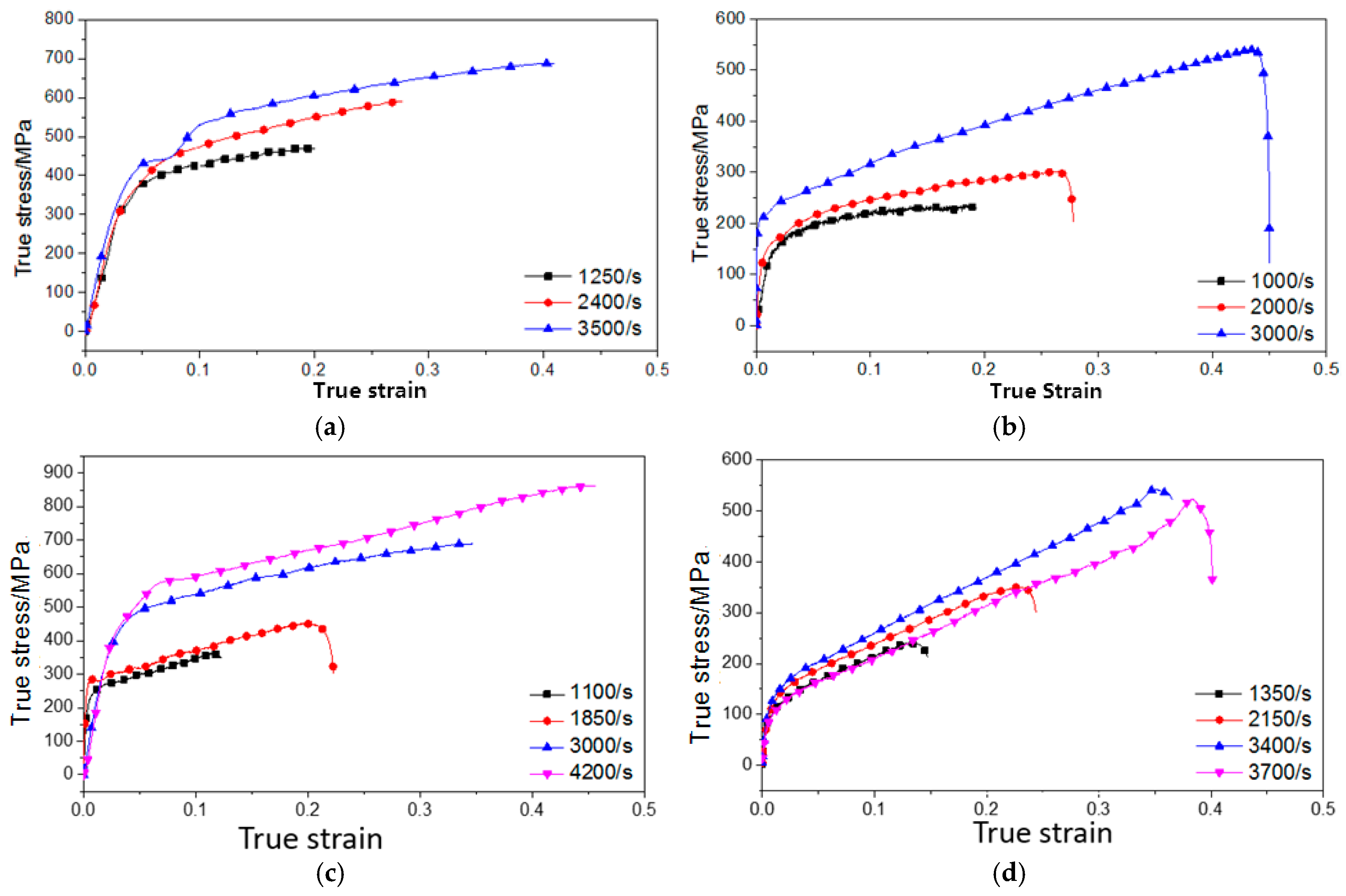

3.2. Dynamic Mechanical Response of Porous Titanium Alloys

SHPB experiments were conducted to yield the true stress–strain curves of the porous titanium alloy specimens (porosity: 26% and 36%) at different strain rates and temperatures. These curves were grouped for the same temperatures and for different strain rates to examine the strain rate effects on alloys under dynamic loading. The true stress and strain values are translated from the engineering value by Equations (2) and (3).

where σ

T is the true stress, ε

T is the true strain; σ

E is the engineering stress, and ε

E is the engineering strain.

