Improved Solar Absorptance of WC/Co Solar Selective Absorbing Coating with Multimodal WC Particles

Abstract

:1. Introduction

2. Materials and Methods

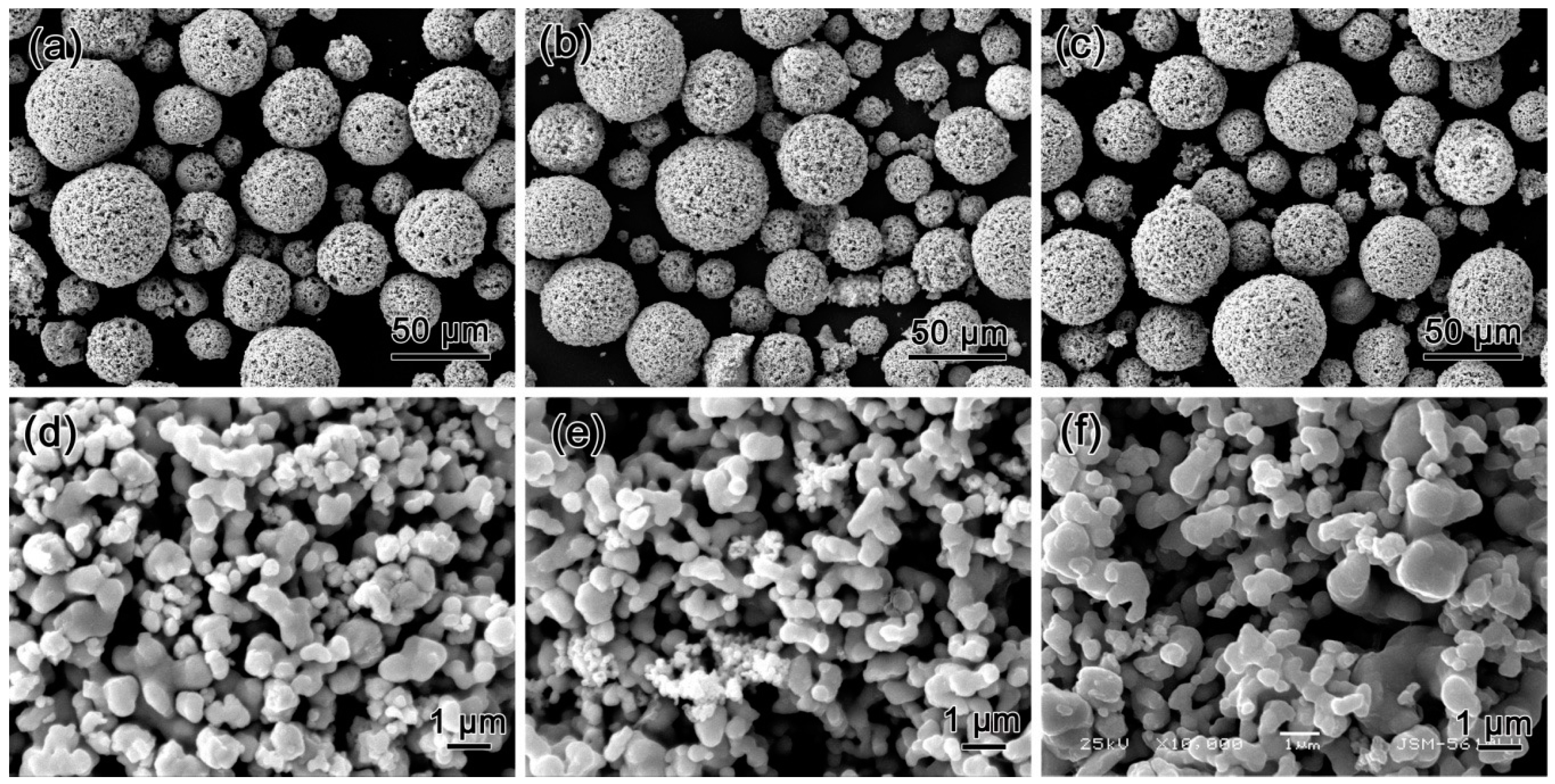

2.1. Agglomerated Feedstock Preparation

2.2. Coating Preparation

2.3. Solar Absorbing Property and Coating Characterization

3. Results

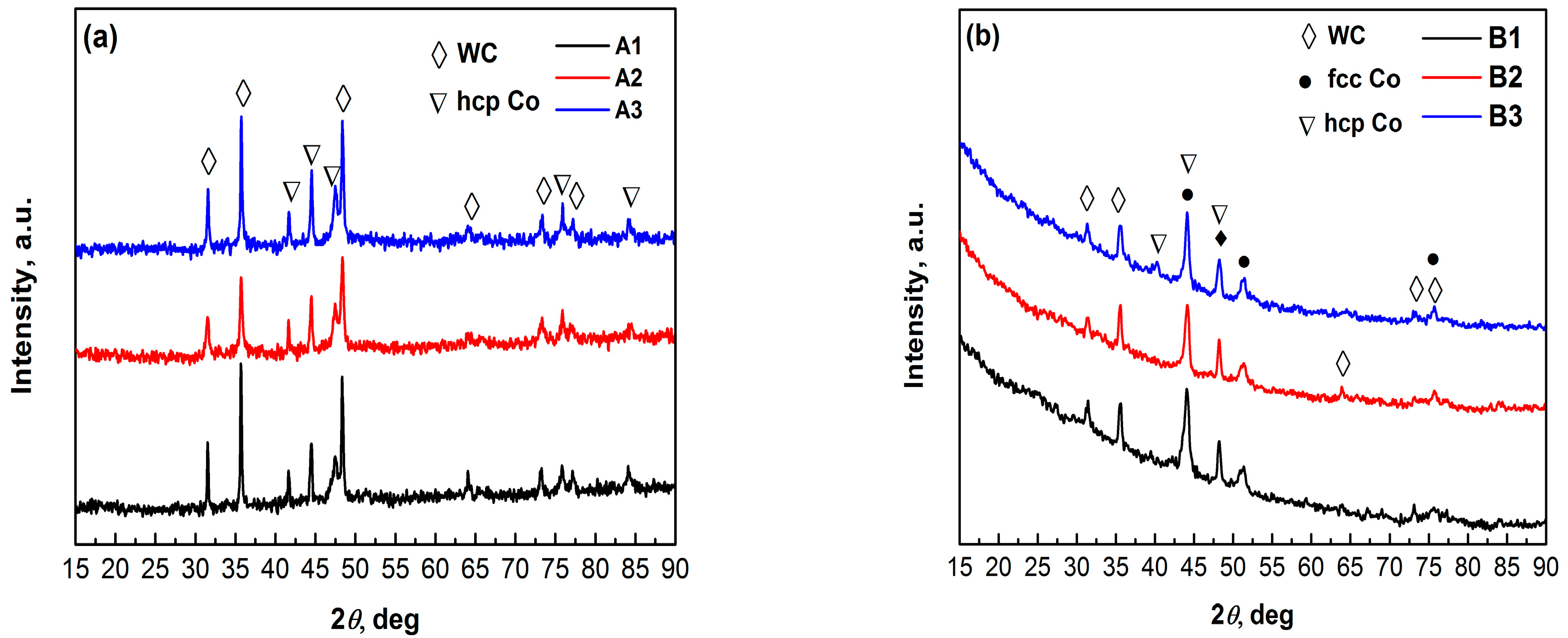

