Assessment of the Residual Life of Steam Pipeline Material beyond the Computational Working Time

Abstract

:1. Introduction

2. Material for Investigations

3. Research Scope and Methodology

- The microstructure of repair circumferential welded joints of components in the pressure part of a boiler was examined, with tests were carried out using a scanning electron microscope (SEM, FEI, Hillsboro, OR, USA) Inspect F on nital-etched metallographic microsections;

- Analysis of precipitation processes was carried out using X-ray analysis of isolated carbides, with the use of a Empyrean diffractometer (XRD, Panalytical, Almelo, Netherlands) and selective diffraction of electrons;

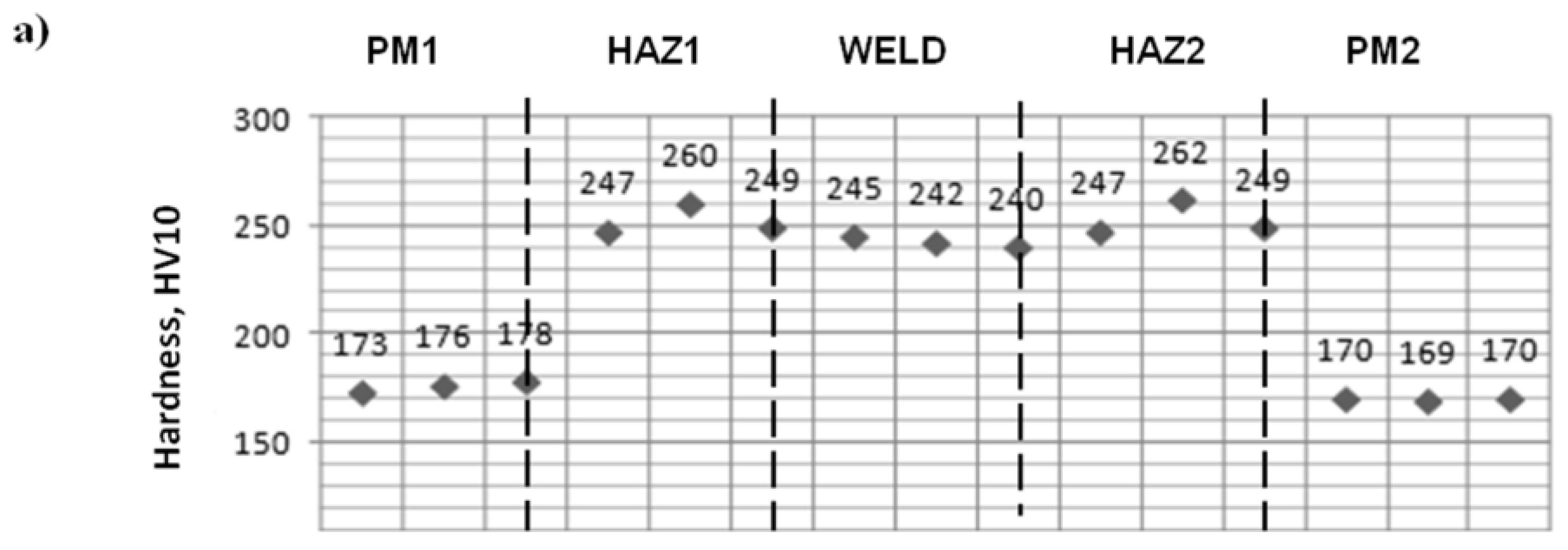

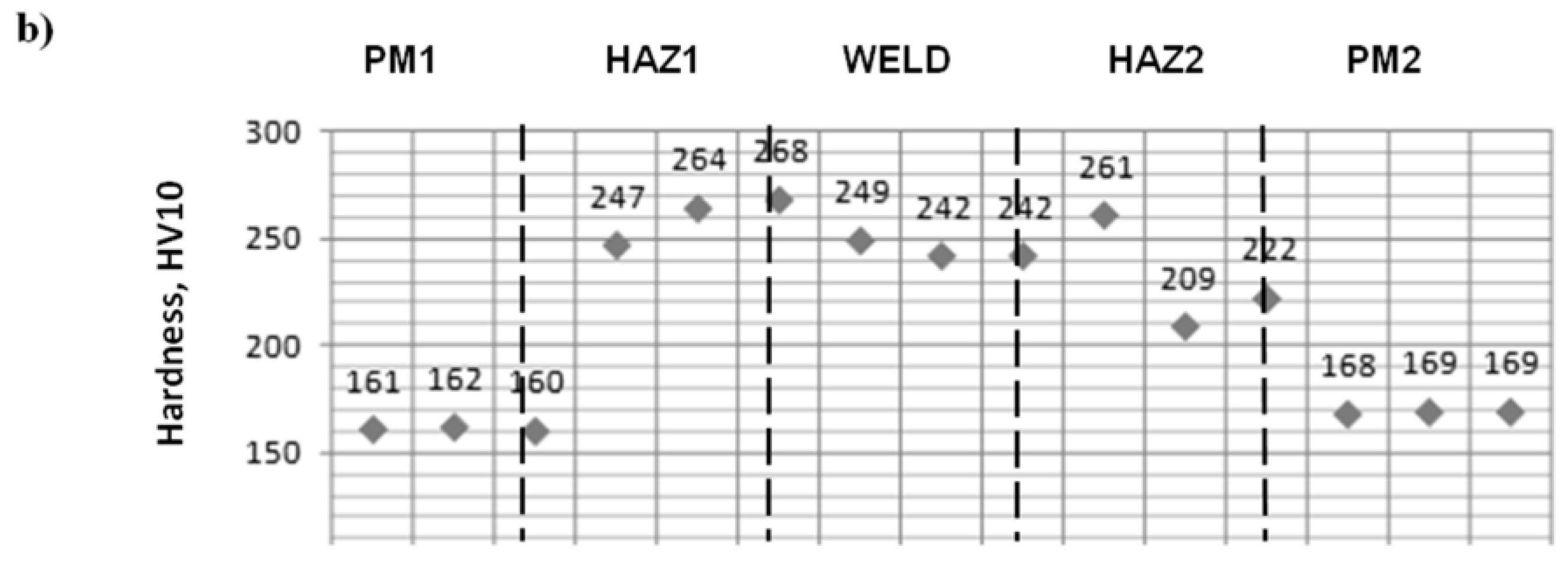

- The level of hardness for individual joint components and its nature in the course from the parent material through the heat-affected zone and weld was obtained, taken by Vickers method using a Future—Tech FM—7 machine (Kawasaki, Japan) at the indenter load of 10 kG;

