The Microstructures and Tensile Properties of As-Extruded Mg–4Sm–xZn–0.5Zr (x = 0, 1, 2, 3, 4 wt %) Alloys

Abstract

:1. Introduction

2. Experimental Procedure

3. Results and Discussion

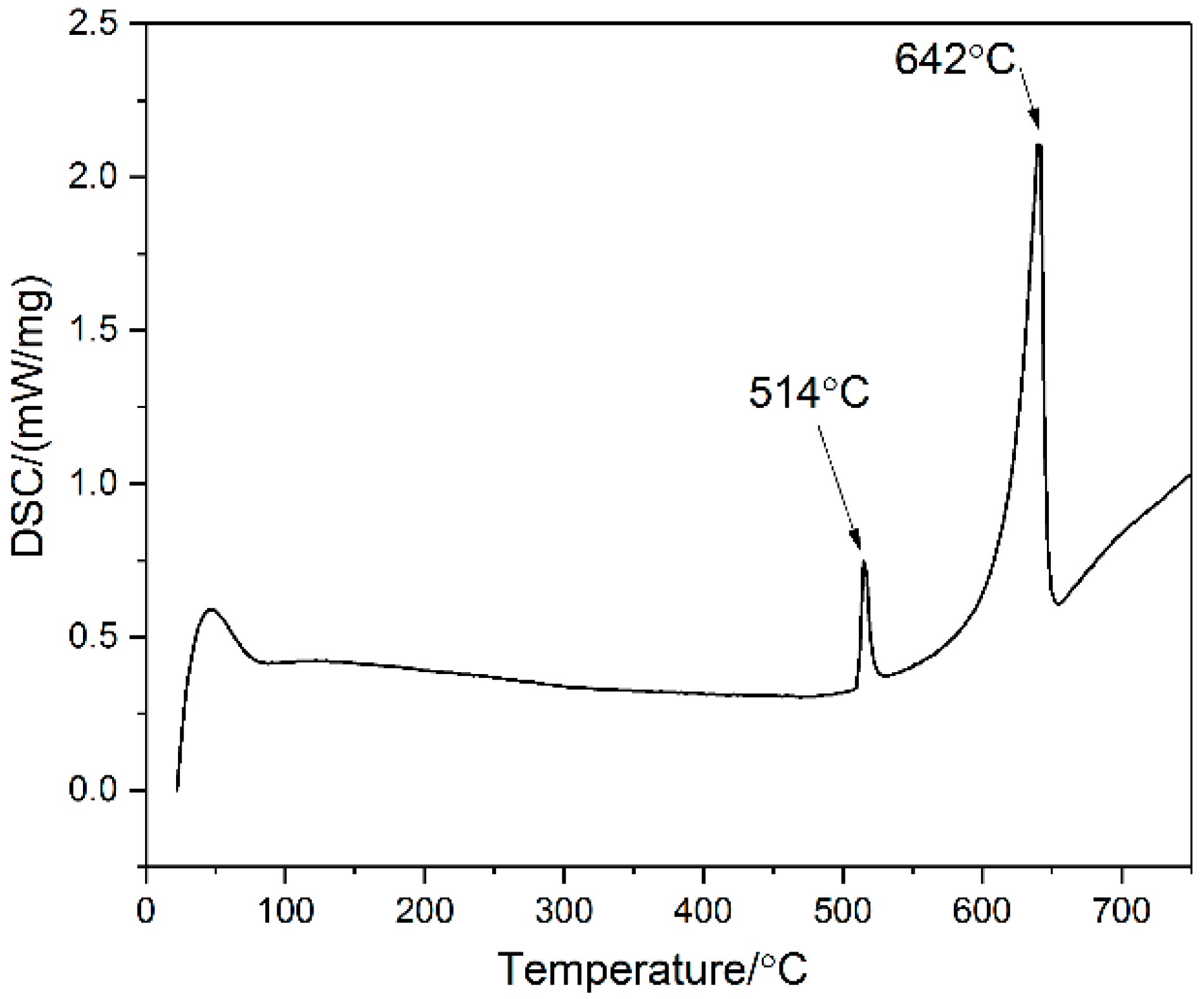

