Variable-Frequency Ultrasonic Treatment on Microstructure and Mechanical Properties of ZK60 Alloy during Large Diameter Semi-Continuous Casting

Abstract

:1. Introduction

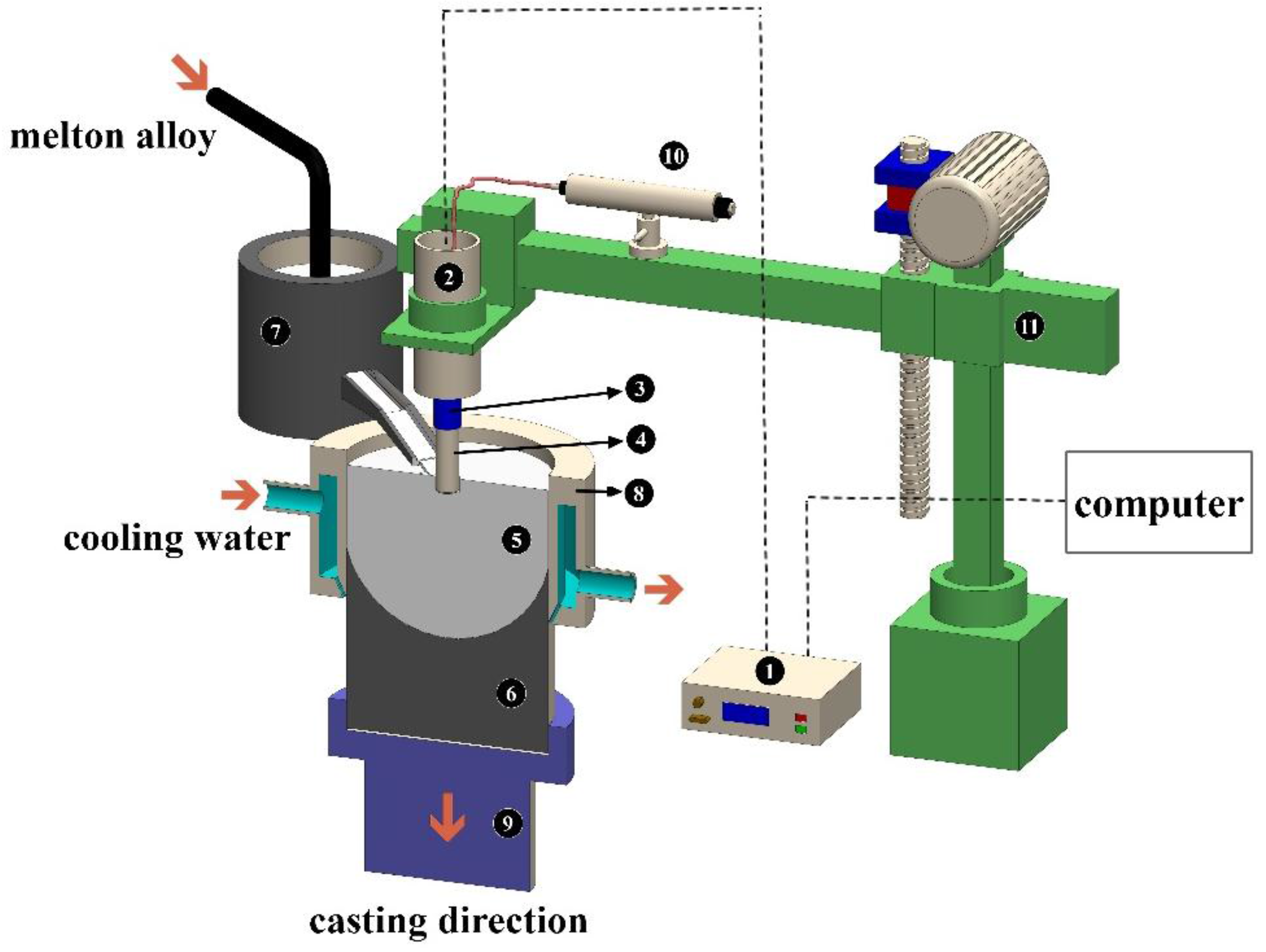

2. Experimental Procedures

2.1. Magnesium Alloy and Experimental Set-Up

