Ultrasonic Guided Wave Propagation through Welded Lap Joints

Abstract

:1. Introduction

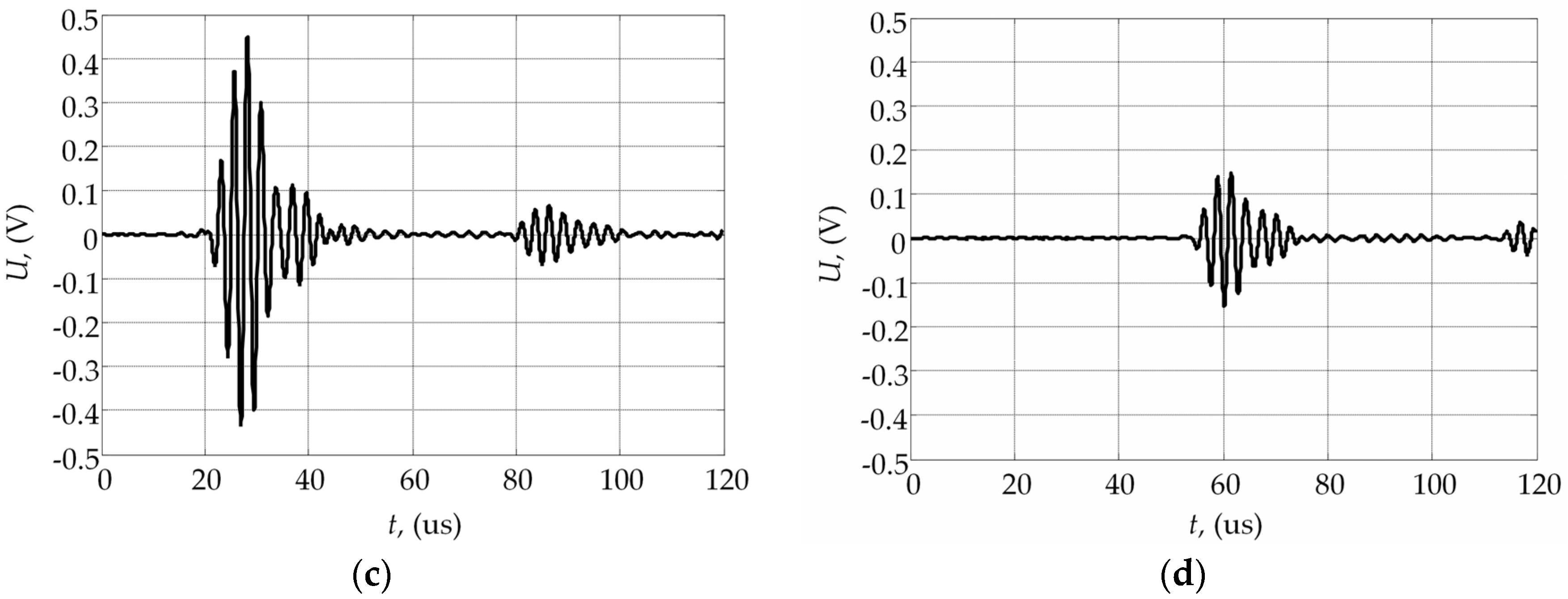

2. Numerical Simulation of the Guided Waves Propagation

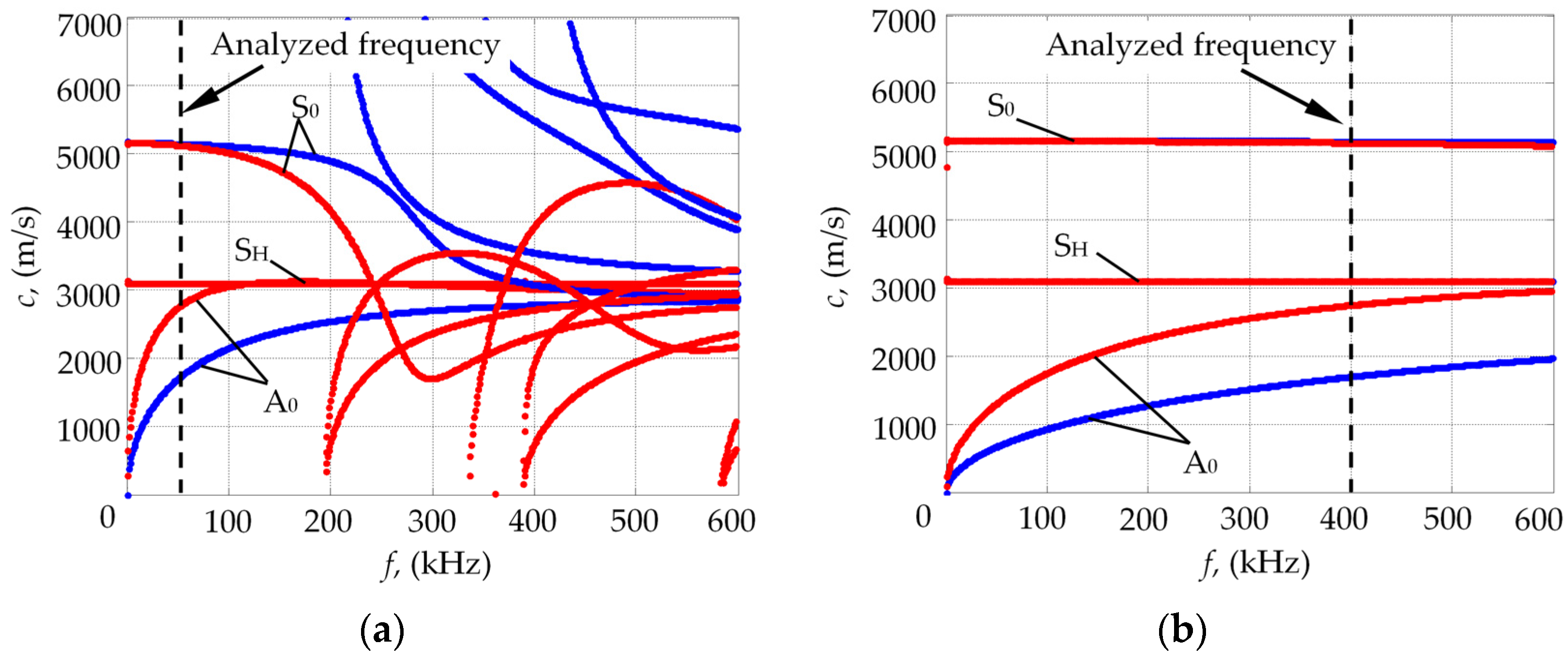

2.1. Dispersion Curves

- the group velocity of the symmetric S0 wave mode is highest, ensuring that it arrives before any other modes, thus making it easier to identify and separate the time interval in the measured signals;

- symmetric S0 wave mode is less sensitive to liquid boundary interaction. It has lower attenuation and leakage losses compared to the asymmetric A0 wave mode, thus it enables stronger signals to be received at a longer propagation distance.

