The Effects of Cr and Al Addition on Transformation and Properties in Low‐Carbon Bainitic Steels

Abstract

:1. Introduction

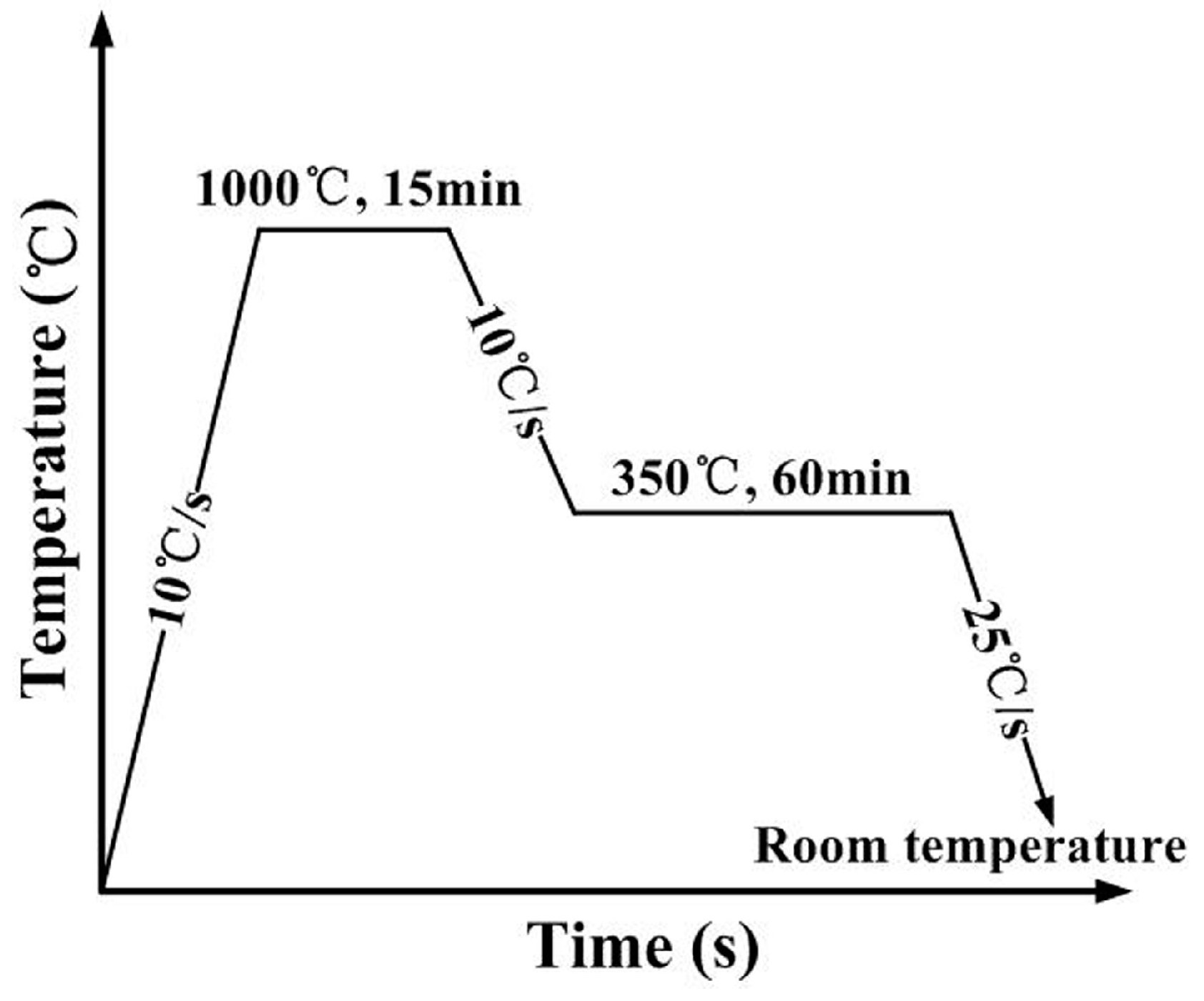

2. Experimental Procedure

3. Results

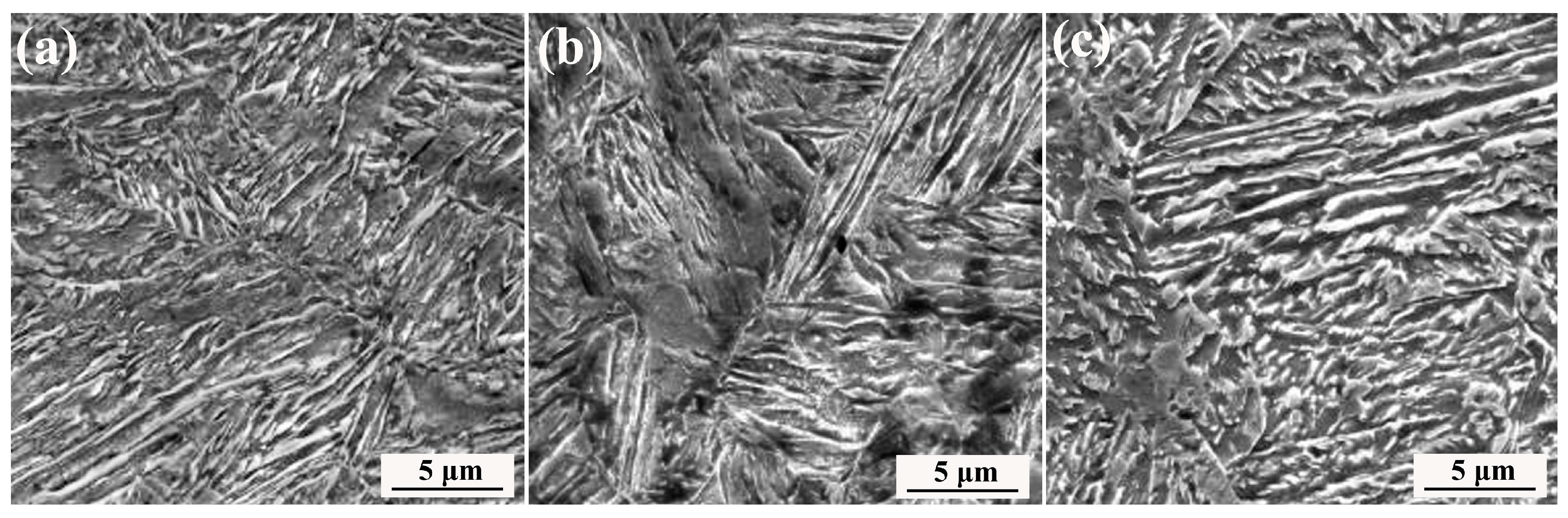

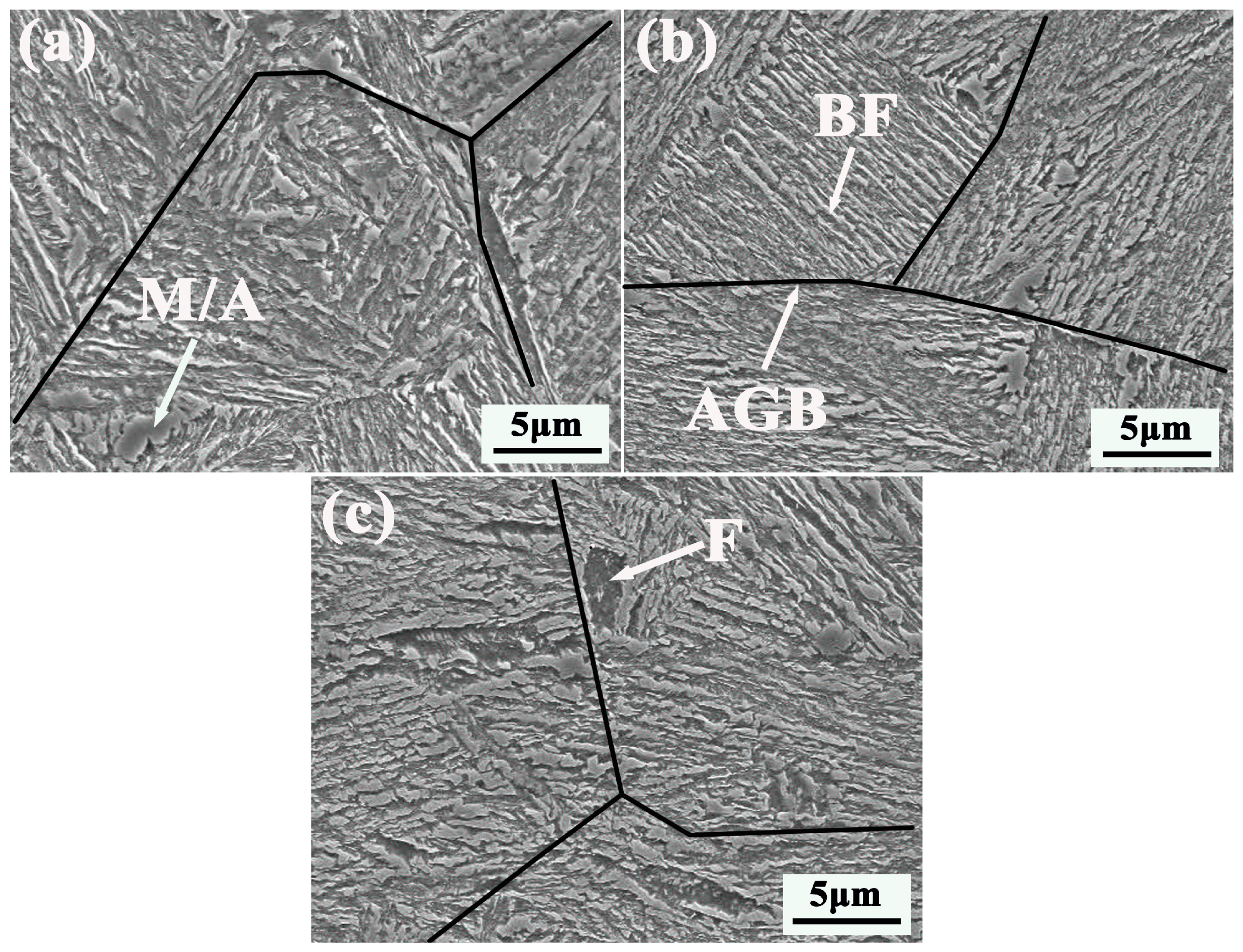

3.1. Microstructure

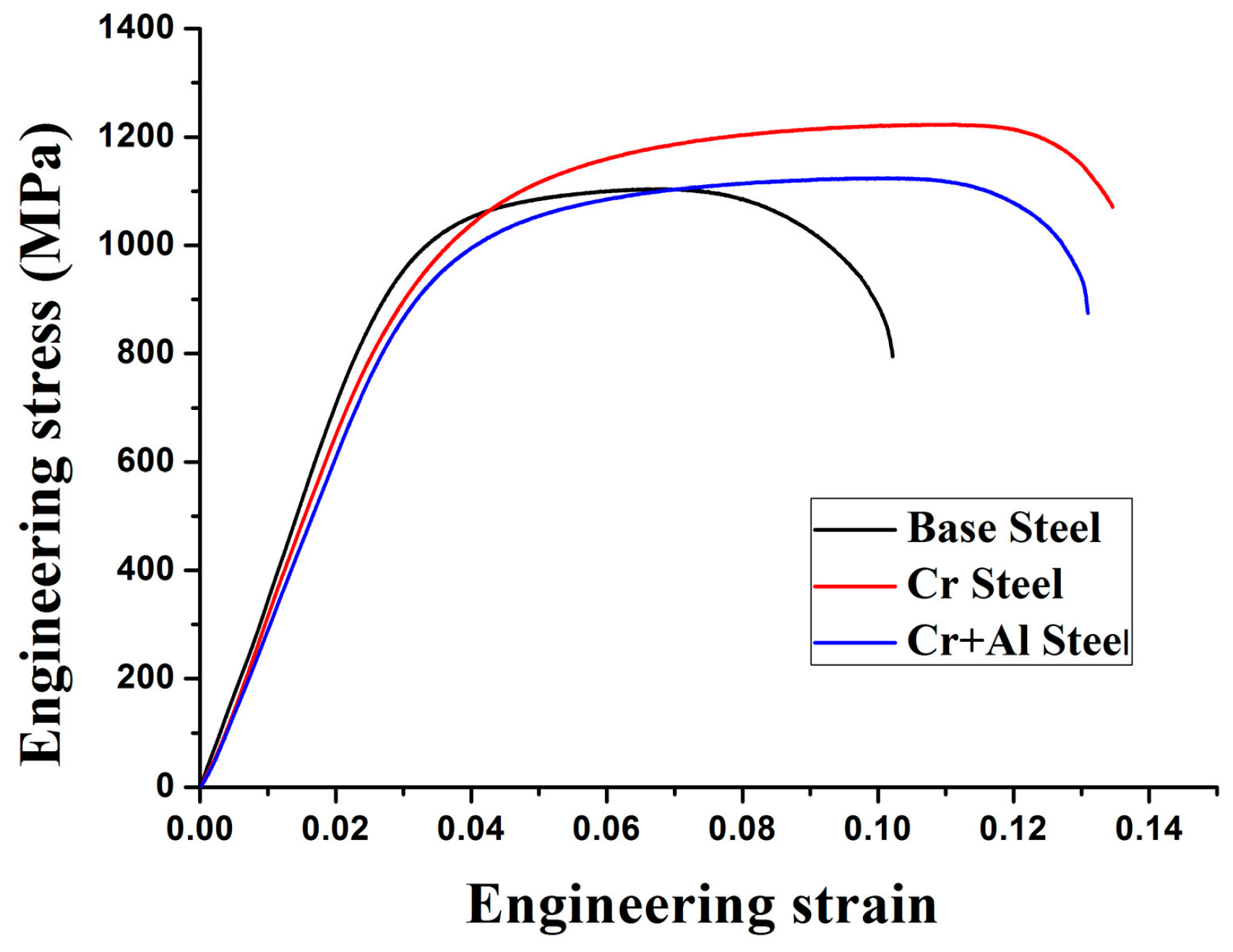

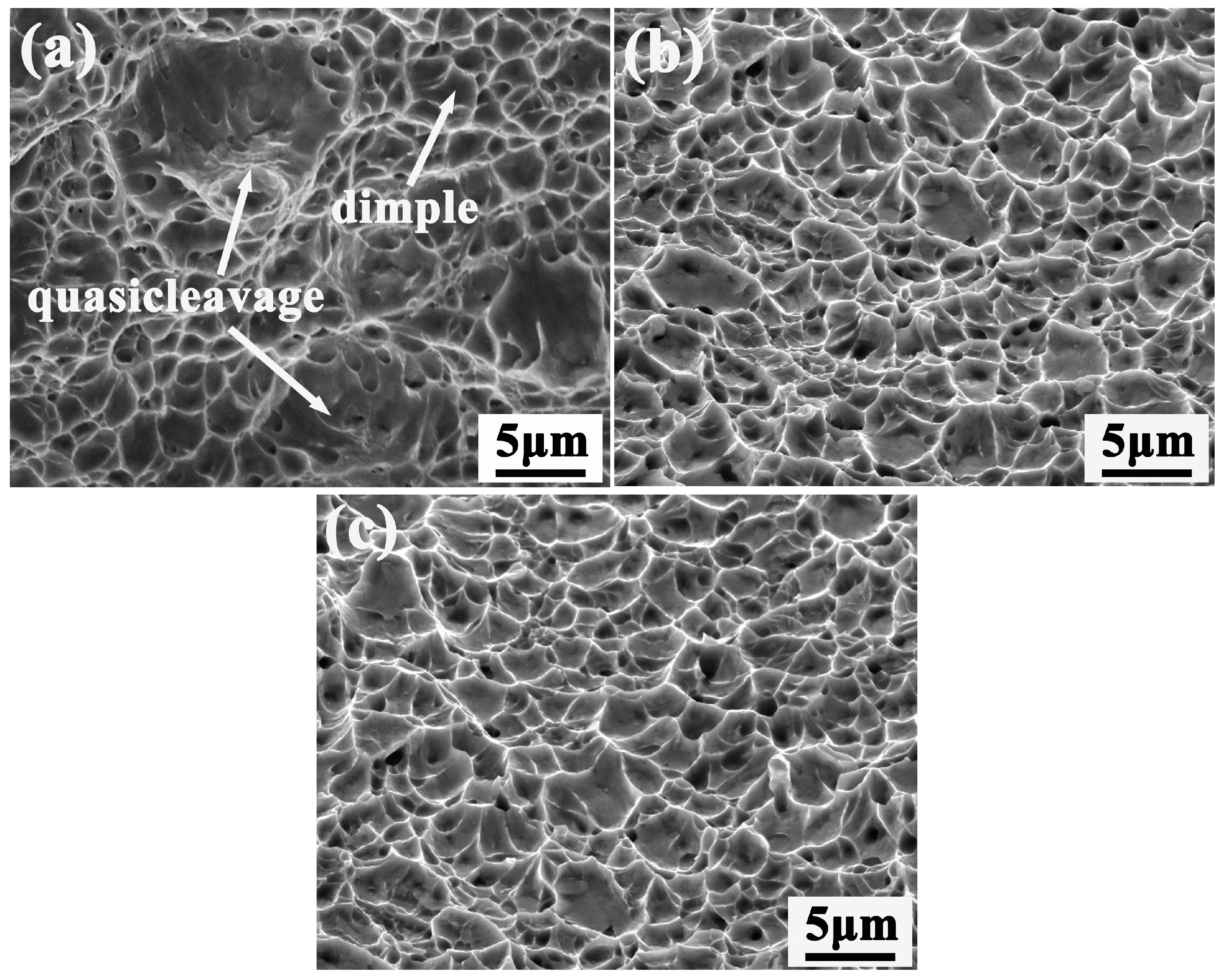

3.2. Mechanical Properties

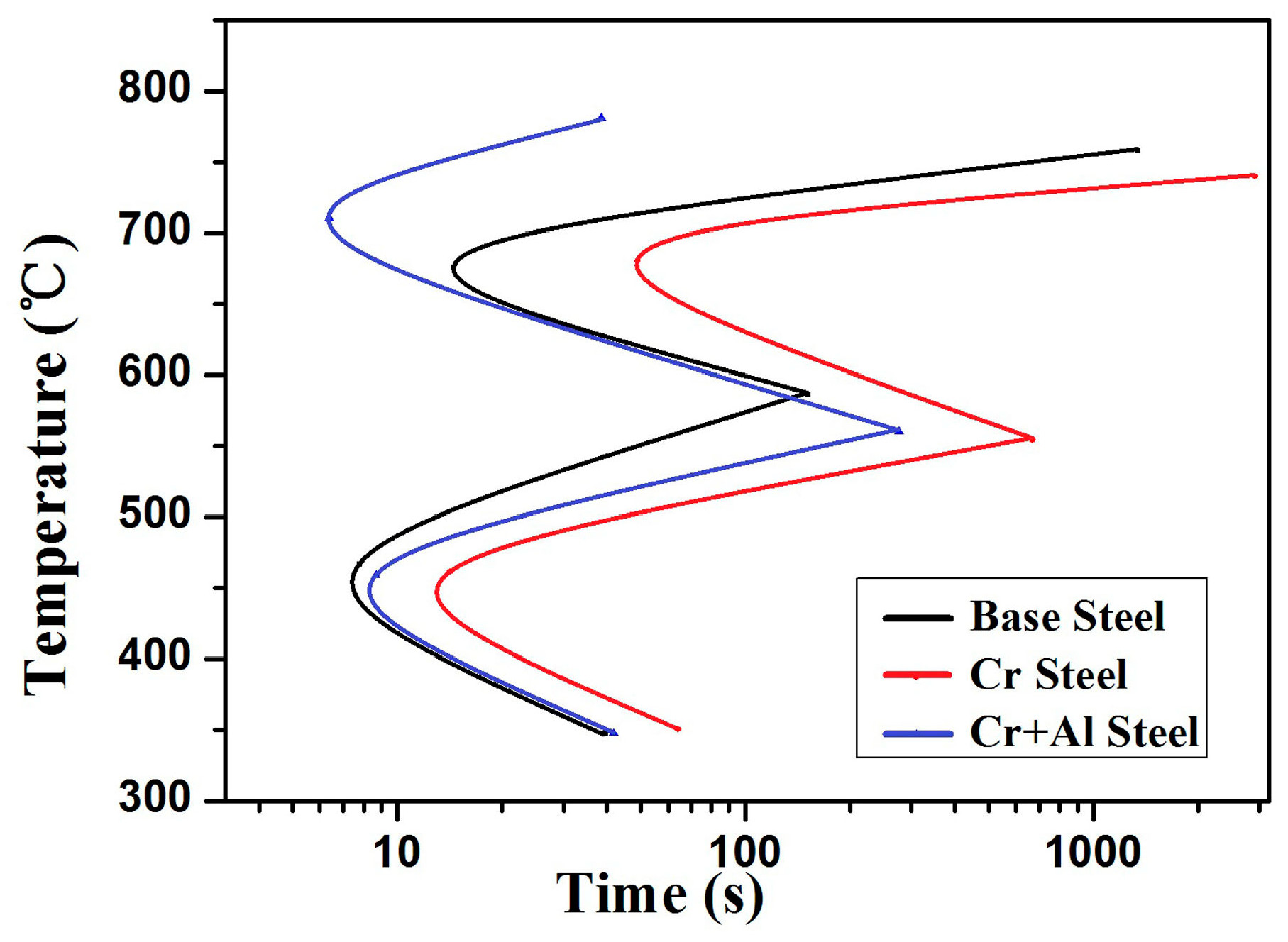

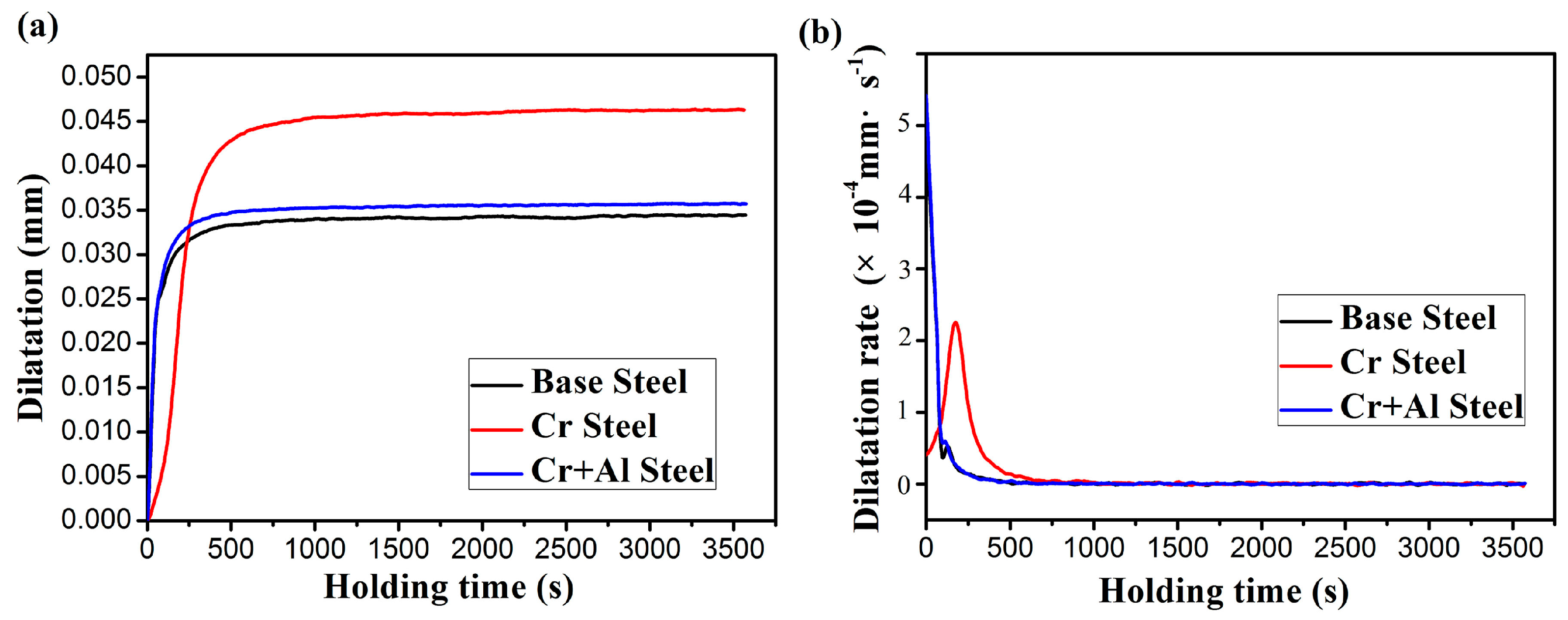