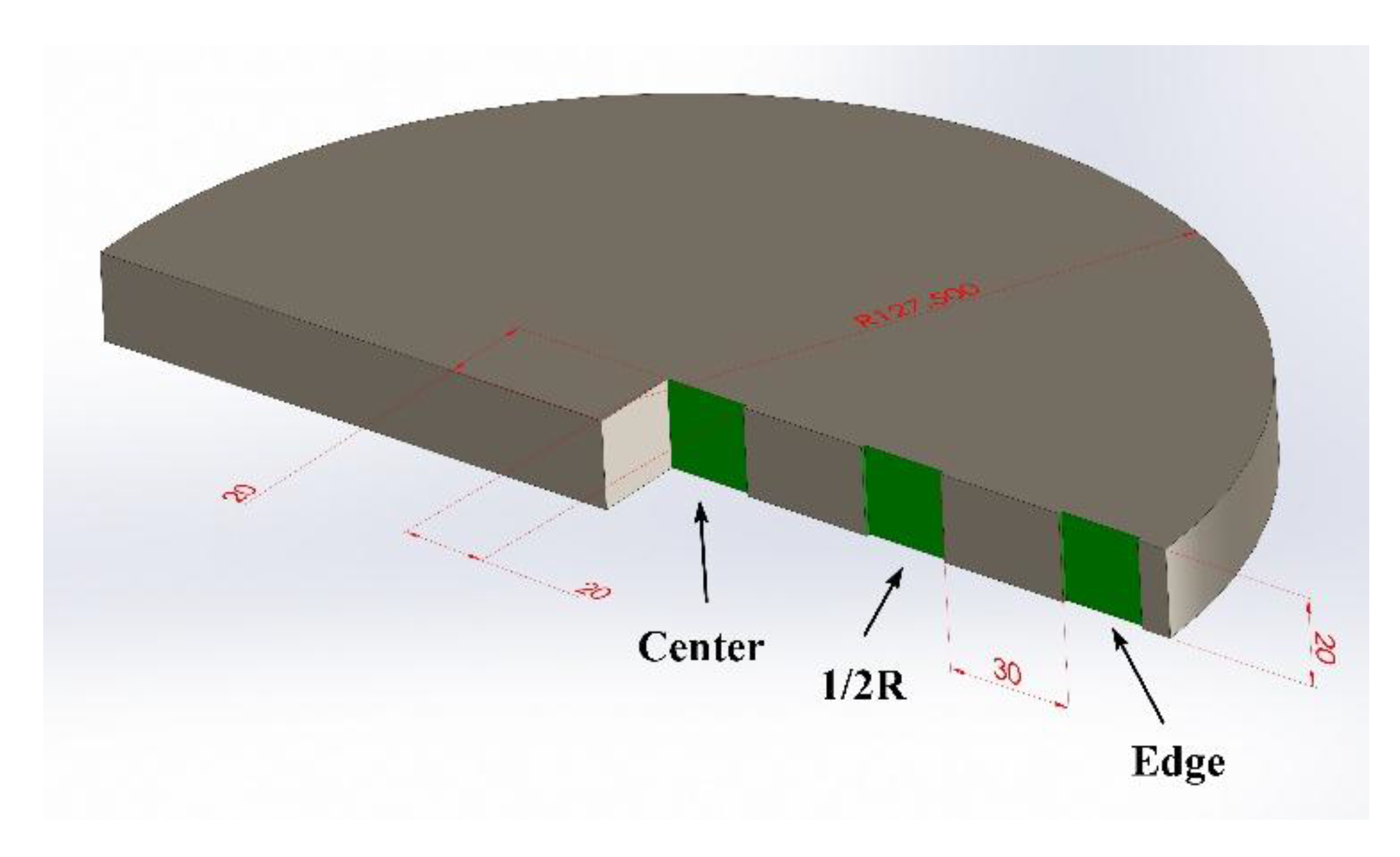

2.2. Casting Procedure and Samples Characterization

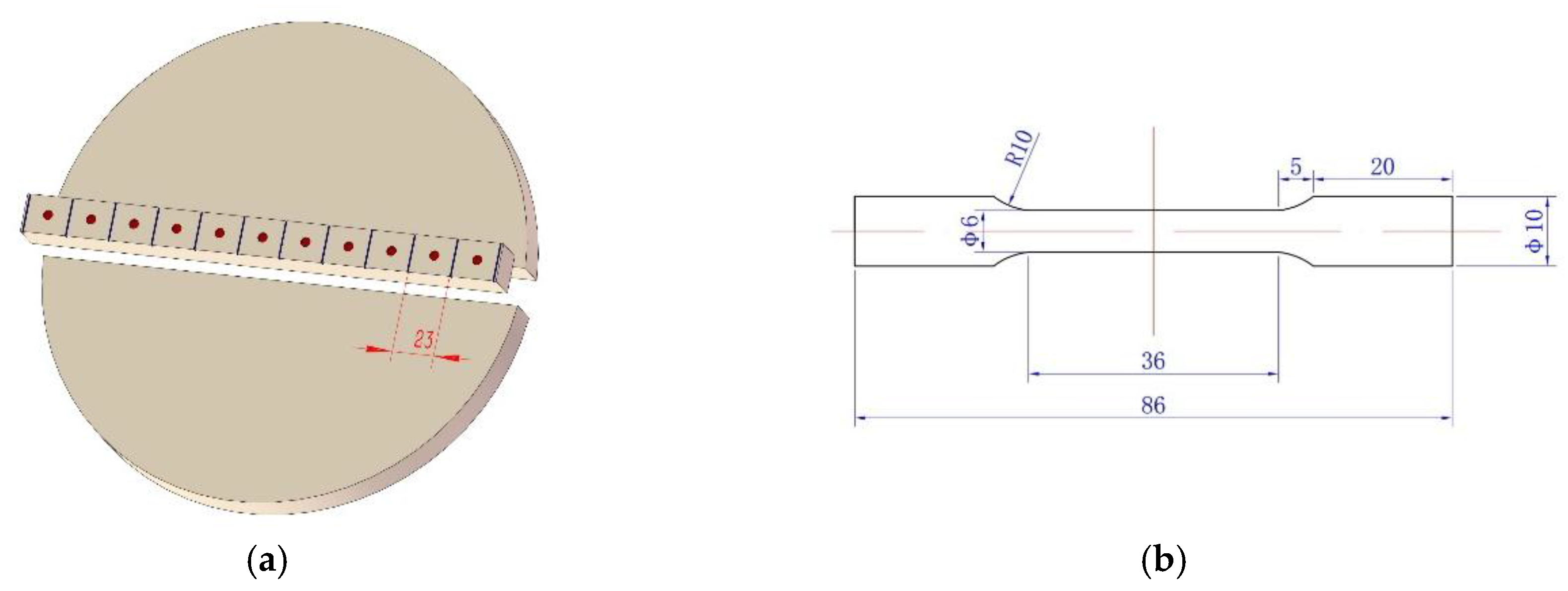

2.3. Mechanical Properties Tests and Segregation Rate Detection

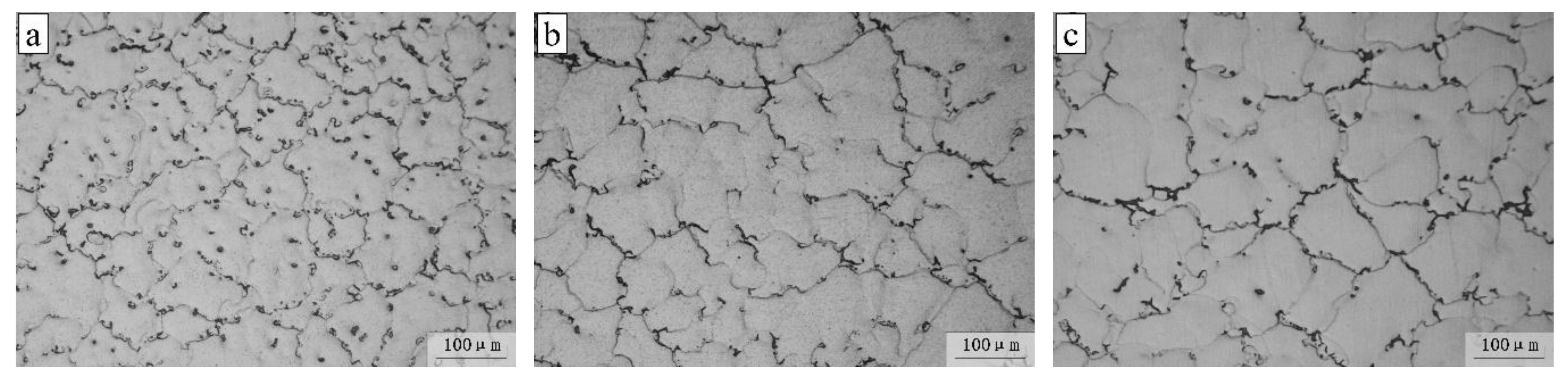

3. Results and Discussion

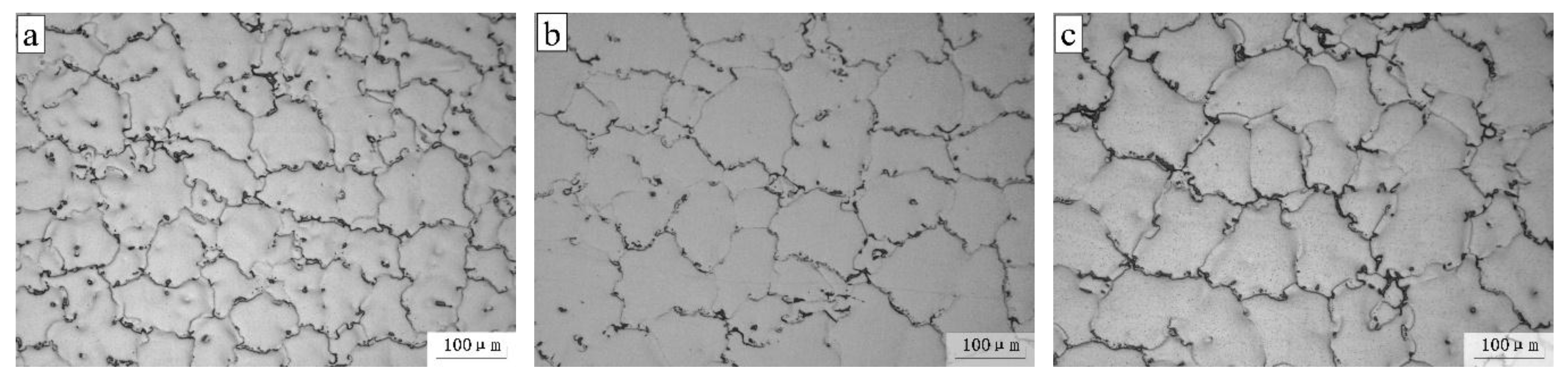