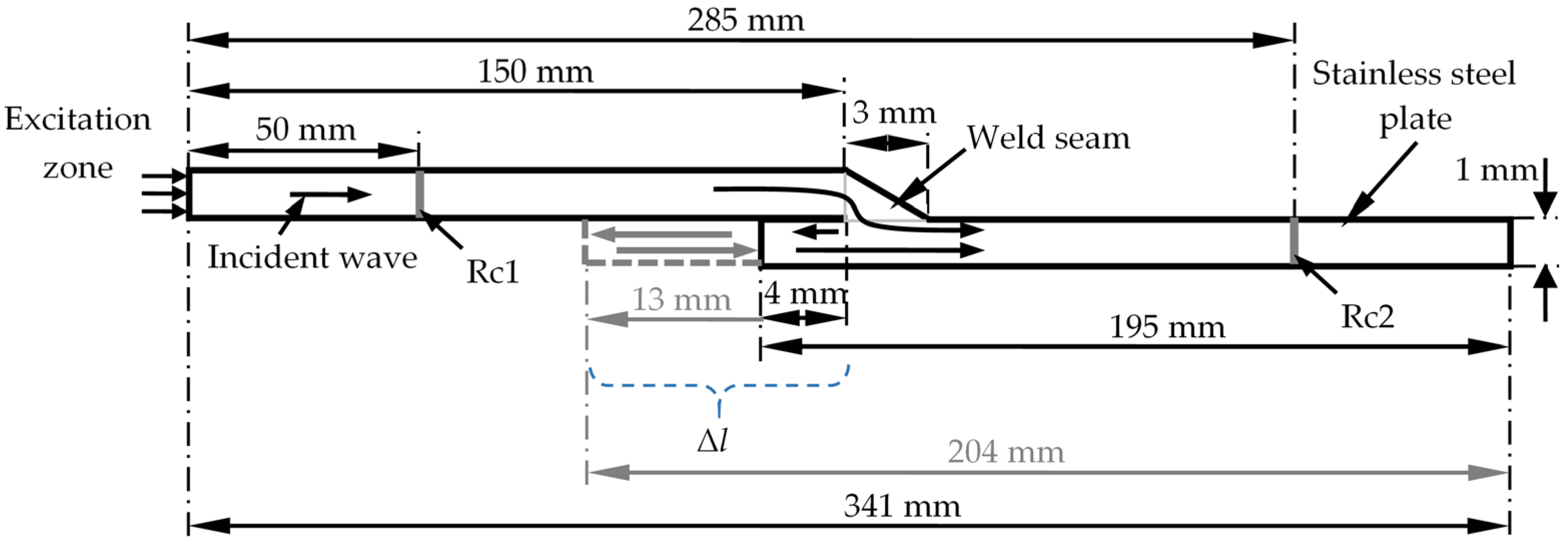

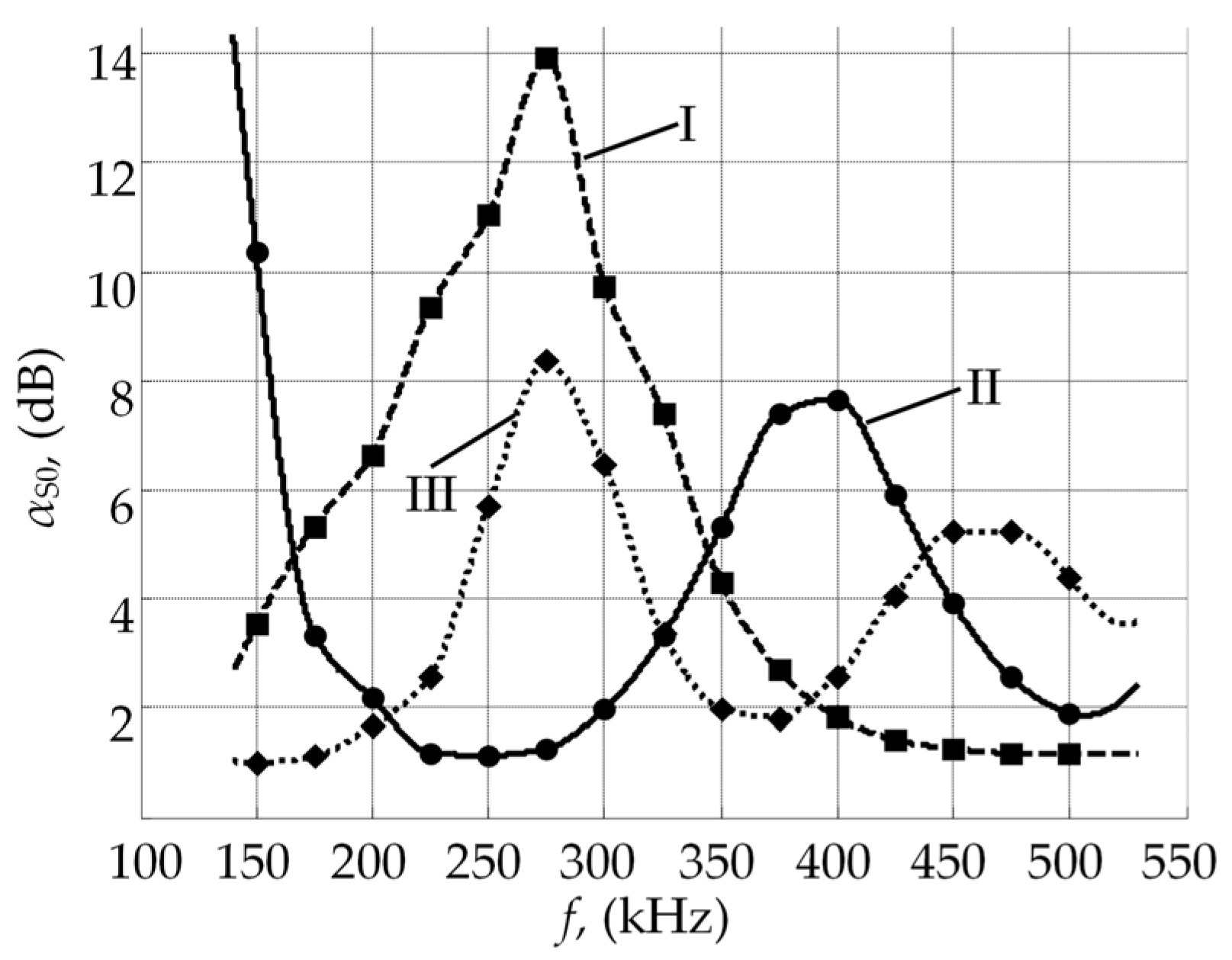

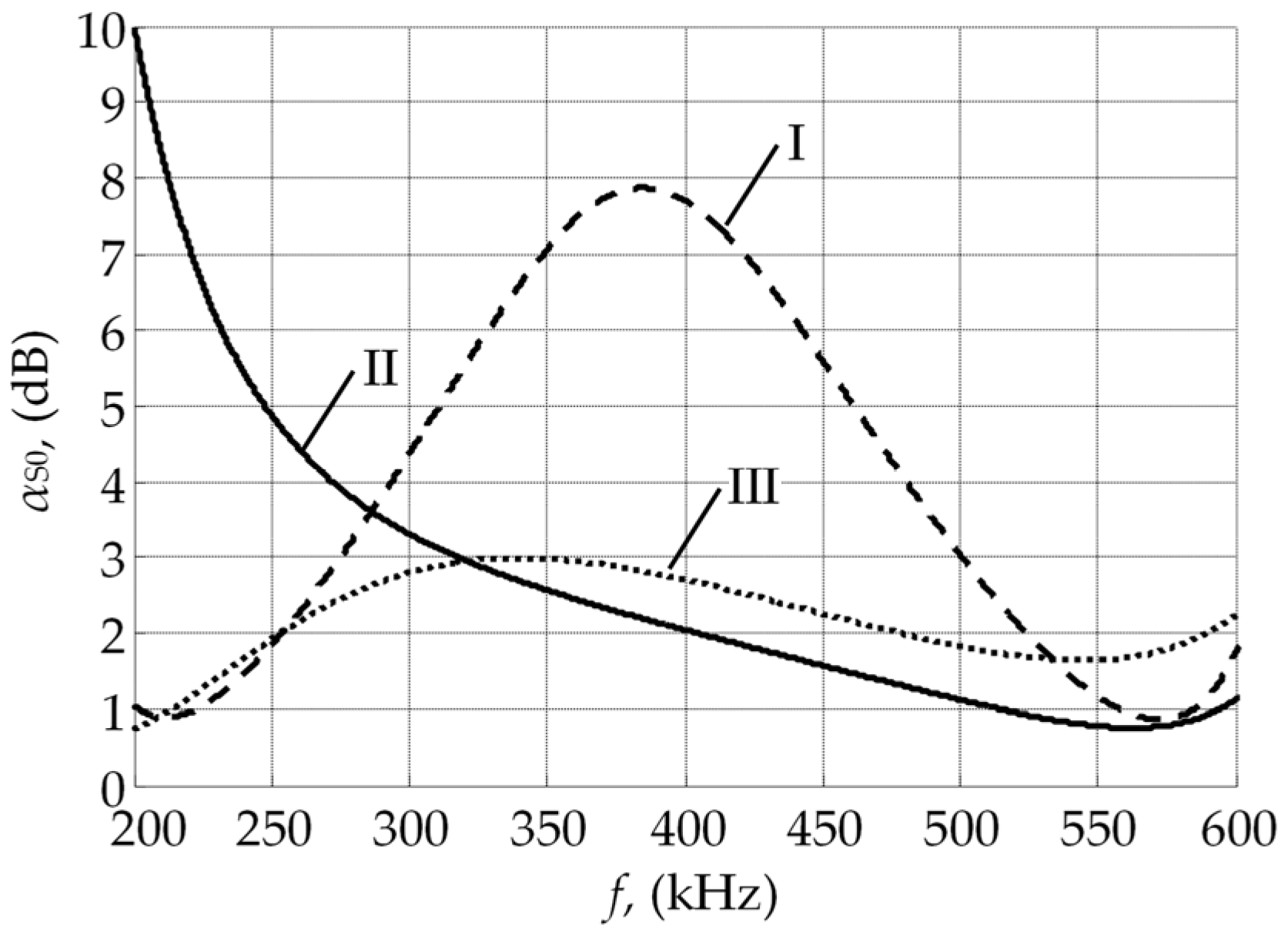

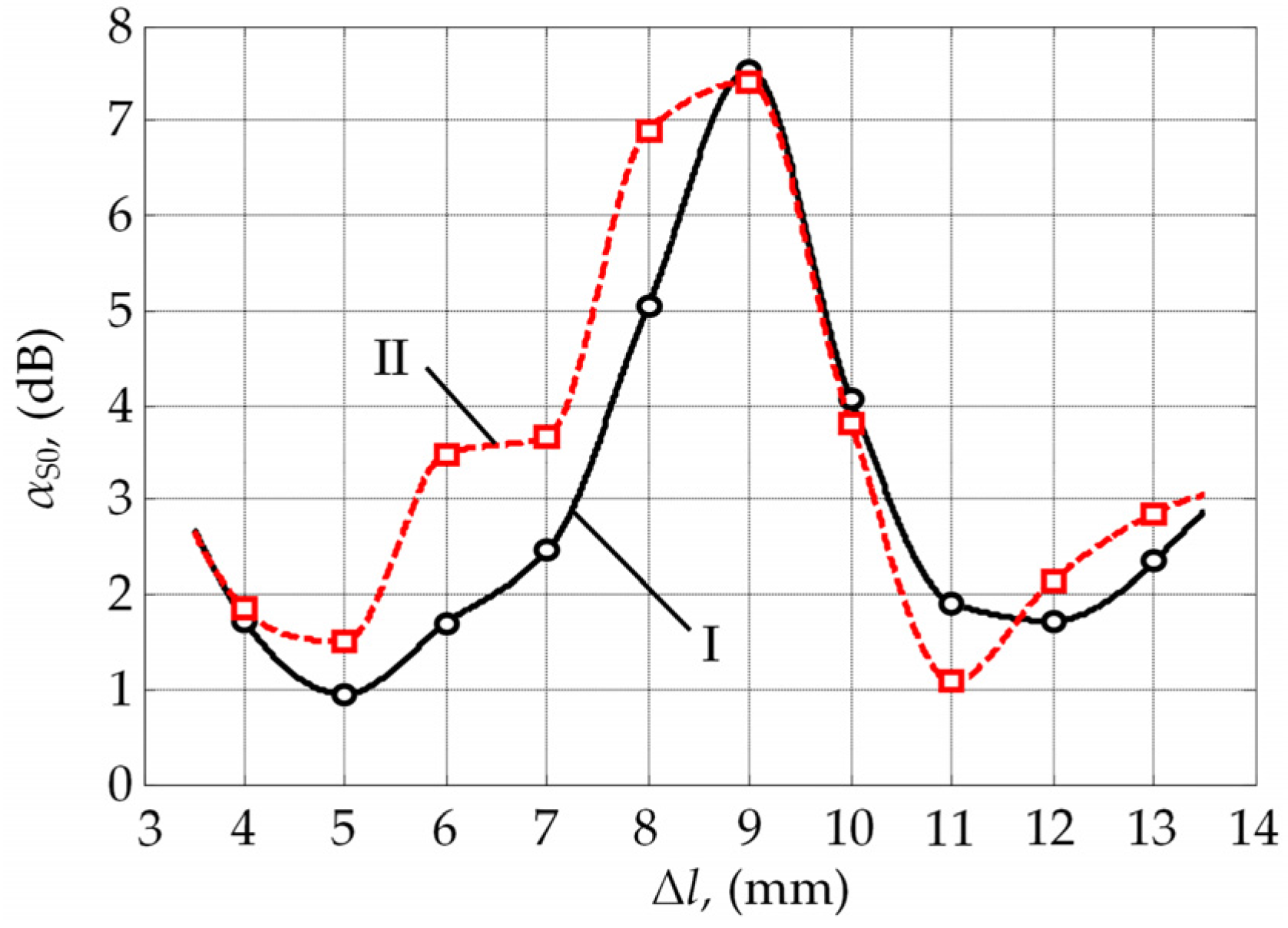

2.2. Transmission Losses Dependence from Lap Joint Width and Operation Frequency

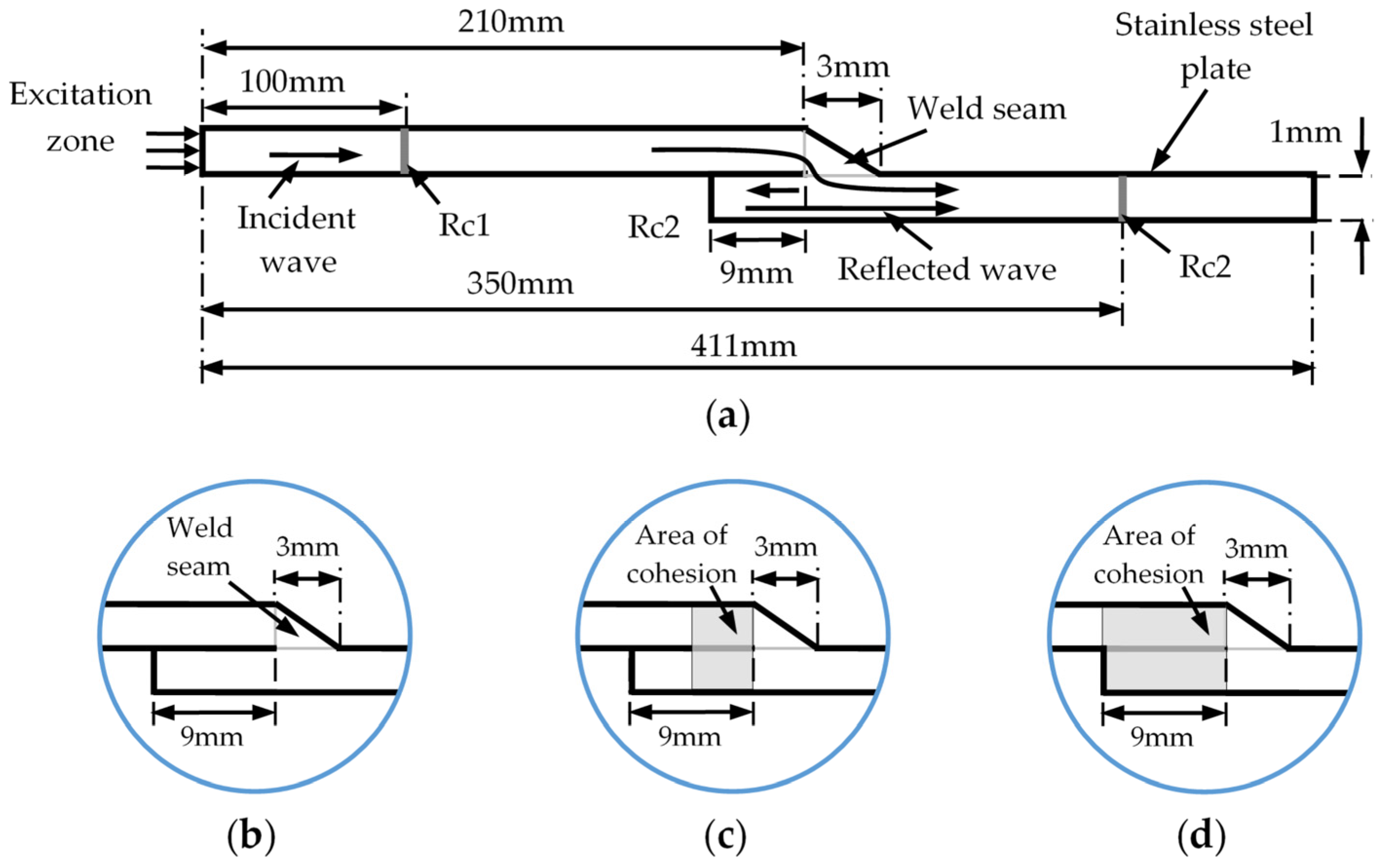

2.3. Transmission Losses Dependence on Plates Bonding

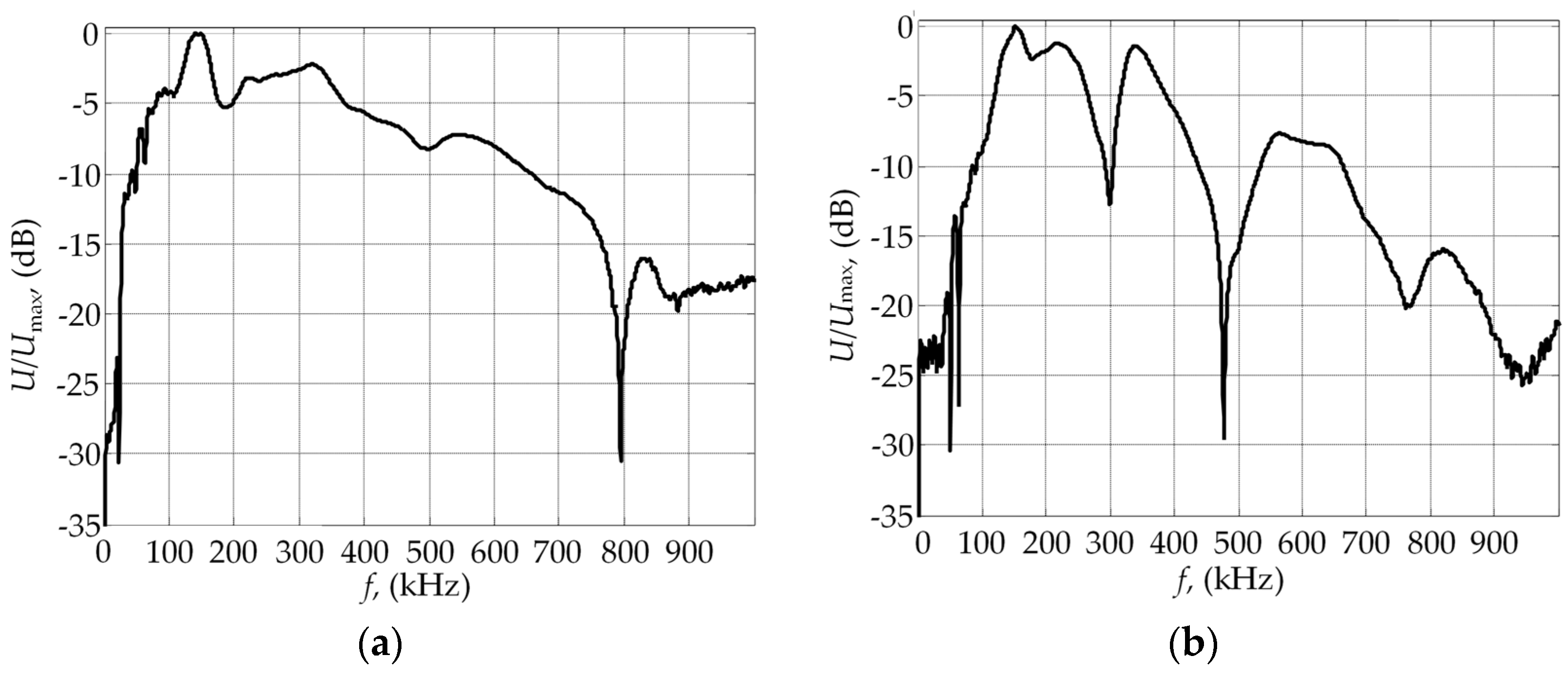

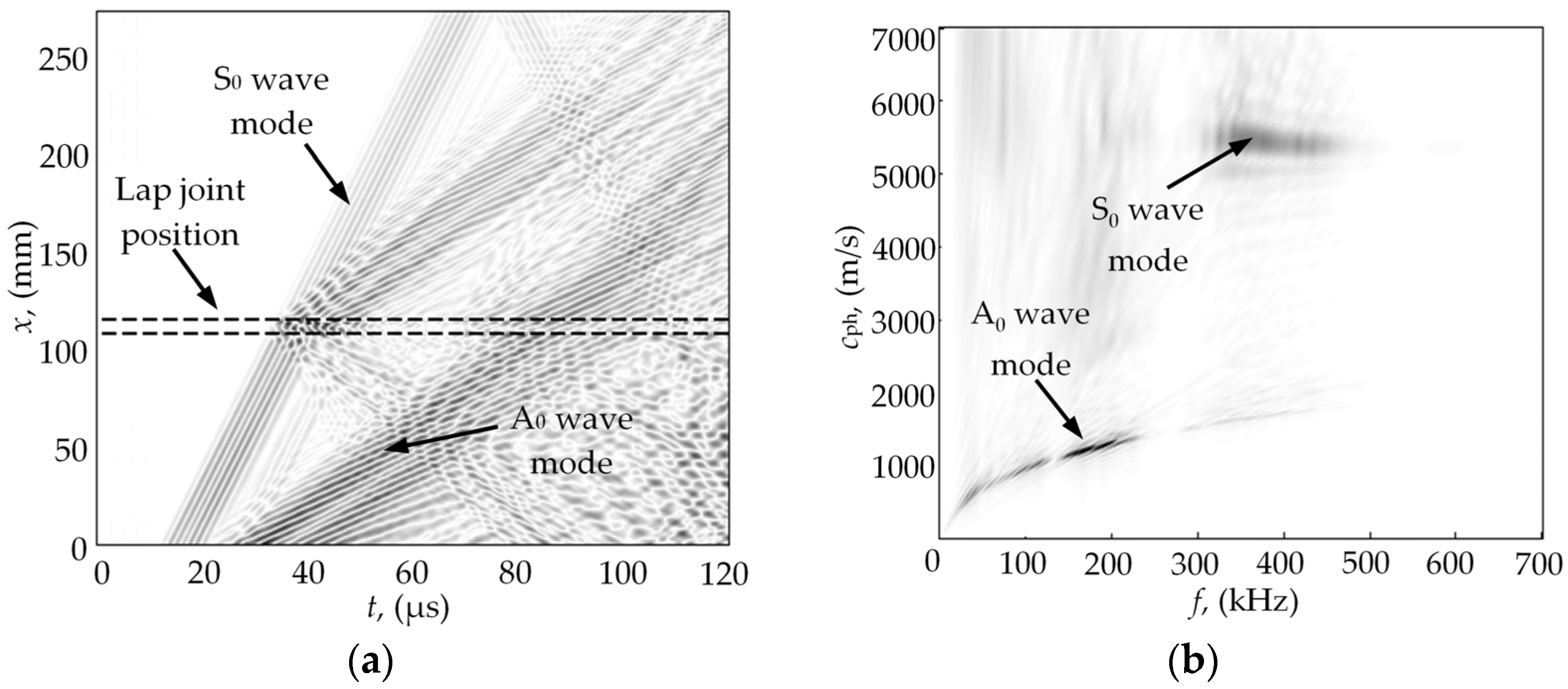

