The Effect of Vibration during Friction Stir Welding on Corrosion Behavior, Mechanical Properties, and Machining Characteristics of Stir Zone

Abstract

:1. Introduction

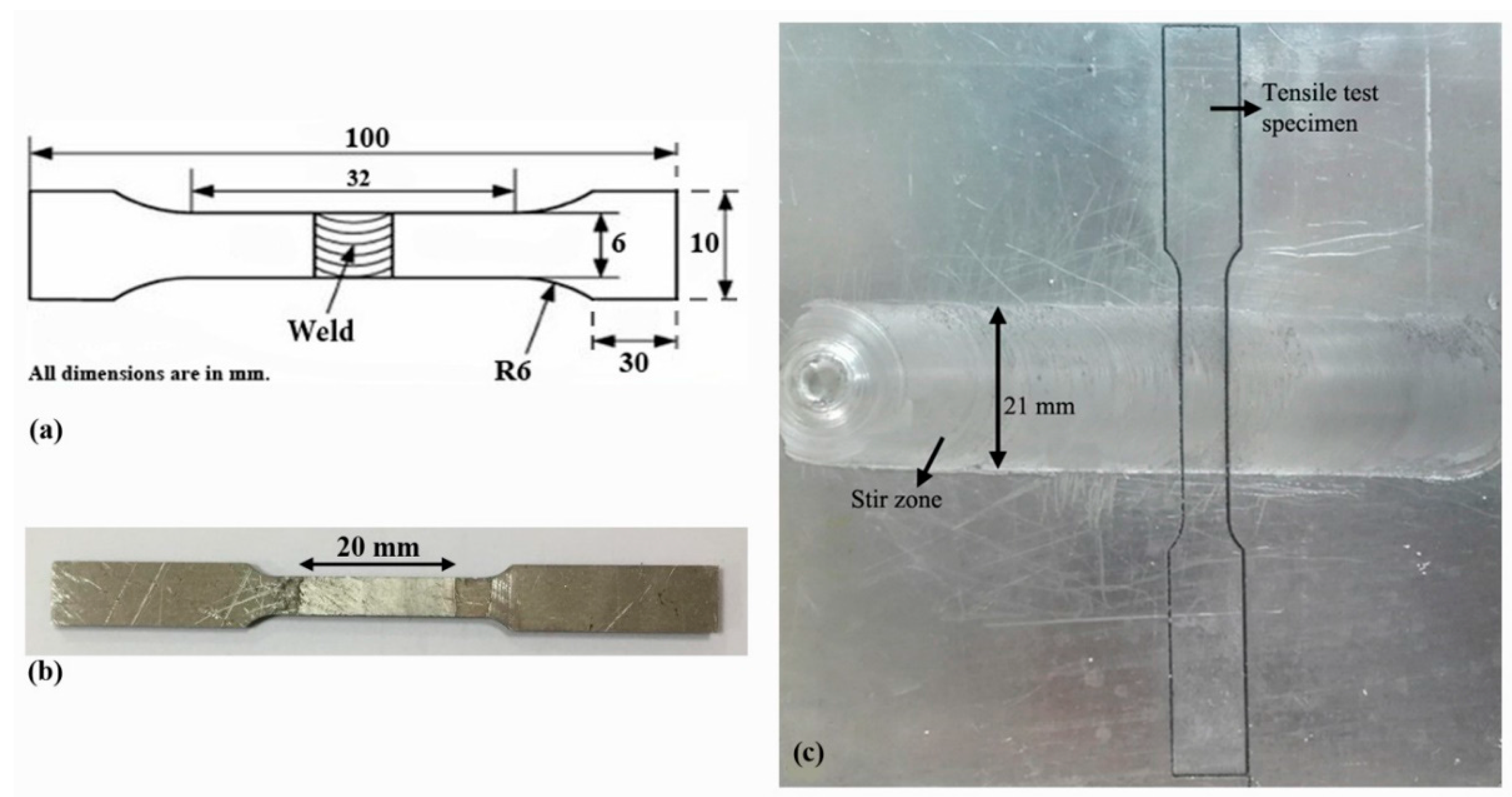

2. Materials and Methods

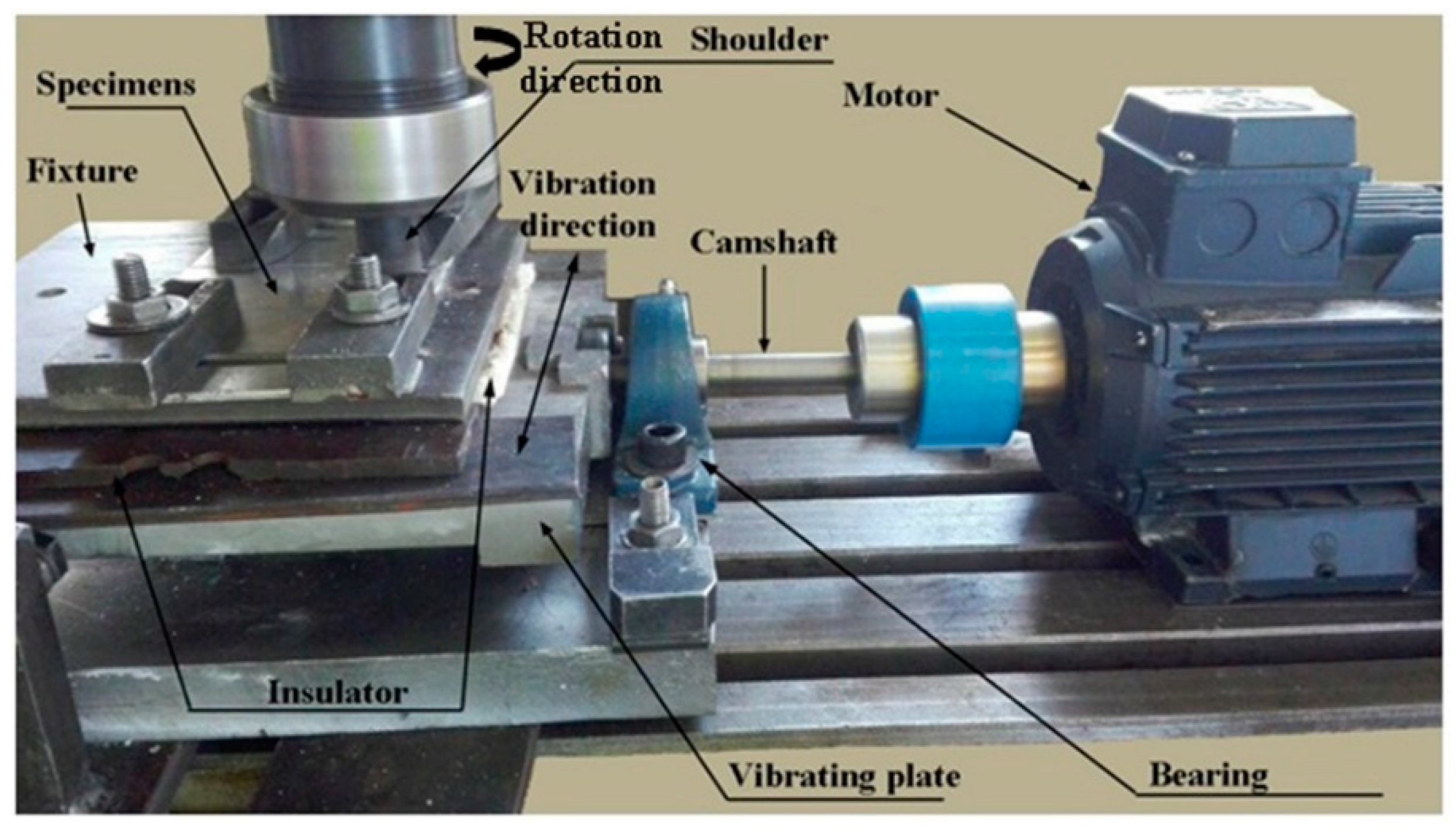

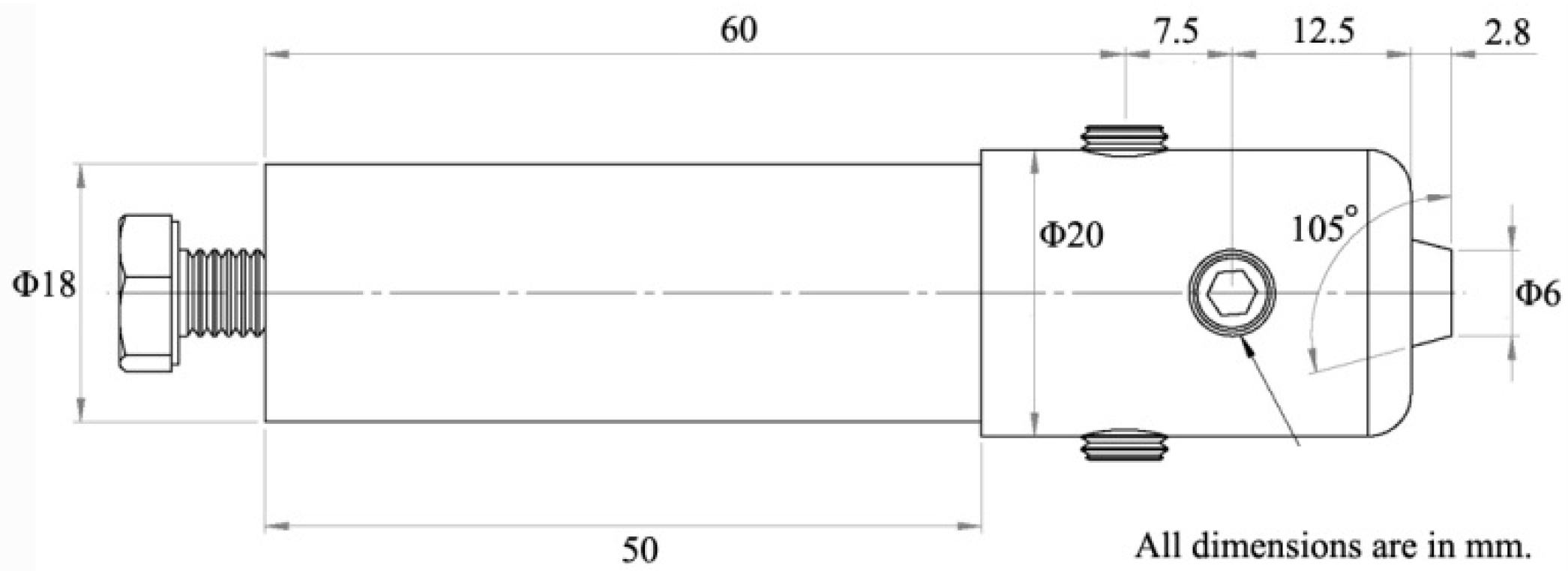

2.1. Welding Process

2.2. Corrosion Test

