In-Situ Investigation of Strain-Induced Martensitic Transformation Kinetics in an Austenitic Stainless Steel by Inductive Measurements

Abstract

:1. Introduction

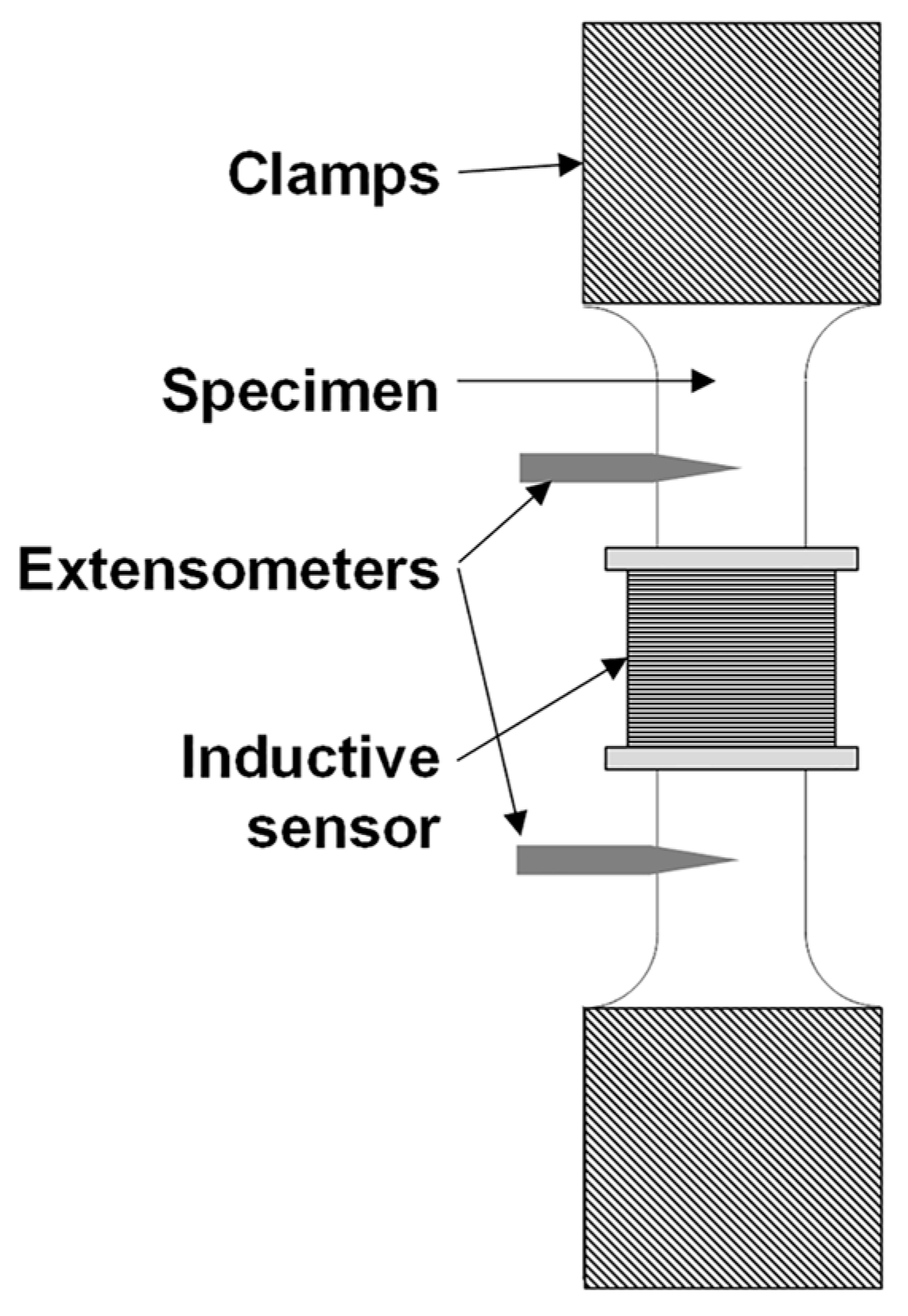

2. Materials and Methods

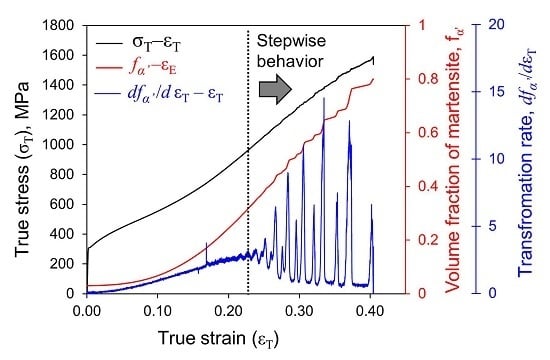

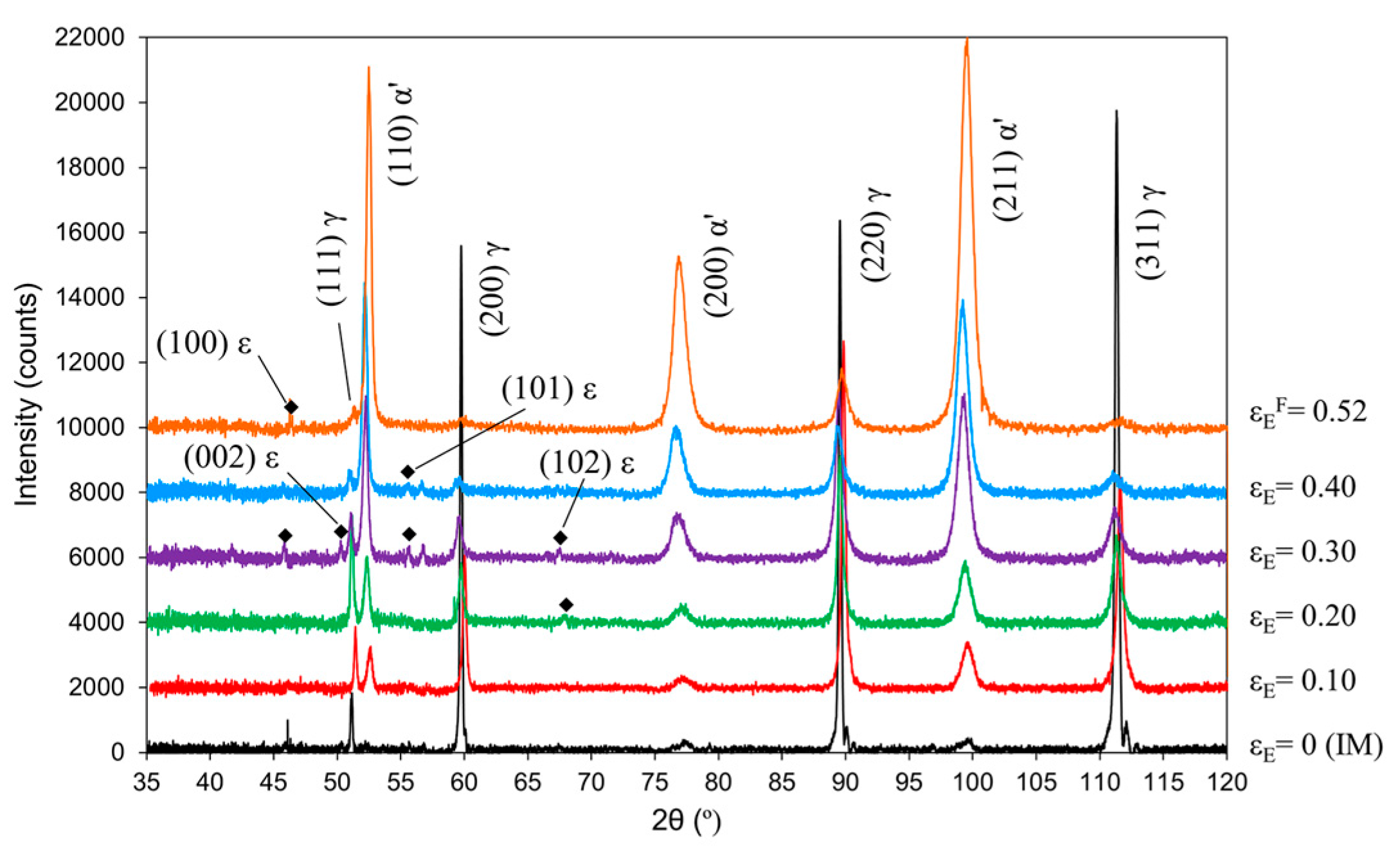

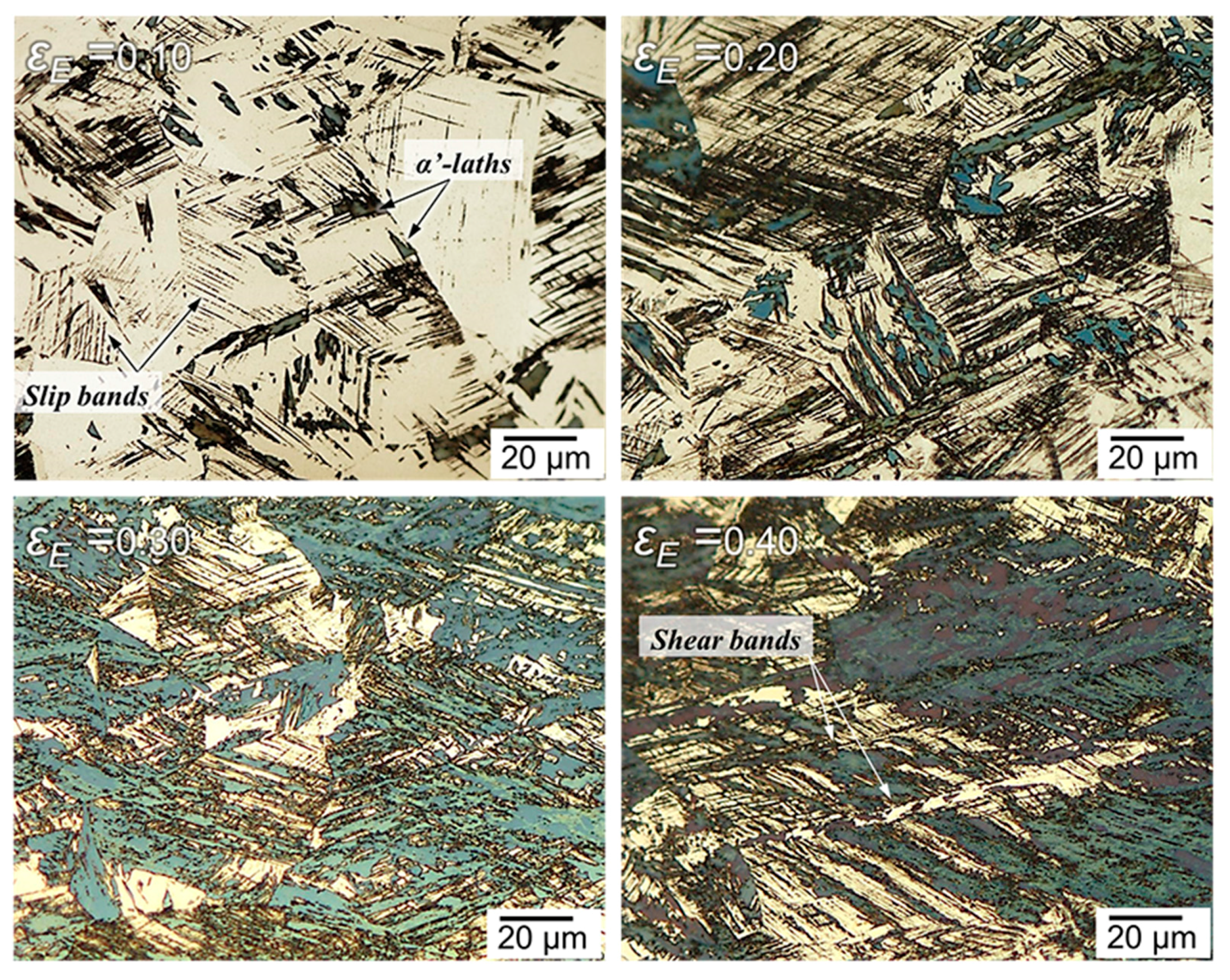

3. Results

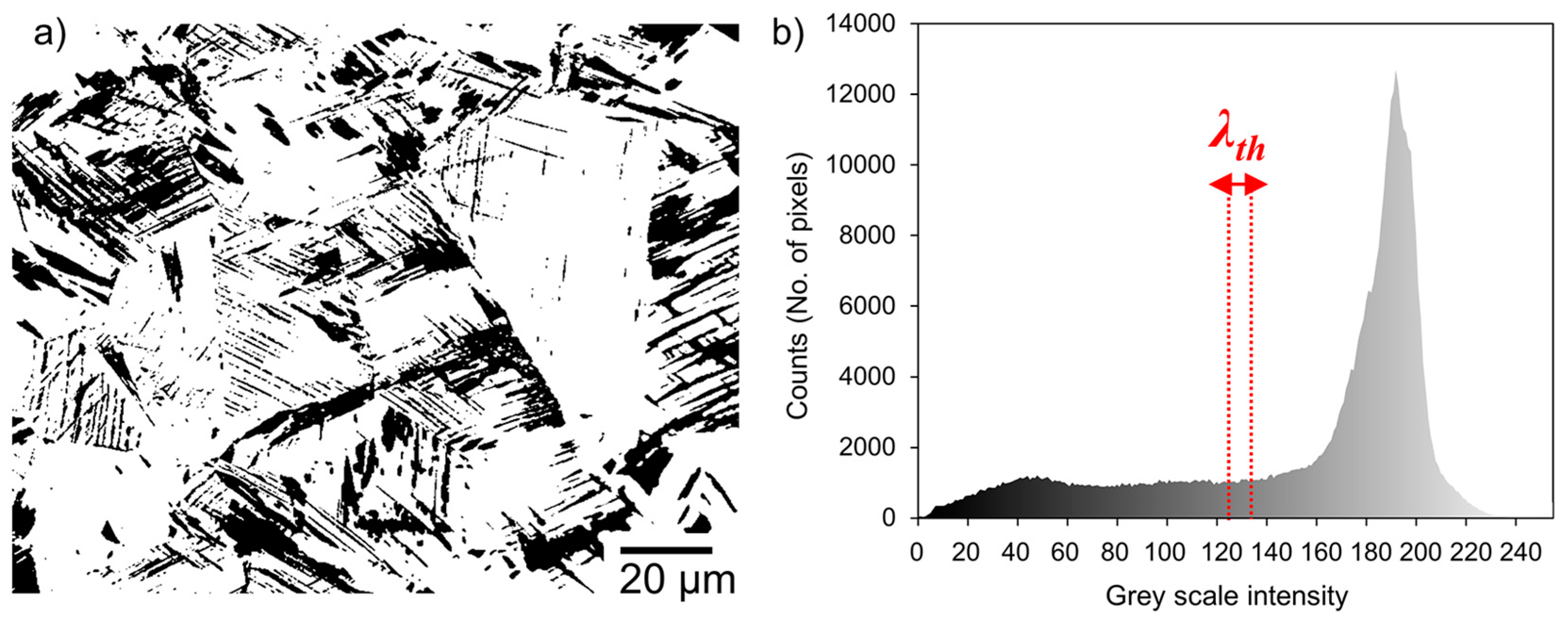

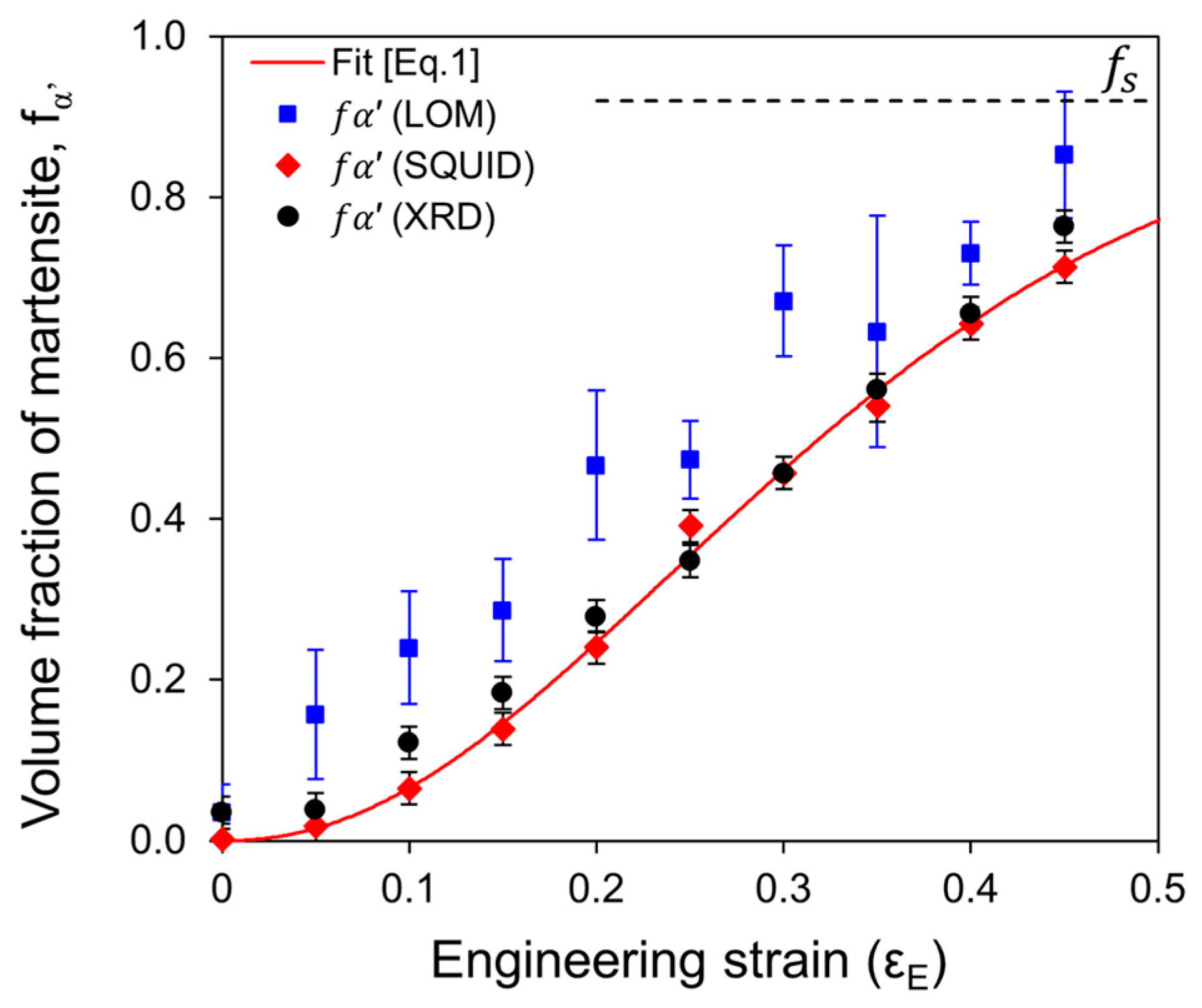

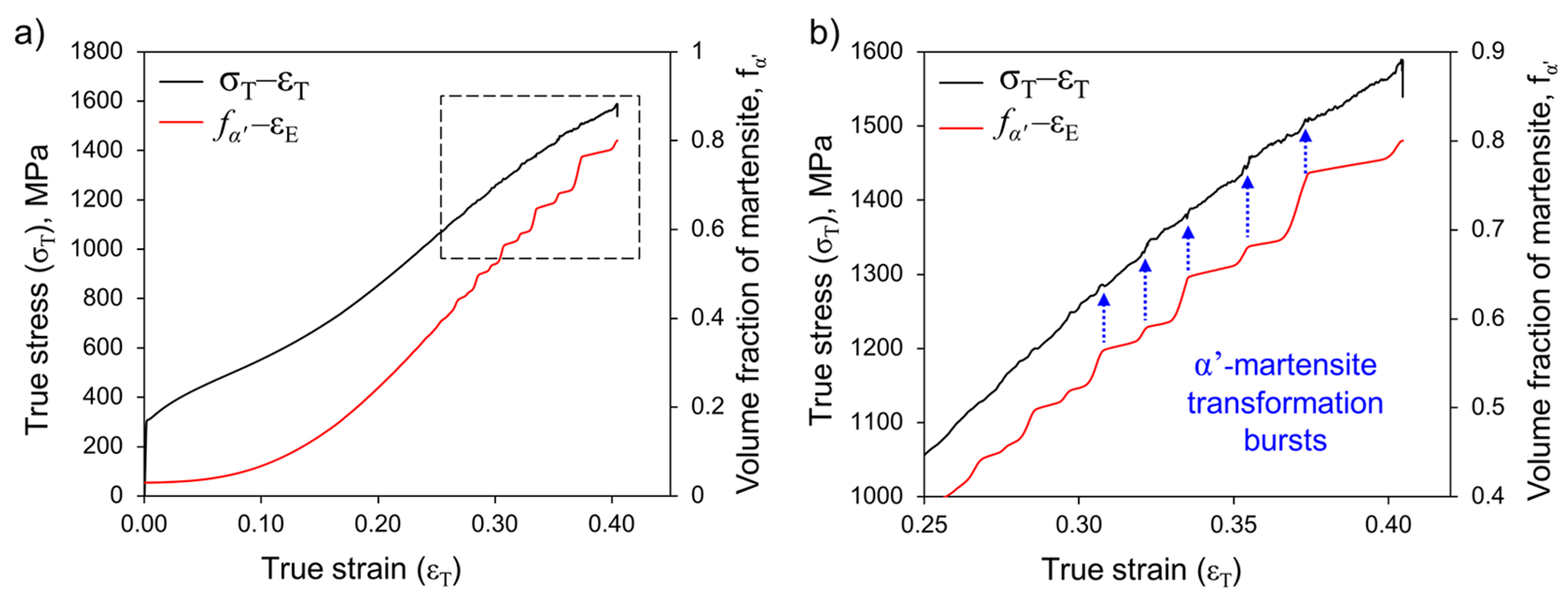

3.1. Ex-Situ Characterizatiton of Strain-Induced α′-Martensite Formation

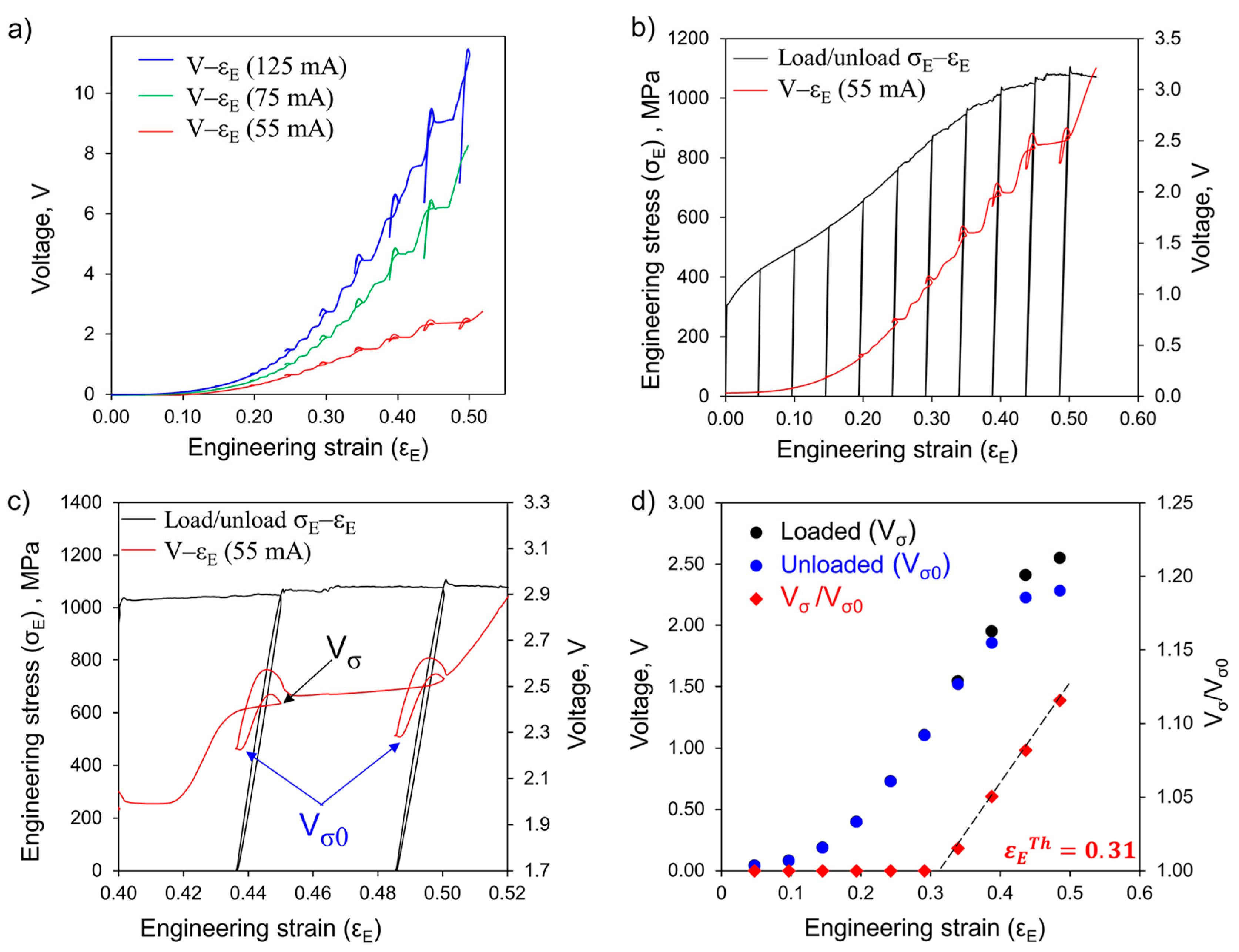

