The Thermal Transformation Arrest Phenomenon in NiCoMnAl Heusler Alloys

Abstract

: In this report, we present findings of systematic research on NiCoMnAl alloys, with the purpose of acquiring a higher thermal transformation arrest temperature (TA). By systematic research, TA in the NiCoMnAl alloy systems was raised up to 190 K, compared to the highest TA of 130 K in NiCoMnIn. For a selected alloy of Ni40Co10Mn33Al17, magnetization measurements were performed under a pulsed high magnetic field, and the critical magnetic field-temperature phase diagram was determined. The magnetic phase diagram for Ni50−xCoxMn50−yAly was also established. Moreover, from the discussion that the formerly called “kinetic arrest phenomenon” has both thermodynamic and kinetic factors, we suggest a terminology change to the “thermal transformation arrest phenomenon”.1. Introduction

1.1. Kinetic Arrest Phenomenon and Thermal Transformation Arrest Phenomenon

It has been reported in Ni(Co)MnIn alloys that the martensitic transformation is interrupted during the cooling process, and the coexisting martensite and parent phases stay “stable” at low temperatures, even when the magnetic field is removed [1,2]. Moreover, as reported by Ito et al., when zero field heating was performed soon after field cooling, the “frozen” parent phase was “unfrozen”, and a heating-induced martensitic transformation could be observed [2]. Based on the above experimental findings, it has been thought that the “frozen” state is caused by kinetic factors that prohibit the transformation from the parent phase to the martensite phase at extremely low temperatures. Hence, this phenomenon has been termed the kinetic arrest (KA) phenomenon, and the corresponding temperature, at which the martensitic transformation is arrested, has been called the KA temperature.

Subsequently, the KA phenomenon was found in other NiMn-based alloy systems, such as Ni33Co13.4Mn39.7Ga13.9 [3], Ni45Co5Mn31Al19 [4] and Ni37Co11Mn42.5Sn9.5 [5]. For these Metamagnetic Shape Memory Alloys (MMSMAs), the ferromagnetic parent phase can be induced by applying a magnetic field from the martensite phase, as first reported in NiCoMnIn [6]. Thus, by magnetization measurements at various temperatures below the reverse martensitic transformation starting temperature (TAs), the magnetic fields of critical transition, i.e., the reverse martensitic transformation finishing magnetic field (HAf) and the forward martensitic transformation starting magnetic field (HMs), can be determined. By summarizing the results of Ni45Co5Mn36.7In13.3 [2], Ni33Co13.4Mn39.7Ga13.9 [3], Ni45Co5Mn31Al19 [4] and Ni37Co11Mn42.5Sn9.5 [5], it can be concluded that the magnetic field hysteresis, which is defined by Hhys = HAf − HMs, greatly increases at low temperatures, which strongly supports the kinetic nature of the KA phenomenon. Moreover, besides the enlargement of the Hhys at low temperatures, other experimental facts also support the kinetic nature of this unique phenomenon. For NiCoMnIn alloys, Ito et al. observed the isothermal behavior of martensitic transformation [7], and Lee et al. investigated the Time-Temperature-Transformation (TTT) diagram [8], where the time-dependent nucleation of the martensite phase has been confirmed. On the other hand, Sharma et al. [1] and Kustov et al. [9] systematically investigated the relaxation behavior during martensitic transformation, where the time-dependent growth of the martensite phase has also been confirmed. Furthermore, Nayak et al. found that the transformation hysteresis changes with the sweeping speed of the temperature and the magnetic field in the NiCoMnSb system [10]. Our group has also confirmed that for NiCoMnIn, the Hhys is greatly enlarged under a pulsed magnetic field, as compared to that under a static magnetic field [11]. Recently, in situ observation by our group has also confirmed that if the thermal activation energy related to the kinetic behavior differs, the optical microstructure also shows distinctive features [12].

