Laser-Driven Ramp Compression to Investigate and Model Dynamic Response of Iron at High Strain Rates

Abstract

:1. Introduction

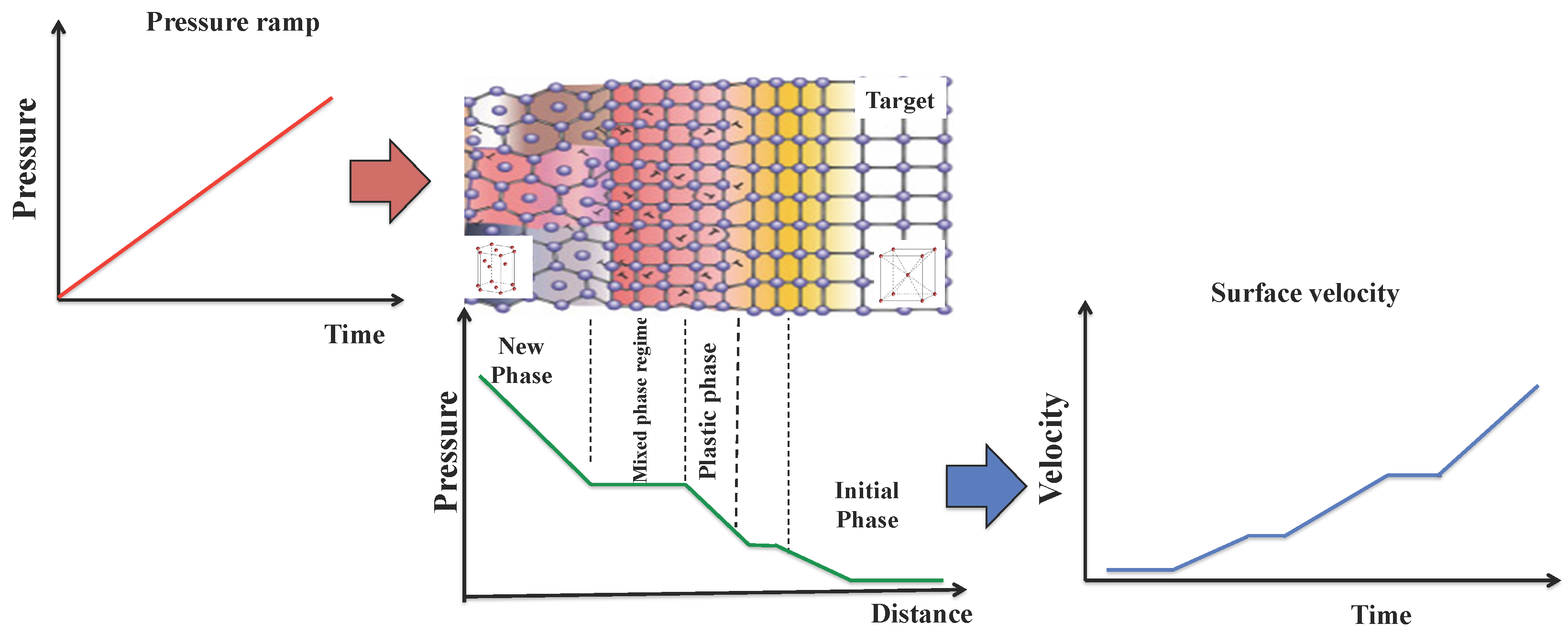

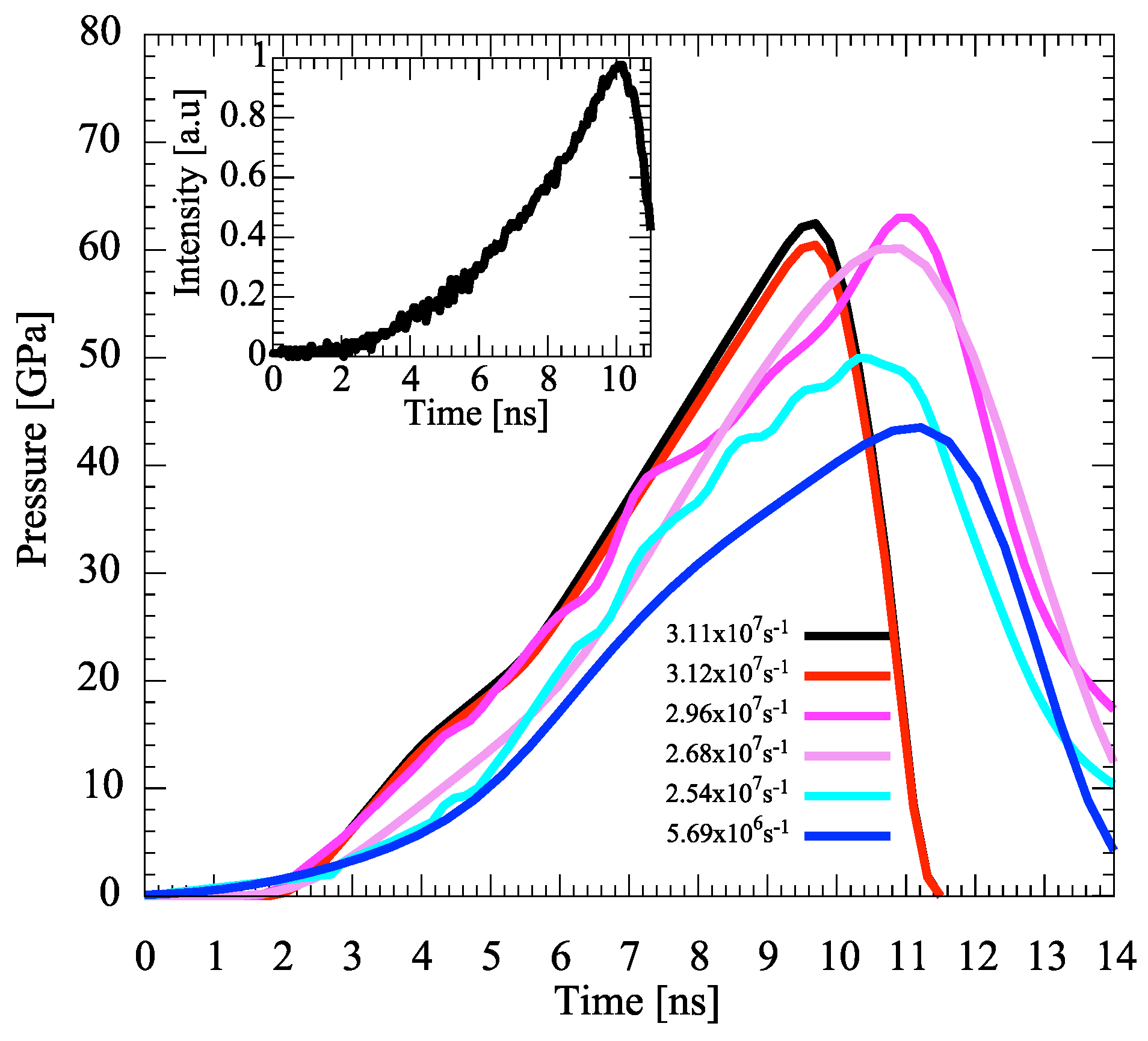

2. Experiments

3. Numerical Simulations

3.1. Elastic-Plastic Model

3.2. Kinetics Model

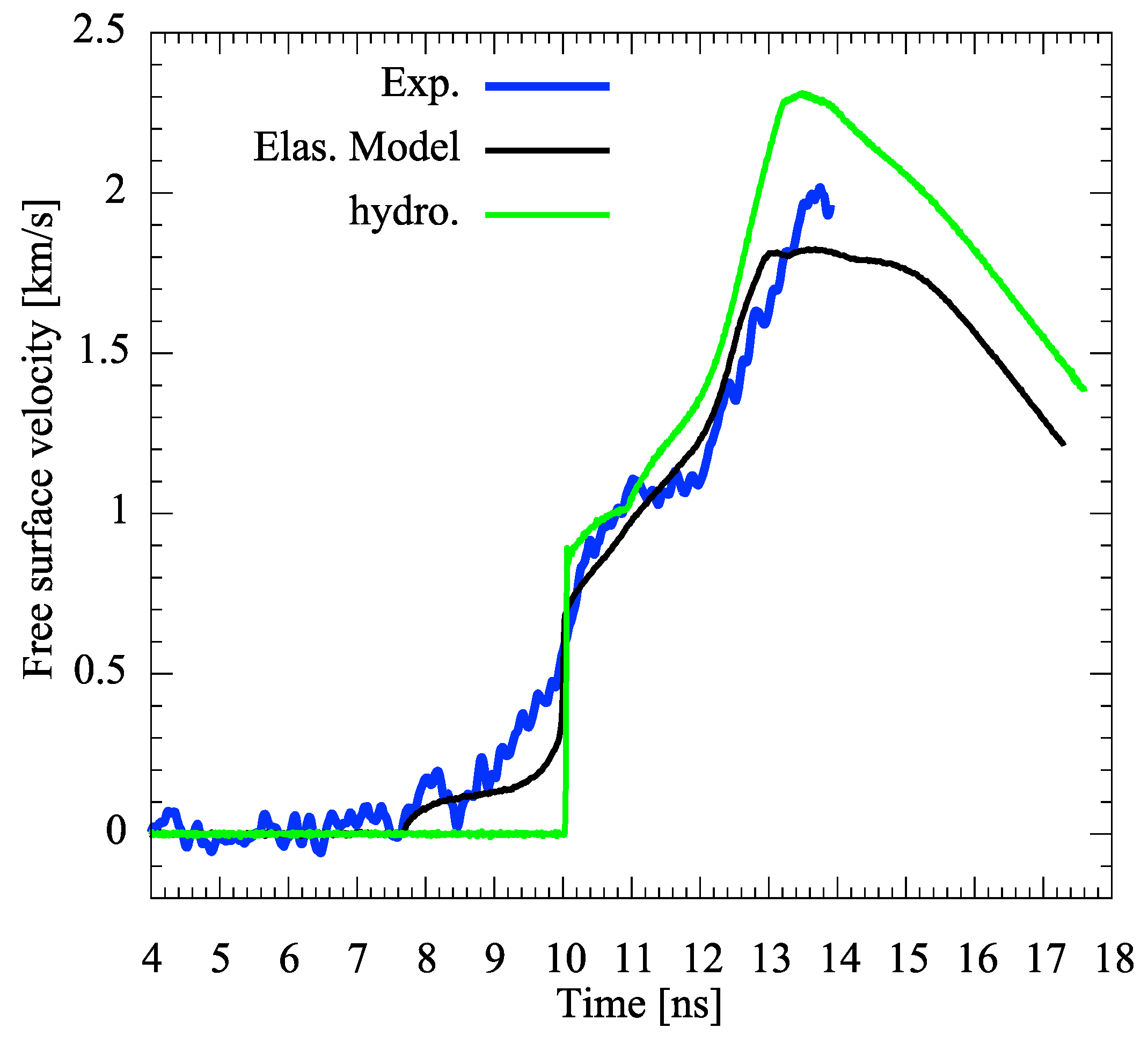

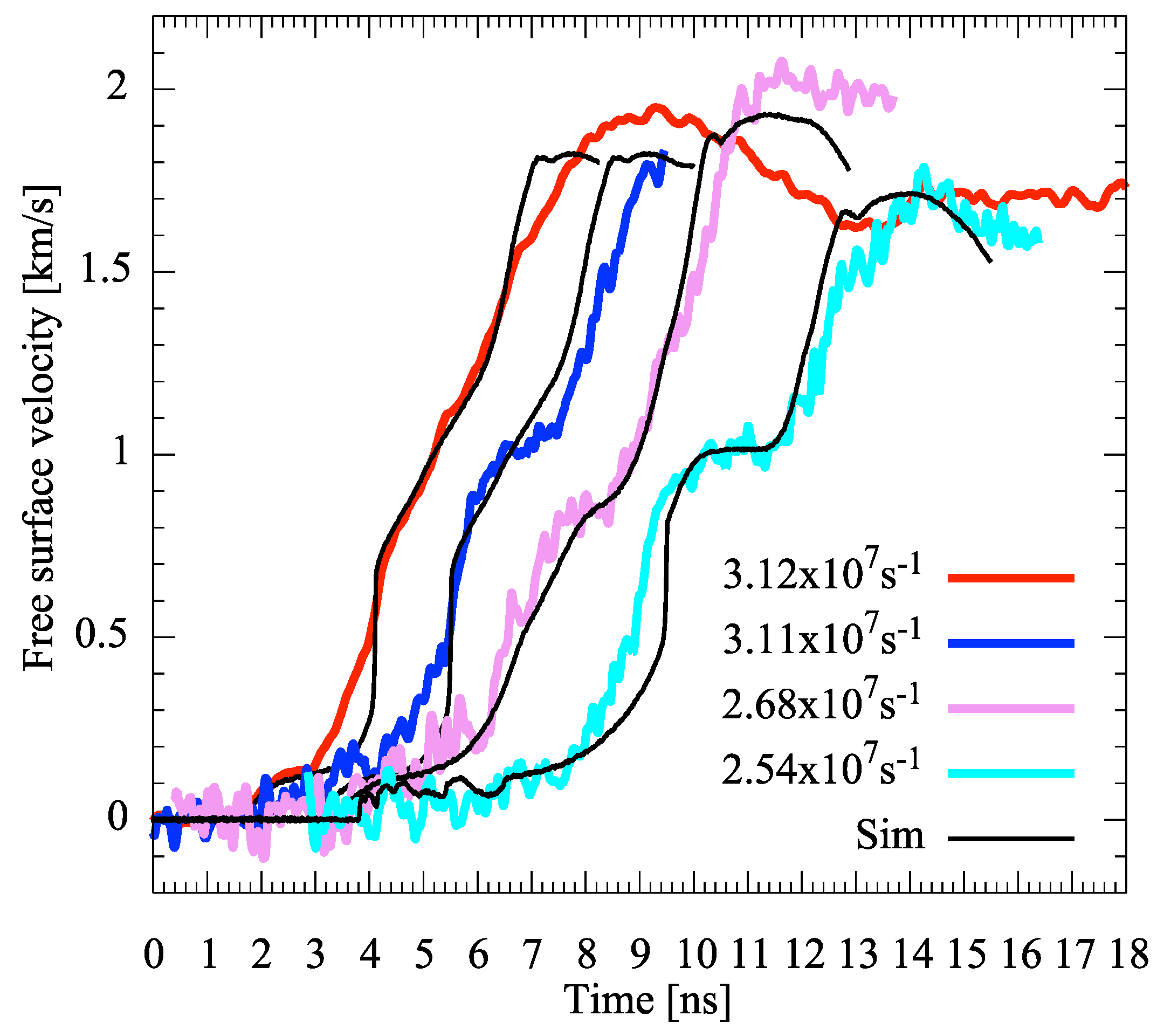

4. Elastic-Plastic Transition

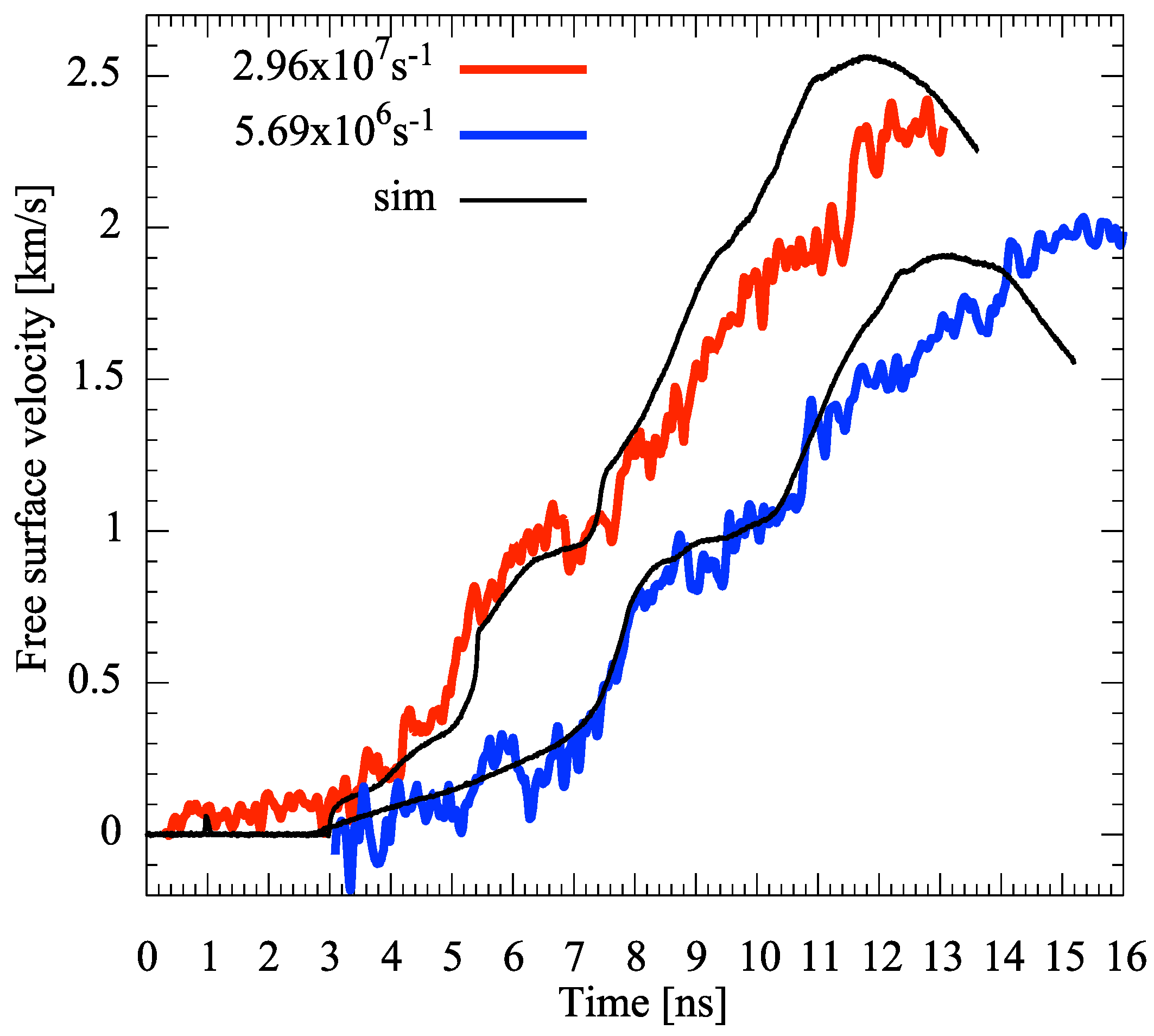

