A | 480 C | N/A |

| 150 nm | 10 nm | 75 nm | 16 nm |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scherge, M.; Brink, A.; Linsler, D. Tribofilms Forming in Oil-Lubricated Contacts. Lubricants 2016, 4, 27. https://doi.org/10.3390/lubricants4030027

Scherge M, Brink A, Linsler D. Tribofilms Forming in Oil-Lubricated Contacts. Lubricants. 2016; 4(3):27. https://doi.org/10.3390/lubricants4030027

Chicago/Turabian StyleScherge, Matthias, Angelika Brink, and Dominic Linsler. 2016. "Tribofilms Forming in Oil-Lubricated Contacts" Lubricants 4, no. 3: 27. https://doi.org/10.3390/lubricants4030027