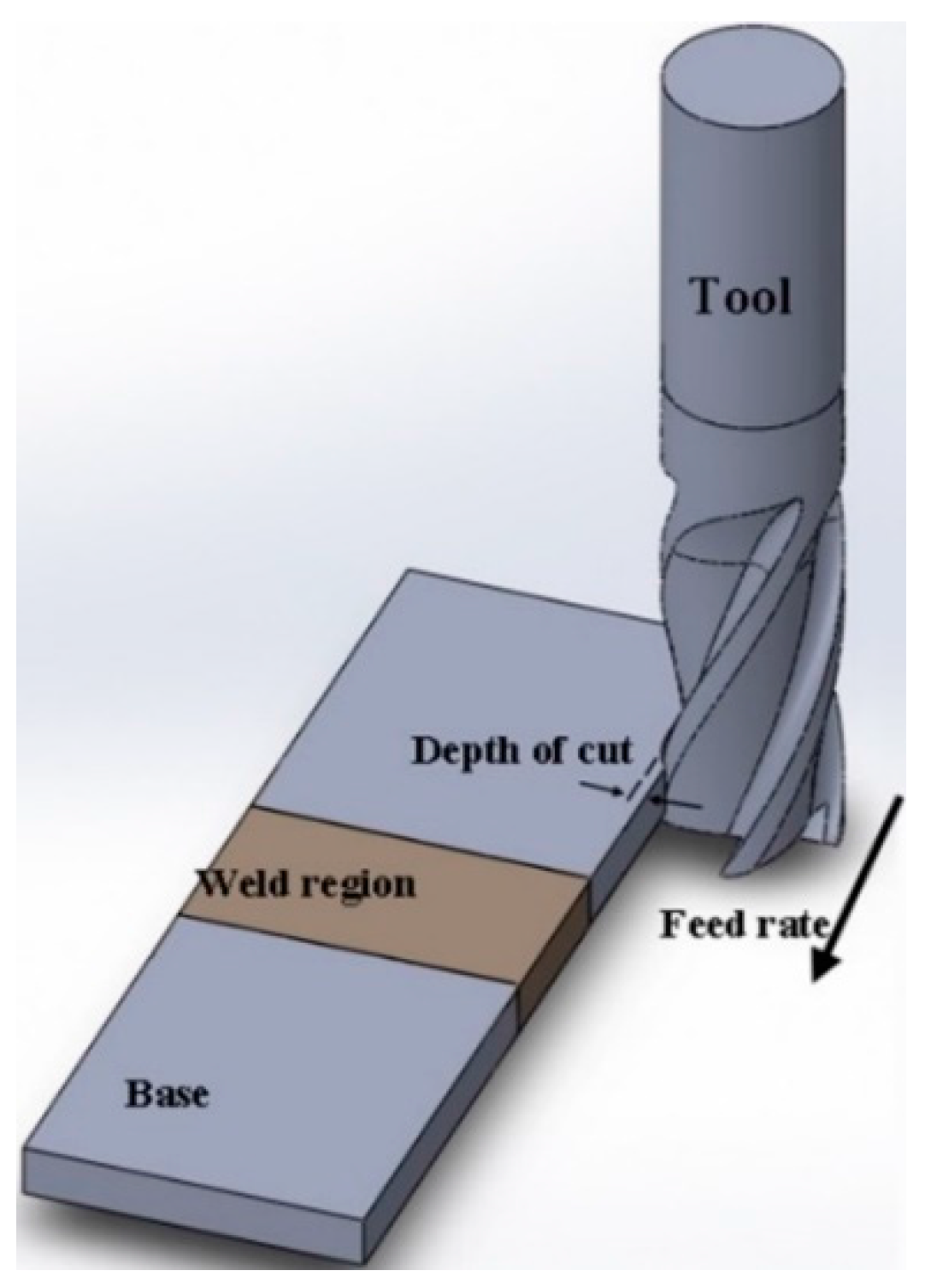

2.3. Machining Setup

3. Results and Discussion

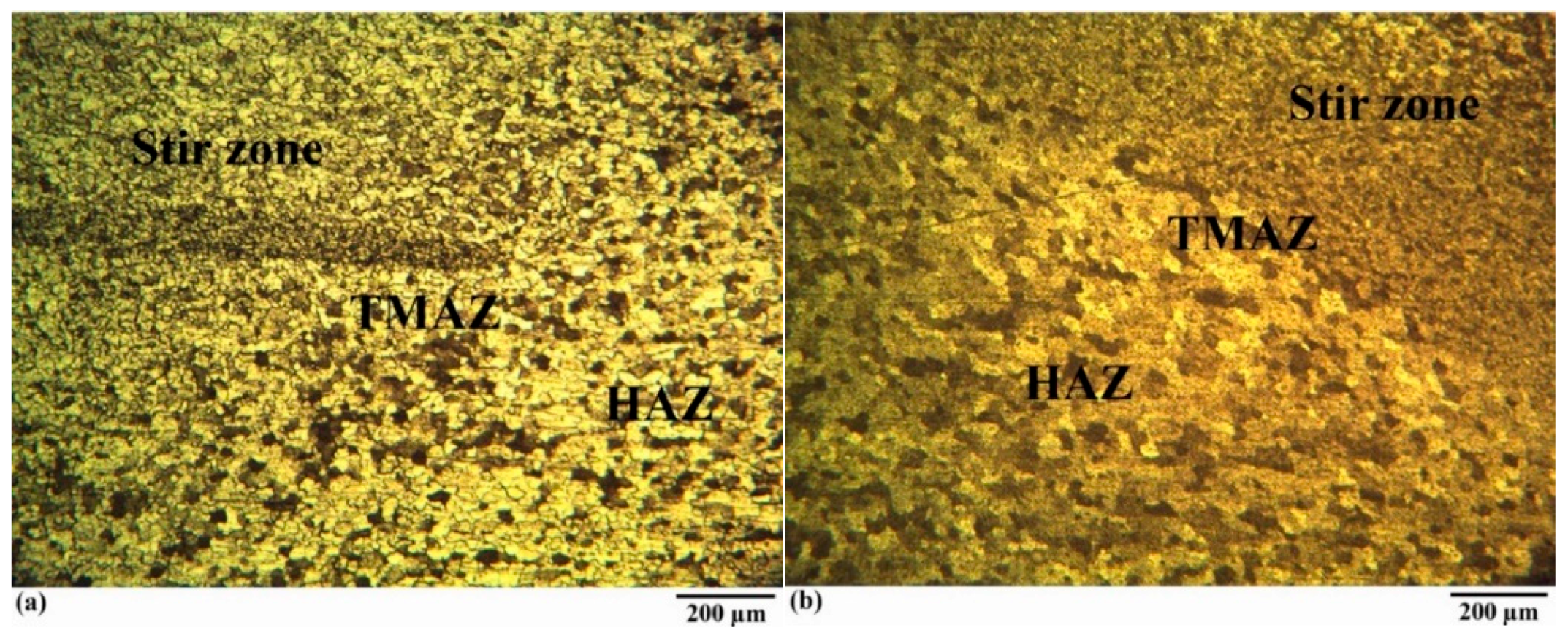

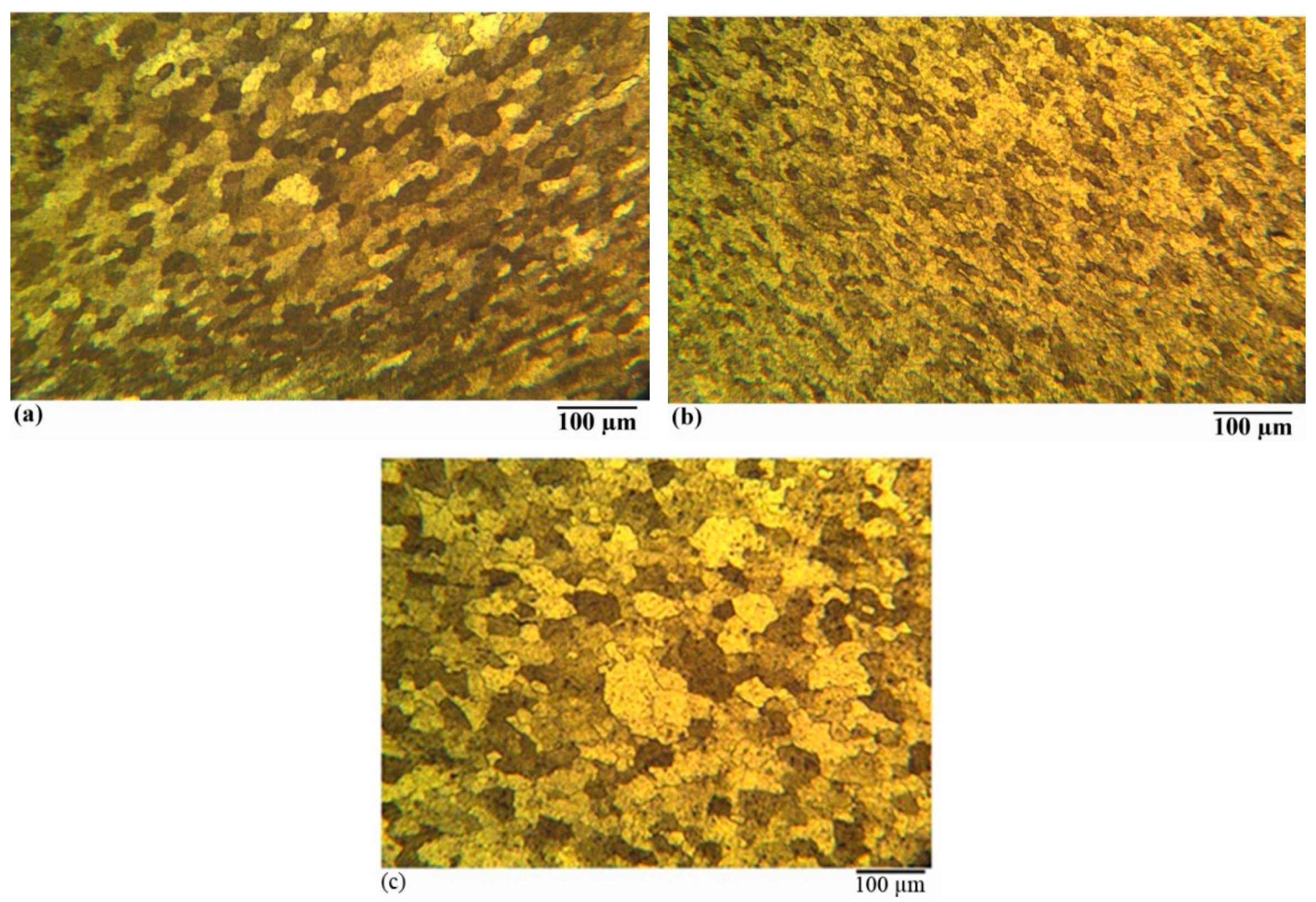

3.1. Microstructure

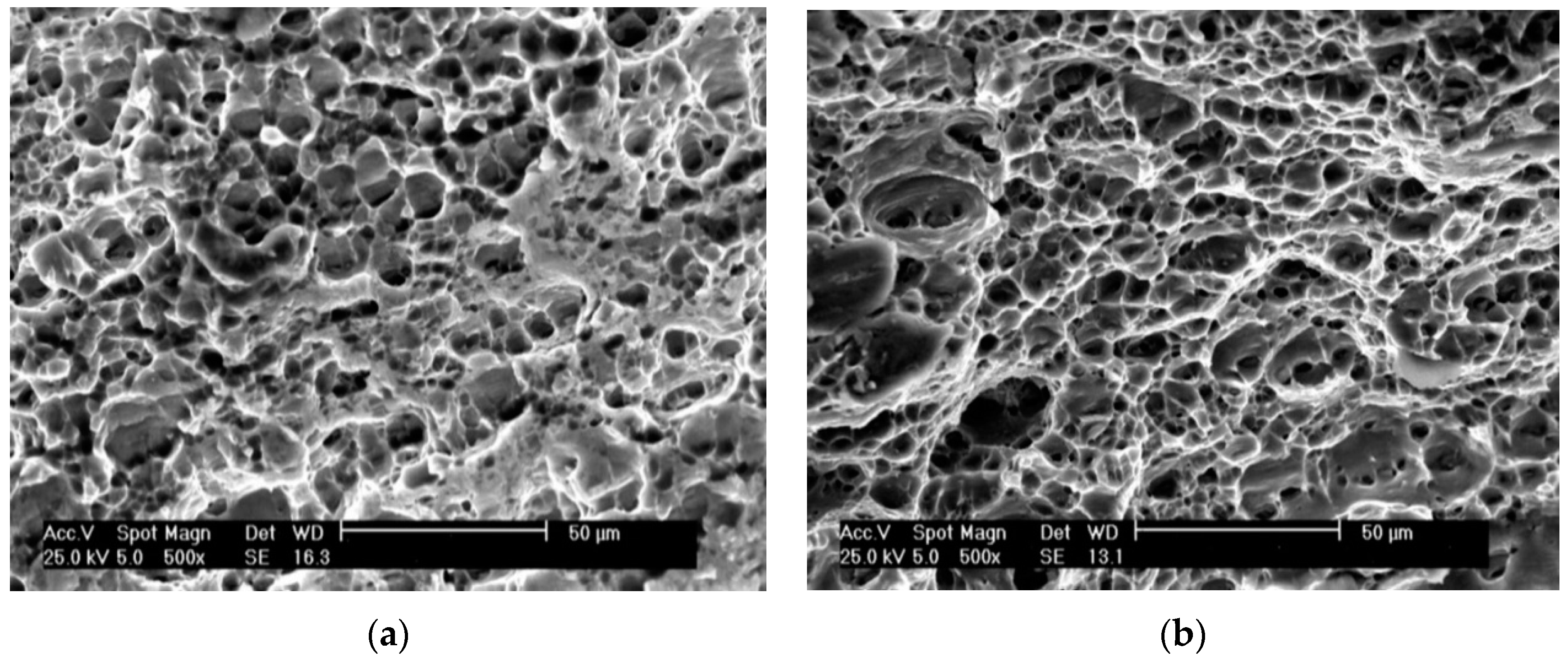

3.2. Mechanical Properties

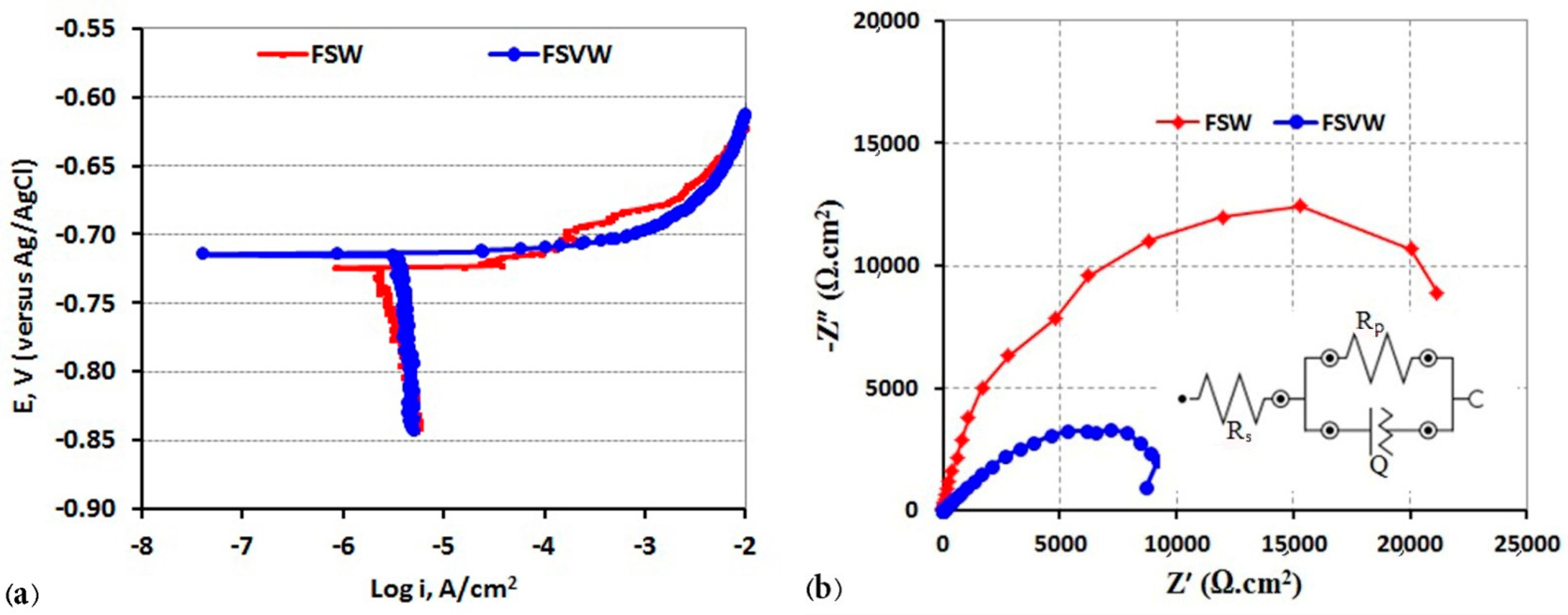

3.3. Corrosion Resistance

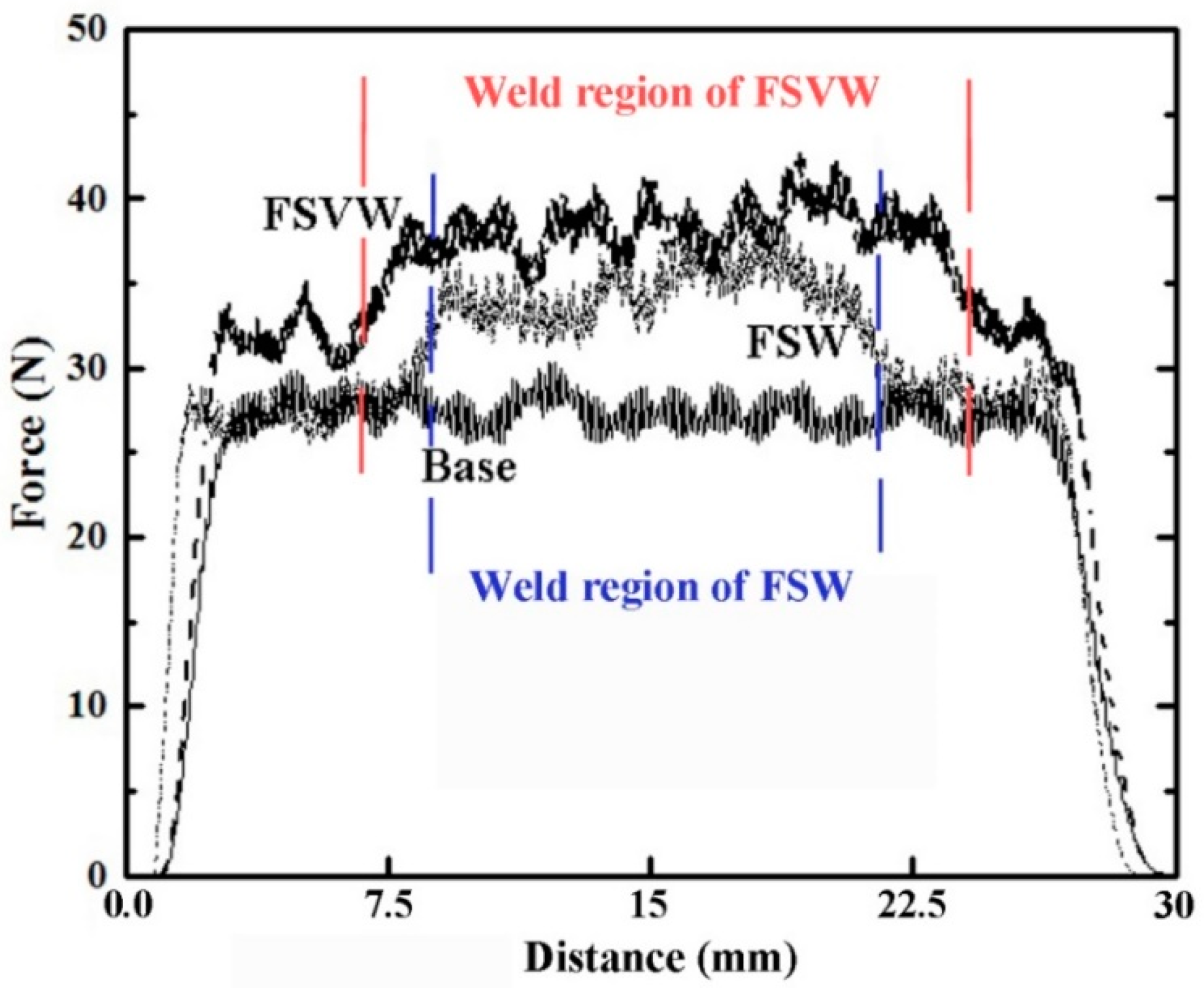