5. Transition Kinetics

6. Discussions

7. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Peyre, P.; Berthe, L.; Scherpereel, X.; Fabbro, R. Laser-shock processing of aluminium-coated 55C1 steel in water-confinement regime, characterization and application to high-cycle fatigue behaviour. J. Mater. Sci 1998, 33, 1421–1429. [Google Scholar] [CrossRef]

- Peyre, P.; Scherpereel, X.; Berthe, L.; Carboni, C.; Fabbro, R.; Béranger, G.; Lemaître, C. Surface modifications induced in 316L steel by laser peening and shot-peening, influence on pitting corrosion resistance. Mater. Sci. Eng. A 2000, 280, 294–302. [Google Scholar] [CrossRef]

- Warren, A.W.; Guo, Y.B.; Chen, S.C. Massive parallel laser shock peening: Simulation, analysis and validation. Int. J. Fatigue 2008, 30, 188–197. [Google Scholar] [CrossRef]

- De Rességuier, T.; Romain, J.P. Investigation of the response of a porous steel to laser driven shocks. Shock Waves 2001, 11, 125–132. [Google Scholar] [CrossRef]

- Berthe, L.; Arrigoni, M.; Boustie, M.; Cuq-Lelandais, J.P.; Broussillou, C.; Fabre, G.; Jeandin, M.; Guipont, V.; Nivard, M. State of the art LASer Adhesion Test (LASAT). Nondestruct. Test. Eval. 2011, 26, 303–317. [Google Scholar] [CrossRef]

- Bégué, G.; Fabre, G.; Guipont, V.; Jeandin, M.; Bilhe, P.; Guédou, J.Y.; Lepoutre, F. Laser Shock Adhesion Test (LASAT) of electron beam physical vapor deposited thermal barrier coatings: Toward an industrial application. Surf. Coat. Technol. 2013, 237, 305–312. [Google Scholar] [CrossRef]

- Amadou, N.; de Resseguier, T.; Brambrink, E.; Benuzzi-Mounaix, A.; Huser, G.; Guyot, F.; Mazevet, S.; Morard, G.; Vinci, T.; Myanishi, K.; et al. Kinetics of the iron α − ε phase transition at high strain rates: Experiment and model. Phys. Rev. B 2016, 93, 214108. [Google Scholar] [CrossRef]