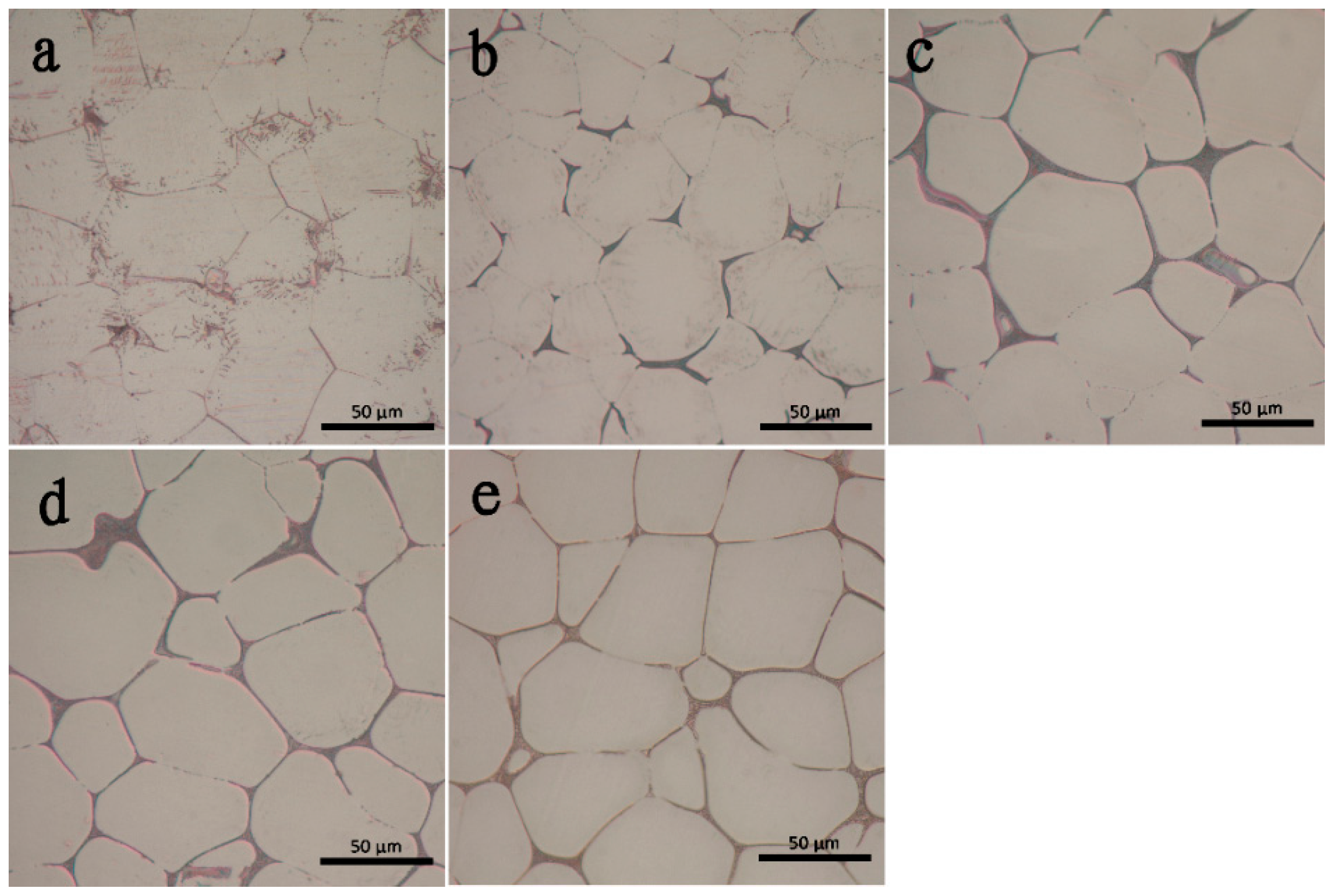

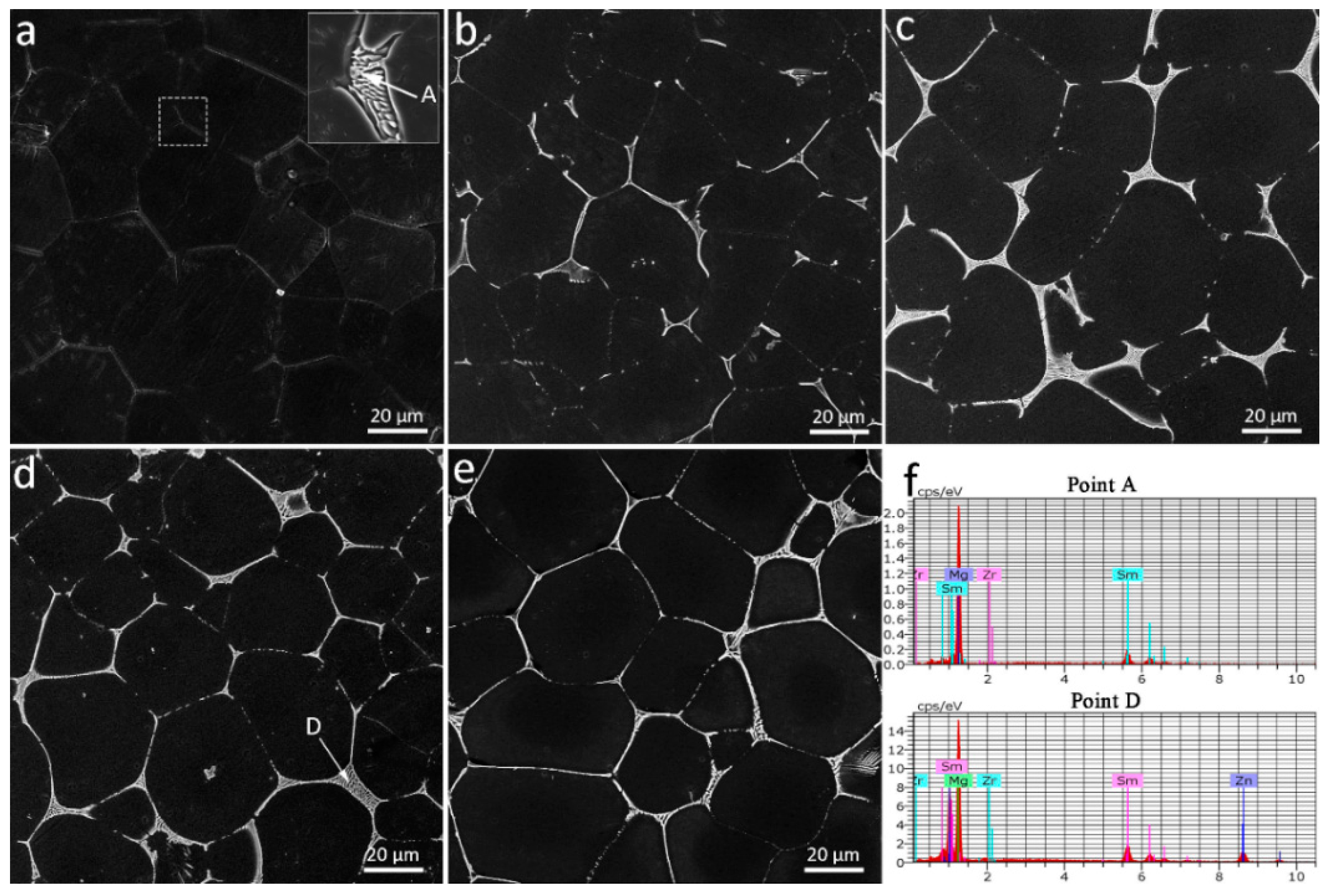