Nevertheless, the derivation by Ito et al. [2] has shown that the KA phenomenon also has a thermodynamic nature. Generally, for the case of magnetic field-induced reverse martensitic transformation, the magnetic field hysteresis loop reflects the dissipation energy during the forward and reverse martensitic transformation. Therefore, the thermodynamic equilibrium condition between the two phases exists between HMs and HAf, and this condition is neither related to nor affected by kinetic factors. Physically, if the magnetization differences between the two phases (ΔM)at HMs and HAf are almost equal, H0 =(HAf +HMs)/2 can be assumed as the equilibrium magnetic field at which the parent phase and the martensite phase have an equal Gibbs free energy under the condition that a small amount of the martensite phase exists in the parent austenite matrix [13]. It can be concluded from [2–5] that H0 increases with decreasing temperature and becomes almost constant below certain temperatures (KA temperatures), which is a common feature of all four alloys. The Clausius-Clapeyron equation between the magnetic field and temperature gives:

In other words, the arrested parent phase during field cooling can be considered to be a thermodynamic phenomenon, while when the magnetic field is removed, it does not transform to the martensite phase, mainly because of kinetic reasons. Therefore, the former name, “kinetic arrest phenomenon”, may mislead as to the nature of this phenomenon. In this article, we suggest and will from now on neutrally call this phenomenon the “thermal transformation arrest (TTA) phenomenon” and the corresponding temperature, at which the forward martensitic transformation stops, to be the “thermal transformation arrest temperature (TA)”.

1.2. Considerations of the Thermal Transformation Arrest Phenomenon for Practical Applications

The TTA phenomenon is not only an interesting physical phenomenon, but it also has important implications for practical applications.

