Ductility of Nanostructured Bainite

Abstract

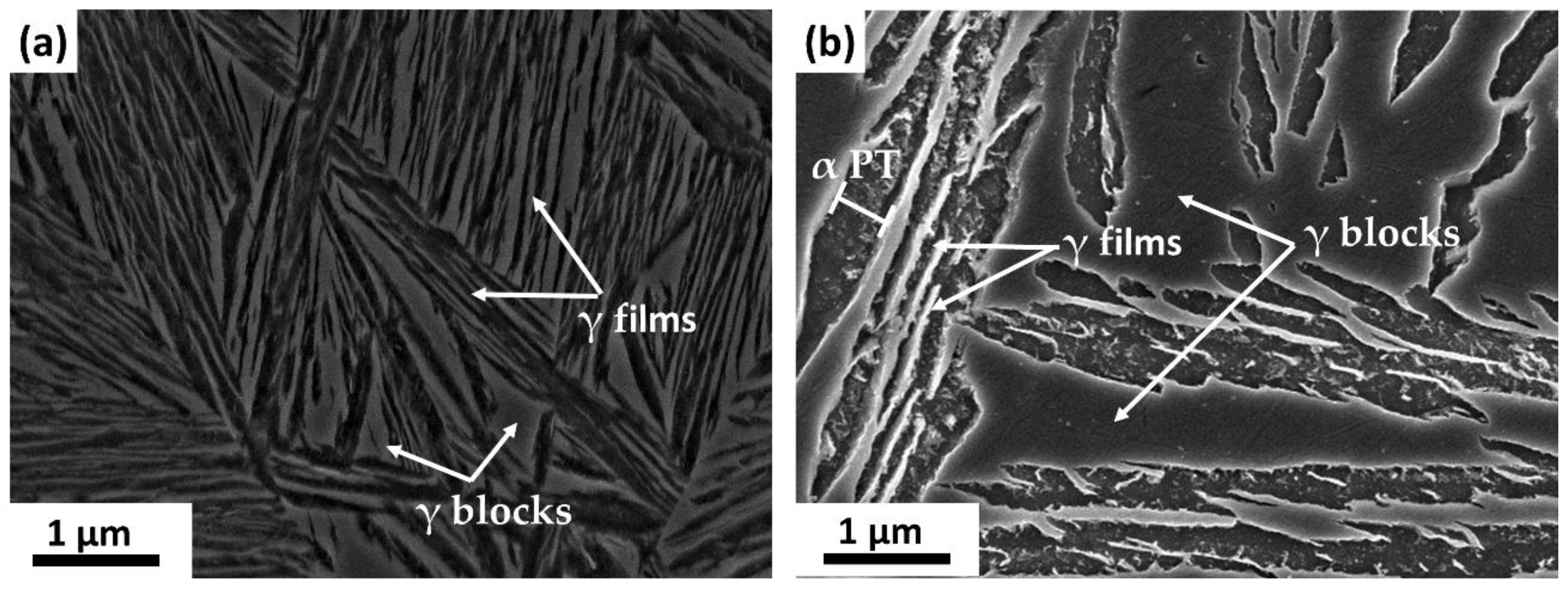

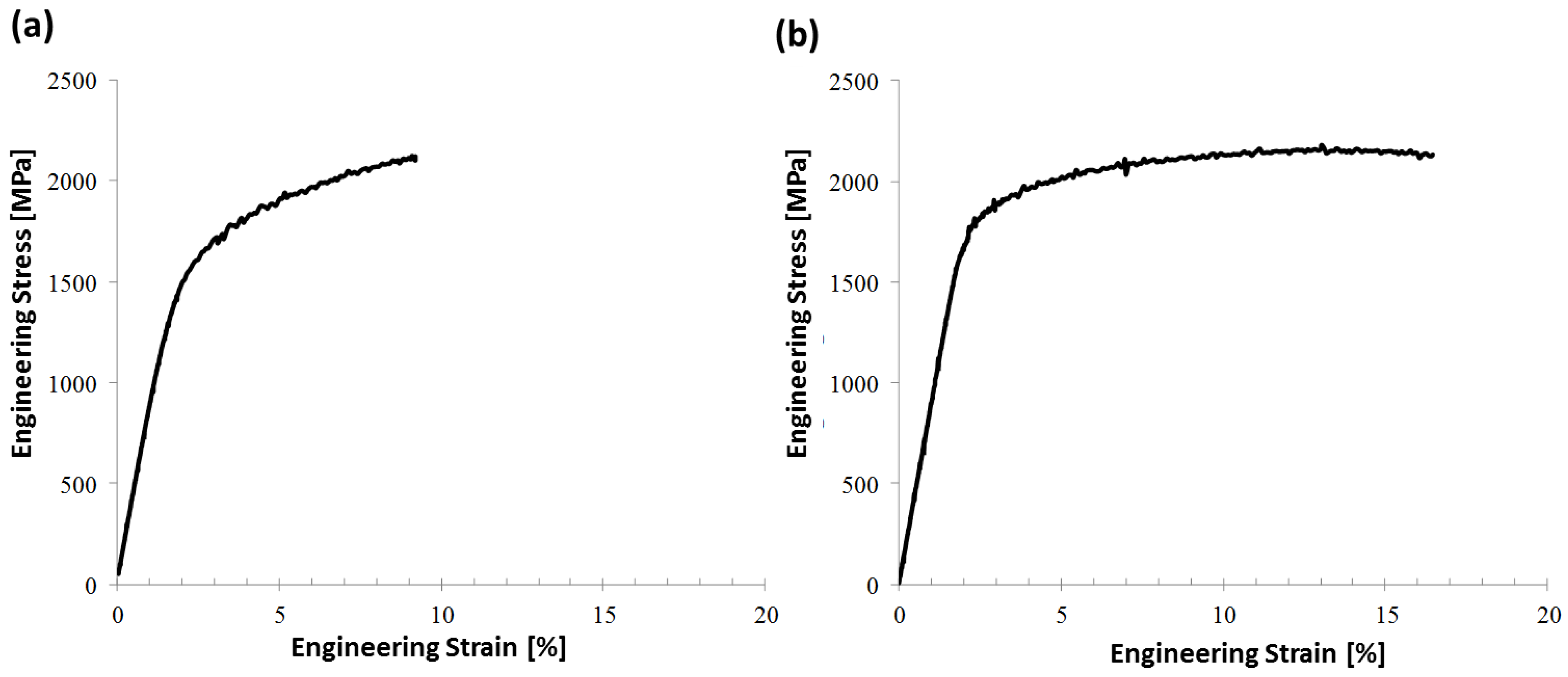

:1. Nanostructured Bainite: Heat-Treatments and Microstructure

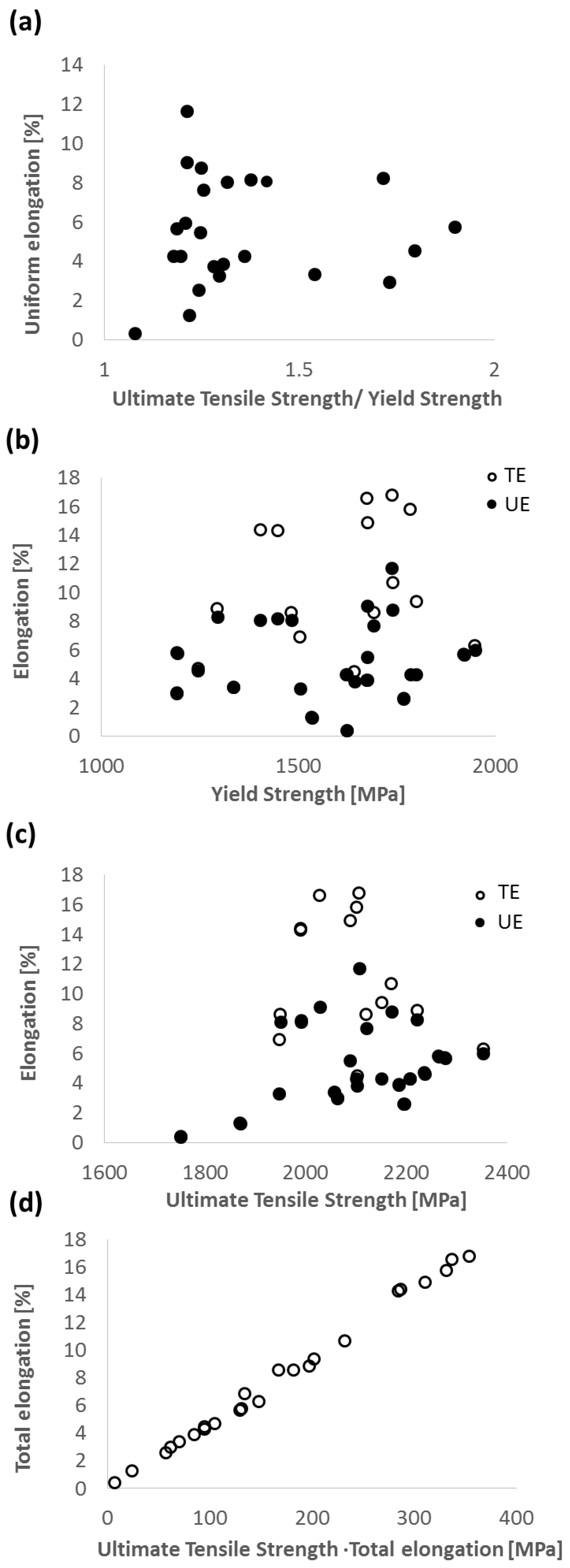

2. Mechanical Properties of Nanostructured Bainite

3. General Considerations on Ductility

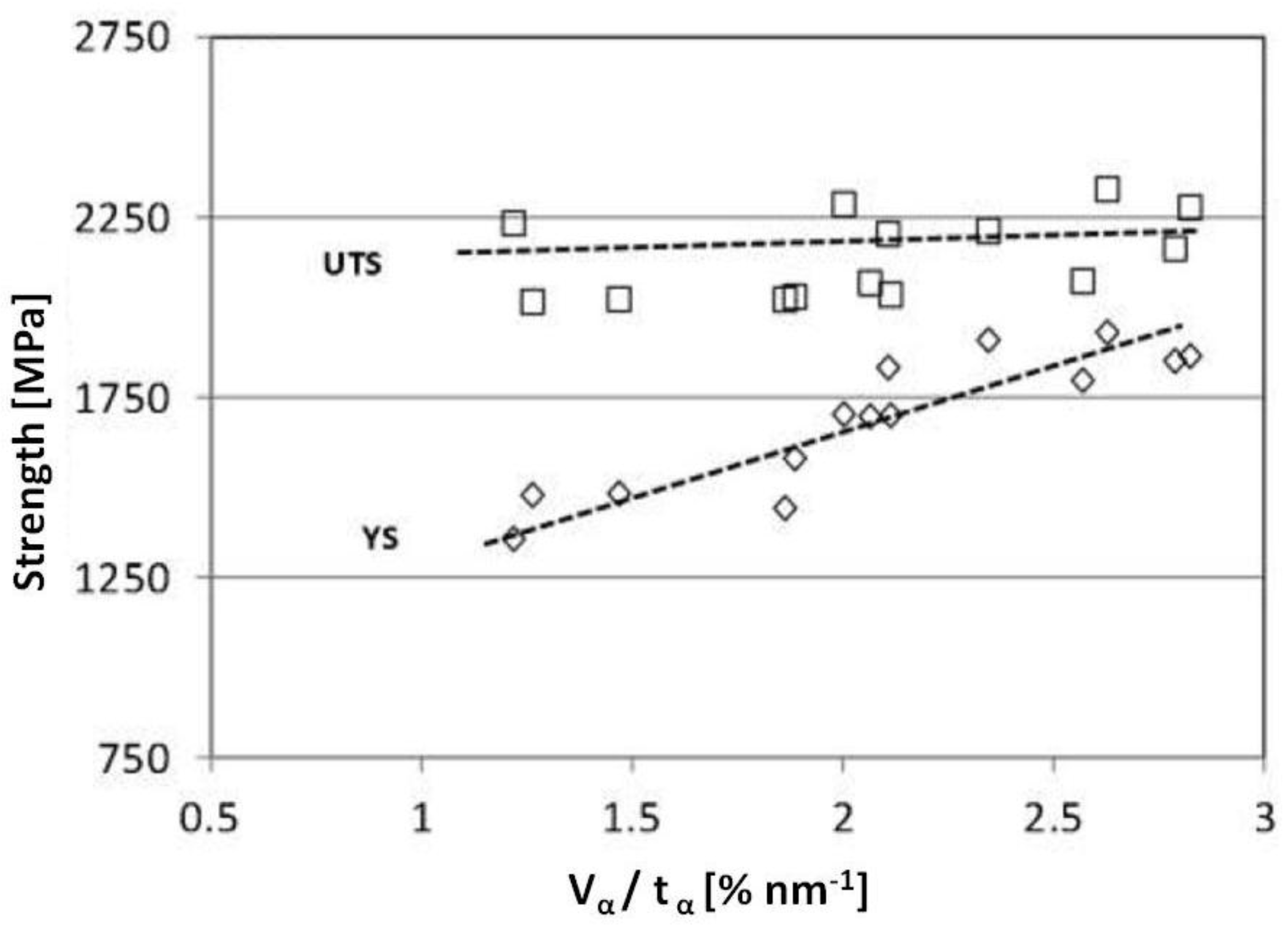

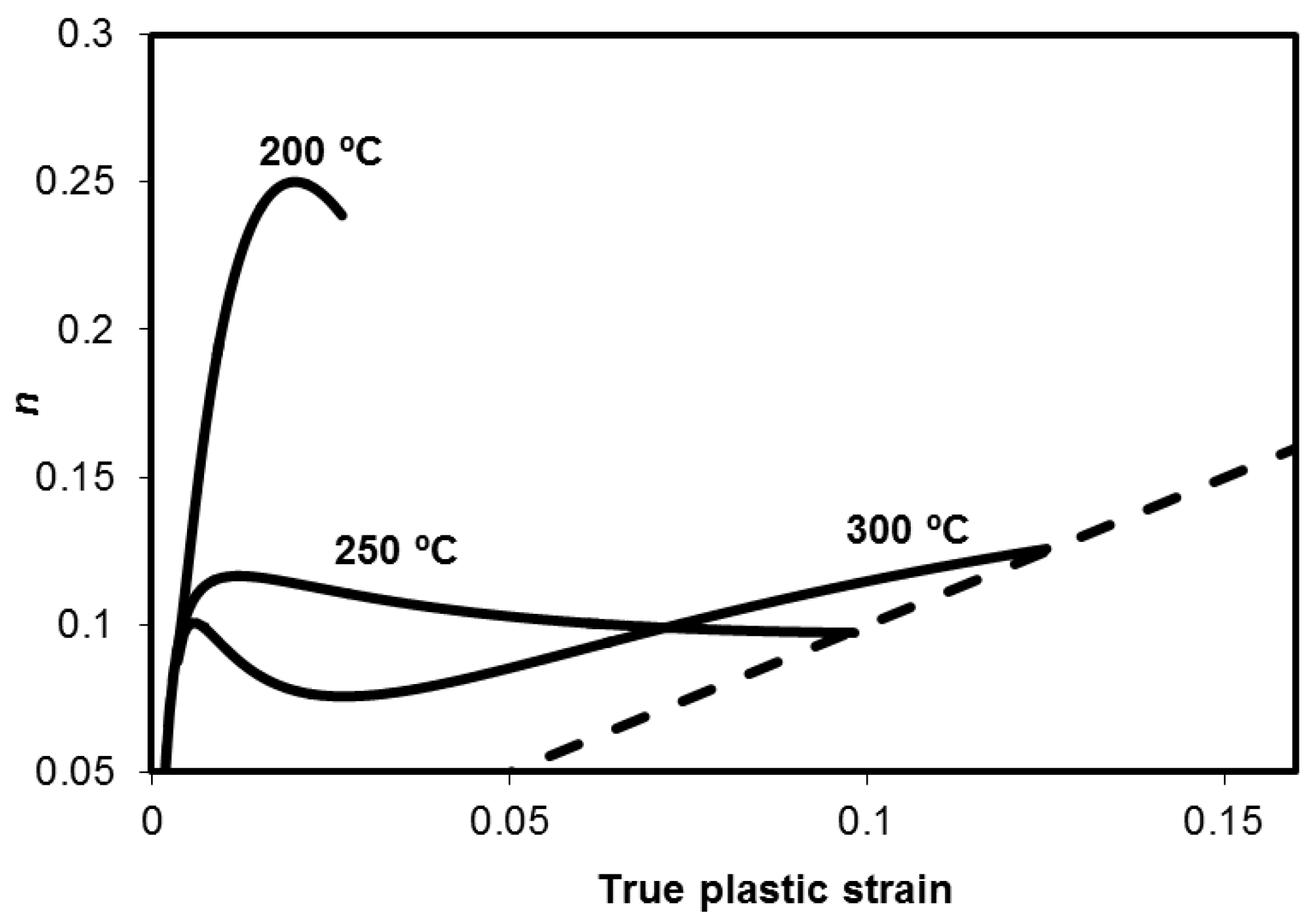

3.1. General Considerations on Work-Hardening

