3D Modelling of Flash Formation in Linear Friction Welded 30CrNiMo8 Steel Chain

Abstract

:1. Introduction

2. Methodology

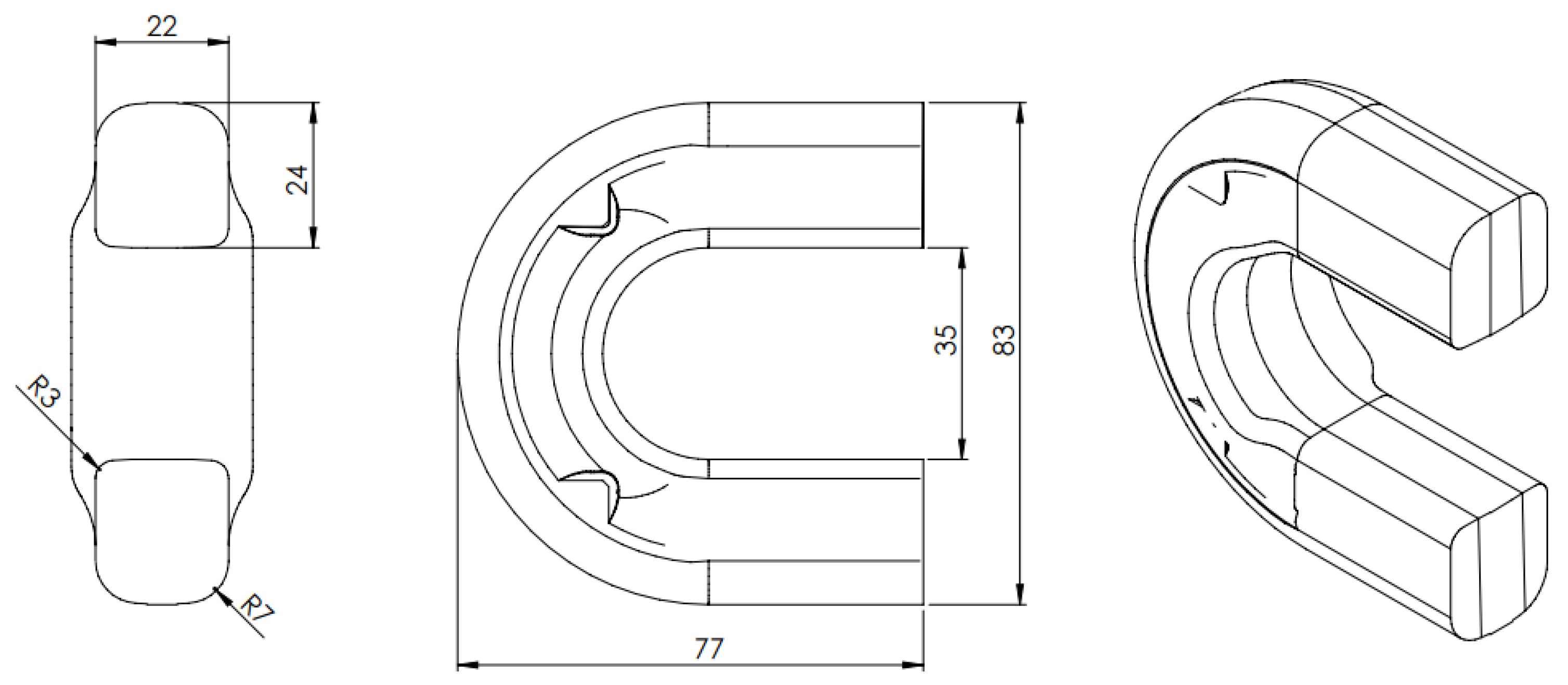

2.1. Experimental Procedure

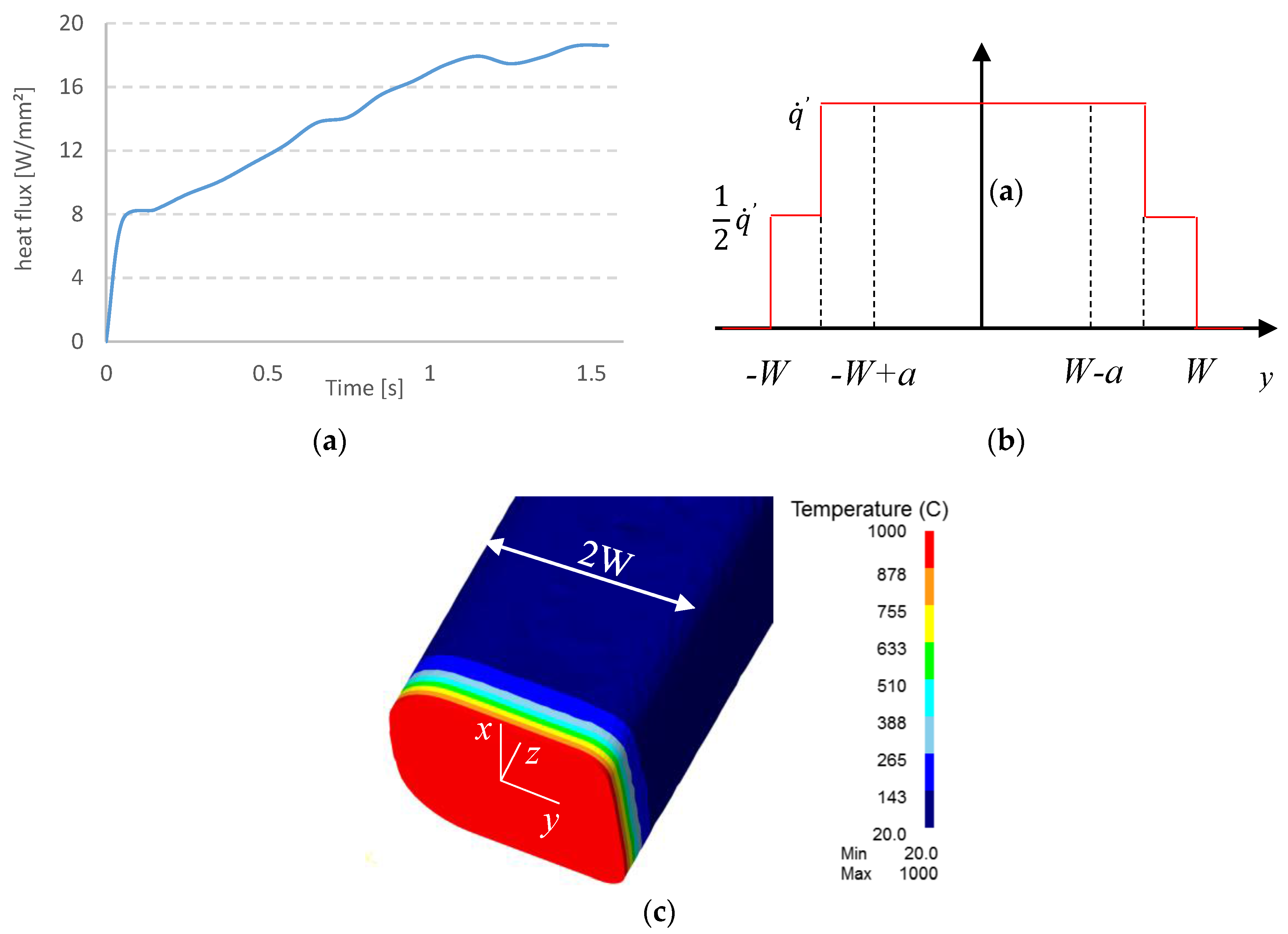