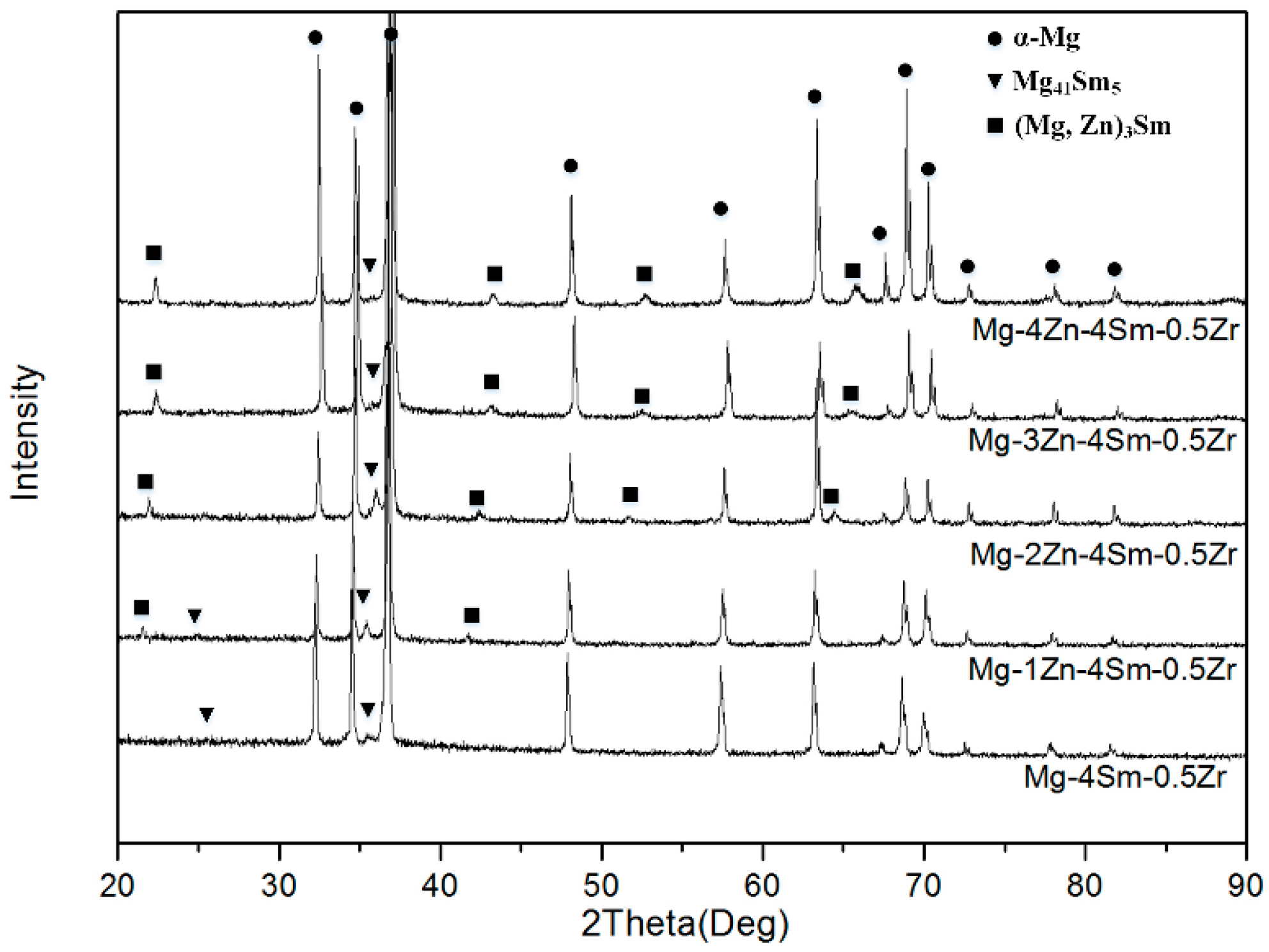

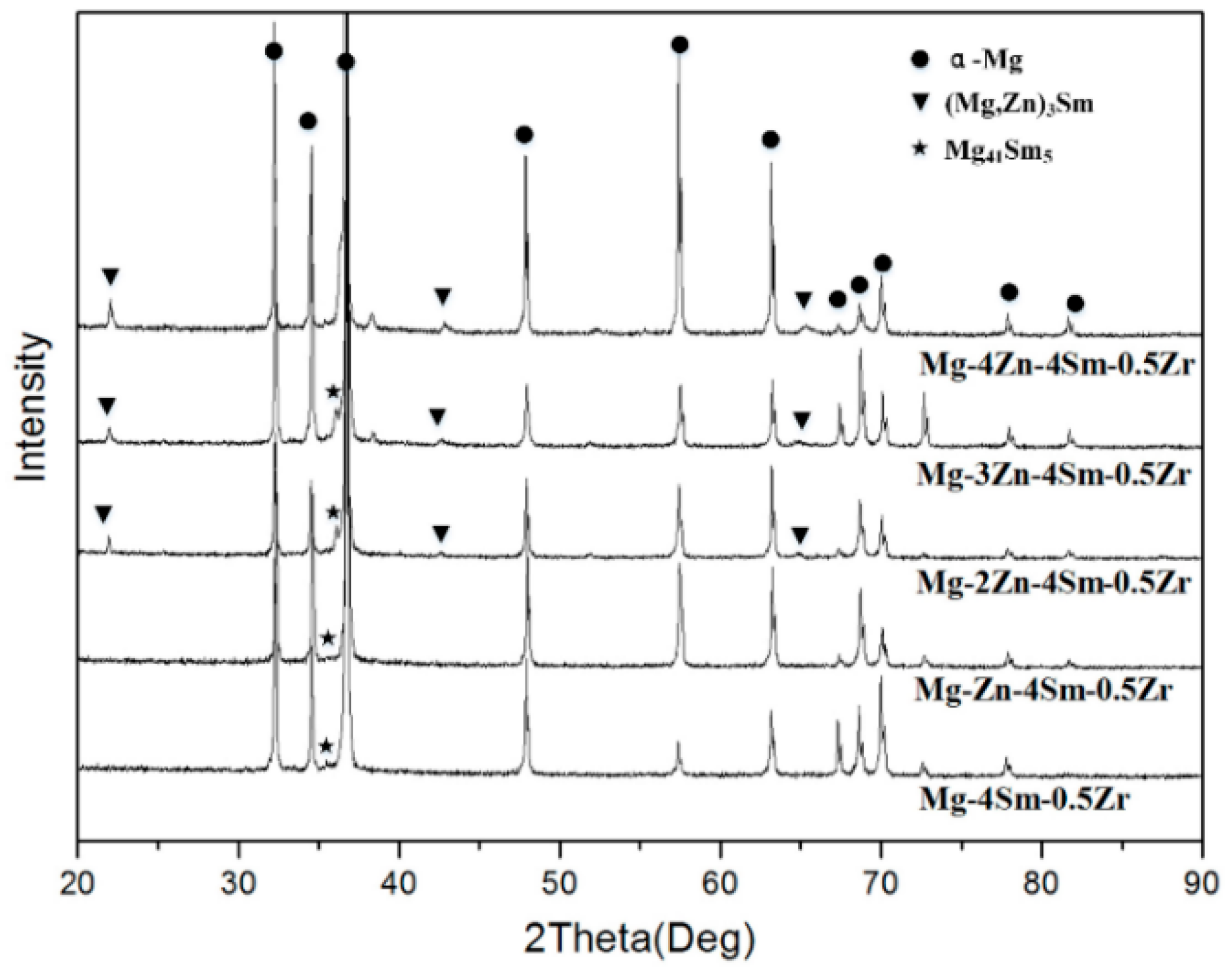