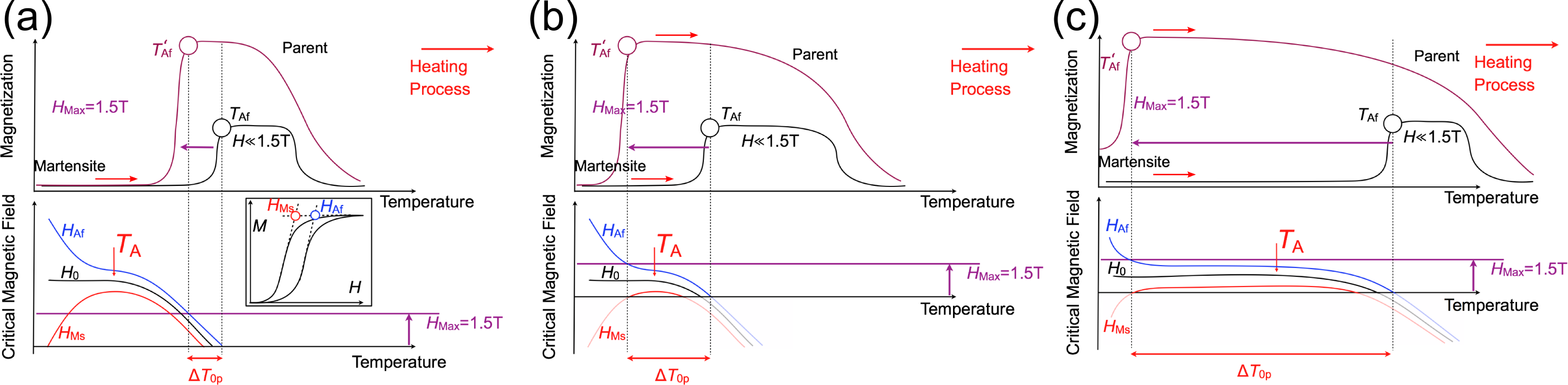

This is shown schematically in Figure 1. In the upper part of Figure 1(a), the results of the thermomagnetization (MT) measurement for a heating process of an MMSMA is shown. Under zero field heating (ZFH), where the applied magnetic field is very small, the martensite phase with weak magnetism changes to the parent phase with ferromagnetism at TAf. While under field heating (FH), where a strong magnetic field is applied, the transformation temperature decreases to T′Af, the MT curve being shown by the purple line. Moreover, when considering practical use, the maximum magnetic field a permanent magnet can produce is around 1.5 T, and thus, the temperature change is small, as indicated by the purple arrow. Since the process of magnetic field-induced reverse martensitic transformation is used for actuators, the consideration only focuses on the heating process, and the temperature range available for practical application is very limited, as shown by ΔT0p. The correspondence of the MT with the critical magnetic field-temperature (H0–T) diagram is shown in the lower part of Figure 1(a), where the definitions of HAf and HMs in the H0–T diagram are schematically shown in the inset. It can be seen that the linear part of the diagram is used and that the bending part corresponding to the TTA phenomenon is not related to this condition. Before proceeding to an explanation of the next figure, it should be pointed out that all the figures shown in Figure 1 are schematic, and this is only the case for an ideal MMSMA. For an actual MMSMA, such as NiCoMnIn, around 3–5 T of magnetic field is required for a reversible MFIT [6]. Therefore, 1.5 T is far from enough. For other systems, the required magnetic field is even larger.

For practical use, a temperature window wider than the narrow one shown in Figure 1(a) is required. As reported earlier, by simple variation of the composition, the horn-shaped H0–T diagram can be easily shifted vertically [15]. Figure 1(b) shows the condition where the diagram is shifted downwards. As the MT curves above show, by applying a magnetic field, TAf decreases more than the condition in Figure 1(a). Therefore, by using the flat portion of the diagram where the TTA phenomenon appears, a wider temperature window becomes available for applications, as shown by ΔT0p.

However, to get an even wider temperature window, attempts must be made to modify the shape of the horn-shaped H0–T diagram. As shown in Figure 1(c), if an alloy with a much higher TA is obtained, a larger temperature range of the flat portion in the H0–T diagram will be obtained, and thus, the upper limit of the temperature window can be greatly raised. Moreover, if the enlargement of Hhys at low temperatures can be suppressed, the lower limit of the temperature window can be further extended, as shown in the lower part of Figure 1(c). However, approaches for modification of the shape of the H0–T diagram have not been reported to date.

1.3. The Purpose of This Study

In this report, we focus on efforts to raise the TA in NiMn-based alloy systems. In NiCoMnIn, the tendency can be concluded from previous reports. It has been found that for Ni50−xCoxMn50−yIny, the TA increases from 73 K [16]to105K[17] with 2.5 at% dopant of Co and to 129 K [2] with 5 at% dopant of Co. Thus, if more Co can be added to NiMnIn, alloys with higher TA can be expected. However, as reported by Ito et al., with a 7.5 at% addition of Co, the parent phase decomposes into two phases [18]. Therefore, we have to search for alloy systems that have larger Co solubility. As shown by Kainuma et al., though both the parent phase and martensite phase of NiMnAl alloy have very weak magnetism, by the substitution of Co for Ni, the magnetism of the parent phase drastically becomes ferromagnetic, while the martensite phase remains as weak magnetism [19]. Therefore, the magnetic relationship in NiCoMnAl between the parent and martensite phases is similar to that of the NiCoMnIn alloy system, and metamagnetic transformation has also been confirmed in NiCoMnAl [19]. In the original report [19], 10 at% of Co was added, and even larger solubility of Co, and, thus, a higher TA, can be expected. In the present research, a systematical investigation on the NiCoMnAl alloy system was carried out, with the purpose of searching for a higher TA.

2. Experimental Procedures

Ni50−xCoxMn50−yAly (x = 5, 10, 15, y = 12–19, CoxAly for short) samples were prepared by induction melting in an argon atmosphere. Heat treatment was conducted at 1,373 K for 24 h, followed by water quenching. Composition analysis was carried out by an Electron Probe Microanalyzer (EPMA), and the results are summarized in Table 1. MT measurements were performed by a Vibration Sample Magnetometer and a SQUIDmagnetometer at a sweeping speed of 2 K/min. Magnetization measurements under a pulsed magnetic field up to 55 T were measured by induction using coaxial pickup coils [20] at the Institute for Solid State Physics, the University of Tokyo.