3.3. Thermal Dilatometry

4. Discussions

4.1. Influence of Cr Addition

4.2. Influence of Al Addition

4.3. Influence of Composited Addition of Cr and Al

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhou, M.X.; Xu, G.; Wang, L.; Yuan, Q. The varying effects of uniaxial compressive stress on the bainitic transformation under different austenitization temperatures. Metals 2016, 6, 119. [Google Scholar] [CrossRef]

- He, J.G.; Zhao, A.M.; Yao, H.; Zhi, C.; Zhao, F.Q. Effect of ausforming temperature on bainite transformation of high carbon low alloy steel. Mater. Sci. Forum. 2015, 817, 454–459. [Google Scholar] [CrossRef]

- Hu, H.J.; Xu, G.; Wang, L.; Zhou, M.X.; Xue, Z.L. Effect of ausforming on the stability of retained austenite in a C-Mn-Si bainitic steel. Met. Mater. Int. 2015, 21, 929–935. [Google Scholar] [CrossRef]

- Zhou, M.X.; Xu, G.; Wang, L.; He, B. Effects of austenitization temperature and compressive stress during bainitic transformation on the stability of retained austenite. T. Indian. I. Metals. 2016, 1–7. [Google Scholar] [CrossRef]

- Jimenez-Melero, E.; Dijk, N.H.V.; Zhao, L.; Sietsma, J.; Offerman, S.E.; Wright, J.P. The effect of aluminium and phosphorus on the stability of individual austenite grains in trip steels. Acta Mater. 2009, 57, 533–543. [Google Scholar] [CrossRef]

- Girault, E.; Mertens, A.; Jacques, P.; Houbaert, Y.; Verlinden, B.; Humbeeck, J.V. Comparison of the effects of silicon and aluminium on the tensile behaviour of multiphase trip-assisted steels. Scripta Mater. 2001, 44, 885–892. [Google Scholar] [CrossRef]

- Heller, T.; Nuss, A. Effect of alloying elements on microstructure and mechanical properties of hot rolled multiphase steels. Ironmak. Steelmak. 2005, 32, 303–308. [Google Scholar] [CrossRef]

- Pereloma, E.V.; Timokhina, I.B.; Russell, K.F.; Miller, M.K. Characterization of clusters and ultrafine precipitates in Nb-containing C–Mn–Si steels. Scripta Mater. 2006, 54, 471–476. [Google Scholar] [CrossRef]

- Shi, W.; Li, L.; Yang, C.X.; Fu, R.Y.; Wang, L.; Wollants, P. Strain-induced transformation of retained austenite in low-carbon low-silicon trip steel containing aluminum and vanadium. Mater. Sci. Eng. A 2006, 429, 247–251. [Google Scholar] [CrossRef]

- Wang, X.D.; Huang, B.X.; Wang, L.; Rong, Y.H. Microstructure and mechanical properties of microalloyed high-strength transformation-induced plasticity steels. Metall. Mater. Trans. A 2008, 39, 1–7. [Google Scholar] [CrossRef]