3.1. Microstructure of As-Cast Alloys

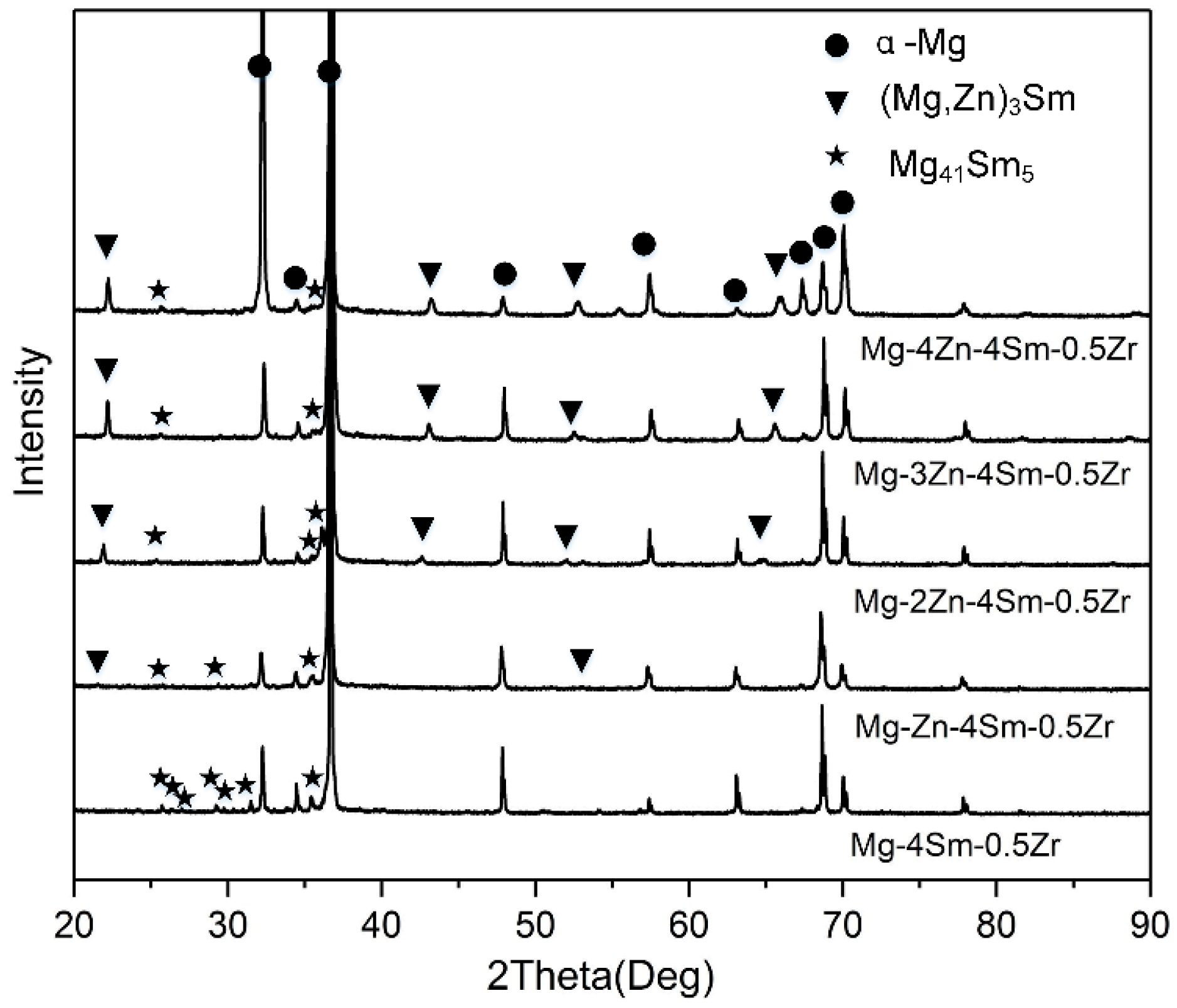

3.2. Microstructures