Permeability Study of Austenitic Stainless Steel Surfaces Produced by Selective Laser Melting

Abstract

:1. Introduction

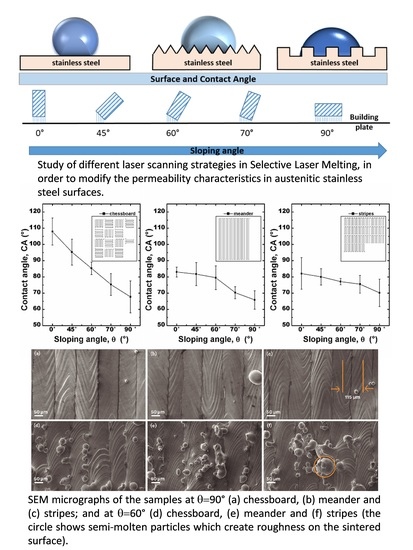

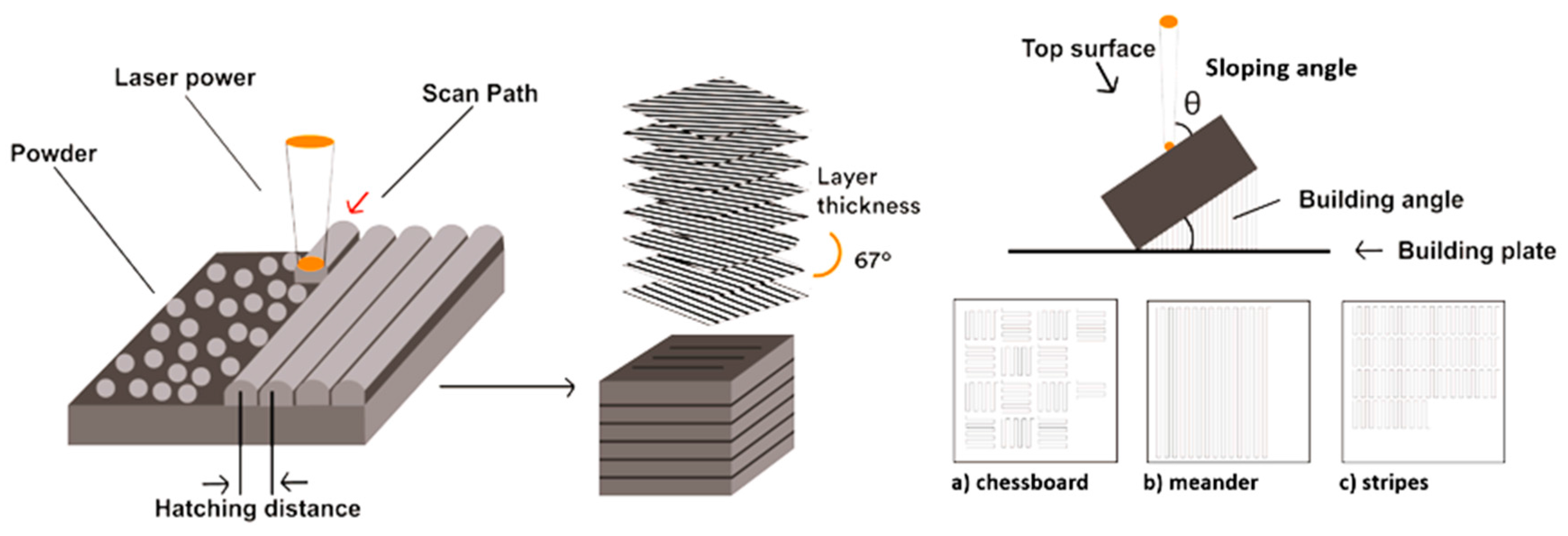

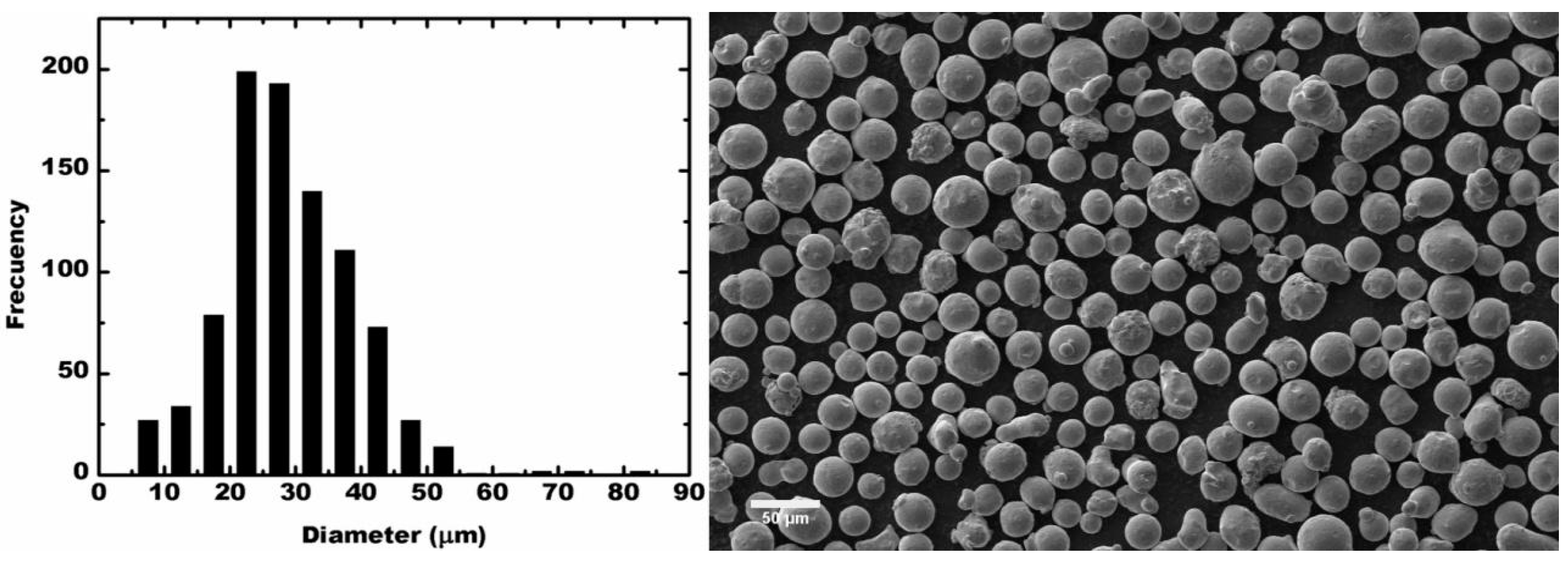

2. Materials and Methods

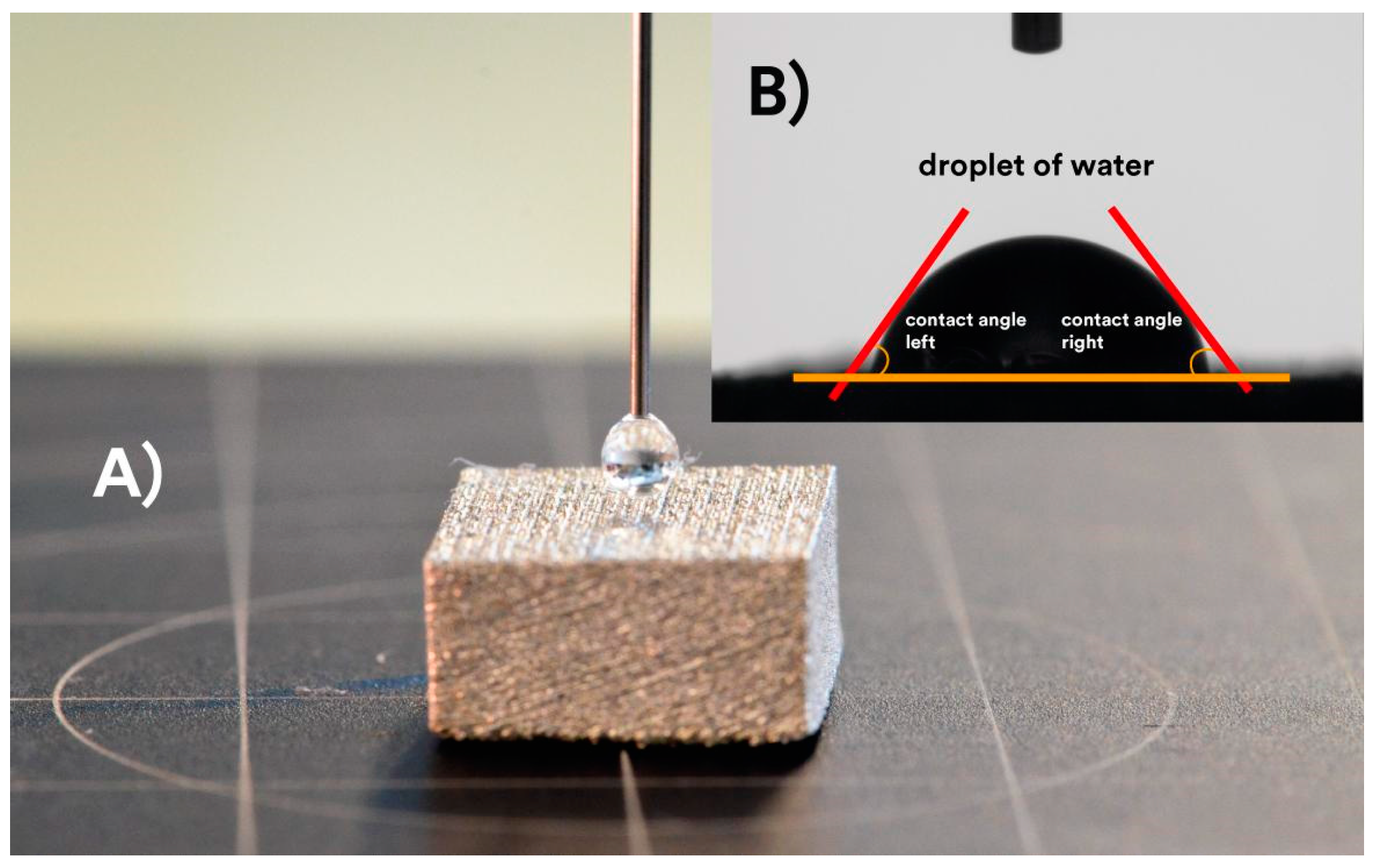

