Tribological Investigation of Layered Zirconium Phosphate in Anhydrous Calcium Grease

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. Tribological Test

2.3. Characterization

3. Results and Discussion

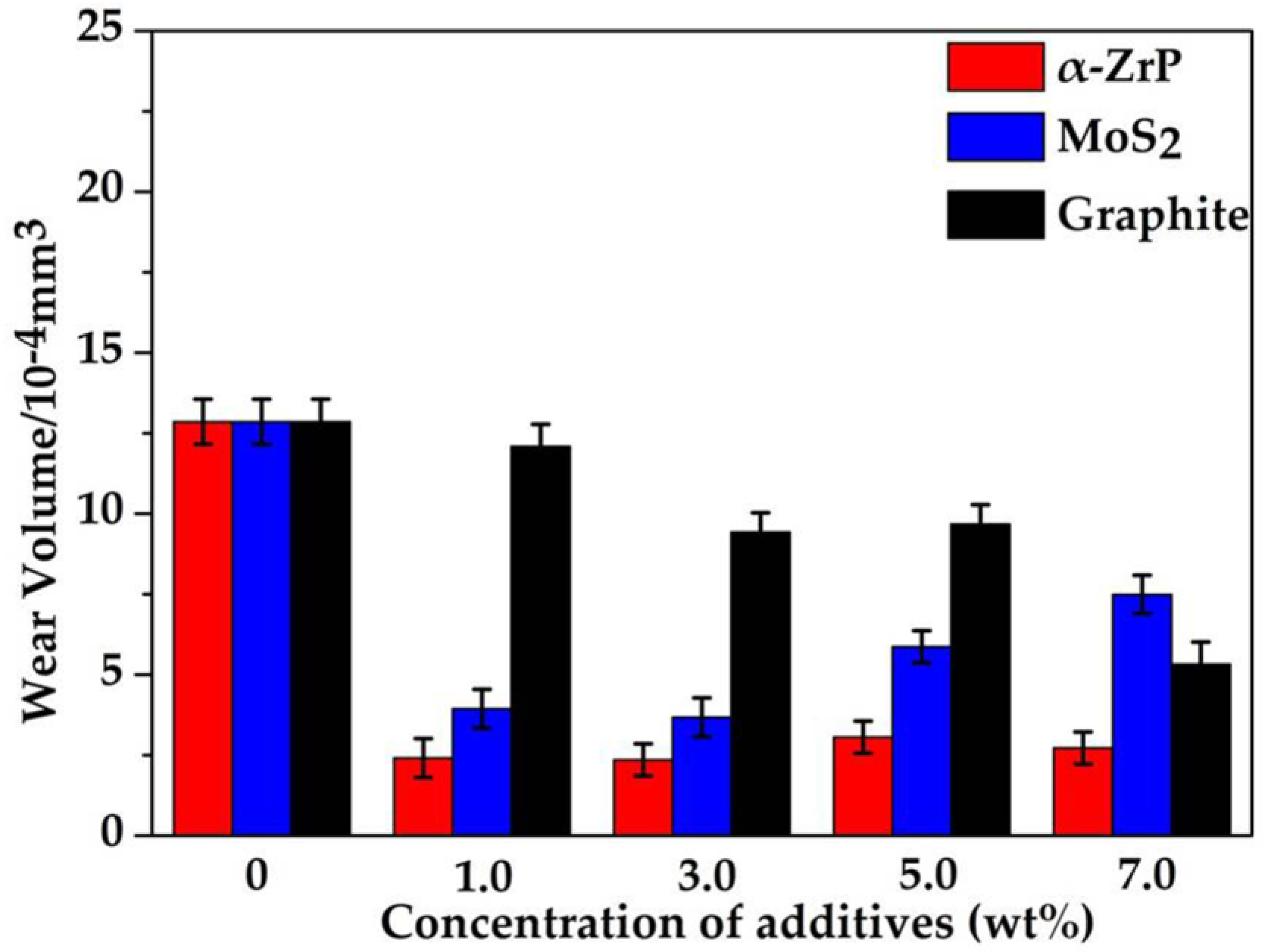

