The Effects of Prestrain and Subsequent Annealing on Tensile Properties of CP-Ti

Abstract

:1. Introduction

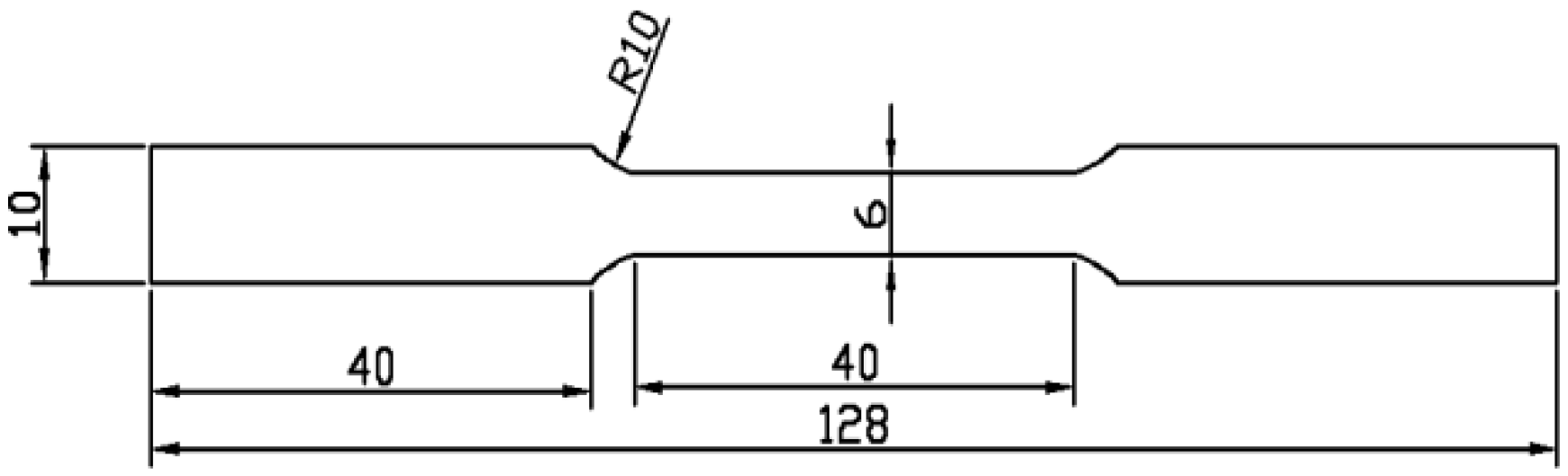

2. Experimental Materials and Procedures

3. Results and Discussion

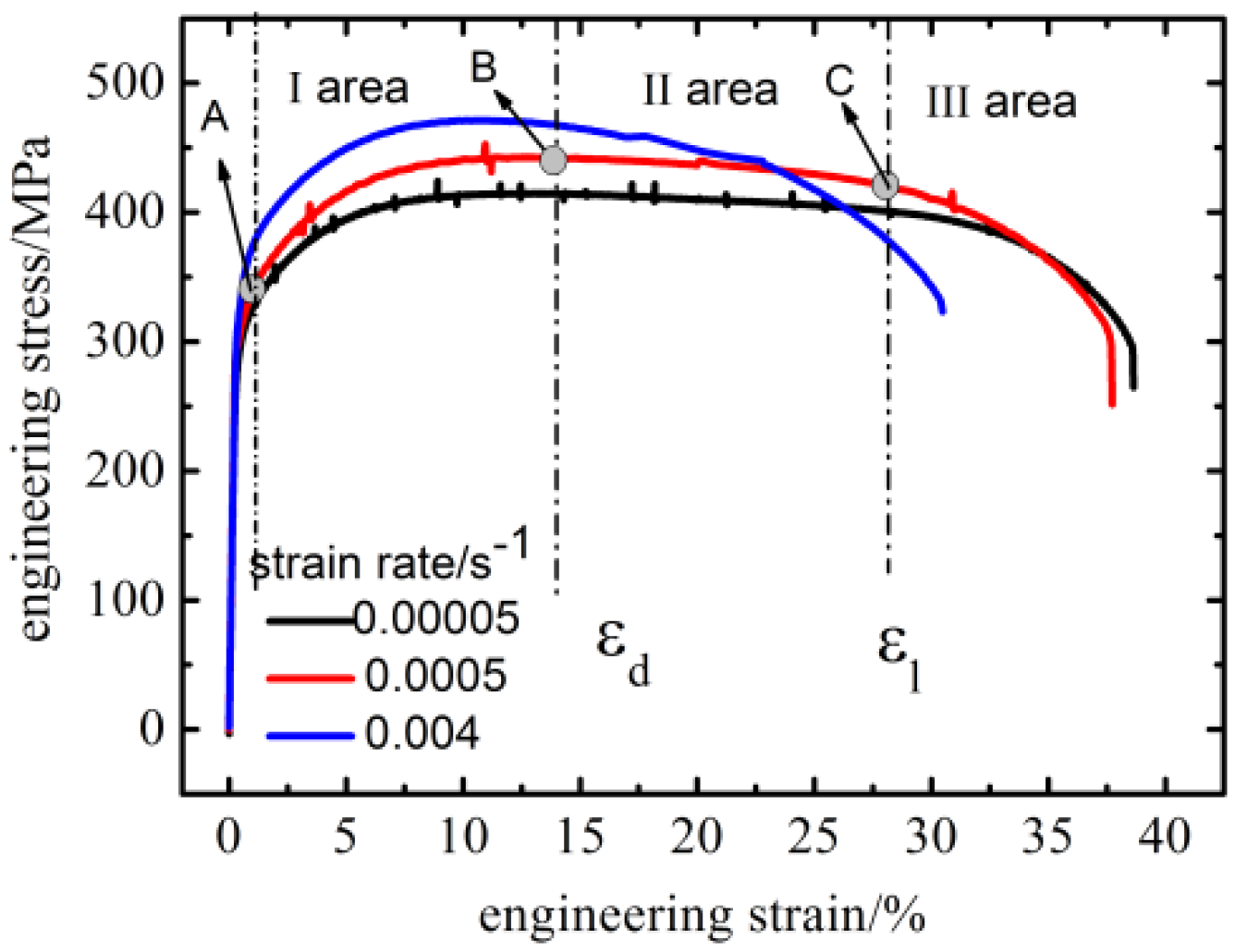

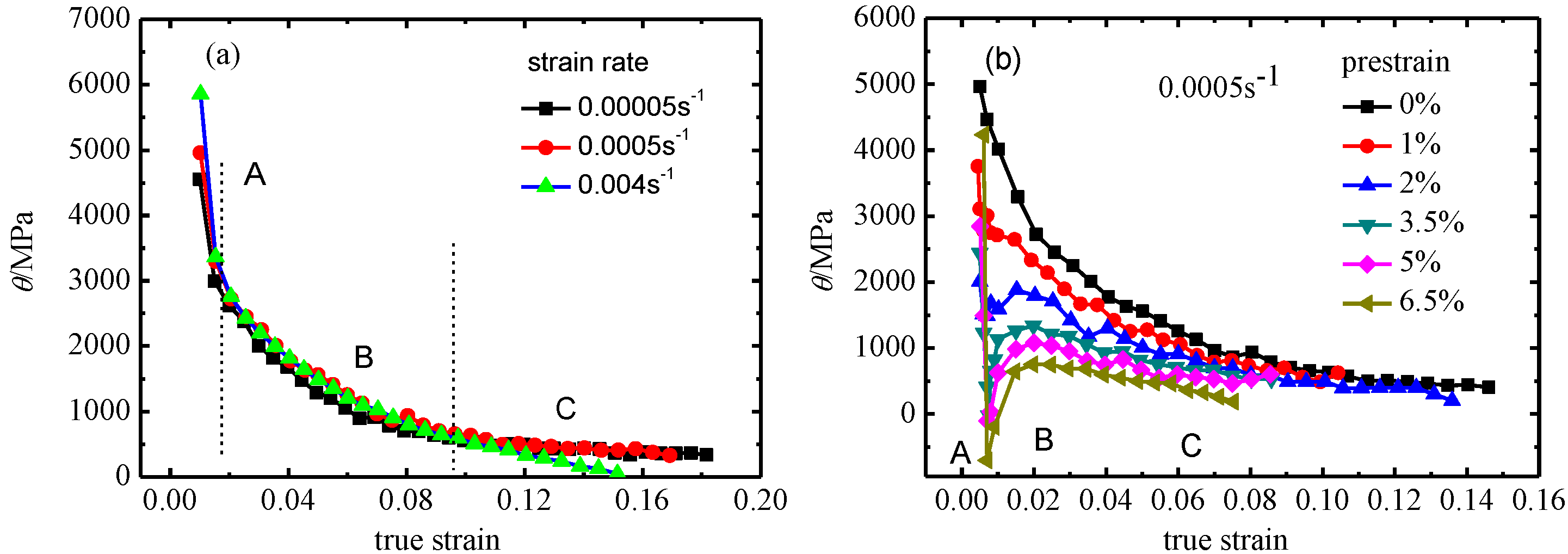

3.1. Tensile Properties of As-Received Commercial Pure (CP)-Ti

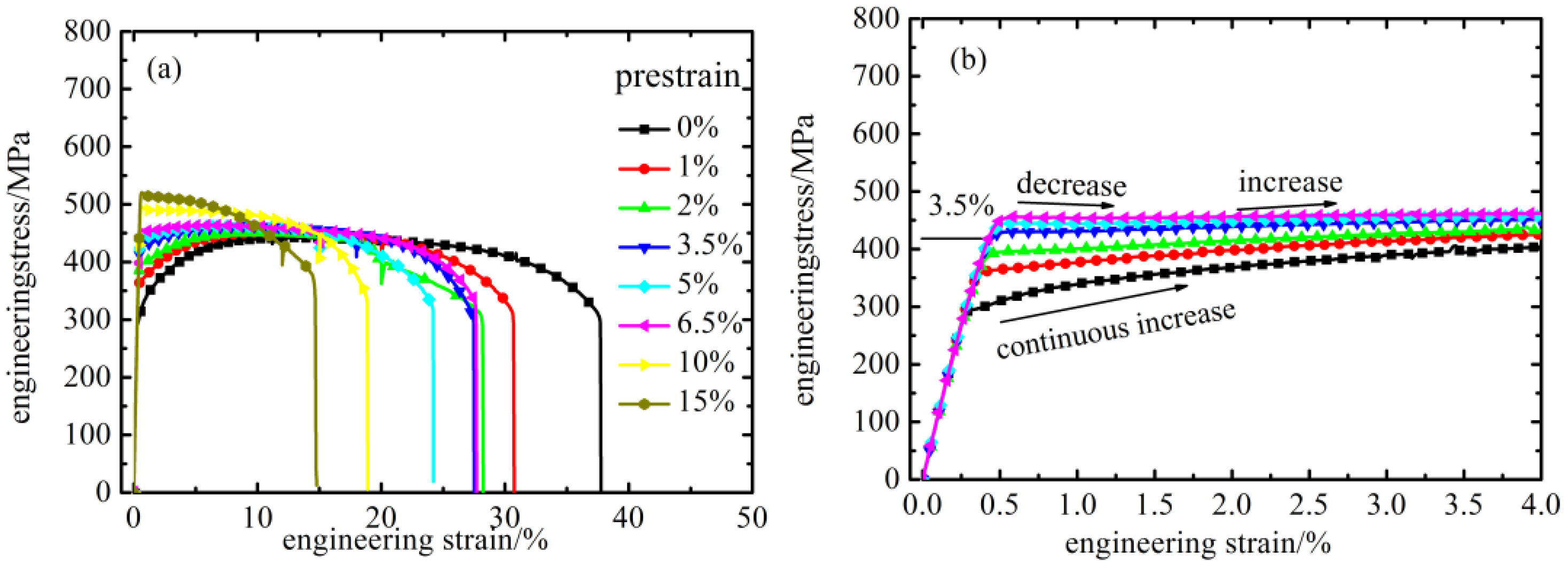

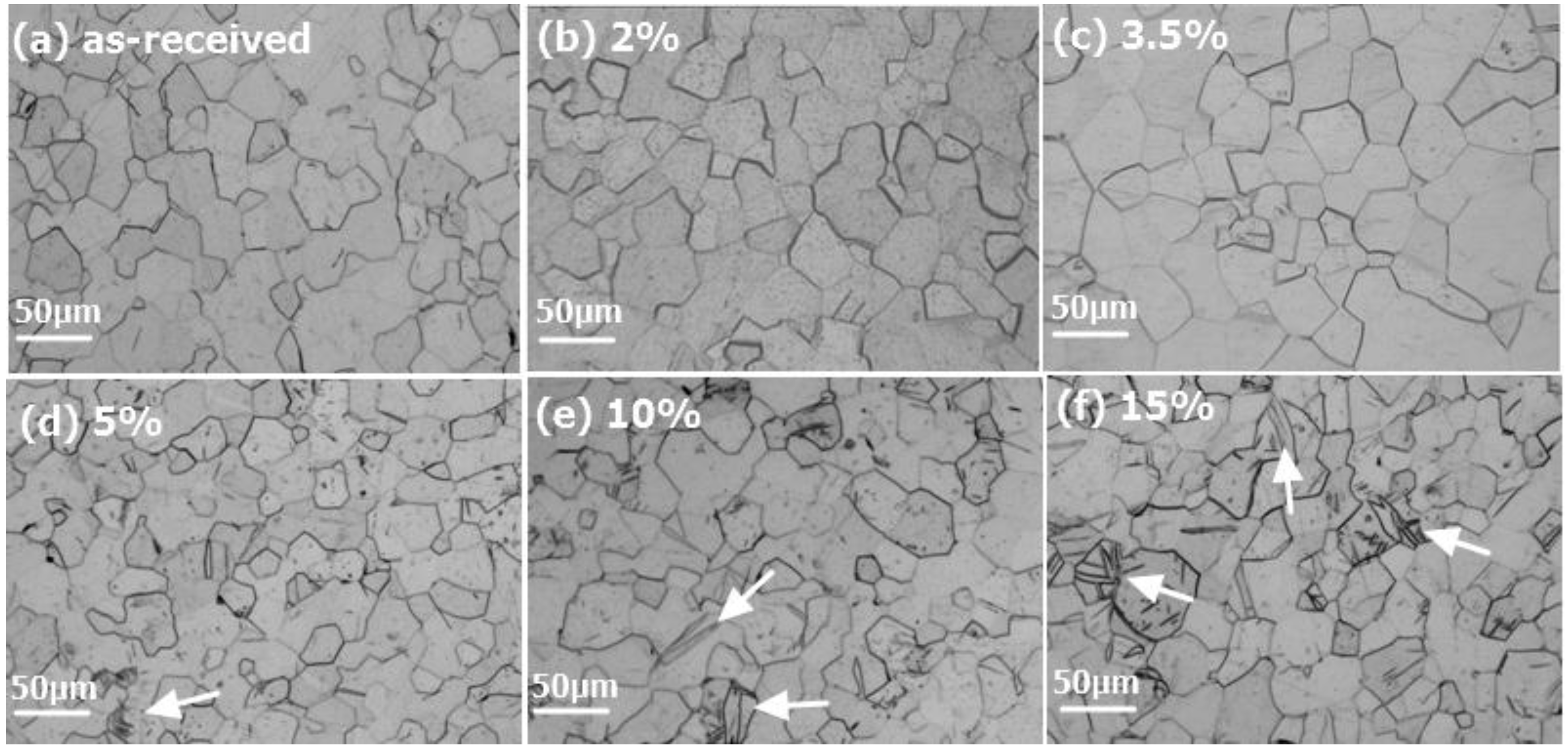

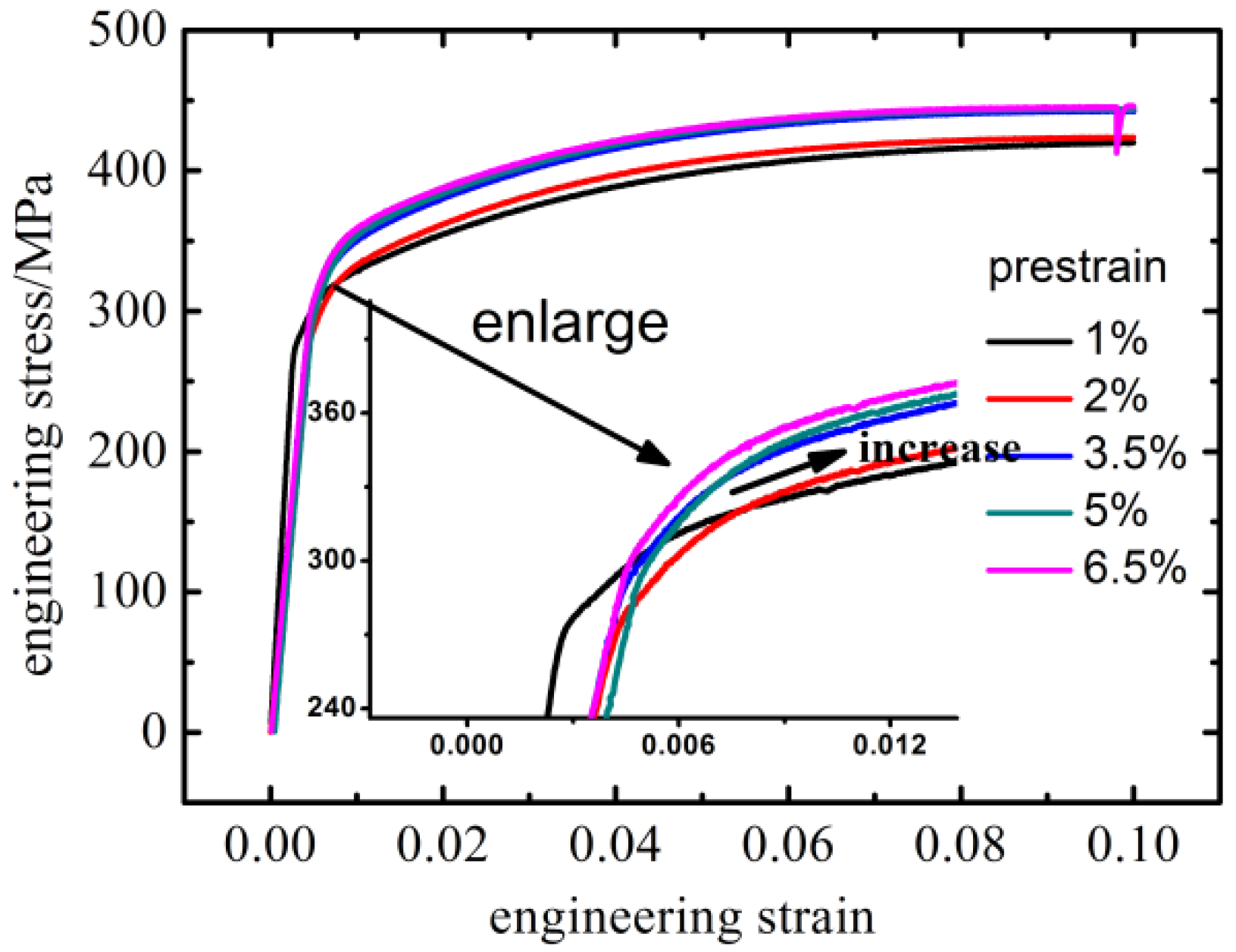

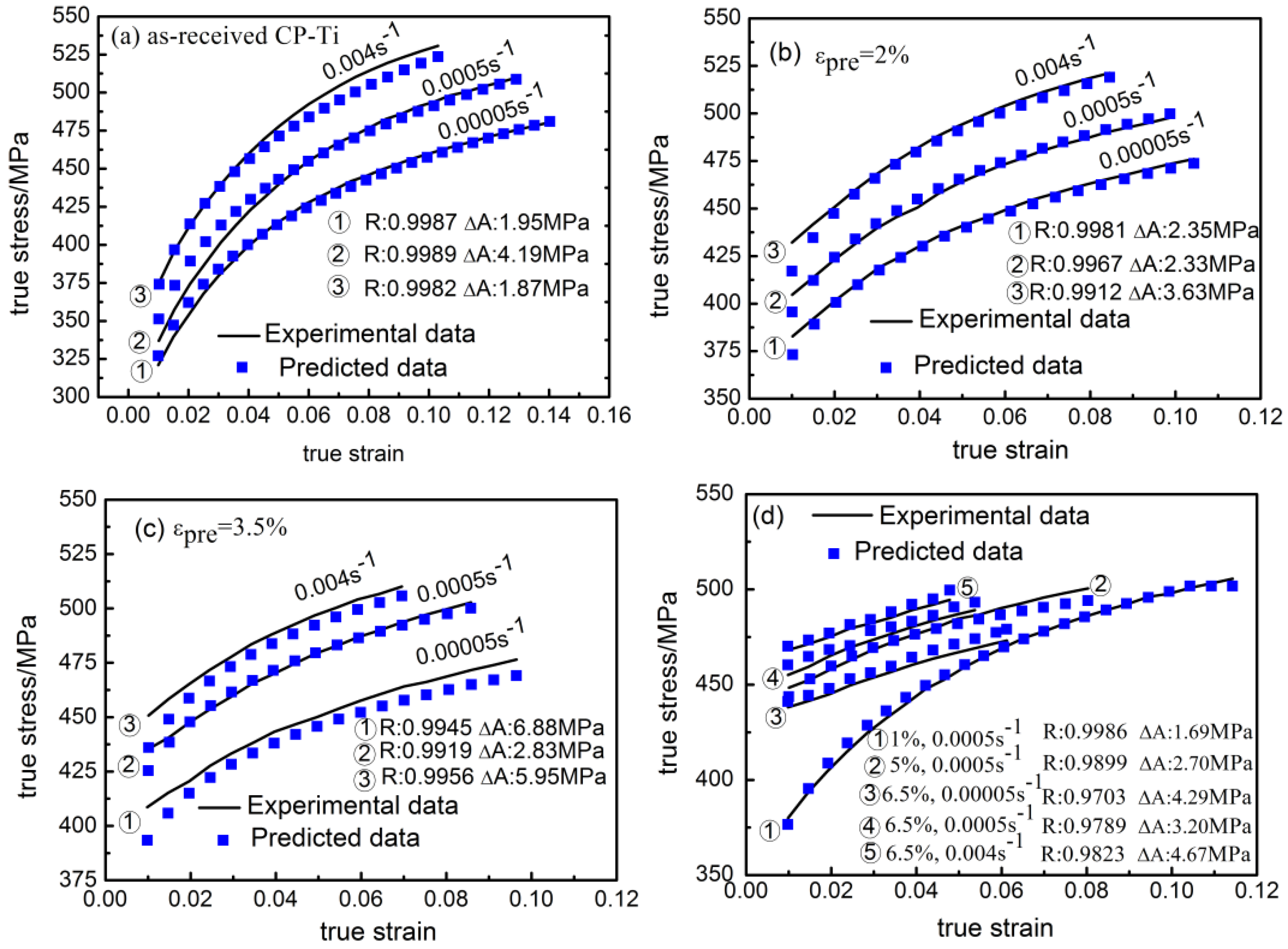

3.2. Tensile Properties of Prestrained Specimens

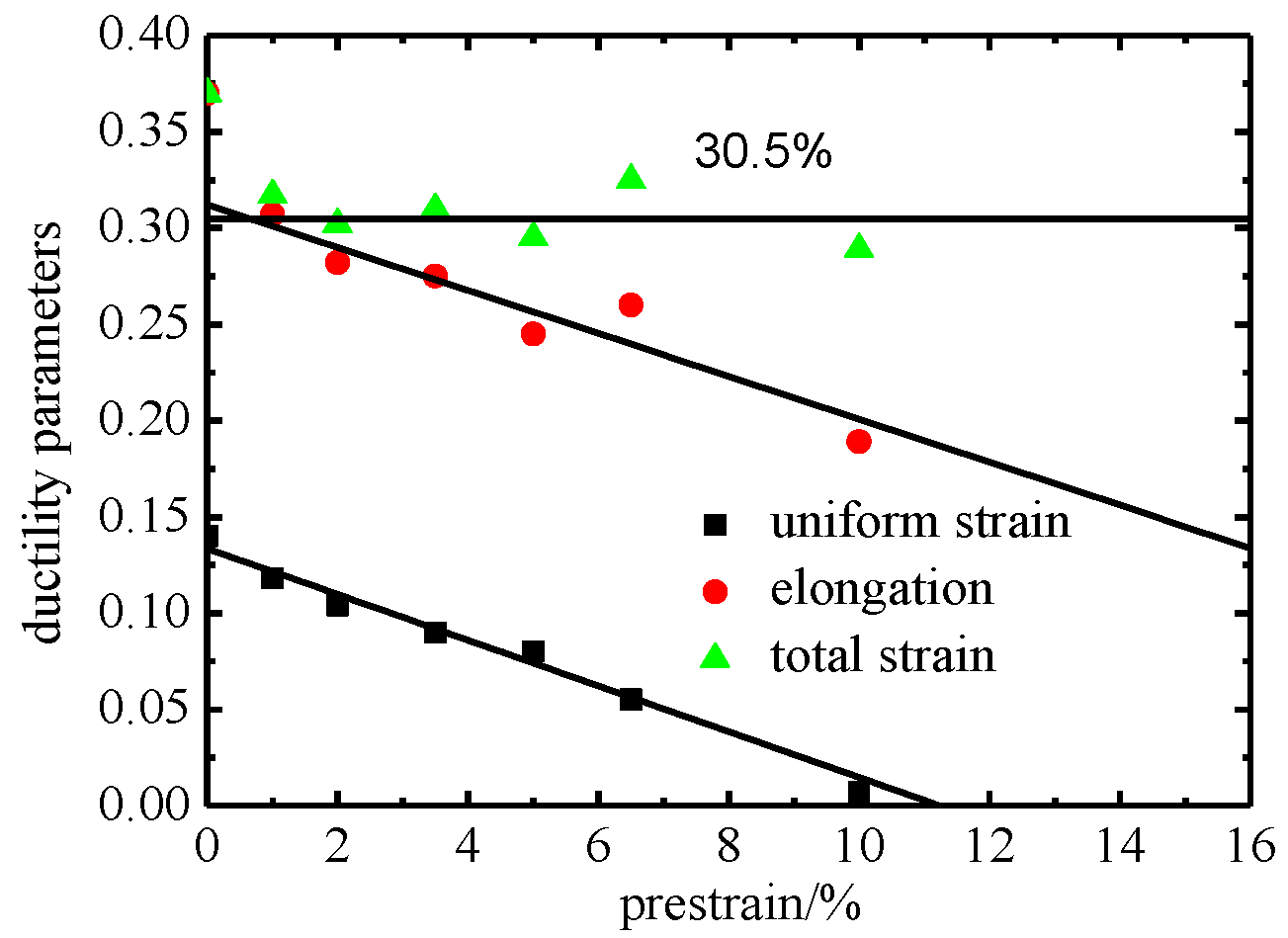

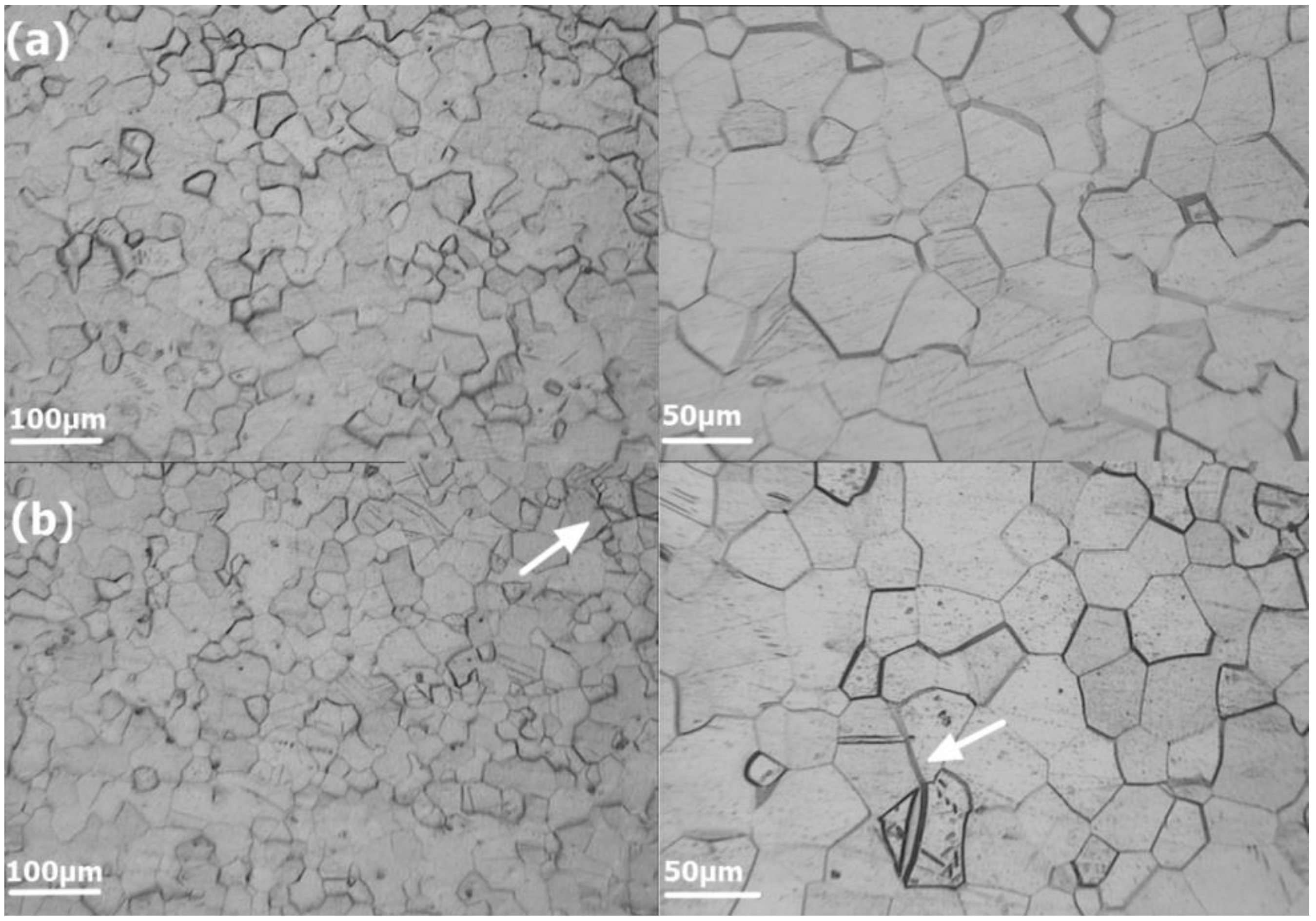

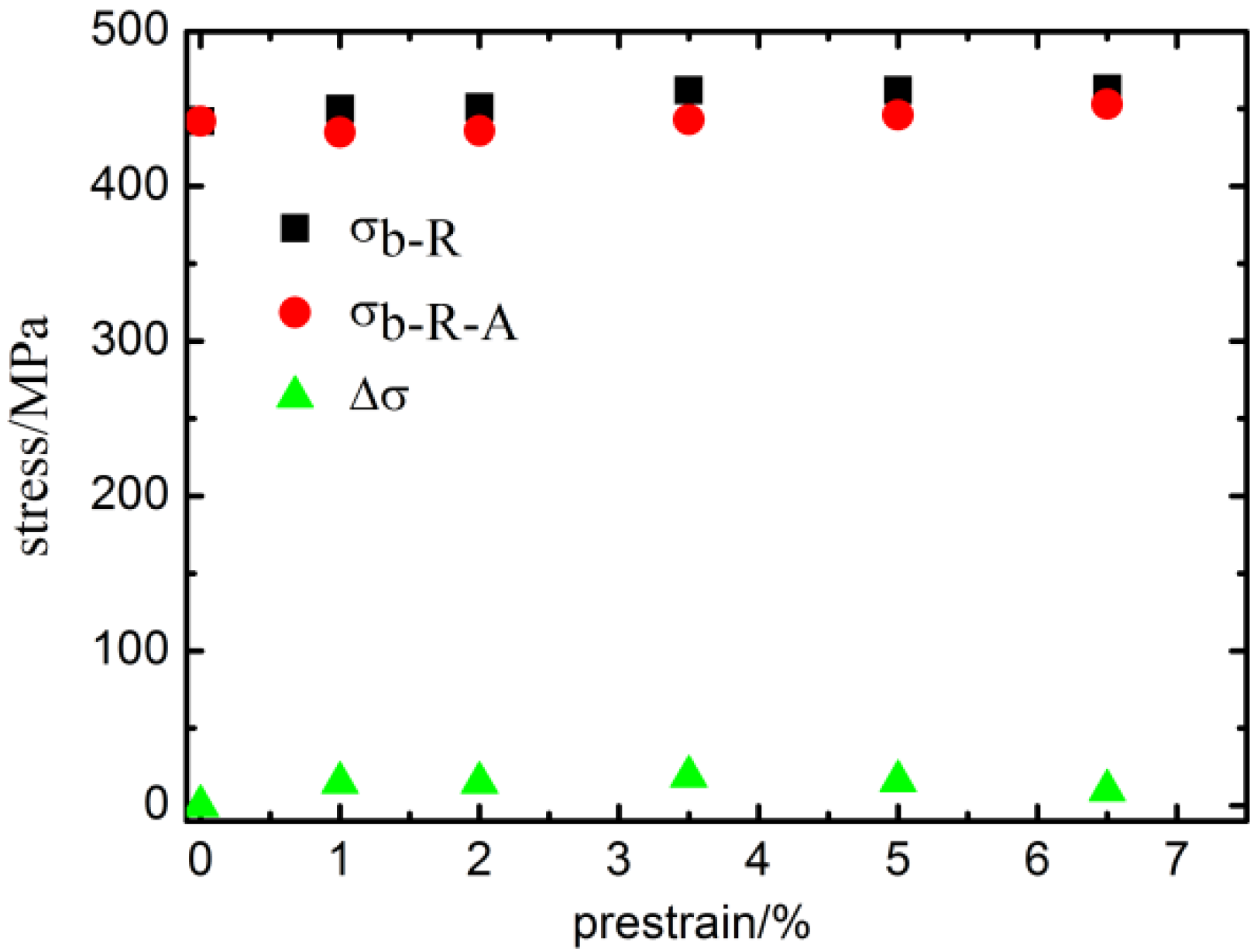

3.3. Tensile Properties of Prestrained Specimens after Annealing