2.1. Contact Angle (CA)

2.2. Roughness

3. Results and Discussion

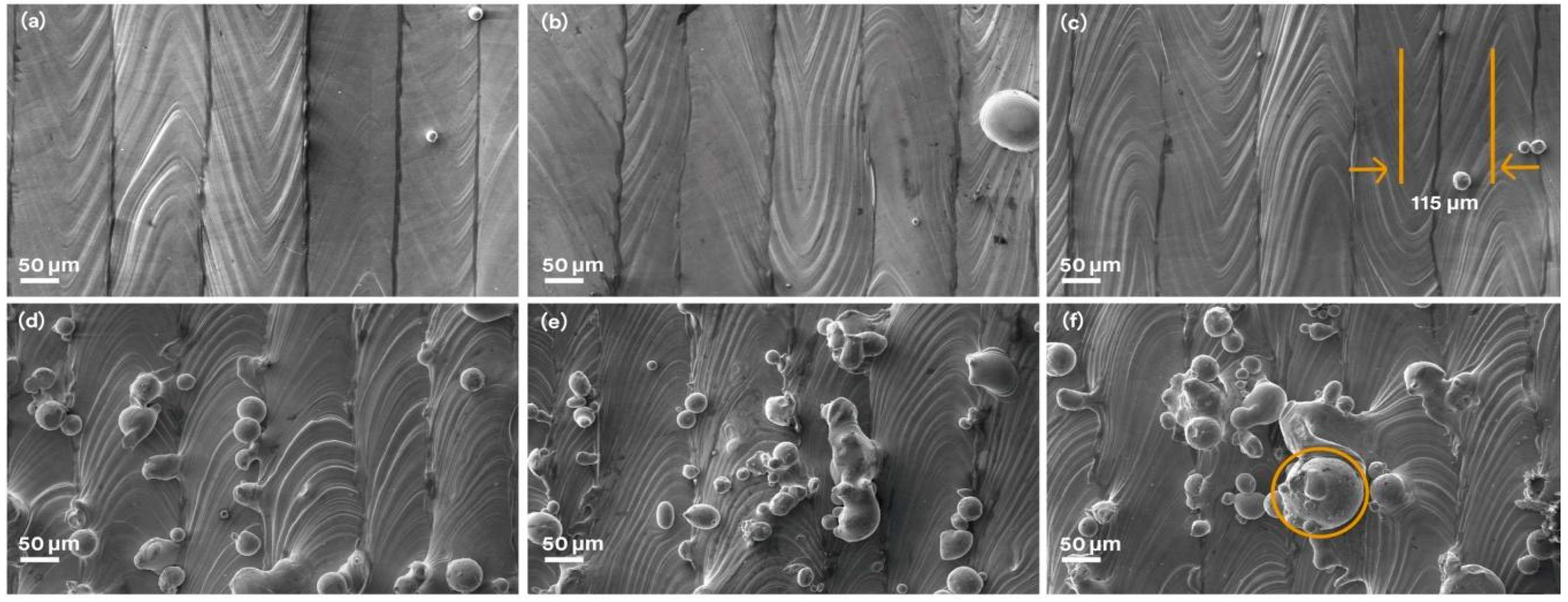

3.1. Scanning Electron Microscope