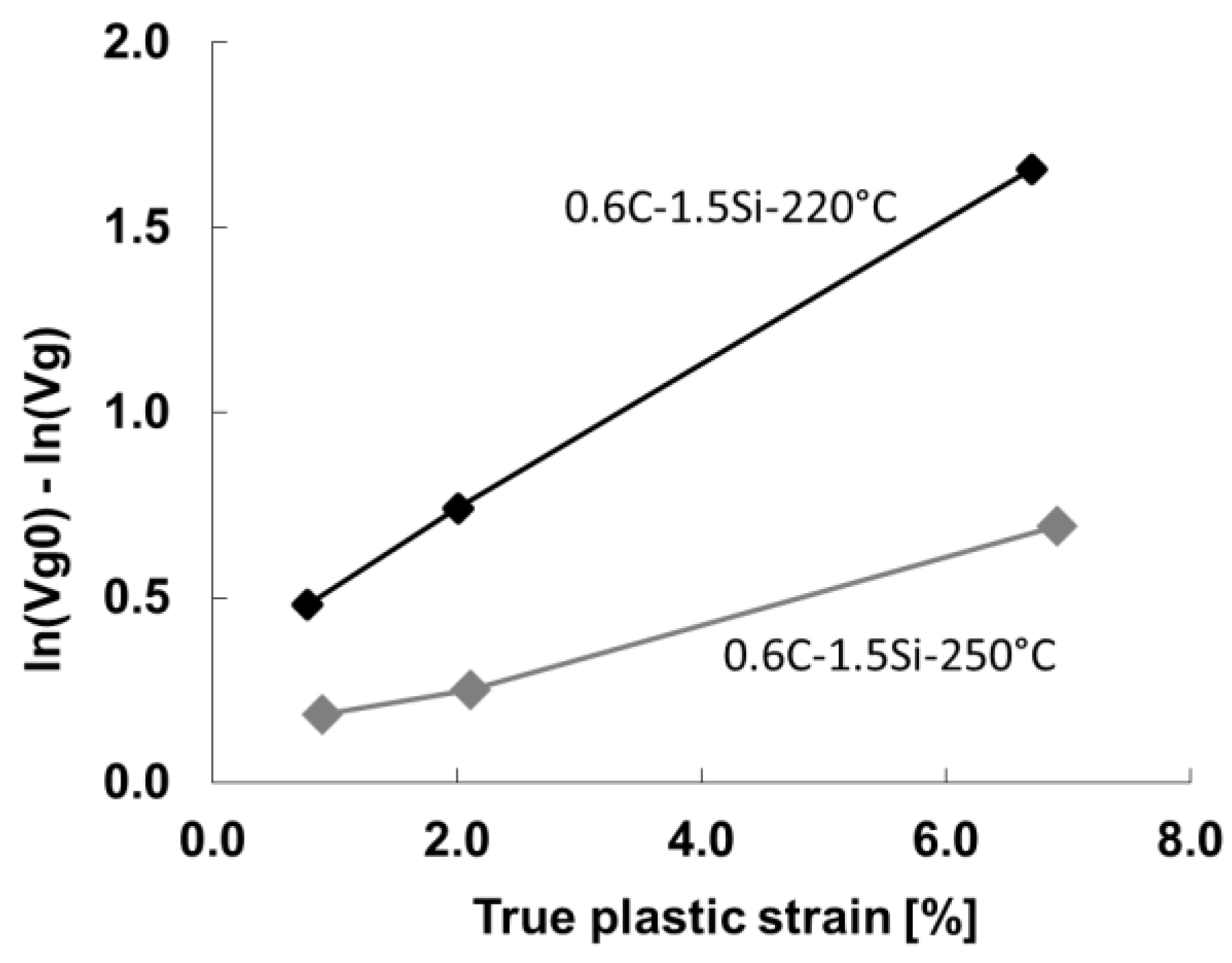

3.2. General Considerations on Fracture Mechanisms

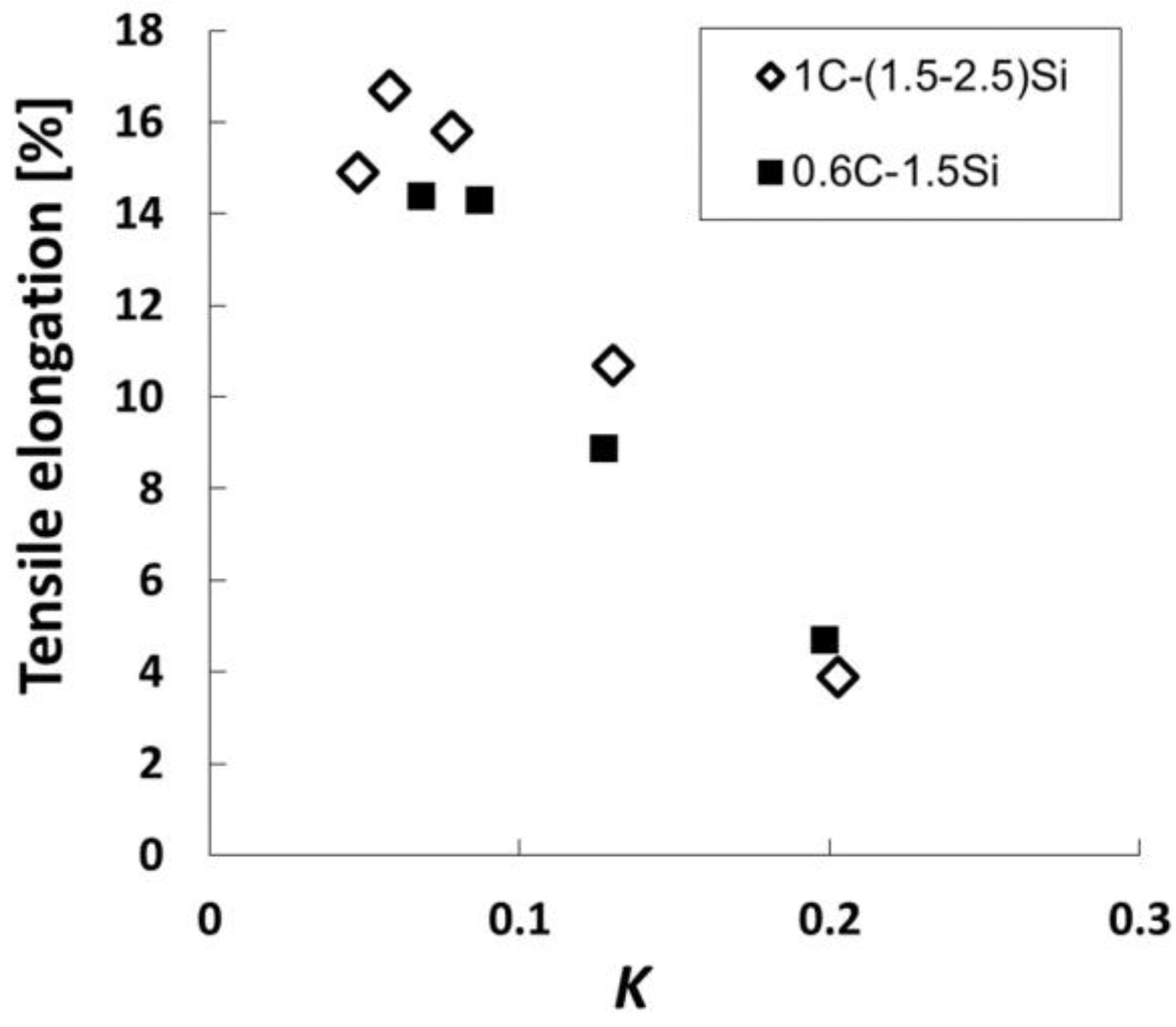

4. Ductility: Work-Hardening and Fracture Mechanisms in Nanostructured Bainite

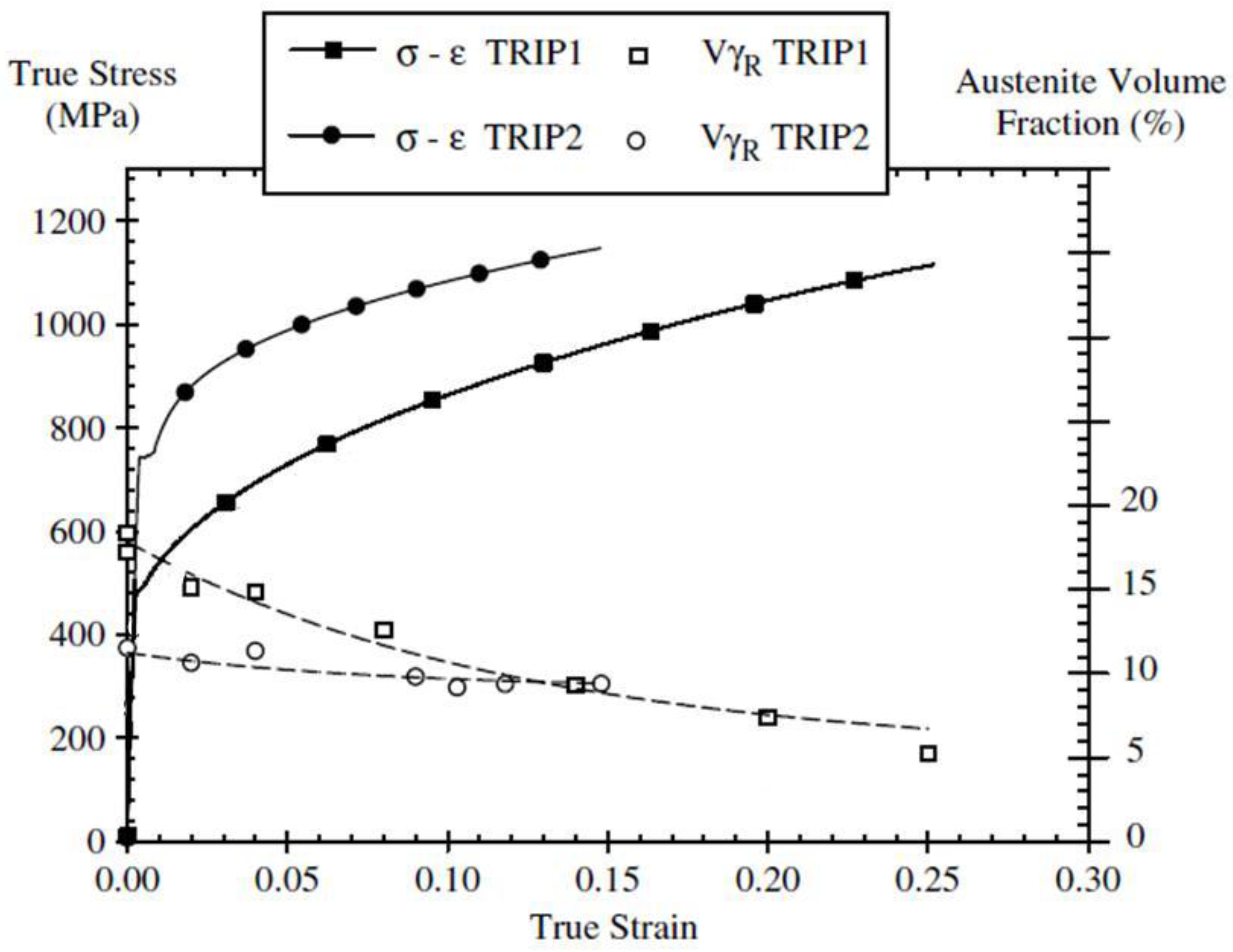

5. Ductility and Retained Austenite Content

6. Retained Austenite Evolution and Mechanical Partitioning

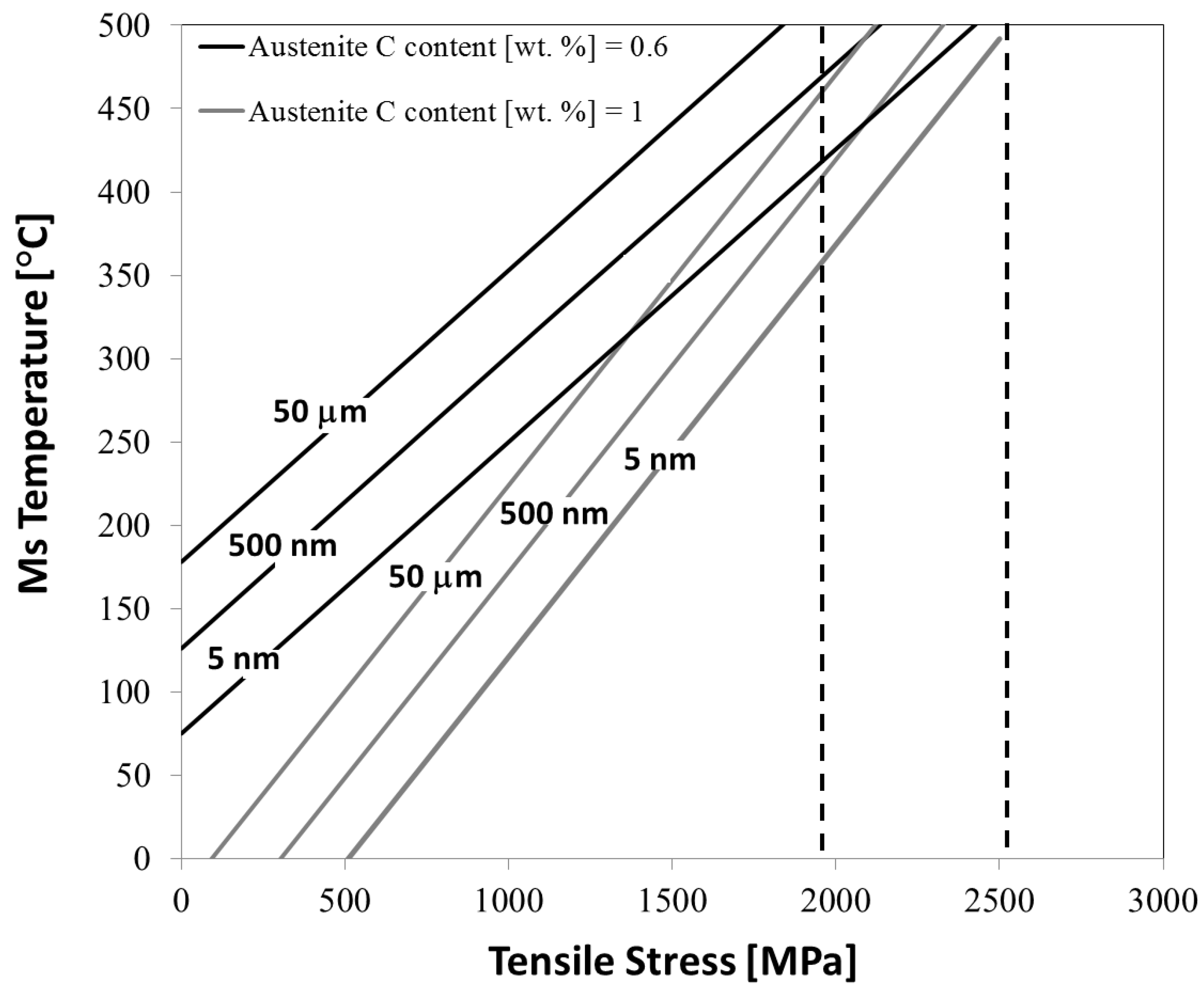

- (1)

- The most favorable orientation of the austenite crystal with the applied stress.

- (2)

- Two austenite C contents, 0.6 and 1 wt %. This covers a range of concentrations in good agreement with the values detected by XRD for the nanobainitic structures examined in the mentioned reference [54].

- (3)

- . This is the necessary condition for stress-assisted martensitic transformation, which represents its similarity to the martensitic transformation on cooling.

7. Mechanical Mismatch of Phases and Ductility

8. Conclusions

Acknowledgments

Conflicts of Interest

References

- Raabe, D.; Ponge, D.; Dmitrieva, O.; Sander, B. Nanoprecipitate-hardened 1.5 GPa steels with unexpected high ductility. Scr. Mater. 2009, 60, 1141–1144. [Google Scholar] [CrossRef]

- Raabe, D. Maraging Steels and Maraging TRIP Steels. Avaliable online: http://www.dierk-raabe.com/martensite-alloys-and-transformations/maraging-trip-steels/ (accessed on 28 November 2016).