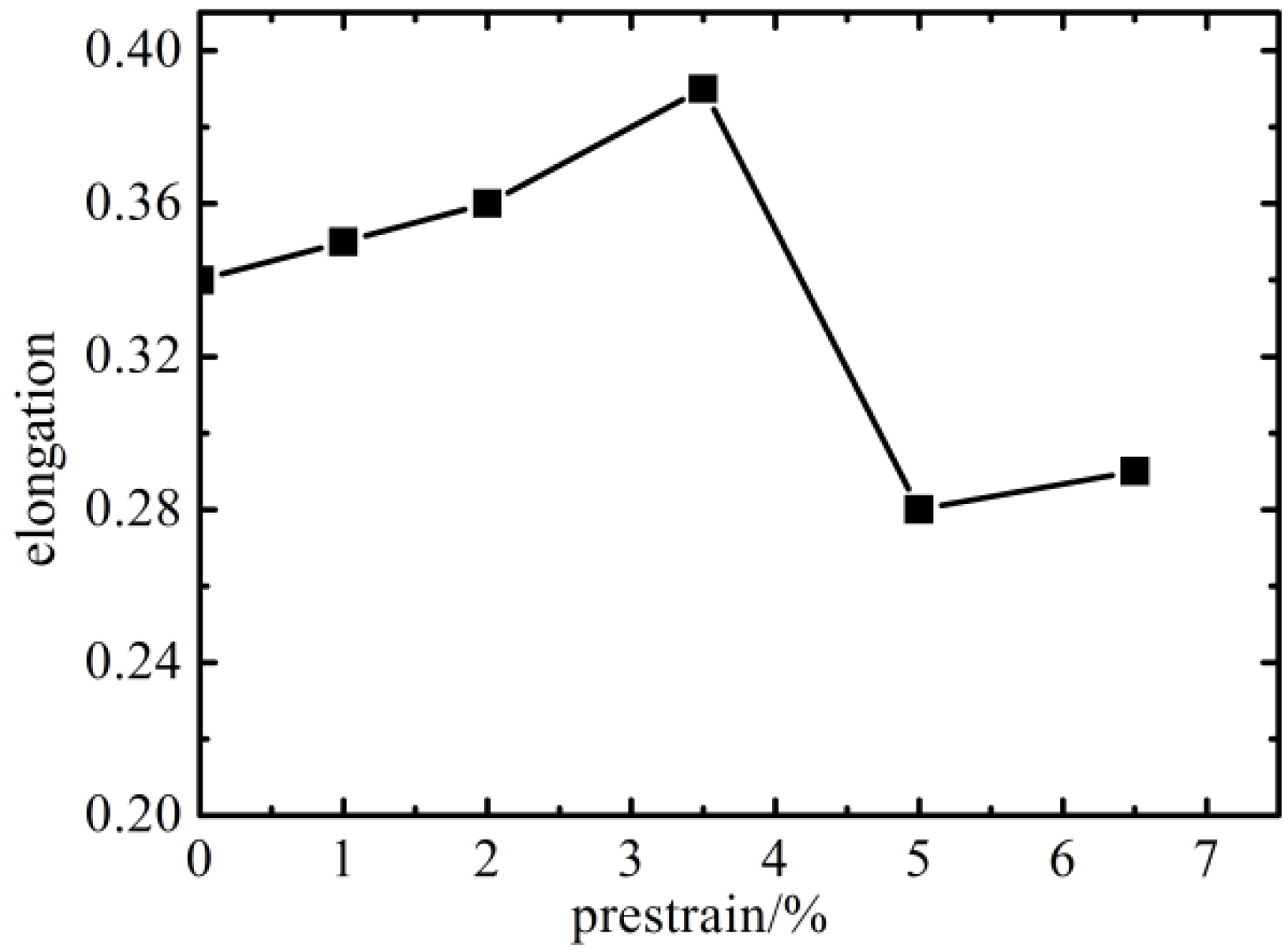

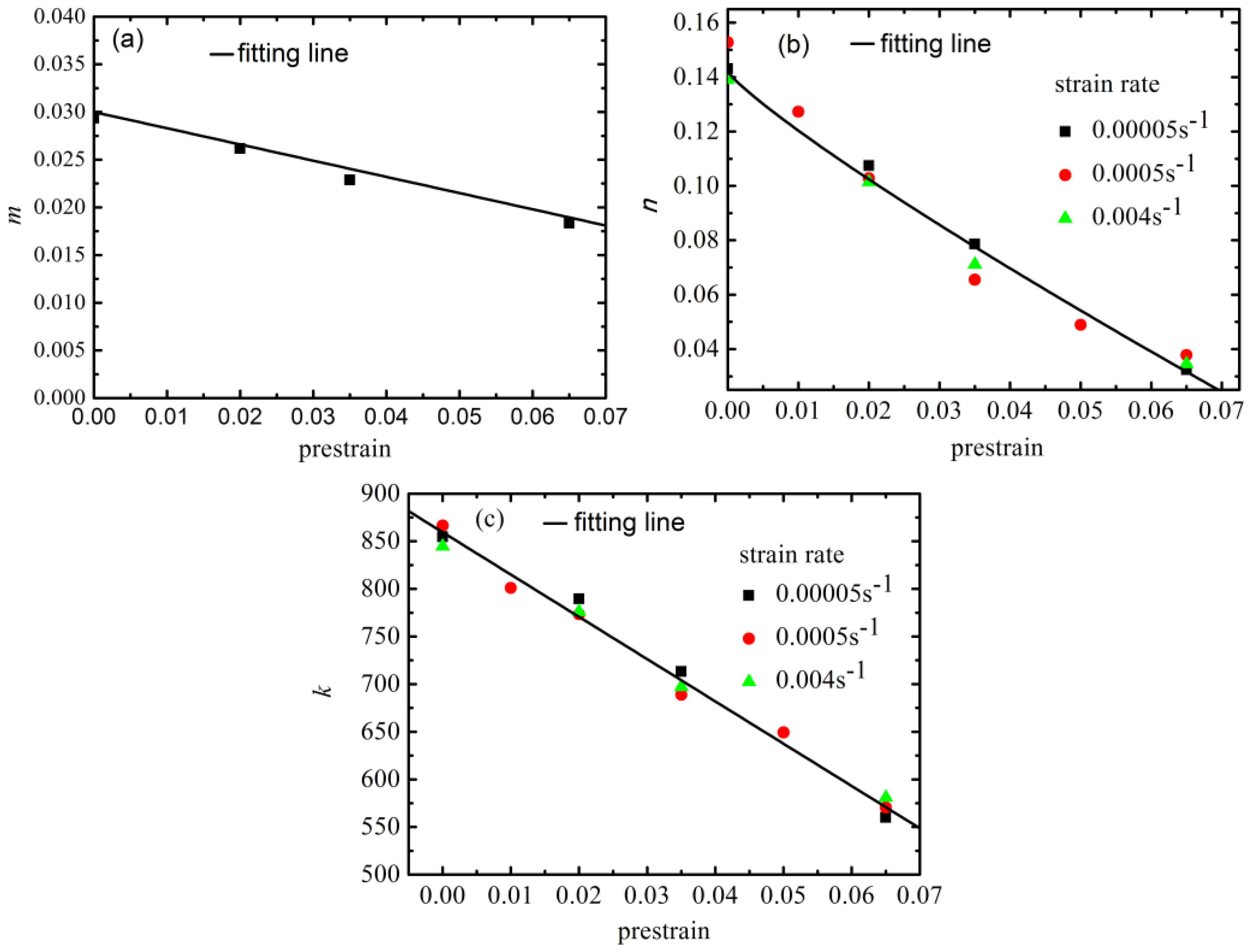

3.4. Constitutive Model of Prestrained CP-Ti

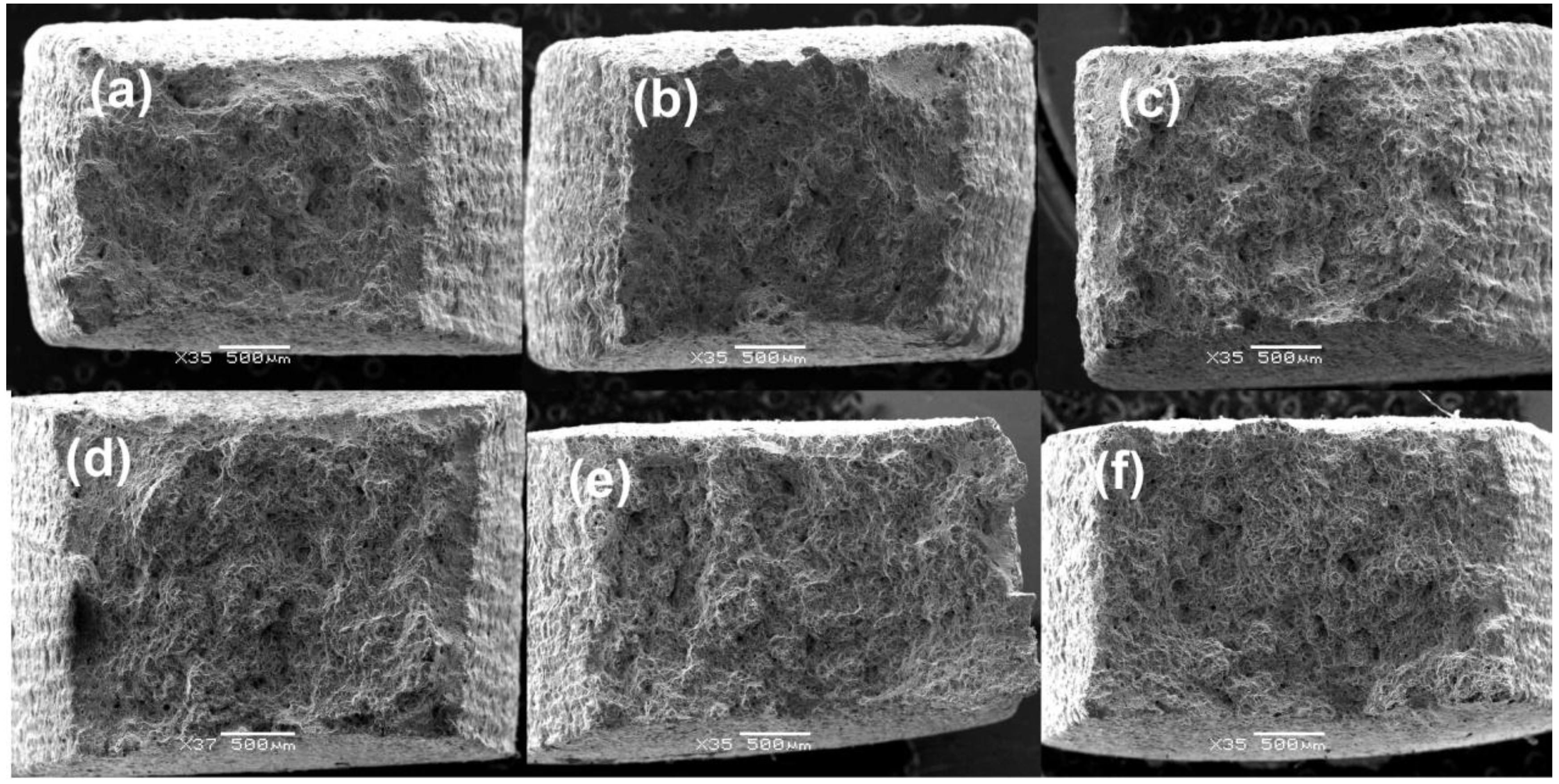

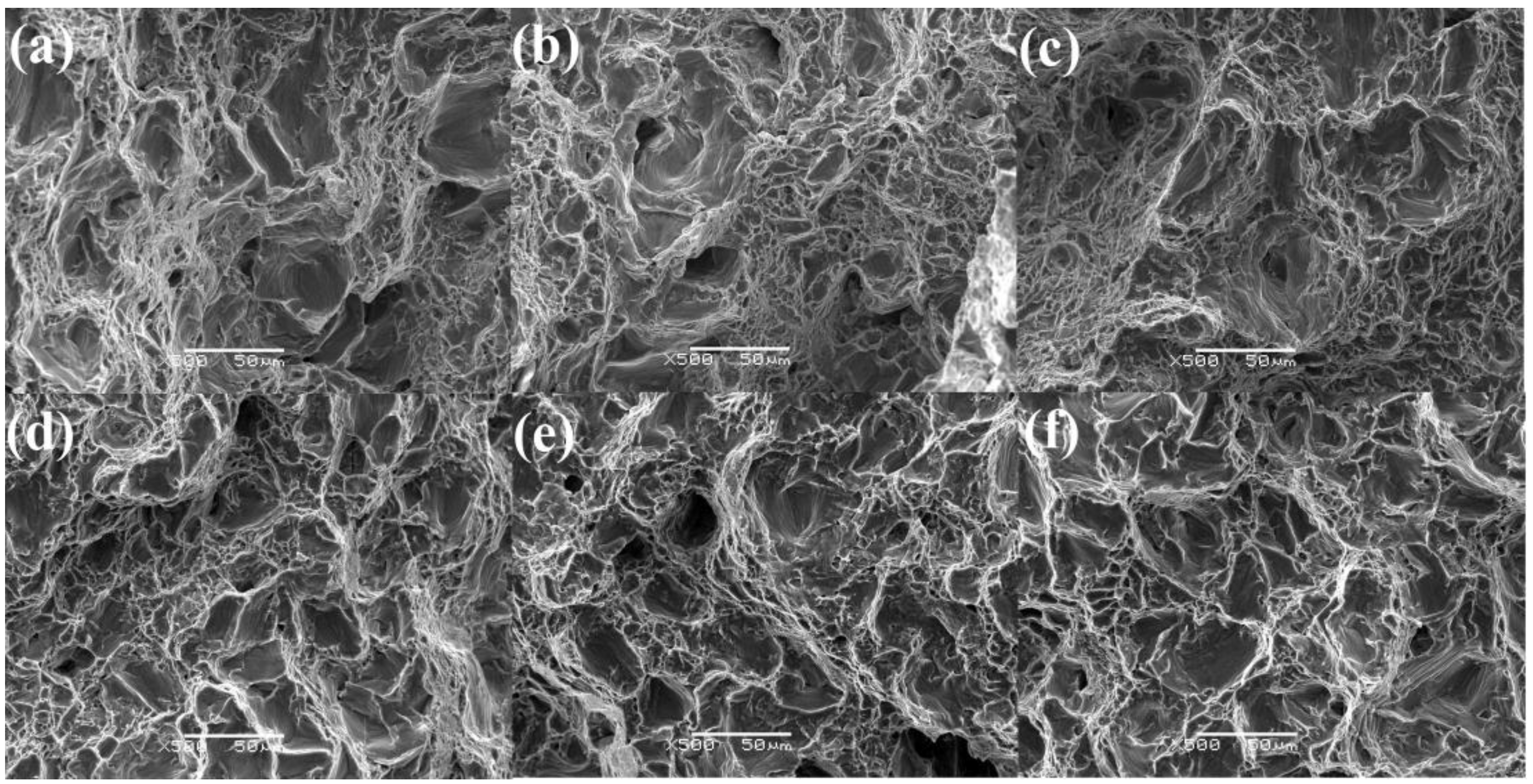

3.5. Fracture Behavior

4. Conclusions

- Engineering yield strength and tensile strength increase with the tensile prestrain. The relationship between prestrain and yield strength can be described by power law. Elongation and uniform strain decrease linearly with increasing the tensile prestrain, and total strain is almost constant, which is slightly less than as-received CP-Ti.

- At the condition of prestrain higher than 3.5%, yield plateau is observed in the engineering stress–strain curves. Through metallographic observations and heat treatment, considerable