3. Results and Discussion

3.1. Thermal Transformation Arrest Temperatures in Co-Doped Alloys

In the CoxAly system, the TTA phenomenon was first realized with the compositions of Co5Aly [4]. As shown in Figure 2(a), the martensitic transformation is interrupted at around 40 K. The application of a magnetic field has a drastic effect on the behavior of martensitic transformation. For this alloy, with the application of a higher magnetic field, the magnetization at low temperatures continues growing, and the martensitic transformation almost stopped under a 7 T field cooling, suggesting a strong arresting.

By the arrangement of composition, the TTA phenomenon was also realized in Co10Alx in this study. Figure 2(b) shows the MT curves of Co10Al17.5 under magnetic fields of 0.05, 1, 3 and 5 T. Martensitic transformation starting temperature (TMs) was observed to decrease with increasing applied magnetic field. As explained in Figure 2(a), with the increase of the applied magnetic field, the magnetization in the low temperatures part also increases. This also indicates the appearance of the TTA phenomenon, and the TA is determined to be around 160 K.

Moreover, Figure 2(c) shows the magnetization curves of Co15Al15 under magnetic fields of 3, 5 and 7 T, which follows Khovaylo et al. [21]. Due to the fact that both the TC and the TAf are high for this sample, the temperature hysteresis could not be fully measured. For this alloy, the martensitic transformation is also interrupted, and the TA is determined to be 190 K. Thus, as shown in Figure 2, the doping of Co into NiMnAl is also found to be effective to raise the TA, and a high TA of about 190 K was obtained in the Co15Alx.

3.2. Magnetization Measurements in Pulsed Magnetic Field

As first reported for NiCoMnIn, the H0–T phase diagram for the alloys with TTA behavior show horn-shaped curves [2]. The HMs and HAf make up the lower and upper branches, respectively, and the H0 becomes constant below the TA. This behavior has been confirmed for the first time in Co5Al19 [4] in the the NiCoMnAl alloy system, and for Co10Al17, the investigation was conducted in this study by magnetization measurements under a pulsed magnetic field.

Figure 3(a) shows the magnetization curves for Co10Al17 up to 55 T at 50, 100, 200 and 300 K. Raw data of the differentiations of magnetization and magnetic field against measurement time are obtained, and the integrals yield the magnetization-magnetic field curves. Normally, calibration for obtaining the integral constants is conducted using the results of the magnetization measurements obtained by SQUID in the low magnetic field region, and the absolute values of magnetization can be also obtained. Especially for the case when a ferromagnetic-like behavior can be observed in low magnetic fields, the calibration becomes very easy. However, the calibration for the integral constants was not successful for this sample, since the magnetism in the martensite phase (which is the only state we can obtain in low magnetic fields) is paramagnetic-like. Therefore, the unit in Figure 3(a) is shown as a.u.. Nevertheless, we can clearly observe that magnetic field-induced reverse martensitic transformation for all the temperatures and an almost full parent phase were obtained, except for 50 K. Moreover, the determination of critical magnetic fields (HMs and HAf) by extrapolation, as shown in Figure 3(a), is also not affected at all by the arbitrary values of magnetization. For 50 K, since the reverse martensitic transformation is not complete, HMs and HAf could not be determined. Therefore, it can be generally concluded that the critical magnetic fields shift higher as the measurement temperature becomes lower.

