Silicon Nitride Bearings for Total Joint Arthroplasty

Abstract

:1. Introduction

2. Materials and Methods

2.1. AMTI Ceramic-on-Polyethylene Hip Simulator Study

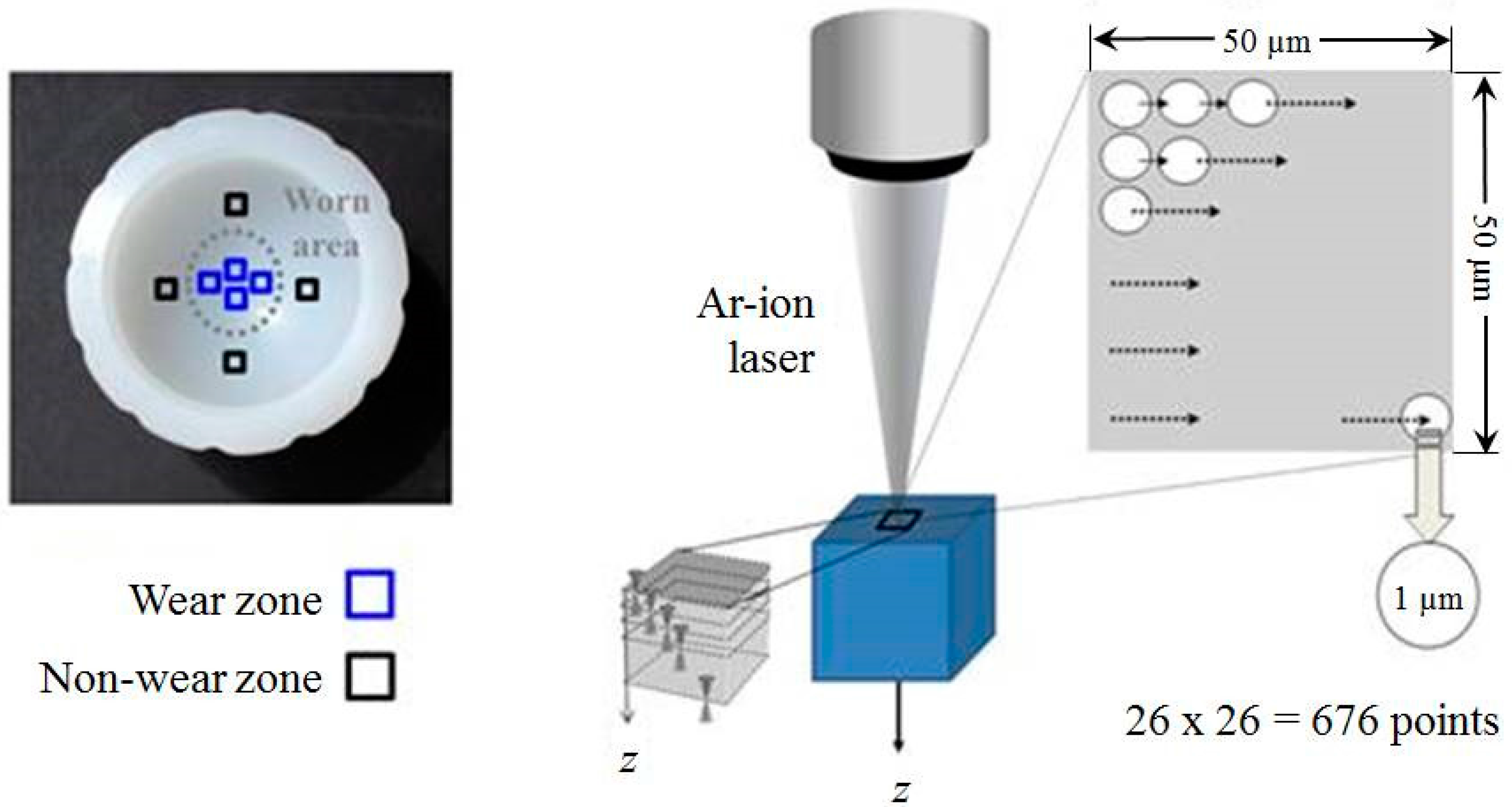

2.2. SWM Ceramic-on-Polyethylene Hip Simulator Study

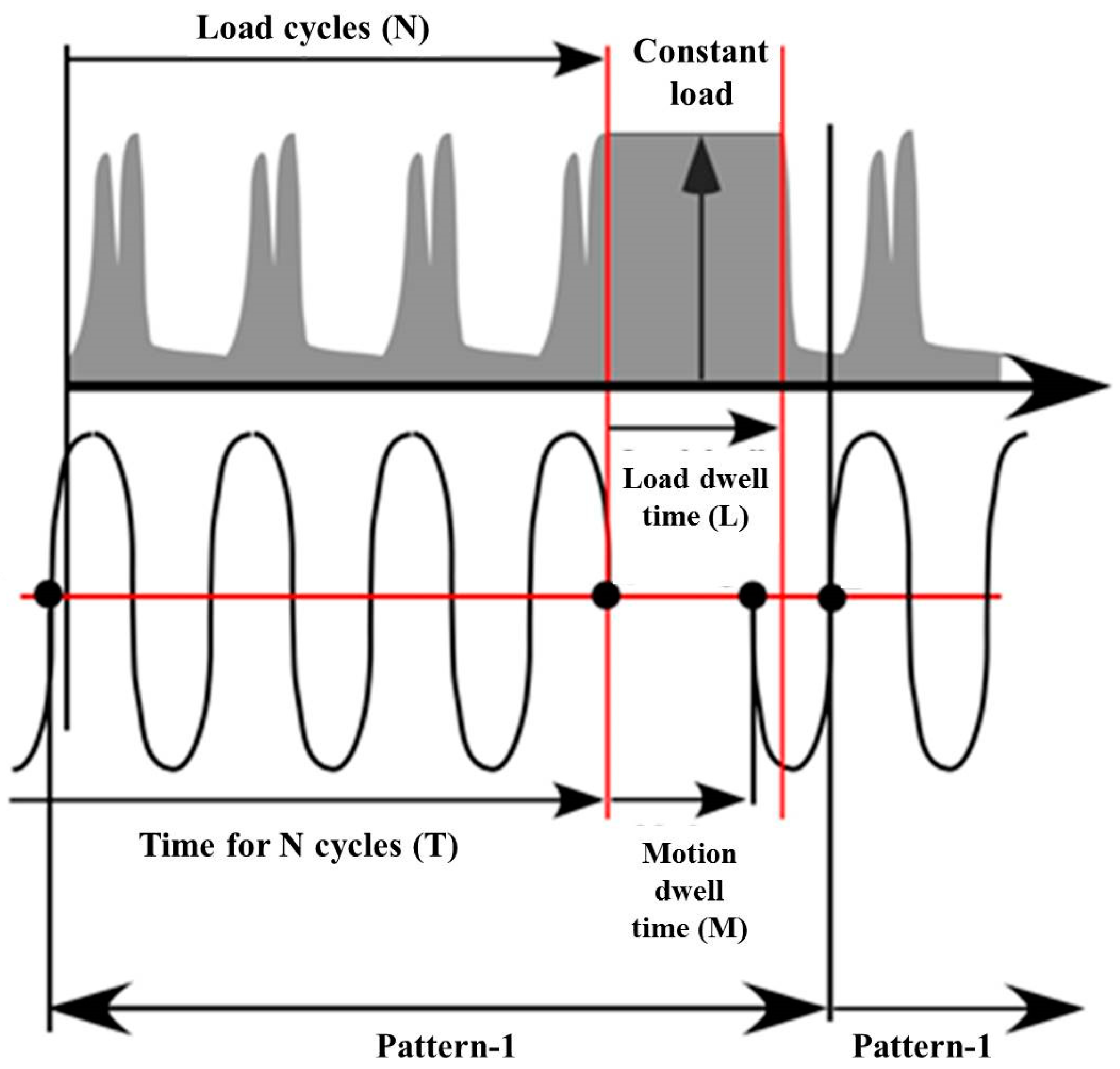

2.3. SWM Ceramic-on Ceramic Hip Simulator Study

3. Results and Discussion

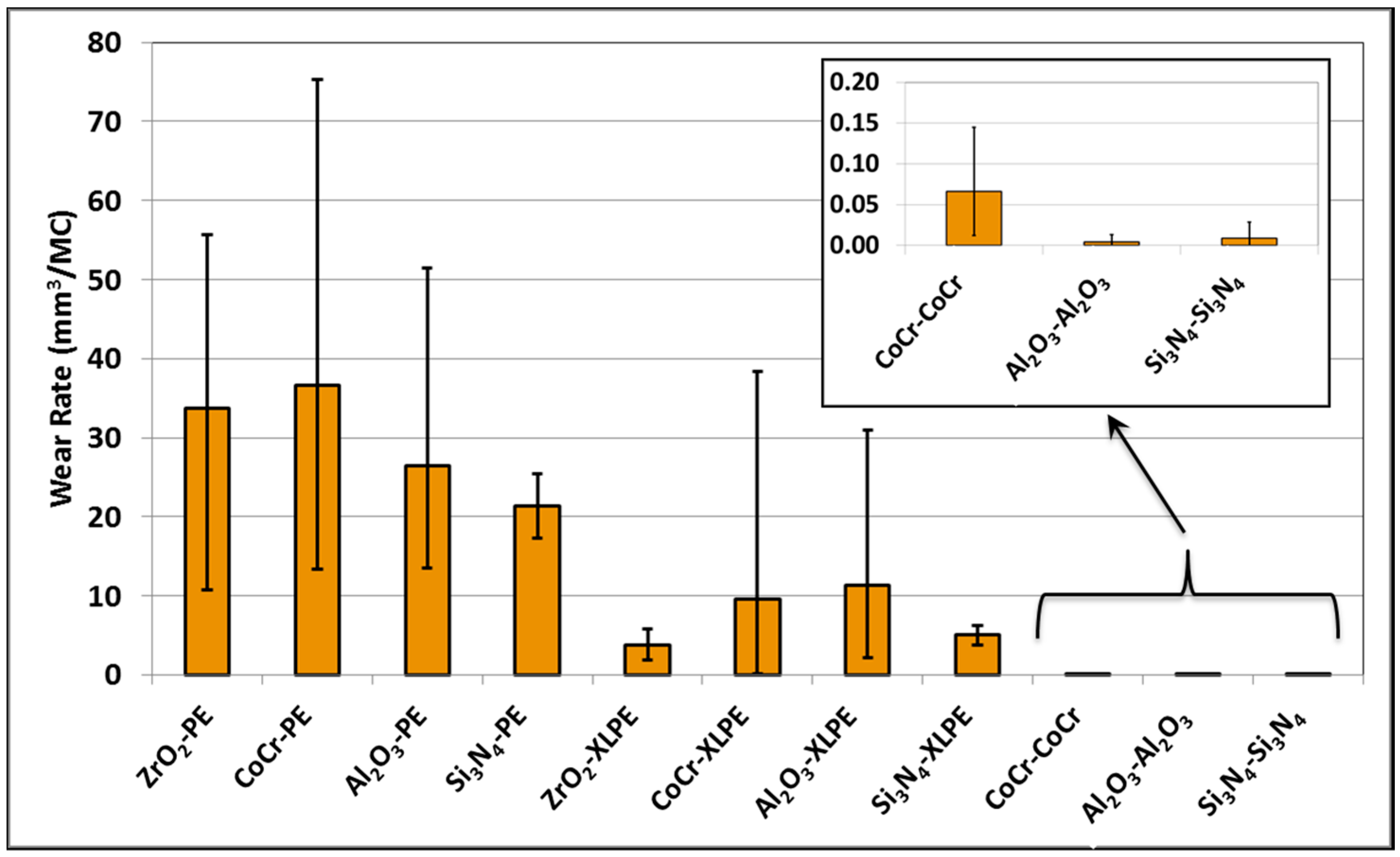

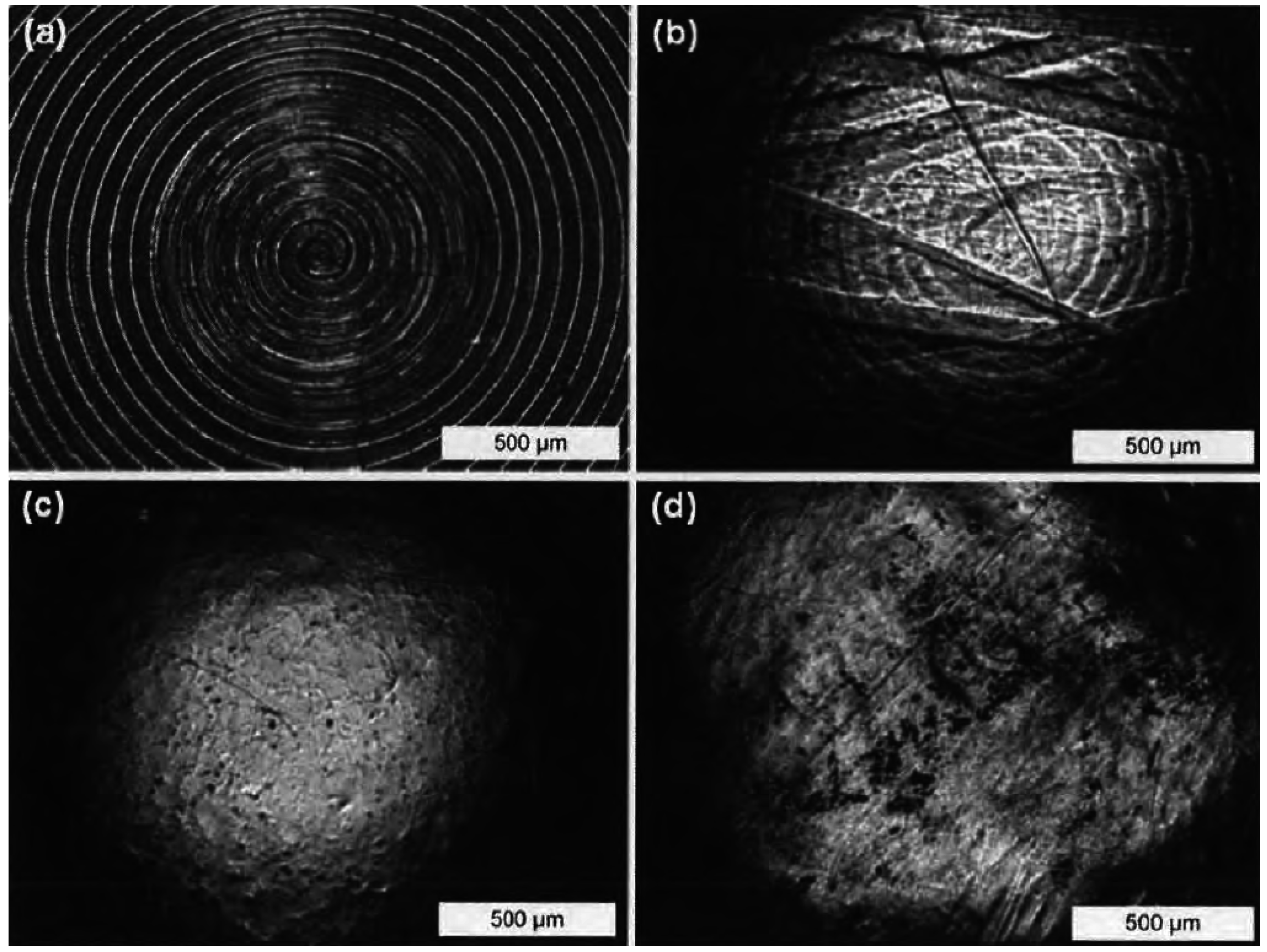

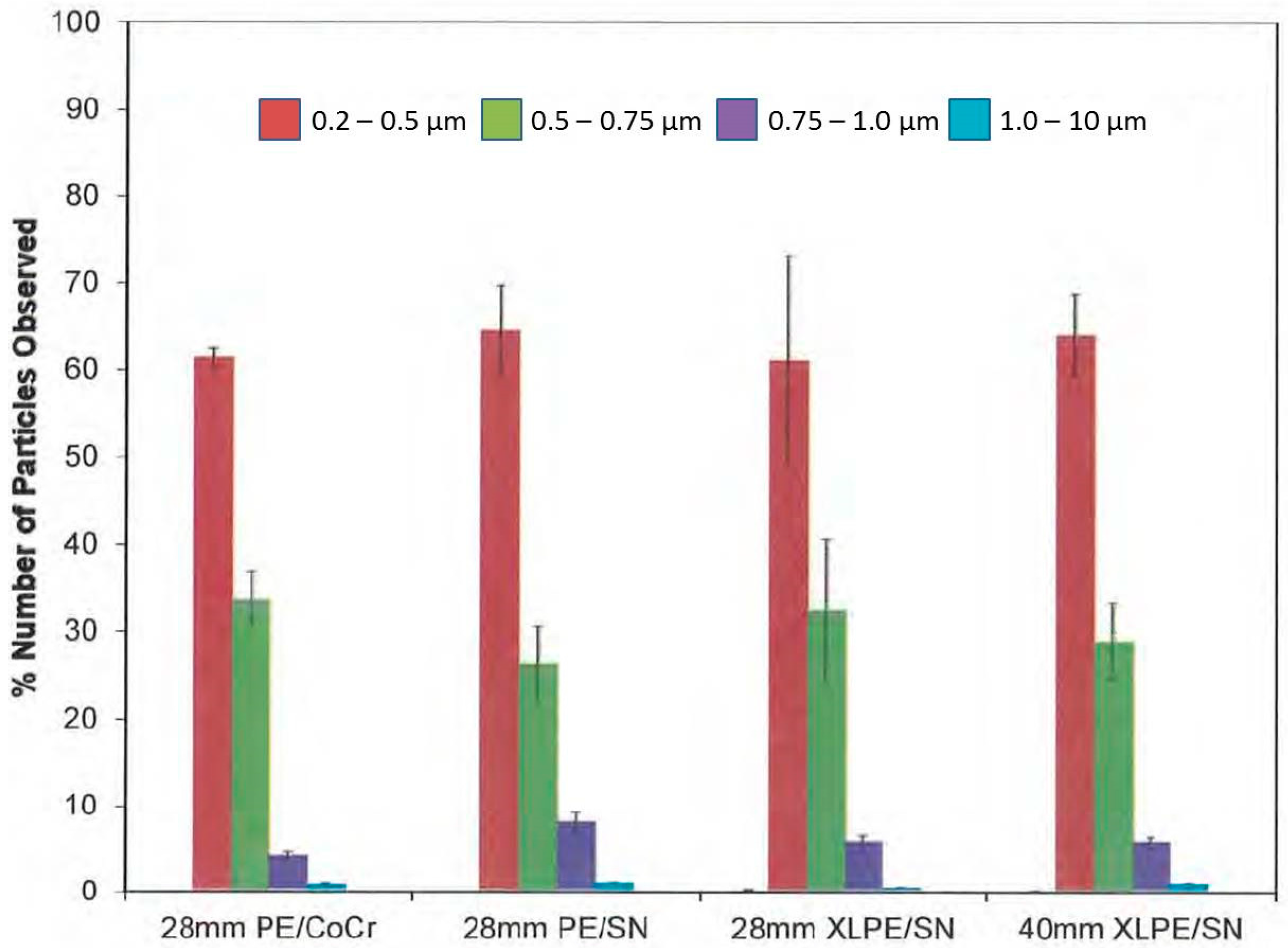

3.1. AMTI Ceramic-on-Polyethylene Hip Simulator Study

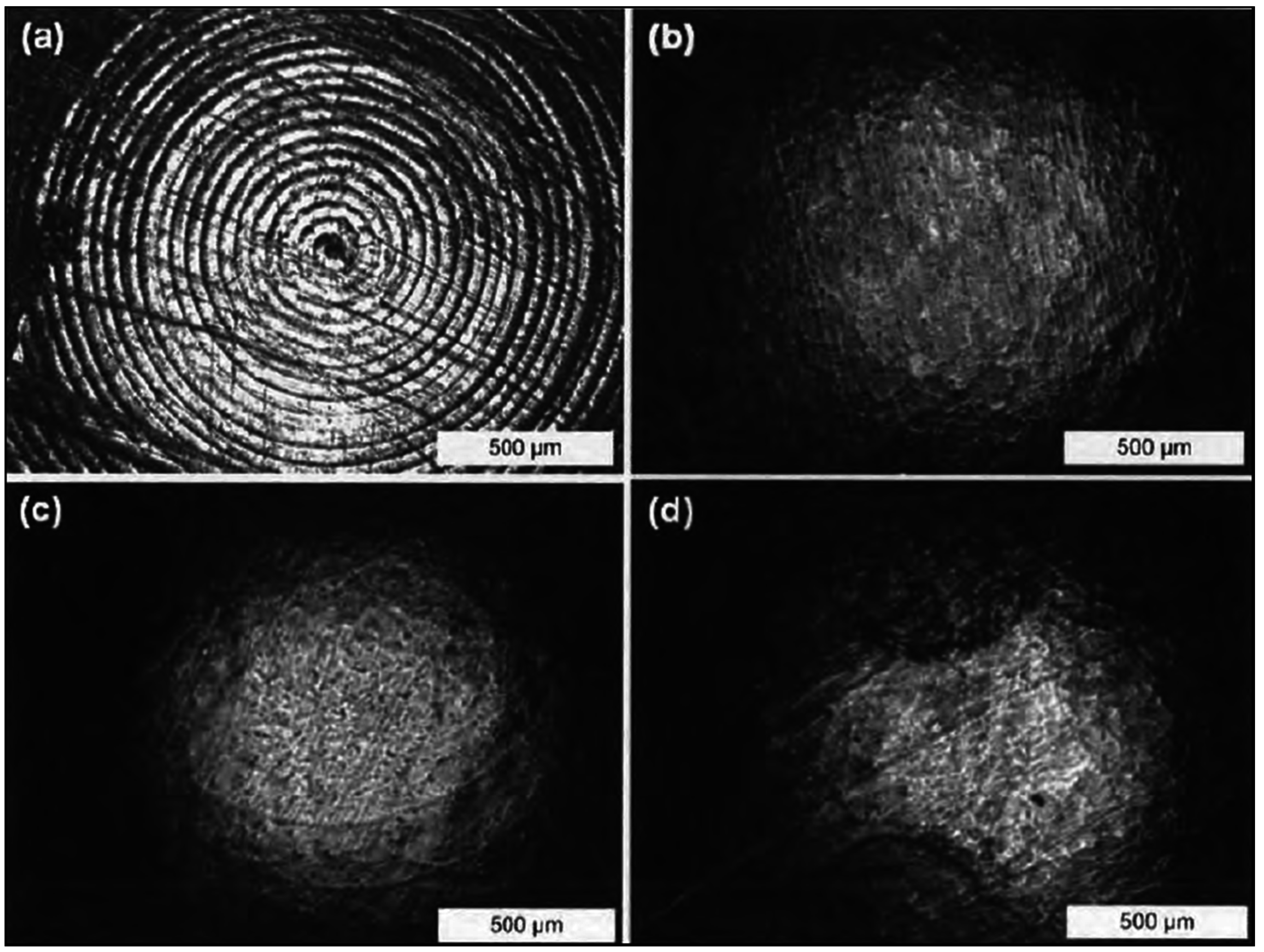

