Exchange Bias and Inverse Magnetocaloric Effect in Co and Mn Co-Doped Ni2MnGa Shape Memory Alloy

Abstract

:1. Introduction

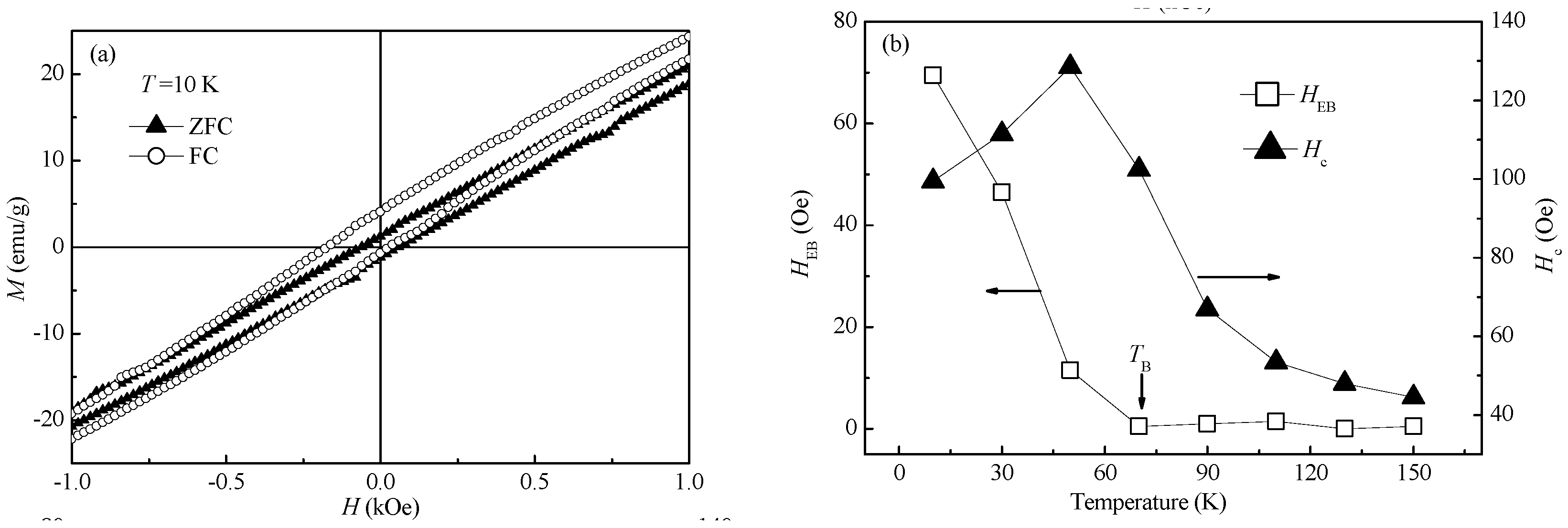

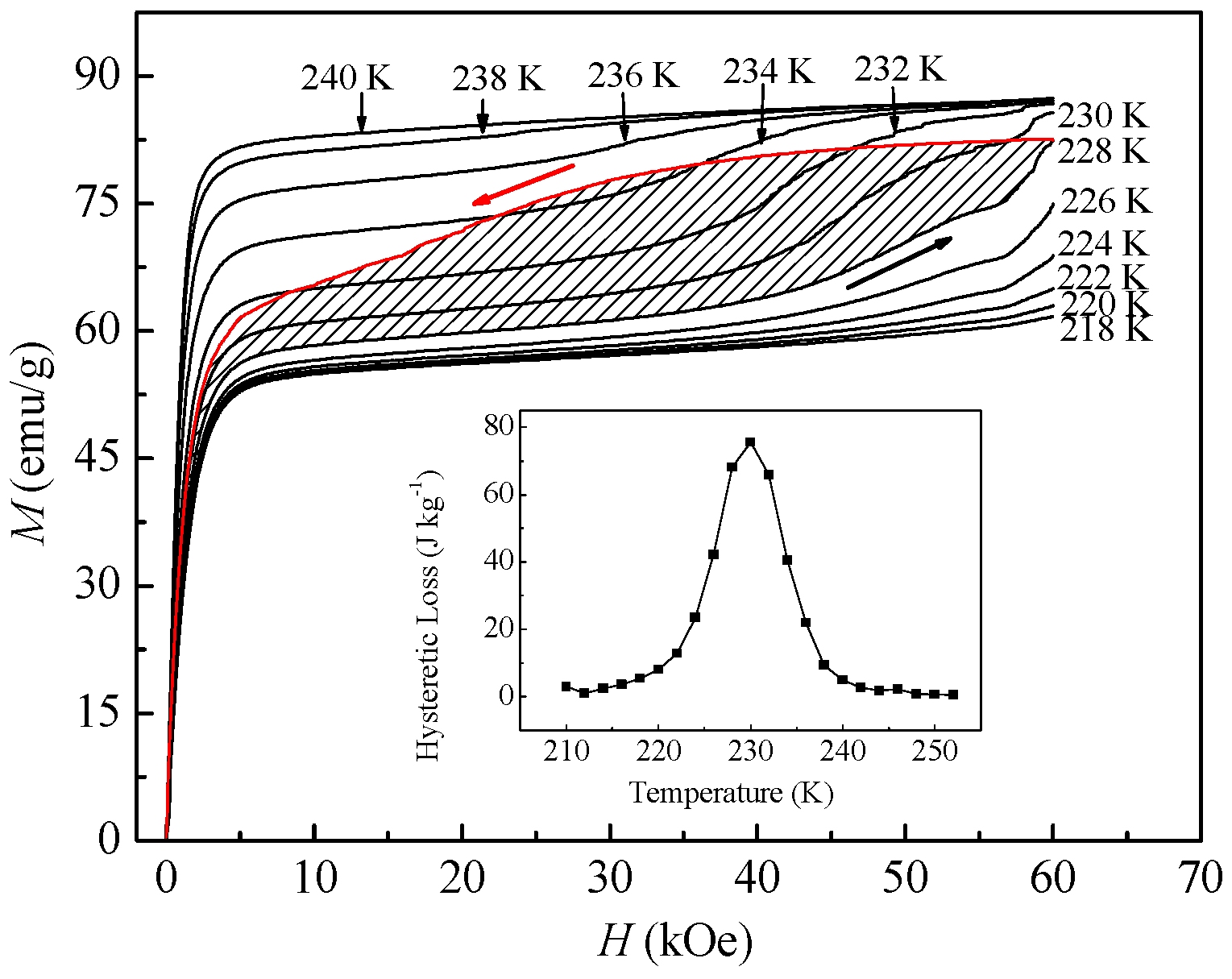

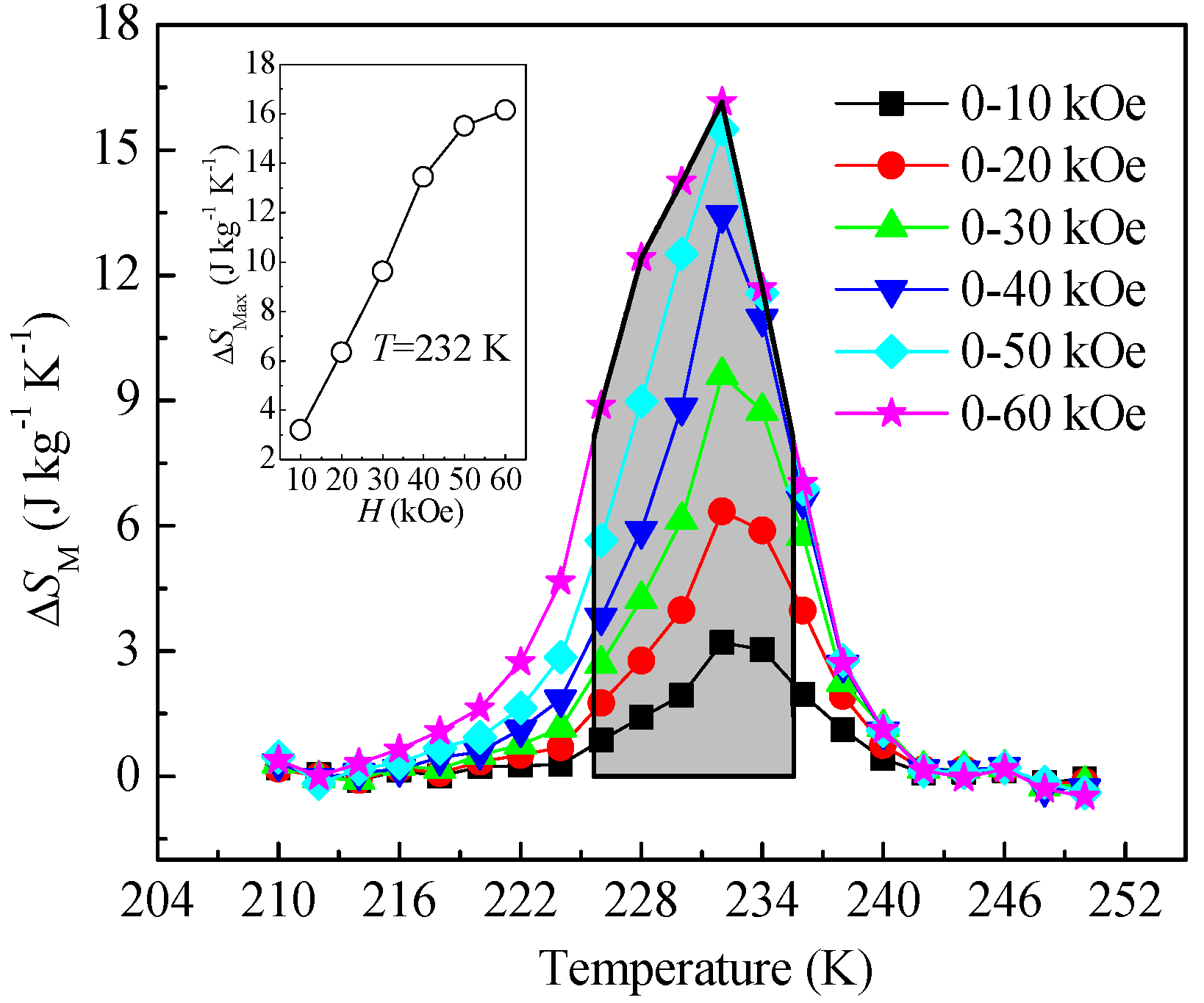

2. Results and Discussion