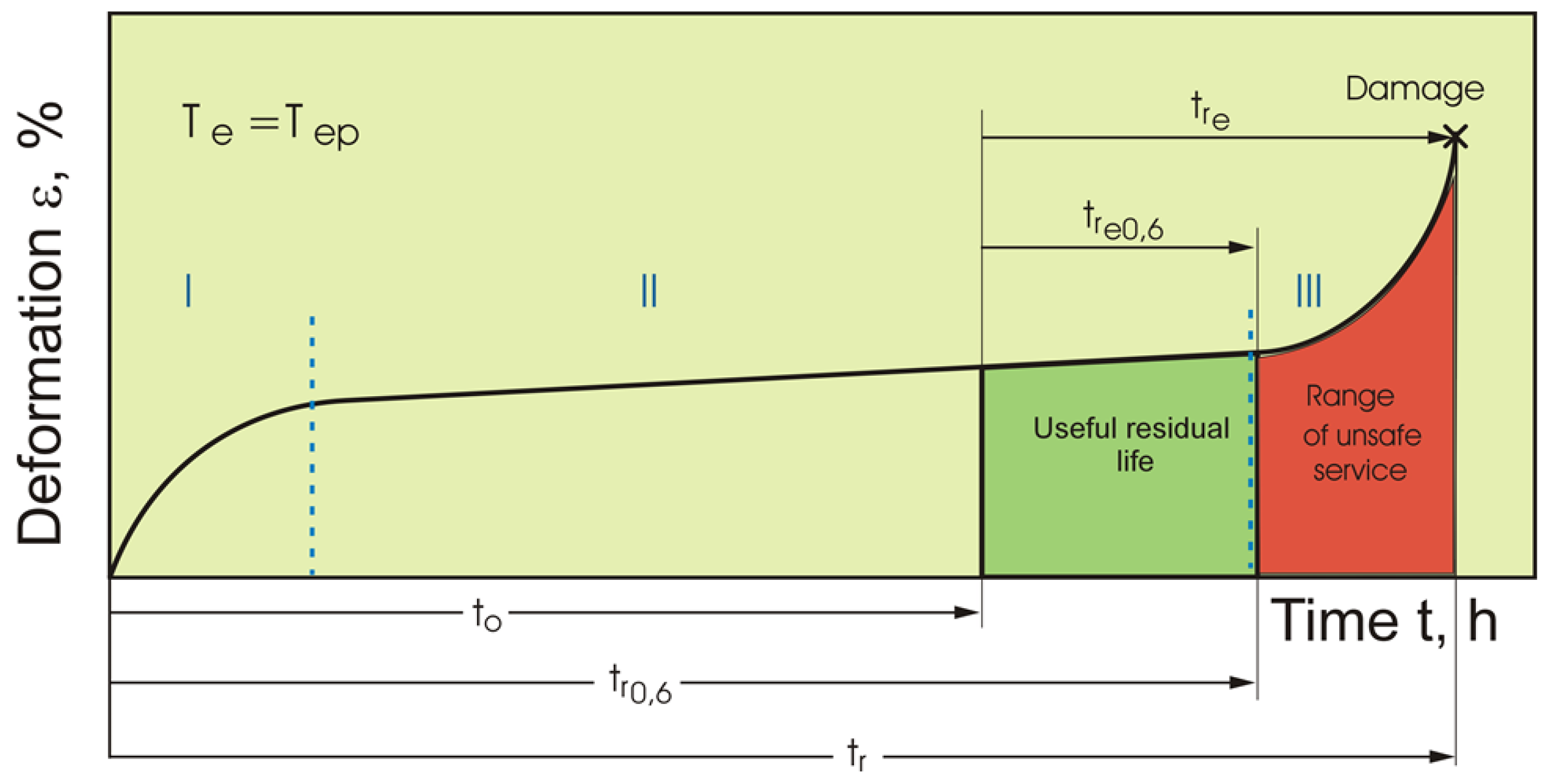

- The material’s residual life was determined based on abridged creep tests at a constant test stress corresponding to the operating one σb = σr = const and at a constant test temperature Tb for each test. The tests were performed using Instron single-sample machines (Norwood, MA, USA) with an accuracy of temperature during the test of ±1 °C.

