Size Effect and Deformation Mechanism in Twinned Copper Nanowires

Abstract

:1. Introduction

2. Simulation Methodology

3. Results and Discussion

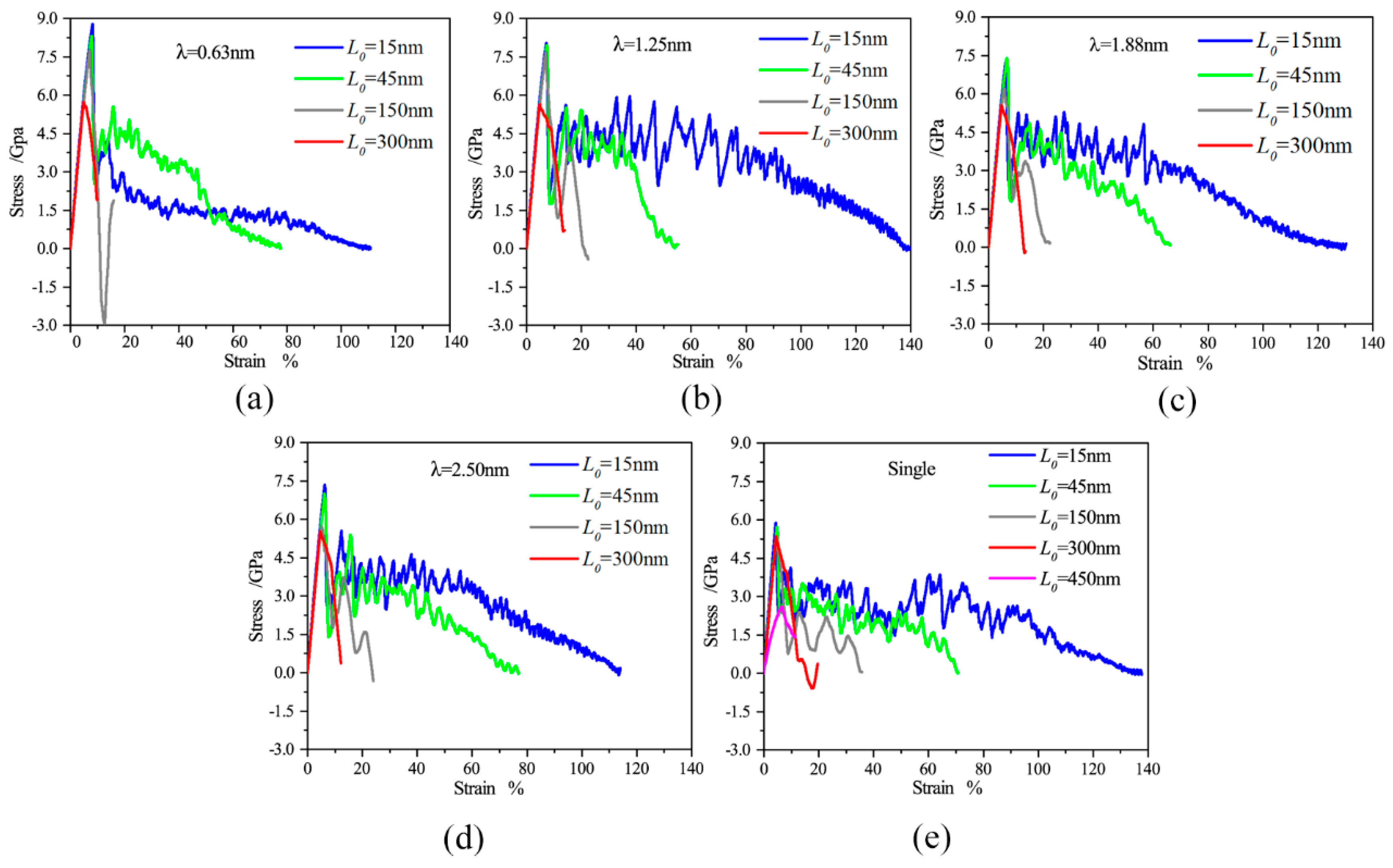

3.1. Length Dependent Stress–Strain Behavior

3.2. Twin Boundary Spacing Dependent Stress–Strain Behavior

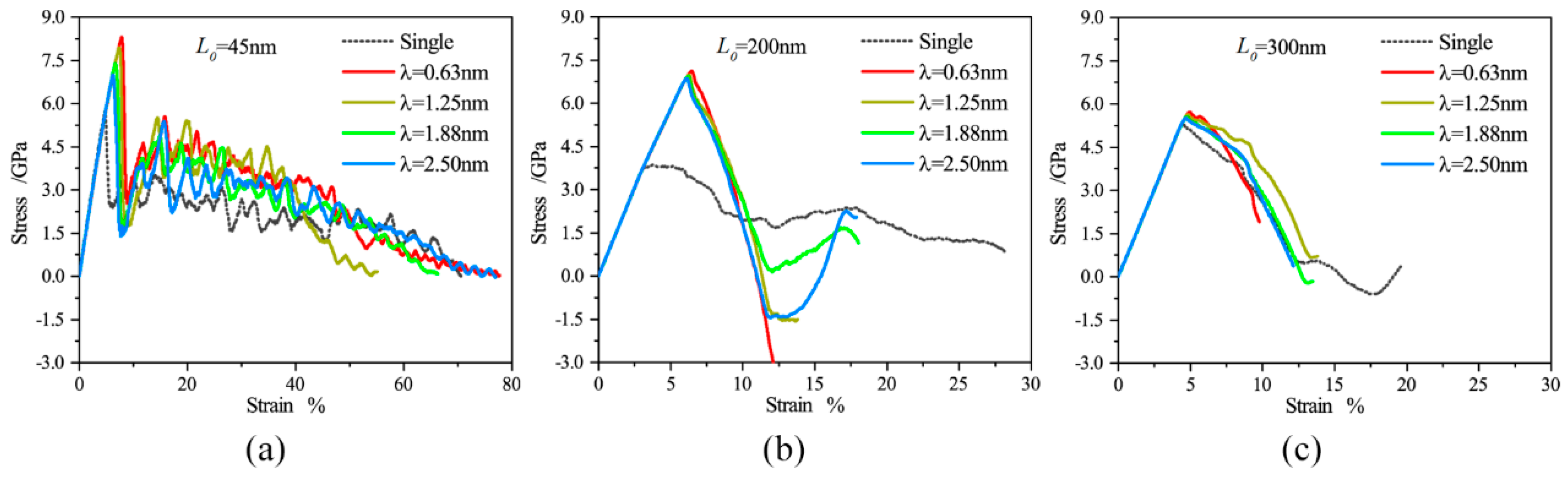

3.3. Intrinsic and Extrinsic Size Effect

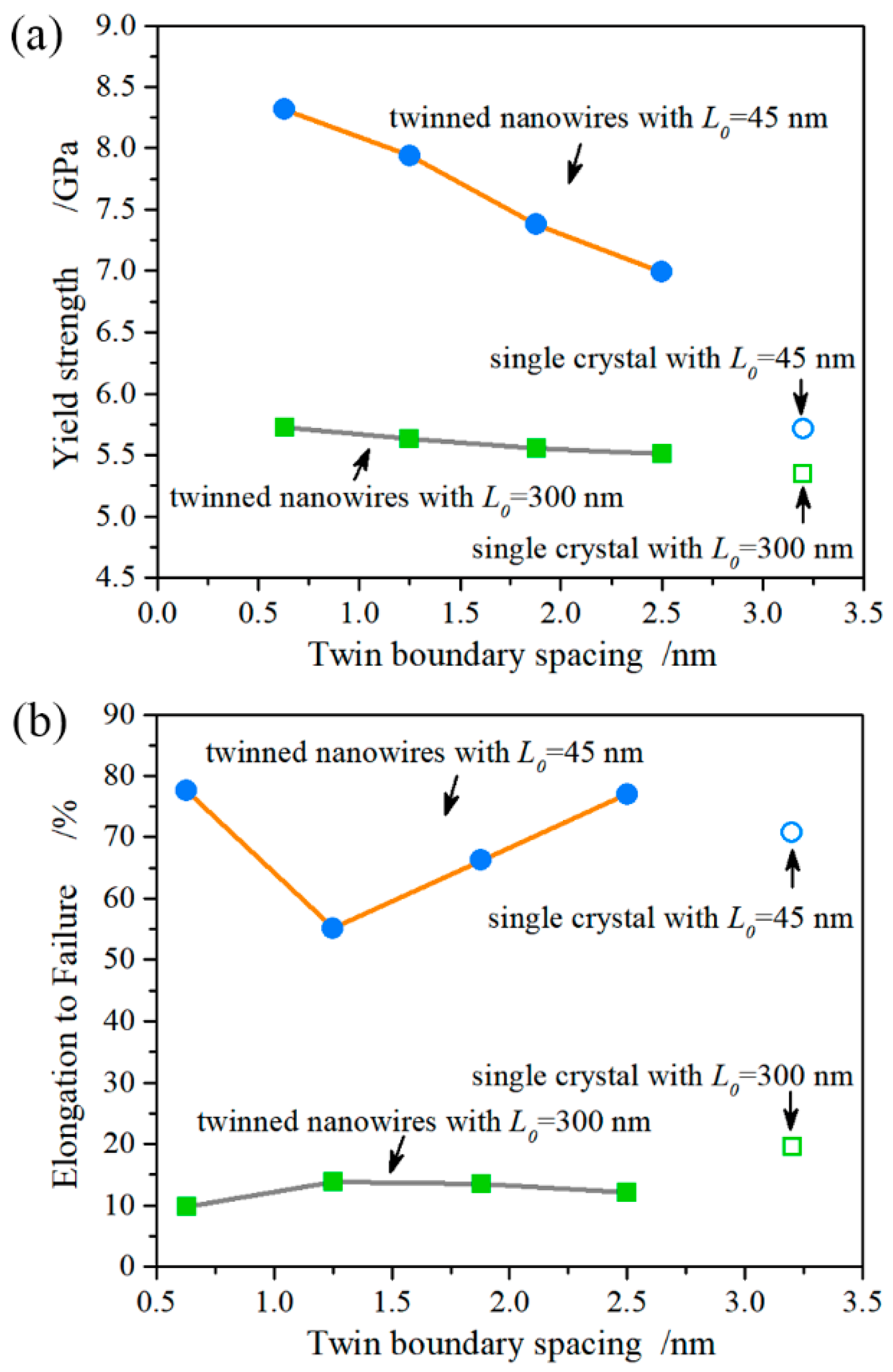

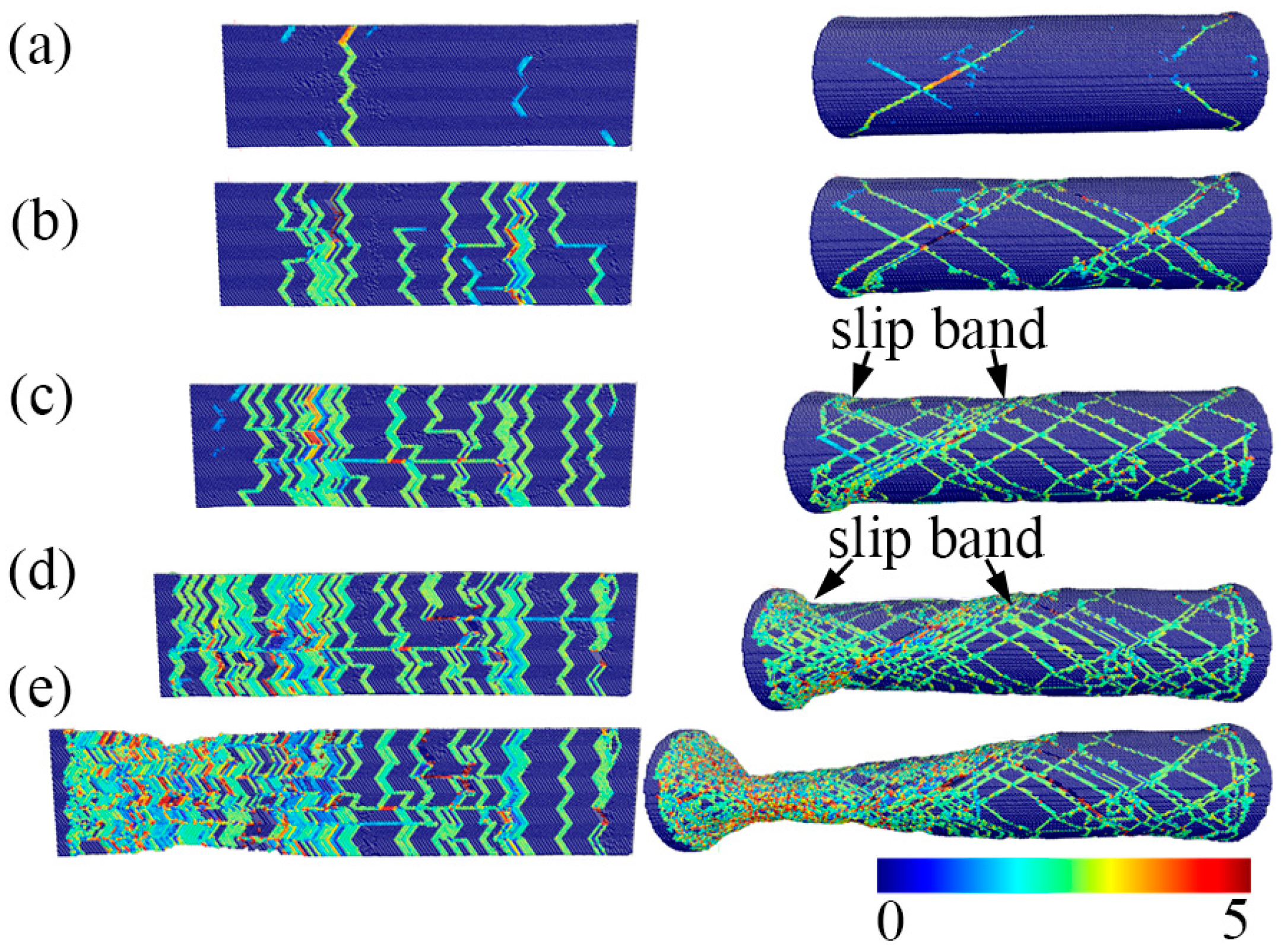

3.4. Atomic-Level Observations of Yield and Deformation Mechanism

3.5. Mechanism of Intrinsic and Extrinsic Size Effects