3.1. Determination of Suitable Concentration of Additives

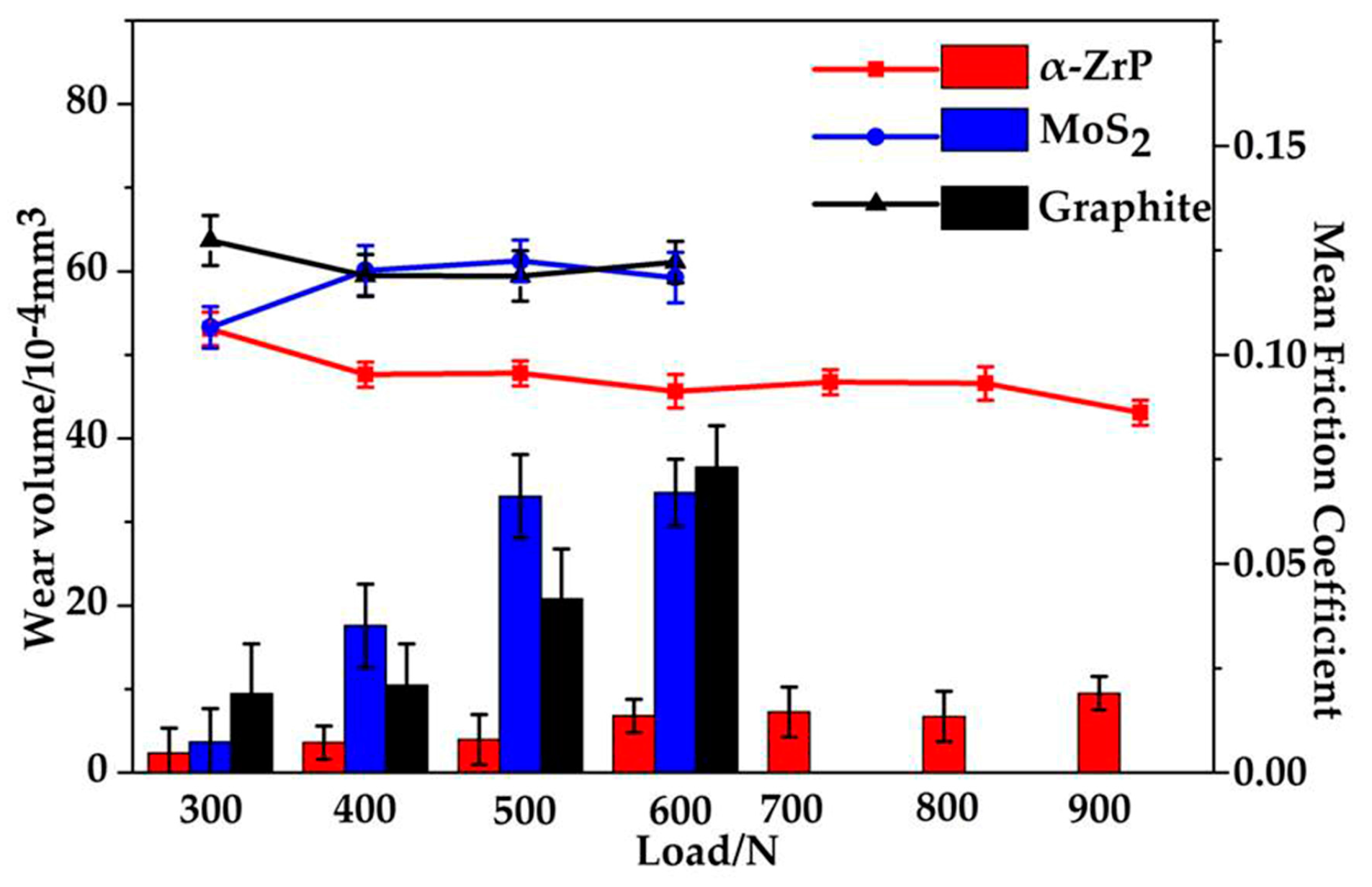

3.2. The Effect of Different Loads on the Performance of Grease

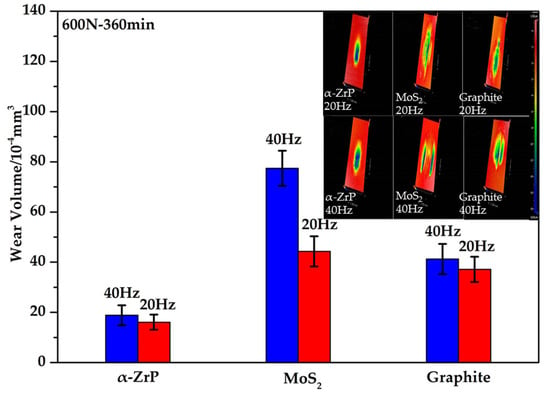

