1. Introduction

Friction and wear are irreversible processes and characterized by energy dissipation with a continuous production of entropy. In general, we observe a cause-effect-chain that we can relate to the friction and wear phenomena. In this paper friction, is considered as an energy expenditure and supply into a tribo-system. Wear is characterized as the dissipation of this energy (loss of material is the most important type of wear).

Similar to the solid rubbing bodies of a tribo-system, a lubricating grease undergoes irreversible changes caused by friction. These changes can be detected as a degradation of the thickener network.

Tribo-systems are energy driven systems. In a number of publications the system reaction is described from an energy point of view. Abdel-Aal [

1] creates an open thermodynamic system to observe the energetic situation of a solid-solid contact during a tribo-process. He described an entropy balance and correlated the wear (as loss of material) with the entropy production. Very early Fleischer [

2] noticed that wear particles leave the tribo-system by taking an energy amount with them. From another point of view Federov [

3] developed an energy balance of the friction process and creates an adaptive and a dissipative space of the tribo-process. In this references the system reaction is described from an energy point of view, showing that stable conditions and a minimum of energy expenditure are reached. Observing the stressed lubricating grease as a subsystem, the same fundamental behaviour can be detected.

Interesting investigations of the structural change inside a grease comes from [

4,

5,

6]. Paszkowski and Olsztynska-Janus [

4] investigated the degradation process of Li-soap lubricating greases. They reported that the change of structural viscosity during a shear process is caused by destruction of hydrogen bonds (OH-groups) between Li-soap-fibres. These authors stated that the degree of disintegration of the greases micro-structure depends mainly on the shear rate. Zhou et al. [

5] made experimental work by using a rheometer. They show a continuous change of thickener structure with a continuous entropy production and differ a non-stationary and a stationary period. Rezasoltani and Khonsari [

6] use the net-penetration to describe the degree of structural degradation. They observe that the shear process breaks down the structure of the grease and results in heat and entropy generation. The authors define a degradation coefficient by correlating rate of entropy generation with mechanical degradation.

