Tensile Ductility of Nanostructured Bainitic Steels: Influence of Retained Austenite Stability

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Heat-Treatment, Tensile Testing and Retained Austenite Measurements

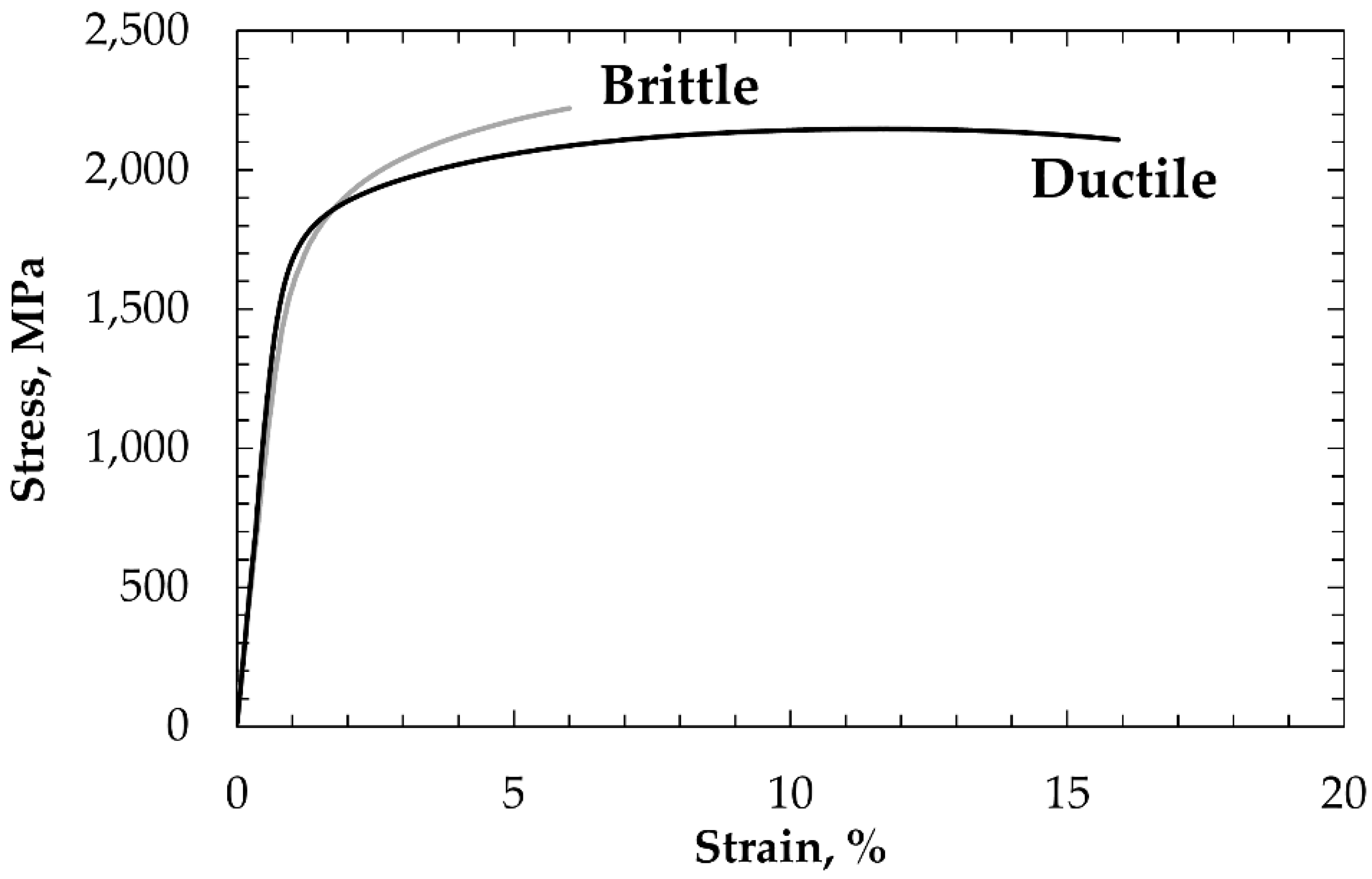

3. Results

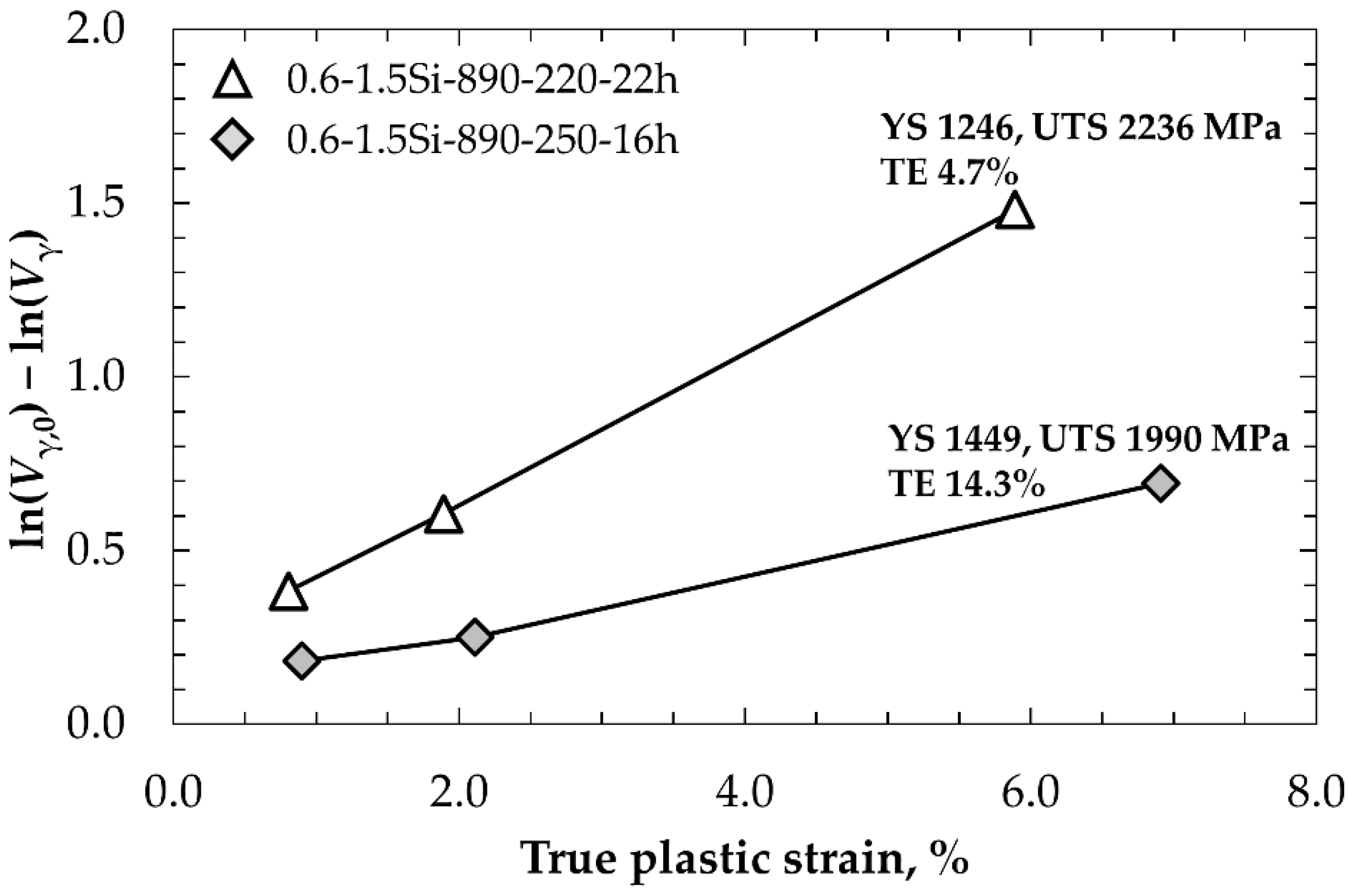

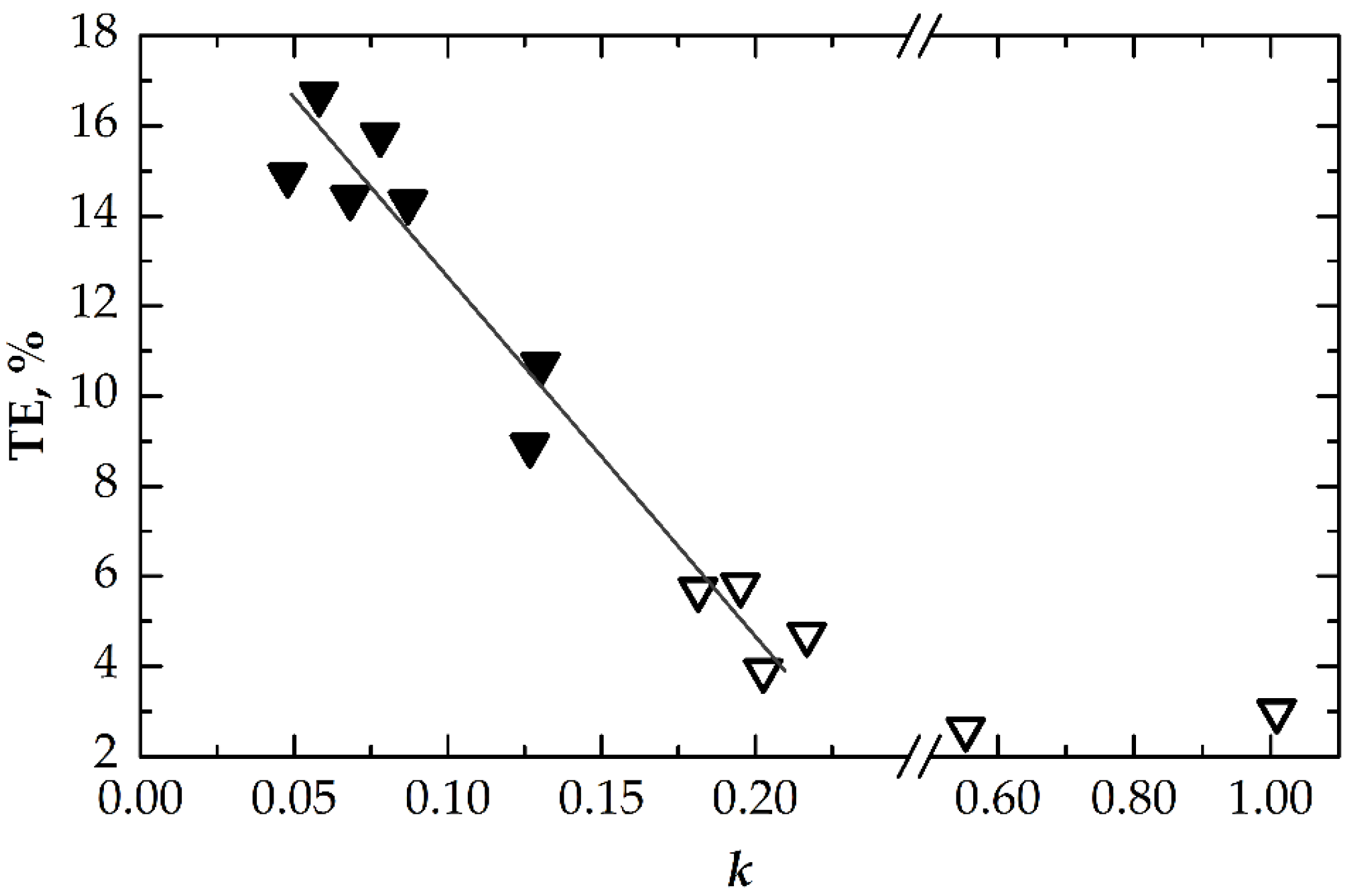

4. Discussion and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Caballero, F.G.; Bhadeshia, H.K.D.H.; Mawella, K.J.A.; Jones, D.G.; Brown, P. Design of novel high strength bainitic steels: Part 1. Mater. Sci. Technol. 2001, 17, 512–516. [Google Scholar] [CrossRef] [Green Version]

- Caballero, F.G.; Bhadeshia, H.K.D.H.; Mawella, K.J.A.; Jones, D.G.; Brown, P. Design of novel high strength bainitic steels: Part 2. Mater. Sci. Technol. 2001, 17, 517–522. [Google Scholar] [CrossRef] [Green Version]

- Caballero, F.G.; Bhadeshia, H.K.D.H.; Mawella, K.J.A.; Jones, D.G.; Brown, P. Very strong low temperature bainite. Mater. Sci. Technol. 2002, 18, 279–284. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Mateo, C.; Caballero, F.G.; Bhadeshia, H.K.D.H. Development of hard bainite. ISIJ Int. 2003, 43, 1238–1243. [Google Scholar] [CrossRef]