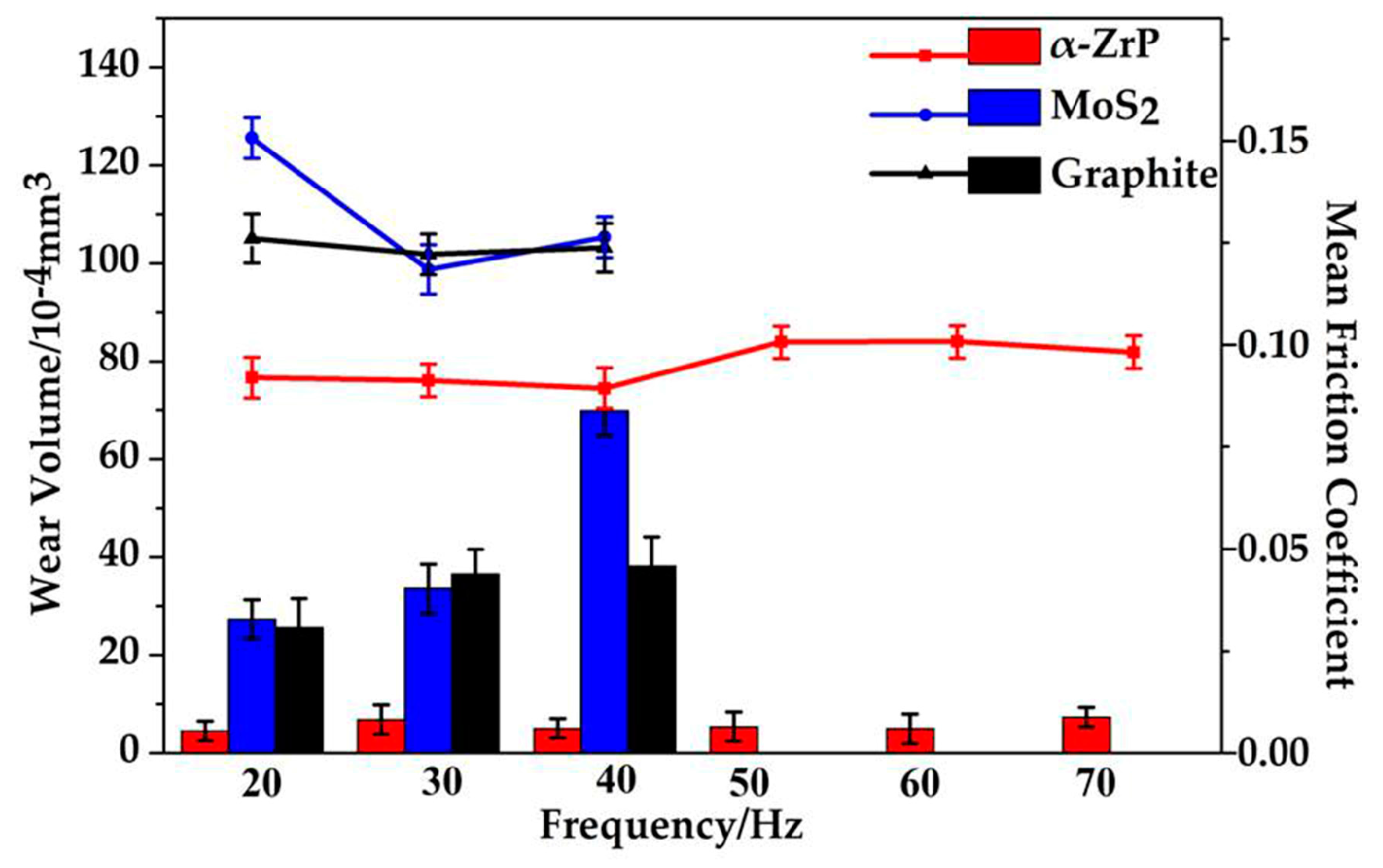

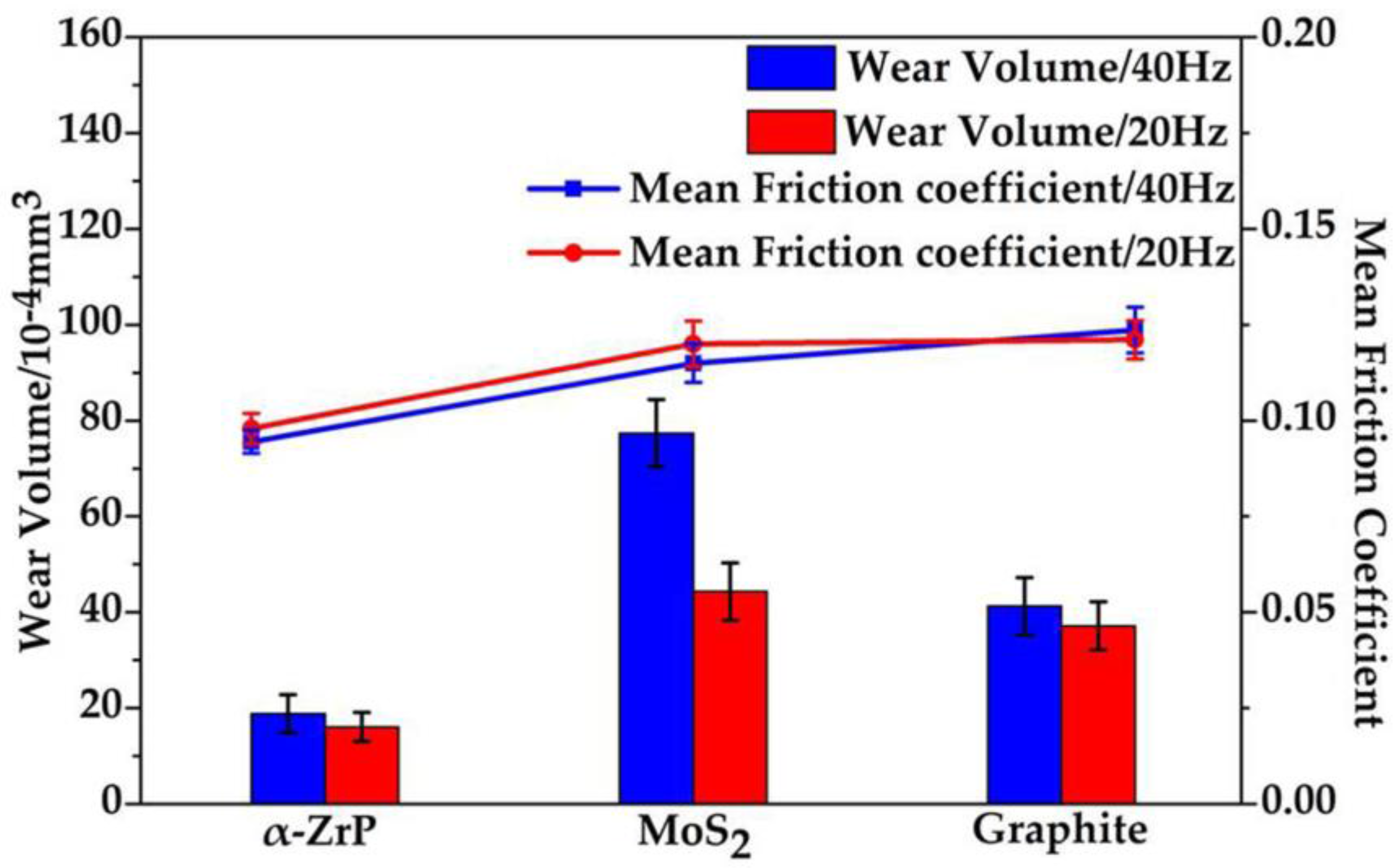

3.3. The Effect of Different Frequencies on the Performance of Grease

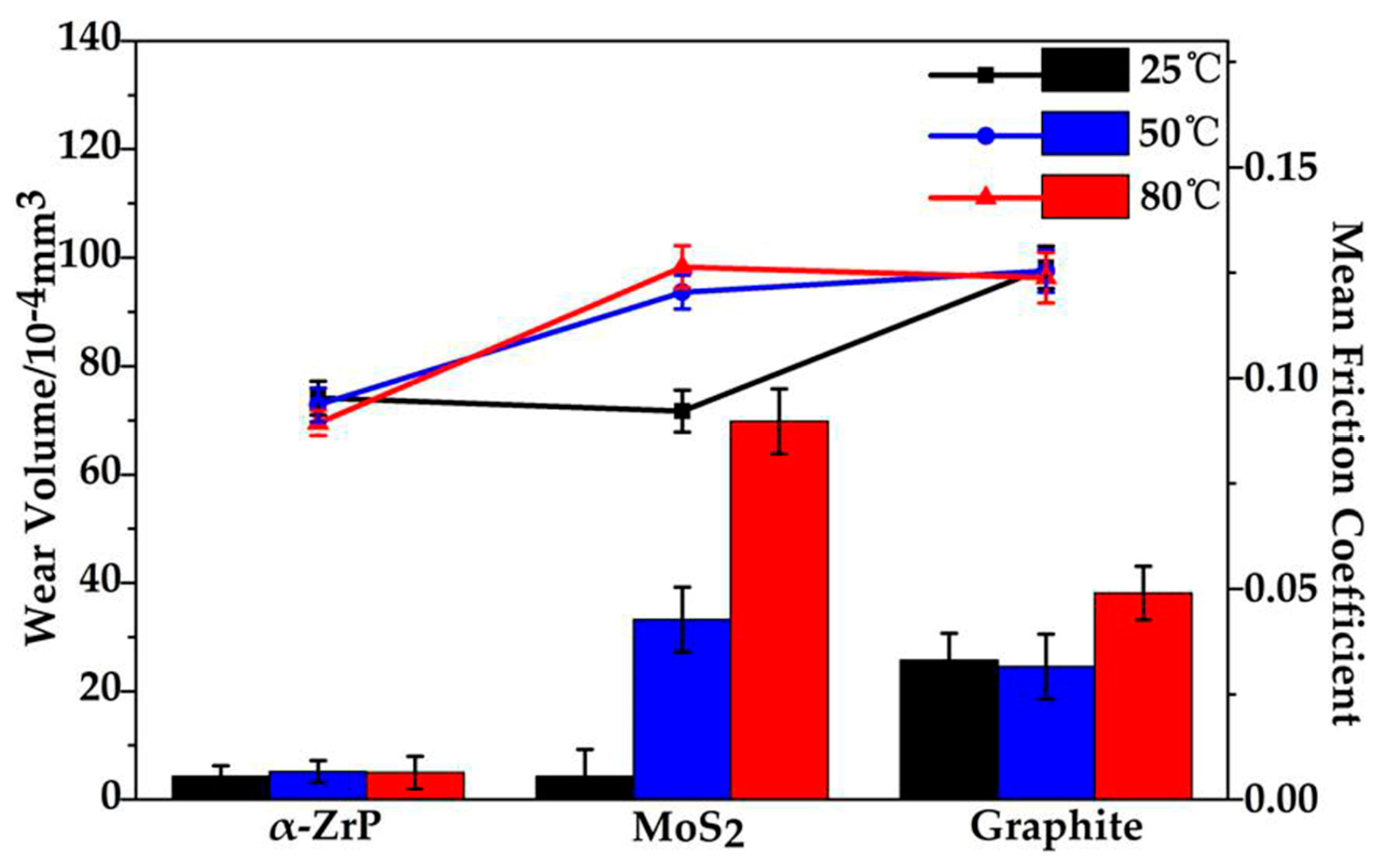

3.4. The Effect of Different Temperatures on the Performance of Grease

3.5. The Effect of Long Durations on the Performance of Grease

4. Conclusions

- α-ZrP is considered to be a promising candidate for lubricant additives because of its outstanding lubricating properties. The maximum applied load and operating frequency for α-ZrP grease can reach up to 900 N, 70 Hz, respectively. α-ZrP grease can run steadily throughout the test and hold the lowest wear volume regardless of severe contact condition.