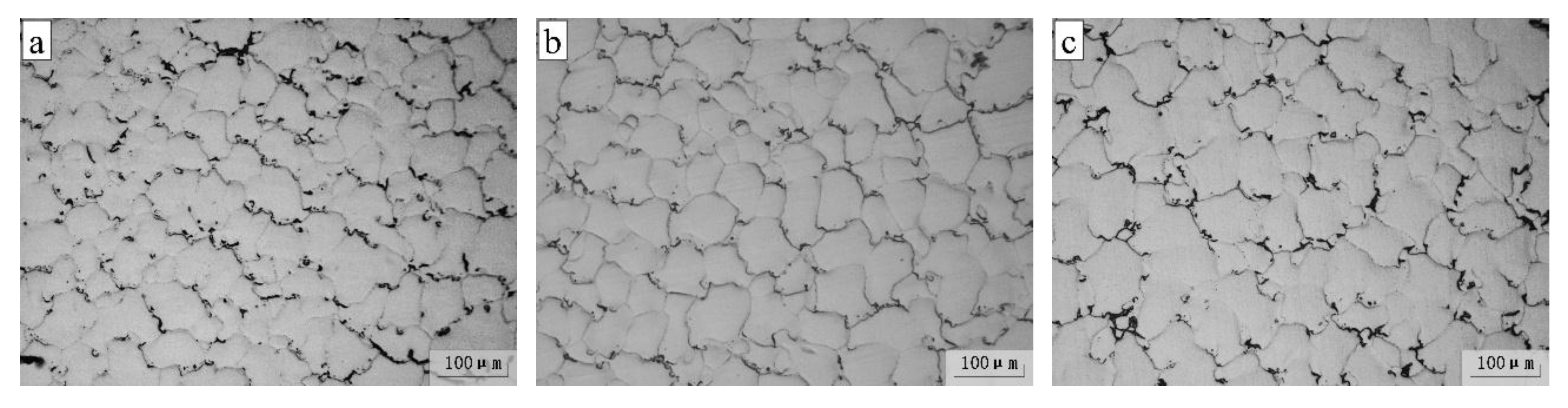

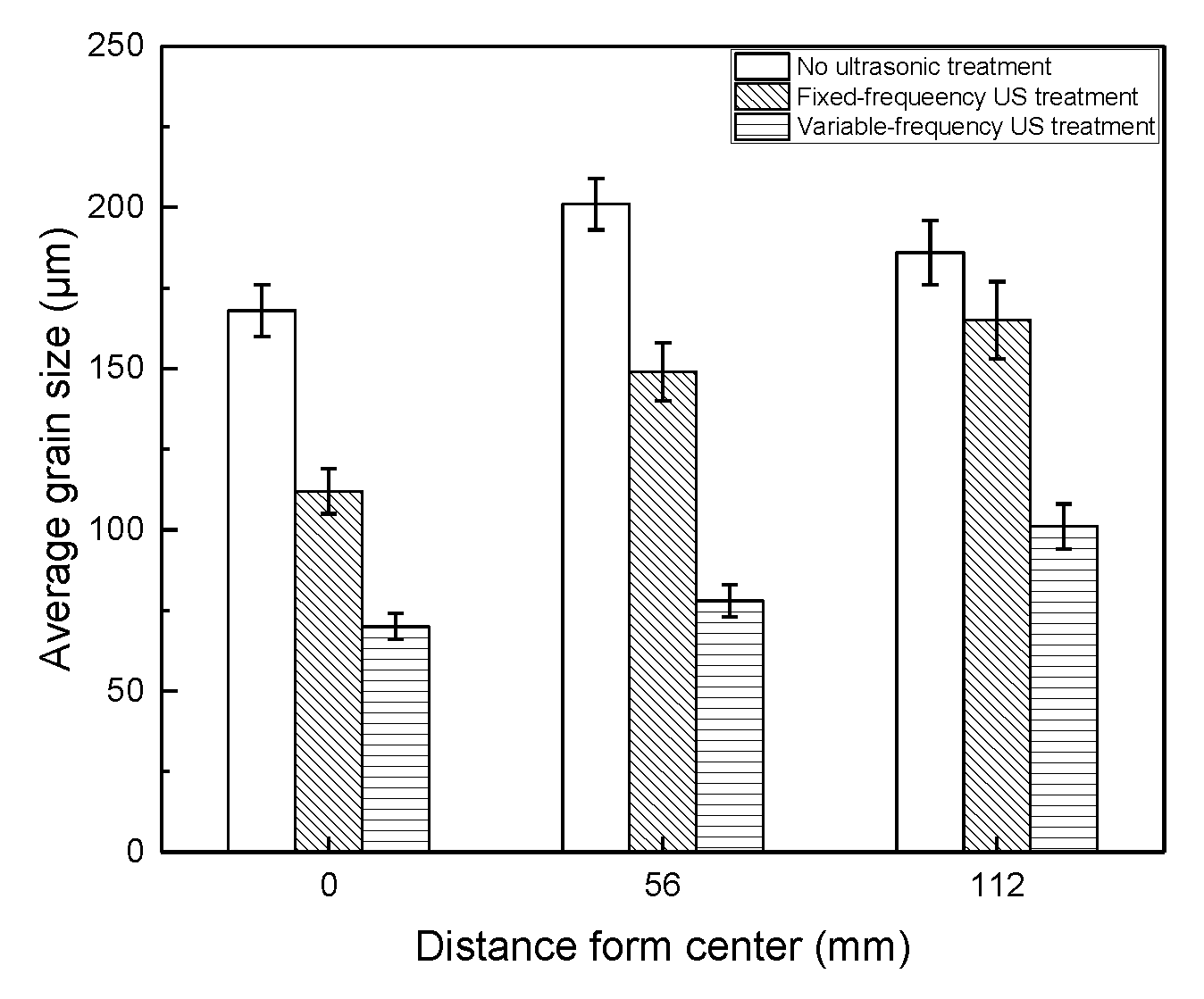

3.1. Microstructure Refinement by Different Ultrasonic Treatments

- (1)

- at the liquid-air interfaces corresponding to a total reflection condition as soft walls;

- (2)

- at the side walls of the horn which represents hard walls;

- (3)

- at the horn tip, where is the amplitude of the wave, is the initial frequency of the wave, is the changing frequency of wave frequency;

- (4)

- at the walls of the crystallizer and liquid cave which represents the impedance boundary condition and is the acoustic input impedance of the external.