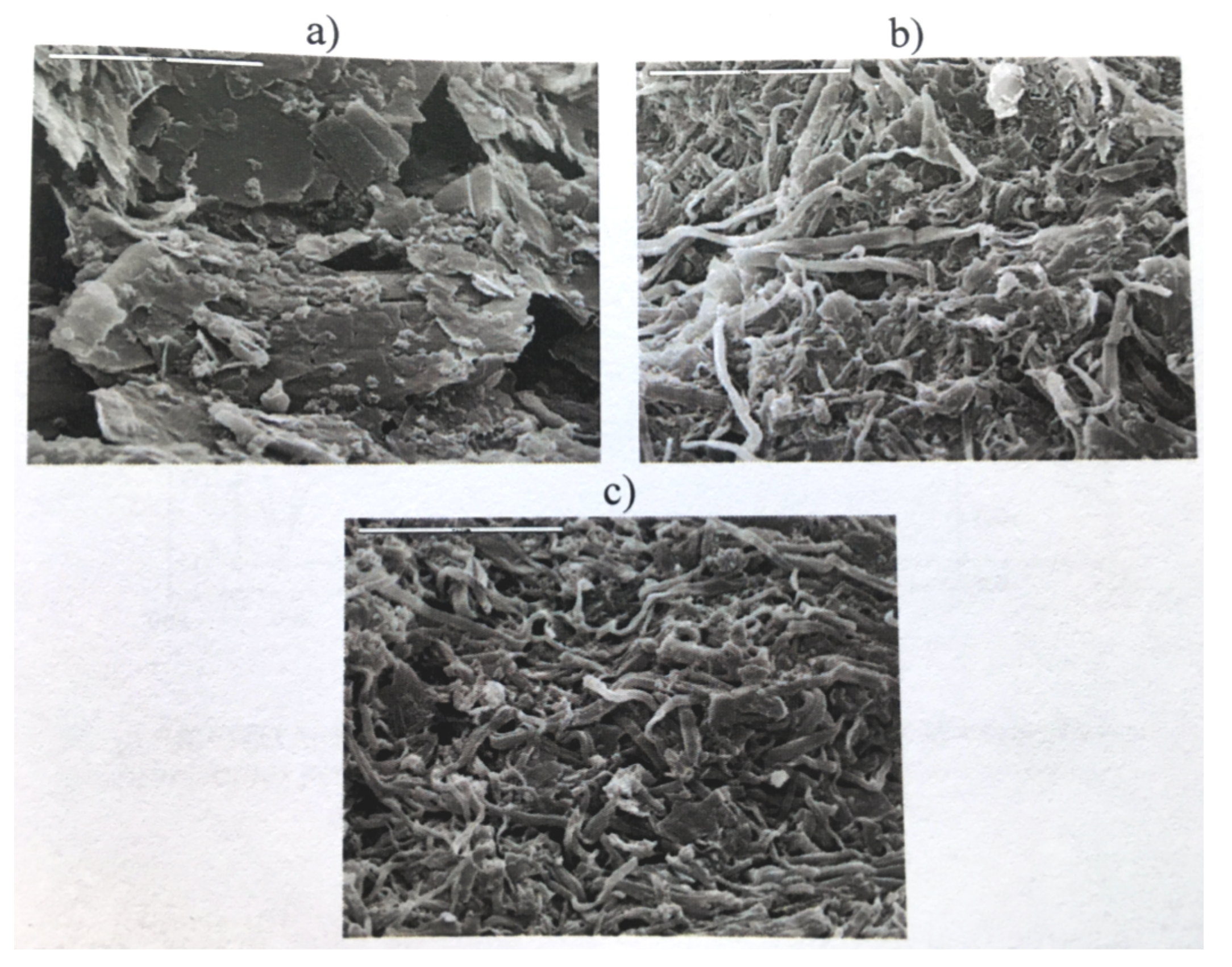

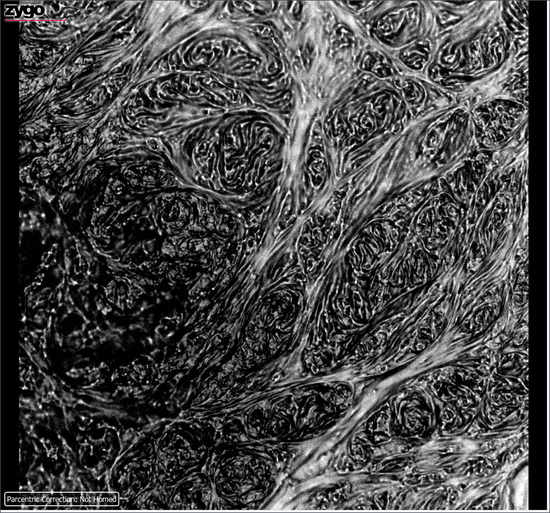

A number of SEM and AFM investigations [

7,

8] present important information about the degradation process. Delgado [

7] shows the sensitivity of a grease structure withs SEM-pictures. He observe the change of the structure influenced by composition and different conditions. Roman et al. [

8] investigate the degradation of thickener structure with AFM and show for selected samples the influence of shear rate and shear time.