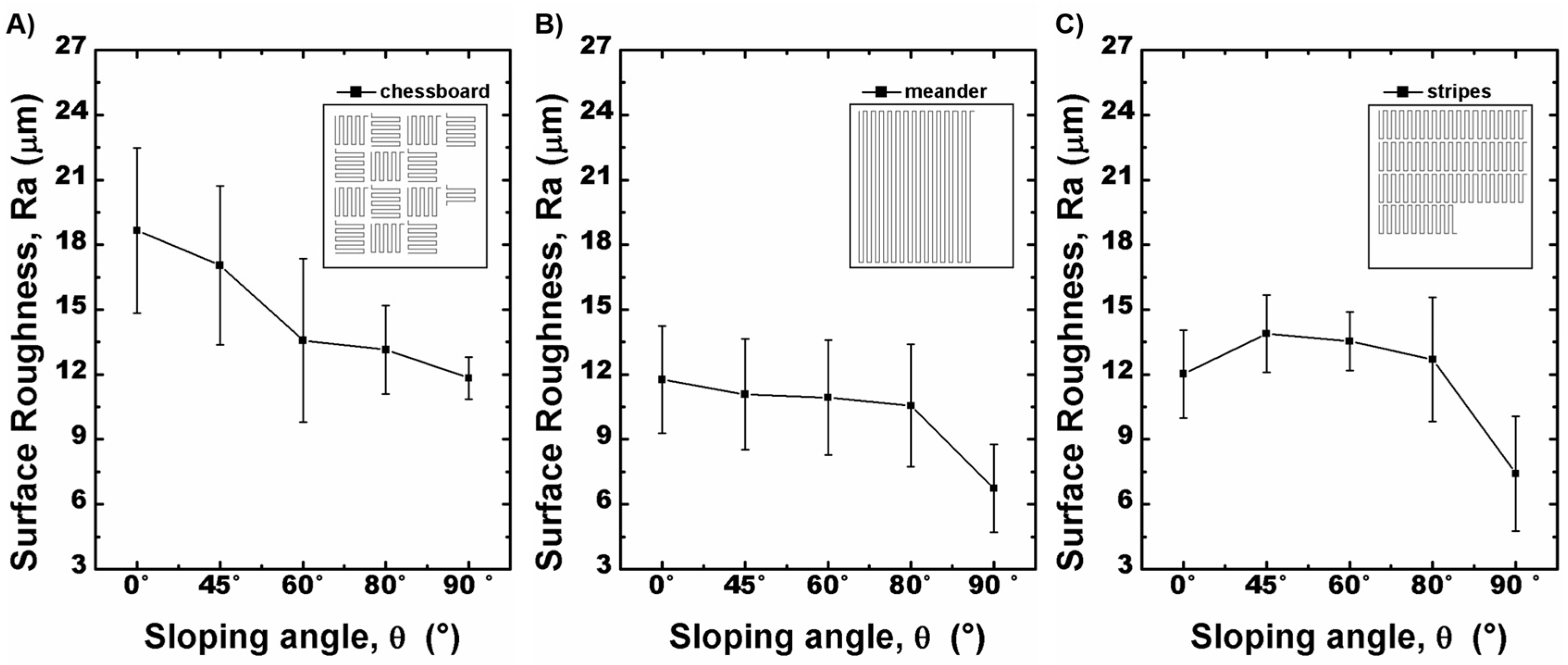

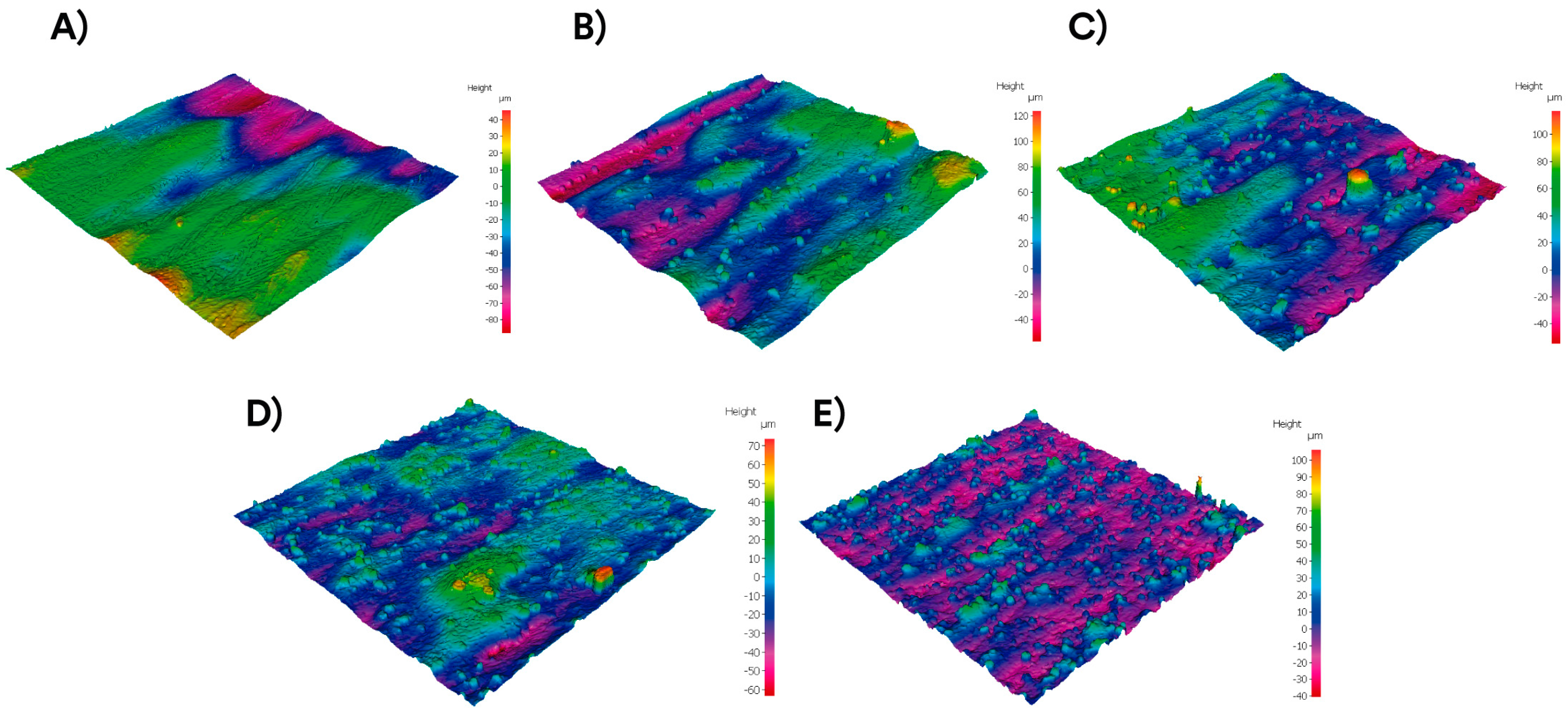

3.2. Roughness

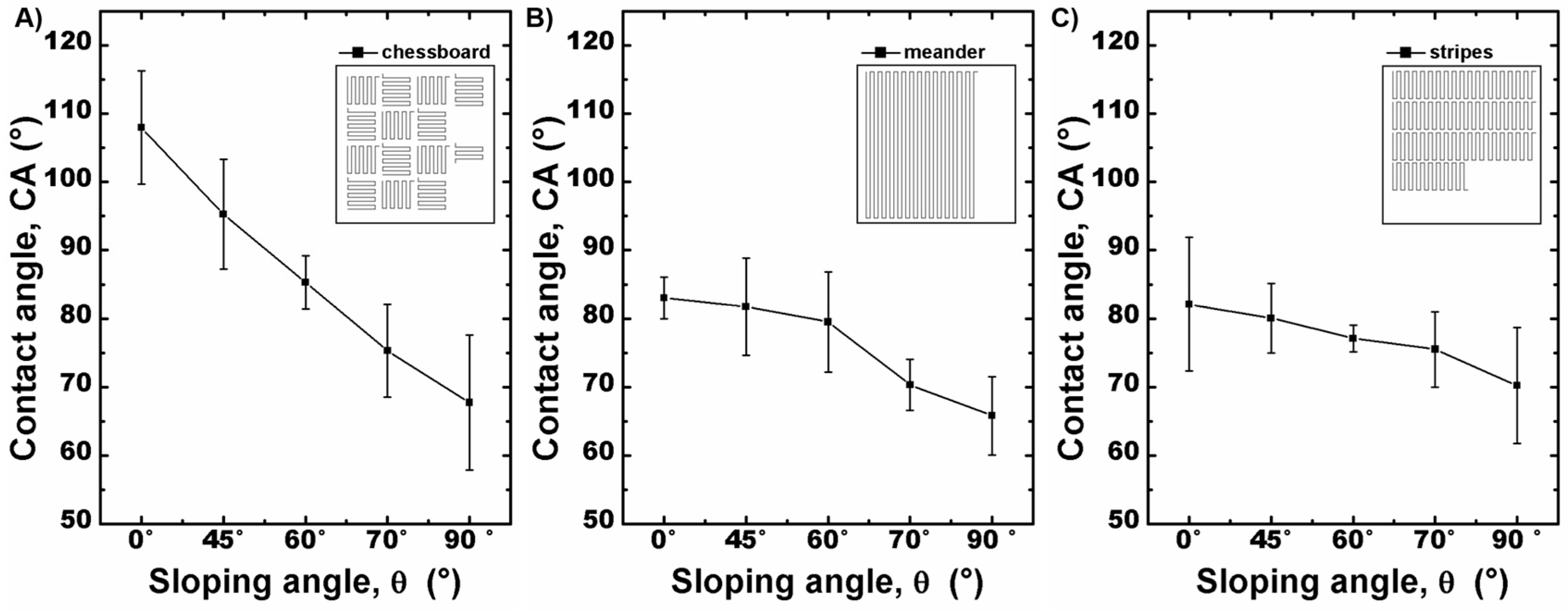

3.3. Contact Angle

4. Conclusions

- The lowest Ra values were found on the surfaces with greater sloping angle. Additionally, these surfaces present fewer desegregated particles.