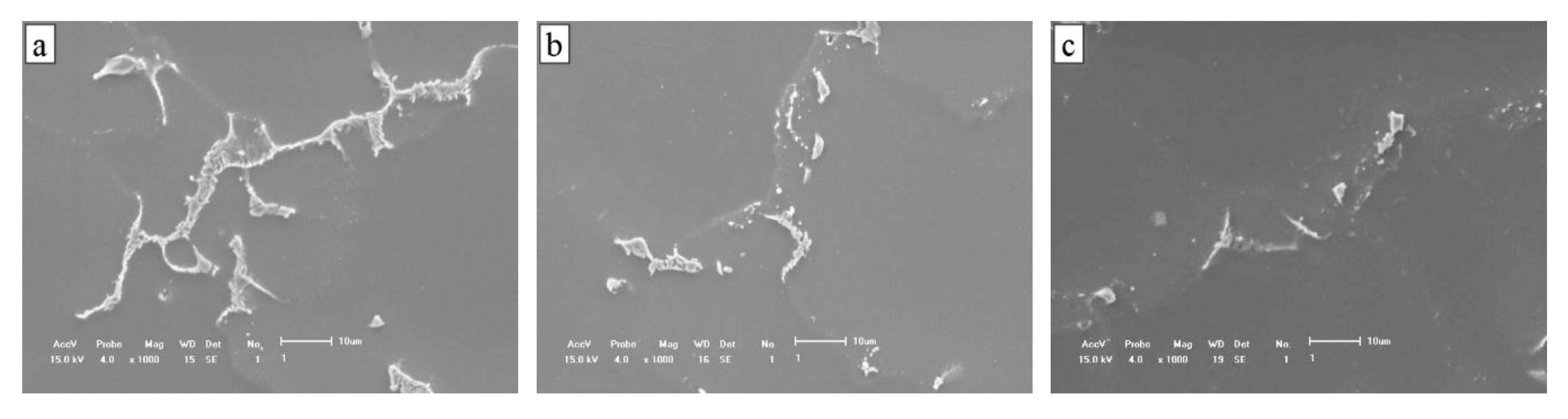

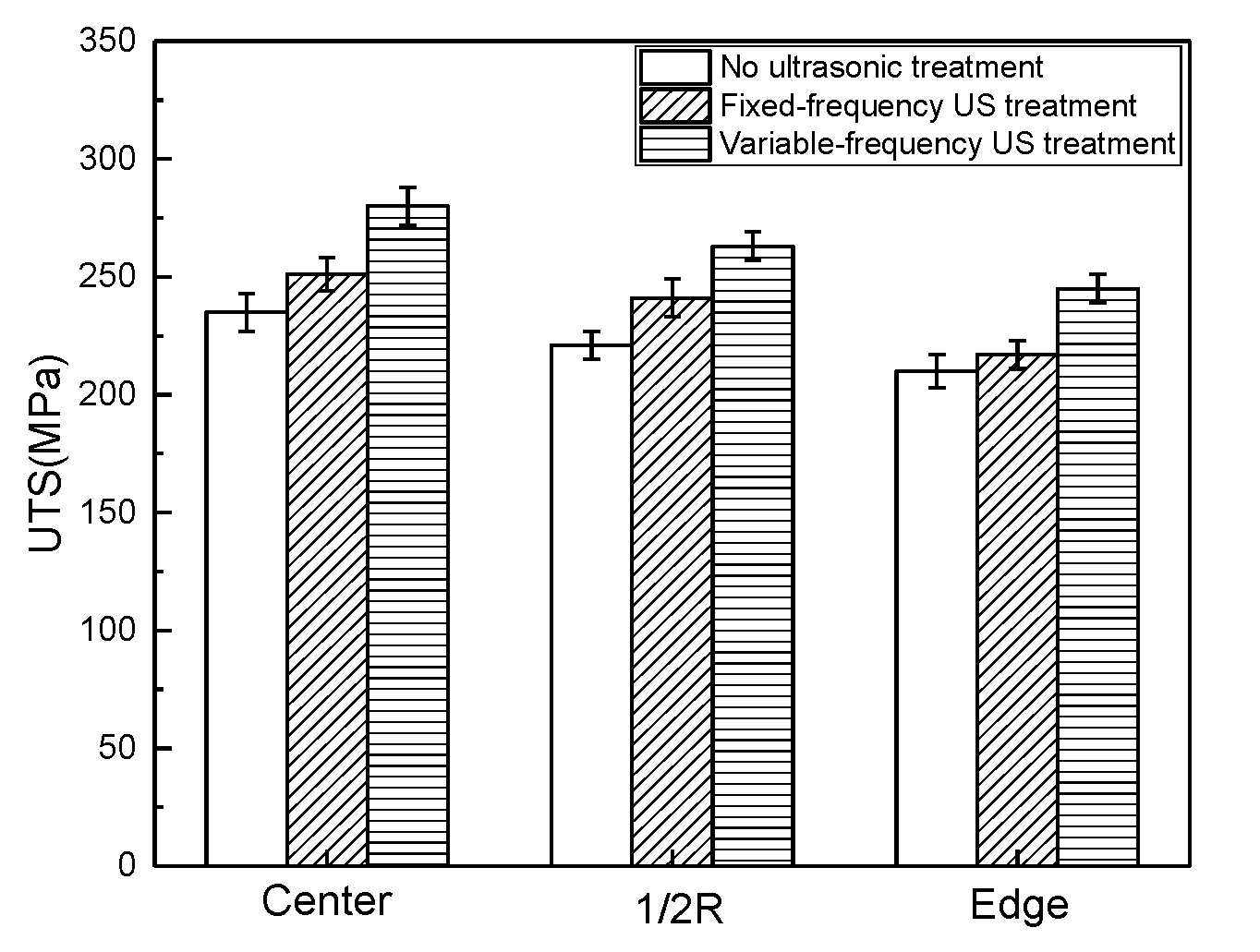

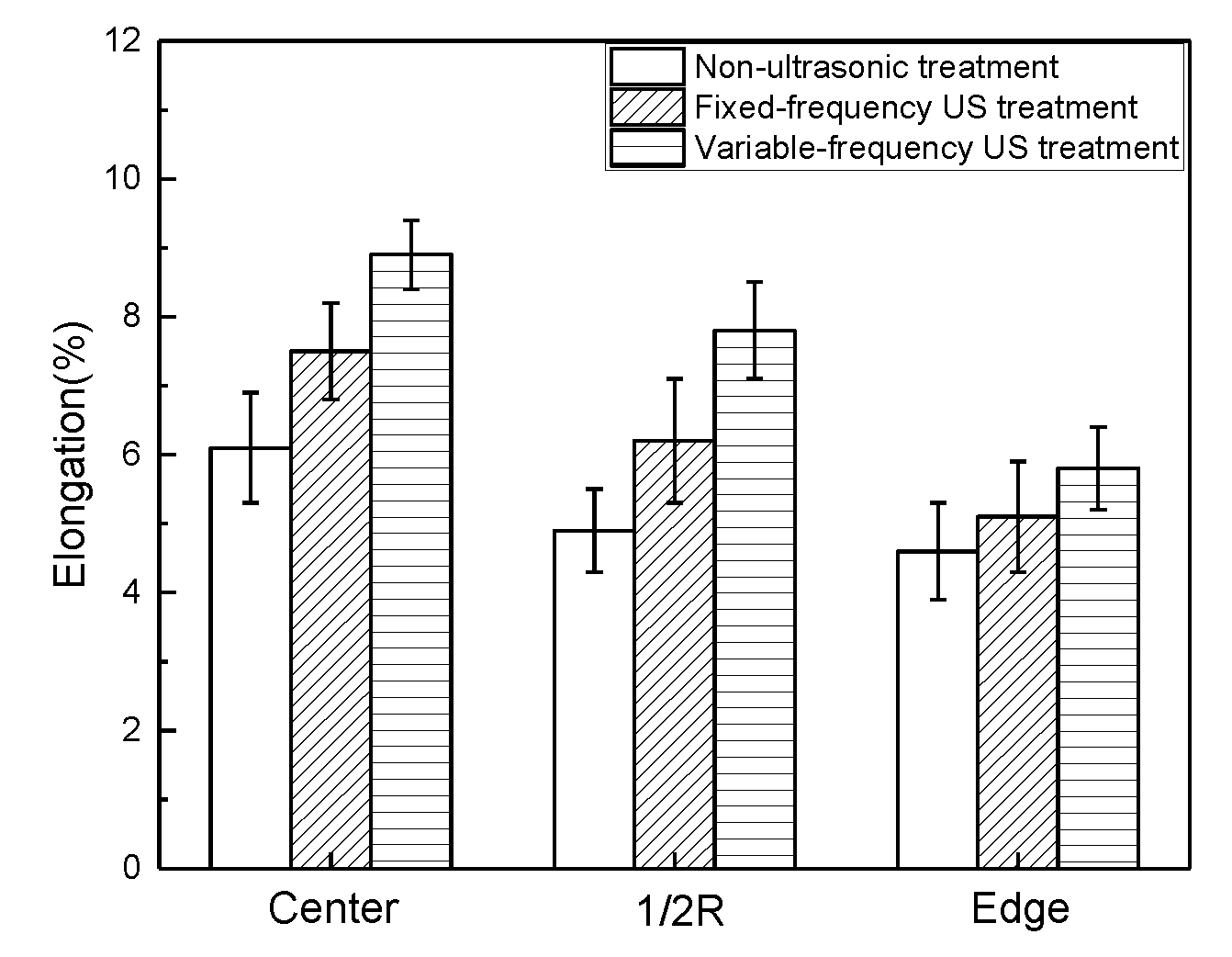

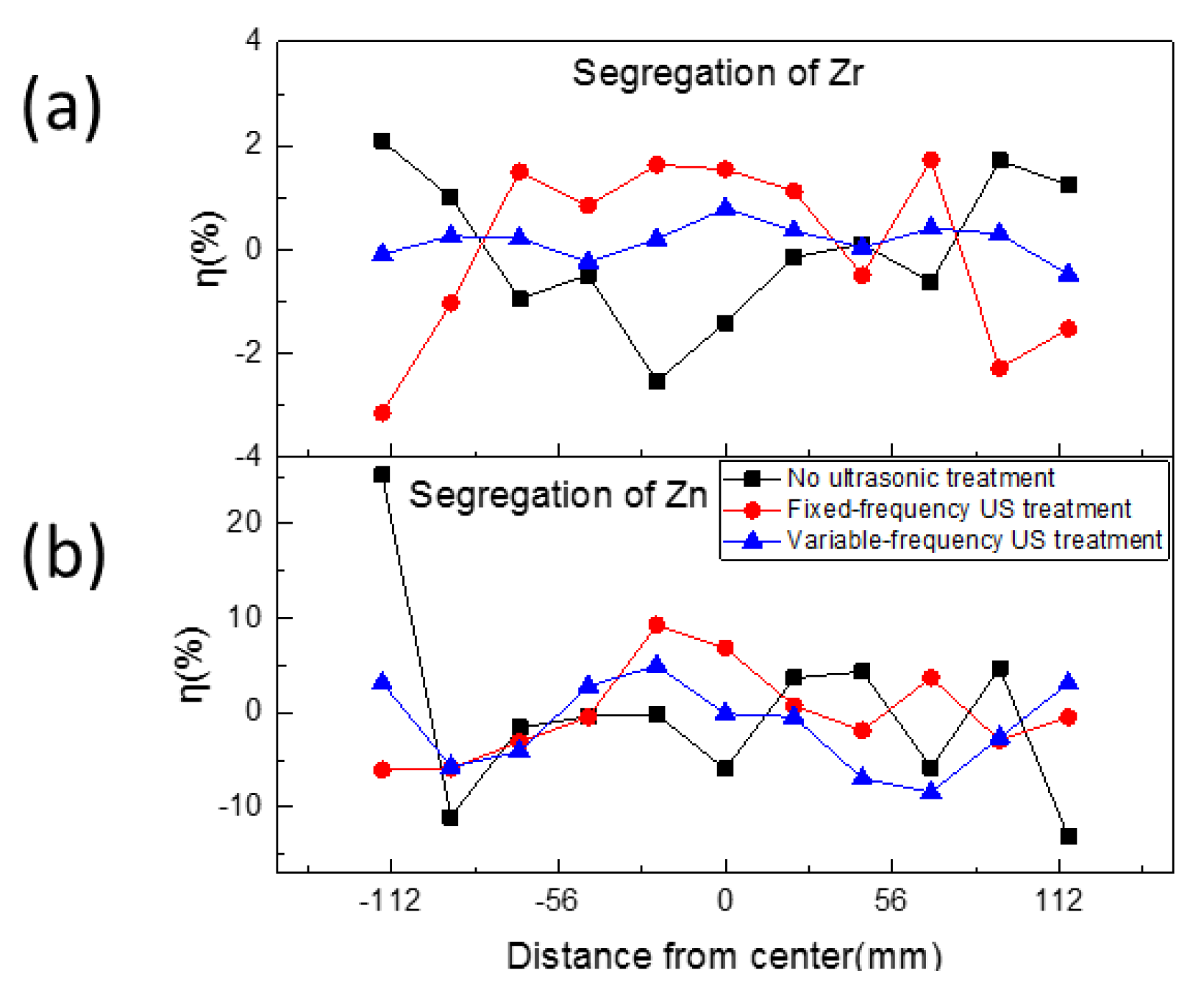

3.2. Mechanical Properties and Segregation

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Staiger, M.P.; Pietak, A.M.; Huadmai, J.; Dias, G. Magnesium and its alloys as orthopedic biomaterials: A review. Biomaterials 2006, 27, 1728–1734. [Google Scholar] [CrossRef] [PubMed]

