Low Cycle Fatigue Behaviour of DP Steels: Micromechanical Modelling vs. Validation

Abstract

:1. Introduction

2. Experimental

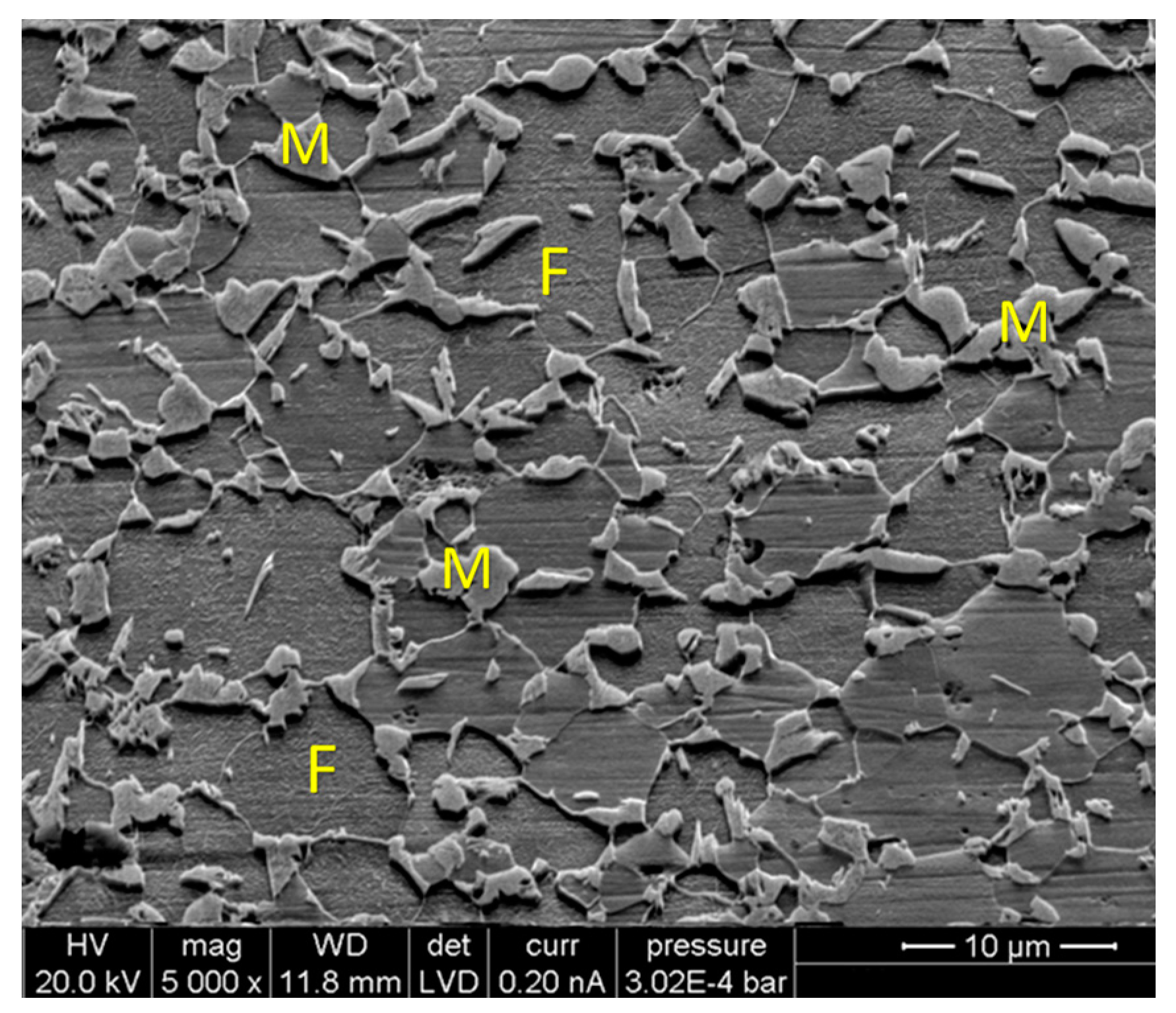

2.1. Material

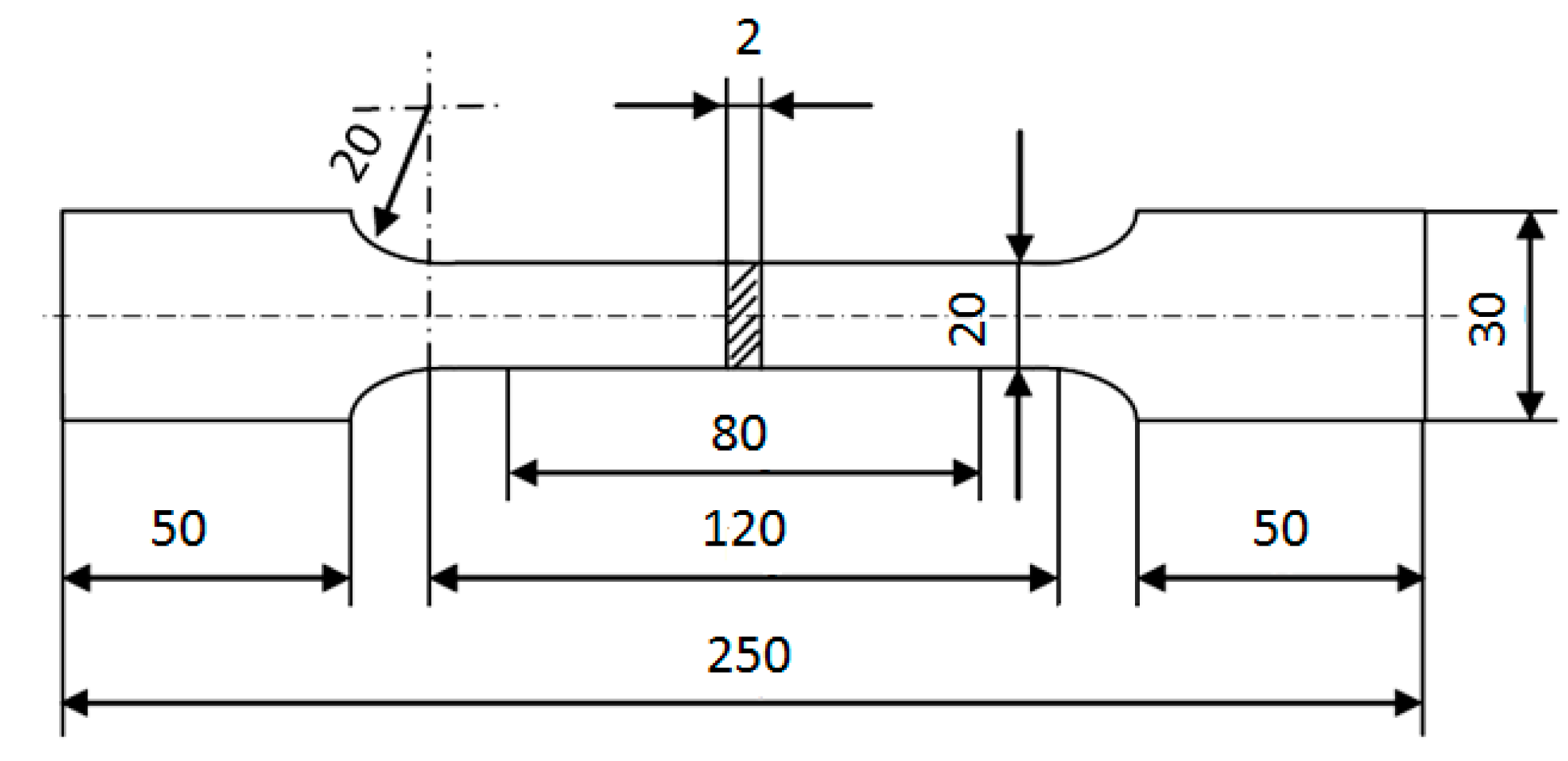

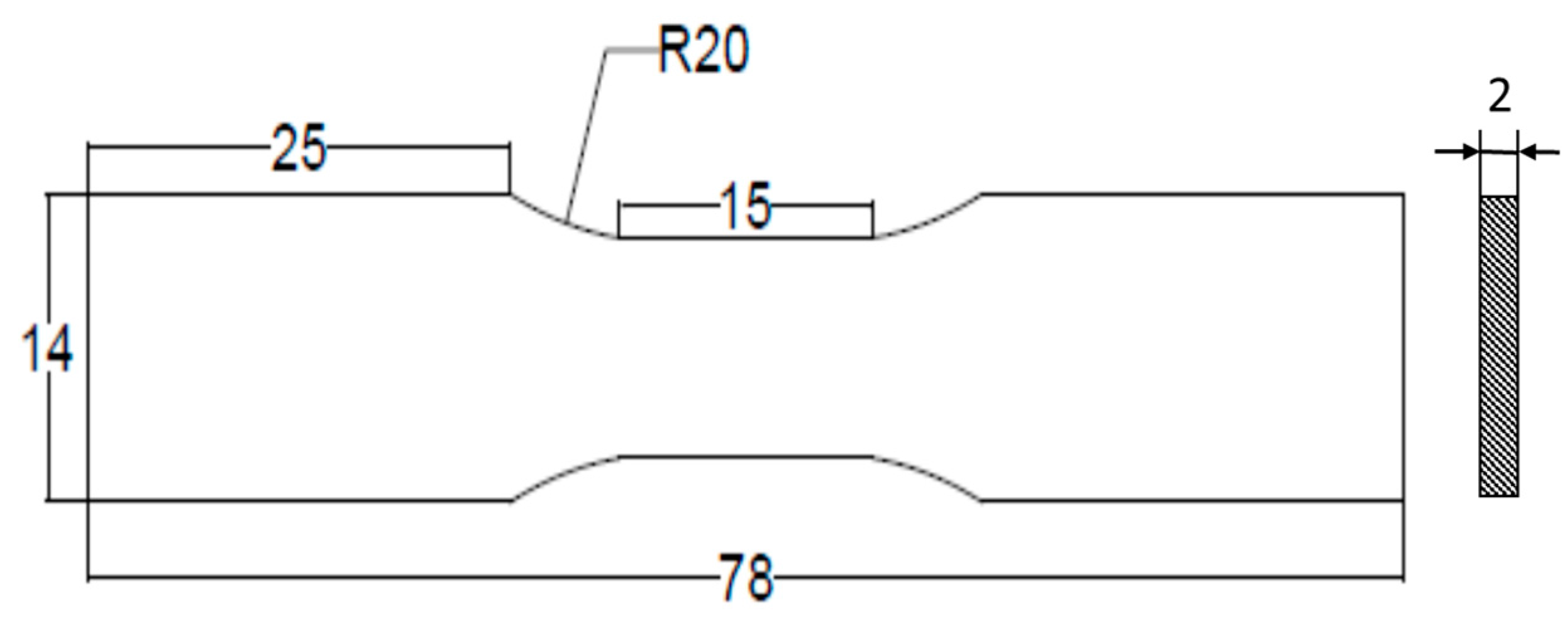

2.2. Mechanical Testing

3. Micromechanical Modelling

3.1. RVE Generation