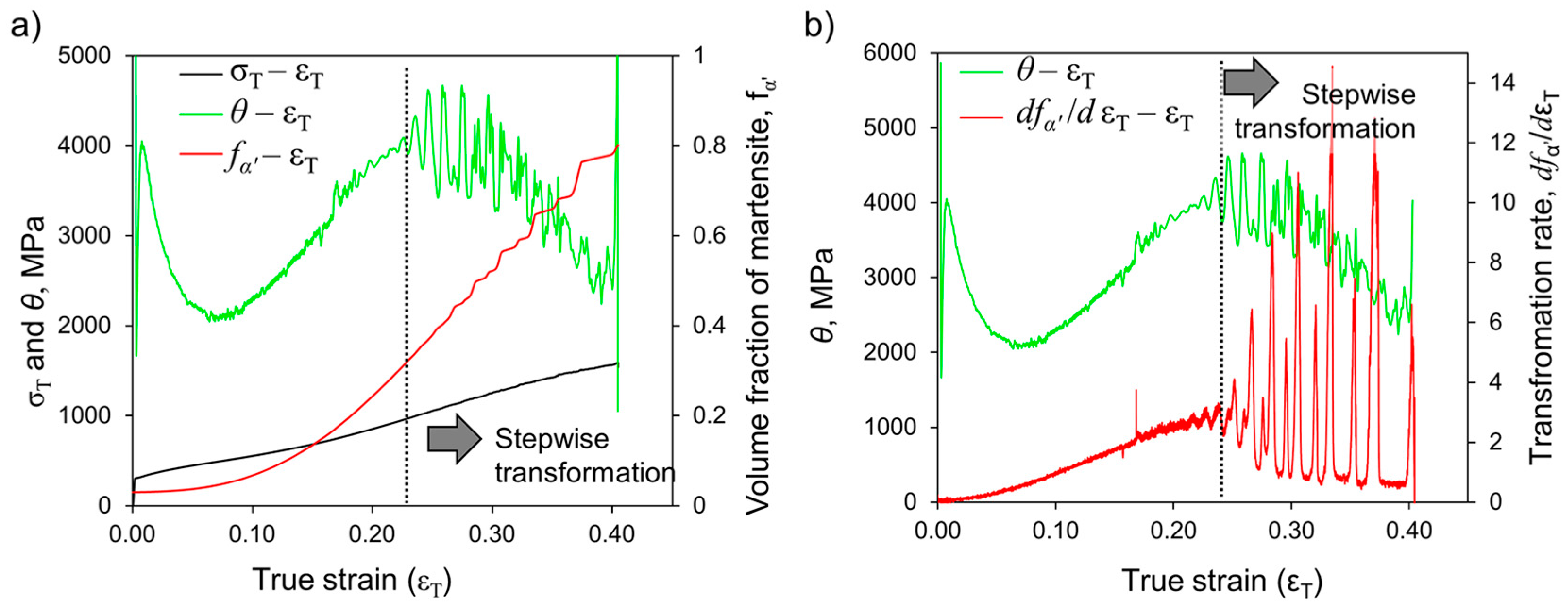

3.2. In-Situ Inductive Measurements

4. Discussion

4.1. Comparing Techniques to Desctibe the Martensitic Transformation Kinetics under Unixial Tension

4.2. The Strain-Induced Martensitic Transformation and Stepwise Behavior

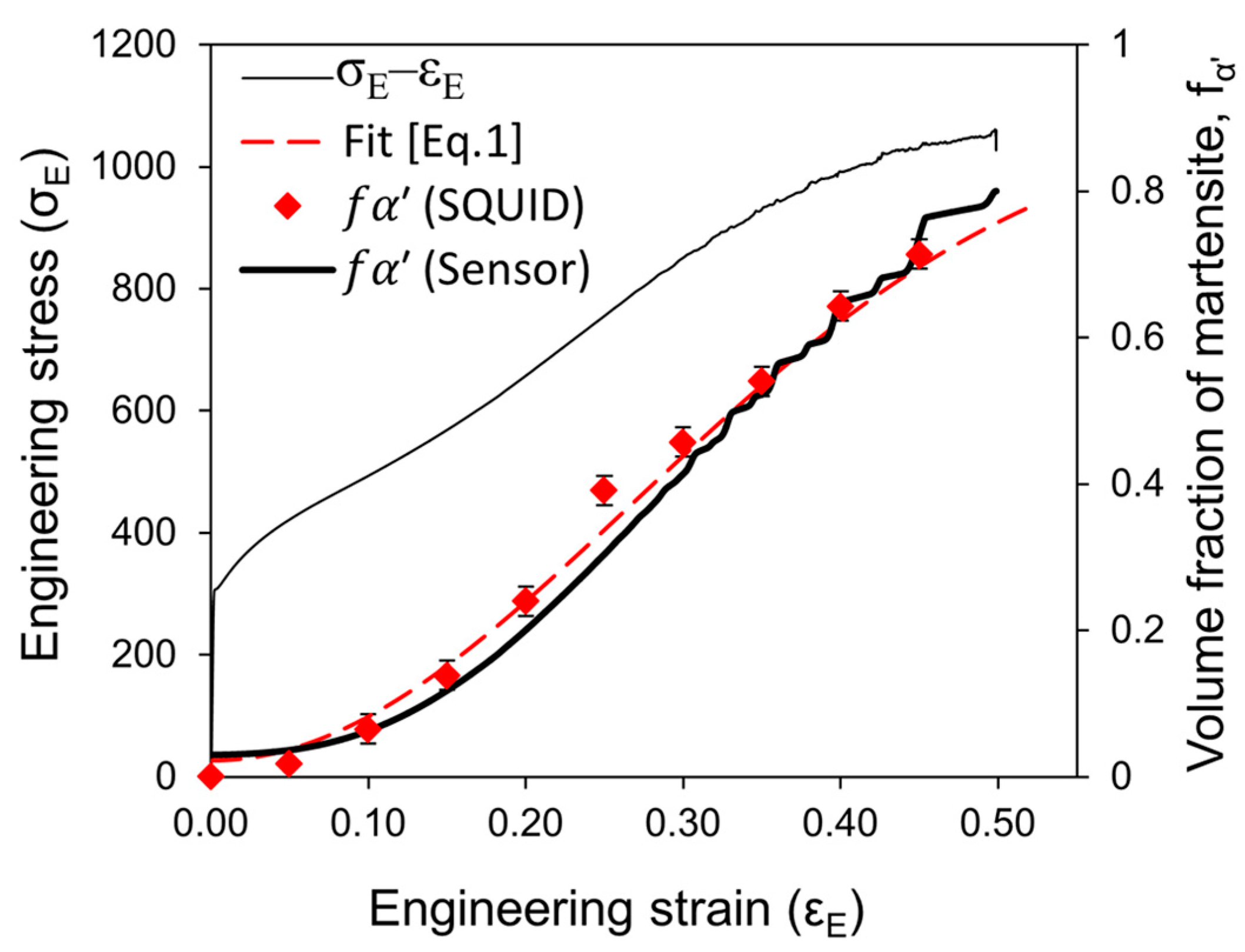

4.3. Validation of the Inductive Sensor as a Technique for In-Situ Characterization of the Strain-Induced Martensitic Transformation

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Olson, G.B.; Cohen, M. A mechanism for the strain-induced nucleation of martensitic transformations. J. Less Common Met. 1972, 28, 107–118. [Google Scholar] [CrossRef]