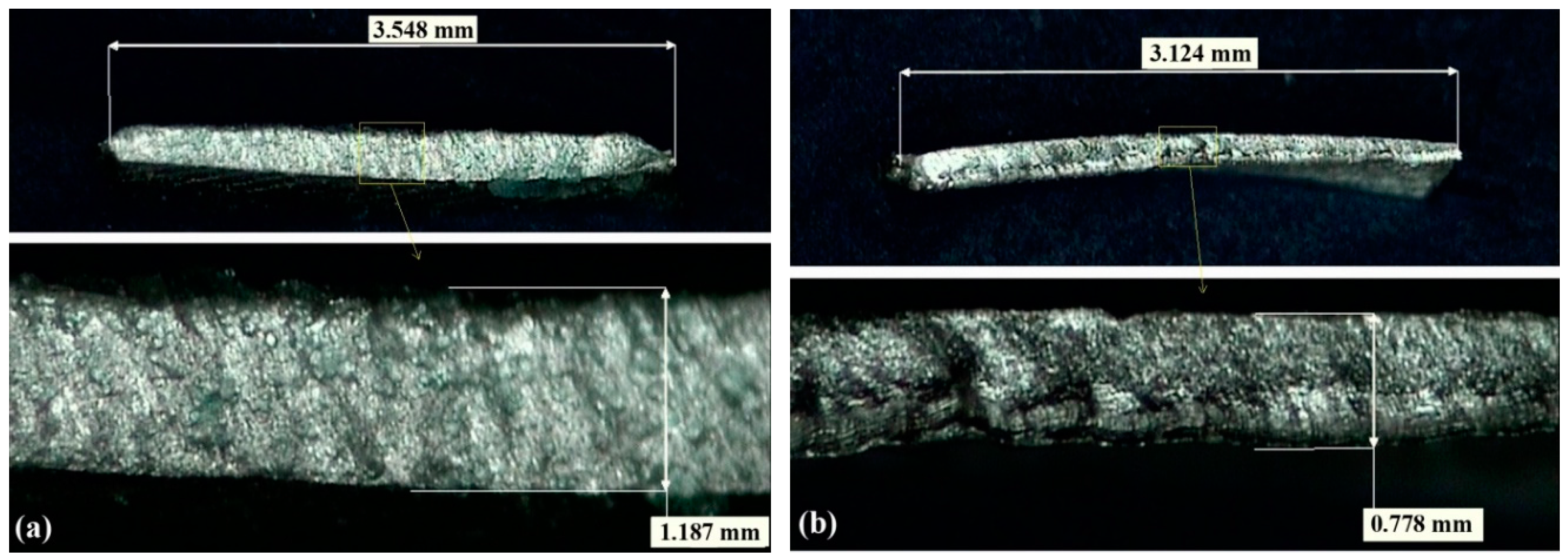

3.4. Machining Characteristics

4. Conclusions

- ➢

- Strength and ductility of FSV-welded specimens are higher than FS welded specimens.

- ➢

- The corrosion resistance of FSV-welded specimens is lower than FS welded specimens.

- ➢

- The machining force for FSV-welded specimens is higher than that for FS welded specimens.

- ➢

- Chip length of FSV-welded specimens is lower than that relating to FS welded specimens and chips are deformed more after removal.

Author Contributions

Conflicts of Interest

References

- Besharati-Givi, M.-K.; Asadi, P. Advances in Friction-Stir Welding and Processing; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Abbasi, M.; Abdollahzadeh, A.; Bagheri, B.; Omidvar, H. The effect of SiC particle addition during FSW on microstructure and mechanical properties of AZ31 magnesium alloy. J. Mater. Eng. Perform. 2015, 24, 5037–5045. [Google Scholar] [CrossRef]

- Çam, G. Friction stir welded structural materials: Beyond Al-alloys. Int. Mater. Rev. 2011, 56, 1–48. [Google Scholar] [CrossRef]

- Keivani, R.; Bagheri, B.; Sharifi, F.; Ketabchi, M.; Abbasi, M. Effects of pin angle and preheating on temperature distribution during friction stir welding operation. Trans. Nonferr. Met. Soc. China 2013, 23, 2708–2713. [Google Scholar] [CrossRef]

- Çam, G.; Mistikoglu, S. Recent developments in friction stir welding of Al-alloys. J. Mater. Eng. Perform. 2014, 23, 1936–1953. [Google Scholar] [CrossRef]