The critical magnetic fields are summarized in Figure 3(b), and the results for Co5Al19 [4] are plotted. For Co10Al17, it can be seen that, below the TA, H0 becomes almost constant, while the Hhys begins to enlarge below this temperature. However, if the results of Co10Al17 and Co5Al19 are compared, one can easily find two differences between them. First, the TA is much higher for Co10Al17, as already stated in Figure 2. Second, the Hhys/2 around TA is only about 2–3 T for Co5Al19, while that of Co10Al17 reaches 10 T. It should be noted that both of the results of the referenced Co5Al19 or Co10Al17 by this study were investigated under a pulsed magnetic field. As stated in the introduction, the Hhys is enlarged under a pulsed magnetic field for the measurement of NiCoMnIn, compared to that under a static magnetic field [11]; a smaller Hhys would be expected for Co10Al17 if the magnetization measurement under a static magnetic field were possible. For investigations on Hhys, recent studies by our group have given some phenomenological understanding of its breakdown and temperature dependency [12,22]. Here, we plot the Hhys/2 for both Co5Al19 and Co10Al17 in Figure 3(c), where the Hhys for 50 K is estimated by the difference of the magnetizing and demagnetizing branches in Figure 3(a) and is shown by an open circle in Figure 3(c). As shown by the findings of Umetsu et al. [22], it is found that both the athermal term (Hμ) and the thermally activated term (HTA) for Co10Al17 are much larger than those of Co5Al19. In Figure 3(c), the red solid line for fitting the Hhys/2 of Co10Al17 is given by [22]:

3.3. Determination of the Magnetic Phase Diagram for Ni50−xCoxMn50−yAly

Figure 4 shows the thermomagnetization curves for CoxAly, where none of the samples show martensitic transformation behaviors. For stoichiometric samples (y = 25), no martensitic transformation can be observed [23], and the samples shown in Figure 4 are nearer stoichiometry than the samples showing martensitic transformations, as illustrated in Figure 2. Only Curie temperature (TC) is observed, and it is defined to be the temperature at which the differentiation shows a minimum (not shown). It can be observed that the TC is greatly raised by the addition of Co content, which is consistent with the former report on CoxAl25 samples [23], and has the same tendency as compared with NiCoMnIn [18,24] and NiCoMnGa [25,26].

Similar measurements of other samples shown in Table 1 were also performed; the obtained TMs and TC are listed in Table 1 and summarized in Figure 5. It can be seen that for the series of samples with the same Co content, the TMs decreases with increasing Al content, which is the same as NiMnAl [28]. However, the decreasing tendency enhances when below the TC, which is similar to the case of NiCoMnIn alloys [18]. The tendencies, as well as the values of the transition temperatures are consistent with former reports [23,27–29], as shown in Figure 5. It should be also pointed out that, for solution-treated NiMnAl ternary alloys, the parent phase with a B2 structure is antiferromagnetic and the TC does not exist [28]. With aging treatment at low temperatures, the crystal structure changes from B2 to L21, and this results in ferromagnetism in the parent phase near the stoichiometric composition [28,30]. Though not shown in this report, NiCoMnAl alloys in this study also showed the same tendency, i.e., the TC increases after aging at low temperatures. The TAs obtained in Figure 2 are also indicated in Figure 5. It was found that the TA does not seem to change in the same series of samples with the same Co composition. Furthermore, the Co addition greatly raises TA. The TTA phenomenon has been schematically explained by Gibbs free energy curves [18] and is believed to be greatly affected by the ferromagnetic state of the parent phase. Therefore, the increase of TA in NiCoMnAl can be easily understood, since the addition of Co strongly raises the TC of the parent phase. Though TA was successfully raised in NiCoMnAl alloys, which satisfies the purpose of this study, the Hhys is greatly enlarged, and this is extremely unfavorable from the viewpoint of applications. To date, the way to decreasing the Hhys is still unknown and remains to be investigated further in the future.

4. Conclusions

In this study, the magnetic properties of the Ni50−xCoxMn50−yAly alloy system were systematically investigated with the purpose of raising the thermal transformation arrest temperature (TA). The TA was raised from 40 K, for the first time in this system, to about 190 K, by the substitution of Co for Ni. Furthermore, the critical magnetic field-temperature phase diagram for Ni40Co10Mn33Al17(Co10Al17) was determined under a pulsed high magnetic field. Magnetic field hysteresis Hhys during the magnetic field-induced reverse martensitic transformation was found to be greatly enlarged below the TA for Co10Al17. The magnetic phase diagram for Ni50−xCoxMn50−yAly was also determined in this study. Finally, a change in terminology is proposed, i.e., from “kinetic arrest phenomenon” to “thermal transformation arrest phenomenon”, which is in line with the experimental results based on phenomenological understandings.