- Celada-Casero, C.; Huang, B.M.; Aranda, M.M.; Yang, J.R.; San Martin, D. Mechanisms of ultrafine-grained austenite formation under different isochronal conditions in a cold-rolled metastable stainless steel. Mater. Charact. 2016, 118, 129–141. [Google Scholar] [CrossRef]

- Perdahcıoğlu, E.S.; Geijselaers, H.J.M.; Groen, M. Influence of plastic strain on deformation-induced martensitic transformations. Scr. Mater. 2008, 58, 947–950. [Google Scholar] [CrossRef]

- Talonen, J.; Hänninen, H. Formation of shear bands and strain-induced martensite during plastic deformation of metastable austenitic stainless steels. Acta Mater. 2007, 55, 6108–6118. [Google Scholar] [CrossRef]

- Celada-Casero, C.; Chao, J.; Urones-Garrote, E.; San Martin, D. Continuous hardening during isothermal aging at 723 k (450 °C) of a precipitation hardening stainless steel. Metall. Mater. Trans. A 2016, 47, 5280–5287. [Google Scholar] [CrossRef]

- Perdahcıoğlu, E.S.; Geijselaers, H.J.M.; Huétink, J. Influence of stress state and strain path on deformation induced martensitic transformations. Mater. Sci. Eng. A 2008, 481–482, 727–731. [Google Scholar]

- Kisko, A.; Misra, R.D.K.; Talonen, J.; Karjalainen, L.P. The influence of grain size on the strain-induced