number of dislocations produced in prestrain is determined as the factor account for the appearance of yield plateau during reloading.

- Dislocations play an important role in strain hardening along cold rolling direction tension. With the increase of strain, the contribution on strain hardening from both the dislocation-associated mechanisms and other mechanisms increases.

- The strain rate sensitivity exponent, strain hardening exponent and strength coefficient decrease with the increase of prestrain. Flow stress of prestrained CP-Ti is predicted accurately by the modified Fields-Backofen model.

- With annealing at 500 °C and 40 min, the 3.5% prestrained specimen shows the highest ductility, and its yield strength is enhanced. The more ductile deformation features on the fracture surfaces after annealing confirms that the ductility of prestrained CP-Ti can be improved by annealing.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ahmed, I.I.; Grant, B.; Sherry, A.H.; Quinta, J. Deformation path effects on the internal stress development in cold worked austenitic steel deformed in tension. Mater. Sci. Eng. A 2014, 614, 326–337. [Google Scholar] [CrossRef]

- Zhang, L.C.; Timokhina, I.B.; La Fontaine, A.; Ringer, S.P.; Hodgson, P.D.; Pereloma, E.V. Effect of pre-straining and bake hardening on the microstructure and mechanical properties of CMnSi TRIP steels. Metall. Ital. 2009, 101, 49–55. [Google Scholar]

- Pereloma, E.; Beladi, H.; Zhang, L.C.; Timokhina, I. Understanding the behavior of advanced high-strength steels using atom probe tomography. Metall. Mater. Trans. A 2012, 43, 3958–3971. [Google Scholar] [CrossRef]