- Ali, Y.H.; Qiu, D.; Jiang, B.; Pan, F.S.; Zhang, M.X. Current research progress in grain refinement of cast magnesium alloys: A review article. J. Alloy. Compd. 2015, 619, 639–651. [Google Scholar] [CrossRef]

- Jin, S.L.; Li, Y.W.; Li, Y.B.; Zhao, L.; Liu, X.H.; Liu, J.; Li, Z.Y. Modified directed melt nitridation of pure aluminum block using magnesium as an external dopant. J. Mater. Sci. 2007, 42, 7311–7315. [Google Scholar] [CrossRef]

- Gupta, N.; Luong, D.D.; Cho, K. Magnesium matrix composite foams-density, mechanical properties, and applications. Metals 2012, 2, 238–252. [Google Scholar] [CrossRef]

- Dieringa, H. Influence of cryogenic temperatures on the microstructure and mechanical properties of magnesium alloys: A review. Metals 2017, 7, 38. [Google Scholar] [CrossRef]

- Huot, J.; Skryabina, N.Y.; Fruchart, D. Application of severe plastic deformation techniques to magnesium for enhanced hydrogen sorption properties. Metals 2012, 2, 329–343. [Google Scholar] [CrossRef]

- Roncevic, I.S.; Metikos-Hukovic, M.; Buzuk, M.; Vladislavic, N. Effective and environmentally friendly nickel coating on the magnesium alloy. Metals 2016, 6, 312. [Google Scholar]

- Wolff, M.; Schaper, J.G.; Suckert, M.R.; Dahms, M.; Feyerabend, F.; Ebel, T.; Willumeit-Romer, R.; Klassen, T. Metal injection molding (MIM) of magnesium and its alloys. Metals 2016, 6, 118. [Google Scholar] [CrossRef]

- Zhang, W.Q.; Xiao, W.L.; Wang, F.; Ma, C.L. Development of heat resistant Mg-Zn-Al-based magnesium alloys by addition of La and Ca: Microstructure and tensile properties. J. Alloy. Compd. 2016, 684, 8–14. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, Z.Q.; Le, Q.C.; Bao, L. The effects of ZnO particles on the grain refinement and mechanical properties of AZ31 magnesium alloys. Trans. Indian Inst. Met. 2016, 69, 1911–1918. [Google Scholar] [CrossRef]

- Yang, P.; Zhao, Z.; Ren, X.P.; Huang, S.D. Microstructure, textures and deformation behaviors of fine-grained magnesium alloy AZ31. J. Mater. Sci. Technol. 2005, 21, 331–337. [Google Scholar]

- Prasad, A.; Uggowitzer, P.J.; Shi, Z.; Atrens, A. Production of high purity magnesium alloys by melt purification with Zr. Adv. Eng. Mater. 2012, 14, 477–490. [Google Scholar] [CrossRef]

- Nogita, K.; Dahle, A.K. Effects of boron on eutectic modification of hypoeutectic Al-Si alloys. Scr. Mater. 2003, 48, 307–313. [Google Scholar] [CrossRef]

- Cao, P.; Qian, M.; StJohn, D.H.; Frost, M.T. Uptake of iron and its effect on grain refinement of pure magnesium by zirconium. Mater. Sci. Technol. 2004, 20, 585–592. [Google Scholar] [CrossRef]

- Cheng, R.J.; Pan, F.S.; Jiang, S.; Li, C.; Jiang, B.; Jiang, X.Q. Effect of Sr addition on the grain refinement of AZ31 magnesium alloys. Prog. Nat. Sci. 2013, 23, 7–12. [Google Scholar] [CrossRef]

- Guo, S.J.; Le, Q.C.; Zhao, Z.H.; Wang, Z.J.; Cui, H.Z. Microstructural refinement of DC cast AZ80 Mg billets by low frequency electromagnetic vibration. Mater. Sci. Eng. A 2005, 404, 323–329. [Google Scholar] [CrossRef]

- Ramirez, A.; Qian, M.; Davis, B.; Wilks, T.; StJohn, D.H. Potency of high-intensity ultrasonic treatment for grain refinement of magnesium alloys. Scr. Mater. 2008, 59, 19–22. [Google Scholar] [CrossRef]

- Eskin, G.I. Broad prospects for commercial application of the ultrasonic (cavitation) melt treatment of light alloys. Ultrason. Sonochem. 2001, 8, 319–325. [Google Scholar] [CrossRef]

- Rashad, M.M. Magnetic properties of nanocrystalline magnesium ferrite by co-precipitation assisted with ultrasound irradiation. J. Mater. Sci. 2007, 42, 5248–5255. [Google Scholar] [CrossRef]

- Lee, Y.C.; Dahle, A.K.; Stjohn, D.H. The role of solute in grain refinement of magnesium. Metall. Mater. Trans. A 2000, 31, 2895–2906. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, Z.Q.; Hu, W.Y.; Le, Q.C.; Bao, L.; Cui, J.Z.; Jiang, J.J. Study on hydrogen removal of AZ91 alloys using ultrasonic argon degassing process. Ultrason. Sonochem. 2015, 26, 73–80. [Google Scholar] [CrossRef] [PubMed]