- Hu, H.J.; Xu, G.; Wang, L.; Xue, Z.L.; Zhang, Y.L.; Liu, G.H. The effects of Nb and Mo addition on transformation and properties in low carbon bainitic steels. Mater. Des. 2015, 84, 95–99. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, T.S.; Lv, B.; Zhang, F.C. Microstructures and mechanical properties of a modified high-C–Cr bearing steel with nano-scaled bainite. Mater. Sci. Eng. A 2015, 628, 327–331. [Google Scholar] [CrossRef]

- Garcia-Mateo, C.; Caballero, F.G.; Bhadeshia, H.K.D.H. Acceleration of low-temperature bainite. ISIJ Int. 2003, 43, 285–288. [Google Scholar] [CrossRef]

- Hu, F.; Wu, K.M.; Zheng, H. Influence of Co and Al on pearlitic transformation in super bainitic steels. Ironmak. Steelmak. 2012, 39, 535–539. [Google Scholar] [CrossRef]

- Hu, F.; Wu, K.M.; Zheng, H. Influence of Co and Al on bainitic transformation in super bainitic steels. Steel Res. Int. 2013, 84, 1060–1065. [Google Scholar] [CrossRef]

- Monsalve, A.; Guzmán, A.; Barbieri, F.D.; Artigas, A.; Carvajal, L.; Bustos, O. Mechanical and microstructural characterization of an aluminum bearing trip steel. Metall. Mater. Trans. A 2016, 47, 3088–3094. [Google Scholar] [CrossRef]

- Meyer, M.D.; Mahieu, J.; Cooman, B.C.D. Empirical microstructure prediction method for combined intercritical annealing and bainitic transformation of trip steel. Mater. Sci. Technol. 2002, 18, 1121–1132. [Google Scholar] [CrossRef]

- You, W.; Xu, W.H.; Liu, Y.X.; Bai, B.Z.; Fang, H.S. Effect of chromium on CCT diagrams of novel air-cooled bainite steels analyzed by neural network. J. Iron. Steel Res. Int. 2007, 14, 39–42. [Google Scholar]

- Chance, J.; Ridley, N. Chromium partitioning during isothermal transformation of a eutectoid steel. Metall. Mater. Trans. A 1981, 12, 1205–1213. [Google Scholar] [CrossRef]

- Kong, L.; Liu, Y.; Liu, J.; Song, Y.; Li, S.; Zhang, R. The influence of chromium on the pearlite-austenite transformation kinetics of the Fe–Cr–C ternary steels. J. Alloy. Compd. 2015, 648, 494–499. [Google Scholar] [CrossRef]

- Zhang, G.H.; Chae, J.Y.; Kim, K.H.; Dong, W.S. Effects of Mn, Si and Cr addition on the dissolution and coarsening of pearlitic cementite during intercritical austenitization in Fe-1mass%C alloy. Mater. Charact. 2013, 81, 56–67. [Google Scholar] [CrossRef]

- Zhou, L.Y.; Liu, Y.Z.; Yuan, F.; Huang, Q.W.; Song, R.B. Effect of Cr on transformation of ferrite and bainite dual phase steels. J. Iron Steel Res. Int. 2009, 21, 37–41. [Google Scholar]

- Zhao, Z.; Cheng, L.; Liu, Y.; Northwood, D.O. A new empirical formula for the bainite upper temperature limit of steel. J. Mater. Sci. 2001, 36, 5045–5056. [Google Scholar] [CrossRef]

- Rowland, E.S.; Lyle, S.R. The application of MS points to case depth measurement. ASM Trans. 1946, 37, 26–47. [Google Scholar]

- Xiao, F.; Liao, B.; Ren, D.; Shan, Y.; Yang, K. Acicular ferritic microstructure of a low-carbon Mn–Mo–Nb microalloyed pipeline steel. Mater. Charact. 2005, 54, 305–314. [Google Scholar] [CrossRef]

- Zhou, M.X.; Xu, G.; Wang, L.; Hu, H.J. Combined effect of the prior deformation and applied stress on the bainite transformation. Met. Mater. Int. 2016, 22, 956–961. [Google Scholar] [CrossRef]

- Lindström, A. Austempered High Silicon Steel: Investigation of Wear Resistance in A Carbide Free Microstructure. Master’s Thesis, Luleå Tekniska Universitet, Sweden, 2006. [Google Scholar]

- Grange, R.A.; Stewart, H.M. The temperature range of martensite formation. Trans. AIME 1946, 167, 467–472. [Google Scholar]

- Steven, W.; Haynes, A.G. The temperature formation of martensite and bainite in low-alloy steels. J. Iron Steel Inst. 1956, 183, 349–359. [Google Scholar]