- Amadou, N.; Brambrink, E.; Benuzzi-Mounaix, A.; Huser, G.; Guyot, F.; Mazevet, S.; Morard, G.; de Resseguier, T.; Vinci, T.; Myanishi, K.; et al. Direct laser-driven ramp compression studies of iron: A first step toward the reproduction of planetary core conditions. High Energy Density Phys. 2013, 9, 243–246. [Google Scholar] [CrossRef]

- Smith, R.F.; Eggert, J.H.; Swift, D.C.; Wang, J.; Duffy, T.S.; Braun, D.G.; Rudd, R.E.; Reisman, D.B.; Davis, J.-P.; Knudson, M.D.; et al. Time-dependence of the alpha to epsilon phase transformation in iron. J. Appl. Phys. 2013, 114, 223507. [Google Scholar] [CrossRef]

- Lorenzana, H.E.; Belak, J.F.; Bradley, K.S.; Bringa, E.M.; Budil, K.S.; Cazamias, J.U.; El-Dasher, B.; Hawreliak, J.A.; Hessler, J.; Kadau, K.; et al. Shocked materials at the intersection of experiment and simulation. Sci. Model. Simul. 2008, 15, 159–186. [Google Scholar] [CrossRef]

- De Rességuier, T.; Loison, D.; Dragon, A.; Lescoute, E. Laser driven compression to investigate shock-induced melting of metals. Metals 2014, 4, 490–502. [Google Scholar] [CrossRef]

- Brambrink, E.; Amadou, N.; Benuzzi-Mounaix, A.; Geissel, M.; Harm, M.; Pelka, A.; Vinci, T.; Koenig, M. Production and diagnostics of dense matter. Contrib. Plasma Phys. 2015, 55, 67–77. [Google Scholar] [CrossRef]

- Swift, D.C.; Kraus, R.G.; Loomis, E.N.; Hicks, D.G.; McNaney, J.M.; Johnson, R.P. Shock formation and the ideal shape of ramp compression waves. Phys. Rev. E 2008, 78, 066115. [Google Scholar] [CrossRef] [PubMed]

- Barker, L.M.; Hollenbach, R.E. Laser interferometer for measuring high velocities of any reflecting surface. J. Appl. Phy. 1972, 43, 4669–4675. [Google Scholar] [CrossRef]

- Ramis, R.; Schmalz, R.; Meyer-ter-Vehn, J. MULTI—A computer code for one-dimensional multigroup radiation hydrodynamics. Comput. Phys. Commun. 1988, 49, 475. [Google Scholar] [CrossRef]

- De Rességuier, T.; Hallouin, M. Effects of the α − ε phase transition on wave propagation and spallation in laser shock-loaded iron. Phys. Rev. B 2008, 77, 174107. [Google Scholar] [CrossRef]

- De Rességuier, T.; Hallouin, M. Interaction of two laser shocks inside iron samples. J. Appl. Phys. 2001, 90, 4377–4384. [Google Scholar] [CrossRef]

- Richtmyer, R.D.; Morton, K.W. Difference methods for initial-value problems. In Interscience Tracts in Pure and Applied Mathematics; Bers, L., Courant, R., Stoker, J.J., Eds.; John Wiley & Sons, Inc.: New York, NY, USA, 1967. [Google Scholar]

- Hiermaire, S.J. Structures under Crash and Impact Continuum Mechanics, Discretization and Experimental Characterization; Springer: New York, NY, USA, 2008. [Google Scholar]

- Wilkins, M.L. Computer Simulation of Dynamic Phenomena; Springer: Berlin, Germany, 1999. [Google Scholar]

- De Rességuier, T.; Hallouin, M. Stress relaxation and precursor decay in laser shock-loaded iron. J. Appl. Phys. 1998, 84, 1932–1938. [Google Scholar] [CrossRef]

- Johnson, J.N.; Rohde, R.W. Dynamic Deformation Twinning in Shock-Loaded Iron. J. Appl. Phys. 1971, 42, 4171–4182. [Google Scholar] [CrossRef]

- Avrami, M. Kinetics of Phase Change. I General Theory. J. Chem. Phys. 1939, 7, 1103–1112. [Google Scholar] [CrossRef]

- Avrami, M. Kinetics of Phase Change. II TransformationTime Relations for Random Distribution of Nuclei. J. Chem. Phys. 1940, 8, 212–224. [Google Scholar] [CrossRef]

- Avrami, M. Granulation, Phase Change, and Microstructure Kinetics of Phase Change. III. J. Chem. Phys. 1941, 9, 177–184. [Google Scholar] [CrossRef]