- Bhadeshia, H.K.D.H. Bainite in Steels, 2nd ed.; Institute of Materials, Maney Publishing: London, UK, 2001. [Google Scholar]

- Timokhina, I.B.; Beladi, H.; Xiong, X.Y.; Adachi, Y.; Hodgson, P.D. Nanoscale microstructural characterization of a nanobainitic steel. Acta Mater. 2011, 59, 5511–5522. [Google Scholar] [CrossRef]

- Caballero, F.G.; Bhadeshia, H.K.D.H. Very strong bainite. Curr. Opin. Solid State Mater. Sci. 2004, 8, 251–257. [Google Scholar] [CrossRef]

- Yang, J.; Wang, T.S.; Zhang, B.; Zhang, F.C. Microstructure and mechanical properties of high-carbon Si-Al-rich steel by low-temperature austempering. Mater. Des. 2012, 35, 170–174. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. Nanostructured bainite. Proc. R. Soc. A Math. Phys. Eng. Sci. 2010, 466, 3–18. [Google Scholar] [CrossRef]

- Sourmail, T.; Caballero, F.G.; Garcia-Mateo, C.; Smanio, V.; Ziegler, C.; Kuntz, M.; Elvira, R.; Leiro, A.; Vuorinen, E.; Teeri, T. Evaluation of potential of high Si high C steel nanostructured bainite for wear and fatigue applications. Mater. Sci. Technol. 2013, 29, 1166–1173. [Google Scholar] [CrossRef]

- Garcia-Mateo, C.; Caballero, F.G.; Sourmail, T.; Kuntz, M.; Cornide, J.; Smanio, V.; Elvira, R. Tensile behaviour of a nanocrystalline bainitic steel containing 3 wt. % silicon. Mater. Sci. Eng. A 2012, 549, 185–192. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Mateo, C.; Caballero, F.G. Ultra-high-strength bainitic steels. ISIJ Int. 2005, 45, 1736–1740. [Google Scholar] [CrossRef]

- Caballero, F.G.; Bhadeshia, H.K.D.H.; Mawella, K.J.A.; Jones, D.G.; Brown, P. Very strong low temperature bainite. Mater. Sci. Technol. 2002, 18, 279–284. [Google Scholar] [CrossRef] [Green Version]

- Caballero, F.G.; Miller, M.K.; Garcia-Mateo, C.; Cornide, J. New experimental evidence of the diffusionless transformation nature of bainite. J. Alloy. Compd. 2013, 577, S626–S630. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. Bainite in silicon steels: New composition-property approach. Part 2. Met. Sci. 1983, 17, 420–425. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H.; Edmonds, D.V. Bainite in silicon steels: New composition-property approach. Part 1. Met. Sci. 1983, 17, 411–419. [Google Scholar] [CrossRef]