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhu, Y.T.; Liao, X.Z.; Wu, X.L. Deformation twinning in nanocrystalline materials. Prog. Mater. Sci. 2012, 57, 1–62. [Google Scholar] [CrossRef]

- Li, X.Y.; Wei, Y.J.; Lu, L.; Lu, K.; Gao, H.J. Dislocation nucleation governed softening and maximum strength in nano-twinned metals. Nature 2010, 464, 877–880. [Google Scholar] [CrossRef] [PubMed]

- Lu, L.; Chen, X.; Huang, X.; Lu, K. Revealing the maximum strength in nanotwinned copper. Science 2009, 323, 607–610. [Google Scholar] [CrossRef] [PubMed]

- Lu, K.; Lu, L.; Suresh, S. Strengthening materials by engineering coherent internal boundaries at the nanoscale. Science 2009, 324, 349–352. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.H.; Lu, L. Work hardening of ultrafine-grained copper with nanoscale twins. Scr. Mater. 2007, 57, 133–136. [Google Scholar] [CrossRef]

- Lu, L.; You, Z.S.; Lu, K. Work hardening of polycrystalline Cu with nanoscale twins. Scr. Mater. 2012, 66, 837–842. [Google Scholar] [CrossRef]

- Shen, Y.F.; Lu, L.; Lu, Q.H.; Jin, Z.H.; Lu, K. Tensile properties of copper with nano-scale twins. Scr. Mater. 2005, 52, 989–994. [Google Scholar] [CrossRef]

- Hodge, A.M.; Wang, Y.M.; Barbee, T.W., Jr. Mechanical deformation of high-purity sputter-deposited nano-twinned copper. Scr. Mater. 2008, 59, 163–166. [Google Scholar] [CrossRef]

- Li, N.; Wang, J.; Mao, S.; Wang, H. In situ nanomechanical testing of twinned metals in a transmission electron microscope. MRS Bull. 2016, 41, 305–313. [Google Scholar] [CrossRef]

- Zhu, L.L.; Ruan, H.H.; Li, X.Y.; Dao, M.; Gao, H.J.; Lu, J. Modeling grain size dependent optimal twin spacing for achieving ultimate high strength and related high ductility in nanotwinned metals. Acta Mater. 2011, 59, 5544–5557. [Google Scholar] [CrossRef]