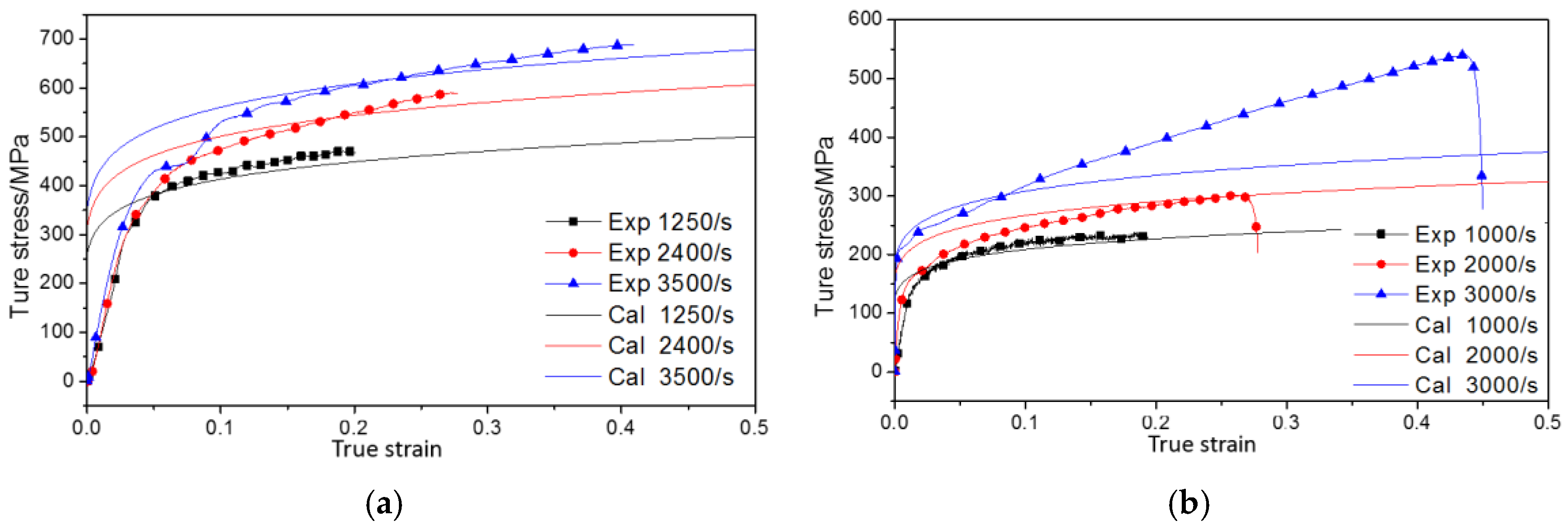

Figure 4 shows the true stress-strain curves of the specimens at

T = 25 °C,

T = 100 °C,

T = 200 °C and

T = 300 °C for various strain rates. Compared with the stress-strain curves obtained under quasistatic compression (

Figure 2), the stress-strain curves under dynamic loading suggest that the yield limits and flow stress values of the alloys increased at high strain rates and their mechanical strength values were higher at high strain rates than at low strain rates. This indicates that the alloy specimens exhibit certain degrees of sensitivity to strain rates. Moreover, the true stress-strain data suggested that the higher the strain rate was, the more discrete the data were. As

Figure 4 shows, when the strain rate reached 4000 s

−1 or higher, the distributions of plastic flow stress were irregular at different temperatures. Thus, the data for both specimens were nonreproducible.

Figure 4 also depicts the deformation of both alloys under dynamic loading during elastic and plastic stages. Unlike compacted materials, these alloy specimens had no plastic flow plateaus in the plastic stage and their stress levels increased when strain levels rose, indicating that strain-hardening rates (

) did not converge to zero as strain levels increased. Moreover, under the same conditions, the strain-hardening rates increased at higher porosity levels and were slightly affected by strain rates, whereas the yield stress and flow stress levels decreased at higher porosity levels. This contrast indicated that high porosity levels led to poor mechanical performance, conforming to the mechanical properties obtained under quasistatic compression.

The strain-rate sensitivity of a porous titanium alloy is typically determined according to the strain-rate effect in the alloy’s microscopic structure and that in the alloy’s substrate. Plastic bending in a microscopic structure under loading leads to a strain-rate effect. Because specimens with open-textured structures were used in this study, plastic bending was likely to occur to pore walls and edges under loading. An analysis of the strain-effects in the specimens’ substrates using the dynamic mechanical properties of pure titanium (TA2) showed that these substrates were highly sensitive to strain rates. Therefore, because the specimens exhibited strain-rate effects, the effects of air in the pores were not considered.