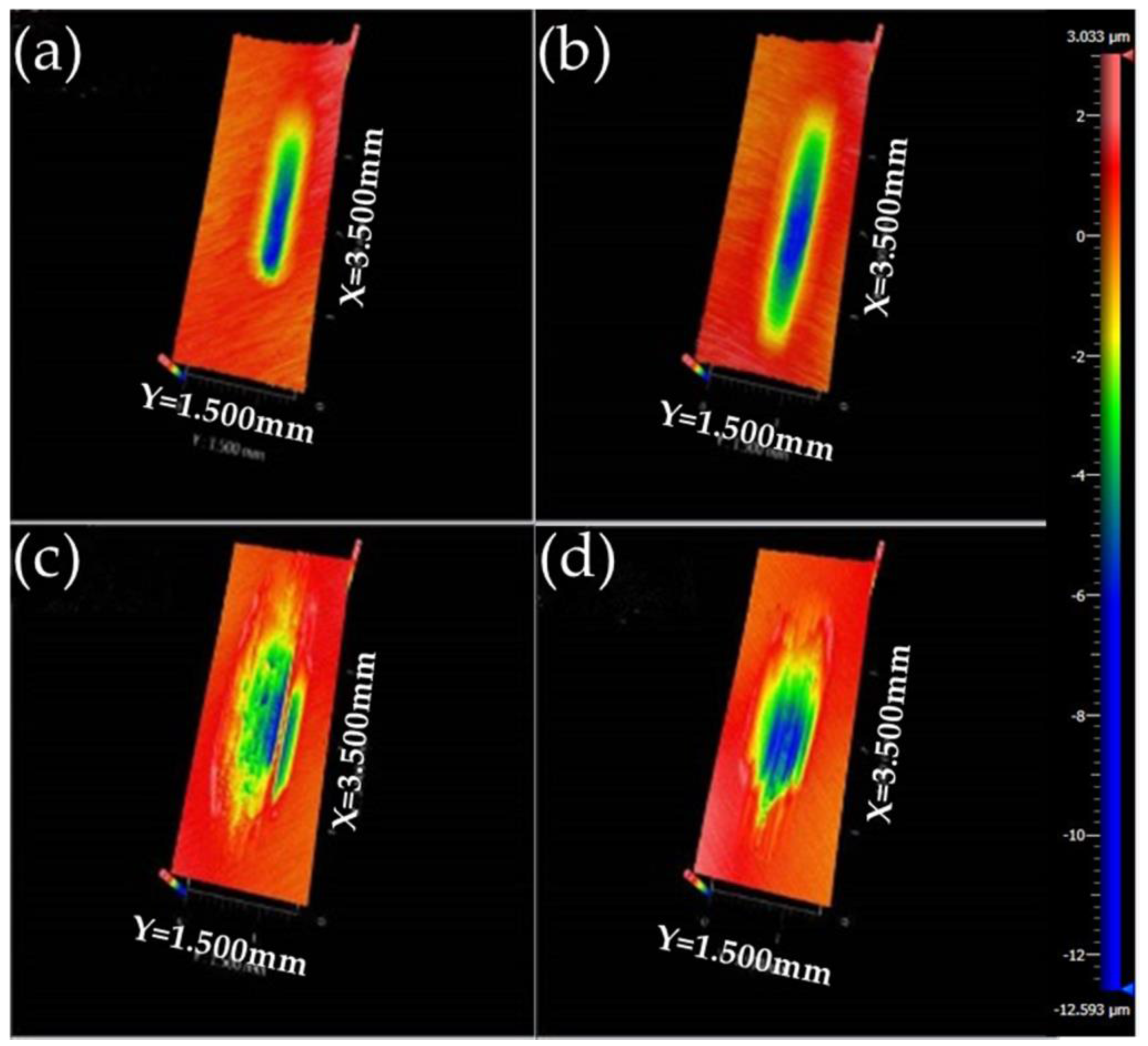

- SEM-EDS and 3D analyses indicate that the outstanding performance of α-ZrP grease comes from a stable and compact tribofilm with low shearing strength, which seems stronger and more durable than MoS2 and graphite.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Holmberg, K.; Siilasto, R.; Laitinen, T.; Andersson, P.; Jäsberg, A. Global energy consumption due to friction in paper machines. Tribol. Int. 2013, 62, 58–77. [Google Scholar] [CrossRef]

- Holmberg, K.; Andersson, P.; Erdemir, A. Global energy consumption due to friction in passenger cars. Tribol. Int. 2012, 47, 221–234. [Google Scholar] [CrossRef]

- Holmberg, K.; Andersson, P.; Nylund, N.-O.; Mäkelä, K.; Erdemir, A. Global energy consumption due to friction in trucks and buses. Tribol. Int. 2014, 78, 94–114. [Google Scholar] [CrossRef]

- Savage, R.H. Graphite lubrication. J. Appl. Phys. 1948, 19, 1–10. [Google Scholar] [CrossRef]