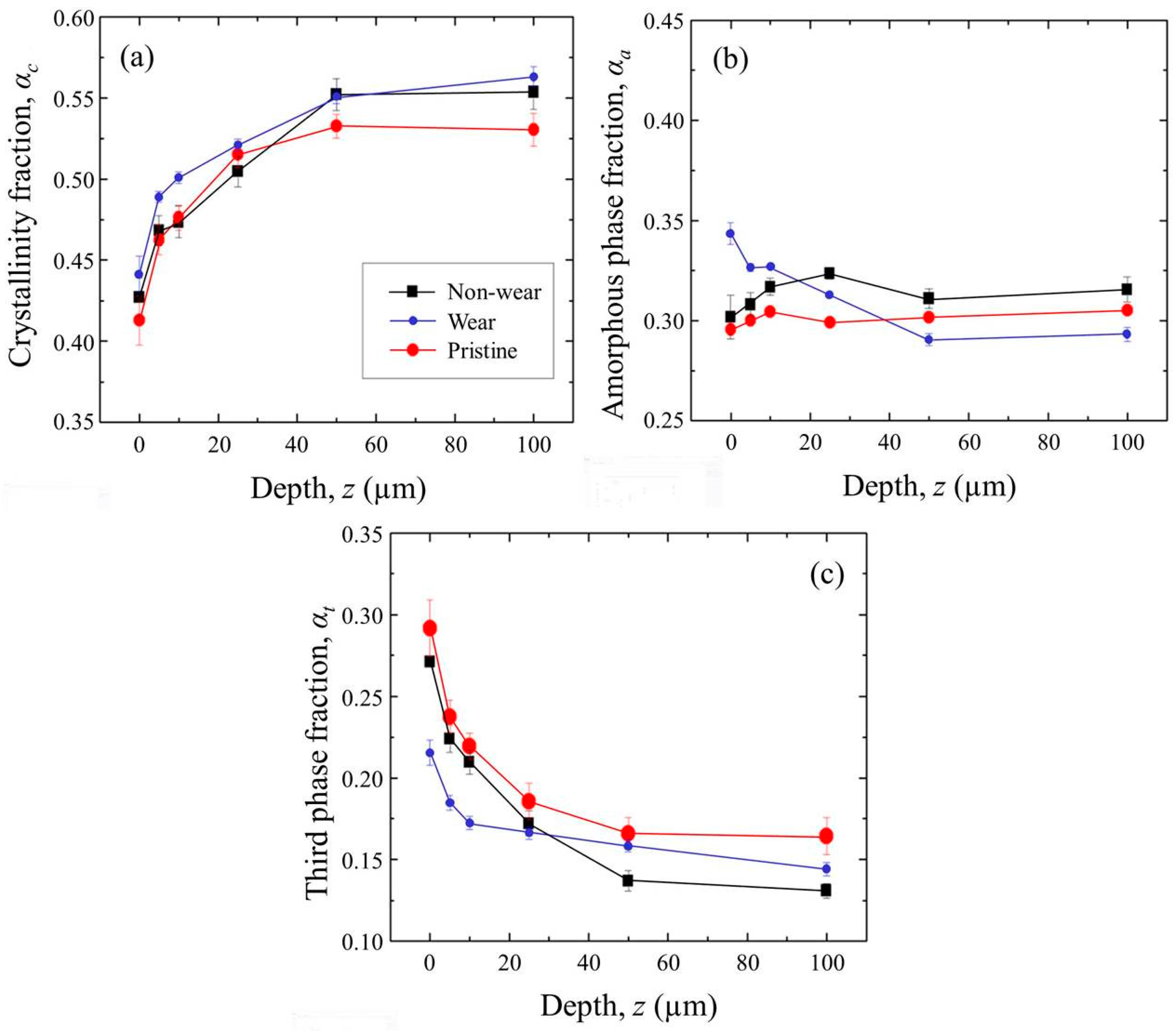

3.2. SWM Ceramic-on-Polyethylene Hip Simulator Study

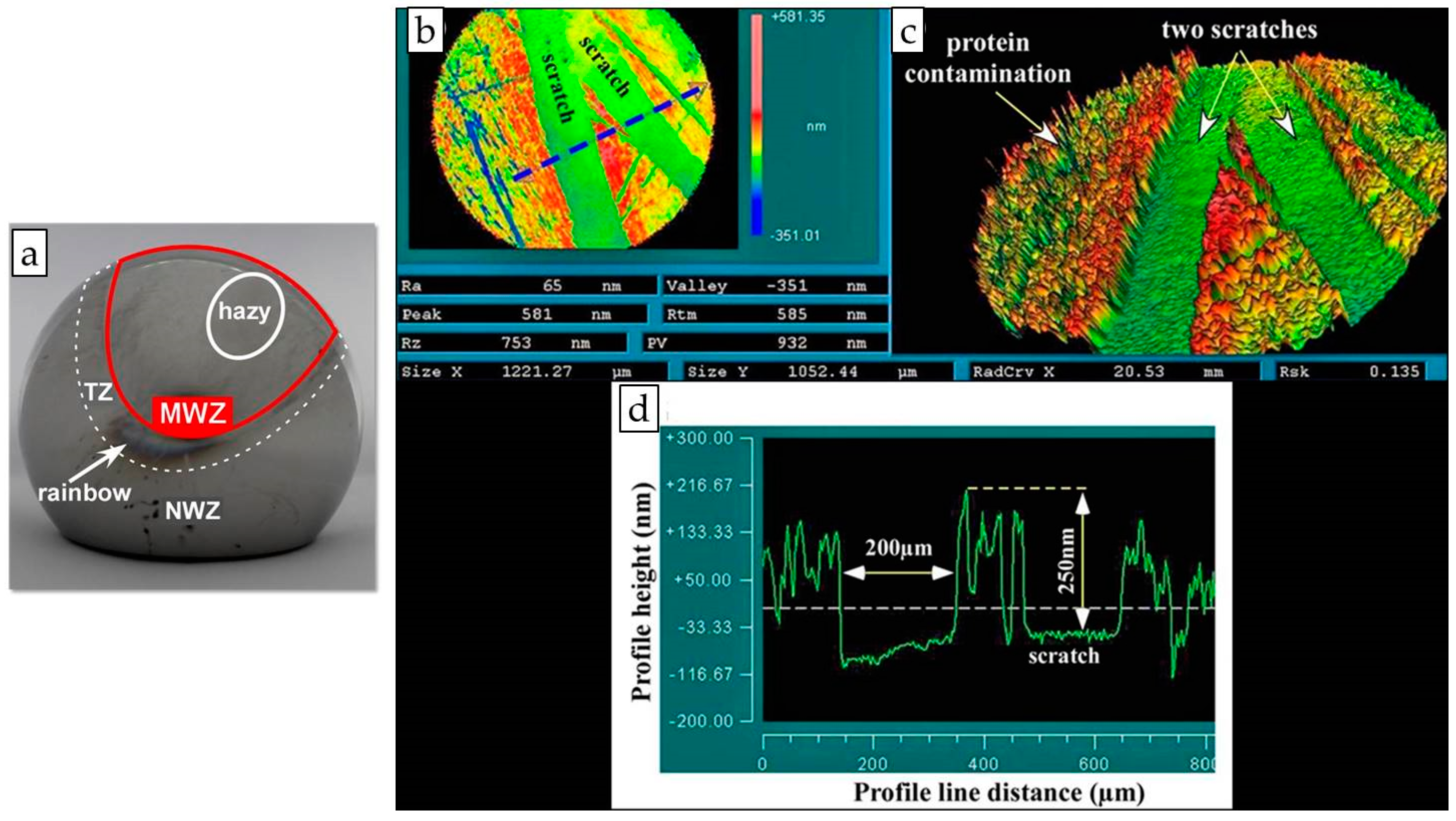

3.3. SWM Ceramic-on-Ceramic Hip Simulator Study

- (1)

- High friction is initially observed during a transient run-in period; but this dramatically declines with increasing sliding distance due to formation of a coherent tribochemical lubricating film.

- (2)

- Reduced friction is maintained by continuous motion at lower loads and higher speeds. These conditions aid in retention of the tribochemical film within the wear track. However, slight perturbations of the wear couple (i.e., displacement of the bearing out of the normal wear track) result in an immediate increase in friction, returning the bearing to its transient run-in period. Reformation of the tribochemical film is necessary to reduce friction to prior low levels.

- (3)

- Conversely, high or oscillating friction, and stick-slip behavior are observed for high-loads (above a critical value), slow speeds, and start-stop cycling, as the bearing transitions from hydrodynamic to boundary film lubrication and back again; and,

- (4)

- The reaction products that form the tribochemical film are soluble and potentially resorbable.