Higher strain rates were achieved at higher impact velocities of the striker bar. However, a high impact velocity resulted in crushing in the pore structures, inducing irregular stress. As such, measurement results were subject to the axial-inertia effect of the specimens, and the axial-inertia effect and strain-rate effect were coupled to the extent that these effects were indistinguishable from one another. These results did not accurately reflect the dynamic mechanical properties of the specimens under strain-rate effects but indicated irregular stress-strain curve distributions at a strain rate of 4000 s−1.

That the strain-hardening rate () increases at high porosity levels can be elucidated by investigating the deformation of porous materials at high strain rates. Extrusions generally occur in a compacted material under impact loading, exposing high-density defects. Thus, such materials exhibit two impact-strengthening effects, i.e., strain-strengthening and strain rate-strengthening effects. A porous material under impact loading is prone to pore collapse-induced deformation, leading to compaction toward the support end. During compaction, this material increases rapidly in density, exhibiting pronounced strain-strengthening effects. Subsequently, substantial strain-strengthening effects can be observed from porous titanium alloys because of their low densities.

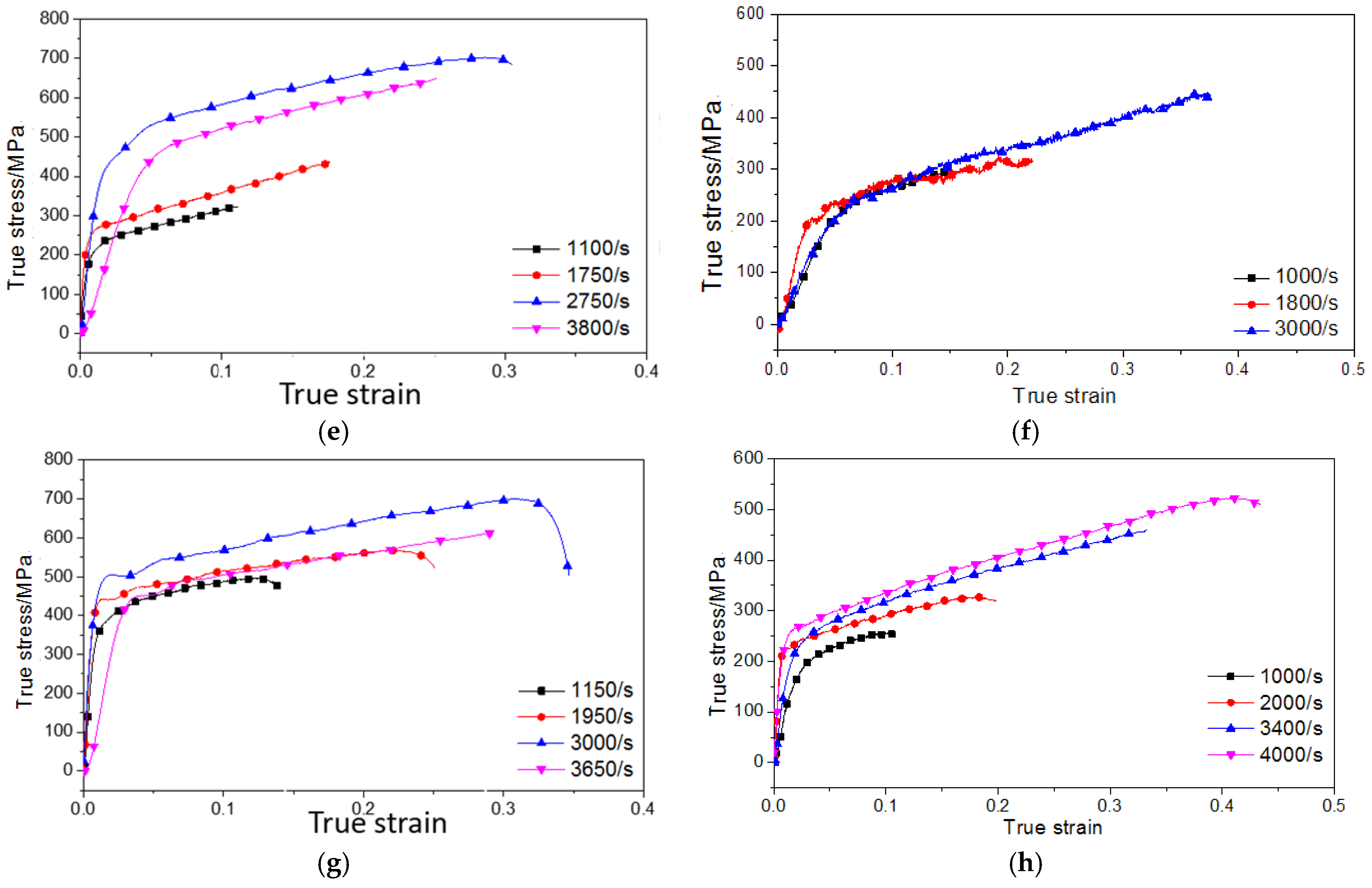

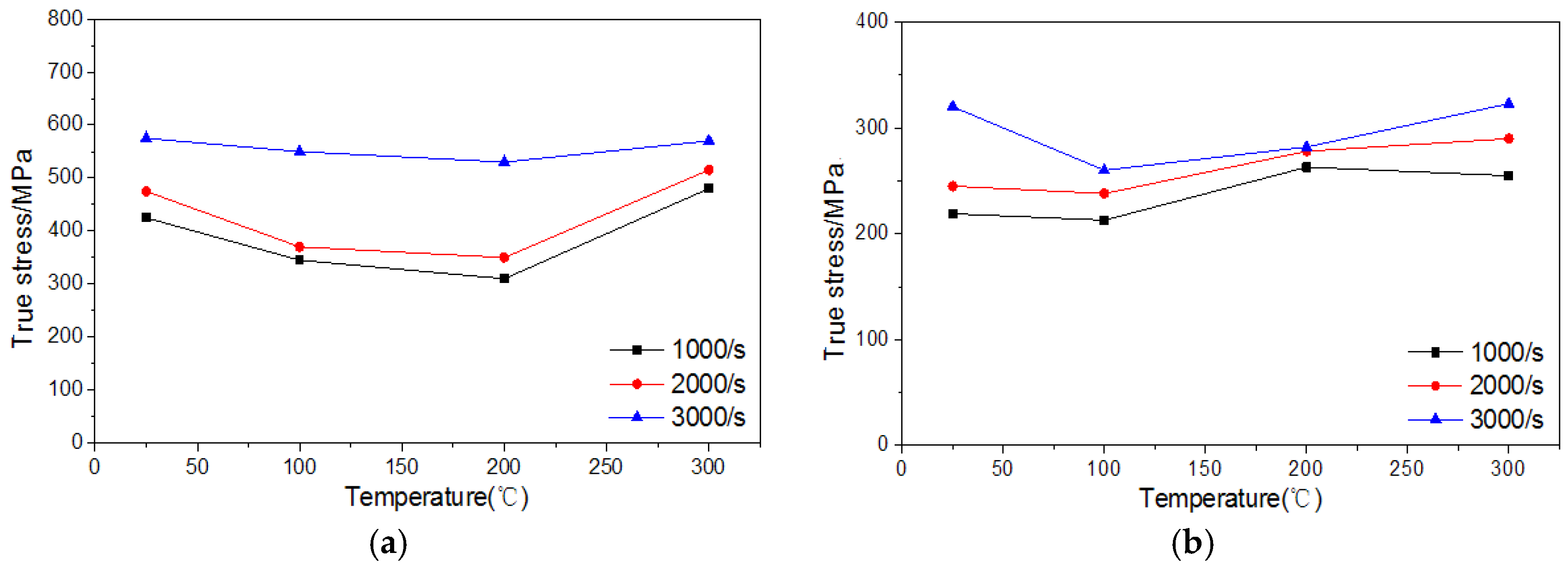

To examine the specimens’ temperature sensitivity, stress-strain curves obtained from the experiments were classified at the same strain rates but different temperatures.

Figure 5 shows the true stress–strain curves obtained from the specimens (porosity: 26% and 36%) at different temperatures and at

= 1000 s

−1,

= 2000 s

−1, and

= 3000 s

−1. At temperatures of less than 200 °C, the yield limit and flow stress of the 26%-porosity specimen declined as the temperature increased, indicating that the presence of temperature-softening effects in the specimen. However, at 300 °C, the yield limit and flow stress increased to levels higher than their room-temperature levels, indicating changes in the specimen’s mechanical properties or microscopic structure at this temperature; these changes were unlikely to be caused by strain-rate effects or strain-hardening effects. In addition, the flow stress of the 36%-porosity specimen only fluctuated slightly as the temperature increased. Thus, its flow-stress variations at various temperatures could not be easily generalized. However, two features of stress-strain curves for the 36%-porosity specimen were observed: the specimen exhibited limited temperature sensitivity at temperatures under 300 °C, and it showed stronger strain-hardening effects at 100 °C than at other temperatures. By contrast, the strain-hardening effects of the 26%-porosity specimen at the same strain rates did not change much despite temperature variations.