martensite formation in tensile straining of an austenitic 15cr-9mn-ni-cu stainless steel. Mater. Sci. Eng. A 2013, 578, 408–416. [Google Scholar] [CrossRef]

- Haušild, P.; Davydov, V.; Drahokoupil, J.; Landa, M.; Pilvin, P. Characterization of strain-induced martensitic transformation in a metastable austenitic stainless steel. Mater. Des. 2010, 31, 1821–1827. [Google Scholar] [CrossRef]

- Hedström, P.; Lindgren, L.E.; Almer, J.; Lienert, U.; Bernier, J.; Terner, M.; Odén, M. Load partitioning and strain-induced martensite formation during tensile loading of a metastable austenitic stainless steel. Metall. Mater. Trans. A 2009, 40, 1039–1048. [Google Scholar] [CrossRef]

- Spencer, K.; Embury, J.D.; Conlon, K.T.; Véron, M.; Bréchet, Y. Strengthening via the formation of strain-induced martensite in stainless steels. Mater. Sci. Eng. A 2004, 387–389, 873–881. [Google Scholar]

- Tian, Y.; Lienert, U.; Borgenstam, A.; Fischer, T.; Hedström, P. Martensite formation during incremental cooling of fe-cr-ni alloys: An in-situ bulk X-ray study of the grain-averaged and single-grain behavior. Scr. Mater. 2017, 136, 124–127. [Google Scholar] [CrossRef]

- Murr, L.E.; Staudhammer, K.P.; Hecker, S.S. Effects of strain state and strain rate on deformation-induced transformation in 304 stainless steel: Part II Microstructural study. Metall. Trans. A 1982, 13, 627–635. [Google Scholar] [CrossRef]

- Talonen, J.; Hänninen, H.; Nenonen, P.; Pape, G. Effect of strain rate on the strain-induced γ → α′-martensite transformation and mechanical properties of austenitic stainless steels. Metall. Mater. Trans. A 2005, 36, 421–432. [Google Scholar] [CrossRef]

- Lichtenfeld, J.A.; Van Tyne, C.J.; Mataya, M.C. Effect of strain rate on stress-strain behavior of alloy 309 and 304l austenitic stainless steel. Metall. Mater. Trans. A 2006, 37, 147–161. [Google Scholar] [CrossRef]