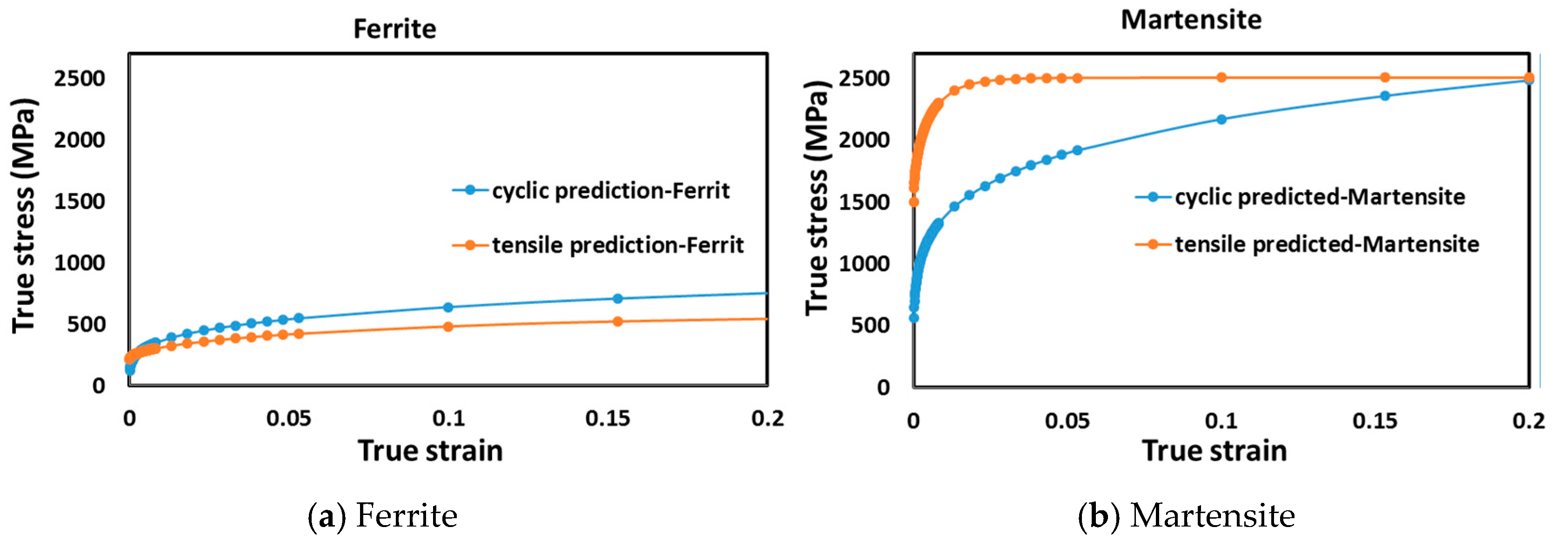

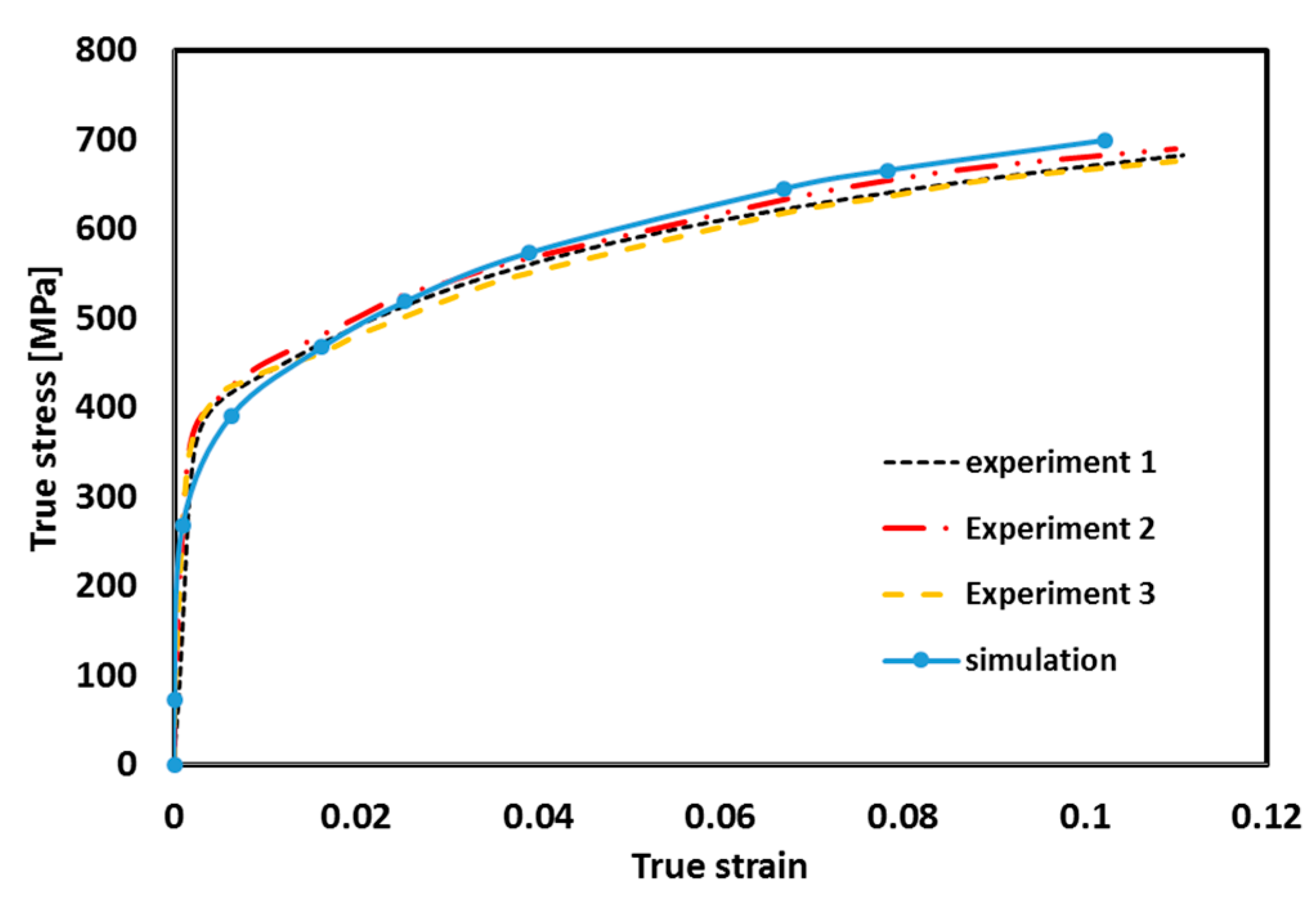

3.2. Single Phase Flow Curve Modelling

3.3. Correlation among Monotonic Flow Curve and Cyclic Behavior of Single Phases

3.4. Kinematic Hardening Parameters for Single Phases

4. Results and Discussion

5. Conclusions

- A micromechanical modelling approach using a 2D representative volume element was successfully employed to estimate the stable hysteresis stress-strain loop of multiphase steel.

- The cyclic behavior of individual phases was predicted using the dislocation density hardening model associated with the basic idea of Lopez and Fatemi [47]. about the correlation between the tensile properties and cyclic deformation.