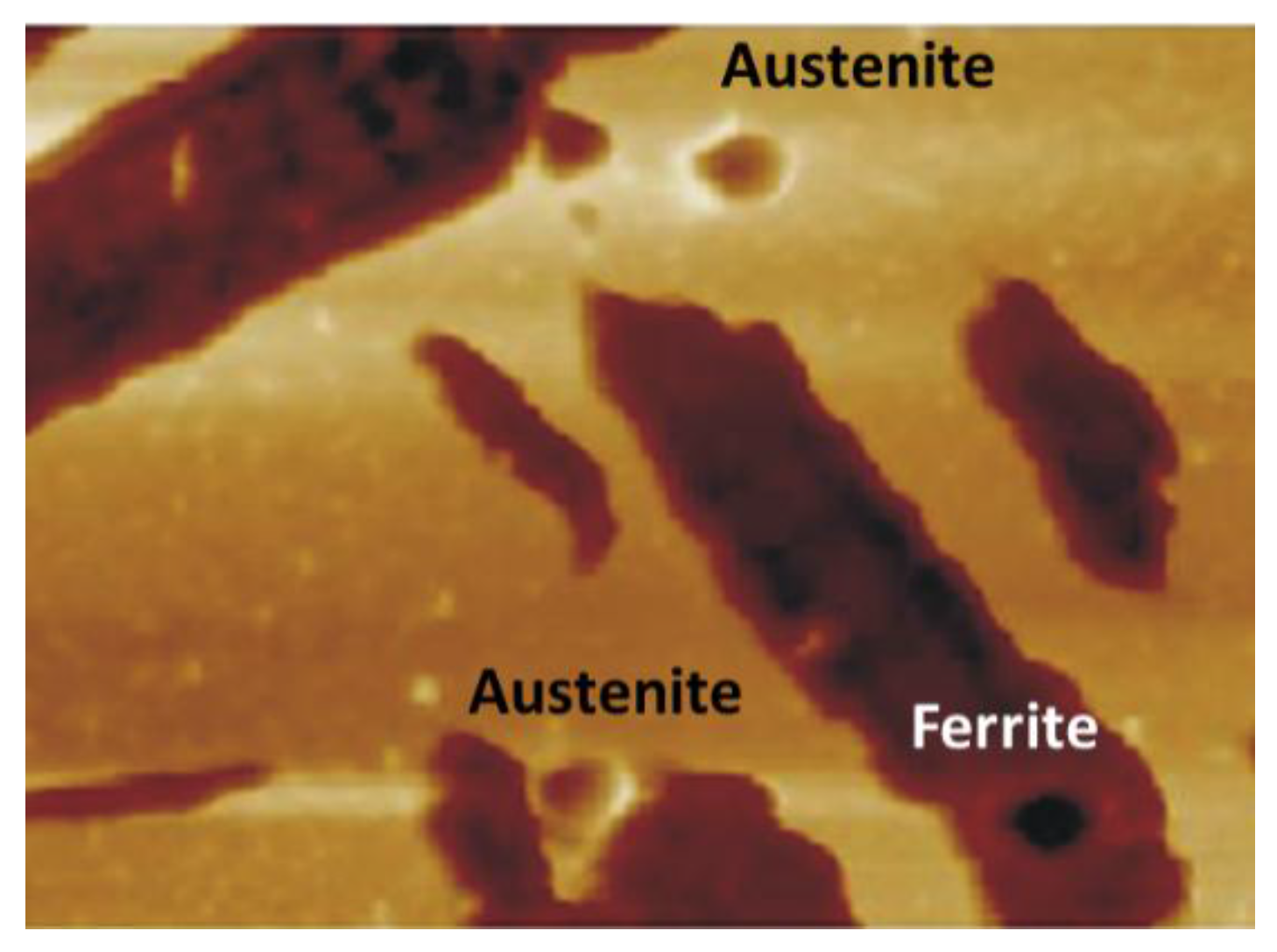

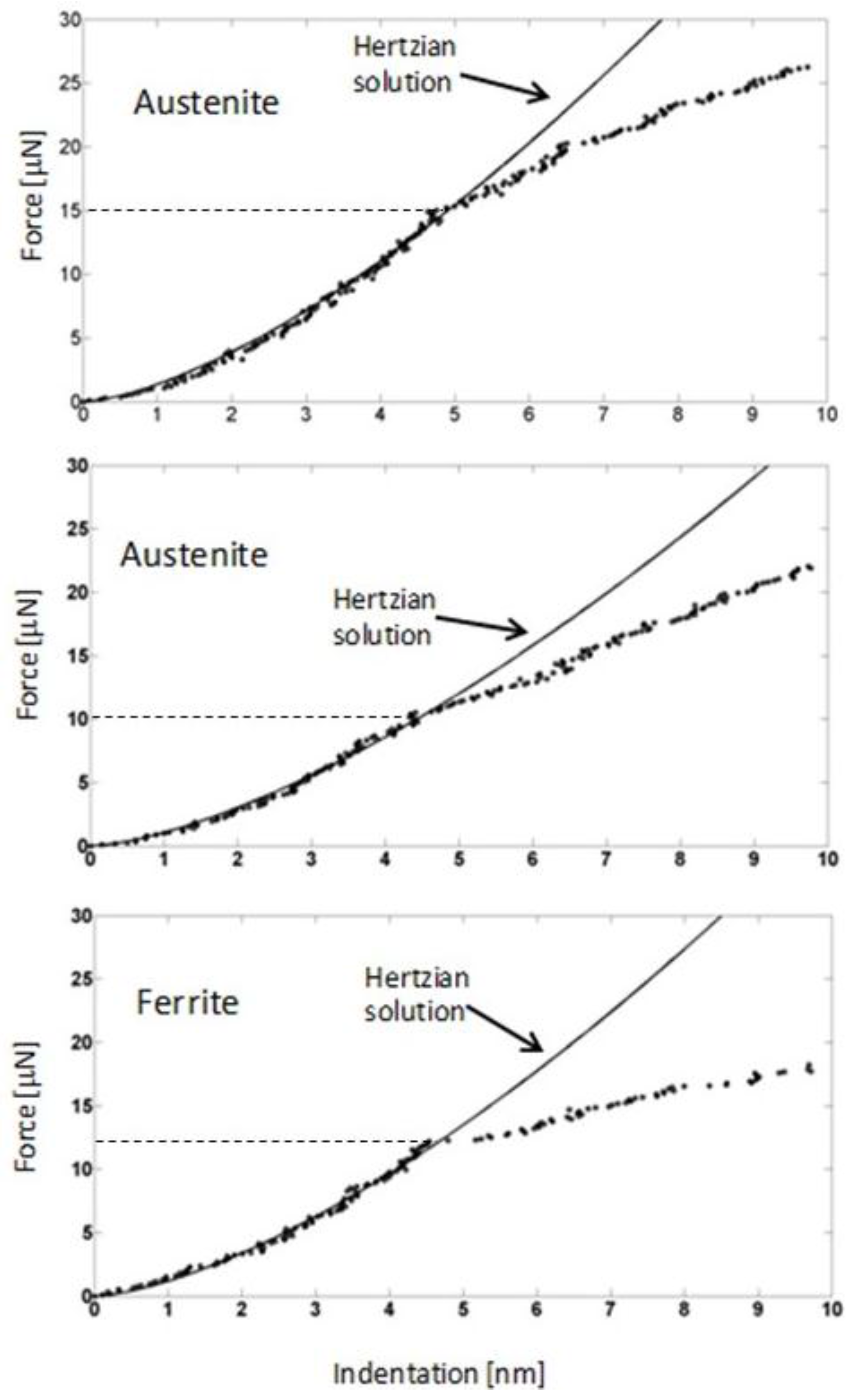

- Morales-Rivas, L.; Gonzalez-Orive, A.; Garcia-Mateo, C.; Hernandez-Creus, A.; Caballero, F.G.; Vazquez, L. Nanomechanical characterization of nanostructured bainitic steel: Peak force microscopy and nanoindentation with afm. Sci. Rep. 2015, 5. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Mateo, C.; Jimenez, J.A.; Yen, H.W.; Miller, M.K.; Morales-Rivas, L.; Kuntz, M.; Ringer, S.P.; Yang, J.R.; Caballero, F.G. Low temperature bainitic ferrite: Evidence of carbon super-saturation and tetragonality. Acta Mater. 2015, 91, 162–173. [Google Scholar] [CrossRef]

- Cohen, M. The strengthening of steel. Trans. Metall. AIME 1962, 224, 638–657. [Google Scholar]

- Christian, J.W. Tetragonal martensites in ferrous alloys—A critique. Mater. Trans. JIM 1992, 33, 208–214. [Google Scholar] [CrossRef]

- Caballero, F.; Miller, M.; Garcia-Mateo, C.; Capdevila, C.; Babu, S. Redistribution of alloying elements during tempering of a nanocrystalline steel. Acta Mater. 2008, 56, 188–199. [Google Scholar] [CrossRef]

- Caballero, F.G.; Miller, M.K.; Clarke, A.J.; Garcia-Mateo, C. Examination of carbon partitioning into austenite during tempering of bainite. Scr. Mater. 2010, 63, 442–445. [Google Scholar] [CrossRef]

- Wilde, J.; Cerezo, A.; Smith, G.D.W. Three-dimensional atomic-scale mapping of a Cottrell atmosphere around a dislocation in iron. Scr. Mater. 2000, 43, 39–48. [Google Scholar] [CrossRef]

- Cornide, J.; Garcia-Mateo, C.; Capdevila, C.; Caballero, F.G. An assessment of the contributing factors to the nanoscale structural refinement of advanced bainitic steels. J. Alloy. Compd. 2013, 577, S43–S47. [Google Scholar] [CrossRef]

- Haidemenopoulos, G.N.; Grujicic, M.; Olson, G.B.; Cohen, M. Transformation microyielding of retained austenite. Acta Metall. 1989, 37, 1677–1682. [Google Scholar] [CrossRef]

- Chatterjee, S.; Bhadeshia, H. Transformation induced plasticity assisted steels: Stress or strain affected martensitic transformation. Mater. Sci. Technol. 2007, 23, 1101–1104. [Google Scholar] [CrossRef]

- Morales-Rivas, L.; Caballero, F.G.; Garcia-Mateo, C. Retained austenite: Stability in a nanostructured bainitic steel. In Encyclopedia of Iron, Steel and Their Alloys; Rafael Colás, G.E.T., Ed.; CRC Press: Cleveland, OH, USA, 2016; Available online: http://www.crcnetbase.com/doi/abs/10.1081/E-EISA-120051968 (accessed on 30 November 2016).

- Garcia-Mateo, C.; Caballero, F.G.; Miller, M.K.; Jimenez, J.A. On measurement of carbon content in retained austenite in a nanostructured bainitic steel. J. Mater. Sci. 2012, 47, 1004–1010. [Google Scholar] [CrossRef]

- Sherif, M.Y.; Mateo, C.G.; Sourmail, T.; Bhadeshia, H.K.D.H. Stability of retained austenite in trip-assisted steels. Mater. Sci. Technol. 2004, 20, 319–322. [Google Scholar] [CrossRef]

- Garcia-Mateo, C.; Caballero, F.G.; Chao, J.; Capdevila, C.; de Andres, C.G. Mechanical stability of retained austenite during plastic deformation of super high strength carbide free bainitic steels. J. Mater. Sci. 2009, 44, 4617–4624. [Google Scholar] [CrossRef]

- Yang, H.-S.; Bhadeshia, H.K.D.H. Austenite grain size and the martensite-start temperature. Scr. Mater. 2009, 60, 493–495. [Google Scholar] [CrossRef]

- Sadeghpour, S.; Kermanpur, A.; Najafizadeh, A. Investigation of the effect of grain size on the strain-induced martensitic transformation in a high-Mn stainless steel using nanoindentation. Mater. Sci. Eng. A 2014, 612, 214–216. [Google Scholar] [CrossRef]

- García-Junceda, A.; Capdevila, C.; Caballero, F.G.; de Andrés, C.G. Dependence of martensite start temperature on fine austenite grain size. Scr. Mater. 2008, 58, 134–137. [Google Scholar] [CrossRef]

- Brandt, M.L.; Olson, G.B. Bainitic stabilization of austenite in low alloy sheet steels. Iron Steel Soc. AIME 1993, 20, 55–60. [Google Scholar]

- Jacques, P.J.; Furnémont, Q.; Lani, F.; Pardoen, T.; Delannay, F. Multiscale mechanics of trip-assisted multiphase steels: I. Characterization and mechanical testing. Acta Mater. 2007, 55, 3681–3693. [Google Scholar] [CrossRef]

- Ryu, J.H.; Kim, D.-I.; Kim, H.S.; Bhadeshia, H.K.D.H.; Suh, D.-W. Strain partitioning and mechanical stability of retained austenite. Scr. Mater. 2010, 63, 297–299. [Google Scholar] [CrossRef]

- Timokhina, I.B.; Hodgson, P.D.; Pereloma, E.V. Effect of microstructure on the stability of retained austenite in transformation-induced-plasticity steels. Metall. Mater. Trans. A 2004, 35, 2331–2341. [Google Scholar] [CrossRef]

- Jacques, P.J.; Ladrière, J.; Delannay, F. On the influence of interactions between phases on the mechanical stability of retained austenite in transformation-induced plasticity multiphase steels. Metall. Mater. Trans. A 2001, 32, 2759–2768. [Google Scholar] [CrossRef]

- Avishan, B.; Garcia-Mateo, C.; Morales-Rivas, L.; Yazdani, S.; Caballero, F.G. Strengthening and mechanical stability mechanisms in nanostructured bainite. J. Mater. Sci. 2013, 48, 6121–6132. [Google Scholar] [CrossRef]

- Young, C.H.; Bhadeshia, H.K.D.H. Strength of mixtures of bainite and martensite. Mater. Sci. Technol. 1994, 10, 209–214. [Google Scholar] [CrossRef]

- Young, C.H.; Bhadeshia, H.K.D.H. Computer modelling for the yield strength of the mixed micro-structures of bainite and martensite. J. Phys. IV 1995, 5, 267. [Google Scholar] [CrossRef]