- Sun, J.; Fang, L.; Sun, K.; Han, J. Direct observation of dislocations originating from perfect twin boundaries. Scr. Mater. 2011, 65, 501–504. [Google Scholar] [CrossRef]

- Sun, J.; Fang, L.; Ma, A.; Jiang, J.; Han, Y.; Chen, H. The fracture behavior of twinned Cu nanowires: A molecular dynamics simulation. Mater. Sci. Eng. A 2015, 634, 86–90. [Google Scholar] [CrossRef]

- Zhu, T.; Gao, H. Plastic deformation mechanism in nano-twinned metals: Insight from molecular dynamics and mechanistic modeling. Scr. Mater. 2012, 66, 843–848. [Google Scholar] [CrossRef]

- Jang, D.C.; Li, X.Y.; Gao, H.J.; Greer, J.R. Deformation mechanisms in nanotwinned metal nanopillars. Nat. Nanotechnol. 2012, 7, 594–601. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Sansoz, F.; Huang, J.; Liu, Y.; Sun, S.; Zhang, Z. Near-ideal theoretical strength in gold nanowires containing angstrom scale twins. Nat. Commun. 2013, 4, 1742. [Google Scholar] [CrossRef] [PubMed]

- Narayanan, S.; Cheng, G.; Zeng, Z.; Zhu, Y.; Zhu, T. Strain hardening and size effect in five-fold twinned ag nanowires. Nano Lett. 2015, 15, 4037–4044. [Google Scholar] [CrossRef] [PubMed]

- Deng, C.; Sansoz, F. Fundamental differences in the plasticity of periodically twinned nanowires in Au, Ag, Al, Cu, Pb and Ni. Acta Mater. 2009, 57, 6090–6101. [Google Scholar] [CrossRef]

- Deng, C.; Sansoz, F. Enabling ultrahigh plastic flow and work hardening in twinned gold nanowires. Nano Lett. 2009, 9, 1517–1522. [Google Scholar] [CrossRef] [PubMed]

- Zhu, T.; Li, J.; Ogata, S.; Yip, S. Mechanics of ultra-strength materials. MRS Bull. 2009, 34, 167–172. [Google Scholar] [CrossRef]

- Zhu, T.; Li, J. Ultra-strength materials. Prog. Mater. Sci. 2010, 55, 710–757. [Google Scholar] [CrossRef]

- Greer, J.R.; De Hosson, J.T.M. Plasticity in small-sized metallic systems: Intrinsic versus extrinsic size effect. Prog. Mater. Sci. 2011, 56, 654–724. [Google Scholar] [CrossRef]

- Deng, C.; Sansoz, F. Repulsive force of twin boundary on curved dislocations and its role on the yielding of twinned nanowires. Scr. Mater. 2010, 63, 50–53. [Google Scholar] [CrossRef]

- Deng, C.; Sansoz, F. Size-dependent yield stress in twinned gold nanowires mediated by site-specific surface dislocation emission. Appl. Phys. Lett. 2009, 95, 79. [Google Scholar] [CrossRef]

- Chen, Z.M.; Jin, Z.H.; Gao, H.J. Repulsive force between screw dislocation and coherent twin boundary in aluminum and copper. Phys. Rev. B 2007, 75, 2288. [Google Scholar] [CrossRef]

- Guo, X.; Xia, Y.Z. Repulsive force vs. Source number: Competing mechanisms in the yield of twinned gold nanowires of finite length. Acta Mater. 2011, 59, 2350–2357. [Google Scholar] [CrossRef]

- Song, H.Y.; Sun, Y. Effect of coherent twin boundary and stacking fault on deformation behaviors of copper nanowires. Comput. Mater. Sci. 2015, 104, 46–51. [Google Scholar] [CrossRef]

- Wang, J.; Sansoz, F.; Deng, C.; Xu, G.; Han, G.; Mao, S.X. Strong hall–petch type behavior in the elastic strain limit of nanotwinned gold nanowires. Nano Lett. 2015, 15, 3865–3870. [Google Scholar] [CrossRef] [PubMed]

- Lu, Q.; You, Z.; Huang, X.; Hansen, N.; Lu, L. Dependence of dislocation structure on orientation and slip systems in highly oriented nanotwinned Cu. Acta Mater. 2017, 127, 85–97. [Google Scholar] [CrossRef]