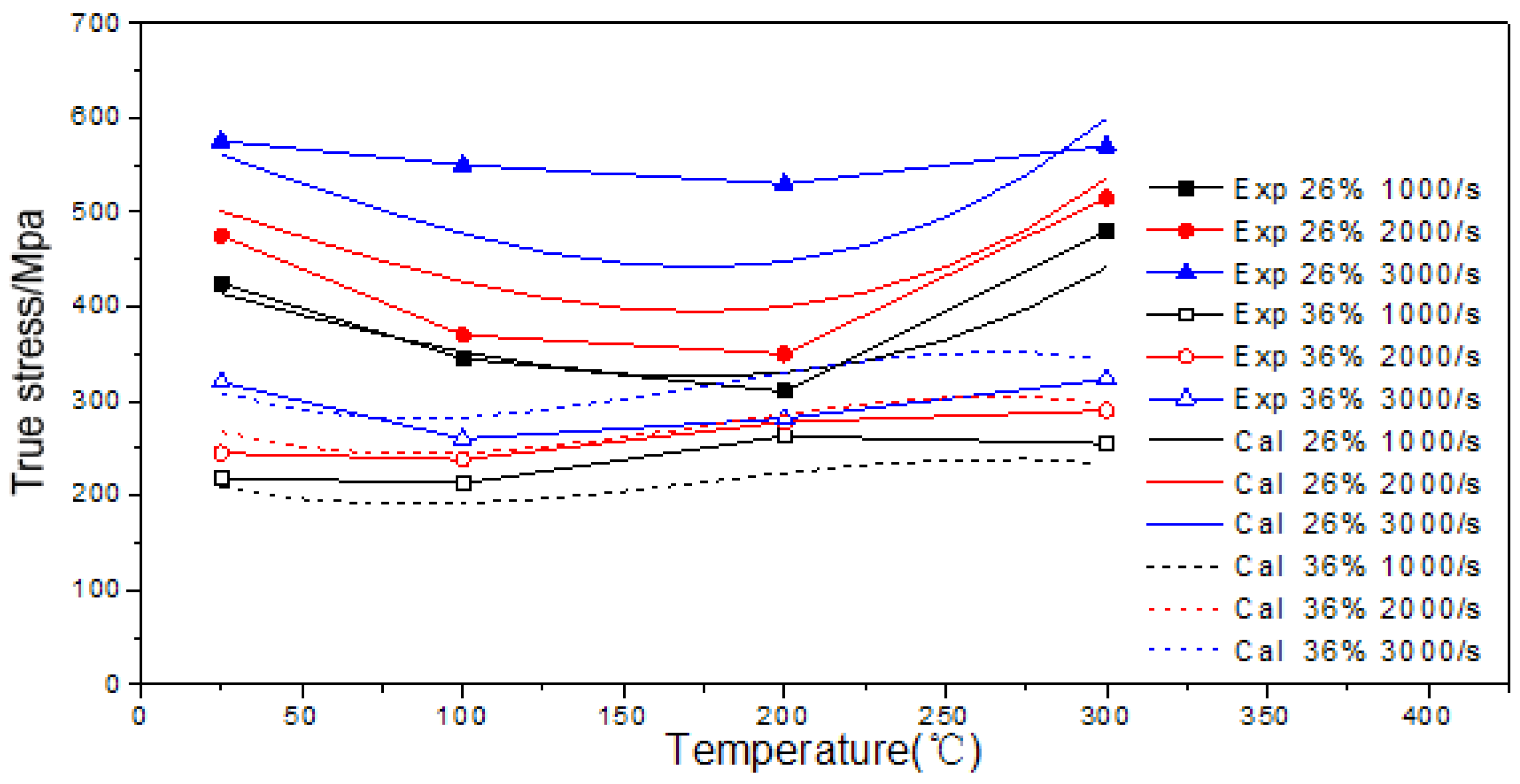

Figure 6 depicts the changes in flow stress in relation to temperature at a stress of 0.1 (ε = 0.1) and at consistent strain rates. This figure illustrates the temperature-softening effects of the 26%-porosity specimen under 200 °C and the substantial increases in these effects at 300 °C. However, the flow stress of the 36%-porosity specimen showed a downward trend at temperatures lower than 100 °C but an upward trend at temperatures higher than 100 °C. The stress-rate sensitivity of the 26%-porosity specimen increased with rising temperatures and decreased once the temperature reached 300 °C, whereas that of the 36%-porosity counterpart decreased with rising temperatures and increased once the temperature reached 300 °C.

Flow stress exhibited similar trends at strain rates of 1000 s−1 and 2000 s−1, but the discreteness of the strain-rate data collected from the specimens increased at a strain rate of 3000 s−1, at which these trends were less noticeable.

Different temperature effects were absorbed between the porous titanium alloy specimens used in this study and compact titanium alloys because the specimens’ mechanical strength levels increased, rather than monotonically decreased, with rising temperatures.