4. Summary and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Taylor, R.M.; Bernero, J.P.; Patel, A.A.; Brodke, D.S.; Khandkar, A.C. Silicon Nitride—A New Material for Spinal Implants. J. Bone Jt. Surg. Br. 2010, 92, 133. [Google Scholar]

- Bal, B.S.; Rahaman, M. The Rationale for Silicon Nitride Bearings in Orthopaedic Applications. In Advances in Ceramics—Electric and Magnetic Ceramics, Bioceramics, Ceramics and Environment; INTECH Open Access Publisher: Rijeka, Croatia, 2011; pp. 421–432. [Google Scholar]

- Bal, B.S.; Rahaman, M.N. Orthopedic Applications of Silicon Nitride Ceramics. Acta Biomater. 2012, 8, 2889–2898. [Google Scholar] [CrossRef] [PubMed]

- Bal, B.S.; Khandkar, A.; Lakshminarayanan, R.; Clarke, I.; Hofmann, A.A.; Rahaman, M.N. Testing of Silicon Nitride Ceramic Bearings for Total Hip Arthroplasty. J. Biomed. Mater. Res. Part B Appl. Biomater. 2008, 87, 447–454. [Google Scholar] [CrossRef] [PubMed]

- Bal, B.S.; Khandkar, A.; Lakshminarayanan, R.; Clarke, I.; Hofmann, A.A.; Rahaman, M.N. Fabrication and Testing of Silicon Nitride Bearings in Total Hip Arthroplasty. J. Arthroplast. 2009, 24, 110–116. [Google Scholar] [CrossRef] [PubMed]

- Neumann, A.; Reske, T.; Held, M.; Jahnke, K.; Ragoss, C.; Maier, H.R. Comparative Investigation of the Biocompatibility of Various Silicon Nitride Ceramic Qualities In Vitro. J. Mater. Sci. Mater. Med. 2004, 15, 1135–1140. [Google Scholar] [CrossRef] [PubMed]

- Gorth, D.J.; Puckett, S.; Ercan, B.; Webster, T.J.; Rahaman, M.; Bal, B.S. Decreased Bacteria Activity on Si3N4 Surfaces Compared with PEEK or Titanium. Int. J. Nanomed. 2012, 7, 4829–4840. [Google Scholar]

- Webster, T.J.; Patel, A.A.; Rahaman, M.N.; Bal, B.S. Anti-Infective and Osteointegration Properties of Silicon Nitride, Poly (Ether Ether Ketone), and Titanium Implants. Acta Biomater. 2012, 8, 4447–4454. [Google Scholar] [CrossRef] [PubMed]

- Fischer, T.E.; Tomizawa, H. Interaction of Tribochemistry and Microfracture in the Friction and Wear of Silicon Nitride. Wear 1985, 105, 29–45. [Google Scholar] [CrossRef]

- Tomizawa, H.; Fischer, T.E. Friction and Wear of Silicon Nitride and Silicon Carbide in Water: Hydrodynamic Lubrication at Low Sliding Speed Obtained by Tribochemical Wear. ASLE Trans. 1987, 30, 41–46. [Google Scholar] [CrossRef]

- Ishigaki, H.; Nagata, R.; Iwasa, M. Effect of Adsorbed Water on Friction of Hot-Pressed Silicon Nitride and Silicon Carbide at Slow Speed Sliding. Wear 1988, 121, 107–116. [Google Scholar] [CrossRef]

- Sasaki, S. The Effects of the Surrounding Atmosphere on the Friction and Wear of Alumina, Zirconia, Silicon Carbide and Silicon Nitride. Wear 1989, 134, 185–200. [Google Scholar] [CrossRef]

- Saito, T.; Imada, Y.; Honda, F. An Analytical Observation of the Tribochemical Reaction of Silicon Nitride Sliding with Low Friction in Aqueous Solutions. Wear 1997, 205, 153–159. [Google Scholar] [CrossRef]

- Zhou, Y.S.; Ikeuchi, K.; Ohashi, M. Comparison of the Friction Properties of Four Ceramic Materials for Joint Replacements. Wear 1997, 210, 171–177. [Google Scholar] [CrossRef]

- Xu, J.; Kato, K. Formation of Tribochemical Layer of Ceramics Sliding in Water and its Role for Low Friction. Wear 2000, 245, 61–75. [Google Scholar] [CrossRef]

- Satoh, T.; Sakaguchi, S.; Hirao, K.; Toriyama, M.; Kanzaki, S. Influence of Aluminum-Oxygen-Yttrium Solid Solution on the Aqueous Tribological Behavior of Silicon Nitride. J. Am. Ceram. Soc. 2001, 84, 462–464. [Google Scholar] [CrossRef]

- Chen, M.; Kato, K.; Adachi, K. The Comparisons of Sliding Speed and Normal Load Effect on Friction Coefficients of Self-Mated Si3N4 and SiC Under Water Lubrication. Tribol. Int. 2002, 35, 129–135. [Google Scholar] [CrossRef]

- Maw, W.; Stevens, F.; Langford, S.C.; Dickinson, J.T. Single Asperity Tribochemical Wear of Silicon Nitride Studied by Atomic Force Microscopy. J. Appl. Phys. 2002, 92, 5103–5109. [Google Scholar] [CrossRef]

- Jahanmir, S. Wear Transitions and Tribochemical Reactions in Ceramics. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2002, 216, 371–385. [Google Scholar] [CrossRef]

- Jahanmir, S.; Ozmen, Y.; Ives, L.K. Water Lubrication of Silicon Nitride in Sliding. Tribol. Lett. 2004, 17, 409–417. [Google Scholar] [CrossRef]

- Nakamura, N.; Hirao, K.; Yamauchi, Y. Tribological Properties of Silicon Nitride Ceramics Modified by Ion Implantation. J. Eur. Ceram. Soc. 2004, 24, 219–224. [Google Scholar] [CrossRef]

- Amutha Rani, D.; Yoshizawa, Y.; Jones, M.I.; Hyuga, H.; Hirao, K.; Yamauchi, Y. Comparison of Tribological Behavior Between α-Sialon/Si3N4 and Si3N4/Si3N4 Sliding Pairs in Water Lubrication. J. Am. Ceram. Soc. 2005, 88, 1655–1658. [Google Scholar] [CrossRef]

- Tang, Q.; Chen, J.; Liu, L. Tribological Behaviours of Carbon Fibre Reinforced PEEK Sliding on Silicon Nitride Lubricated with Water. Wear 2010, 269, 541–546. [Google Scholar] [CrossRef]

- Ferreira, V.; Yoshimura, H.N.; Sinatora, A. Ultra-Low Friction Coefficient in Alumina–Silicon Nitride Pair Lubricated with Water. Wear 2012, 296, 656–659. [Google Scholar] [CrossRef]

- Gee, M.G. Wear Testing and Ceramics. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 1994, 208, 153–166. [Google Scholar] [CrossRef]

- Dante, R.C.; Kajdas, C.K. A Review and a Fundamental Theory of Silicon Nitride Tribochemistry. Wear 2012, 288, 27–38. [Google Scholar] [CrossRef]

- Scholes, S.C.; Unsworth, A.; Goldsmith, A.A.J. A Frictional Study of Total Hip Joint Replacements. Phys. Med. Biol. 2000, 45, 3721–3735. [Google Scholar] [CrossRef] [PubMed]

- Cho, H.J.; Wei, W.J.; Kao, H.C.; Cheng, C.K. Wear Behavior of UHMWPE Sliding on Artificial Hip Arthroplasty Materials. Mater. Chem. Phys. 2004, 88, 9–16. [Google Scholar] [CrossRef]

- Xiong, D.; Ge, S. Friction and Wear Properties of UHMWPE/Al2O3 Ceramic under Different Lubricating Conditions. Wear 2001, 250, 242–245. [Google Scholar] [CrossRef]

- Sawyer, W.G.; Argibay, N.; Burris, D.L.; Krick, B.A. Mechanistic Studies in Friction and Wear of Bulk Materials. Annu. Rev. Mater. Res. 2013, 44, 395–427. [Google Scholar] [CrossRef]

- McKellop, H.; Clarke, I.; Markolf, K.; Amstutz, H. Friction and Wear Properties of Polymer, Metal, and Ceramic Prosthetic Joint Materials Evaluated on a Multichannel Screening Device. J. Biomed. Mater. Res. 1981, 15, 619–653. [Google Scholar] [CrossRef] [PubMed]

- Olofsson, J.; Grehk, T.; Berlind, T. Evaluation of Silicon Nitride as a Wear Resistant and Resorbable Alternative for Total Hip Joint Replacement. Biomatter 2012, 2, 94–102. [Google Scholar] [CrossRef] [PubMed]

- Mazzocchi, M.; Bellosi, A. On the Possibility of Silicon Nitride as a Ceramic for Structural Orthopaedic Implants. Part I: Processing, Microstructure, Mechanical Properties, Cytotoxicity. J. Mater. Sci. Mater. Med. 2008, 19, 2881–2887. [Google Scholar] [CrossRef] [PubMed]

- Mazzocchi, M.; Gardini, D.; Traverso, P.L.; Faga, M.G.; Bellosi, A. On the Possibility of Silicon Nitride as a Ceramic for Structural Orthopaedic Implants. Part II: Chemical Stability and Wear Resistance in Body Environment. J. Mater. Sci. Mater. Med. 2008, 19, 2889–2901. [Google Scholar] [CrossRef] [PubMed]

- Affatato, S.; Spinelli, M.; Zavalloni, M.; Mazzega-Fabbro, C.; Viceconti, M. Tribology and Total Hip Joint Replacement: Current Concepts in Mechanical Simulation. Med. Eng. Phys. 2008, 30, 1305–1317. [Google Scholar] [CrossRef] [PubMed]

- Kaddick, C.; Wimmer, M.A. Hip Simulator Wear Testing According to the Newly Introduced Standard ISO 14242. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2001, 215, 429–442. [Google Scholar] [CrossRef]

- McEntire, B.J.; Lakshminarayanan, R.; Thirugnanasambandam, P.; Seitz-Sampson, J.; Bock, R.; O’Brien, D. Processing and Characterization of Silicon Nitride Bioceramics. Bioceram. Dev. Appl. 2016, 6, 1000093. [Google Scholar] [CrossRef]

- Taddei, P.; Affatato, S.; Fagnano, C.; Bordini, B.; Tinti, A.; Toni, A. Vibrational Spectroscopy of Ultra-High Molecular Weight Polyethylene Hip Prostheses: Influence of the Sterilisation Method on Crystallinity and Surface Oxidation. J. Mol. Struct. 2002, 613, 121–129. [Google Scholar] [CrossRef]

- Mutter, R.; Stille, W.; Strobl, G. Transition Regions and Surface Melting in Partially Crystalline Polyethylene: A Raman Spectroscopic Study. J. Polym. Sci. Part B Polym. Phys. 1993, 31, 99–105. [Google Scholar] [CrossRef]

- Strobl, G.R.; Hagedorn, W. Raman Spectroscopic Method for Determining the Crystallinity of Polyethylene. J. Polym. Sci. Polym. Phys. Ed. 1978, 16, 1181–1193. [Google Scholar] [CrossRef]

- Rull, F.; Prieto, A.C.; Casado, J.M.; Sobron, F.; Edwards, H.G.M. Estimation of Crystallinity in Polyethylene by Raman Spectroscopy. J. Raman Spectrosc. 1993, 24, 545–550. [Google Scholar] [CrossRef]

- Glotin, M.; Mandelkern, L. A Raman Spectroscopic Study of the Morphological Structure of the Polyethylenes. Colloid Polym. Sci. 1982, 260, 182–192. [Google Scholar] [CrossRef]

- Naylor, C.C.; Meier, R.J.; Kip, B.J.; Williams, K.P.; Mason, S.M.; Conroy, N.; Gerrard, D.L. Raman Spectroscopy Employed for the Determination of the Intermediate Phase in Polyethylene. Macromolecules 1995, 28, 2969–2978. [Google Scholar] [CrossRef]

- Taddei, P.; Di Foggia, M.; Affatato, S. Raman Characterisation of Conventional and Cross-Linked Polyethylene in Acetabular Cups Run on a Hip Joint Simulator. J. Raman Spectrosc. 2011, 42, 1344–1352. [Google Scholar] [CrossRef]

- McKellop, H.; Lu, B.; Benya, P.; Park, S.H. Friction, Lubrication and Wear of Cobalt-Chromium Alumina and Zirconia Hip Prostheses Compared on a Joint Simulator. In Transactions of the Orthopaedic Research Society; Orthopaedic Research Society: Washington, DC, USA, 1992. [Google Scholar]

- Standard Specification for High-Purity Dense Aluminum Oxide for Medical Applications; ASTM F603-00; Document Center Inc.: Belmont, CA, USA, 2000.