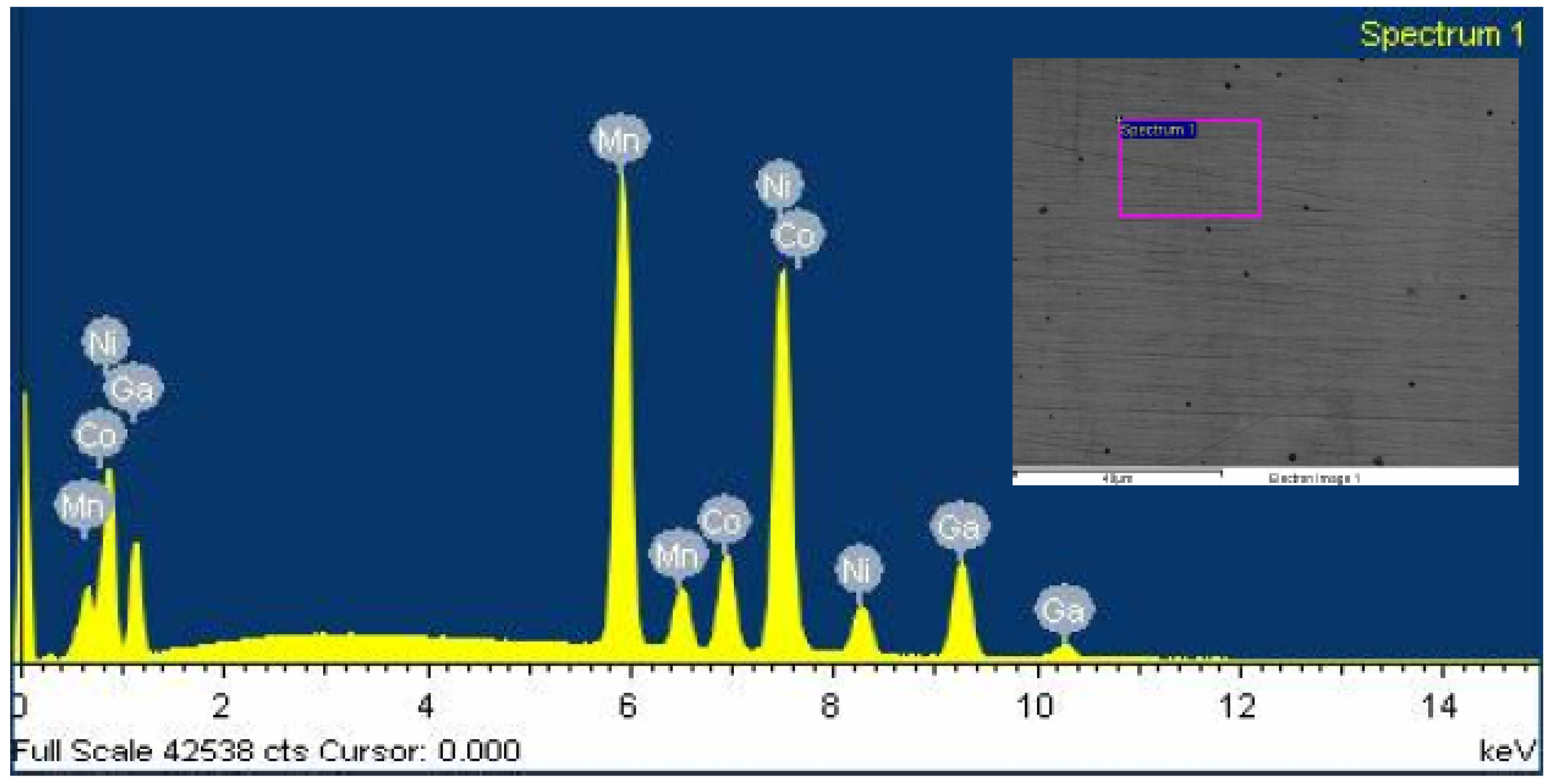

3. Experimental Section

4. Conclusions

Conflict of Interest

References

- Vasil’ev, A.N.; Bozhko, A.D.; Khovailo, V.V.; Dikshtein, I.E.; Shavrov, V.G.; Buchelnikov, V.D.; Matsumoto, M.; Suzuki, S.; Takagi, T.; Tani, J. Structural and magnetic phase transitions in shape-memory alloys Ni2 + xMn1 − xGa. Phys. Rev. B 1999, 59, 1113–1120. [Google Scholar]

- Hu, F.X.; Shen, B.G.; Sun, J.R. Magnetic entropy change in Ni51.5Mn22.7Ga25.8 alloy. Appl. Phys. Lett. 2000, 76, 3460–3463. [Google Scholar] [CrossRef]

- Pareti, L.; Solzi, M.; Albertini, F.; Paoluzi, A. Giant entropy change at the co-occurrence of structural and magnetic transitions in the Ni2.19Mn0.81Ga Heusler alloy. Eur. Phys. J. B 2003, 32, 303–307. [Google Scholar] [CrossRef]