of Solution-Treated Alloys

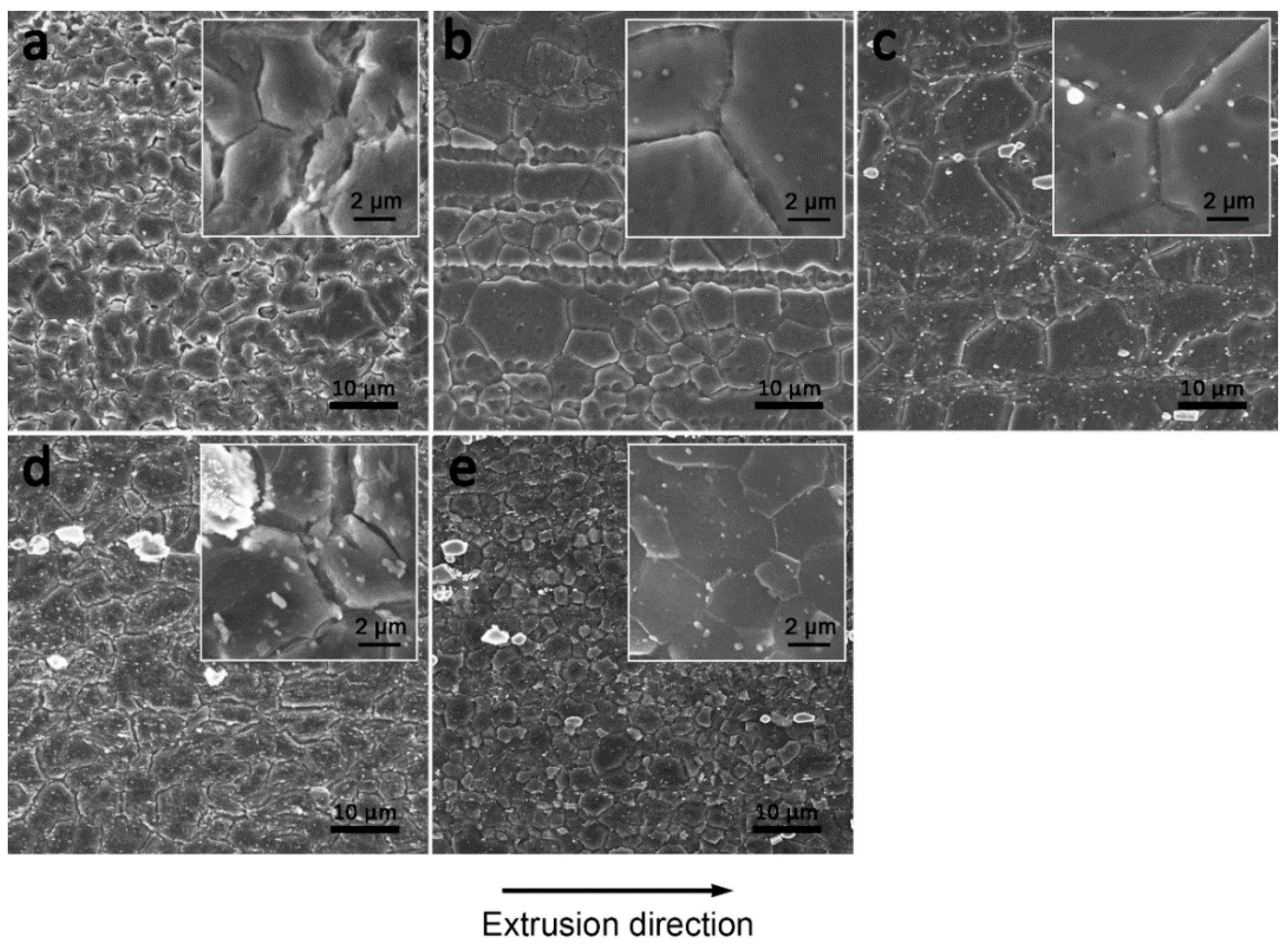