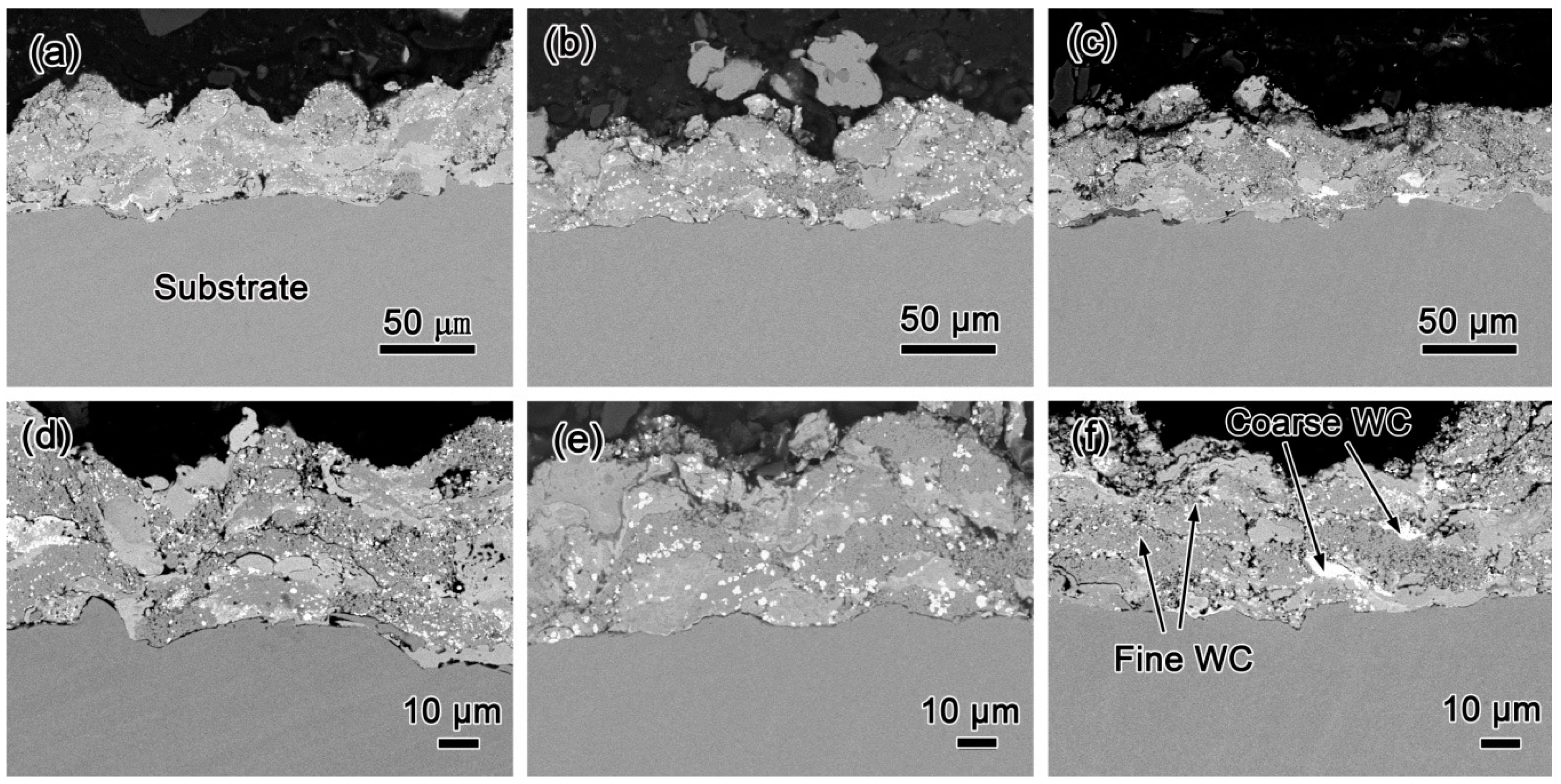

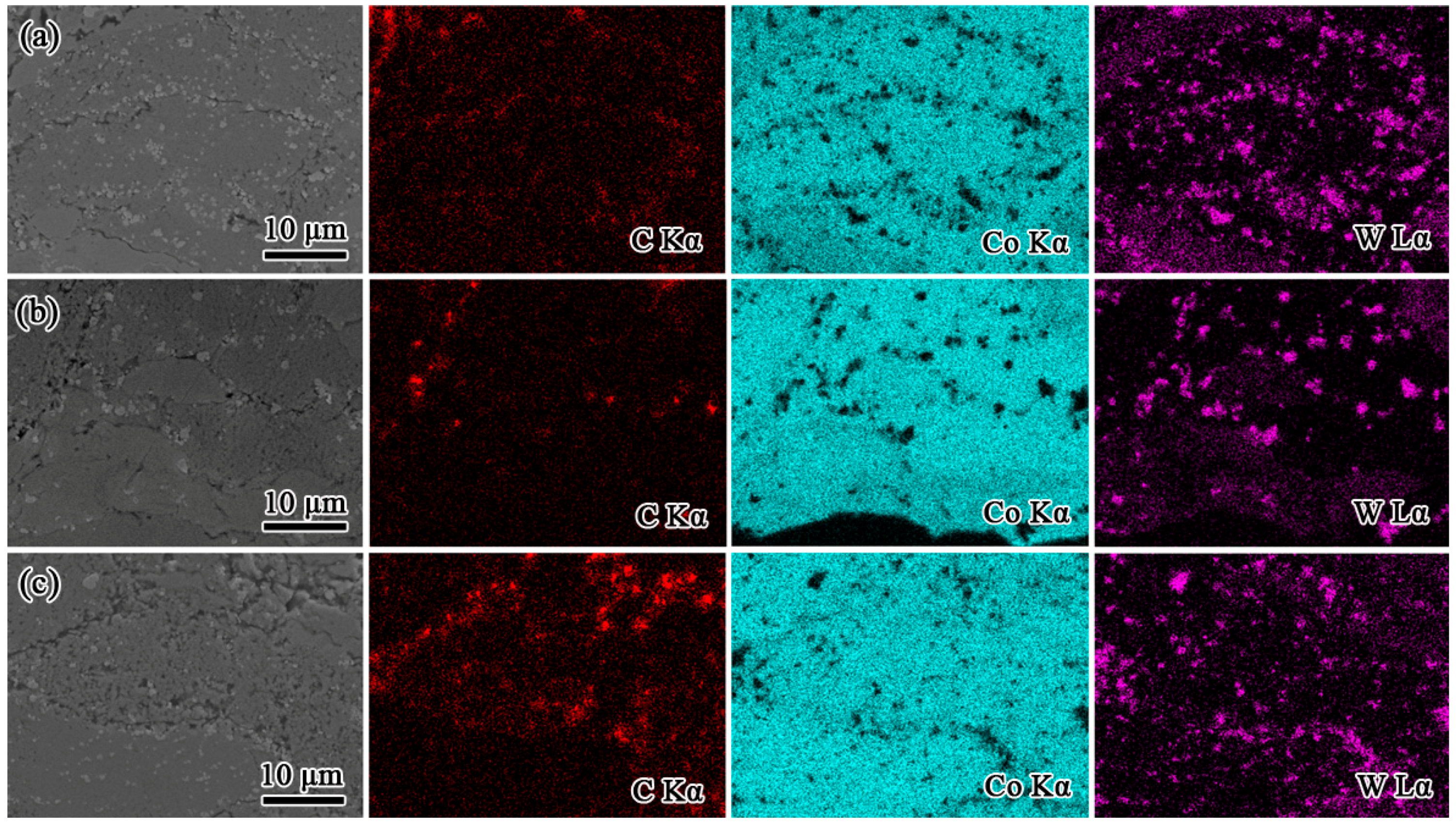

3.1. Phases Analysis

3.2. Solar Absorptance of the As-Deposited Coatings

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- De Villiers Lovelock, H.L. Powder/processing/structure relationships in WC-Co thermal spray coatings: A review of the published literature. J. Therm. Spray Technol. 1998, 7, 357–373. [Google Scholar] [CrossRef]

- Moon, J.; Lu, D.; VanSaders, B.; Kim, T.K.; Kong, S.D.; Jin, S.; Chen, R.; Liu, Z. High performance multi-scaled nanostructured spectrally selective coating for concentrating solar power. Nano Energy 2014, 8, 238–246. [Google Scholar] [CrossRef]

- Nuru, Z.Y.; Arendse, C.J.; Nemutudi, R.; Nemraoui, O.; Maaza, M. Pt-Al2O3 nanocoatings for high temperature concentrated solar thermal power applications. Phys. B Condens. Matter 2012, 407, 1634–1637. [Google Scholar] [CrossRef]

- Céspedes, E.; Wirz, M.; Sánchez-García, J.A.; Alvarez-Fraga, L.; Escobar-Galindo, R.; Prieto, C. Novel Mo-Si3N4 based selective coating for high temperature concentrating solar power applications. Sol. Energy Mater. Sol. Cells 2014, 122, 217–225. [Google Scholar] [CrossRef]