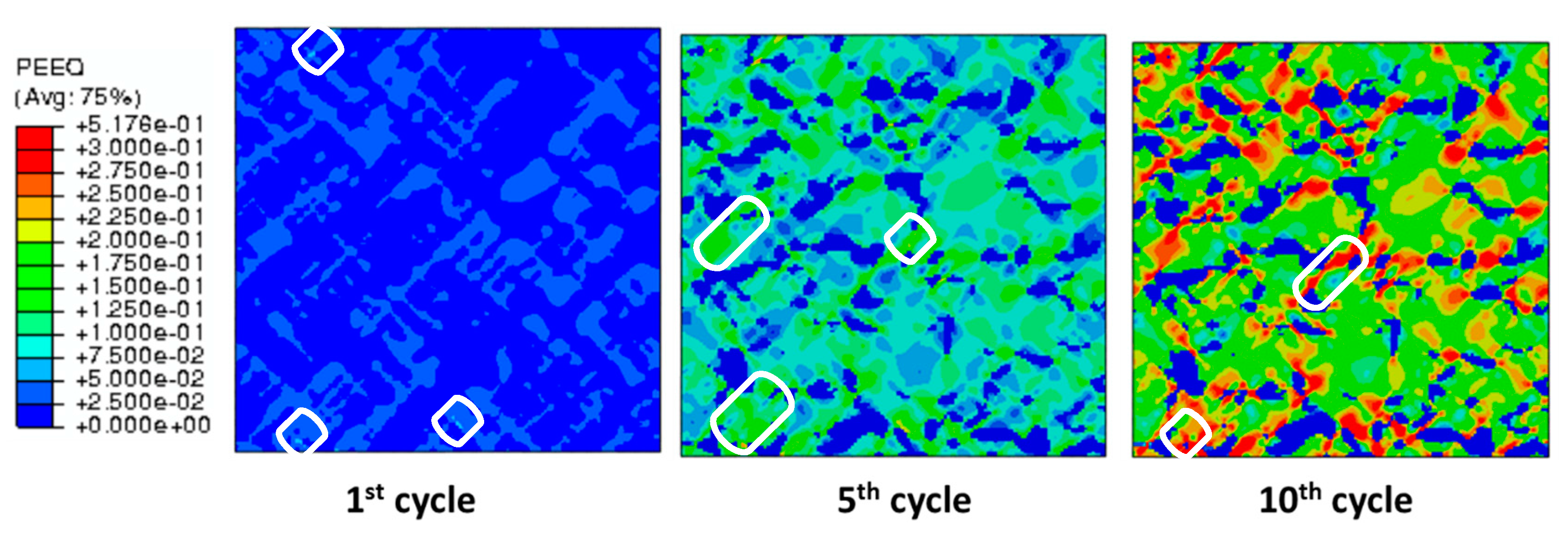

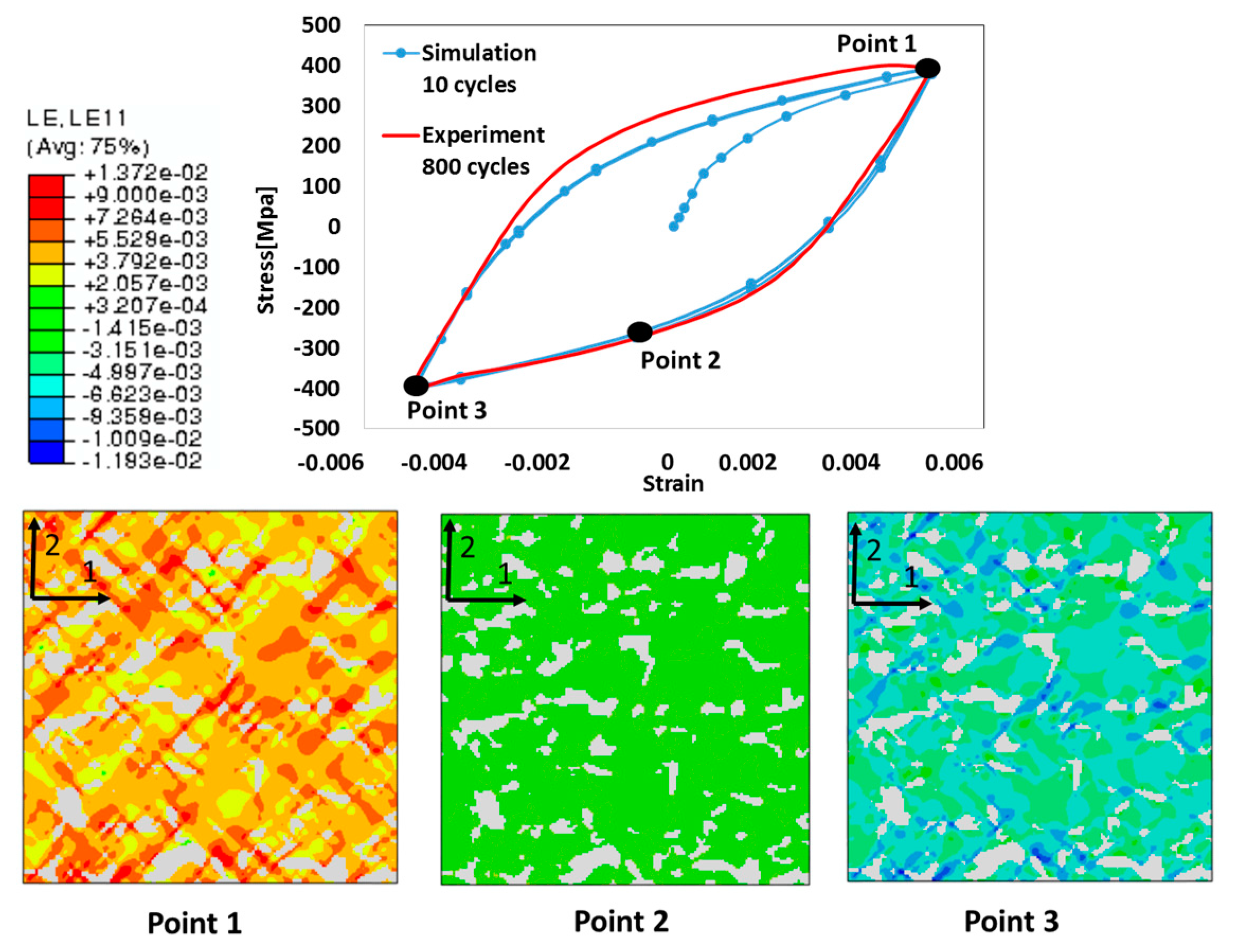

- The simulation shows the acceptable cyclic hardening/softening behavior for single phases. Also, the difference in the cyclic behavior of single phases resulted in an inhomogeneous strain accumulation in soft ferrite.