2.2. Energy Input

2.3. Numerical Simulation

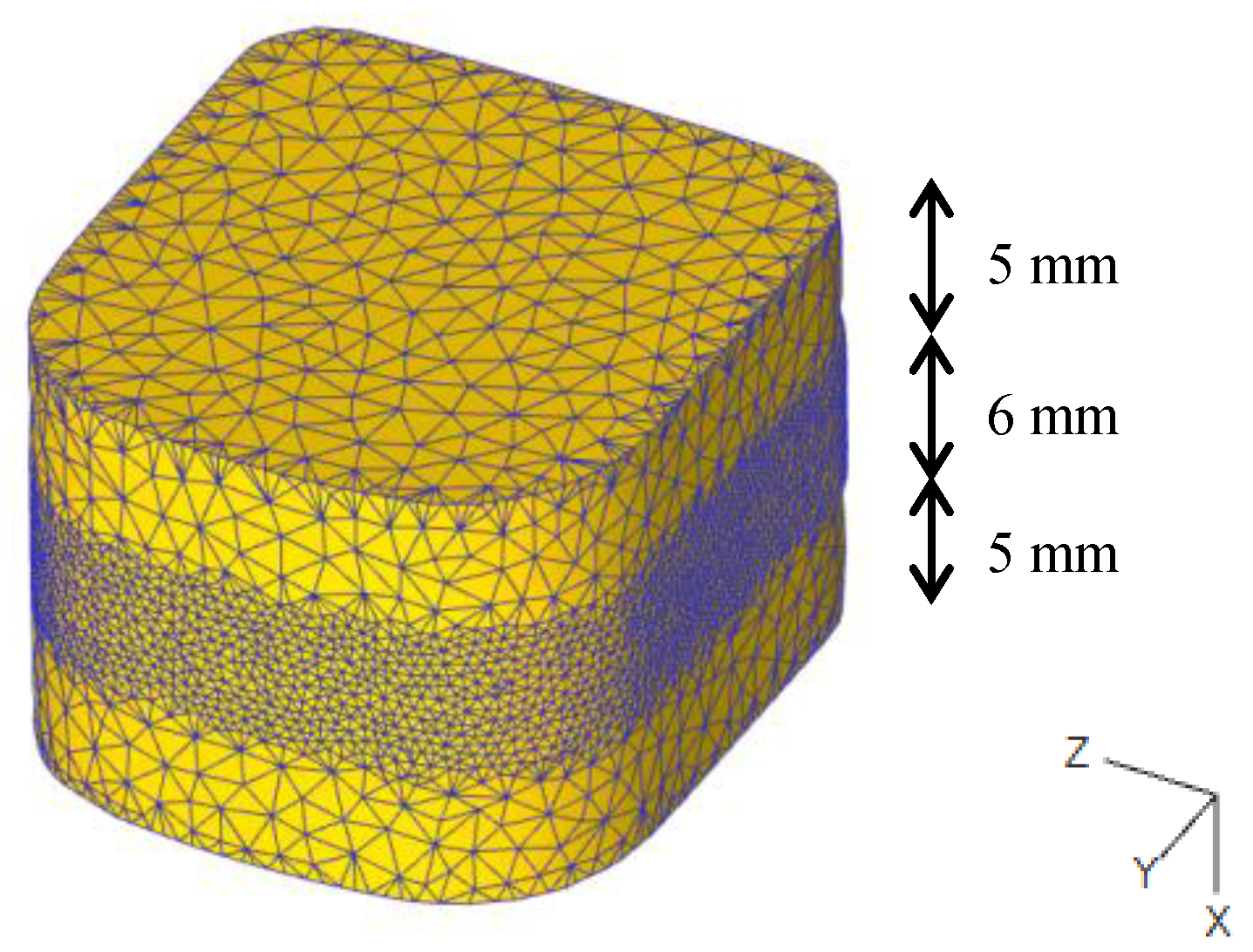

2.3.1. Mesh Characteristics

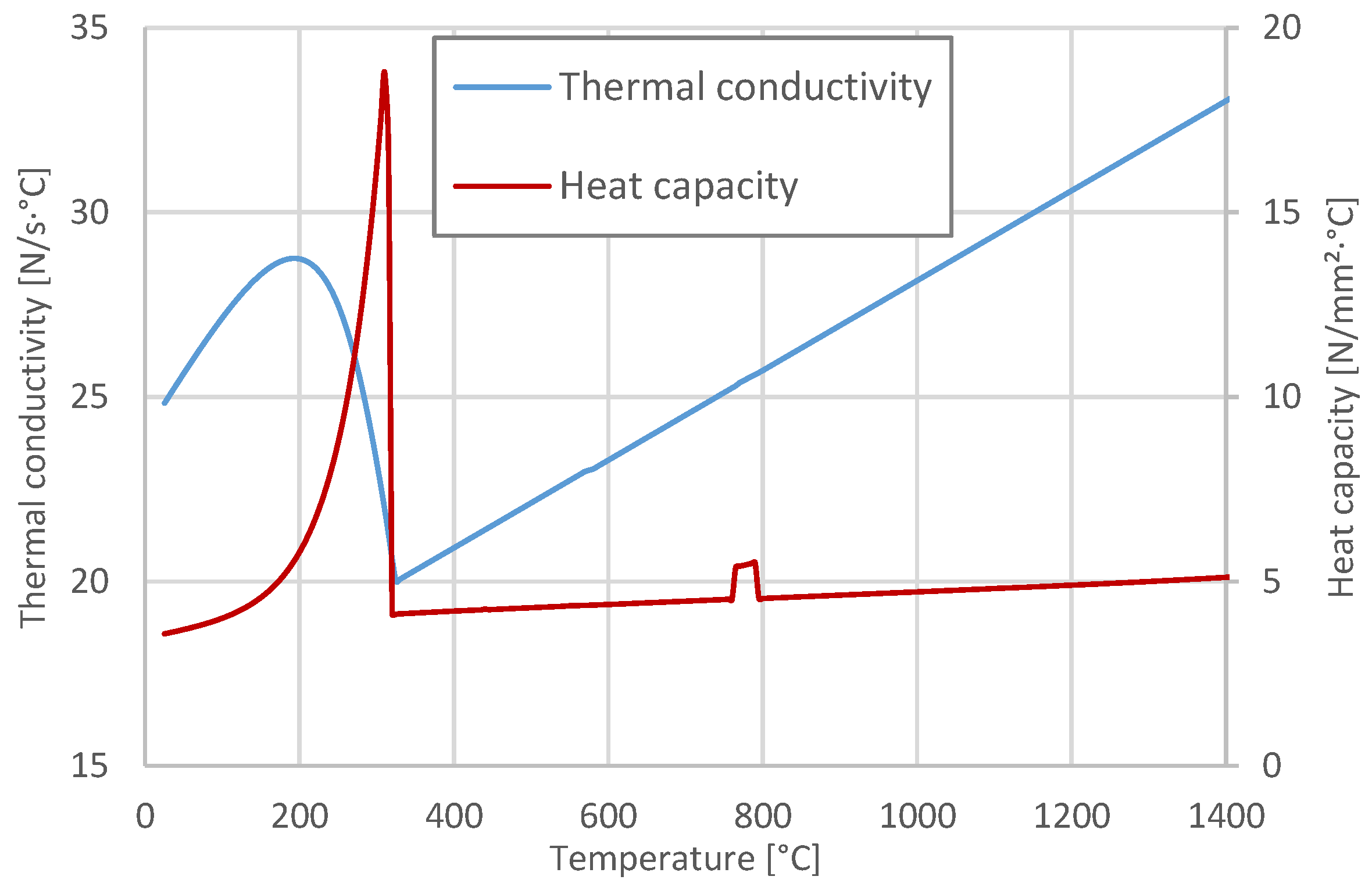

2.3.2. Material Model

2.3.3. Thermal Model

2.3.4. Thermo-Mechanical Model

3. Results and Discussion

3.1. Temperature Evolution

3.2. Flash Formation

Partial Unbonding

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Song, X.; Xie, M.; Hofmann, F.; Jun, T.S.; Connolley, T.; Reinhard, C.; Atwood, R.C.; Connor, L.; Drakopoulos, M.; Harding, S.; et al. Residual stresses in Linear Friction Welding of aluminium alloys. Mater. Des. 2013, 50, 360–369. [Google Scholar] [CrossRef]