- Garcia-Mateo, C.; Caballero, F.; Bhadeshia, H. Low temperature bainite. J. Phys. IV 2003, 112, 285–288. [Google Scholar] [CrossRef] [Green Version]

- Caballero, F.G.; Bhadeshia, H.K.D.H. Very strong bainite. Curr. Opin. Solid State Mater. Sci. 2004, 8, 251–257. [Google Scholar] [CrossRef]

- Wang, T.S.; Li, X.Y.; Zhang, F.C.; Zheng, Y.Z. Microstructures and mechanical properties of 60Si2CrVa steel by isothermal transformation at low temperature. Mater. Sci. Eng. A 2006, 438–440, 1124–1127. [Google Scholar] [CrossRef]

- Soliman, M.; Palkowski, H. Ultra-fine bainite structure in hypo-eutectoid steels. ISIJ Int. 2007, 47, 1703–1710. [Google Scholar] [CrossRef]

- Timokhina, I.B.; Beladi, H.; Xiong, X.Y.; Adachi, Y.; Hodgson, P.D. Nanoscale microstructural characterization of a nanobainitic steel. Acta Mater. 2011, 59, 5511–5522. [Google Scholar] [CrossRef]

- Garcia-Mateo, C.; Caballero, F.G.; Sourmail, T.; Kuntz, M.; Cornide, J.; Smanio, V.; Elvira, R. Tensile behaviour of a nanocrystalline bainitic steel containing 3 wt % silicon. Mater. Sci. Eng. A 2012, 549, 185–192. [Google Scholar] [CrossRef] [Green Version]

- Sourmail, T.; Caballero, F.G.; Garcia-Mateo, C.; Smanio, V.; Ziegler, C.; Kuntz, M.; Elvira, R.; Leiro, A.; Vuorinen, E.; Teeri, T. Evaluation of potential of high si high c steel nanostructured bainite for wear and fatigue applications. Mater. Sci. Technol. 2013, 29, 1166–1173. [Google Scholar] [CrossRef]

- Sourmail, T.; Smanio, V.; Ziegler, C.; Heuer, V.; Kuntz, M.; Caballero, F.G.; Garcia-Mateo, C.; Cornide, J.; Elvira, R.; Leiro, A.; et al. Novel Nanostructured Bainitic Steel Grades to Answer the Need for High-Performance Steel Components (Nanobain); European Commission: Luxembourg, Luxembourg, 2013. [Google Scholar]

- Garbarz, B.; Burian, W. Microstructure and properties of nanoduplex bainite–austenite steel for ultra-high-strength plates. Steel Res. Int. 2014, 85, 1620–1628. [Google Scholar] [CrossRef]

- Soliman, M.; Palkowski, H. Development of the low temperature bainite. Arch. Civ. Mech. Eng. 2016, 16, 403–412. [Google Scholar] [CrossRef]

- Garcia-Mateo, C.; Caballero, F.G.; Bhadeshia, H.K.D.H. Acceleration of low-temperature bainite. ISIJ Int. 2003, 43, 1821–1825. [Google Scholar] [CrossRef]

- Tump, A.; Brandt, R. Graded high-strength spring-steels by a special inductive heat Treatment. IOP Conf. Ser. Mater. Sci. Eng. 2016, 118, 012021. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. Nanostructured bainite. Proc. R. Soc. A 2010, 466, 3–18. [Google Scholar] [CrossRef]

- Sandvik, B.P.J.; Navalainen, H.P. Structure-property relationships in commercial low-alloy bainitic-austenitic steel with high strength, ductility, and toughness. Met. Technol. 1981, 8, 213–220. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. Bainite in Steels. Transformations, Microstructure and Properties, 2nd ed.; Institute of Materials, Minerals and Mining: London, UK, 2001. [Google Scholar]

- Garcia-Mateo, C.; Caballero, F.G. The role of retained austenite on tensile properties of steels with bainitic microstructures. Mater. Trans. JIM 2005, 46, 1839–1846. [Google Scholar] [CrossRef]

- Morales-Rivas, L.; Garcia-Mateo, C.; Kuntz, M.; Sourmail, T.; Caballero, F.G. Induced martensitic transformation during tensile test in nanostructured bainitic steels. Mater. Sci. Eng. A 2016, 662, 169–177. [Google Scholar] [CrossRef]