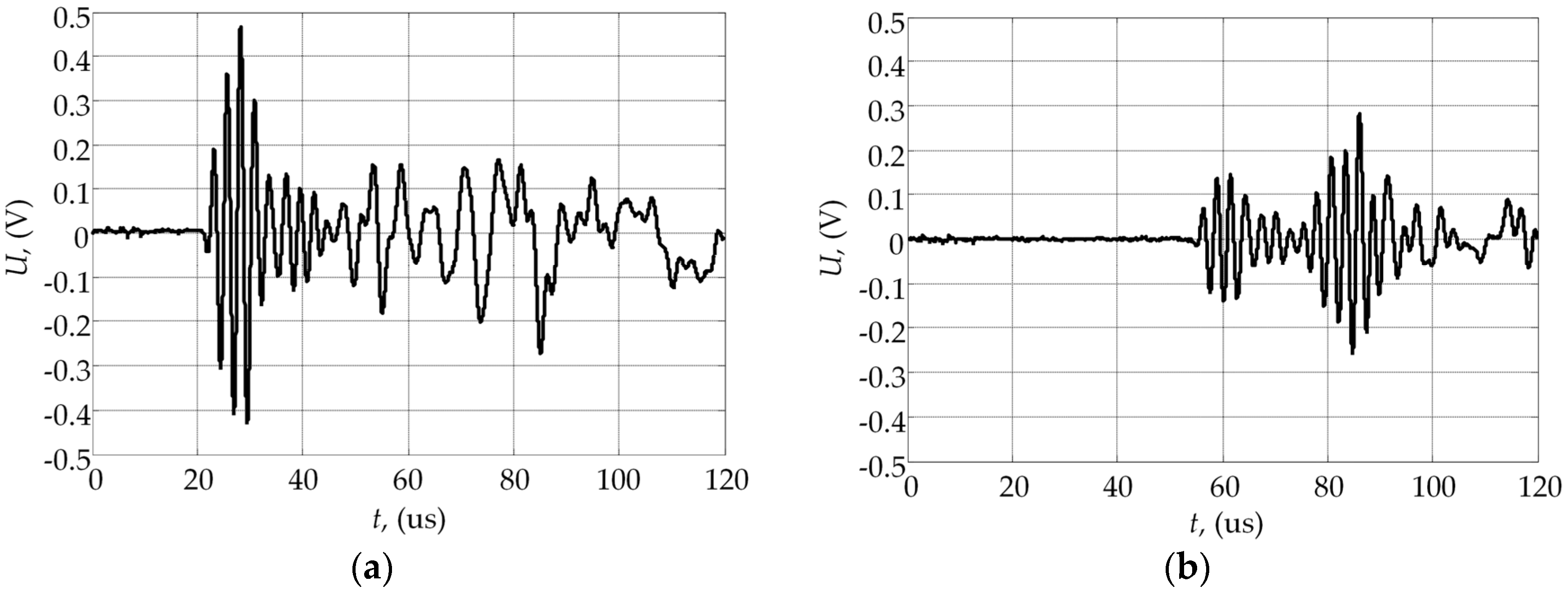

3. Experimental Investigation of Guided Wave Propagation through Lap Joints

4. Conclusions

Author Contributions

Conflicts of Interest

References

- Kasai, N.; Sekine, K.; Maruyama, H. Non-destructive evaluation method for far-side corrosion type flaws in oil storage tank bottom floors using the magnetic flux leakage technique. J. Jpn. Pet. Inst. 2008, 46, 126–132. [Google Scholar] [CrossRef]