- Bhamji, I.; Preuss, M.; Threadgill, P.L.L.; Addison, A.C.C. Solid state joining of metals by linear friction welding: a literature review. Mater. Sci. Technol. 2011, 27, 2–12. [Google Scholar] [CrossRef]

- Buffa, G.; Cammalleri, M.; Campanella, D.; Fratini, L. Shear coefficient determination in linear friction welding of aluminum alloys. Mater. Des. 2015, 82, 238–246. [Google Scholar] [CrossRef]

- Shtrikman, M.M. Linear friction welding. Weld. Int. 2010, 24, 563–569. [Google Scholar] [CrossRef]

- Nicholas, E.D. Friction Processing Technologies. Weld. World. 2003, 47, 2–9. [Google Scholar] [CrossRef]

- Bhamji, I.; Addison, A.C.; Threadgill, P.L.; Preuss, M. Welding in Aerospace Engineering; Woodhead Publishing Limited: Cambridge, UK, 2012. [Google Scholar]

- Mucic, K.; Fuchs, F.; Enzinger, N. Process optimization for linear friction welding of high strength chain. In Proceedings of the EUROJOIN Conference, Pula, Croatia, 24–26 May 2012. [Google Scholar]

- Çetinkaya, C.; Arabaci, U. Flash butt welding application on 16MnCr5 chain steel and investigations of mechanical properties. Mater. Des. 2006, 27, 1187–1195. [Google Scholar] [CrossRef]

- Mucic, K.; Enzinger, N.; Fuchs, F. Linear Friction Welding of High Strength Chains. In Proceedings of the 9th International Conference, Chicago, IL, USA, 4–8 June 2012. [Google Scholar]

- McAndrew, A.R.; Colegrove, P.A.; Addison, A.C.; Flipo, B.C.D.; Russell, M.J. Modelling the influence of the process inputs on the removal of surface contaminants from Ti-6Al-4V linear friction welds. Mater. Des. 2015, 66, 183–195. [Google Scholar] [CrossRef] [Green Version]

- McAndrew, A.R.; Colegrove, P.A.; Addison, A.C.; Flipo, B.C.D.; Russell, M.J. Energy and Force Analysis of Ti-6Al-4V Linear Friction Welds for Computational Modeling Input and Validation Data. Metall. Mater. Trans. A. 2014, 13, 6118–6128. [Google Scholar] [CrossRef] [Green Version]

- Turner, R.; Gebelin, J.C.; Ward, R.M.; Reed, R.C. Linear friction welding of Ti-6Al-4V: Modelling and validation. Acta Mater. 2011, 59, 3792–3803. [Google Scholar] [CrossRef]

- Fratini, L.; Buffa, G.; Campanella, D.; Spisa, D.L. Investigations on the linear friction welding process through numerical simulations and experiments. Mater. Des. 2012, 40, 285–291. [Google Scholar] [CrossRef]

- Li, W.; Wang, F.; Shi, S.; Ma, T.; Li, J.; Vairis, A. 3D Finite Element Analysis of the Effect of Process Parameters on Linear Friction Welding of Mild Steel. J. Mater. Eng. Perform. 2014, 23, 4010–4018. [Google Scholar] [CrossRef]

- Buffa, G.; Campanella, D.; Pellegrino, S.; Fratini, L. Weld quality prediction in linear friction welding of AA6082-T6 through an integrated numerical tool. J. Mater. Process. Technol. 2016, 231, 389–396. [Google Scholar] [CrossRef]