3.3. The Drucker-Prager (DP) Model

The DP model is a constitutive model applied to the finite element simulation of micromachining processes; it describes stress-strain relationships in detail. Each term in the model contains piecewise functions, thus corresponding closely with the specimens’ plastic mechanical properties and ensuring selectivity for fitting. The DP model was used to examine the patterns of plastic flow variations.

The DP model is expressed by

where

is the strain-hardening term,

is the strain-rate strengthening term,

is the temperature-softening term,

is the yield limit,

is the plastic strain,

is the reference plastic strain,

is the breaking strain,

n is the hardening exponent,

m1 and

m2 are strain-rate effect exponents,

is the strain rate,

is the reference strain rate,

is the critical strain rate,

–

are polynomial coefficients,

T is the temperature,

is the melting point of the material, and

is the critical temperature.

Fitting was conducted through the method of separating variables for each term in the DP model. Experimental data were fitted through linear regression and polynomial fitting to yield constitutive equation parameters.

Fitting was first performed on the strain-hardening term. A DP model with reference strain rates and under room-temperature conditions was used to describe the stress-strain relationship under quasistatic conditions. No noticeable plastic-flow plateaus were generated in the specimens because deformation and densification occurred simultaneously. Thus, the fitting was performed using equations with strain-hardening terms smaller than the breaking strain ().

The strain-hardening term was converted into Equation (7). In a log–log graph, this equation is a straight line with an intercept of

and a slope of

, in which

is defined as the yield limit under quasistatic conditions and the reference plastic strain (

) is defined as the nonproportional compressive strain (which was set to be 0.2% in all experiments of the present study). The hardening exponent (

n) was obtained through the fitting of quasistatic true stress-strain data.

This fitting yielded the strain-hardening parameters of the 26%- and 36%-porosity titanium alloy specimens (

Table 5).

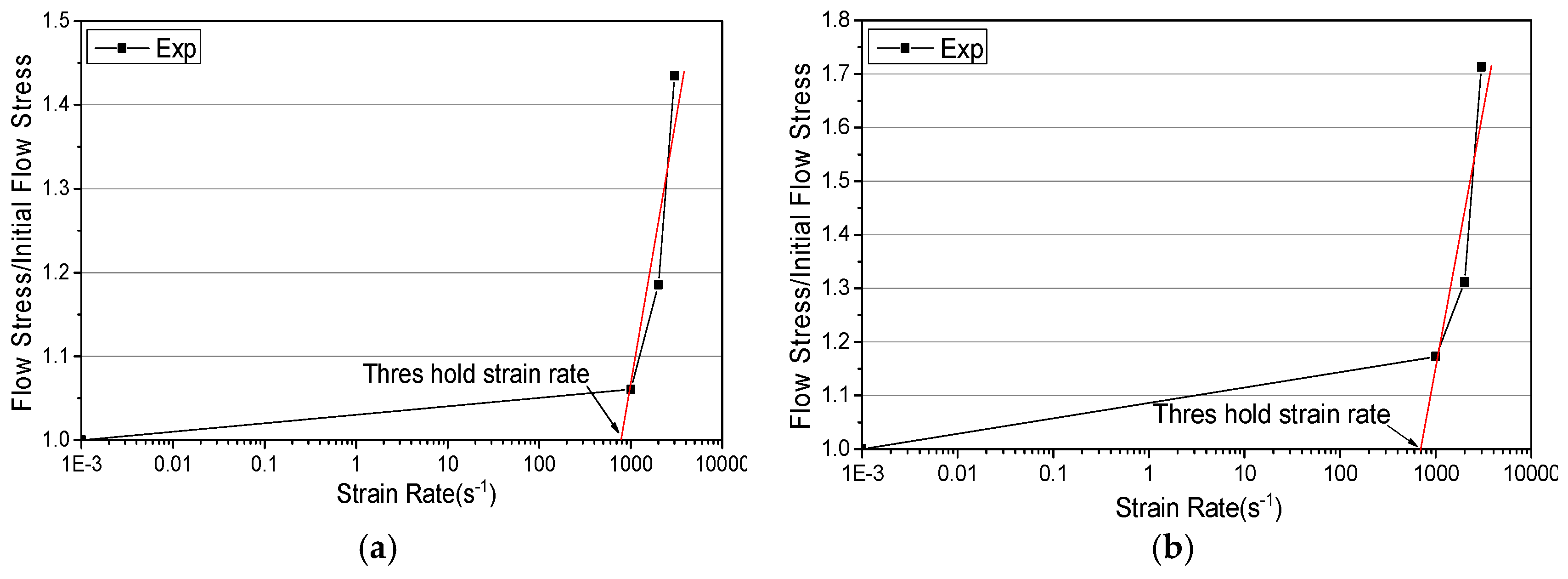

Second, fitting was performed on strain-rate strengthening terms. The DP model was employed under room-temperature conditions to describe the stress-strain relationship at different strain rates at room temperature. Comparing flow stress values at the same room temperature but various strain rates with flow stress values under quasistatic conditions (ε = 0.1) yielded strain-rate strengthening coefficients for different strain rates. In