- Garcia-Mateo, C.; Caballero, F.G.; Chao, J.; Capdevila, C.; de Andres, C.G. Mechanical stability of retained austenite during plastic deformation of super high strength carbide free bainitic steels. J. Mater. Sci. 2009, 44, 4617–4624. [Google Scholar] [CrossRef]

- Avishan, B.; Garcia-Mateo, C.; Yazdani, S.; Caballero, F.G. Retained austenite thermal stability in a nanostructured bainitic steel. Mater. Charact. 2013, 81, 105–110. [Google Scholar] [CrossRef] [Green Version]

- Sherif, M.Y.; Mateo, C.G.; Sourmail, T.; Bhadeshia, H. Stability of retained austenite in trip-assisted steels. Mater. Sci. Technol. 2004, 20, 319–322. [Google Scholar] [CrossRef]

| Reference in [12] | UTS, MPa | TE, % | γres = 1 − Vβ, % | tβ, nm |

|---|---|---|---|---|

| 1CSi-220 | ~2070 | 7 | 34 | 28 |

| 1CSi-250 | ~2200 | 21 | 36 | 28 |

| Reference | C | Si | Mn | Cr | Mo | V |

|---|---|---|---|---|---|---|

| 0.6C-1.5Si | 0.67 | 1.67 | 1.32 | 1.73 | 0.15 | 0.12 |

| 1C-1.5Si | 1.05 | 1.60 | 0.74 | 1.05 | 0.07 | - |

| 1C-2.5Si | 0.99 | 2.47 | 0.74 | 0.97 | 0.03 | - |

| Reference | Vγ,0, % | YS0.2%, MPa | UTS, MPa | TE, % | k |

|---|---|---|---|---|---|

| 0.6C-1.5Si-890-250-16h | 18 | 1448 | 1990 | 14.3 | 0.087 |

| 0.6C-1.5Si-890-220-22h | 22 | 1246 | 2236 * | 4.7 * | 0.217 |

| 0.6C-1.5Si-950-250-22h | 23 | 1404 | 1990 | 14.4 | 0.068 |

| 0.6C-1.5Si-950-220-40h | 24 | 1295 | 2221 | 8.9 | 0.127 |

| H0.6C-1.5Si-890-220-22h | 21 | 1193 | 2158 * | 5.8 * | 0.195 |

| 1C-2.5Si-950-220-22h | 43 | 1675 | 2185 * | 3.9 * | 0.203 |

| 1C-2.5Si-950-220-70h | 33 | 1921 | 2277 * | 5.7 * | 0.181 |

| 1C-2.5Si-950-250-16h | 37 | 1738 | 2106 | 16.8 | 0.058 |

| 1C-2.5Si-950-250-40h | 35 | 1785 | 2101 | 15.8 | 0.078 |

| 1C-2.5Si-1050-220-40h | 41 | 1768 | 2195 * | 2.6 * | 0.553 |

| 1C-2.5Si-1050-250-25h | 34 | 1676 | 2088 | 14.9 | 0.048 |

| 1C-1.5Si-950-220-22h | 40 | 1192 | 2063 * | 3.0 * | 1.009 |

| 1C-1.5Si-950-250-16h | 33 | 1740 | 2170 | 10.7 | 0.130 |

© 2017 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sourmail, T.; Garcia-Mateo, C.; Caballero, F.G.; Morales-Rivas, L.; Rementeria, R.; Kuntz, M. Tensile Ductility of Nanostructured Bainitic Steels: Influence of Retained Austenite Stability. Metals 2017, 7, 31. https://doi.org/10.3390/met7010031

Sourmail T, Garcia-Mateo C, Caballero FG, Morales-Rivas L, Rementeria R, Kuntz M. Tensile Ductility of Nanostructured Bainitic Steels: Influence of Retained Austenite Stability. Metals. 2017; 7(1):31. https://doi.org/10.3390/met7010031

Chicago/Turabian StyleSourmail, Thomas, Carlos Garcia-Mateo, Francisca G. Caballero, Lucia Morales-Rivas, Rosalia Rementeria, and Matthias Kuntz. 2017. "Tensile Ductility of Nanostructured Bainitic Steels: Influence of Retained Austenite Stability" Metals 7, no. 1: 31. https://doi.org/10.3390/met7010031