- Caballero, F.G.; García-Mateo, C.; Capdevila, C.; de Andrés, C.G. Advanced Ultrahigh Strength Bainitic Steels. Mater. Manuf. Process. 2007, 22, 502–506. [Google Scholar] [CrossRef] [Green Version]

- Singh, S.B.; Bhadeshia, H.K.D.H. Estimation of bainite plate-thickness in low-alloy steels. Mater. Sci. Eng. A 1998, 245, 72–79. [Google Scholar] [CrossRef]

- Garcia-Mateo, C.; Sourmail, T.; Caballero, F.G.; Smanio, V.; Kuntz, M.; Ziegler, C.; Leiro, A.; Vuorinen, E.; Elvira, R.; Teeri, T. Nanostructured steel industrialisation: Plausible reality. Mater. Sci. Technol. 2014, 30, 1071–1078. [Google Scholar] [CrossRef]

- Chang, L.C.; Bhadeshia, H.K.D.H. Austenite films in bainitic microstructures. Mater. Sci. Technol. 1995, 11, 105–108. [Google Scholar] [CrossRef]

- Underwood, E.E. Quantitative Microscopy; McGraw-Hill: New York, NY, USA, 1968; Volume 78. [Google Scholar]

- Lan, H.-F.; Liu, X.-H.; Du, L.-X. Ultra-hard bainitic steels processed through low temperature heat treatment. Adv. Mater Res. 2011, 156–157, 1708–1712. [Google Scholar] [CrossRef]

- Wang, M.M.; Tasan, C.C.; Ponge, D.; Dippel, A.C.; Raabe, D. Nanolaminate transformation-induced plasticity-twinning-induced plasticity steel with dynamic strain partitioning and enhanced damage resistance. Acta Mater. 2015, 85, 216–228. [Google Scholar] [CrossRef]

- Jacques, P.J. Transformation-induced plasticity for high strength formable steels. Curr. Opin. Solid State Mater. Sci. 2004, 8, 259–265. [Google Scholar] [CrossRef]

- Ludwigson, D.C.; Berger, J.A. Plastic behaviour of metastable austenitic stainless steels. J. Iron Steel Inst. 1969, 207, 63–69. [Google Scholar]

- Jacques, P.J.; Girault, E.; Harlet, Ph.; Delanny, F. The developments of cold-rolled trip-assisted multiphase steels. Low silicon trip-assisted multiphase steels. ISIJ Int. 2001, 41, 1061–1067. [Google Scholar] [CrossRef]

- Jacques, P.J.; Furnemont, Q.; Mertens, A.; Delanny, F. On the sources of work hardening by transformation-induced plasticity. Philos. Mag. 2001, 81, 1789–1812. [Google Scholar] [CrossRef]

- Deep, G.; Williams, W.M. Isothermic annealing of bainite. Can. Metall. Q 1975, 14, 85–96. [Google Scholar] [CrossRef]

- Papaefthymiou, S. Failure Mechanisms of Multiphase Steels. Ph.D. Thesis, Rheinisch-Westfälische Technische Hochschule Aachen (RWTH) (Aachen University), Aachen, Germany, 2005. [Google Scholar]

- Sourmail, T.; Galtier, A.; Sanz, R.P.; Janisch, R.; Sampath, S.; Müller, I.; Kerscher, E.; Rementeria, R.; Garcia-Mateo, C.; Caballero, F.G.; et al. Understanding Basic Mechanism to Optimize and Predict in Service Properties of Nanobainitic Steels (Mecbain). Final Report.; Reference RFSR-CT-2012-00017; European Commission: Luxembourg, 2017; in press. [Google Scholar]

- Morales-Rivas, L.; Yen, H.W.; Huang, B.M.; Kuntz, M.; Caballero, F.G.; Yang, J.R.; Garcia-Mateo, C. Tensile response of two nanoscale bainite composite-like structures. JOM 2015, 67, 2223–2235. [Google Scholar] [CrossRef]

- Chatterjee, S.; Bhadeshia, H. Trip-assisted steels: Cracking of high-carbon martensite. Mater. Sci. Technol. 2006, 22, 645–649. [Google Scholar] [CrossRef]

- Sandvik, B.P.J.; Nevalainen, H.P. Structure-property relationships in commercial low-alloy bainitic-austenitic steel with high-strength, ductility, and toughness. Met. Technol. 1981, 8, 213–220. [Google Scholar] [CrossRef]

- Garcia-Mateo, C.; Caballero, F.G. The role of retained austenite on tensile properties of steels with bainitic microstructures. Mater. Trans. JIM 2005, 46, 1839–1846. [Google Scholar] [CrossRef]

- Knijf, D.D. Influence of Quenching and Partitioning Parameters on the Microstructure and Mechanical Properties of Advanced High Strength Steels. Ph.D. Thesis, Faculteit Ingenieurswetenschappen (Ghent University), Ghent, Belgium, June 2015. [Google Scholar]

- McCoy, R.A.; Gerberich, W.W. Hydrogen embrittlement studies of a trip steel. Metall. Trans. 1973, 4, 539–547. [Google Scholar] [CrossRef]

- Hirth, J.P. Effects of hydrogen on the properties of iron and steel. Metall. Trans. 2005, 52, 1223–1228. [Google Scholar] [CrossRef]

- Ronevich, J.A.; Speer, J.G.; Matlock, D.K. Hydrogen embrittlement of commercially produced advanced high strength sheet steels. SAE Int. J. Mater. Manuf. 2010, 3, 255–267. [Google Scholar] [CrossRef]

- Ryu, J.H. Hydrogen Embrittlement in Trip and Twip Steels. Ph.D. Thesis, Pohang University of Science and Technology, Pohang, Korea, 2012. [Google Scholar]

- Miihkinen, V.T.T.; Edmonds, D.V. Tensile deformation of two experimental high-strength bainitic low-alloy steels containing silicon. Mater. Sci. Technol. 1987, 3, 432–440. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. The dimensions of steel. Ironmak. Steelmak. 2007, 34, 194–199. [Google Scholar] [CrossRef]

- Sherif, M.Y. Characterisation and Development of Nanostructured, Ultrahigh Strength, and Ductile Bainitic Steels. Ph.D. Thesis, University of Cambridge, Cambridge, UK, 2006. [Google Scholar]

- Sourmail, T.; Garcia-Mateo, C.; Caballero, F.G.; Morales-Rivas, L.; Rementeria, R.; Kuntz, M. Tensile ductility of nanostructured bainitic steels: Influence of retained austenite stability. Mater. Sci. Eng. A 2016. submitted for publication. [Google Scholar]

- Sugimoto, K.; Kobayashi, M.; Hashimoto, S. Ductility and strain-induced transformation in a high-strength transformation-induced plasticity-aided dual-phase steel. Metall. Trans. A 1992, 23, 3085–3091. [Google Scholar] [CrossRef]

- Pyshmintev, I.Y.; de Meyer, M.; de CooMan, B.C.; Savray, R.A.; Shveykin, V.P.; VerMelen, M. The influence of the stress state on the plasticity of transformation induced plasticity-aided steel. Metall. Mater. Trans. A 2002, 33A, 16591667. [Google Scholar]