- Abbasi, M.; Bagheri, B.; Keivani, R. Thermal analysis of friction stir welding process and investigation into affective parameters using simulation. J. Mech. Sci. Technol. 2015, 29, 861–866. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z. Friction stir welding and processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Lienert, T.; Mishra, R.; Mahoney, M. Friction Stir Welding and Processing; ASM International: Materials Park, OH, USA, 2007; pp. 123–154. [Google Scholar]

- Watanabe, T.; Takayama, H.; Yanagisawa, A. Joining of aluminum alloy to steel by friction stir welding. J. Mater. Process. Technol. 2006, 178, 342–349. [Google Scholar] [CrossRef]

- Kalaki, A.; Ketabchi, M.; Abbasi, M. Thixo-joining of D2 and M2 tool steels: Analysis of microstructure and mechanical properties. Int. J. Mater. Res. 2014, 105, 764–769. [Google Scholar] [CrossRef]

- Urbikain, G.; Perez, J.M.; López de Lacalle, L.N.; Andueza, A. Combination of friction drilling and form tapping processes on dissimilar materials for making nutless joints. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016. [Google Scholar] [CrossRef]

- Elanchezhian, C.; Ramnath, B.V.; Venkatesan, P.; Sathish, S.; Vignesh, T.; Siddharth, R.; Vinay, B.; Gopinath, K. Parameter optimization of friction stir welding of AA8011-6062 using mathematical method. Procedia Eng. 2014, 97, 775–782. [Google Scholar] [CrossRef]

- Jafari, M.; Abbasi, M.; Poursina, D.; Gheysarian, A.; Bagheri, B. Microstructures and mechanical properties of friction stir welded dissimilar steel-copper joints. J. Mech. Sci. Technol. 2017, 31, 1135–1142. [Google Scholar] [CrossRef]

- Peel, M.; Steuwer, A.; Preuss, M.; Withers, P. Microstructure, mechanical properties and residual stresses as a function of welding speed in aluminium AA5083 friction stir welds. Acta Mater. 2003, 51, 4791–4801. [Google Scholar] [CrossRef]

- Yong-Jai, K.; Seong-Beom, S.; Dong-Hwan, P. Friction stir welding of 5052 aluminum alloy plates. Trans. Nonferr. Met. Soc. China 2009, 19, s23–s27. [Google Scholar]

- Kumar, P.V.; Reddy, G.M.; Rao, K.S. Microstructure and pitting corrosion of armor grade AA7075 aluminum alloy friction stir weld nugget zone—Effect of post weld heat treatment and addition of boron carbide. Def. Technol. 2015, 11, 166–173. [Google Scholar] [CrossRef]

- Maggiolino, S.; Schmid, C. Corrosion resistance in FSW and in MIG welding techniques of AA6XXX. J. Mater. Process. Technol. 2008, 197, 237–240. [Google Scholar] [CrossRef]

- Serio, L.; Palumbo, D.; Galietti, U.; De Filippis, L.; Ludovico, A. Monitoring of the friction stir welding process by means of thermography. Nondestruct. Test. Eval. 2016, 31, 371–383. [Google Scholar] [CrossRef]

- Serio, L.M.; Palumbo, D.; De Filippis, L.A.C.; Galietti, U.; Ludovico, A.D. Effect of friction stir process parameters on the mechanical and thermal behavior of 5754-H111 aluminum plates. Materials 2016, 9, 122. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Lee, C.G.; Kim, S.-J. Fatigue crack propagation behavior of friction stir welded 5083-H32 and 6061-T651 aluminum alloys. Mater. Sci. Eng. A 2008, 478, 56–64. [Google Scholar] [CrossRef]

- D’Urso, G.; Giardini, C.; Lorenzi, S.; Pastore, T. Fatigue crack growth in the welding nugget of FSW joints of a 6060 aluminum alloy. J. Mater. Process. Technol. 2014, 214, 2075–2084. [Google Scholar] [CrossRef]

- Casalino, G.; Campanelli, S.L.; Contuzzi, N.; Angelastro, A.; Ludovico, A.D. Laser-assisted friction stir welding of aluminum alloy lap joints: Microstructural and microhardness characterizations. In Proceedings of the SPIE LASE—International Society for Optics and Photonics, San Francisco, CA, USA, 20 February 2014. [Google Scholar]

- Amini, S.; Amiri, M. Study of ultrasonic vibrations’ effect on friction stir welding. Int. J. Adv. Manuf. Technol. 2014, 73, 127–135. [Google Scholar] [CrossRef]

- Liu, X.; Lan, S.; Ni, J. Electrically assisted friction stir welding for joining Al 6061 to TRIP 780 steel. J. Mater. Process. Technol. 2015, 219, 112–123. [Google Scholar] [CrossRef]

- ASTM E3-11, Standard Guide for Preparation of Metallographic Specimens; ASTM International: West Conshohocken, PA, USA, 2011. [CrossRef]

- Kaibyshev, R.; Shipilova, K.; Musin, F.; Motohashi, Y. Continuous dynamic recrystallization in an Al–Li–Mg–Sc alloy during equal-channel angular extrusion. Mater. Sci. Eng. A 2005, 396, 341–351. [Google Scholar] [CrossRef]

- Rahmi, M.; Abbasi, M. Friction stir vibration welding process: Modified version of friction stir welding process. Int. J. Adv. Manuf. Technol. 2016, 90, 1–11. [Google Scholar] [CrossRef]

- Barooni, O.; Abbasi, M.; Givi, M.; Bagheri, B. New method to improve the microstructure and mechanical properties of joint obtained using FSW. Int. J. Adv. Manuf. Technol. 2017, 1–8. [Google Scholar] [CrossRef]

- Hull, D.; Bacon, D.J. Introduction to Dislocations; Elsevier: Amsterdam, The Netherlands, 2011; Volume 37. [Google Scholar]

- Fouladi, S.; Abbasi, M. The effect of friction stir vibration welding process on characteristics of SiO2 incorporated joint. J. Mater. Process. Technol. 2017, 243, 23–30. [Google Scholar] [CrossRef]