- Zhang, Q.-C. Optimizing analysis of W-AlN cermet solar absorbing coatings. J. Phys. D Appl. Phys. 2001, 34, 3113. [Google Scholar] [CrossRef]

- Toor, F.; Guneratne, A.C.; Temchenko, M. Metal-dielectric frequency-selective surface for high performance solar window coatings. SPIE Proc. 2016. [Google Scholar] [CrossRef]

- Teixeira, V.; Sousa, E.; Costa, M.F.; Nunes, C.; Rosa, L.; Carvalho, M.J.; Collares-Pereira, M.; Roman, E.; Gago, J. Spectrally selective composite coatings of Cr-Cr2O3 and Mo-Al2O3 for solar energy applications. Thin Solid Films 2001, 392, 320–326. [Google Scholar] [CrossRef]

- Dent, A.H.; Horlock, A.J.; McCartney, D.G.; Harris, S.J. Microstructure formation in high velocity oxy-fuel thermally sprayed Ni-Cr-Mo-B alloys. Mater. Sci. Eng. A 2000, 283, 242–250. [Google Scholar] [CrossRef]

- Li, C.J.; Ohmori, A.; Harada, Y. Effect of powder structure on the structure of thermally sprayed WC-Co coatings. J. Mater. Sci. 1996, 31, 785–794. [Google Scholar] [CrossRef]

- Ma, N.; Guo, L.; Cheng, Z.; Wu, H.; Ye, F.; Zhang, K. Improvement on mechanical properties and wear resistance of HVOF sprayed WC-12Co coatings by optimizing feedstock structure. Appl. Surf. Sci. 2014, 320, 364–371. [Google Scholar] [CrossRef]

- Sánchez, E.; Bannier, E.; Salvador, M.D.; Bonache, V.; García, J.C.; Morgiel, J.; Grzonka, J. Microstructure and Wear Behavior of Conventional and Nanostructured Plasma-Sprayed WC-Co Coatings. J. Therm. Spray Technol. 2010, 19, 964–974. [Google Scholar] [CrossRef]

- Pan, Y.; Li, D.Y.; Zhang, H. Enhancing the wear resistance of sintered WC-Co composite by adding pseudo-elastic TiNi constituent. Wear 2011, 271, 1916–1921. [Google Scholar] [CrossRef]

- Juang, R.-C.; Yeh, Y.-C.; Chang, B.-H.; Chen, W.-C.; Chung, T.-W. Preparation of solar selective absorbing coatings by magnetron sputtering from a single stainless steel target. Thin Solid Films 2010, 518, 5501–5504. [Google Scholar] [CrossRef]

- Qiao, Y.; Fischer, T.E.; Dent, A. The effects of fuel chemistry and feedstock powder structure on the mechanical and tribological properties of HVOF thermal-sprayed WC-Co coatings with very fine structures. Surf. Coat. Technol. 2003, 172, 24–41. [Google Scholar] [CrossRef]

- Shipway, P.H.; McCartney, D.G.; Sudaprasert, T. Sliding wear behaviour of conventional and nanostructured HVOF sprayed WC-Co coatings. Wear 2005, 259, 820–827. [Google Scholar] [CrossRef]