- Chhowalla, M.; Amaratunga, G.A. Thin films of fullerene-like MoS2 nanoparticles with ultra-low friction and wear. Nature 2000, 407, 164–167. [Google Scholar] [CrossRef] [PubMed]

- Bowden, F.P.; Tabor, D. The Friction and Lubrication of Solids; Oxford University Press: Oxford, UK, 2001; Volume 1. [Google Scholar]

- Dienwiebel, M.; Verhoeven, G.S.; Pradeep, N.; Frenken, J.W.; Heimberg, J.A.; Zandbergen, H.W. Superlubricity of graphite. Phys. Rev. Lett. 2004, 92, 126101. [Google Scholar] [CrossRef] [PubMed]

- Kamel, B.M.; Mohamed, A.; El Sherbiny, M.; Abed, K.; Abd-Rabou, M. Tribological properties of graphene nanosheets as an additive in calcium grease. J. Dispers. Sci. Technol. 2017, 38, 1495–1500. [Google Scholar] [CrossRef]

- Battez, A.H.; Rico, J.F.; Arias, A.N.; Rodriguez, J.V.; Rodriguez, R.C.; Fernandez, J.D. The tribological behaviour of ZnO nanoparticles as an additive to PAO6. Wear 2006, 261, 256–263. [Google Scholar] [CrossRef]