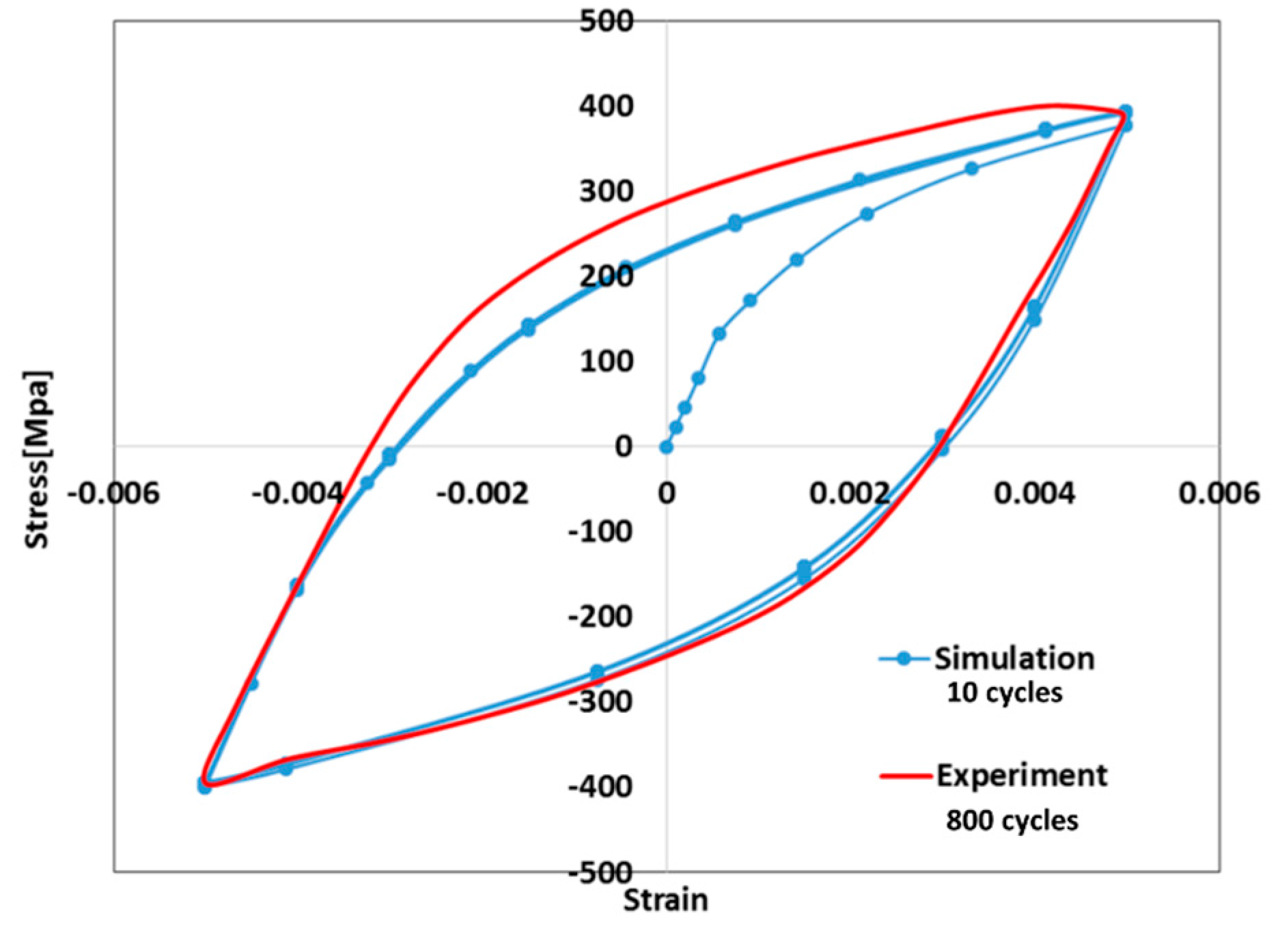

- The comparison between experimental and simulated hysteresis stress-strain loop showed good agreement. Therefore, this approach can be considered as a method to predict the stabilised stress-strain hysteresis loop of dual phase steel.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Nam, W.J.; Bae, C.M. Microstructural evolution and its relation to mechanical properties in a drawn dual-phase steel. J. Mater. Sci. 1999, 34, 5661–5668. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H.; Honeycombe, R.W.K. Steels: Microstructure and Properties; Butterworth-Heinemann (Elsevier): Oxford, UK, 2006. [Google Scholar]

- Ramazani, A.; Mukherjee, K.; Schwedt, A.; Goravanchi, P.; Prahl, U.; Bleck, W. Quantification of the effect of transformation-induced geometrically necessary dislocations on the flow-curve modelling of dual-phase steels. Int. J. Plast. 2013, 43, 128–152. [Google Scholar] [CrossRef]

- Bleck, W. Cold-rolled, high-strength sheet steels for auto applications. JOM 1996, 48, 26–30. [Google Scholar] [CrossRef]

- Ramazani, A.; Mukherjee, K.; Abdurakhmanov, A.; Abbasi, M.; Prahl, U. Characterization of Microstructure and Mechanical Properties of Resistance Spot Welded DP600 Steel. Metals 2015, 5, 1704–1716. [Google Scholar] [CrossRef]

- Ramazani, A.; Mukherjee, K.; Prahl, U.; Bleck, W. Transformation-induced, geometrically necessary, dislocation-based flow curve modeling of dual-phase steel: effect of grain size. Metall. Trans. A 2012, 43, 3850–3869. [Google Scholar] [CrossRef]

- Schijve, J. Fatigue of Structures and Materials, 2nd ed.; Springer: Houten, The Netherlands, 2009. [Google Scholar]