Acknowledgments

This work was supported by a Grant-in-Aid for Scientific Research and by a grant from the Japan Society for the Promotion of Science (JSPS). This work was also partially supported by MEXT, Japan, through a Grant-in-Aid for Scientific Research (23340096). A part of this work was carried out at the Center for Low Temperature Science, Institute for Materials Research, Tohoku University.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Sharma, V.K.; Chattopadhyay, M.K.; Roy, S.B. Kinetic arrest of the first order austenite to martensite phase transition in Ni50Mn34In16: Dc magnetization studies. Phys. Rev. B 2007, 76, 140401. [Google Scholar]

- Ito, W.; Ito, K.; Umetsu, R.Y.; Kainuma, R.; Koyama, K.; Watanabe, K.; Fujita, A.; Oikawa, K.; Ishida, K.; Kanomata, T. Kinetic arrest of martensitic transformation in the NiCoMnIn metamagnetic shape memory alloy. Appl. Phys. Lett 2008, 92, 021908. [Google Scholar]

- Xu, X.; Ito, W.; Umetsu, R.Y.; Koyama, K.; Kainuma, R.; Ishida, K. Kinetic arrest of martensitic transformation in Ni33.0Co13.4Mn39.7Ga13.9 metamagnetic shape memory alloys. Mater. Trans 2010, 51, 469–471. [Google Scholar]

- Xu, X.; Ito, W.; Tokunaga, M.; Umetsu, R.Y.; Kainuma, R.; Ishida, K. Kinetic arrest of martensitic transformation in NiCoMnAl metamagnetic shape memory alloys. Mater. Trans 2010, 51, 1357–1360. [Google Scholar]

- Umetsu, R.Y.; Ito, K.; Ito, W.; Koyama, K.; Kanomata, T.; Ishida, K.; Kainuma, R. Kinetic arrest behavior in martensitic transformation of NiCoMnSn metamagnetic shape memory alloy. J. Alloys Compd 2011, 509, 1389–1393. [Google Scholar]

- Kainuma, R.; Imano, Y.; Ito, W.; Sutou, Y.; Morito, H.; Okamoto, S.; Kitakami, O.; Oikawa, K.; Fujita, A.; Kanomata, T.; et al. Magnetic-field-induced shape recovery by reverse phase transformation. Nature 2006, 439, 957–960. [Google Scholar]

- Ito, W.; Umetsu, R.Y.; Kainuma, R.; Kakeshita, T.; Ishida, K. Heat-induced and isothermal martensitic transformations from kinetically arrested parent phase in NiCoMnIn metamagnetic shape memory alloy. Scr. Mater 2010, 63, 73–76. [Google Scholar]

- Lee, Y.; Todai, M.; Okuyama, T.; Fukuda, T.; Kakeshita, T.; Kainuma, R. Isothermal nature of martensitic transformation in an Ni45Co5Mn36.5In13.5 magnetic shape memory alloy. Scr. Mater 2011, 64, 927–930. [Google Scholar]

- Kustov, S.; Golovin, I.; Corró, M.; Cesari, E. Isothermal martensitic transformation in metamagnetic shape memory alloys. J. Appl. Phys 2010, 107, 053525. [Google Scholar]

- Nayak, A.K.; Suresh, K.G.; Nigam, A.K. Metastability of magneto-structural transition revealed by sweep rate dependence of magnetization in Ni45Co5Mn38Sb12 Heusler alloy. J. Appl. Phys 2011, 109, 07A906. [Google Scholar]

- Xu, X.; Ito, W.; Katakura, I.; Tokunaga, M.; Kainuma, R. In situ optical microscopic observation of NiCoMnIn metamagnetic shape memory alloy under pulsed high magnetic field. Scr. Mater 2011, 65, 946–949. [Google Scholar]