- Gonzalez-Rodriguez, P.; van den Nieuwenhuijzen, K.J.; Lette, W.; Schipper, D.J.; ten Elshof, J.E. Tribochemistry of bismuth and bismuth salts for solid lubrication. ACS Appl. Mater. Interfaces 2016, 8, 7601–7606. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Xu, H.; Zuo, Z.; Lin, Z.; Ferdov, S.; Dong, J. Hydrothermal synthesis of copper zirconium phosphate hydrate [Cu(OH)2Zr(HPO4)2·2H2O] and an investigation of its lubrication properties in grease. ACS Appl. Mater. Interfaces 2013, 5, 7989–7994. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Zhang, X.; Xu, H.; Dong, J. Tribological investigation of two different layered zirconium phosphates as grease additives under reciprocating sliding test. Tribol. Lett. 2016, 64, 1. [Google Scholar] [CrossRef]

- Clearfield, A.; Stynes, J. The preparation of crystalline zirconium phosphate and some observations on its ion exchange behaviour. J. Inorg. Nucl. Chem. 1964, 26, 117–129. [Google Scholar] [CrossRef]

- Radulescu, A.; Radulescu, I. Rheological models for lithium and calcium greases. Mechanics 2016, 59, 67–70. [Google Scholar]

- Kamel, B.M.; Mohamed, A.; El Sherbiny, M.; Abed, K. Rheology and thermal conductivity of calcium grease containing multi-walled carbon nanotube. Fuller. Nanotub. Carbon Nanostruct. 2016, 24, 260–265. [Google Scholar] [CrossRef]

- Sahoo, R.; Biswas, S. Effect of layered MoS2 nanoparticles on the frictional behavior and microstructure of lubricating greases. Tribol. Lett. 2014, 53, 157–171. [Google Scholar] [CrossRef]

- Huang, H.; Tu, J.; Zou, T.; Zhang, L.; He, D. Friction and wear properties of IF–MoS2 as additive in paraffin oil. Tribol. Lett. 2005, 20, 247–250. [Google Scholar] [CrossRef]

- Xu, Y.; Geng, J.; Zheng, X.; Dearn, K.D.; Hu, X. Friction-induced transformation from graphite dispersed in esterified bio-oil to graphene. Tribol. Lett. 2016, 63, 1–11. [Google Scholar] [CrossRef]

- Fan, X.; Xia, Y.; Wang, L.; Li, W. Multilayer graphene as a lubricating additive in bentone grease. Tribol. Lett. 2014, 55, 455–464. [Google Scholar] [CrossRef]

| Grease Property | Test Standard | Base Grease | α-ZrP | MoS2 | Graphite |

|---|---|---|---|---|---|

| Dropping point (°C) | ASTM D 566 | 159 | 153 | 158 | 160 |

| Cone penetration (0.1 mm) | ASTM D 217 | 315 | 310 | 303 | 309 |

| Wear scar diameter (WSD/mm) 1 | ASTM D 2266 | 0.45 | 0.34 | 0.51 | 0.43 |

| Maximum non-seizure load (PB/N) 2 | ASTM D 2596 | 549 | 1236 | 696 | 618 |

| Welded point (PD/N) 3 | ASTM D 2596 | 1569 | 1961 | 1961 | 1569 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dai, Y.; Niu, W.; Zhang, X.; Xu, H.; Dong, J. Tribological Investigation of Layered Zirconium Phosphate in Anhydrous Calcium Grease. Lubricants 2017, 5, 22. https://doi.org/10.3390/lubricants5030022

Dai Y, Niu W, Zhang X, Xu H, Dong J. Tribological Investigation of Layered Zirconium Phosphate in Anhydrous Calcium Grease. Lubricants. 2017; 5(3):22. https://doi.org/10.3390/lubricants5030022

Chicago/Turabian StyleDai, Yingjing, Wenxing Niu, Xiaosheng Zhang, Hong Xu, and Jinxiang Dong. 2017. "Tribological Investigation of Layered Zirconium Phosphate in Anhydrous Calcium Grease" Lubricants 5, no. 3: 22. https://doi.org/10.3390/lubricants5030022