- Wang, X.; Zurob, H.S.; Xu, G.; Ye, Q.; Bouaziz, O.; Embury, D. Influence of microstructural length scale on the strength and annealing behavior of pearlite, bainite, and martensite. Metall. Mater. Trans. A 2013, 44, 1454–1461. [Google Scholar] [CrossRef]

- Wang, X.L.; Wu, K.M.; Hu, F.; Yu, L.; Wan, X.L. Multi-step isothermal bainitic transformation in medium-carbon steel. Scripta Mater. 2014, 74, 56–59. [Google Scholar] [CrossRef]

- Cornide, J.; Garcia-Mateo, C.; Capdevila, C.; Caballero, F.G. An assessment of the contributing factors to the nanoscale structural refinement of advanced bainitic steels. J. Alloy. Compd. 2012, 577, S43–S47. [Google Scholar] [CrossRef]

- Hu, H.J.; Xu, G.; Zhou, M.X.; Yuan, Q. Effect of Mo content on microstructure and property of low-carbon bainitic steels. Metals 2016, 6, 173. [Google Scholar] [CrossRef]

- Shi, J.; Sun, X.; Wang, M.; Hui, W.; Dong, H.; Cao, W. Enhanced work-hardening behavior and mechanical properties in ultrafine-grained steels with large-fractioned metastable austenite. Scripta Mater. 2010, 63, 815–818. [Google Scholar] [CrossRef]

- Straumal, B.B.; Baretzky, B.; Kogtenkova, O.A.; Straumal, A.B.; Sidorenko, A.S. Wetting of grain boundaries in Al by the solid Al3Mg2 phase. J. Mater. Sci. 2010, 45, 2057–2061. [Google Scholar] [CrossRef]

- Ahmad, E.; Manzoor, T.; Ziai, M.M.A.; Hussain, N. Effect of martensite morphology on tensile deformation of dual-phase steel. J. Mater. Eng. Perform. 2012, 21, 1–6. [Google Scholar] [CrossRef]

- Caballero, F.G.; Bhadeshia, H.K.D.H. Very strong bainite. Curr. Opin. Solid State Mater. Sci. 2004, 8, 251–257. [Google Scholar] [CrossRef]

- Fonstein, N.; Yakubovsky, O.; Bhattacharya, D.; Siciliano, F. Effect of niobium on the phase transformation behavior of aluminum containing steels for trip products. Mater. Sci. Forum. 2005, 500–501, 453–460. [Google Scholar] [CrossRef]

| Steels | C | Si | Mn | Cr | Mo | Al | N | P | S |

|---|---|---|---|---|---|---|---|---|---|

| A (base) | 0.218 | 1.831 | 2.021 | / | 0.227 | / | <0.003 | <0.006 | <0.003 |

| B (Cr) | 0.221 | 1.792 | 1.983 | 1.002 | 0.229 | / | <0.003 | <0.006 | <0.003 |

| C (Cr + Al) | 0.219 | 1.824 | 2.041 | 1.021 | 0.230 | 0.502 | <0.003 | <0.006 | <0.003 |

| Base | Cr | Cr + Al | |

|---|---|---|---|

| Prior-austenite grain size | 30.8 ± 9.4 | 29.4 ± 9.1 | 32.6 ± 8.5 |

| Steels | V(BF) (%) | V(RA) (%) |

|---|---|---|

| A (base) | 45.6 | 3.5 |

| B (Cr) | 68.4 | 11.5 |

| C (Cr + Al) | 48.6 | 10.7 |

| Steels | UTS (MPa) | YS (MPa) | TE (%) | UTS × TE (GPa%) |

|---|---|---|---|---|

| A (base) | 1103 ± 18 | 867 ± 22 | 10.2 ± 0.4 | 11.25 ± 0.007 |

| B (Cr) | 1238 ± 21 | 889 ± 18 | 13.1 ± 0.8 | 16.22 ± 0.017 |

| C (Cr + Al) | 1124 ± 15 | 873 ± 16 | 12.8 ± 0.5 | 14.39 ± 0.008 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, J.; Xu, G.; Zhou, M.; Hu, H.; Wan, X. The Effects of Cr and Al Addition on Transformation and Properties in Low‐Carbon Bainitic Steels. Metals 2017, 7, 40. https://doi.org/10.3390/met7020040

Tian J, Xu G, Zhou M, Hu H, Wan X. The Effects of Cr and Al Addition on Transformation and Properties in Low‐Carbon Bainitic Steels. Metals. 2017; 7(2):40. https://doi.org/10.3390/met7020040

Chicago/Turabian StyleTian, Junyu, Guang Xu, Mingxing Zhou, Haijiang Hu, and Xiangliang Wan. 2017. "The Effects of Cr and Al Addition on Transformation and Properties in Low‐Carbon Bainitic Steels" Metals 7, no. 2: 40. https://doi.org/10.3390/met7020040