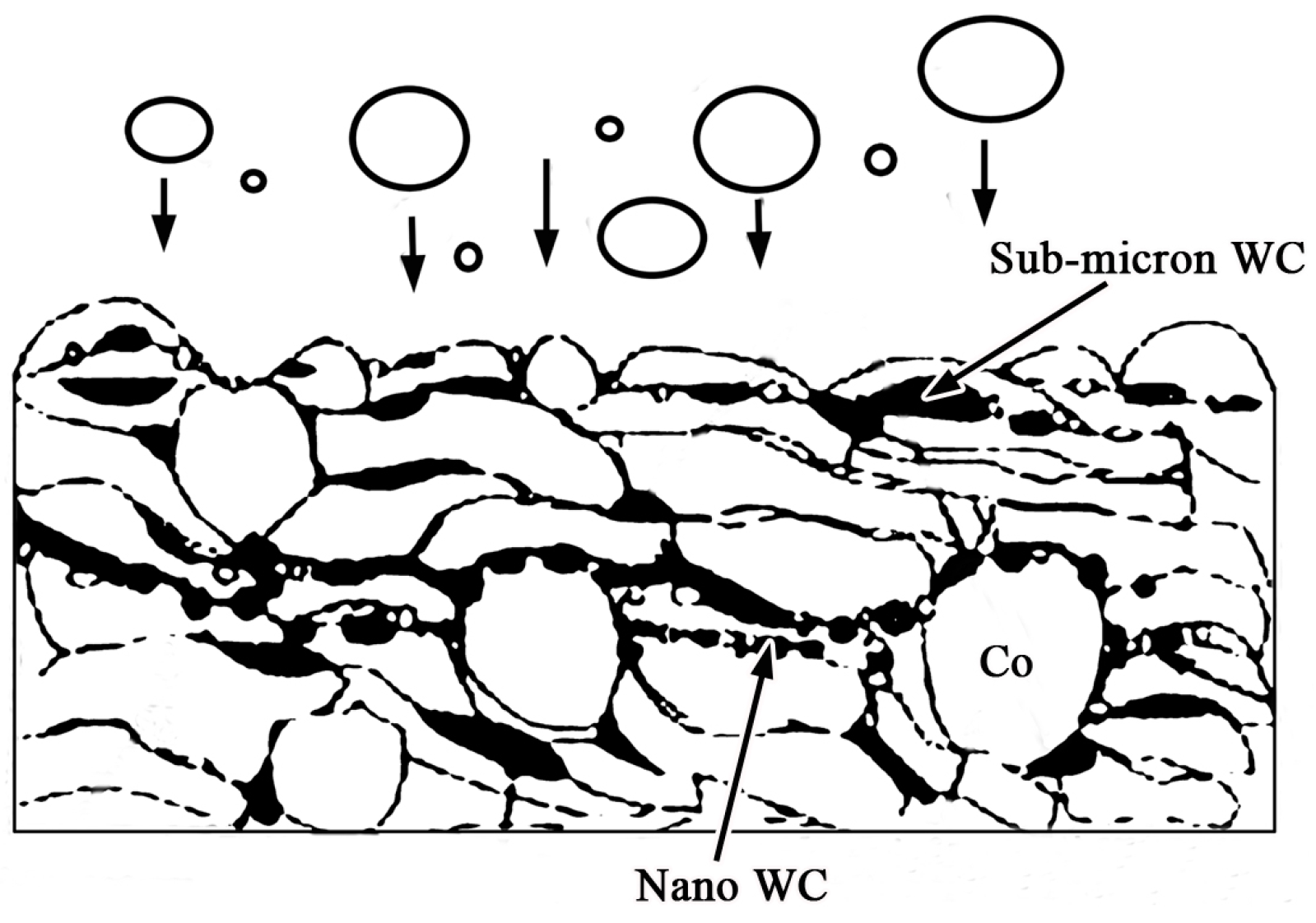

- Skandan, G.; Yao, R.; Sadangi, R.; Kear, B.H.; Qiao, Y.; Liu, L.; Fischer, T.E. Multimodal coatings: A new concept in thermal spraying. J. Therm. Spray Technol. 2000, 9, 329–331. [Google Scholar] [CrossRef]

- Skandan, G.; Yao, R.; Kear, B.H.; Qiao, Y.; Liu, L.; Fischer, T.E. Multimodal powders: A new class of feedstock material for thermal spraying of hard coatings. Scr. Mater. 2001, 44, 1699–1702. [Google Scholar] [CrossRef]

- Liu, H.D.; Wan, Q.; Xu, Y.R.; Luo, C.; Chen, Y.M.; Fu, D.J.; Ren, F.; Luo, G.; Cheng, X.D.; Hu, X.J.; et al. Long-term thermal stability of CrAlO-based solar selective absorbing coating in elevated temperature air. Sol. Energy Mater. Sol. Cells 2015, 134, 261–267. [Google Scholar] [CrossRef]