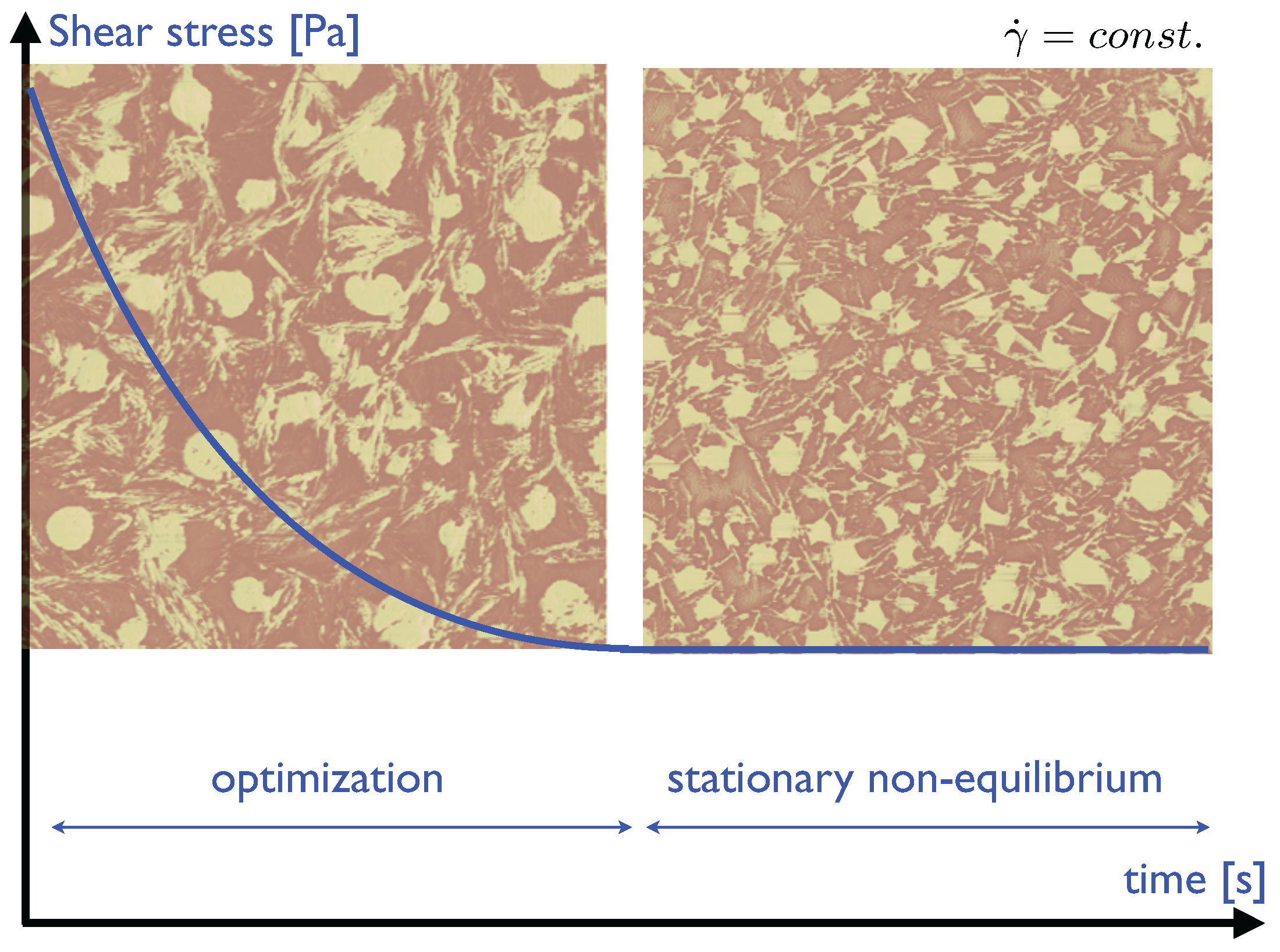

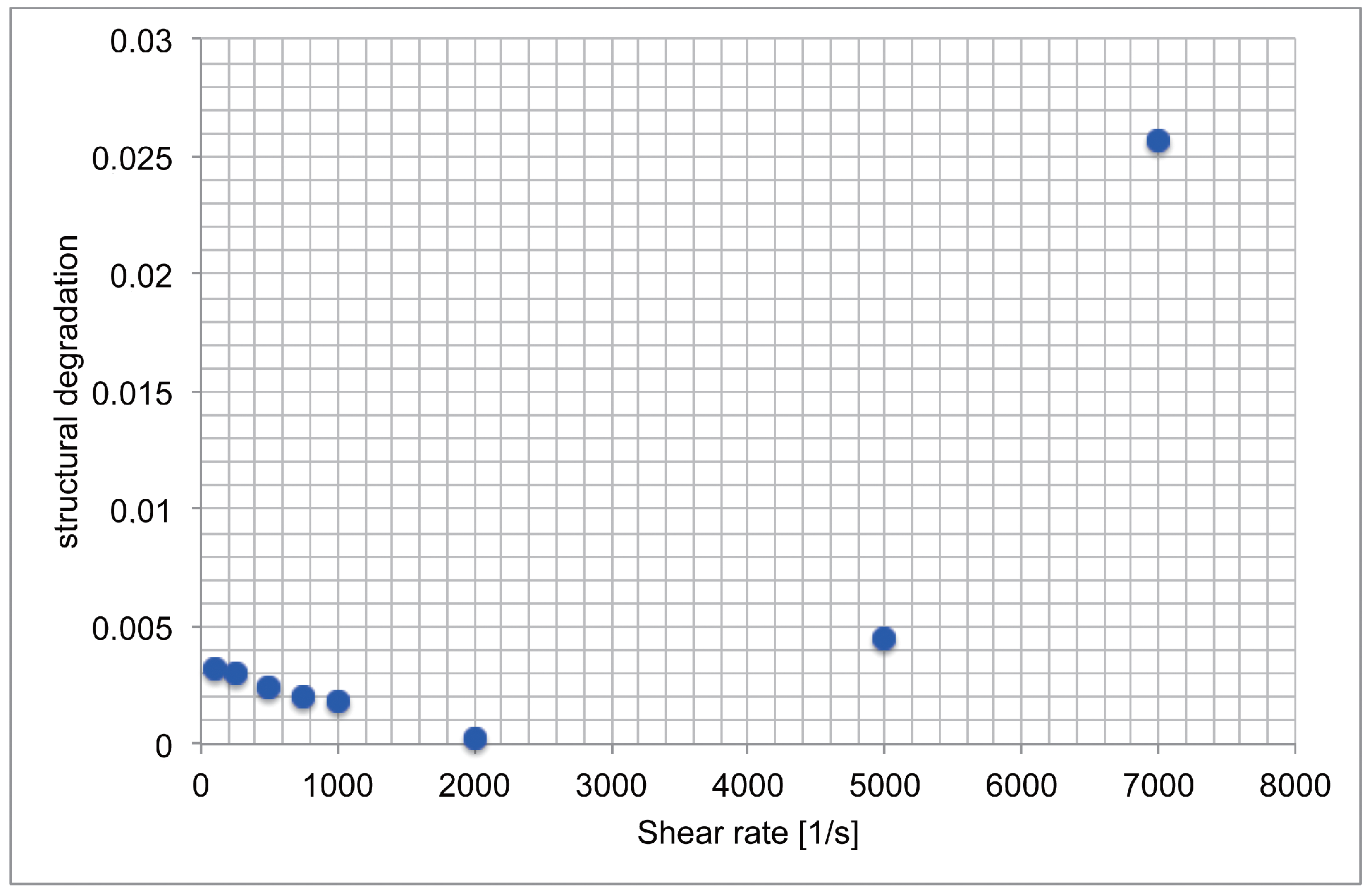

The drop of shear stress in a rotational rheometer test is a good example for the indirect measurement of structural changes during a friction process (see

Figure 1).

Many of the well known phenomena in tribology, like the so called running-in period of surface rougness, the running-in process for abrasion wear, or the formation of a tribofilm can be characterized as self-optimizing processes. That means that the system follows the natural effort to come into a stable situation after working in instability with the help of self-optimized parameters (roughness height, roughness distribution, tribo-film thickness or spatial and temporary patterns).

It is assumed, that these phenomena also occur in the stressed lubricating grease and lead to an optimized dissipative grease structure.

One aim of the current paper is an analytical investigation of this assumption.