- Baeka, J.; Kim, Y.; Kim, C.; Kim, W.; Seok, C. Effects of pre-strain on the mechanical properties of API 5L X65 pipe. Mater. Sci. Eng. A 2010, 527, 1473–1479. [Google Scholar] [CrossRef]

- Robertson, L.T.; Hilditch, T.B.; Hodgson, P.D. The effect of prestrain and bake hardening on the low-cycle fatigue properties of TRIP steel. Int. J. Fatigue 2008, 30, 587–594. [Google Scholar] [CrossRef]

- Lee, W.S.; Lin, C.F. Effects of prestrain and strain rate on dynamic deformation characteristics of 304L stainless steel: Part 1—Mechanical behavior. Mater. Sci. Technol. 2002, 18, 869–876. [Google Scholar] [CrossRef]

- Lee, W.S.; Lin, C.F. Effects of prestrain and strain rate on dynamic deformation characteristics of 304L stainless steel: Part 2—Microstructural study. Mater. Sci. Technol. 2002, 18, 877–884. [Google Scholar] [CrossRef]

- Whittaker, M.T.; Evans, W.J. Effect of prestrain on the fatigue properties of Ti834. Int. J. Fatigue 2009, 31, 1751–1757. [Google Scholar] [CrossRef]

- Whittaker, M.; Jones, P.; Pleydell-Pearce, C.; Rugg, D.; Williams, S. The effect of prestrain on low and high temperature creep in Ti834. Mater. Sci. Eng. A 2010, 527, 6683–6689. [Google Scholar] [CrossRef]

- Song, Z.Y.; Sun, Q.Y.; Xiao, L.; Liu, L.; Sun, J. Effect of prestrain and aging treatment on microstructures and tensile properties of Ti–10Mo–8V–1Fe–3.5Al alloy. Mater. Sci. Eng. A 2010, 527, 691–698. [Google Scholar] [CrossRef]

- Werber, A.; Liewald, M. Measurement and analysis of differential work hardening behavior of pure titanium sheet using spline function. Int. J. Mater. Form. 2011, 4, 193–204. [Google Scholar]

- Wowk, D.; Pilkey, K. Effect of prestrain with a path change on the strain rate sensitivity of AA5754 sheet. Mater. Sci. Eng. A 2009, 520, 174–178. [Google Scholar] [CrossRef]

- Sarker, D.; Friedman, J.; Chen, D.L. Influence of pre-strain on de-twinning activity in an extruded AM30 magnesium alloy. Mater. Sci. Eng. A 2014, 605, 73–79. [Google Scholar] [CrossRef]

- Sarker, D.; Chen, D.L. Dependence of compressive deformation on pre-strain and loading direction in an extruded magnesium alloy: Texture, twinning and de-twinning. Mater. Sci. Eng. A 2014, 596, 134–144. [Google Scholar] [CrossRef]