- As the sloping angle diminishes, the accumulation of semi-melted particles increases, increasing the roughness of the surface.

- The meander and stripes scanning strategies showed one-dimensional scenes in which the balling effect is smaller with respect to the chessboard scanning laser. The chessboard scanning strategy showed a continuous change in the scanning direction in the SLM process, which generates a surface with greater roughness.

- The layer-by-layer overlay in the SLM process showed that the one-dimensional scanning direction creates a smooth surface with a slight change in the contact angle.

- The three conditions studied showed that the surface roughness might have the same value but different contact angles, indicating that the permeability can be controlled without a significant detriment to surface quality.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yadroitsev, I.; Krakhmalev, P.; Yadroitsava, I. Selective laser melting of Ti6Al4V alloy for biomedical applications: Temperature monitoring and microstructural evolution. J. Alloys Compd. 2014, 583, 404–409. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Am. J. Phys. 2015, 2, 41101–41122. [Google Scholar] [CrossRef]

- Mu, Y. 3D Printing of Metals. Metals 2016, 7, 403. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Bertrand, P.; Smurov, I. Parametric analysis of the selective laser melting process. Appl. Surf. Sci. 2007, 253, 8064–8069. [Google Scholar] [CrossRef]

- Li, R.; Shi, Y.; Liu, J.; Xie, Z.; Wang, Z. Selective laser melting W-10 wt.% Cu composite powders. Int. J. Adv. Manuf. Technol. 2010, 48, 597–605. [Google Scholar] [CrossRef]

- Jhabvala, J.; Boillat, E.; André, C.; Glardon, R. An innovative method to build support structures with a pulsed laser in the selective laser melting process. Int. J. Adv. Manuf. Technol. 2012, 59, 137–142. [Google Scholar] [CrossRef]

- Wang, F. Mechanical property study on rapid additive layer manufacture Hastelloy X alloy by selective laser melting technology. Int. J. Adv. Manuf. Technol. 2012, 58, 545–551. [Google Scholar] [CrossRef]

- Deing, A.; Luthringer, B.; Laipple, D.; Ebel, T.; Willumeit, R. A porous TiAl6V4 implant material for medical application. Int. J. Biomater. 2014, 2014, 904230. [Google Scholar] [CrossRef] [PubMed]

- Taniguchi, N.; Fujibayashi, S.; Takemoto, M.; Sasaki, K.; Otsuki, B. Effect of pore size on bone in growth into porous titanium implants fabricated by additive manufacturing: An in vivo experiment. Mater. Sci. Eng. C 2016, 59, 690–701. [Google Scholar] [CrossRef] [PubMed]

- Brandt, M.; Sun, S.J.; Leary, M.; Feih, S.; Elambasseril, J.; Liu, Q.C. High-Value SLM Aerospace Components: From Design to Manufacture. Adv. Mater. Res. 2013, 633, 135–147. [Google Scholar] [CrossRef]

- Seabra, M.; Azevedo, J.; Araújo, A.; Reis, L.; Pinto, E.; Alves, N. Selective laser melting (SLM) and topology optimization for lighter aerospace components. Procedia Struct. Integr. 2016, 1, 289–296. [Google Scholar] [CrossRef]

- Strano, G.; Hao, L.; Everson, R.M.; Evans, K.E. Surface roughness analysis, modelling and prediction in selective laser melting. J. Mater. Process. Technol. 2013, 213, 589–597. [Google Scholar] [CrossRef]

- Fischer, P.; Romano, V.; Weber, H.P.; Karapatis, N.P.; Boillat, E.; Glardon, R. Sintering of commercially pure titanium powder with a Nd:YAG laser source. Acta Mater. 2003, 51, 1651–1662. [Google Scholar] [CrossRef]

- Campbell, R.I.; Martorelli, M.; Lee, H.S. Surface roughness visualisation for rapid prototyping models. Comput. Aided Des. Appl. 2002, 34, 717–725. [Google Scholar] [CrossRef]

- Kruth, J.P.; Badrossamay, M.; Yasa, E.; Deckers, J.; Thijs, L.; Van Humbeeck, J. Part and material properties in selective laser melting of metals. In Proceedings of the 16th International Symposium on Electromachining, Shanghai, China, 19–23 April 2010. [Google Scholar]