- Lee, M.G.; Lim, H.; Adams, B.L.; Hirth, J.P.; Wagoner, R.H. A dislocation density-based single crystal constitutive equation. Int. J. Plast. 2010, 26, 925–938. [Google Scholar] [CrossRef]

- Hobbacher, A.F. Recommendations for Fatigue Design of Welded Joints and Components; IIW Collection; Springer: Cham, Switzerland, 2016. [Google Scholar]

- Ramazani, A.; Kazemiabnavi, S.; Larson, R. Quantification of ferrite-martensite interface in dual phase steels: A first-principles study. Acta Mater. 2016, 116, 231–237. [Google Scholar] [CrossRef]

- Sun, X.; Choi, K.S.; Liu, W.N.; Khaleel, M.A. Predicting failure modes and ductility of dual phase steels using plastic strain localization. Int. J. Plast. 2009, 25, 1888–1909. [Google Scholar] [CrossRef]

- Shen, H.P.; Lei, T.C.; Liu, J.Z. Microscopic deformation behaviour of martensitic-ferritic dual-phase steels. Mater. Sci. Technol. 1986, 2, 28–33. [Google Scholar] [CrossRef]

- Mazinani, M.; Poole, W.J. Effect of Martensite Plasticity on the deformation behavior of a low-carbon dual-phase steel. Metall. Mater. Trans. A 2007, 38, 328–339. [Google Scholar] [CrossRef]

- Ramazani, A.; Ebrahimi, Z.; Prahl, U. Study the effect of martensite banding on the failure initiation in dual-phase steel. Comput. Mater. Sci. 2014, 87, 241–247. [Google Scholar] [CrossRef]

- Suresh, S. Fatigue of Materials, 2nd ed.; Cambridge University Press: Cambridge, UK, 2002. [Google Scholar]

- Sherman, A.M.; Davies, R.G. Fatigue of a dual-phase steel. Metall. Trans. A 1979, 10, 929–933. [Google Scholar] [CrossRef]