4. Results

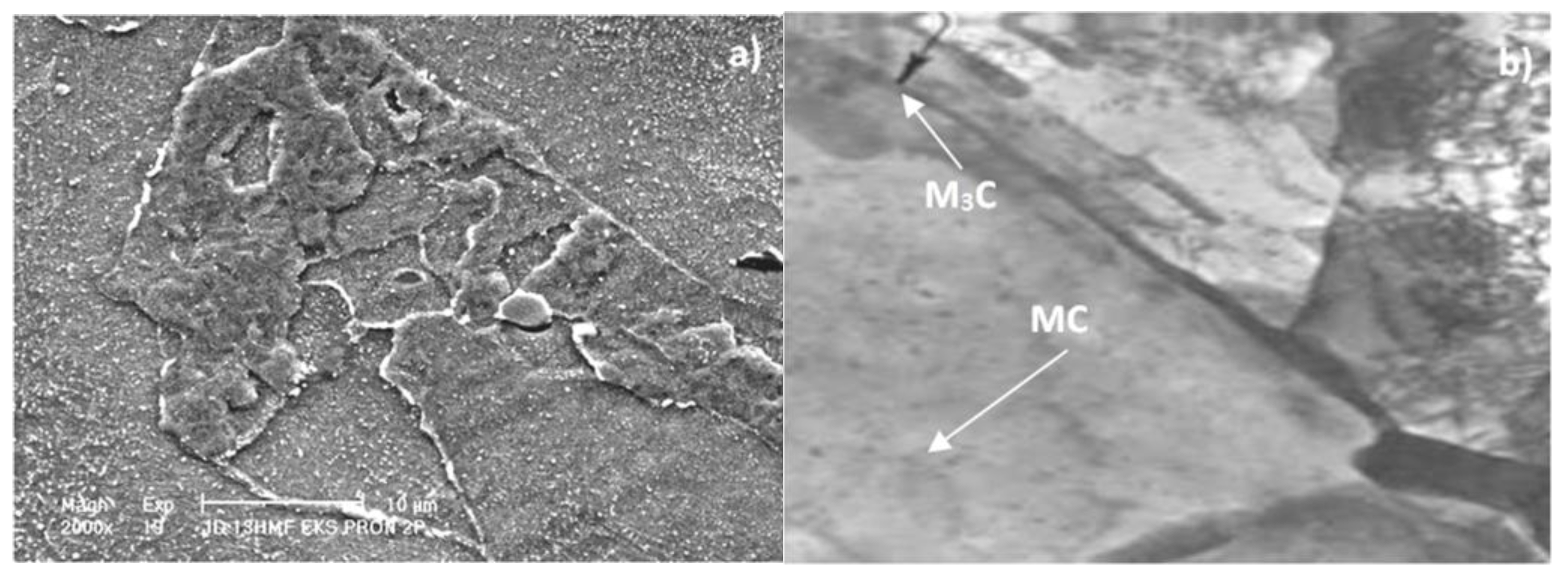

4.1. Microstructure Investigations: Structure of Steel in the As-Received Condition

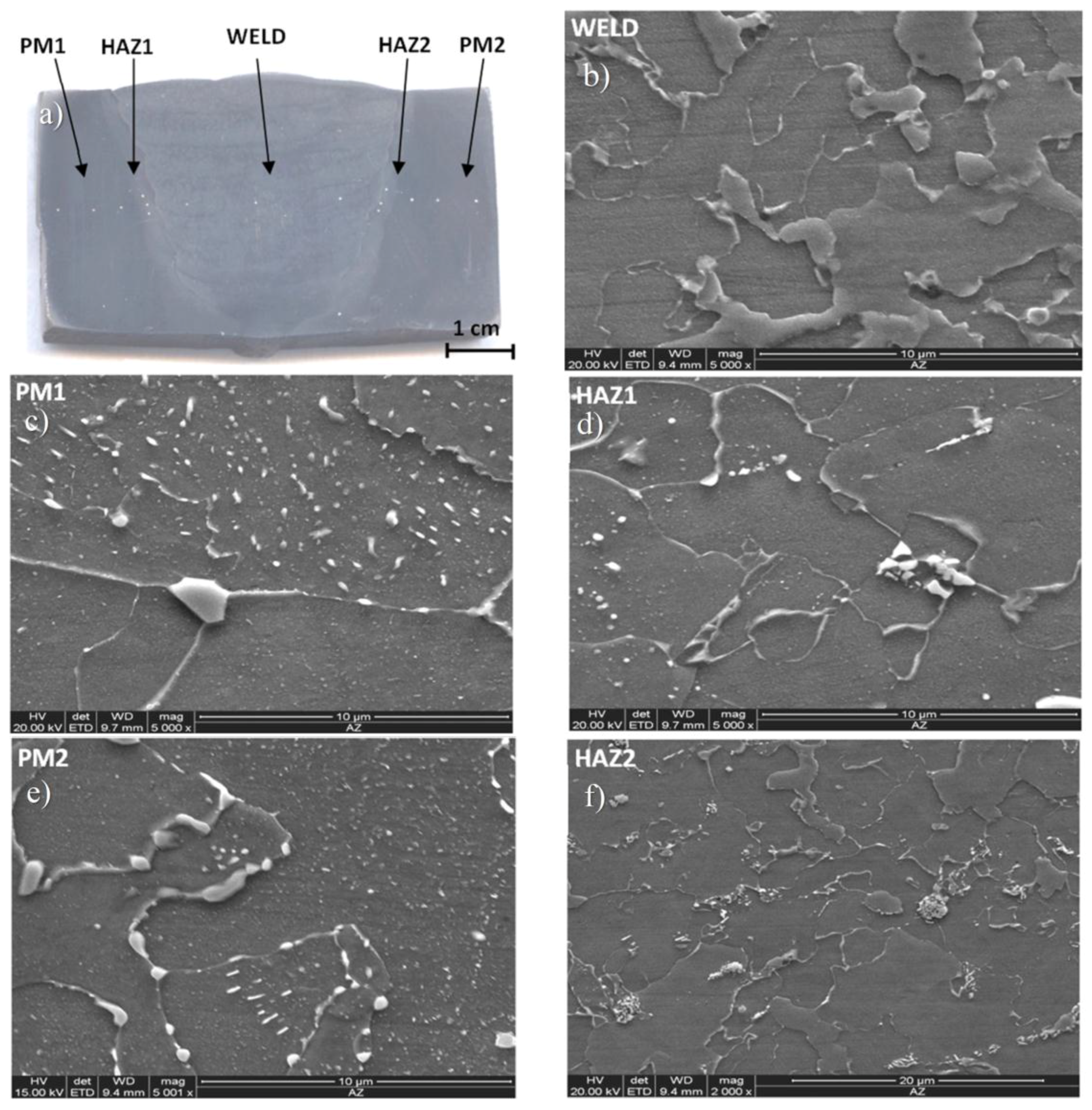

4.2. Evaluation of the Microstructure of Repair Welded Joints

4.3. X-ray Analysis of Phase Composition of Precipitated Carbide Isolates

4.4. Hardness Evaluation of Repair Welded Joints

4.5. Abridged Creep Tests

5. Conclusions

- The set of destructive materials tests presented in this paper allows for the evaluation of material condition and determination of suitability for service of repair. It is of particular importance for the operation of steam pipelines beyond the design service time.

- The evaluation of the material condition of repair welded joints is made based on a comprehensive summary of the results of investigations on mechanical properties, microstructure and abridged creep tests. These results are in turn a part of the database of the materials’ characteristics for steels and their welded joints with materials showing varying degrees of degradation. This database is used in diagnostic tests for pressure parts of boiler elements.

- The quantitative dimension of suitability for service of the material of repair welded joints is achieved by extrapolating the straight line obtained in abridged creep tests from logtr = f(Tb) at σb = const towards the temperature of assumed operation, which allows residual life tre and disposable residual life tb to be determined for the working temperature.

- The knowledge of the share of disposable residual life tbe in residual life tre (tbe/tre) allows the safe time of service of the examined joints to be determined for the required performance parameters.