- Yusuf, S.; Chen, Y.; Boardman, R.; Yang, S.; Gao, N. Investigation on Porosity and Microhardness of 316L Stainless Steel Fabricated by Selective Laser Melting. Metals 2017, 7, 64. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Hao, L. Effect of Layer Thickness in Selective Laser Melting on Microstructure of Al/5 wt % Fe2O3 Powder Consolidated Parts. Sci. World J. 2014, 231, 112–121. [Google Scholar]

- Islam, M.; Purtonen, T.; Piili, H.; Salminen, A.; Nyrhilä, O. Temperature Profile and Imaging Analysis of Laser Additive Manufacturing of Stainless Steel. Phys. Procedia 2013, 41, 835–842. [Google Scholar] [CrossRef]

- Gu, D.; Shen, Y. Balling phenomena during direct laser sintering of multi-component Cu-based metal powder. J. Alloys Compd. 2007, 432, 163–166. [Google Scholar] [CrossRef]

- Tabernero, I.; Lamikiz, A.; Martínez, S.; Ukar, E.; López De Lacalle, L.N. Modelling of energy attenuation due to powder flow-laser beam interaction during laser cladding process. J. Mater. Process. Technol. 2012, 212, 516–522. [Google Scholar] [CrossRef]

- Mumtaz, K.; Hopkinson, N. Top surface and side roughness of Inconel 625 parts processed using selective laser melting. Rapid Prototyp. J. 2009, 15, 96–103. [Google Scholar] [CrossRef]

- McDonnell, A.M.P.; Beving, D.; Wang, A.; Chen, W.; Yan, Y. Hydrophilic and Antimicrobial Zeolite Coatings for Gravity-Independent Water Separation. Adv. Funct. Mater. 2005, 15, 336–340. [Google Scholar] [CrossRef]

- Liu, J.; Aguilar, G.; Munoz, R.; Yan, Y. Hydrophilic zeolite coatings for improved heat transfer: A quantitative analysis. AIChE J. 2008, 54, 779–790. [Google Scholar] [CrossRef]

- Takata, Y.; Hidaka, S.; Yamashita, A.; Yamamoto, H. Evaporation of water drop on a plasma-irradiated hydrophilic surface. Int. J. Heat Fluid Flow 2004, 25, 320–328. [Google Scholar] [CrossRef]

- Niemi, R.; Mahiout, A.; Siivinen, J.; Mahlberg, R.; Likonen, J.; Nikkola, J.; Mannila, J.; Vuorio, T.; Johansson, L.S.; Söderberg, O.; et al. Surface pretreatment of austenitic stainless steel and copper by chemical, plasma electrolytic or CO2 cryoblasting techniques for sol-gel coating. Surf. Coat. Technol. 2010, 204, 2424–2431. [Google Scholar] [CrossRef]

- Patankar, N.A. Mimicking the lotus effect: Influence of double roughness structures and slender pillars. Langmuir 2004, 20, 8209–8213. [Google Scholar] [CrossRef] [PubMed]

- Cao, L.; Jones, A.K.; Sikka, V.K.; Wu, J.; Gao, D. Anti-icing superhydrophobic coatings. Langmuir 2009, 25, 12444–12448. [Google Scholar] [CrossRef] [PubMed]

- Zorba, V.; Persano, L.; Pisignano, D.; Athanassiou, A.; Stratakis, E.; Cingolani, R.; Tzanetakis, P.; Fotakis, C. Making silicon hydrophobic: Wettability control by two-lengthscale simultaneous patterning with femtosecond laser irradiation. Nanotechnology 2006, 17, 3234. [Google Scholar] [CrossRef]

- Baldacchini, T.; Carey, J.E.; Zhou, M.; Mazur, E. Superhydrophobic surfaces prepared by microstructuring of silicon using a femtosecond laser. Langmuir 2006, 22, 4917–4919. [Google Scholar] [CrossRef] [PubMed]

- Jagannathan, R.; Mehta, R.V. Continuous, Atmospheric Process to Create Organic Clusters and Nanostructured, Functional Films. Adv. Funct. Mater. 2006, 16, 633–639. [Google Scholar] [CrossRef]

- Wang, Q.; Cui, Z.; Xiao, Y.; Chen, Q. Stable highly hydrophobic and oleophilic meshes for oil-water separation. Appl. Surf. Sci. 2007, 253, 9054–9060. [Google Scholar] [CrossRef]

- Chen, L.J.; Chen, M.; Zhou, H.D.; Chen, J.M. Preparation of super-hydrophobic surface on stainless steel. Appl. Surf. Sci. 2008, 255, 3459–3462. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Kam, D.H.; Song, L.; Mazumder, J. Characterization of Individual Microneedles Formed on Alloy Surfaces by Femtosecond Laser Ablation. Metall. Mater. Trans. A 2012, 43, 2574–2580. [Google Scholar] [CrossRef]