- Trice, J.; Favazza, C.; Garcia, H.; Sureshkumar, R.; Kalyanaraman, R. Design and optimization of plasmonic-based metal-dielectric nanocomposite materials for energy applications. Physics 2010. [Google Scholar] [CrossRef]

- Schaadt, D.M.; Feng, B.; Yu, E.T. Enhanced semiconductor optical absorption via surface plasmon excitation in metal nanoparticles. Appl. Phys. Lett. 2005, 86, 063106. [Google Scholar] [CrossRef]

- Pillai, S.; Catchpole, K.R.; Trupke, T.; Zhang, G.; Zhao, J.; Green, M.A. Enhanced emission from Si-based light-emitting diodes using surface plasmons. Appl. Phys. Lett. 2006, 88, 161102. [Google Scholar] [CrossRef]

- Cole, J.R.; Halas, N.J. Optimized plasmonic nanoparticle distributions for solar spectrum harvesting. Appl. Phys. Lett. 2006, 89, 153120. [Google Scholar] [CrossRef]

- Granqvist, C.G. Solar energy materials. Appl. Phys. A 1991, 52, 83–93. [Google Scholar] [CrossRef]

- Yuan, F.H.; Chen, Z.X.; Huang, Z.W.; Wang, Z.G.; Zhu, S.J. Oxidation behavior of thermal barrier coatings with HVOF and detonation-sprayed NiCrAlY bondcoats. Corros. Sci. 2008, 50, 1608–1617. [Google Scholar] [CrossRef]

- Stewart, D.A.; Shipway, P.H.; McCartney, D.G. Microstructural evolution in thermally sprayed WC-Co coatings: Comparison between nanocomposite and conventional starting powders. Acta Mater. 2000, 48, 1593–1604. [Google Scholar] [CrossRef]

- Verdian, M.M.; Raeissi, K.; Salehi, M. Corrosion performance of HVOF and APS thermally sprayed NiTi intermetallic coatings in 3.5% NaCl solution. Corros. Sci. 2010, 52, 1052–1059. [Google Scholar] [CrossRef]

- Kittel, C. Introduction to Solid State Physics, 8th ed.; John Wiley and Sons, Ltd.: New York, NY, USA, 2005. [Google Scholar]

| Sample Number | Composition, wt % |

|---|---|

| A1 | 80% Co + 20% sub-micrometer WC |

| A2 | 80% Co + 20% nanometer WC |

| A3 | 80% Co + 10% sub-micrometer WC + 10% nanometer WC |

| Parameters | Value |

|---|---|

| Spray distance, mm | 240 |

| Powder feed rate, g/min | 12 |

| Fuel (propane) pressure, MPa | 0.6 |

| Fuel gas (propane) flow rate, L/min | 40 |

| Oxygen pressure, MPa | 0.8 |

| Oxygen flow rate, L/min | 220 |

| Carrier gas nitrogen pressure, MPa | 1.0 |

| Carrier gas nitrogen flow rate, g/min | 10 |

| Gun traverse speed vertical plane, mm/s | 60 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Ouyang, T.; Duan, X.; Ke, C.; Zhang, X.; Min, J.; Li, A.; Guo, W.; Cheng, X. Improved Solar Absorptance of WC/Co Solar Selective Absorbing Coating with Multimodal WC Particles. Metals 2017, 7, 137. https://doi.org/10.3390/met7040137

Wang X, Ouyang T, Duan X, Ke C, Zhang X, Min J, Li A, Guo W, Cheng X. Improved Solar Absorptance of WC/Co Solar Selective Absorbing Coating with Multimodal WC Particles. Metals. 2017; 7(4):137. https://doi.org/10.3390/met7040137

Chicago/Turabian StyleWang, Xiaobo, Taoyuan Ouyang, Xiaohua Duan, Chengzhu Ke, Xuemin Zhang, Jie Min, Aang Li, Weiyang Guo, and Xudong Cheng. 2017. "Improved Solar Absorptance of WC/Co Solar Selective Absorbing Coating with Multimodal WC Particles" Metals 7, no. 4: 137. https://doi.org/10.3390/met7040137