- Zhao, X.; Lu, C.; Tieu, A.K.; Pei, L.; Zhang, L.; Su, L. Deformation mechanisms in nanotwinned copper by molecular dynamics simulation. Mater. Sci. Eng. A 2017, 687, 343–351. [Google Scholar] [CrossRef]

- Deng, C.; Sansoz, F. Effects of twin and surface facet on strain-rate sensitivity of gold nanowires at different temperatures. Phys. Rev. B 2010, 81, 155430. [Google Scholar] [CrossRef]

- Mishin, Y.; Mehl, M.J.; Papaconstantopoulos, D.A.; Voter, A.F.; Kress, J.D. Structural stability and lattice defects in copper: Ab initio, tight-binding, and embedded-atom calculations. Phys. Rev. B 2001, 63, 224106. [Google Scholar] [CrossRef]

- Hoover, W.G. Constant-pressure equations of motion. Phys. Rev. A 1986, 34, 2499–2500. [Google Scholar] [CrossRef]

- Nose, S. A unified formulation of the constant temperature molecular-dynamics methods. J. Chem. Phys. 1984, 81, 511–519. [Google Scholar] [CrossRef]

- Tsuzuki, H.; Branicio, P.S.; Rino, J.P. Structural characterization of deformed crystals by analysis of common atomic neighborhood. Comput. Phys. Commun. 2007, 177, 518–523. [Google Scholar] [CrossRef]

- Zimmerman, J.A.; Kelchner, C.L.; Klein, P.A.; Hamilton, J.C.; Foiles, S.M. Surface step effects on nanoindentation. Phys. Rev. Lett. 2001, 87, 165507. [Google Scholar] [CrossRef] [PubMed]

- Plimpton, S. Fast parallel algorithms for short-range molecular-dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Wu, Z.X.; Zhang, Y.W.; Jhon, M.H.; Gao, H.J.; Srolovitz, D.J. Nanowire failure: Long = brittle and short = ductile. Nano Lett. 2012, 12, 910–914. [Google Scholar] [CrossRef] [PubMed]

- Han, J.; Fang, L.; Sun, J.P.; Han, Y.; Sun, K. Length-dependent mechanical properties of gold nanowires. J. Appl. Phys. 2012, 112, 114314. [Google Scholar] [CrossRef] [PubMed]

- Jang, D.; Cai, C.; Greer, J.R. Influence of homogeneous interfaces on the strength of 500 nm diameter Cu nanopillars. Nano Lett. 2011, 11, 1743–1746. [Google Scholar] [CrossRef] [PubMed]

- Afanasyev, K.A.; Sansoz, F. Strengthening in gold nanopillars with nanoscale twins. Nano Lett. 2007, 7, 2056–2062. [Google Scholar] [CrossRef]

- Deng, C.; Sansoz, F. Near-Ideal strength in gold nanowires achieved through microstructural design. ACS Nano 2009, 3, 3001–3008. [Google Scholar] [CrossRef] [PubMed]

- Cao, A.J.; Wei, Y.G.; Mao, S.X. Deformation mechanisms of face-centered-cubic metal nanowires with twin boundaries. Appl. Phys. Lett. 2007, 90, 151909. [Google Scholar] [CrossRef]

- Wu, Z.X.; Zhang, Y.W.; Jhon, M.H.; Greer, J.R.; Srolovitz, D.J. Nanostructure and surface effects on yield in Cu nanowires. Acta Mater. 2013, 61, 1831–1842. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, J.; Li, C.; Han, J.; Shao, X.; Yang, X.; Liu, H.; Song, D.; Ma, A. Size Effect and Deformation Mechanism in Twinned Copper Nanowires. Metals 2017, 7, 438. https://doi.org/10.3390/met7100438

Sun J, Li C, Han J, Shao X, Yang X, Liu H, Song D, Ma A. Size Effect and Deformation Mechanism in Twinned Copper Nanowires. Metals. 2017; 7(10):438. https://doi.org/10.3390/met7100438

Chicago/Turabian StyleSun, Jiapeng, Cheng Li, Jing Han, Xiaoyan Shao, Xiaowei Yang, Huan Liu, Dan Song, and Aibin Ma. 2017. "Size Effect and Deformation Mechanism in Twinned Copper Nanowires" Metals 7, no. 10: 438. https://doi.org/10.3390/met7100438