- Marcos, J.; Mañosa, L.; Planes, A.; Casanova, F.; Batlle, X.; Labarta, A. Multiscale origin of the magnetocaloric effect in Ni-Mn-Ga shape-memory alloys. Phys. Rev. B 2003, 68, 094401:1–094404:6. [Google Scholar]

- Pasquale, M.; Sasso, C.P.; Lewis, L.H.; Giudici, L.; Lograsso, T.; Schlagel, D. Magnetostructural transition and magnetocaloric effect in Ni55Mn20Ga25 single crystals. Phys. Rev. B 2005, 72. [Google Scholar] [CrossRef]

- Stadler, S.; Khan, M.; Mitchell, J.; Ali, N.; Gomes, A.M.; Dubenko, I.; Takeuchi, A.Y.; Guimaraes, A.P. Magnetocaloric properties of Ni2Mn1 − xCuxGa. Appl. Phys. Lett. 2006, 88, 192511:1–192511:3. [Google Scholar]

- Giguère, A.; Foldeaki, M.; Ravi Gopal, B.; Chahine, R.; Bose, T.K.; Frydman, A.; Barclay, J.A. Direct measurement of the “giant” adiabatic temperature change in Gd5Si2Ge2. Phys. Rev. Lett. 1999, 83, 2262–2265. [Google Scholar] [CrossRef]

- Tegus, O.; Bruck, E.; Zhang, L.; Dagula; Buschow, K.H.J.; de Boer, F.R. Magnetic-phase transitions and magnetocaloric effects. Physica B 2002, 319, 174–192. [Google Scholar] [CrossRef]

- Han, Z.D.; Wang, D.H.; Zhang, C.L.; Tang, S.L.; Gu, B.X.; Du, Y.W. Large magnetic entropy changes in the Ni45.4Mn41.5In13.1 ferromagnetic shape memory alloy. Appl. Phys. Lett. 2006, 89, 182507:1–182507:3. [Google Scholar]

- Krenke, T.; Duman, E.; Acet, M.; Wassermann, E.F.; Moya, X.; Mañosa, L.; Planes, A. Inverse magnetocaloric effect in ferromagnetic Ni-Mn-Sn alloys. Nat. Mater. 2005, 4, 450–454. [Google Scholar] [CrossRef]

- Moya, X.; Mañosa, L.; Planes, A.; Aksoy, S.; Acet, M.; Wassermann, E.F.; Krenke, T. Cooling and heating by adiabatic magnetization in the Ni50Mn34In16 magnetic shape-memory alloy. Phys. Rev. B 2007, 75, 184412:1–184412:5. [Google Scholar]

- Pathak, A.K.; Dubenko, I.; Karaca, H.E.; Stadler, S.; Ali, N. Large inverse magnetic entropy changes and magnetoresistance in the vicinity of a field-induced martensitic transformation in Ni50 − xCoxMn32 − yFeyGa18. Appl. Phys. Lett. 2010, 97, 062505:1–062505:3. [Google Scholar]

- Wang, B.M.; Ren, P.; Liu, Y.; Wang, L. Enhanced magnetoresistance through magnetic-field-induced phase transition in Ni2MnGa co-doped with Co and Mn. J. Magn. Magn. Mater. 2010, 322, 715–717. [Google Scholar] [CrossRef]

- Enkovaara, J.; Heczko, O.; Ayuela, A.; Nieminen, R.M. Coexistence of ferromagnetic and antiferromagnetic order in Mn-doped Ni2MnGa. Phys. Rev. B 2003, 67, 212405:1–212405:4. [Google Scholar]

- Yu, S.Y.; Cao, Z.X.; Ma, L.; Liu, G.D.; Chen, J.L.; Wu, G.H.; Zhang, B.; Zhang, X.X. Realization of magnetic field-induced reversible martensitic transformation in NiCoMnGa alloys. Appl. Phys. Lett. 2007, 91, 102507:1–102507:3. [Google Scholar]