- Mediratta, S.R.; Ramaswamy, V.; Rao, P.R. Influence of ferrite-martensite microstructural morphology on the low cycle fatigue of a dual-phase steel. Int. J. Fatigue 1985, 7, 107–115. [Google Scholar] [CrossRef]

- Hadianfard, M.J. Low cycle fatigue behavior and failure mechanism of a dual-phase steel. Mater. Sci. Eng. A 2009, 499, 493–499. [Google Scholar] [CrossRef]

- Paul, S.K.; Stanford, N.; Hilditch, T. Effect of martensite morphology on low cycle fatigue behaviour of dual phase steels: Experimental and microstructural investigation. Mater. Sci. Eng. A 2015, 644, 53–60. [Google Scholar] [CrossRef]

- McDowell, D.L.; Dunne, F.P.E. Microstructure-sensitive computational modeling of fatigue crack formation. Int. J. Fatigue 2010, 32, 1521–1542. [Google Scholar] [CrossRef]

- Mughrabi, H. Cyclic slip irreversibility and fatigue life: A microstructure-based analysis. Acta Mater. 2013, 61, 1197–1203. [Google Scholar] [CrossRef]

- Mughrabi, H. Cyclic plasticity and fatigue of metals. J. Phys. IV Colloq. 1993, 3, 659–668. [Google Scholar] [CrossRef]

- Shenoy, M.; Tjiptowidjojo, Y.; McDowell, D. Microstructure-sensitive modeling of polycrystalline IN 100. Int. J. Plast. 2008, 24, 1694–1730. [Google Scholar] [CrossRef]

- Shenoy, M.; Zhang, J.; McDowell, D.L. Estimating fatigue sensitivity to polycrystalline Ni-base superalloy microstructures using a computational approach. Fatigue Fract. Eng. Mater. Struct. 2007, 30, 889–904. [Google Scholar] [CrossRef]

- Steglich, D.; Pirondi, A.; Bonora, N.; Brocks, W. Micromechanical modelling of cyclic plasticity incorporating damage. Int. J. Solids Struct. 2005, 42, 337–351. [Google Scholar] [CrossRef]

- Paul, S.K. Effect of material inhomogeneity on the cyclic plastic deformation behavior at the microstructural level: Micromechanics-based modeling of dual-phase steel. Model. Simul. Mater. Sci. Eng. 2013, 21, 055001. [Google Scholar] [CrossRef]

- Moeini, G.; Ramazani, A.; Sundararaghavan, V.; Könke, C. Micromechanical modeling of fatigue behavior of DP steels. Mater. Sci. Eng. A 2017, 689, 89–95. [Google Scholar] [CrossRef]

- ASTM. E562-11, Standard Test Method for Determining Volume Fraction by Systematic Manual Point Count. In ASTM E562; ASTM International: West Conshokocken, PA, USA, 2013. [Google Scholar]

- ISO 6892-1:2016, Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. Available online: https://www.iso.org/standard/61856.html (accessed on 29 June 2017).

- Krahmer, D.M.; Polvorosa, R.; López de Lacalle, L.N.; Alonso-Pinillos, U.; Abate, G.; Riu, F. Alternatives for Specimen Manufacturing in Tensile Testing of Steel Plates. Exp. Tech. 2016, 40, 1555–1565. [Google Scholar] [CrossRef]

- ASTM. E606/E606M-12, Standard Test Method for Strain-Controlled Fatigue Testing; ASTM International: West Conshokocken, PA, USA, 2012. [Google Scholar]

- Ramazani, A.; Mukherjee, K.; Prahl, U.; Bleck, W. Modelling the effect of microstructural banding on the flow curve behaviour of dual-phase (DP) steels. Comput. Mater. Sci. 2012, 52, 46–54. [Google Scholar] [CrossRef]

- Ramazani, A.; Mukherjee, K.; Quade, H.; Prahl, U.; Bleck, W. Correlation between 2D and 3D flow curve modelling of DP steels using a microstructure-based RVE approach. Mater. Sci. Eng. A 2013, 550, 129–139. [Google Scholar] [CrossRef]

- Rodriguez, R.-M.; Gutiérrez, I. Unified Formulation to Predict the Tensile Curves of Steels with Different Microstructures. Mater. Sci. Forum 2003, 426, 4525–4530. [Google Scholar] [CrossRef]

- Bergström, Y. A dislocation model for the stress-strain behaviour of polycrystalline α-Fe with special emphasis on the variation of the densities of mobile and immobile dislocations. Mater. Sci. Eng. 1970, 5, 193–200. [Google Scholar] [CrossRef]

- Estrin, Y.; Mecking, H. A unified phenomenological description of work hardening and creep based on one-parameter models. Acta Metall. 1984, 32, 57–70. [Google Scholar] [CrossRef]

- Sevillano, J. Flow stress and work hardening. In Materials Science and Technology; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 1993. [Google Scholar]

- Anderson, E.; Bode, R.; Dorn, J.E.; Spreadborough, J. Effects of alloying elements on the mechanical properties of steels at low temperatures. Met. Sci. J. 1969, 3, 201–208. [Google Scholar] [CrossRef]

- Thomser, C. Modelling of the Mechanical Properties of Dual Phase Steels Based on Microstructure. Ph.D. Thesis, RWTH Aachen University, Aachen, Germany, 2009. [Google Scholar]