2. Process Stability

Self-optimization as an reaction of the system to an arising instability can be investigated by observing the transition from stability to instability [

9,

10]. Therefor the criterion is

which is the second variation of entropy production rate [

11]. If Equation (3) is violated, destabilization occurs and facilitates the process of self-optimization. Analogues to the process of solid friction [

9], self-optimization during the fluid friction inside a grease film is investigated .

Nosonovsky [

9] proposed the entropy production rate with

with

F friction coefficient,

normal force,

V velocity and

T the temperature. For the fluid friction it is proposed

with

shear stress,

shear rate and

stressed volume. Consider first the situation that entropy production depends on the shear rate

. Other influences like shear stress, temperature etc. are not involved in this step of the investigations. It follows

This means that, if the slope of a friction curve becomes negative, a process destabilization occurs.

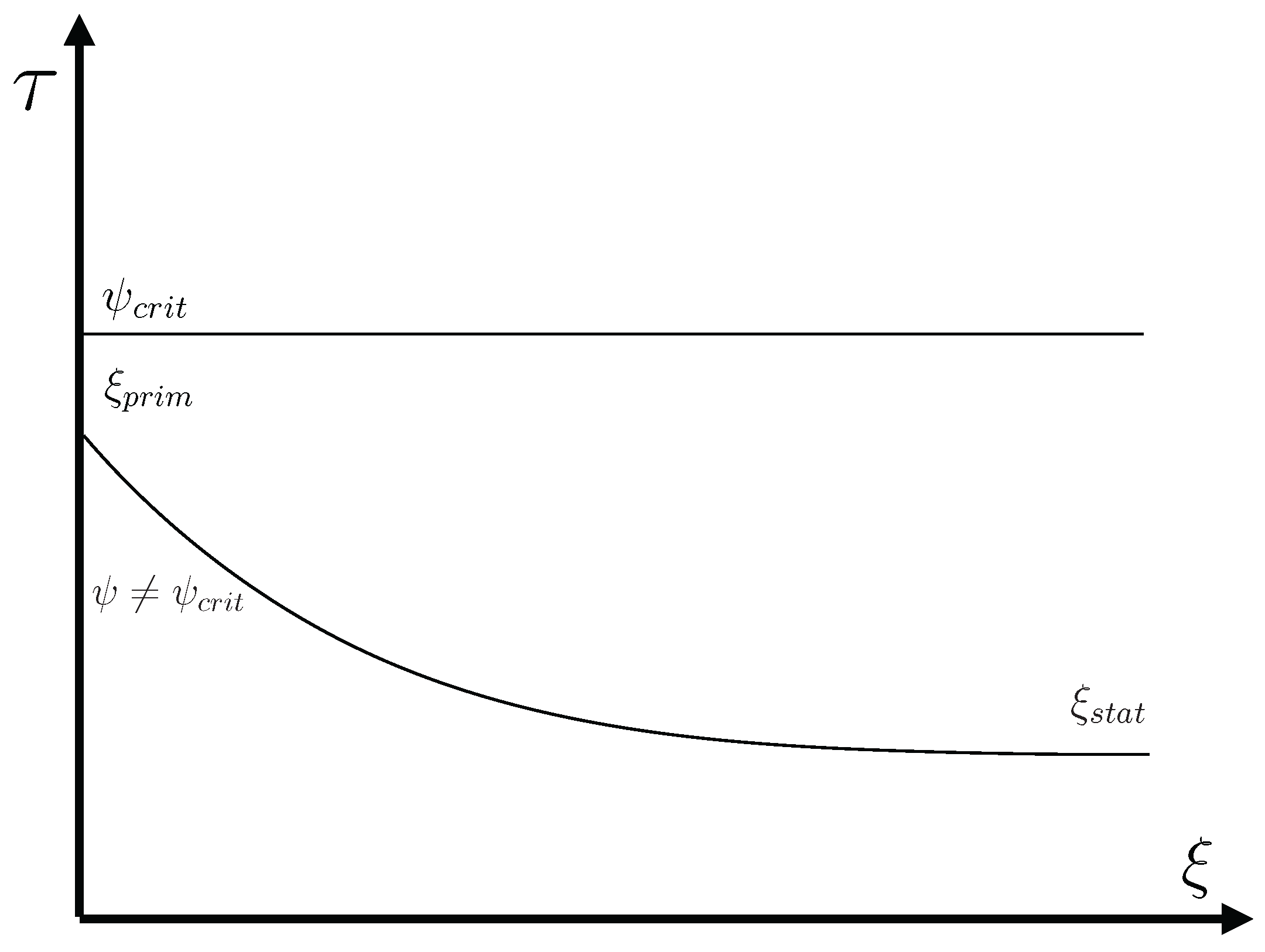

An important parameter of lubricating greases is the content of solid material called thickener. For a metal soap grease this parameter is the soap content (%). That thickener content decribed as is a microgeometric parameter and stays constant during the friction process. If the slope of a -curve is 0, the transition from stationary to non-stationary state occurs.

It is known, that there exists a correlation between thickener content and the formation of a thickener structure (see

Figure 2). Formation, distribution and geometry of the thickener characterize the grease structure. The parameter

describes a temporary state of the grease structure and is not constant during the time dependent friction process.

The stability criterion now is

Suppose now that a certain value exists

with a primary structure

and the slope of the friction curve

. It characterized the transition from stability to instability. In other words, in this case the friction of the initial structure does not depend on the structure evolution. The friction maximum at the beginning of the process depends on

. If there is a value

with a lower friction compared with

a destabilization occurs and an optimization process will be activated. The result is a new stationary state with a new stationary structure

(Figure

3).