- Kasai, N.; Fujiwara, Y.; Sekine, K.; Sakamoto, T. Evaluation of back-side flaws of the bottom plates of an oil-storage tank by the RFECT. NDT E Int. 2008, 41, 525–529. [Google Scholar] [CrossRef]

- Bagavathiappan, S.; Lahiri, B.B.; Saravanan, T.; Philip, J.; Jayakumar, T. Infrared thermography for condition monitoring—A review. Infrared Phys. Technol. 2013, 60, 35–55. [Google Scholar] [CrossRef]

- Marinetti, S.; Vavilov, V. IR thermographic detection and characterization of hidden corrosion in metals: General analysis. Corros. Sci. 2010, 52, 865–872. [Google Scholar] [CrossRef]

- Edalati, K.; Rastkhah, N.; Kermani, A.; Seiedi, M.; Movafeghi, A. The use of radiography for thickness measurement and corrosion monitoring in pipes. Int. J. Press. Vessels Pip. 2006, 83, 736–741. [Google Scholar] [CrossRef]

- Nowak, M.; Baran, I.; Schmidt, J.; Ono, K. Acoustic emission method for solving problems in double bottom storage tanks. J. Acoust. Emiss. 2009, 27, 272–280. [Google Scholar]

- Rose, J.L. Ultrasonic guided waves in structural health monitoring. Key Eng. Mater. 2004, 270–273, 14–21. [Google Scholar] [CrossRef]

- Zhao, X.; Royer, R.L.; Owens, S.E.; Rose, J.L. Ultrasonic Lamb wave tomography in structural health monitoring. Smart Mater. Struct. 2011, 20, 105002. [Google Scholar] [CrossRef]