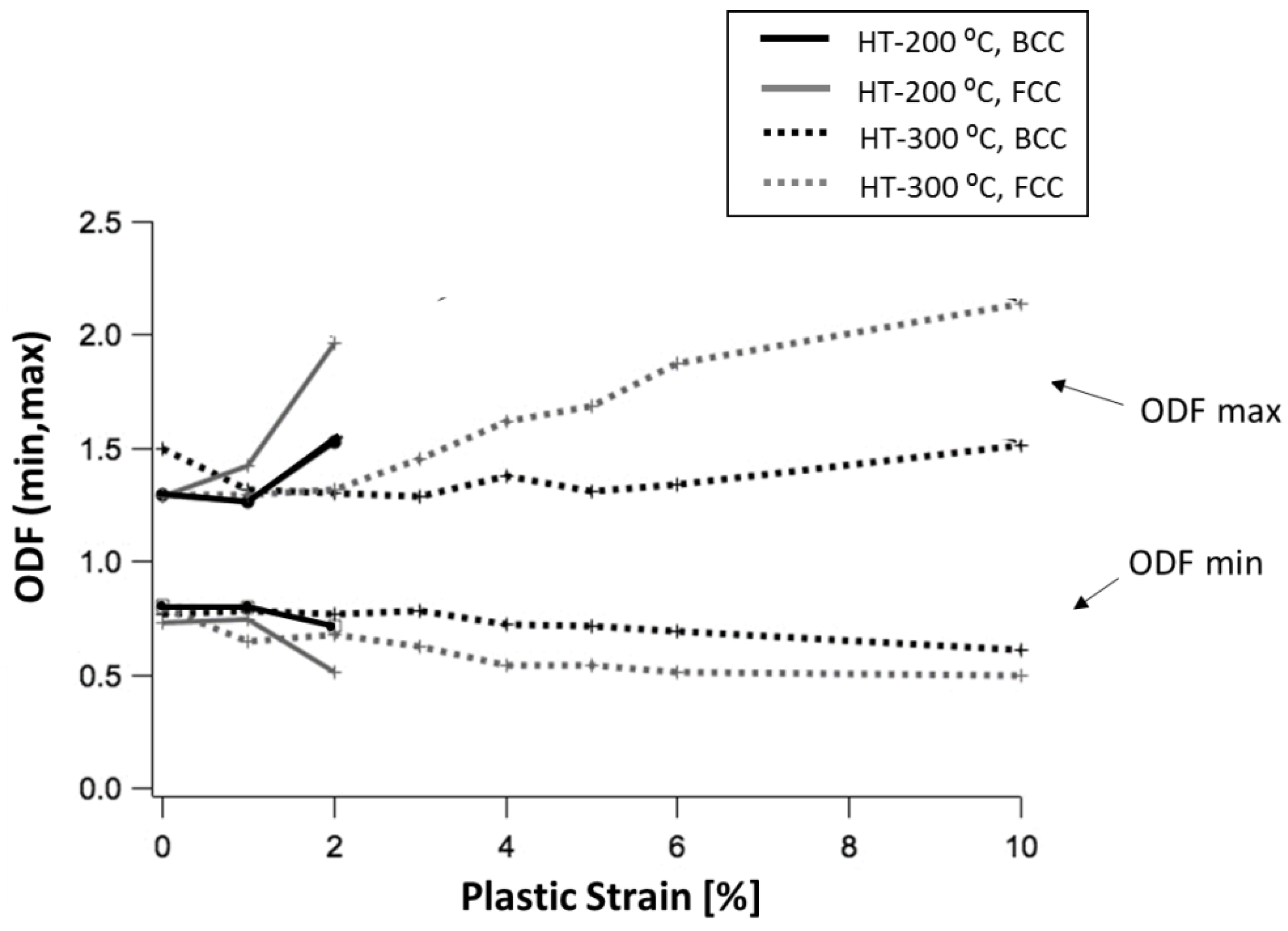

- Babu, S.S.; Vogel, S.; Garcia-Mateo, C.; Clausen, B.; Morales-Rivas, L.; Caballero, F.G. Microstructure evolution during tensile deformation of a nanostructured bainitic steel. Scr. Mater. 2013, 69, 777–780. [Google Scholar] [CrossRef]

- Shi, J.; Turteltaub, S.; Giessen, E.V.D. Analysis of grain size effects on transformation-induced plasticity based on a discrete dislocation-transformation model. J. Mech. Phys. Solids 2010, 58, 1863–1878. [Google Scholar] [CrossRef]

- Ghosh, G.; Olson, G.B. Kinetics of fcc → bcc heterogeneous martensitic nucleation—II. Thermal activation. Acta Metall. Mater. 1994, 42, 3371–3379. [Google Scholar] [CrossRef]

- Yang, H.S.; Suh, D.W.; Bhadeshia, H. More Complete Theory for the Calculation of the Martensite-Start Temperature in Steels. ISIJ Int. 2012, 52, 164–166. [Google Scholar] [CrossRef]

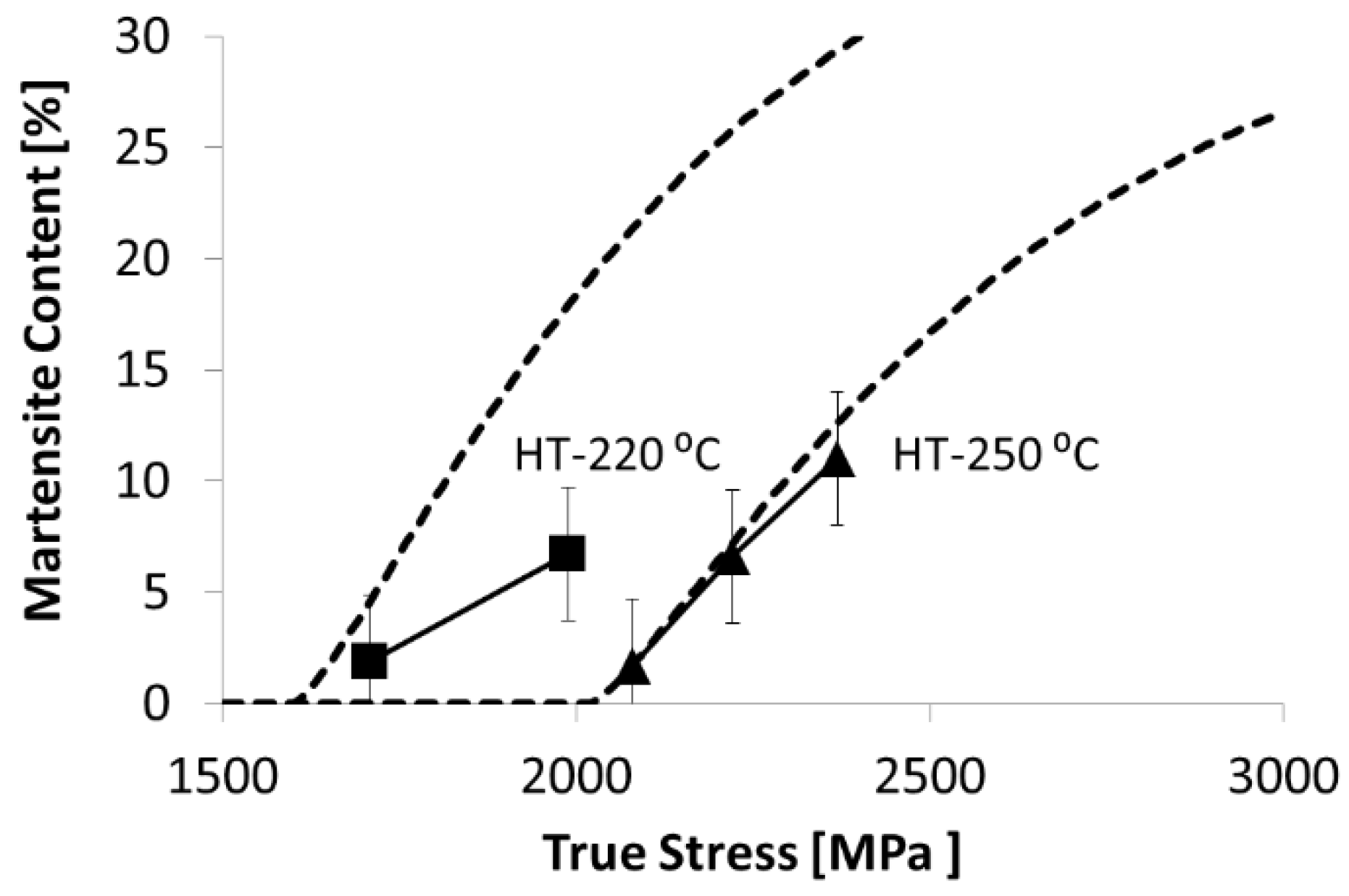

- Morales-Rivas, L.; Garcia-Mateo, C.; Kuntz, M.; Sourmail, T.; Caballero, F.G. Induced martensitic transformation during tensile test in nanostructured bainitic steels. Mater. Sci. Eng. A 2016, 662, 169–177. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morales-Rivas, L.; Garcia-Mateo, C.; Sourmail, T.; Kuntz, M.; Rementeria, R.; Caballero, F.G. Ductility of Nanostructured Bainite. Metals 2016, 6, 302. https://doi.org/10.3390/met6120302

Morales-Rivas L, Garcia-Mateo C, Sourmail T, Kuntz M, Rementeria R, Caballero FG. Ductility of Nanostructured Bainite. Metals. 2016; 6(12):302. https://doi.org/10.3390/met6120302

Chicago/Turabian StyleMorales-Rivas, Lucia, Carlos Garcia-Mateo, Thomas Sourmail, Matthias Kuntz, Rosalia Rementeria, and Francisca G. Caballero. 2016. "Ductility of Nanostructured Bainite" Metals 6, no. 12: 302. https://doi.org/10.3390/met6120302