- Ramazani, A.; Abbasi, M.; Kazemiabnavi, S.; Schmauder, S.; Larson, R.; Prahl, U. Development and application of a microstructure-based approach to characterize and model failure initiation in DP steels using XFEM. Mater. Sci. Eng. A 2016, 660, 181–194. [Google Scholar] [CrossRef]

- Ramazani, A.; Chang, Y.; Prahl, U. Characterization and modeling of failure initiation in bainite-aided DP steel. Adv. Eng. Mater. 2014, 16, 1370–1380. [Google Scholar] [CrossRef]

- Dewa, R.; Kim, S.; Kim, W.; Kim, E. Effect of strain range on the low cycle fatigue in alloy 617 at high temperature. Metals 2017, 7, 54. [Google Scholar] [CrossRef]

- Dewa, R.; Kim, S.; Kim, W.; Kim, E. Understanding low cycle fatigue behavior of alloy 617 base metal and weldments at 900 °C. Metals 2016, 6, 178. [Google Scholar] [CrossRef]

- Branco, R.; Costa, J.; Antunes, F.; Perdigão, S. Monotonic and cyclic behavior of DIN 34CrNiMo6 tempered alloy steel. Metals 2016, 6, 98. [Google Scholar] [CrossRef]

- Landgraf, R.W.; Morrow, J.; Endo, T. Determination of cyclic stress-strain curve. J. Mater. 1969, 4, 176–188. [Google Scholar]

- Smith, R.W.; Hirschberg, M.H.; Manson, S.S. Fatigue Behavior under Strain Cycling in Low and Intermediate Life Range; NACA TN D-1574; National Advisory Committee for Aeronautics, Lewis Research Center: Cleveland, OH, USA, 1963. [Google Scholar]

- Lopez, Z.; Fatemi, A. A method of predicting cyclic stress-strain curve from tensile properties for steels. Mater. Sci. Eng. A 2012, 556, 540–550. [Google Scholar] [CrossRef]

- Prager, W. A New method of analyzing stresses and strains in work-hardening plastic solids. J. Appl. Mech. 1956, 23, 493–496. [Google Scholar]

- Armstrong, P.; Frederick, C. A Mathematical Representation of the Multiaxial Bauschinger Effect; CEGB Report No. RD/B/N 731; Research & Development Departement: Berkeley, CA, USA, 1966. [Google Scholar]

- Chaboche, J.L. On some modifications of kinematic hardening to improve the description of ratchetting effects. Int. J. Plast. 1991, 7, 661–678. [Google Scholar] [CrossRef]

- Ohno, N.; Wang, J.D. Kinematic hardening rules with critical state of dynamic recovery, part I: Formulation and basic features for ratchetting behavior. Int. J. Plast. 1993, 9, 375–390. [Google Scholar] [CrossRef]

- Bari, S.; Hassan, T. Kinematic hardening rules in uncoupled modeling for multiaxial ratcheting simulation. Int. J. Plast. 2001, 17, 885–905. [Google Scholar] [CrossRef]

- Tu, S.-T.; Zhang, X.-C. Fatigue crack initiation mechanisms. Ref. Modul. Mater. Sci. Mater. Eng. 2016, 1–23. [Google Scholar]

- Ramazani, A.; Schwedt, A.; Aretz, A.; Prahl, U. Failure initiation in dual-phase steel. Key Eng. Mater. 2013, 586, 67–71. [Google Scholar] [CrossRef]

| Chemical Composition (wt %) | |||||||

|---|---|---|---|---|---|---|---|

| C | Mn | Si | P | S | Al | Cr | Mo |

| 0.099 | 1.23 | 0.079 | 0.012 | 0.001 | 0.894 | 0.04 | 0.195 |

| Sy (MPa) | Su (MPa) | El (%) |

|---|---|---|

| 402 | 616 | 23.1 |

| α | Taylor Factor M | Shear Modulus µ (MPa) | Burgers Vector b (m) | Dislocation Mean Free Path L (m) | Recovery Rate kr | ||

|---|---|---|---|---|---|---|---|

| Ferrite | Martensite | Ferrite | Martensite | ||||

| 0.33 | 3 | 80,000 | 2.5 × 10−10 | dα | 3.8 × 10−8 | 10−5/dα | 41 |

| Phase | σ0 (MPa) | C1 (MPa) | C2 (MPa) | C3 (MPa) | γ1 | γ2 | γ3 |

|---|---|---|---|---|---|---|---|

| Ferrite | 119 | 113,358 | 19,591 | 3450.5 | 1177 | 111.81 | 7.0668 |

| Martensite | 563.16 | 10,333 | 49,958 | 2.5 × 105 | 8.2915 | 99.816 | 768.79 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moeini, G.; Ramazani, A.; Myslicki, S.; Sundararaghavan, V.; Könke, C. Low Cycle Fatigue Behaviour of DP Steels: Micromechanical Modelling vs. Validation. Metals 2017, 7, 265. https://doi.org/10.3390/met7070265

Moeini G, Ramazani A, Myslicki S, Sundararaghavan V, Könke C. Low Cycle Fatigue Behaviour of DP Steels: Micromechanical Modelling vs. Validation. Metals. 2017; 7(7):265. https://doi.org/10.3390/met7070265

Chicago/Turabian StyleMoeini, Ghazal, Ali Ramazani, Sebastian Myslicki, Veera Sundararaghavan, and Carsten Könke. 2017. "Low Cycle Fatigue Behaviour of DP Steels: Micromechanical Modelling vs. Validation" Metals 7, no. 7: 265. https://doi.org/10.3390/met7070265