- Grupp, T.M.; Holderied, M.; Mulliez, M.A.; Streller, R.; Jäger, M.; Blömer, W.; Utzschneider, S. Biotribology of a Vitamin E-Stabilized Polyethylene for Hip Arthroplasty—Influence of Artificial Ageing and Third-Body Particles on Wear. Acta Biomater. 2014, 10, 3068–3078. [Google Scholar] [CrossRef] [PubMed]

- Affatato, S.; Bracco, P.; Costa, L.; Villa, T.; Quaglini, V.; Toni, A. In Vitro Wear Performance of Standard, Crosslinked, and Vitamin-E-Blended UHMWPE. J. Biomed. Mater. Res. A 2012, 100, 554–560. [Google Scholar] [CrossRef] [PubMed]

- Galvin, A.L.; Jennings, L.M.; Tipper, J.L.; Ingham, E.; Fisher, J. Wear and Creep of Highly Crosslinked Polyethylene against Cobalt Chrome and Ceramic Femoral Heads. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2010, 224, 1175–1183. [Google Scholar] [CrossRef]

- Al-Hajjar, M.; Jennings, L.M.; Begand, S.; Oberbach, T.; Delfosse, D.; Fisher, J. Wear of Novel Ceramic-on-Ceramic Bearings Under Adverse and Clinically Relevant Hip Simulator Conditions. J. Biomed. Mater. Res. Part B Appl. Biomater. 2013, 101, 1456–1462. [Google Scholar] [CrossRef] [PubMed]

- Johnson, A.J.; Loving, L.; Herrera, L.; Delanois, R.E.; Wang, A.; Mont, M.A. Short-Term Wear Evaluation of Thin Acetabular Liners on 36-mm Femoral Heads. Clin. Orthop. Relat. Res. 2014, 472, 624–629. [Google Scholar] [CrossRef] [PubMed]

- Halma, J.J.; Señaris, J.; Delfosse, D.; Lerf, R.; Oberbach, T.; van Gaalen, S.M.; de Gast, A. Edge Loading Does Not Increase Wear Rates of Ceramic-on-Ceramic and Metal-on-Polyethylene Articulations. J. Biomed. Mater. Res. Part B Appl. Biomater. 2014, 102, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Greer, K.; Chan, F.; Liao, P.; McNulty, D.; King, R. Wear of Crosslinked UHMWPE as a Function of Irradiation Dose and Crosslink Density. In Proceedings of the 48th Annual Meeting of the Orthopaedic Research Society, Dallas, TX, USA, 10–13 February 2002; Paper No. 0052. Orthopaedic Research Society Press: Rosemont, IL, USA, 2002; Volume 24. [Google Scholar]

- Endo, M.; Tipper, J.L.; Barton, D.C.; Stone, M.H.; Ingham, E.; Fisher, J. Comparison of Wear, Wear Debris and Functional Biological Activity of Moderately Crosslinked and Non-Crosslinked Polyethylenes in Hip Prostheses. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2002, 216, 111–122. [Google Scholar] [CrossRef]

- Galvin, A.L.; Tipper, J.L.; Jennings, L.M.; Stone, M.H.; Jin, Z.M.; Ingham, E.; Fisher, J. Wear and Biological Activity of Highly Crosslinked Polyethylene in the Hip under Low Serum Protein Concentrations. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2007, 221, 1–10. [Google Scholar] [CrossRef]

- Smith, S.L.; Unsworth, A. A Comparison between Gravimetric and Volumetric Techniques of Wear Measurement of UHMWPE Acetabular Cups against Zirconia and Cobalt-Chromium-Molybdenum Femoral Heads in a Hip Simulator. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 1999, 213, 475–483. [Google Scholar] [CrossRef]

- Saikko, V.; Ahlroos, T.; Calonius, O.; Kera, J. Wear Simulation of Total Hip Prostheses with Polyethylene against CoCr, Alumina and Diamond-Like Carbon. Biomaterials 2001, 22, 1507–1514. [Google Scholar] [CrossRef]

- Barbour, P.S.M.; Stone, M.H.; Fisher, J. A Hip Joint Simulator Study Using Simplified Loading and Motion Cycles Generating Physiological Wear Paths and Rates. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 1999, 213, 455–467. [Google Scholar] [CrossRef]

- Barbour, P.S.; Stone, M.H.; Fisher, J. A Hip Joint Simulator Study Using New and Physiologically Scratched Femoral Heads with Ultra-High Molecular Weight Polyethylene Acetabular Cups. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2000, 214, 569–576. [Google Scholar] [CrossRef]

- Kaddick, C.; Pfaff, H.G. Results of Hip Simulator Testing with Various Wear Couples. In Bioceramics in Joint Arthroplasty, Proceedings of the 7th International BIOLOX® Symposium, Stuttgard, Germany, 15–16 March 2002; Garino, J.P., Willmann, G., Eds.; Georg Thieme Verlag Publisher: Stuttgart, Germany, 2002; pp. 16–20. [Google Scholar]

- Okazaki, Y. Effect of Head Size on Wear Properties of Metal-on-Metal Bearings of Hip Prostheses, and Comparison with Wear Properties of Metal-on-Polyethylene Bearings using Hip Simulator. J. Mech. Behav. Biomed. Mater. 2014, 31, 152–163. [Google Scholar] [CrossRef] [PubMed]

- Bowsher, J.G.; Clarke, I.C. Thermal Conductivity of Femoral Ball Strongly Influenced UHMWPE Wear in a Hip Simulator. In Proceedings of the Transactions of the 53rd Annual Meeting of the Orthopaedic Research Society, San Diego, CA, USA, 11–14 February 2007; Orthopaedic Research Society: San Diego, CA, USA, 2007; p. 278. [Google Scholar]

- Zietz, C.; Fabry, C.; Middelborg, L.; Fulda, G.; Mittelmeier, W.; Bader, R. Wear Testing and Particle Characterisation of Sequentially Crosslinked Polyethylene Acetabular Liners using Different Femoral Head Sizes. J. Mater. Sci. Mater. Med. 2013, 24, 2057–2065. [Google Scholar] [CrossRef] [PubMed]

- Masson, B.; Pandorf, T. Wear Behavior of AMC Ceramics on PE in Hip Prostheses. J. Bone Jt. Surg. Br. 2011, 93, 221. [Google Scholar]

- Lee, R.; Essner, A.; Wang, A.; Jaffe, W.L. Scratch and Wear Performance of Prosthetic Femoral Head Components against Crosslinked UHMWPE Sockets. Wear 2009, 267, 1915–1921. [Google Scholar] [CrossRef]

- Liao, Y.-S.; Greer, K.; Alberts, A. Effect of Head Material and Roughness on the Wear of 7.5 MRad Crosslinked-Remelted UHMWPE Acetabular Inserts. In Proceedings of the 54th Annual Meeting of the Orthopaedic Research Society, San Francisco, CA, USA, 2–5 March 2008; Orthopaedic Research Society Press: Rosemont, IL, USA, 2008; p. 1901. [Google Scholar]

- Bigsby, R.J.A.; Hardaker, C.S.; Fisher, J. Wear of Ultra-High Molecular Weight Polyethylene Acetabular Cups in a Physiological Hip Joint Simulator in the Anatomical Position using Bovine Serum as a Lubricant. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 1997, 211, 265–269. [Google Scholar] [CrossRef]

- Williams, S.; Butterfield, M.; Stewart, T.; Ingham, E.; Stone, M.; Fisher, J. Wear and Deformation of Ceramic-on-Polyethylene Total Hip Replacements with Joint Laxity and Swing Phase Microseparation. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2003, 217, 147–153. [Google Scholar] [CrossRef]

- Roy, M.E.; Whiteside, L.A.; Magill, M.E.; Katerberg, B.J. Reduced Wear of Cross-Linked UHMWPE Using Magnesia-Stabilized Zirconia Femoral Heads in a Hip Simulator. Clin. Orthop. Relat. Res. 2011, 469, 2337–2345. [Google Scholar] [CrossRef] [PubMed]

- Puppulin, L.; Kumakura, T.; Yamamoto, K.; Pezzotti, G. Structural Profile of Ultra-High Molecular Weight Polyethylene in Acetabular Cups Worn on Hip Simulators Characterized by Confocal Raman Spectroscopy. J. Orthop. Res. 2011, 29, 893–899. [Google Scholar] [CrossRef] [PubMed]

- Oral, E.; Christensen, S.D.; Malhi, A.S.; Wannomae, K.K.; Muratoglu, O.K. Wear Resistance and Mechanical Properties of Highly Cross-Linked, Ultrahigh-Molecular Weight Polyethylene Doped with Vitamin E. J. Arthroplast. 2006, 21, 580–591. [Google Scholar] [CrossRef] [PubMed]

- Affatato, S.; Frigo, M.; Toni, A. An In Vitro Investigation of Diamond-Like Carbon as a Femoral Head Coating. J. Biomed. Baterials Res. 2000, 53, 221–226. [Google Scholar] [CrossRef]

- Billi, F.; Benya, P.; Kavanaugh, A.; Adams, J.; McKellop, H.; Ebramzadeh, E. An Accurate and Extremely Sensitive Method to Separate, Display, and Characterize Wear Debris: Part 2: Metal and Ceramic Particles. Clin. Orthop. Relat. Res. 2012, 470, 339–350. [Google Scholar] [CrossRef] [PubMed]

- Davidson, J.A.; Poggie, R.A.; Mishra, A.K. Abrasive Wear of Ceramic, Metal, and UHMWPE Bearing Surfaces from Third-Body Bone, PMMA Bone Cement, and Titanium Debris. Biomed. Mater. Eng. 1994, 4, 213–229. [Google Scholar] [PubMed]

- Garvin, K.L.; Hartman, C.W.; Mangla, J.; Murdoch, N.; Martell, J.M. Wear Analysis in THA Utilizing Oxidized Zirconium and Crosslinked Polyethylene. Clin. Orthop. Relat. Res. 2009, 467, 141–145. [Google Scholar] [CrossRef] [PubMed]