Figure 7, the straight line indicates changes in strain-rate strengthening coefficients under dynamic conditions; the intersection between the line and coordinate axis is the lower limit of the critical-strain-rate range (whereas its upper limit is 1000 s

−1); and the critical-strain-rate ranges of the 26%- and 36%-porosity specimens are 800–1000 s

−1 and 700–1000 s

−1, respectively. From these ranges, adequate critical strain rates (

) were selected.

To conduct fitting using equations with strain-hardening terms larger than the selected threshold critical strain rates (

), the strain-rate strengthening term was converted into Equation (9). In a log–log graph, this equation is a straight line with a slope of

and an intercept of

, in which the reference strain rate (

) was set to be 0.001. The strain-rate strengthening coefficients of both alloys at the strain rates of 1000 s

−1, 2000 s

−1 and 3000 s

−1 at room temperature were fitted to yield strain-rate sensitivity exponents

m1 and

m2.

This fitting yielded strain-rate strengthening term parameters from the DP model for both specimens (

Table 6).

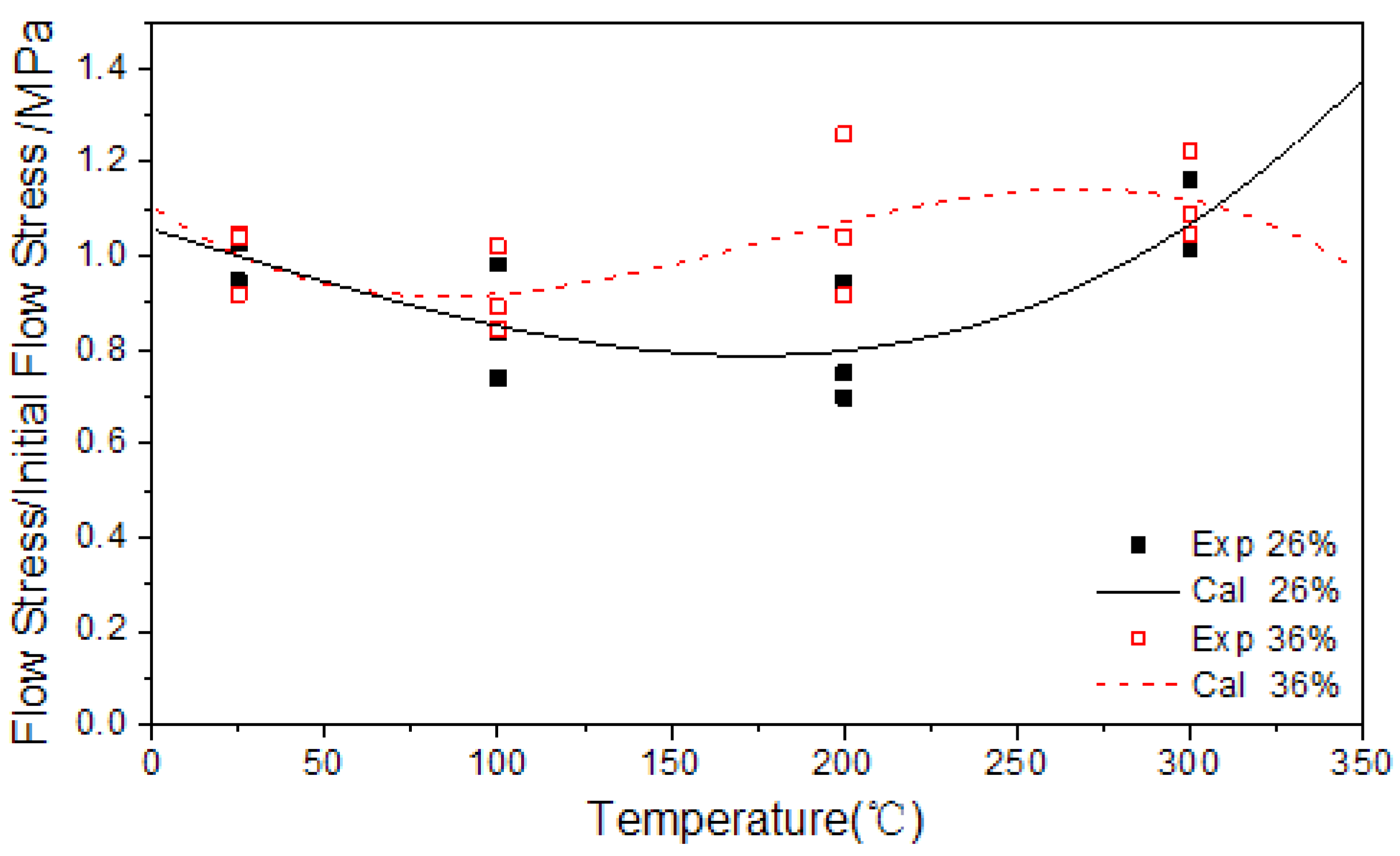

Fitting was performed on temperature-softening terms. The flow stress values of the alloy specimens changed nonlinearly with temperature; thus, linear decrease equations with temperature-softening terms greater than the critical temperature () were not adequate for the fitting. Instead, polynomial equations obtained from the temperature-softening terms in the model were used to describe the temperature effects of the specimens.

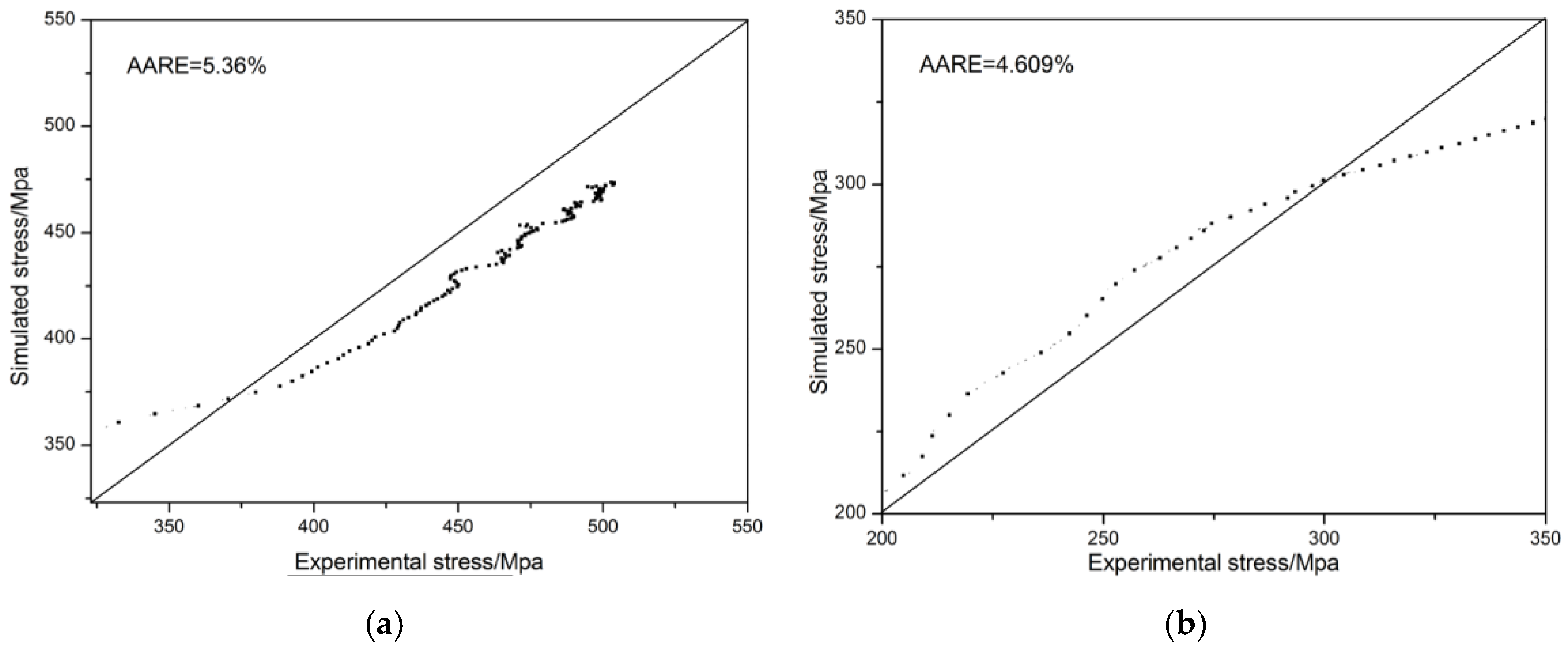

During the fitting, flow stress (ε = 0.1) values for identical strain rates at 25 °C, 100 °C, 200 °C and 300 °C was divided by the initial flow stress and the corresponding strain-rate strengthening coefficients to derive temperature-effect coefficients for the alloys at these different temperatures (

Figure 8). Polynomial fitting was subsequently performed on these temperature-effect coefficients to yield polynomial coefficients

–

(

Table 7).