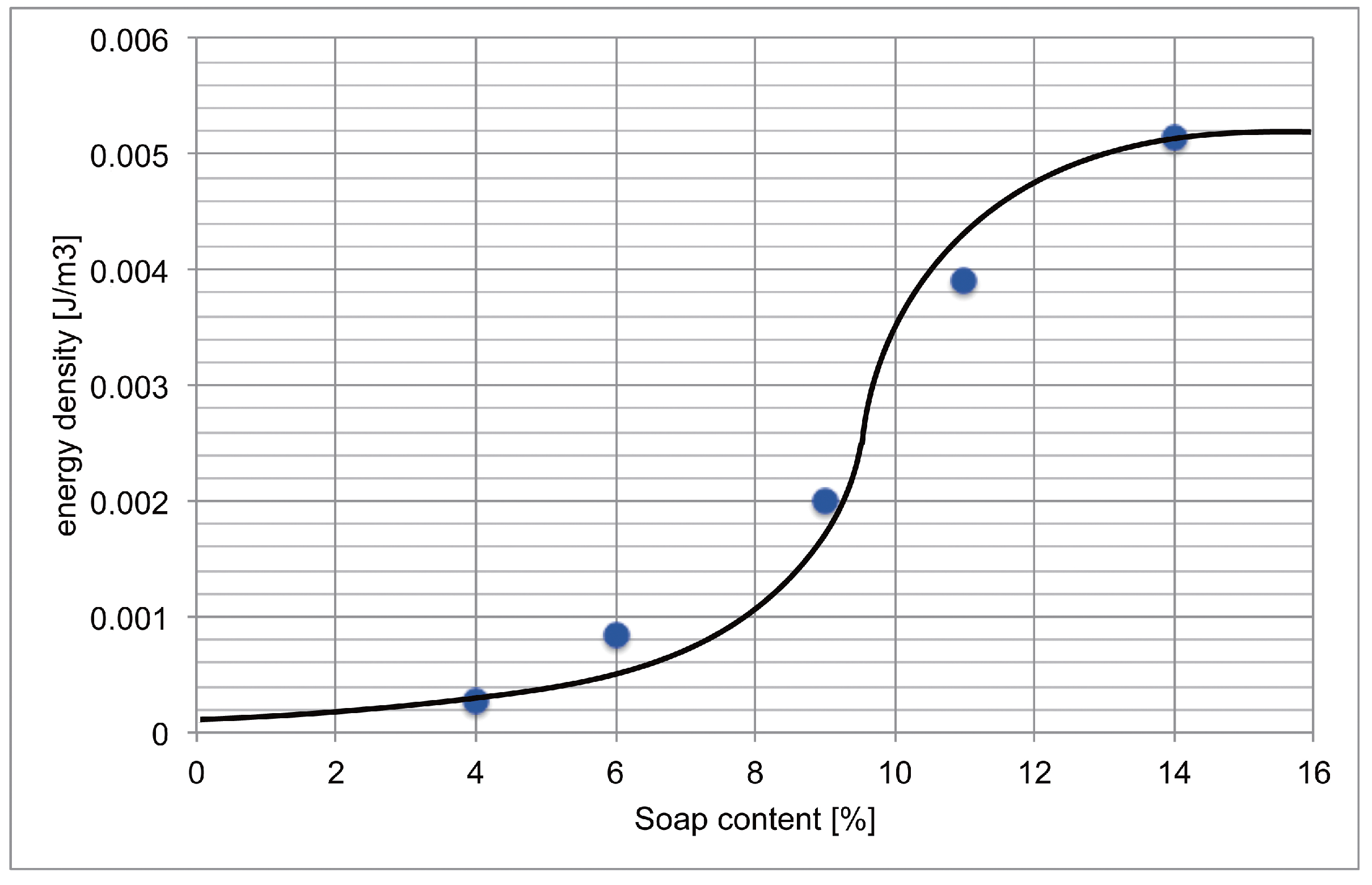

Experimental results of rheometer tests are presented in

Figure 4. The value of the energy density on the ordinate represents the friction behaviour.

To get information about the friction behaviour inside a grease film rheometer tests were done. A rheometer MCR 302 by Anton Paar Germany GmbH, Ostfildern, Germany with a plate-plate system was used. Test temperature was C. To compare the friction behaviour oscillating tests (amplitude sweep) with a frequency of 10 Hz were made and the expended mechanical energy quantified at a deformation of . These conditions were realized by all tests and all samples. The tests were repeated 3 times. The used sample was a grease with a naphtenic base oil (115 mm/s), a Li-soap and a percentage of 2.5% polyethylene. The test were made with samples with 5 different Li-soap contents.

In the light of the described criterion for stabilization, a process of self-optimization occurs in the range of thickener content. Of course further investigations are necessary to prove this assumption.

3. Period of Self-Optimization

In this section we assume a process of self-optimization with an optimized grease structure. The consequence of that process is a decreasing friction and wear process. It delivers, in our case, a decreasing structural degradation during an increasing tribological stress. An experimental example is shown in

Figure 5.

The experimental procedure to obtain the results presented in this figure is described in [

12]. The period of decreasing structural degradation (wear of a lubricant) with an increasing shear rate is investigated below. This analysis follows the work of [

13].