- Post, J.; Nolles, H.; Datta, K.; Geijselaers, H.J.M. Experimental determination of the constitutive behaviour of a metastable austenitic stainless steel. Mater. Sci. Eng. A 2008, 498, 179–190. [Google Scholar] [CrossRef]

- Hedström, P.; Lienert, U.; Almer, J.; Odén, M. Stepwise transformation behavior of the strain-induced martensitic transformation in a metastable stainless steel. Scr. Mater. 2007, 56, 213–216. [Google Scholar] [CrossRef]

- Celada Casero, C.; San Martín, D. Austenite formation in a cold-rolled semi-austenitic stainless steel. Metall. Mater. Trans. A 2014, 45, 1767–1777. [Google Scholar] [CrossRef]

- Jia, N.; Eisenlohr, P.; Roters, F.; Raabe, D.; Zhao, X. Orientation dependence of shear banding in face-centered-cubic single crystals. Acta Mater. 2012, 60, 3415–3434. [Google Scholar] [CrossRef]

- Olson, G.B.; Cohen, M. Kinetics of strain-induced martensitic nucleation. Metall. Trans. A 1975, 6, 791–795. [Google Scholar] [CrossRef]

- Shin, H.C.; Ha, T.K.; Chang, Y.W. Kinetics of deformation induced martensitic transformation in a 304 stainless steel. Scr. Mater. 2001, 45, 823–829. [Google Scholar] [CrossRef]

- Post, J.; Huetink, J.; Geijselaers, H.J.M.; Voncken, R.M.J. Fem simulations of a multi stage forming process on sandvik maraging steel 1rk91 describing the stress assisted and the strain induced martensite formation. J. Phys. IV 2003, 112, 417–420. [Google Scholar] [CrossRef]

- Zhao, L.; van Dijk, N.H.; Brück, E.; Sietsma, J.; van der Zwaag, S. Magnetic and X-ray diffraction measurements for the determination of retained austenite in trip steels. Mater. Sci. Eng. A 2001, 313, 145–152. [Google Scholar] [CrossRef]

- San Martín, D.; Aarts, K.W.P.; Rivera-Díaz-del-Castillo, P.E.J.; van Dijk, N.H.; Brück, E.; van der Zwaag, S. Isothermal martensitic transformation in a 12cr-9ni-4mo-2cu stainless steel in applied magnetic fields. J. Mag. Mag. Mater. 2008, 320, 1722–1728. [Google Scholar] [CrossRef]

- Mumtaz, K.; Takahashi, S.; Echigoya, J.; Kamada, Y.; Zhang, L.F.; Kikuchi, H.; Ara, K.; Sato, M. Magnetic measurements of martensitic transformation in austenitic stainless steel after room temperature rolling. J. Mater. Sci. 2004, 39, 85–97. [Google Scholar] [CrossRef]

- De Abreu, H.F.G.; da Silva, M.J.G.; Herculano, L.F.G.; Bhadeshia, H. Texture analysis of deformation induced martensite in an aisi 301l stainless steel: Microtexture and macrotexture aspects. Mater. Res. 2009, 12, 291–297. [Google Scholar] [CrossRef]

- Patel, J.R.; Cohen, M. Criterion for the action of applied stress in the martensitic transformation. Acta Metall. 1953, 1, 531–538. [Google Scholar] [CrossRef]

- Hollomon, J.H. Tensile deformation. Trans. Metall. Soc. AIME 1945, 162, 268–290. [Google Scholar]

- Talonen, J. Effect of Strain-Induced α′-Martensite Transformation on Mechanical Properties of Metastable Austenitic Stainless Steels; Helsinki University of Technology: Helsinki, Finland, 2007. [Google Scholar]

- Post, J. On the Constitutive Behaviour of Sandvik Nanoflex TM—Modelling Experiments and Multi-Stage Forming; University of Twente: Enschede, The Netherlands, 2004. [Google Scholar]

- Radu, M.; Valy, J.; Gourgues, A.F.; Strat, F.L.; Pineau, A. Continuous magnetic method for quantitative monitoring of martensitic transformation in steels containing metastable austenite. Scr. Mater. 2005, 52, 525–530. [Google Scholar] [CrossRef]

| C | Cr | Ni | Si | Mn | Mo |

|---|---|---|---|---|---|

| Max 0.15 | 16–18 | 6.5–9 | <1.5 | <2 | <0.8 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Celada-Casero, C.; Kooiker, H.; Groen, M.; Post, J.; San-Martin, D. In-Situ Investigation of Strain-Induced Martensitic Transformation Kinetics in an Austenitic Stainless Steel by Inductive Measurements. Metals 2017, 7, 271. https://doi.org/10.3390/met7070271

Celada-Casero C, Kooiker H, Groen M, Post J, San-Martin D. In-Situ Investigation of Strain-Induced Martensitic Transformation Kinetics in an Austenitic Stainless Steel by Inductive Measurements. Metals. 2017; 7(7):271. https://doi.org/10.3390/met7070271

Chicago/Turabian StyleCelada-Casero, Carola, Harm Kooiker, Manso Groen, Jan Post, and David San-Martin. 2017. "In-Situ Investigation of Strain-Induced Martensitic Transformation Kinetics in an Austenitic Stainless Steel by Inductive Measurements" Metals 7, no. 7: 271. https://doi.org/10.3390/met7070271