- Bühr, C.; Colegrove, P.A.; McAndrew, A.R. An Efficient Numerical Modelling Approach to Predict Residual Stresses in Ti-6Al-4V Linear Friction Welds. In Proceedings of the 10th International Conference on Trend in Welding Research & 10th International Welding Symposium of Japan Welding Society (9WS), Tokyo, Japan, 11–14 October 2016. [Google Scholar]

- McAndrew, A.R.; Colegrove, P.A.; Flipo, B.C.D.; Bühr, C. 3D modelling of Ti–6Al–4V linear friction welds. Sci. Technol. Weld. Join. 2017, 22, 496–504. [Google Scholar] [CrossRef]

- Ofem, U.U.; Colegrove, P.A.; Addison, A.; Russell, M.J. Energy and force analysis of linear friction welds in medium carbon steel. Sci. Technol. Weld. Join. 2010, 15, 479–485. [Google Scholar] [CrossRef] [Green Version]

- Kreyszig, E. Advanced Engineering Mathematics: Maple Computer Guide; Wiley, John & Sons, Incorporated: New York, NY, USA, 2000. [Google Scholar]

- Effertz, P.S.; Fuchs, F.; Enzinger, N. Modelling the flash formation of linear friction welded 30CrNiMo8 high strength steel chains. Int. J. Adv. Manuf. Technol. 2017, 92, 2479–2486. [Google Scholar] [CrossRef]

- Gao, Z.; Niu, J.T.; Krumphals, F.; Enzinger, N.; Mitsche, S.; Sommitsch, C. FE modelling of microstructure evolution during friction stir spot welding in AA6082-T6. Weld. World. 2013, 57, 895–902. [Google Scholar] [CrossRef]

- Pashazadeh, H.; Teimournezhad, J.; Masoumi, A. Numerical investigation on the mechanical, thermal, metallurgical and material flow characteristics in friction stir welding of copper sheets with experimental verification. Mater. Des. 2014, 55, 619–632. [Google Scholar] [CrossRef]

- Stummer, M. Eigenschaften von 30CrNiMo8 Für Die Simulation; TU Graz: Graz, Austria, 2014. [Google Scholar]

- Sorina-Müller, J.; Rettenmayr, M.; Schneefeld, D.; Roder, O.; Fried, W. FEM simulation of the linear friction welding of titanium alloys. Comput. Mater. Sci. 2010, 48, 749–758. [Google Scholar] [CrossRef]

- McAndrew, A.R. 2D linear friction weld modelling of a Ti–6Al–4V T–joint. J. Eng. Sci. Tech. Rev. 2015, 6, 44–48. [Google Scholar]

- Addison, A.C. Linear friction welding information for production engineering. In TWI Industrial Member Report Summary; TWI: Granta Park, UK, September 2010. [Google Scholar]

- Bhamji, I.; Preuss, M.; Threadgill, P.L.; Moat, R.J.; Addison, A.C.; Peel, M.J. Linear friction welding of AISI 316L stainless steel. Mater. Sci. Eng. A 2010, 528, 680–690. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Effertz, P.; Fuchs, F.; Enzinger, N. 3D Modelling of Flash Formation in Linear Friction Welded 30CrNiMo8 Steel Chain. Metals 2017, 7, 449. https://doi.org/10.3390/met7100449

Effertz P, Fuchs F, Enzinger N. 3D Modelling of Flash Formation in Linear Friction Welded 30CrNiMo8 Steel Chain. Metals. 2017; 7(10):449. https://doi.org/10.3390/met7100449

Chicago/Turabian StyleEffertz, Pedro, Franz Fuchs, and Norbert Enzinger. 2017. "3D Modelling of Flash Formation in Linear Friction Welded 30CrNiMo8 Steel Chain" Metals 7, no. 10: 449. https://doi.org/10.3390/met7100449