- The examined repair welded joints are suitable for operation for a limited time resulting from the disposable residual life determined for defined temperature and stress parameters of further service.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Dobrzański, J. Materials science interpretation of the life of steels for power plants. Open Access Libr. 2011, 3, 1–228. [Google Scholar]

- Golański, G.; Zieliński, A.; Słania, J.; Jasak, J. Mechanical properties of Vm12 steel after 30,000 hrs of ageing at 600 °C temperature. Arch. Metall. Mater. 2014, 59, 1351–1354. [Google Scholar]

- Zieliński, A.; Golański, G. The influence of repair welded joint on the life of steam pipeline made of Cr-Mo steel serviced beyond the calculated working time. Arch. Metall. Mater. 2015, 60, 1045–1049. [Google Scholar] [CrossRef]

- Cao, J.; Gong, Y.; Yang, Z.G.; Luo, X.M.; Gu, F.M.; Hu, Z.F. Creep fracture behavior of dissimilar weld joints between T92 martensitic and HR3C austenitic steels. Int. J. Press. Vessels Pip. 2011, 88, 94–98. [Google Scholar] [CrossRef]

- Laha, K. Integrity Assessment of Similar and Dissimilar Fusion Welded Joints of Cr-Mo-W Ferritic Steels under Creep Condition. Procedia Eng. 2014, 86, 195–202. [Google Scholar] [CrossRef]

- Sawada, K.; Tabuchi, M.; Hongo, H.; Watanabe, T.; Kimura, K. Z-Phase formation in welded joints of high chromium ferritic steels after long-term creep. Mater. Charact. 2008, 59, 1161–1167. [Google Scholar] [CrossRef]

- Zieliński, A.; Sroka, M.; Miczka, M.; Śliwa, A. Forecasting the particle diameter size distribution in P92 (X10CrWMoVNb9-2) steel after long-term ageing at 600 and 650 °C. Arch. Metall. Mater. 2016, 61, 753–760. [Google Scholar]

- Golański, G.; Zieliński, A.; Zielińska-Lipiec, A. Degradation of microstructure and mechanical properties in martensitic cast steel after ageing. Materialwiss. Werkst. 2015, 46, 248–255. [Google Scholar] [CrossRef]

- Zieliński, A.; Golański, G.; Sroka, M.; Tański, T. Influence of long-term service on microstructure, mechanical properties, and service life of HCM12A steel. Mater. High Temp. 2016, 33, 24–32. [Google Scholar] [CrossRef]

- Zieliński, A.; Golański, G.; Sroka, M.; Dobrzański, J. Estimation of long-term creep strength in austenitic power plant steels. Mater. Sci. Technol.-Lond. 2016, 32, 780–785. [Google Scholar] [CrossRef]

- Dobrzański, J.; Hernas, A.; Moskal, G. Microstructural degradation in power plant steels. In Power Plant Life Management and Performance Improvement; Oakey, J.E., Ed.; Woodhead Publishing Limited: Sawston, UK, 2011. [Google Scholar]

- Falat, L.; Svoboda, M.; Výrostková, A.; Petryshynets, I.; Sopko, M. Microstructure and creep characteristics of dissimilar T91/TP316H martensitic/austenitic welded joint with Ni-based weld metal. Mater. Charact. 2012, 72, 15–23. [Google Scholar] [CrossRef]

- Kim, M.-Y.; Kwak, S.-C.; Choi, I.-S.; Lee, Y.-K.; Suh, J.-Y.; Fleury, E.; Jung, W.-S.; Son, T.-H. High-temperature tensile and creep deformation of cross-weld specimens of weld joint between T92 martensitic and Super304H austenitic steels. Mater. Charact. 2014, 97, 161–168. [Google Scholar] [CrossRef]

- Sroka, M.; Zieliński, A.; Mikuła, J. The service life of the repair welded joint of Cr-Mo/Cr-Mo-V. Arch. Metall. Mater. 2016, 61, 969–974. [Google Scholar] [CrossRef]

- Zieliński, A.; Golański, G.; Sroka, M. Influence of long-term ageing on the microstructure and mechanical properties of T24 steel. Mater. Sci. Eng. A. 2017, 682, 664–672. [Google Scholar]

- PN-EN 10216-2. Pipes for Pressure Purposes with Specified Elevated Temperature Properties; Boiler Tubes: Brussels, Belgium, 2014.