- Lowe, M.J.S.; Alleyne, D.N.; Cawley, P. Defect detection in pipes using guided waves. Ultrasonics 1998, 36, 147–154. [Google Scholar] [CrossRef]

- Alleyne, D.N.; Pavlakovic, B.; Lowe, M.J.S.; Cawley, P. Rapid, long range inspection of chemical plant pipework using guided waves. AIP Conf. Proc. 2001, 557, 180–187. [Google Scholar]

- Demma, A.; Cawley, P.; Lowe, M.; Roosenbrand, A.G.; Pavlakovic, B. The reflection of guided waves from notches in pipes: A guide for interpreting corrosion measurements. NDT E Int. 2004, 37, 167–180. [Google Scholar] [CrossRef]

- Leinov, E.; Lowe, M.J.S.; Cawley, P. Investigation of guided wave propagation and attenuation in pipe buried in sand. J. Sound Vib. 2015, 347, 96–114. [Google Scholar] [CrossRef]

- Rose, J.L.; Avioli, M.J.; Mudge, P.; Sanderson, R. Guided wave inspection potential of defects in rail. NDT E Int. 2004, 37, 153–161. [Google Scholar] [CrossRef]

- Moustakidis, S.; Kappatos, V.; Karlsson, P.; Selcuk, C.; Gan, T.; Hrissagis, K. An intelligent methodology for railways monitoring using ultrasonic guided waves. J. Nondestruct. Eval. 2014, 33, 694–710. [Google Scholar] [CrossRef]

- Legg, M.; Yücel, M.K.; Kappatos, V.; Selcuk, C.; Gan, T. Increased range of ultrasonic guided wave testing of overhead transmission line cables using dispersion compensation. Ultrasonics 2015, 62, 35–45. [Google Scholar] [CrossRef] [PubMed]

- Diligent, O.; Grahn, T.; Boström, A.; Cawley, P.; Lowe, M.J.S. The low-frequency reflection and scattering of the S0 Lamb mode from a circular through-thickness hole in a plate: Finite Element, analytical and experimental studies. J. Acoust. Soc. Am. 2002, 112, 2589–2601. [Google Scholar] [CrossRef] [PubMed]

- Demma, A.; Cawley, P.; Lowe, M. Scattering of the fundamental shear horizontal mode from steps and notches in plates. J. Acoust. Soc. Am. 2003, 113, 1880–1891. [Google Scholar] [CrossRef] [PubMed]

- Diligent, O.; Lowe, M.J.S. Reflection of the S0 Lamb mode from a flat bottom circular hole. J. Acoust. Soc. Am. 2005, 118, 2869–2879. [Google Scholar] [CrossRef]

- Ma, J.; Cawley, P. Low-frequency pulse echo reflection of the fundamental shear horizontal mode from part-thickness elliptical defects in plates. J. Acoust. Soc. Am. 2010, 127, 3485–3493. [Google Scholar] [CrossRef] [PubMed]

- Carandente, R.; Ma, J.; Cawley, P. The scattering of the fundamental torsional mode from axi-symmetric defects with varying depth profile in pipes. J. Acoust. Soc. Am. 2010, 127, 3440–3448. [Google Scholar] [CrossRef] [PubMed]

- Løvstad, A.; Cawley, P. The reflection of the fundamental torsional guided wave from multiple circular holes in pipes. NDT E Int. 2011, 44, 553–562. [Google Scholar] [CrossRef]

- Løvstad, A.; Cawley, P. The reflection of the fundamental torsional mode from pit clusters in pipes. NDT E Int. 2012, 46, 83–93. [Google Scholar] [CrossRef]

- Cobb, A.C.; Kwun, H.; Caseres, L.; Janega, G. Torsional guided wave attenuation in piping from coating, temperature, and large-area corrosion. NDT E Int. 2012, 47, 163–170. [Google Scholar] [CrossRef]

- Carandente, R.; Lovstad, A.; Cawley, P. The influence of sharp edges in corrosion profiles on the reflection of guided waves. NDT E Int. 2012, 52, 57–68. [Google Scholar] [CrossRef]

- Kwun, H.; Kim, S.Y.; Choi, M.S.; Walker, S.M. Torsional guided-wave attenuation in coal-tar-enamel-coated, buried piping. NDT E Int. 2004, 37, 663–665. [Google Scholar] [CrossRef]

- Chen, F.; Wilcox, P.D. The effect of load on guided wave propagation. Ultrasonics 2007, 47, 111–122. [Google Scholar] [CrossRef] [PubMed]

- Lanza di Scalea, F.; Rizzo, P.; Marzani, A. Propagation of ultrasonic guided waves in lap-shear adhesive joints: Case of incident A0 Lamb wave. J. Acoust. Soc. Am. 2004, 115, 146–156. [Google Scholar] [CrossRef] [PubMed]

- Santos, M.J.; Faia, P. Propagation of ultrasonic lamb waves in aluminium adhesively bonded lap joints and in single plates. Res. Nondestruct. Eval. 2009, 20, 178–191. [Google Scholar] [CrossRef]

- Castaings, M. SH ultrasonic guided waves for the evaluation of interfacial adhesion. Ultrasonics 2014, 54, 1760–1775. [Google Scholar] [CrossRef] [PubMed]

- Dalton, R.P.; Cawley, P.; Lowe, M.J.S. The potential of guided waves for monitoring large areas of metallic aircraft fuselage structure. J. Nondestruct. Eval. 2001, 20, 29–46. [Google Scholar] [CrossRef]

- Choi, M.S.; Kim, S.J. Reflection and transmission of normal incidence SH0 waves at a lap joint of two plates of the same material and thickness. J. Korean Phys. Soc. 2006, 49, 1955–1960. [Google Scholar]

- Siryabe, E.; Renier, M.; Meziane, A.; Castaings, M. The transmission of lamb waves across adhesively bonded lap joints to evaluate interfacial adhesive properties. Phys. Procedia 2015, 70, 541–544. [Google Scholar] [CrossRef]

- Rhee, I.; Choi, E.; Roh, Y. Guided wave propagation induced by piezoelectric actuator in bolted thin steel members. KSCE J. Civ. Eng. 2012, 16, 398–406. [Google Scholar] [CrossRef]