- Xu, X.; Katakura, I.; Kihara, T.; Tokunaga, M.; Ito, W.; Umetsu, R.Y.; Kainuma, R. Optical microscopic study on NiCoMnAl metamagnetic shape memory alloy by in situ observation under a pulsed high magnetic field. Mater. Trans 2013, 3, 357–362. [Google Scholar]

- Tong, H.C.; Wayman, C.M. Characteristic temperatures and other properties of thermoelastic martensites. Acta Metall 1974, 22, 887–896. [Google Scholar]

- Cesari, E.; Kustov, S.; Salas, D. Entropy changes in ferromagnetic shape memory alloys. Mater. Sci. Forum 2011, 684, 49–60. [Google Scholar]

- Umetsu, R.Y.; Kusakari, Y.; Kanomata, T.; Suga, K.; Sawai, Y.; Kindo, K.; Oikawa, K.; Kainuma, R.; Ishida, K. Metamagnetic behaviour under high magnetic fields in Ni50Mn50−x Inx (x = 14.0 and 15.6) shape memory alloys. J. Phys. D 2009, 42, 075003. [Google Scholar]

- Umetsu, R.Y.; Ito, W.; Ito, K.; Koyama, K.; Fujita, A.; Oikawa, K.; Kanomata, T.; Kainuma, R.; Ishida, K. Anomaly in entropy change between parent and martensite phases in the Ni50Mn34In16 Heusler alloy. Scr. Mater 2009, 60, 25–28. [Google Scholar]

- Ito, W. Martensitic Transformation and Magnetic Properties in Ni-Mn Based Metamagnetic Shape Memory Alloys. Ph.D. Thesis, Tohoku University, 2009..

- Ito, W.; Imano, Y.; Kainuma, R.; Sutou, Y.; Oikawa, K.; Ishida, K. Martensitic and magnetic transformation behaviors in Heusler-type NiMnln and NiCoMnln metamagnetic shape memory alloys. Metall. Mater. Trans. A 2007, 38A, 759–766. [Google Scholar]

- Kainuma, R.; Ito, W.; Umetsu, R.Y.; Oikawa, K.; Ishida, K. Magnetic field-induced reverse transformation in B2-type NiCoMnAl shape memory alloys. Appl. Phys. Lett 2008, 93, 091906. [Google Scholar]

- Kindo, K. 100 T magnet developed in Osaka. Phys. B Cond. Mat 2001, 294, 585–590. [Google Scholar]

- Khovaylo, V.V.; Lyange, M.; Skokov, K.; Gutfleisch, O.; Chatterjee, R.; Xu, X.; Kainuma, R. Adiabatic temperature change in metamagnetic Ni(Co)-Mn-Al Heusler alloys. Mater. Sci. Forum 2013, 738–739, 446–450. [Google Scholar]

- Umetsu, R.Y.; Endo, K.; Kondo, A.; Kindo, K.; Ito, W.; Xu, X.; Kanomata, T.; Kainuma, R. Magnetoresistance and transformation hysteresis in the Ni50Mn34.6In15.6 metamagnetic shape memory alloys. Mater. Trans 2013, 3, 291–296. [Google Scholar]

- Okubo, A.; Xu, X.; Umetsu, R.Y.; Kanomata, T.; Ishida, K.; Kainuma, R. Magnetic properties of Co50−x Nix Mn25Al25 alloys with B2 structure. J. Appl. Phys 2011, 109, 07B114. [Google Scholar]

- Wu, Z.G.; Liu, Z.H.; Yang, H.; Liu, Y.N.; Wu, G.H. Effect of Co addition on martensitic phase transformation and magnetic properties of Mn50Ni40−x In10Cox polycrystalline alloys. Intermetallics 2011, 19, 1839–1848. [Google Scholar]

- Yu, S.Y.; Cao, Z.X.; Ma, L.; Liu, G.D.; Chen, J.L.; Wu, G.H.; Zhang, B.; Zhang, X.X. Realization of magnetic field-induced reversible martensitic transformation in NiCoMnGa alloys. Appl. Phys. Lett 2007, 91, 102507. [Google Scholar]