- Zieliński, A.; Dobrzański, J.; Purzyńska, H.; Golański, G. Properties, structure and creep resistance of austenitic steel Super 304H. Mater. Test. 2015, 57, 859–865. [Google Scholar] [CrossRef]

- Zieliński, A.; Sroka, M.; Hernas, A.; Kremzer, M. The effect of long-term impact of elevated temperature on changes in microstructure and mechanical properties of HR3C steel. Arch. Metall. Mater. 2016, 61, 761–766. [Google Scholar] [CrossRef]

| Repair Welded Joint Made from Pipeline Sections after Long-Term Service, Marked ZS1 | ||

| Steel grade: 14MoV6-3 Service time: material after 169,000 h service, marked ZS1 |  |  |

| Dimensions: 273 × 32 (Dn × gn) | ||

| Working parameters of sections after service t0 = 538 °C; p0 = 13.0 Mpa | ||

| Material for investigations: repair circumferential welded joint made under industrial conditions | ||

| Repair Welded Joint Made from Pipeline Sections in the As-Received Condition (before Service) and after Long-Term Service, Marked ZS2 | ||

| Steel grade: 14MoV6-3 Service time: material in the as-received condition/material after 169,000 h service, marked ZS2 |  | |

| Dimensions: 273 × 32 (Dn × gn) | ||

| Working parameters of sections after service t0 = 538 °C; p0 = 13.0 Mpa | ||

| Material for investigations: repair circumferential welded joint made under industrial conditions | ||

| Grade of Material | Content of Elements (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Mn | Si | P | S | Cu | Cr | Ni | Mo | Others | |

| 14MoV6-3 according to [16] | 0.10 0.18 | 0.40 0.70 | 0.15 0.35 | max 0.04 | max 0.04 | max 0.25 | 0.30 0.60 | max 0.30 | 0.50 0.65 | V 0.22–0.35 Al max 0.02 |

| 14MoV6-3 169,000 h service Designation ZS1-PM1 | 0.16 | 0.58 | 0.35 | 0.017 | 0.018 | 0.20 | 0.46 | 0.23 | 0.62 | V 0.29 Al 0.026 |

| 14MoV6-3 169,000 h service Designation ZS1-PM2 | 0.16 | 0.58 | 0.35 | 0.017 | 0.020 | 0.20 | 0.46 | 0.23 | 0.63 | V 0.29 Al 0.024 |

| 14MoV6-3 in the as-received condition Designation ZS2-PM1 | 0.17 | 0.51 | 0.22 | 0.008 | 0.006 | 0.11 | 0.53 | 0.11 | 0.52 | V 0.26 Al 0.013 |

| 14MoV6-3 169,000 h service Designation ZS2-PM2 | 0.16 | 0.59 | 0.34 | 0.018 | 0.018 | 0.21 | 0.48 | 0.22 | 0.59 | V 0.28 Al 0.023 |

| Material for Investigations | Figure No. | Description of Microstructure Material Condition—Exhaustion Degree | Hardness HV10 | |

|---|---|---|---|---|

| Repair welded joint Designation ZS1 | PM1 | Figure 3 | Ferritic-bainitic structure. No discontinuities or micro-cracks are observed in the structure. Bainitic areas: class I/II, precipitates: class A. Damaging processes: class 0. CLASS 2, EXHAUSTION DEGREE: approx. 0.3 ÷ 0.4. | 173 |

| PM2 | 169 | |||

| HAZ1 | No discontinuities or micro-cracks are found in the structure. | 247 | ||

| WELD | 240 | |||

| HAZ2 | 247 | |||

| Repair welded joint Designation ZS2 | PM1 | Figure 4 | Ferritic-bainitic structure. No discontinuities or micro-cracks are observed in the structure. Bainitic areas: class 0; precipitates: class 0; Damaging processes: class 0. MATERIAL CONDITION: CLASS 0; EXHAUSTION DEGREE: ~0. | 160 |