- Krahmer, D.M.; Polvorosa, R.; de Lacalle, L.L.; Alonso-Pinillos, U.; Abate, G.; Riu, F. Alternatives for specimen manufacturing in tensile testing of steel plates. Exp. Tech. 2016, 40, 1555–1565. [Google Scholar] [CrossRef]

- Dieter, G. Mechanical Metallurgy, 1988, SI Metric Edition; McGraw-Hill: New York, NY, USA, 2005; ISBN 0-07-100406-8. [Google Scholar]

- Callister, W.D.; Rethwisch, D.G. Materials Science and Engineering; John Wiley & Sons: New York, NY, USA, 2011. [Google Scholar]

- Naderi, M.; Abbasi, M.; Saeed-Akbari, A. Enhanced mechanical properties of a hot-stamped advanced high-strength steel via tempering treatment. Metall. Mater. Trans. A 2013, 44, 1852–1861. [Google Scholar] [CrossRef]

- Ma, Z.; Pilchak, A.; Juhas, M.; Williams, J. Microstructural refinement and property enhancement of cast light alloys via friction stir processing. Scr. Mater. 2008, 58, 361–366. [Google Scholar] [CrossRef]

- Schempp, P.; Cross, C.; Häcker, R.; Pittner, A.; Rethmeier, M. Influence of grain size on mechanical properties of aluminium GTA weld metal. Weld. World 2013, 57, 293–304. [Google Scholar] [CrossRef]

- Hansen, N. The effect of grain size and strain on the tensile flow stress of aluminium at room temperature. Acta Metall. 1977, 25, 863–869. [Google Scholar] [CrossRef]

- Spittle, J.; Cushway, A. Influences of superheat and grain structure on hot-tearing susceptibilities of AI–Cu alloy castings. Met. Technol. 1983, 10, 6–13. [Google Scholar] [CrossRef]

- Estrin, Y.Z.; Zabrodin, P.; Braude, I.; Grigorova, T.; Isaev, N.; Pustovalov, V.; Fomenko, V.; Shumilin, S. Low-temperature plastic deformation of AZ31 magnesium alloy with different microstructures. Low Temp. Phys. 2010, 36, 1100–1106. [Google Scholar] [CrossRef]

- Ramazani, A.; Abbasi, M.; Prahl, U.; Bleck, W. Failure analysis of DP600 steel during the cross-die test. Comput. Mater. Sci. 2012, 64, 101–105. [Google Scholar] [CrossRef]

- Münstermann, S.; Uthaisangsuk, V.; Prahl, U.; Bleck, W. Experimental and numerical failure criteria for sheet metal forming. Steel Res. Int. 2007, 78, 762–770. [Google Scholar] [CrossRef]

- Davis, J.R. Corrosion of Weldments; ASM International: Geauga County, OH, USA, 2006. [Google Scholar]

- Gharavi, F.; Matori, K.A.; Yunus, R.; Othman, N.K.; Fadaeifard, F. Corrosion behavior of Al6061 alloy weldment produced by friction stir welding process. J. Mater. Res. Technol. 2015, 4, 314–322. [Google Scholar] [CrossRef]

- Masuoka, T.; Mayuzumi, M.; Tani, J.-I.; Arai, T. Effect of work hardening on stress corrosion cracking propagation in SUS316L stainless steel. Zair. Kankyo 2007, 56, 93–98. [Google Scholar] [CrossRef]

- Zhao, Z.L.; Ai, C.H.; Liu, L. The effect of grain size on cutting force in end milling of inconel 718C. In Materials Science Forum; Trans Tech Publications: Zürich, Switzerland, 2010; pp. 484–487. [Google Scholar]

- Komatsu, T.; Yoshino, T.; Matsumura, T.; Torizuka, S. Effect of crystal grain size in stainless steel on cutting process in micromilling. Procedia CIRP 2012, 1, 150–155. [Google Scholar] [CrossRef]

- Del Valle, J.; Carreño, F.; Ruano, O.A. Influence of texture and grain size on work hardening and ductility in magnesium-based alloys processed by ECAP and rolling. Acta Mater. 2006, 54, 4247–4259. [Google Scholar] [CrossRef]

| Experiment | Vibration | Rotation Speed (rpm) | Transverse Speed (mm/min) |

|---|---|---|---|

| FSW | − | 1200 | 30 |

| FSVW | + | 1200 | 30 |

| Items | Specifications |

|---|---|

| Tool material | HSS |

| Number of Flutes | 4 |

| Helical angle (°) | 35 |

| Diameter (mm) | 10 |

| Rake angle (°) | 7 |

| Gash angle (°) | 40 |

| Dish angle (°) | 4 |

| Radial primary clearance angle (°) | 8 |

| Radial secondary clearance angle (°) | 15 |

| Items | Specifications |

|---|---|

| Spindle speed (rpm) | 360 |

| Feed per tooth (mm/edge) | 0.033 |

| Feed rate (mm/min) | 45 |

| Depth of cut (mm) | 1 |

| Tool and work engagement (mm) | 3 |

| Cutting length (mm) | 30 ± 2 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fouladi, S.; Ghasemi, A.H.; Abbasi, M.; Abedini, M.; Khorasani, A.M.; Gibson, I. The Effect of Vibration during Friction Stir Welding on Corrosion Behavior, Mechanical Properties, and Machining Characteristics of Stir Zone. Metals 2017, 7, 421. https://doi.org/10.3390/met7100421

Fouladi S, Ghasemi AH, Abbasi M, Abedini M, Khorasani AM, Gibson I. The Effect of Vibration during Friction Stir Welding on Corrosion Behavior, Mechanical Properties, and Machining Characteristics of Stir Zone. Metals. 2017; 7(10):421. https://doi.org/10.3390/met7100421

Chicago/Turabian StyleFouladi, Sajad, Amir H. Ghasemi, Mahmoud Abbasi, Morteza Abedini, Amir Mahyar Khorasani, and Ian Gibson. 2017. "The Effect of Vibration during Friction Stir Welding on Corrosion Behavior, Mechanical Properties, and Machining Characteristics of Stir Zone" Metals 7, no. 10: 421. https://doi.org/10.3390/met7100421