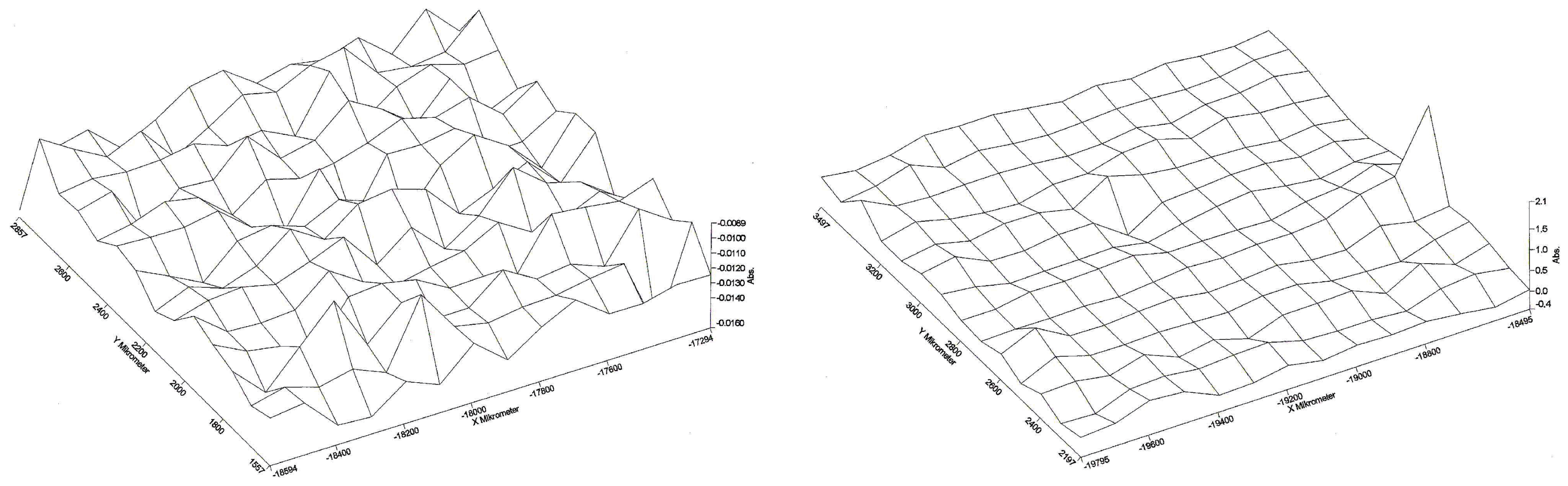

System entropy is described as

with

being the entropy production and

the entropy flow. The tribologcal process leads to a gradient of density inside the grease film [

14]. The assumption follows, that a diffusion process happens between unchanged and changed grease structure. An example for the evolution of the density distribution is presented in

Figure 6 (from IR-microscopy). Observing the entropy production of the described tribo-system (stressed grease film), two dissipative processes were considered. These processes are friction and diffusion.

In the thermodynamics of irreversible processes, linear relations between thermodynamic forces

X and fluxes

J are assumed [

15].

For the investigated system follows the entropy production rate

for the stationary state and the thermal conductivity process (according to [

13])

and for the diffusion process

with

T the temperature,

the thermal conductivity coefficient,

the chemical potential and

the transport coefficient. For

is proposed:

. The assumption was made (in application of [

13]) that the degradation of the grease structure is proportional to the transport coefficient

.

To analyze the stationary state, we assume that

is influenced by

. The entropy production rate is written now as

where

is the integration constant. For stationary conditions it can be seen from Equation (

15) that with an increase in

a decrease of

can be expected. Analogous to [

13] it is assumed that the transport coefficient

is proportional to wear, or with other words, to the process of structural degradation. We find the phenomenon that with an increasing tribological stress

in a stationary period, the structural degradation decreases (as presented in

Figure 5).

In a second step, the dependence of

on

T is investigated. It is found

an assumption is made with

and

As seen in Equation (

20) with increasing temperature the parameter comes closer to a limiting value. For the investigated topic, this limiting value could be presented by the base oil properties. The degradation curve will never fall below the base oil curve. The behaviour during the optimized region seems similar to the well known process behaviour.

4. Conclusions

Creating a sub-tribo-system by investigating the stressed lubricating grease delivers the possibility to observe some special phenomena. The assumption is made that the formation of dissipative structures is possible for stressed greases too. The checking of the stability criterion delivers information about the process conditions for the optimization. Consideration of micro-geometrical parameters opens new possibilities to describe the correlation between evolution of the structure and friction behaviour during the optimization period.

Under assumption of an optimization process, the phenomenon of a decreasing wear and increasing stress is investigated. An observation of an experimental result is described by formulating the entropy production rate.