- Bhobe, P.A.; Priolkar, K.R.; Sarode, P.R. Factors influencing the martensitic transformation in Ni50Mn35Sn15: An EXAFS study. J. Phys. Condens. Mater. 2008, 20. [Google Scholar] [CrossRef]

- Khan, M.; Dubenko, I.; Stadler, S.; Ali, N. Exchange bias in bulk Mn rich Ni-Mn-Sn Heusler alloys. J. Appl. Phys. 2007, 102, 113914:1–113914:4. [Google Scholar]

- Pathak, A.K.; Khan, M.; Gautam, B.R.; Stadler, S.; Dubenko, I.; Ali, N. Exchange bias in bulk Ni-Mn-In-based Heusler alloys. J. Magn. Magn. Mater. 2009, 321, 963–965. [Google Scholar] [CrossRef]

- Wang, B.M.; Liu, Y.; Wang, L.; Huang, S.L.; Zhao, Y.; Yang, Y.; Zhang, H. Exchange bias and its training effect in the martensitic state of bulk polycrystalline Ni49.5Mn34.5In16. J. Appl. Phys. 2008, 104, 043916:1–043916:4. [Google Scholar]

- Wang, B.M.; Liu, Y.; Xia, B.; Ren, P.; Wang, L. Large exchange bias obtainable through zero-field cooling from an unmagnetized state in Ni-Mn-Sn alloys. J. Appl. Phys. 2012, 111, 043912:1–043912:7. [Google Scholar]

- Wang, B.M.; Liu, Y.; Ren, P.; Xia, B.; Ruan, K.B.; Yi, J.B.; Ding, J.; Li, X.G.; Wang, L. Large exchange bias after zero-field cooling from an unmagnetized state. Phys. Rev. Lett. 2011, 106, 077203:1–077203:4. [Google Scholar]

- Nogués, J.; Schuller, I.K. Exchange bias. J. Magn. Magn. Mater. 1999, 192, 203–232. [Google Scholar] [CrossRef]

- Gschneidner, K.A., Jr.; Pecharsky, V.K.; Tsokol, A.O. Recent developments in magnetocaloric materials. Rep. Prog. Phys. 2005, 68, 10–1088. [Google Scholar]

- Khovaylo, V.V.; Skokov, K.P.; Koshkid’ko, Y.S.; Koledov, V.V.; Shavrov, V.G.; Buchelnikov, V.D.; Taskaev, S.V.; Miki, H.; Takagi, T.; Vasiliev, A.N. Adiabatic temperature change at first-order magnetic phase transitions: Ni2.19Mn0.81Ga as a case study. Phys. Rev. B 2008, 78, 060403:1–060403:4. [Google Scholar]

- Pecharsky, V.K.; Gschneidner, K.A., Jr. Giant magnetocaloric effect in Gd5(Si2Ge2). Phys. Rev. Lett. 1997, 78, 4494–4497. [Google Scholar] [CrossRef]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Wang, B.; Liu, Y. Exchange Bias and Inverse Magnetocaloric Effect in Co and Mn Co-Doped Ni2MnGa Shape Memory Alloy. Metals 2013, 3, 69-76. https://doi.org/10.3390/met3010069

Wang B, Liu Y. Exchange Bias and Inverse Magnetocaloric Effect in Co and Mn Co-Doped Ni2MnGa Shape Memory Alloy. Metals. 2013; 3(1):69-76. https://doi.org/10.3390/met3010069

Chicago/Turabian StyleWang, Baomin, and Yong Liu. 2013. "Exchange Bias and Inverse Magnetocaloric Effect in Co and Mn Co-Doped Ni2MnGa Shape Memory Alloy" Metals 3, no. 1: 69-76. https://doi.org/10.3390/met3010069