- Hashemi, P.M.; Borhani, E.; Nourbakhsh, M.S. A review on nanostructured stainless steel implants for biomedical application. Nanomed. J. 2016, 3, 202–216. [Google Scholar]

- Saha Podder, A.; Bhanja, A. Applications of Stainless Steel in Automobile Industry. Adv. Mater. Res. 2013, 794, 731–740. [Google Scholar] [CrossRef]

- Li, L.; Breedveld, V.; Hess, D.W. Creation of Superhydrophobic Stainless Steel Surfaces by Acid Treatments and Hydrophobic Film Deposition. ACS Appl. Mater. Interfaces 2012, 4, 4549–4556. [Google Scholar] [CrossRef] [PubMed]

- Antony, K.; Arivazhagan, N.; Senthilkumaran, K. Studies on wettability of stainless steel 316L powder in laser melting process. J. Eng. Sci. Technol. 2014, 9, 533–544. [Google Scholar]

- Goclawski, J.; Urbaniak-Domagala, W. The method of solid-liquid contact angle measurement using the images of sessile drops with shadows on substratum. In Proceedings of the 2007 International Conference on Perspective Technologies and Methods in MEMS Design, Lviv-Polyana, Ukraine, 23–26 May 2007. [Google Scholar] [CrossRef]

- Król, M.; Dobrzański, L.A.; Reimann, Ł.; Czaja, I. Surface quality in selective laser melting of metal powders. Arch. Mater. Sci. Eng. 2013, 60, 87–92. [Google Scholar]

- Frantsen, J.E.; Mathiesen, T. Specifying Stainless Steel Surface for the Brewery, Dairy and Pharmaceutical Sectors. In Proceedings of the CORROSION 2009, Atlanta, GA, USA, 22–26 March 2009. [Google Scholar]

- Li, R.; Liu, J.; Shi, Y.; Wang, L.; Jiang, W. Balling behavior of stainless steel and nickel powder during selective laser melting process. Int. J. Adv. Manuf. Technol. 2012, 59, 1025–1035. [Google Scholar] [CrossRef]

- Gu, H.; Gong, H.; Pal, D.; Rafi, K.; Starr, T.; Stucker, B. Influences of Energy Density on Porosity and Microstructure of Selective Laser Melted 17-4PH Stainless Steel. In Proceedings of the 24th Annual International Solid Freeform Fabrication Symposium: An Additive Manufacturing Conference, Austin, TX, USA, 12–13 August 2013. [Google Scholar]

- Gu, D.; Shen, Y. Processing conditions and microstructural features of porous 316L stainless steel components by DMLS. Appl. Surf. Sci. 2008, 255, 1880–1887. [Google Scholar] [CrossRef]

- Fox, J.C.; Moylan, S.P.; Lane, B.M. Effect of Process Parameters on the Surface Roughness of Overhanging Structures in Laser Powder Bed Fusion Additive Manufacturing. Procedia CIRP 2016, 45, 131–134. [Google Scholar] [CrossRef]

- Bogacz, W.; Lemanowicz, M.; Al-Rashed, M.H.; Nakonieczny, D.; Piotrowski, T.; Wójcik, J. Impact of roughness, wettability and hydrodynamic conditions on the incrustation on stainless steel surfaces. Appl. Therm. Eng. 2017, 112, 352–361. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Laser Power (W) | 200 |

| Layer Thickness (µm) | 50 |

| Scan speed (mm/s) | 2000 |

| Hatch spacing (mm) | 0.115 |

| Energy density (J/mm2) | 0.884 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Segura-Cardenas, E.; Ramirez-Cedillo, E.G.; Sandoval-Robles, J.A.; Ruiz-Huerta, L.; Caballero-Ruiz, A.; Siller, H.R. Permeability Study of Austenitic Stainless Steel Surfaces Produced by Selective Laser Melting. Metals 2017, 7, 521. https://doi.org/10.3390/met7120521

Segura-Cardenas E, Ramirez-Cedillo EG, Sandoval-Robles JA, Ruiz-Huerta L, Caballero-Ruiz A, Siller HR. Permeability Study of Austenitic Stainless Steel Surfaces Produced by Selective Laser Melting. Metals. 2017; 7(12):521. https://doi.org/10.3390/met7120521

Chicago/Turabian StyleSegura-Cardenas, Emmanuel, Erick Guadalupe Ramirez-Cedillo, Jesús Alejandro Sandoval-Robles, Leopoldo Ruiz-Huerta, Alberto Caballero-Ruiz, and Hector Rafael Siller. 2017. "Permeability Study of Austenitic Stainless Steel Surfaces Produced by Selective Laser Melting" Metals 7, no. 12: 521. https://doi.org/10.3390/met7120521