- Duvall, G.E.; Graham, R.A. Phase transitions under shock-wave loading. Rev. Mod. Phys. 1977, 49, 523–579. [Google Scholar] [CrossRef]

- Meyers, M.A.; Murr, L.E. Defect generation in shockwave deformation. In Shock Waves and High-Strain-Rate Phenomena in Metals, Concepts and Applications; Meyers, M.A., Murr, L.E., Eds.; Plenum Press: New York, NY, USA, 1981; pp. 487–530. [Google Scholar]

- Caspersen, K.J.; Lew, A.; Ortiz, M.; Carter, E.A. Importance of Shear in the bcc-to-hcp Transformation in Iron. Phys. Rev. Lett. 2004, 93, 115501. [Google Scholar] [CrossRef] [PubMed]

- Cui, X.; Zhu, W.; He, H.; Deng, X.; Li, Y. Phase transformation of iron under shock compression: Effects of voids and shear stress. Phys. Rev. B 2008, 78, 024115. [Google Scholar] [CrossRef]

- Ma, Y.; Selvi, E.; Levitas, V.I.; Hashemi, J. Effect of shear strain on the α-ϵ phase transition of iron: A new approach in the rotational diamond anvil cell. J. Phys. Condens. Matt. 2006, 18, S1075–S1082. [Google Scholar] [CrossRef] [PubMed]

- Forbes, J.F. Experimental Investigation of the Kinetics of the Shock-Induced Alpha to Epsilon Phase Transformation in Armco Iron; Naval Surface Weapons Center; White Oak Laboratory: Silver Spring, MD, USA, 1977; pp. 72–90. [Google Scholar]

- Barker, L.M.; Hollenbach, R.E. Shock wave study of the α − ε phase transition in iron. J. Appl. Phys. 1974, 45, 4872–4887. [Google Scholar] [CrossRef]

- Boettger, J.C.; Wallace, D.C. Metastability and dynamics of the shock-induced phase transition in iron. Phys. Rev. B 1997, 55, 2840–2849. [Google Scholar] [CrossRef]

- Jensen, B.J.; Gray, G.T., III; Hixson, R.S. Direct measurements of the α-ϵ transition stress and kinetics for shocked iron. J. Appl. Phys. 2009, 105, 103502. [Google Scholar] [CrossRef]

- Bastea, M.; Bastea, S.; Becker, R. High pressure phase transformation in iron under fast compression. J. Appl. Phys. 2009, 95, 241911. [Google Scholar] [CrossRef]

- Hawreliak, J.; Colvin, J.D.; Eggert, J.H.; Kalantar, D.H.; Lorenzana, H.E.; Stölken, J.S.; Davies, H.M.; Germann, T.C.; Holian, B.L.; Kadau, K.; et al. Atomistic simulations of shock-induced transformations and their orientation dependence in bcc Fe single crystals. Phys. Rev. B 2006, 74, 184107. [Google Scholar] [CrossRef]

- Blank, V.D.; Estrin, E.I. Hysteresis and kinetics of low-temperature polymorphic transformations under pressure. In Phase Transitions in Solids Under High Pressure; CRC Press, Taylor and Francis Group: Boca Raton, FL, USA, 2014; Chapter 14; pp. 382–423. [Google Scholar]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amadou, N.; Brambrink, E.; De Rességuier, T.; Manga, A.O.; Aboubacar, A.; Borm, B.; Molineri, A. Laser-Driven Ramp Compression to Investigate and Model Dynamic Response of Iron at High Strain Rates. Metals 2016, 6, 320. https://doi.org/10.3390/met6120320

Amadou N, Brambrink E, De Rességuier T, Manga AO, Aboubacar A, Borm B, Molineri A. Laser-Driven Ramp Compression to Investigate and Model Dynamic Response of Iron at High Strain Rates. Metals. 2016; 6(12):320. https://doi.org/10.3390/met6120320

Chicago/Turabian StyleAmadou, Nourou, Erik Brambrink, Thibaut De Rességuier, Adamou Ousmane Manga, Almoustapha Aboubacar, Björn Borm, and Anaïs Molineri. 2016. "Laser-Driven Ramp Compression to Investigate and Model Dynamic Response of Iron at High Strain Rates" Metals 6, no. 12: 320. https://doi.org/10.3390/met6120320