- Saikko, V.; Ahlroos, T. Type of Motion and Lubricant in Wear Simulation of Polyethylene Acetabular Cup. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 1999, 213, 301–310. [Google Scholar] [CrossRef]

- Affatato, S.; Bordini, B.; Fagnano, C.; Taddei, P.; Tinti, A.; Toni, A. Effects of the Sterilisation Method on the Wear of UHMWPE Acetabular Cups Tested in a Hip Joint Simulator. Biomaterials 2002, 23, 1439–1446. [Google Scholar] [CrossRef]

- Smith, S.L.; Unsworth, A. A Five-Station Hip Joint Simulator. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2001, 215, 61–64. [Google Scholar] [CrossRef]

- Fisher, J.; Galvin, A.; Tipper, J.; Stewart, T.; Stone, M.; Ingham, E. Comparison of the Functional Biological Activity and Osteolytic Potential of Ceramic on Ceramic and Cross Linked Polyethylene Bearings in the Hip. In Bioceramics and Alternative Bearings in Joint Arthroplasty, Proceedings of the 10th BIOLOX® Symposium, Washington, DC, USA, 10–11 June 2005; D’Antonio, J.A., Dietrich, M., Eds.; Steinkopff Verlag: Darmstadt, Germany, 2005; pp. 21–24. [Google Scholar]

- Jedenmalm, A.; Affatato, S.; Taddei, P.; Leardini, W.; Gedde, U.W.; Fagnano, C.; Viceconti, M. Effect of Head Surface Roughness and Sterilization on Wear of UHMWPE Acetabular Cups. J. Biomed. Mater. Res. A 2009, 90, 1032–1042. [Google Scholar] [CrossRef] [PubMed]

- Smith, S.L.; Unsworth, A. Simplified Motion and Loading Compared to Physiological Motion and Loading in a Hip Joint Simulator. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2000, 214, 233–238. [Google Scholar] [CrossRef]

- Affatato, S.; Zavalloni, M.; Spinelli, M.; Costa, L.; Bracco, P.; Viceconti, M. Long-Term In Vitro Wear Performance of an Innovative Thermo-Compressed Cross-Linked Polyethylene. Tribol. Int. 2010, 43, 22–28. [Google Scholar] [CrossRef]

- Clarke, I.C.; Gustafson, A.; Jung, H.; Fujisawa, A. Hip-Simulator Ranking of Polyethylene Wear: Comparisons between Ceramic Heads of Different Sizes. Acta Orthop. Scand. 1996, 67, 128–132. [Google Scholar] [CrossRef] [PubMed]

- Ezzet, K.A.; Hermida, J.C.; Steklov, N.; D’Lima, D.D. Wear of Polyethylene against Oxidized Zirconium Femoral Components. Effect of Aggressive Kinematic Conditions and Malalignment in Total Knee Arthroplasty. J. Arthroplast. 2012, 27, 116–121. [Google Scholar] [CrossRef] [PubMed]

- Takahashi, Y.; Masaoka, T.; Yamamoto, K.; Shishido, T.; Tateiwa, T.; Kubo, K.; Pezzotti, G. Vitamin-E Blended and Infused Highly Cross-Linked Polyethylene for Total Hip Arthroplasty: A Comparison of Three-Dimensional Crystalline Morphology and Strain Recovery Behavior. J. Mech. Behav. Biomed. Mater. 2014, 36, 59–70. [Google Scholar] [CrossRef]

- Affatato, S.; Freccero, N.; Taddei, P. The Biomaterials Challenge: A Comparison of Polyethylene Wear Using a Hip Joint Simulator. J. Mech. Behav. Biomed. Mater. 2016, 53, 40–48. [Google Scholar] [CrossRef]

- Tipper, J.L.; Galvin, A.L.; Williams, S.; McEwen, H.M.J.; Stone, M.H.; Ingham, E.; Fisher, J. Isolation and Characterization of UHMWPE Wear Particles Down to Ten Nanometers in Size from In Vitro Hip and Knee Joint Simulators. J. Biomed. Mater. Res. 2006, 78A, 473–480. [Google Scholar]

- Shen, F.-W.; Lu, Z.; McKellop, H.A. Wear versus Thickness and other Features of 5-Mrad Crosslinked UHMWPE Acetabular Liners. Clin. Orthop. Relat. Res. 2011, 469, 395–404. [Google Scholar] [CrossRef]

- Sorimachi, T.; Clarke, I.C.; Williams, P.A.; Gustafson, A.; Yamamoto, K. Third-Body Abrasive Wear Challenge of 32 mm Conventional and 44 mm Highly Crosslinked Polyethylene Liners in a Hip Simulator Model. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2009, 223, 607–623. [Google Scholar] [CrossRef]

- Herrera, L.; Lee, R.; Essner, A.; Longaray, J.; Wang, A.; Dumbleton, J.H.; Lovell, T. Hip Simulator Evaluation of the Effect of Femoral Head Size and Liner Thickness on the Wear of Sequentially Crosslinked Acetabular Liners. In Proceedings of the 53rd Annual Meeting of the Orthopaedic Research Society, San Diego, CA, USA, 11–14 February 2007; Orthopaedic Research Society Press: Rosemont, IL, USA, 2007; p. 181. [Google Scholar]

- Kubo, K.; Clarke, I.C.; Sorimachi, T.; Williams, P.A.; Donaldson, T.K.; Yamamoto, K. Aggressive 3rd-Body Wear Challenge to Highly Crosslinked Polyethylene: A Hip Simulator Model. Wear 2009, 267, 734–742. [Google Scholar] [CrossRef]

- Galvin, A.; Brockett, C.; Williams, S. Comparison of Wear of Ultra-High Molecular Weight Polyethylene Acetabular Cups against Surface-Engineered Femoral Heads. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2008, 222, 1073–1080. [Google Scholar] [CrossRef]

- De Villiers, D.; Traynor, A.; Collins, S.N.; Banfield, S.; Housden, J.; Shelton, J.C. Chromium Nitride Coating for Large Diameter Metal-on-Polyethylene Hip Bearings Under Extreme Adverse Hip Simulator Conditions. Wear 2015, 328–329, 363–368. [Google Scholar] [CrossRef]

- Affatato, S.; Zavalloni, M.; Taddei, P.; Di Foggia, M.; Fagnano, C.; Viceconti, M. Comparative Study on the Wear Behaviour of Different Conventional and Cross-Linked Polyethylenes for Total Hip Replacemen. Tribol. Int. 2008, 41, 813–822. [Google Scholar] [CrossRef]

- Estok, D.M.; Burroughs, B.R.; Muratoglu, O.K.; Harris, W.H. Comparison of Hip Simulator Wear of 2 Different Highly Cross-Linked Ultra High Molecular Weight Polyethylene Acetabular Components Using both 32- and 38-mm Femoral Heads. J. Arthroplast. 2007, 22, 581–589. [Google Scholar] [CrossRef]

- Shishido, T.; Clarke, I.C.; Williams, P.; Boehler, M.; Asano, T.; Shoji, H.; Masaoka, T.; Yamamoto, K.; Imakiire, A. Clinical and Simulator Wear Study of Alumina Ceramic THR to 17 Years and Beyond. J. Biomed. Mater. Res. B Appl. Biomater. 2003, 67, 638–647. [Google Scholar] [CrossRef] [PubMed]

- Oonishi, H.; Clarke, I.C.; Williams, P.A.; Shishido, T.; Gustafson, A. Characterization of Steady-State Wear in All-Alumina THR to 20 MC. Key Eng. Mater. 2001, 218–220, 587–590. [Google Scholar] [CrossRef]

- Clarke, I.C.; Lazennec, J.Y.; Smith, E.J.; Sugano, N.; McEntire, B.J.; Pezzotti, G. Ceramic-on-Ceramic Bearings: Simulator Wear Compared to Clinical Retrieval Data. In Material for Total Joint Arthroplasty—Biotribology of Potential Bearings; Sonntag, R., Kretzer, J.P., Eds.; Imperial College Press: London, UK, 2015; pp. 85–131. [Google Scholar]

- Clarke, I.C.; Green, D.D.; Williams, P.S.; Kubo, K.; Pezzotti, G.; Lombardi, A.; Turnbull, A.; Donaldson, T.K. Hip-Simulator Wear Studies of an Alumina-Matrix Composite (AMC) Ceramic Compared to Retrieval Studies of AMC Balls with 1–7 Years Follow-Up. Wear 2009, 267, 702–709. [Google Scholar] [CrossRef]

- Bracco, P.; Brach del Prever, E.M.; Cannas, M.; Luda, M.P.; Costa, L. Oxidation Behaviour in Prosthetic UHMWPE Components Sterilised with High Energy Radiation in a Low-Oxygen Environment. Polym. Degrad. Stab. 2006, 91, 2030–2038. [Google Scholar] [CrossRef]

- Bracco, P.; Brunella, V.; Luda, M.P.; Brach del Prever, E.M.; Zanetti, M.; Costa, L. Oxidation Behaviour in Prosthetic UHMWPE Components Sterilised with High-Energy Radiation in the Presence of Oxygen. Polym. Degrad. Stab. 2006, 91, 3057–3064. [Google Scholar] [CrossRef]

- Costa, L.; Luda, M.P.; Trossarelli, L. Ultra High Molecular Weight Polyethylene—II. Thermal- and Photo-Oxidation. Polym. Degrad. Stab. 1997, 58, 41–54. [Google Scholar] [CrossRef]

- Wannomae, K.K.; Bhattacharyya, S.; Freiberg, A.; Estok, D.; Harris, W.H.; Muratoglu, O. In Vivo Oxidation of Retrieved Cross-Linked Ultra-High-Molecular-Weight Polyethylene Acetabular Components with Residual Free Radicals. J. Arthroplast. 2006, 21, 1005–1011. [Google Scholar] [CrossRef] [PubMed]

- Bhateja, S.K.; Andrews, E.H.; Yarbrough, S.M. Radiation Induced Crystallinity Changes in Linear Polyethylenes: Long Term Aging Effects. Polym. J. 1989, 21, 739–750. [Google Scholar] [CrossRef]

- Premnath, V.; Harris, W.H.; Jasty, M.; Merrill, E.W. Gamma Sterilization of UHMWPE Articular Implants: An Analysis of the Oxidation Problem. Biomaterials 1996, 17, 1741–1753. [Google Scholar] [CrossRef]

- Yeom, B.; Yu, Y.-J.; McKellop, H.A.; Salovey, R. Profile of Oxidation in Irradiated Polyethylene. J. Polym. Sci. Part A Polym. Chem. 1998, 36, 329–339. [Google Scholar] [CrossRef]

- Medel, F.J.; Rimnac, C.M.; Kurtz, S.M. On the Assessment of Oxidative and Microstructural Changes after In Vivo Degradation of Historical UHMWPE Knee Components by Means of Vibrational Spectroscopies and Nanoindentation spectroscopies and nanoindentation. J. Biomed. Mater. Res. 2009, 89A, 530–538. [Google Scholar] [CrossRef] [PubMed]