- Comot, P.; Bocher, P.; Belanger, P. Ultrasonic guided wave inspection of Inconel 625 brazed lap joints. Proc. SPIE 2016, 9804, 980408. [Google Scholar]

- Hayashi, T.; Song, W.; Rose, J.L. Guided wave dispersion curves for a bar with an arbitrary cross-section, a rod and rail example. Ultrasonics 2003, 41, 175–183. [Google Scholar] [CrossRef]

- Hayashi, T.; Kawashima, K.; Rose, J.L. Calculation for guided waves in pipes and rails. Key Eng. Mater. 2004, 270–273, 410–415. [Google Scholar] [CrossRef]

- Mažeika, L.; Kažys, R.; Raišutis, R.; Šliteris, R. Ultrasonic guided wave tomography for the inspection of the fuel tanks floor. Int. J. Mater. Prod. Technol. 2011, 41, 128–139. [Google Scholar] [CrossRef]

- Moser, F.; Jacobs, L.; Qu, J. Application of Finite Element Methods to Study Transient Wave Propagation in Elastic Wave Guides; Thompson, D., Chimenti, D., Eds.; Springer: New York, NY, USA, 1998; pp. 161–167. [Google Scholar]

- Moser, F.; Jacobs, L.J.; Qu, J. Modeling elastic wave propagation in waveguides with the finite element method. NDT E Int. 1999, 32, 225–234. [Google Scholar] [CrossRef]

- Cerniglia, D.; Pantano, A.; Montinaro, N. 3D simulations and experiments of guided wave propagation in adhesively bonded multi-layered structures. NDT E Int. 2010, 43, 527–535. [Google Scholar] [CrossRef]

- Sorohan, Ş.; Constantin, N.; Găvan, M.; Anghel, V. Extraction of dispersion curves for waves propagating in free complex waveguides by standard finite element codes. Ultrasonics 2011, 51, 503–515. [Google Scholar] [CrossRef] [PubMed]

- Noh, G.; Bathe, K. An explicit time integration scheme for the analysis of wave propagations. Comput. Struct. 2013, 129, 178–193. [Google Scholar] [CrossRef]

- Asmus, A.; Lammering, R. Actual time integration methods for elastic wave propagation analysis. PAMM 2014, 14, 857–858. [Google Scholar] [CrossRef]

- Mirbagheri, Y.; Nahvi, H.; Parvizian, J.; Düster, A. Reducing spurious oscillations in discontinuous wave propagation simulation using high-order finite elements. Comput. Math. Appl. 2015, 70, 1640–1658. [Google Scholar] [CrossRef]

- Mal, A.; Lih, S.; Guo, D. Ultrasonic Characterization of Defects in Lap Joints; Thompson, D., Chimenti, D., Eds.; Springer: New York, NY, USA, 1995; pp. 2059–2064. [Google Scholar]

- Chang, Z.; Guo, D.; Mal, A. Lamb Wave Propagation across a Lap Joint; Thompson, D., Chimenti, D., Eds.; Springer: New York, NY, USA, 1996; pp. 185–192. [Google Scholar]

- Vladišauskas, A.; Šliteris, R.; Raišutis, R.; Seniūnas, G. Contact ultrasonic transducers for mechanical scanning systems. Ultragarsas (Ultrasound) 2010, 65, 30–35. [Google Scholar]

- Vladišauskas, A.; Raišutis, R.; Šliteris, R.; Seniūnas, G.; Jankauskas, A. Investigation of the characteristics of the low frequency broadband contact transducers. Ultragarsas (Ultrasound) 2010, 65, 41–44. [Google Scholar]

- Vladišauskas, A.; Mažeika, L.; Šliteris, R.; Raišutis, R.; Jankauskas, A. Pulse and frequency responses of broadband low frequency ultrasonic transducers. Ultragarsas (Ultrasound) 2011, 66, 32–39. [Google Scholar] [CrossRef]

- Alleyne, D.N.; Cawley, P. A 2-dimensional Fourier transform method for the quantitative measurement of Lamb modes. In Proceedings of the 17th Annual Review, La Jolla, CA, USA, 15–20 July 1990; Volume 2, pp. 1143–1146.

- Duflo, H.; Morvan, B.; Izbicki, J.-L. Interaction of lamb waves on bonded composite plates with defects. Compos. Struct. 2007, 79, 229–233. [Google Scholar] [CrossRef]

- Ruzzene, M. Frequency-wavenumber domain filtering for improved damage visualization. Smart Mater. Struct. 2007, 16, 2116. [Google Scholar] [CrossRef]

- Michaels, T.E.; Michaels, J.E.; Ruzzene, M. Frequency–wavenumber domain analysis of guided wavefields. Ultrasonics 2011, 51, 452–466. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.; Tian, Z. Lamb wave structural health monitoring using a hybrid PZT-laser vibrometer approach. Struct. Health Monit. 2013, 12, 469–483. [Google Scholar] [CrossRef]

- Tian, Z.; Yu, L. Lamb wave frequency-wavenumber analysis and decomposition. J. Intell. Mater. Syst. Struct. 2014, 25, 1107–1123. [Google Scholar] [CrossRef]

- Yu, L.; Tian, Z. Case study of guided wave propagation in a one-side water-immersed steel plate. Case Stud. Nondestruct. Test. Eval. 2015, 3, 1–8. [Google Scholar] [CrossRef]

| Guided Wave Mode | Phase Velocity cph, m/s | Group Velocity cgr, m/s |

|---|---|---|

| Asymmetric A0 | 1701 | 2751 |

| Symmetric S0 | 5156 | 5134 |

| Shear horizontal SH | 3106 | 3106 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jankauskas, A.; Mazeika, L. Ultrasonic Guided Wave Propagation through Welded Lap Joints. Metals 2016, 6, 315. https://doi.org/10.3390/met6120315

Jankauskas A, Mazeika L. Ultrasonic Guided Wave Propagation through Welded Lap Joints. Metals. 2016; 6(12):315. https://doi.org/10.3390/met6120315

Chicago/Turabian StyleJankauskas, Audrius, and Liudas Mazeika. 2016. "Ultrasonic Guided Wave Propagation through Welded Lap Joints" Metals 6, no. 12: 315. https://doi.org/10.3390/met6120315