- Fabbrici, S.; Albertini, F.; Paoluzi, A.; Bolzoni, F.; Cabassi, R.; Solzi, M.; Righi, L.; Calestani, G. Reverse magnetostructural transformation in Co-doped NiMnGa multifunctional alloys. Appl. Phys. Lett 2009, 95, 022508. [Google Scholar]

- Krén, E.; Nagy, E.; Nagy, I.; Pál, L.; Szabó, P. Structures and phase transformations in Mn-Ni system near equiatomic concentration. J. Phys. Chem. Solids 1968, 29, 101–108. [Google Scholar]

- Kainuma, R.; Gejima, F.; Sutou, Y.; Ohnuma, I.; Ishida, K. Ordering, martensitic and ferromagnetic transformations in Ni-Al-Mn Heusler shape memory alloys. Mater. Trans 2000, 41, 943–949. [Google Scholar]

- Kim, Y.; Han, W.B.; Kim, H.S.; An, H.H.; Yoon, C.S. Phase transitions and magnetocaloric effect of Ni1.7Co0.3Mn1+x Al1−x Heusler alloys. J. Alloys Compd 2013, 557, 265–269. [Google Scholar]

- Ziebeck, K.R.A.; Webster, P.J. Helical magnetic order in Ni2MnAl. J. Phys. F Met. Phys 1975, 5, 1756–1766. [Google Scholar]

| Nominal | Ni at% | Co at% | Mn at% | Al at% | TC | TMs |

|---|---|---|---|---|---|---|

| Co5Al18.5 | 44.7 | 5.1 | 32.0 | 18.2 | - | 322 |

| Co5Al20 | 44.4 | 5.1 | 30.5 | 20.0 | 269 | 129 |

| Co5Al21 | 44.4 | 5.1 | 29.4 | 21.1 | 257 | - |

| Co10Al17 | 39.7 | 10.2 | 33.7 | 16.4 | 428 | 351 |

| Co10Al17.5 | 39.9 | 10.1 | 33.3 | 16.7 | 423 | 252 |

| Co10Al19 | 39.9 | 10.1 | 30.6 | 19.4 | 394 | - |

| Co15Al12 | 34.7 | 14.8 | 38.8 | 11.7 | - | 525 |

| Co15Al14 | 34.5 | 14.8 | 37.0 | 13.7 | 527 | 450 |

| Co15Al14.5 | 35.0 | 15.2 | 35.6 | 14.2 | 516 | 390 |

| Co15Al14.8 | 35.0 | 15.0 | 35.6 | 14.4 | 360 | |

| Co15Al15 | 34.5 | 15.0 | 35.8 | 14.7 | 514 | 332 |

| Co15Al15.5 | 34.5 | 15.1 | 35.4 | 15.0 | 510 | - |

| Co15Al17 | 34.9 | 15.3 | 32.8 | 17.0 | 503 | - |

© 2013 by the authors; licensee MDPI, Basel, Switzerland This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Xu, X.; Ito, W.; Tokunaga, M.; Kihara, T.; Oka, K.; Umetsu, R.Y.; Kanomata, T.; Kainuma, R. The Thermal Transformation Arrest Phenomenon in NiCoMnAl Heusler Alloys. Metals 2013, 3, 298-311. https://doi.org/10.3390/met3030298

Xu X, Ito W, Tokunaga M, Kihara T, Oka K, Umetsu RY, Kanomata T, Kainuma R. The Thermal Transformation Arrest Phenomenon in NiCoMnAl Heusler Alloys. Metals. 2013; 3(3):298-311. https://doi.org/10.3390/met3030298

Chicago/Turabian StyleXu, Xiao, Wataru Ito, Masashi Tokunaga, Takumi Kihara, Kengo Oka, Rie Y. Umetsu, Takeshi Kanomata, and Ryosuke Kainuma. 2013. "The Thermal Transformation Arrest Phenomenon in NiCoMnAl Heusler Alloys" Metals 3, no. 3: 298-311. https://doi.org/10.3390/met3030298