- Blanchet, T.A.; Burroughs, B.R. Numerical Oxidation Model for Gamma Radiation-Sterilized UHMWPE: Consideration of Dose-Depth Profile. J. Biomed. Mater. Res. 2001, 58, 684–693. [Google Scholar] [CrossRef] [PubMed]

- Pezzotti, G. Bioceramics for Hip Joints: The Physical Chemistry Viewpoint. Materials (Basel) 2014, 7, 4367–4410. [Google Scholar] [CrossRef]

- Pezzotti, G.; Bal, B.S.; Casagrande, E.; Sugano, N.; McEntire, B.J.; Zhu, W.; Puppulin, L. On the Molecular Interaction between Ceramic Femoral Heads and Polyethylene Liners in Artificial Hip Joints: II. Molecular Scale Phenomena. 2016; in press. [Google Scholar]

- Liu, F.; Fisher, J.; Jin, Z. Effect of Motion Inputs on the Wear Prediction of Artificial Hip Joints. Tribol. Int. 2013, 63, 105–114. [Google Scholar] [CrossRef] [PubMed]

- Zietz, C.; Fabry, C.; Reinders, J.; Dammer, R.; Kretzer, J.P.; Bader, R.; Sonntag, R. Wear Testing of Total Hip Replacements Under Severe Conditions. Expert Rev. Med. Devices 2015, 12, 393–410. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, A.L.L.; Trigo, F.C.; Martins, F.P.R. Quantitative Evaluation of Parameters Used in Wear Testing Simulators of Total Hip Arthroplasty Components. Wear 2014, 313, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Maskiewicz, V.K.; Williams, P.A.; Prates, S.J.; Bowsher, J.G.; Clarke, I.C. Characterization of Protein Degradation in Serum-Based Lubricants during Simulation Wear Testing of Metal-on-Metal Hip Prostheses. J. Biomed. Mater. Res. Part B Appl. Biomater. 2010, 94B, 429–440. [Google Scholar] [CrossRef] [PubMed]

- Myant, C.; Underwood, R.; Fan, J.; Cann, P.M. Lubrication of Metal-on-Metal Hip Joints: The Effect of Protein Content and Load on Film Formation and Wear. J. Mech. Behav. Biomed. Mater. 2012, 6, 30–40. [Google Scholar] [CrossRef] [PubMed]

- Sun, D.; Wharton, J.A.; Wood, R.J.W. The Effects of Proteins and pH on Tribo-Corrosion Performance of Cast CoCrMo: A Combined Electrochemical and Tribological Study. Tribol. Surfaces Interfaces 2008, 2, 150–160. [Google Scholar] [CrossRef]

- Vrbka, M.; Křupka, I.; Hartl, M.; Návrat, T.; Gallo, J.; Galandáková, A. In Situ Measurements of Thin Films in Bovine Serum Lubricated Contacts Using Optical Interferometry. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2014, 228, 149–158. [Google Scholar] [CrossRef] [PubMed]

- Lu, Z.; McKellop, H. Frictional Heating of Bearing Materials Tested in a Hip Joint Wear Simulator. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 1997, 211, 101–108. [Google Scholar] [CrossRef]

- Good, V.; Clarke, I.C.; Gustafson, A.; Braham, A.; Downs, B.; Sorensen, K.; Anissian, L. Dose Response of Protein Concentration to Wear in PTFE and UHMWPE. In Proceedings of the 45th Annual Meeting of the Orthopaedic Research Society, Anaheim, CA, USA, 1–4 February 1999; Orthopaedic Research Society: Anaheim, CA, USA, 1999; p. 839. [Google Scholar]

- Liao, Y.-S.; Benya, P.D.; McKellop, H.A. Effect of Protein Lubrication on the Wear Properties of Materials for Prosthetic Joints. J. Biomed. Mater. Res. 1999, 48, 465–473. [Google Scholar] [CrossRef]

- Clarke, I.C.; Gustafson, A. Clinical and Hip Simulator Comparisons of Ceramic-on-Polyethylene and Metal-on-Polyethylene Wear. Clin. Orthop. Relat. Res. 2000, 379, 34–40. [Google Scholar] [CrossRef] [PubMed]

- Bell, J.; Tipper, J.L.; Ingham, E.; Stone, M.H.; Fisher, J. The Influence of Phospholipid Concentration in Protein-Containing Lubricants on the Wear of Ultra-High Molecular Weight Polyethylene in Artificial Hip Joints. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2001, 215, 259–263. [Google Scholar] [CrossRef]

- Wang, A.; Essner, A.; Schmidig, G. The Effects of Lubricant Composition on In Vitro Wear Testing of Polymeric Acetabular Components. J. Biomed. Mater. Res. B Appl. Biomater. 2004, 68, 45–52. [Google Scholar] [CrossRef] [PubMed]

- Tsai, S.; Salehi, A.; Aldinger, P.; Hunter, G. Heat Generation and Dissipation Behavior of Various Orthopaedic Bearing Materials. Key Eng. Mater. 2006, 309–311, 1291–1294. [Google Scholar] [CrossRef]

- Guenther, L.E.; Turgeon, T.R.; Bohm, E.R.; Brandt, J.-M. The Biochemical Characteristics of Wear Testing Lubricants Affect Polyethylene Wear in Orthopaedic Pin-on-Disc Testing. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2015, 229, 77–90. [Google Scholar] [CrossRef] [PubMed]

- Myshkin, N.K.; Petrokovets, M.I.; Kovalev, A.V. Tribology of Polymers: Adhesion, Friction, Wear, and Mass-Transfer. Tribol. Int. 2005, 38, 910–921. [Google Scholar] [CrossRef]

- Galetz, M.C.; Seiferth, S.H.; Theile, B.; Glatzel, U. Potential for Adhesive Wear in Friction Couples of UHMWPE Running Against Oxidized Zirconium, Titanium Nitride Coatings, and Cobalt-Chromium Alloys. J. Biomed. Mater. Res. B Appl. Biomater. 2010, 93, 468–475. [Google Scholar] [CrossRef] [PubMed]

- Wang, A.; Essner, A.; Polineni, V.K.; Stark, C.; Dumbleton, J.H. Lubrication and Wear of Ultra-High Molecular Weight Polyethylene in Total Joint Replacements. Tribol. Int. 1998, 31, 17–33. [Google Scholar] [CrossRef]

- Lee, S.K.; Lawn, B.R. Contact Fatigue in Silicon Nitride. J. Am. Ceram. Soc. 1999, 82, 1281–1288. [Google Scholar] [CrossRef]

- Lawn, B.R.; Lee, S.K.; Peterson, I.M.; Wuttiphan, S. Model of Strength Degradation from Hertzian Contact Damage in Tough Ceramics. J. Am. Ceram. Soc. 1998, 81, 1509–1520. [Google Scholar] [CrossRef]

- Lee, K.S.; Jung, Y.; Peterson, I.M.; Lawn, B.R.; Kim, D.; Lee, S.K. Model for Cyclic Fatigue of Quasi-Plastic Ceramics in Contact with Spheres. J. Am. Ceram. Soc. 2000, 83, 2255–2262. [Google Scholar] [CrossRef]

- Zhu, W.; Puppulin, L.; Leto, A.; Takahashi, Y.; Sugano, N.; Pezzotti, G. In Situ Measurements of Local Temperature and Contact Stress Magnitude during Wear of Ceramic-on-Ceramic Hip Joints. J. Mech. Behav. Biomed. Mater. 2014, 31, 68–76. [Google Scholar] [CrossRef] [PubMed]

- Sonntag, R.; Reinders, J.; Rieger, J.S.; Heitzmann, D.W.W.; Kretzer, J.P. Hard-on-Hard Lubrication in the Artificial Hip Under Dynamic Loading Conditions. PLoS ONE 2013, 8, e71622. [Google Scholar] [CrossRef] [PubMed]

- Bergstrom, L.; Pugh, R.J. Interfacial Characterization of Silicon Nitride Powders. J. Am. Ceram. Soc. 1989, 72, 103–109. [Google Scholar] [CrossRef]

- NIST-JANAF Thermochemical Tables. Available online: http://kinetics.nist.gov/janaf/ (accessed on 12 October 2016).

- Mizutani, T.; Nagase, H.; Fujiwara, N.; Ogoshi, H. Silicic Acid Polymerization Catalyzed by Amines and Polyamines. Bull. Chem. Soc. Jpn. 1998, 71, 2017–2022. [Google Scholar] [CrossRef]

- Sui, X.; Wang, B.; Liu, Y.; Wu, H.; Li, Q.; Zhang, Q. Study on Microstructure of Polysilicic Acid in High Salinity. J. Appl. Sci. Eng. Innov. 2014, 1, 44–48. [Google Scholar]

- Zhu, W.; McEntire, B.J.; Enomoto, Y.; Boffelli, M.; Pezzotti, G. Point-Defect Populations as Induced by Cation/Anion Substitution in β-Si3N4 Lattice—A Cathodoluminescence Study. J. Phys. Chem. C 2015, 119, 3279–3287. [Google Scholar] [CrossRef]

- Gates, R.S.; Hsu, M.; Klaus, E.E. Tribochemical Mechanism of Alumina with Water. Tribol. Trans. 2008, 32, 357–363. [Google Scholar] [CrossRef]

- Fischer, T.E.; Zhu, Z.; Kim, H.; Shin, D.S. Genesis and Role of Wear Debris in Sliding Wear of Ceramics. Wear 2000, 245, 53–60. [Google Scholar] [CrossRef]

- Brockett, C.; Williams, S.; Jin, Z.; Isaac, G.; Fisher, J. Friction of Total Hip Replacements with Different Bearings and Loading Conditions. J. Biomed. Mater. Res. Part B Appl. Biomater. 2006, 81B, 508–515. [Google Scholar] [CrossRef] [PubMed]

- Mattei, L.; Di Puccio, F.; Piccigallo, B.; Ciulli, E. Lubrication and Wear Modelling of Artificial Hip Joints: A Review. Tribol. Int. 2011, 44, 532–549. [Google Scholar] [CrossRef]

- Iliev, C. Wear of Water Lubricated Silicon Nitride in Ball on Disc Test. Tribol. Mater. Surfaces Interfaces 2010, 4, 15–25. [Google Scholar] [CrossRef]

- Heshmat, H.; Jahanmir, S. Tribological Behavior of Ceramics at High Sliding Speeds in Steam. Tribol. Lett. 2004, 17, 359–366. [Google Scholar] [CrossRef]

- Cheong, Y.S.; Mukundhan, P.; Du, H.H.; Withrow, S.P. Improved Oxidation Resistance of Silicon Nitride by Aluminum Implantation: I, Kinetics and Oxide Characteristics. J. Am. Ceram. Soc. 2000, 83, 154–160. [Google Scholar] [CrossRef]

- Cheong, Y.S.; Mukundhan, P.; Du, H.H.; Withrow, S.P. Improved Oxidation Resistance of Silicon Nitride by Aluminum Implantation: II, Analysis and Optimization. J. Am. Ceram. Soc. 2000, 83, 161–165. [Google Scholar] [CrossRef]