- Hu, Z.; Li, X.; Yan, H.; Wu, X.Q.; Qun, H.; Lin, J.W. Effects of ultrasonic vibration on microstructure evolution and elevated-temperature mechanical properties of hot-extruded Mg-6Al-0.8Zn-2.0Sm wrought magnesium alloys. J. Alloy. Compd. 2016, 685, 58–64. [Google Scholar] [CrossRef]

- Xue, H.S.; Li, D.; Yang, G.; Zhang, D.F. Ultrasonic effects on microstructure evolution and mechanical properties of AZ80 magnesium alloy. Rare Met. Mater. Eng. 2016, 45, 1401–1405. [Google Scholar]

- Fang, X.; Wu, S.; Lü, S.; Wang, J.; Yang, X. Microstructure evolution and mechanical properties of quasicrystal-reinforced Mg-Zn-Y alloy subjected to ultrasonic vibration. Mater. Sci. Eng. A 2016, 679, 372–378. [Google Scholar] [CrossRef]

- Gao, D.; Li, Z.; Han, Q.; Zhai, Q. Effect of ultrasonic power on microstructure and mechanical properties of AZ91 alloy. Mater. Sci. Eng. A 2009, 502, 2–5. [Google Scholar] [CrossRef]

- Eskin, G.I. Principles of ultrasonic treatment: Application for light alloys melts. Adv. Perform. Mater. 1997, 4, 223–232. [Google Scholar] [CrossRef]

- Xi, X.; Cegla, F.B.; Lowe, M.; Thiemann, A.; Nowak, T.; Mettin, R.; Holsteyns, F.; Lippert, A. Study on the bubble transport mechanism in an acoustic standing wave field. Ultrasonics 2011, 51, 1014–1025. [Google Scholar] [CrossRef] [PubMed]

- Rae, J.; Ashokkumar, M.; Eulaerts, O.; von Sonntag, C.; Reisse, J.; Grieser, F. Estimation of ultrasound induced cavitation bubble temperatures in aqueous solutions. Ultrason. Sonochem. 2005, 12, 325–329. [Google Scholar] [CrossRef] [PubMed]

- Vanhille, C.; Campos-Pozuelo, C. Acoustic cavitation mechanism: A nonlinear model. Ultrason. Sonochem. 2012, 19, 217–220. [Google Scholar] [CrossRef] [PubMed]

- Feng, R.; Zhao, Y.Y.; Zhu, C.P.; Mason, T.J. Enhancement of ultrasonic cavitation yield by multi-frequency sonication. Ultrason. Sonochem. 2002, 9, 231–236. [Google Scholar] [CrossRef]

- Lee, C.D. Effect of grain size on the tensile properties of magnesium alloy. Mater. Sci. Eng. A 2007, 459, 355–360. [Google Scholar] [CrossRef]

- Ma, C.; Liu, M.; Wu, G.; Ding, W.; Zhu, Y. Tensile properties of extruded ZK60–RE alloys. Mater. Sci. Eng. A 2003, 349, 207–212. [Google Scholar] [CrossRef]

- Maeng, D.Y.; Kim, T.S.; Lee, J.H.; Hong, S.J.; Seo, S.K.; Chun, B.S. Microstructure and strength of rapidly solidified and extruded Mg-Zn alloys. Scr. Mater. 2000, 43, 385–389. [Google Scholar] [CrossRef]

- Madelin, G.; Grucker, D.; Franconi, J.M.; Thiaudiere, E. Magnetic resonance imaging of acoustic streaming: Absorption coefficient and acoustic field shape estimation. Ultrasonics 2006, 44, 272–278. [Google Scholar] [CrossRef] [PubMed]

- Frenkel, V.; Gurka, R.; Liberzon, A.; Shavit, U.; Kimmel, E. Preliminary investigations of ultrasound induced acoustic streaming using particle image velocimetry. Ultrasonics 2001, 39, 153–156. [Google Scholar] [CrossRef]

- Frampton, K.D.; Minor, K.; Martin, S. Acoustic streaming in micro-scale cylindrical channels. Appl. Acoust. 2004, 65, 1121–1129. [Google Scholar] [CrossRef]

| Element | Zn | Zr | Fe | Cu | Si | Ni | Mg |

|---|---|---|---|---|---|---|---|

| wt % | 5.720 | 0.644 | 0.018 | 0.013 | 0.026 | 0.010 | Balance |

| Name | Value | Description |

|---|---|---|

| 1820 kg/m3 | Density of magnesium alloy | |

| 4000 m/s | Speed of sound in magnesium alloy | |

| 0.0279 dB/cm | Attenuation coefficient | |

| 20 kHz | Initial frequency of the wave | |

| 200 Hz | Changing frequency of wave frequency | |

| 3.2 106 Pa | Source pressure amplitude | |

| 4.2 107 Pa· s/m | Acoustic input impedance |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Le, Q.; Wang, X.; Liao, Q.; Chu, C. Variable-Frequency Ultrasonic Treatment on Microstructure and Mechanical Properties of ZK60 Alloy during Large Diameter Semi-Continuous Casting. Metals 2017, 7, 173. https://doi.org/10.3390/met7050173

Chen X, Le Q, Wang X, Liao Q, Chu C. Variable-Frequency Ultrasonic Treatment on Microstructure and Mechanical Properties of ZK60 Alloy during Large Diameter Semi-Continuous Casting. Metals. 2017; 7(5):173. https://doi.org/10.3390/met7050173

Chicago/Turabian StyleChen, Xingrui, Qichi Le, Xibo Wang, Qiyu Liao, and Chaoyang Chu. 2017. "Variable-Frequency Ultrasonic Treatment on Microstructure and Mechanical Properties of ZK60 Alloy during Large Diameter Semi-Continuous Casting" Metals 7, no. 5: 173. https://doi.org/10.3390/met7050173