- Hama, T.; Nagao, H.; Kuchinomachi, Y.; Takuda, H. Effect of pre-strain on work-hardening behavior of magnesium alloy sheets upon cyclic loading. Mater. Sci. Eng. A 2014, 591, 69–77. [Google Scholar] [CrossRef]

- Chen, L.; Li, J.; Zhang, Y.; Lu, W.; Zhang, L.C.; Wang, L.; Zhang, D. Effect of low-temperature pre-deformation on precipitation behavior and microstructure of a Zr-Sn-Nb-Fe-Cu-O alloy during fabrication. J. Nucl. Sci. Technol. 2016, 53, 496–507. [Google Scholar] [CrossRef]

- Zherebtsov, S.V.; Dyakonov, G.S.; Salem, A.A.; Malysheva, S.P.; Salishchev, G.; Semiatin, S.L. Evolution of grain and subgrain structure during cold rolling of commercial-purity titanium. Mater. Sci. Eng. A 2011, 528, 3474–3479. [Google Scholar] [CrossRef]

- Chun, Y.B.; Yu, S.H.; Semiatin, S.L.; Hwang, S.K. Effect of deformation twinning on microstructure and texture evolution during cold rolling of CP-titanium. Mater. Sci. Eng. A 2005, 398, 209–219. [Google Scholar] [CrossRef]

- Nasiri-Abarbekoh, H.; Ekrami, A.; Ziaei-Moayyed, A.A.; Shohani, M. Effects of rolling reduction on mechanical properties anisotropy of commercially pure titanium. Mater. Des. 2012, 34, 268–274. [Google Scholar] [CrossRef]

- Chichili, D.R.; Ramseh, K.T.; Hemker, K.J. The high-strain-rate response of alpha-titanium: Experiments, deformation mechanisms and modeling. Acta Mater. 1998, 46, 1025–1043. [Google Scholar] [CrossRef]

- Peng, J.; Zhou, C.Y.; Dai, Q.; He, X.H. The temperature and stress dependent primary creep of CP-Ti at low and intermediate temperature. Mater. Sci. Eng. A 2014, 611, 123–135. [Google Scholar] [CrossRef]

- Zhao, X.C.; Yang, X.R.; Liu, X.Y.; Wang, C.T.; Huang, Y.; Langdon, T.G. Processing of commercial purity titanium by ECAP using a 90 degrees die at room temperature. Mater. Sci. Eng. A 2014, 607, 482–489. [Google Scholar] [CrossRef]

- Sordi, V.L.; Ferrante, M.; Kawasaki, M.; Langdon, T.G. Microstructure and tensile strength of grade 2 titanium processed by equal-channel angular pressing. J. Mater. Sci. 2012, 47, 7870–7876. [Google Scholar] [CrossRef]

- Roodposhit, P.S.; Farahbakhsh, N.; Sarkar, A.; Murty, K.L. Microstructural approach to equal channel angular processing of commercially pure titanium—A review. T. Nonferr. Metal. Soc. 2015, 25, 1353–1366. [Google Scholar] [CrossRef]

- Salem, A.A.; Kalidindi, S.R.; Doherty, R.D. Strain hardening of titanium: Role of deformation twinning. Acta Mater. 2003, 51, 4225–4237. [Google Scholar] [CrossRef]

- Salem, A.A.; Kalidindi, S.R.; Doherty, R.D. Strain hardening regimes and microstructure evolution during large strain compression of high purity titanium. Scr. Mater. 2002, 46, 419–423. [Google Scholar] [CrossRef]

- Becker, H.; Pantleon, W. Work-hardening stages and deformation mechanism maps during tensile deformation of commercially pure titanium. Comp. Mater. Sci. 2013, 76, 52–59. [Google Scholar] [CrossRef]

- Hama, T.; Nagao, H.; Kobuki, A.; Fujimoto, H.; Takuda, H. Work-hardening and twinning behaviors in a commercially pure titanium sheet under various loading paths. Mater. Sci. Eng. A 2015, 620, 390–398. [Google Scholar] [CrossRef] [Green Version]

- Li, L.; Zhang, Z.; Shen, G. Effect of Grain Size on the Tensile Deformation Mechanisms of Commercial Pure Titanium as Revealed by Acoustic Emission. J. Mater. Eng. Perform. 2015, 24, 1975–1986. [Google Scholar] [CrossRef]

- Ghaderi, A.; Barnett, M. Sensitivity of deformation twinning to grain size in titanium and magnesium. Acta Mater. 2011, 59, 7824–7839. [Google Scholar] [CrossRef]

- Amouzou, K.E.A.; Richeton, T.; Roth, A.; Lebyodkin, M.A.; Lebedkina, T.A. Micromechanical modeling of hardening mechanisms in commercially pure α-titanium in tensile condition. Int. J. Plast. 2016, 80, 222–240. [Google Scholar] [CrossRef]

- Won, W.J.; Park, K.T.; Hong, S.G.; Lee, C.S. Anisotropic yielding behavior of rolling textured high purity titanium. Mater. Sci. Eng. A 2015, 637, 215–221. [Google Scholar] [CrossRef]

- Roth, A.; Lebyodkin, M.A.; Lebedkina, T.A.; Lecomte, J.S.; Richeton, T.; Amouzou, K.E.A. Mechanisms of anisotropy of mechanical properties of α-titanium in tension conditions. Mater. Sci. Eng. A 2014, 596, 236–243. [Google Scholar] [CrossRef]

- Barkia, B.; Doquet, V.; Couzini, J.; Guillot, I.; Hripre, E. In situ monitoring of the deformation mechanisms in titanium with different oxygen contents. Mater. Sci. Eng. A 2015, 636, 91–102. [Google Scholar] [CrossRef]

- Shi, J.; Sha, A.X. GJB 3763A. In Heat Treatment for Titanium and Titanium Alloys; Defense Science and Technology Industry Committee: Beijing, China, 2004. [Google Scholar]

- Fields, D.S.; Backofen, W.A. Determination of strain hardening characteristics by torsion testing. Proc. Am. Soc. Test. Mater. 1957, 57, 1259–1272. [Google Scholar]

- Chuluunbat, T.; Lu, C.; Kostryzhev, A.; Tieu, K. Investigation of X70 line pipe steel fracture during single edge-notched tensile testing using acoustic emission monitoring. Mater. Sci. Eng. A 2015, 640, 471–479. [Google Scholar] [CrossRef]

- Chauhan, A.; Litvinov, D.; Aktaa, J. High temperature tensile properties and fracture characteristics of bimodal 12Cr-ODS steel. J. Nucl. Mater. 2016, 468, 1–8. [Google Scholar] [CrossRef]

| Element | Ti | Fe | C | N | H | O |

|---|---|---|---|---|---|---|

| Composition | Balance | 0.06 | 0.01 | <0.01 | 0.001 | 0.12 |

| Prestrain (εpre)/% | Annealing | |||

|---|---|---|---|---|

| 500 °C, 30 min | 500 °C, 40 min | 500 °C, 60 min | 600 °C, 30 min | |

| 1 | √ | √ | - | √ |

| 2 | √ | √ | √ | - |

| 3.5 | √ | √ | √ | √ |

| 5 | √ | √ | √ | - |

| 6.5 | √ | √ | - | √ |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, L.; Zhou, C.-Y.; He, X.-H. The Effects of Prestrain and Subsequent Annealing on Tensile Properties of CP-Ti. Metals 2017, 7, 99. https://doi.org/10.3390/met7030099

Chang L, Zhou C-Y, He X-H. The Effects of Prestrain and Subsequent Annealing on Tensile Properties of CP-Ti. Metals. 2017; 7(3):99. https://doi.org/10.3390/met7030099

Chicago/Turabian StyleChang, Le, Chang-Yu Zhou, and Xiao-Hua He. 2017. "The Effects of Prestrain and Subsequent Annealing on Tensile Properties of CP-Ti" Metals 7, no. 3: 99. https://doi.org/10.3390/met7030099