- Mukundhan, P.; Du, H.H.; Withrow, S.P. Oxidation Studies of Aluminum-Implanted NBD 200 Silicon Nitride. J. Am. Ceram. Soc. 2002, 85, 865–872. [Google Scholar] [CrossRef]

- McEntire, B.; Lakshminarayanan, R. Coated Implants and Related Methods. U.S. Patent 9,051,639, 9 June 2015. [Google Scholar]

- Shankar, S.; Prakash, L.; Kalayarasan, M. Finite Element Analysis of Different Contact Bearing Couples for Human Hip Prosthesis. Int. J. Biomed. Eng. Technol. 2013, 11, 66–80. [Google Scholar] [CrossRef]

- Hodaei, M.; Farhang, K.; Maani, N. A Contact Model for Establishment of Hip Joint Implant Wear Metrics. J. Biomed. Sci. Eng. 2014, 7, 228–242. [Google Scholar] [CrossRef]

- Shankar, S.; Nithyaprakash, R. Wear Prediction on Silicon Nitride Bearing Couple in Human Hip Prosthesis using Finite Element Concepts. Proc. Inst. Mech. Eng. Part J. J. Tribol. 2014, 228, 717–724. [Google Scholar] [CrossRef]

- Glyn-Jones, S.; Thomas, G.E.R.; Garfjeld-Roberts, P.; Gundle, R.; Taylor, A.; McLardy-Smith, P.; Murray, D.W. Highly Crosslinked Polyethylene in Total Hip Arthroplasty Decreases Long-term Wear: A Double-blind Randomized Trial. Clin. Orthop. Relat. Res. 2014, 473, 432–438. [Google Scholar] [CrossRef] [PubMed]

- Sato, T.; Nakashima, Y.; Akiyama, M.; Yamamoto, T.; Mawatari, T.; Itokawa, T.; Ohishi, M.; Motomura, G.; Hirata, M.; Iwamoto, Y. Comparison of Polyethylene Wear between Highly Crosslinked and Annealed UHMWPE and Conventional UHMWPE Against Ceramic Heads in Total Hip Arthroplasty. Key Eng. Mater. 2013, 529–530, 279–284. [Google Scholar] [CrossRef]

- Kim, Y.-H.; Park, J.-W.; Kulkarni, S.S.; Kim, Y.-H. A Randomised Prospective Evaluation of Ceramic-on-Ceramic and Ceramic-on-Highly Cross-Linked Polyethylene Bearings in the Same Patients with Primary Cementless Total Hip Arthroplasty. Int. Orthop. 2013, 37, 2131–2137. [Google Scholar] [CrossRef] [PubMed]

- Topolovec, M.; Milošev, I. A Comparative Study of Four Bearing Couples of the Same Acetabular and Femoral Component: A Mean Follow-Up of 11.5 Years. J. Arthroplast. 2014, 29, 176–180. [Google Scholar] [CrossRef] [PubMed]

- Pezzotti, G.; Yamamoto, K. Artificial Hip Joints: The Biomaterials Challenge. J. Mech. Behav. Biomed. Mater. 2014, 31, 3–20. [Google Scholar] [CrossRef] [PubMed]

- Moro, T.; Kyomoto, M.; Ishihara, K.; Saiga, K.; Hashimoto, M.; Tanaka, S.; Ito, H.; Tanaka, T.; Oshima, H.; Kawaguchi, H.; et al. Grafting of Poly(2-methacryloyloxyethyl phosphorylcholine) on Polyethylene Liner in Artificial Hip Joints Reduces Production of Wear Particles. J. Mech. Behav. Biomed. Mater. 2014, 31, 100–106. [Google Scholar] [CrossRef] [PubMed]

- Takatori, Y.; Moro, T.; Ishihara, K.; Kamogawa, M.; Oda, H.; Umeyama, T.; Kim, Y.T.; Ito, H.; Kyomoto, M.; Tanaka, T.; et al. Clinical and Radiographic Outcomes of Total Hip Replacement with Poly(2-methacryloyloxyethyl phosphorylcholine)—Grafted Highly Cross-Linked Polyethylene Liners: Three-Year Results of a Prospective Consecutive Series. Mod. Rheumatol. 2015, 25, 286–291. [Google Scholar] [CrossRef] [PubMed]

| Femoral Head Material | Testing Machine | Bearing Size | UHMWPE & Sterilization Method | Wear Rate (mm3/Mc) | Range (mm3/Mc) |

|---|---|---|---|---|---|

| Si3N4 | AMTI | 28 | PE, ETO | 66.0 ± 5.8 | 60.3–71.9 |

| CoCr | AMTI | 28 | PE, ETO | 53.1 ± 4.8 | 47.5–56 |

| Si3N4 | AMTI | 28 | XLPE, 78.5 KGy, ETO | 5.0 ± 1.3 | 3.5–6.0 |

| Si3N4 | AMTI | 40 | XLPE, 78.5 KGy, ETO | 9.1 ± 1.6 | 8.1–10.9 |

| CoCr | SWM | 28 | PE, 25–40 KGy | 17.6 ± 0.7 | 16.7–18.1 |

| Si3N4 | SWM | 28 | PE, 25–40 KGy | 21.3 ± 4.1 | 16.7–24.3 |

| # of Cycles | Femoral Heads | Acetabular Liners | ||||||

|---|---|---|---|---|---|---|---|---|

| Si3N4 Group | CoCr Group | Si3N4 Group | CoCr Group | |||||

| Mean | Max | Mean | Max | Mean | Max | Mean | Max | |

| 1 Mc | 4.3 | 7 | 8.6 | 19 | 77 | 177 | 106 | 276 |

| 3 Mc | 18 | 37 | 101 | 381 | 76 | 177 | 99 | 199 |

| 5 Mc | 15 | 24 | 112 | 410 | 93 | 190 | 102 | 187 |

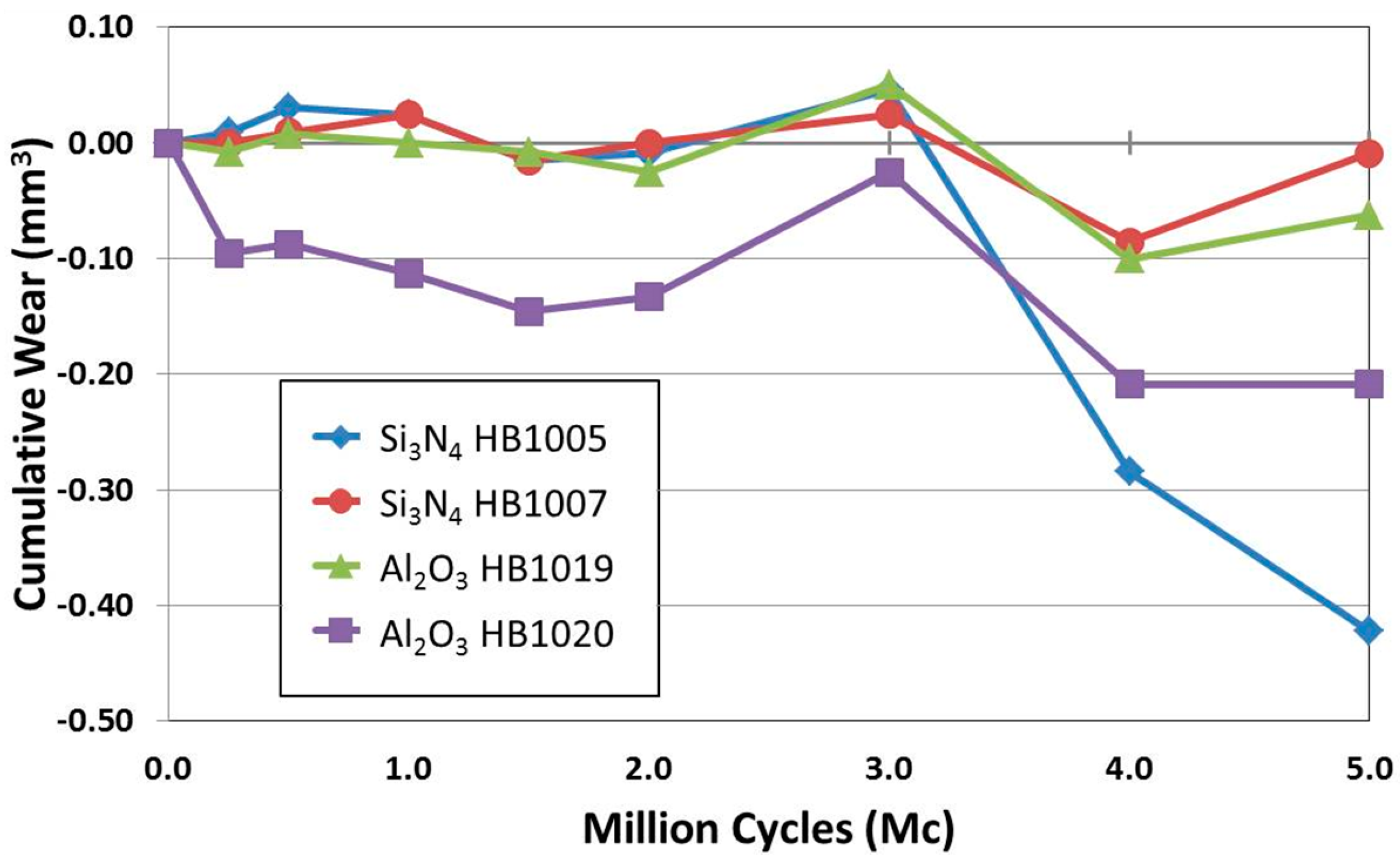

| Material | Bearing Size | Wear Rate (mm3/Mc) | ||

|---|---|---|---|---|

| Head | Liner | Combined | ||

| Silicon Nitride | 28 mm | 0.007 ± 0.009 | −0.014 ± 0.017 | −0.007 ± 0.017 |

| Alumina | 28 mm | 0.004 ± 0.013 | −0.020 ± 0.012 | −0.017 ± 0.012 |

| Silicon Nitride | 40 mm | −0.023 ± 0.003 | −0.029 ± 0.022 | −0.052 ± 0.014 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

McEntire, B.J.; Lakshminarayanan, R.; Ray, D.A.; Clarke, I.C.; Puppulin, L.; Pezzotti, G. Silicon Nitride Bearings for Total Joint Arthroplasty. Lubricants 2016, 4, 35. https://doi.org/10.3390/lubricants4040035

McEntire BJ, Lakshminarayanan R, Ray DA, Clarke IC, Puppulin L, Pezzotti G. Silicon Nitride Bearings for Total Joint Arthroplasty. Lubricants. 2016; 4(4):35. https://doi.org/10.3390/lubricants4040035

Chicago/Turabian StyleMcEntire, Bryan J., Ramaswamy Lakshminarayanan, Darin A. Ray, Ian C. Clarke, Leonardo Puppulin, and Giuseppe Pezzotti. 2016. "Silicon Nitride Bearings for Total Joint Arthroplasty" Lubricants 4, no. 4: 35. https://doi.org/10.3390/lubricants4040035