| PM2 | Ferritic-bainitic structure. No discontinuities or micro-cracks are observed in the structure. Bainitic areas: class I/II, precipitates: class A. Damaging processes: class 0. CLASS 2, EXHAUSTION DEGREE: approx. 0.3 ÷ 0.4. | 168 | ||

| HAZ1 | No discontinuities or micro-cracks are found in the structure. | 247 | ||

| WELD | 242 | |||

| HAZ2 | 168 | |||

| Material Condition | Phase Composition of Carbides | Precipitation Sequence |

|---|---|---|

| As-received condition 14MoV6-3 steel | M3C MC | M3C + MC |

| 14MoV6-3 steel 169,000 h service Designation ZS1-PM1 | Isovit Cr23C6—main phase Cementite Fe3C VC | M23C6 main_ph. + M3C av + MC nw |

| 14MoV6-3 steel 169,000 h service Designation ZS2-PM2 | Isovit Cr23C6—main phase Cementite Fe3C VC | M23C6 main_ph. + M3C av + MC nw |

| Test Specimen Designation | Working Parameters | Test Stress σb (Mpa) | Test Temperature, Tb (°C) | |||||

|---|---|---|---|---|---|---|---|---|

| 600 | 620 | 640 | 660 | 680 | ||||

| Pressure Pr (MPa) | Temperature Tr (°C) | Time to Rupture, tr (h) | ||||||

| Repair welded joint made from materials after 169,000 h service Designation ZS1 | - | - | 50 | (3127) | 1197 | 559 | 234 | 120 |

| Repair welded joint made from material in the as-received condition and material after 169,000 h service Designation ZS2 | - | - | (3161) | 1178 | 822 | 179 | 103 | |

| Parent material after 169,000 h service Designation PM | 13.0 | 538 | 55 | (286) | (1365) | 559 | 429 | 196 |

| Repair welded joint made from materials after 169,000 h service Designation ZS1 | - | - | 2834 | 672 | 373 | 189 | 97 | |

| Repair welded joint made from material in the as-received condition and material after 169,000 h service Designation ZS2 | - | - | (2592) | 1297 | 481 | 191 | 84 | |

| Test Specimen Designation | Adopted Operating Stress σr (MPa) | Adopted Further Operation Temperature Tr (°C) | Estimated Life Time (h) | |

|---|---|---|---|---|

| Residual tre | Disposable Residual Life tb (about 0.6 tre) | |||

| Joint from materials after long-term service Designation ZS1 | 50 | 538 | 25,000 | 15,000 |

| Joint from material in the as-received condition and material after long-term service Designation ZS2 | 60,000 | 36,000 | ||

| Native material Designation PM1 | 55 | 20,000 | 12,000 | |

| Joint from materials after long-term service Designation ZS1 | 23,000 | 13,800 | ||

| Joint from material in the as-received condition and material after long-term service Designation ZS2 | 58,000 | 34,800 | ||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sroka, M.; Zieliński, A.; Dziuba-Kałuża, M.; Kremzer, M.; Macek, M.; Jasiński, A. Assessment of the Residual Life of Steam Pipeline Material beyond the Computational Working Time. Metals 2017, 7, 82. https://doi.org/10.3390/met7030082

Sroka M, Zieliński A, Dziuba-Kałuża M, Kremzer M, Macek M, Jasiński A. Assessment of the Residual Life of Steam Pipeline Material beyond the Computational Working Time. Metals. 2017; 7(3):82. https://doi.org/10.3390/met7030082

Chicago/Turabian StyleSroka, Marek, Adam Zieliński, Maria Dziuba-Kałuża, Marek Kremzer, Magdalena Macek, and Artur Jasiński. 2017. "Assessment of the Residual Life of Steam Pipeline Material beyond the Computational Working Time" Metals 7, no. 3: 82. https://doi.org/10.3390/met7030082