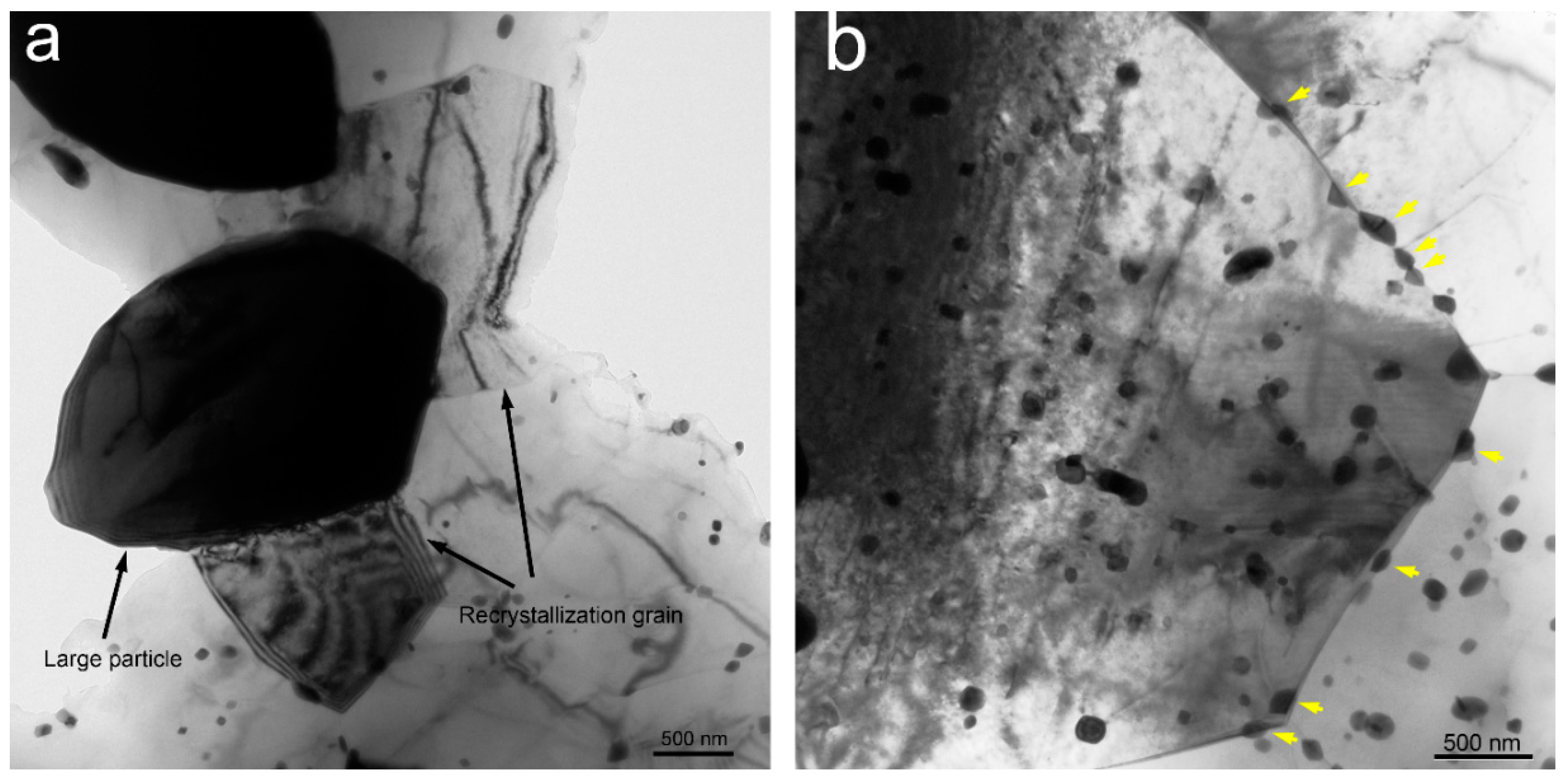

3.3. Microstructures of As-Extruded Alloys

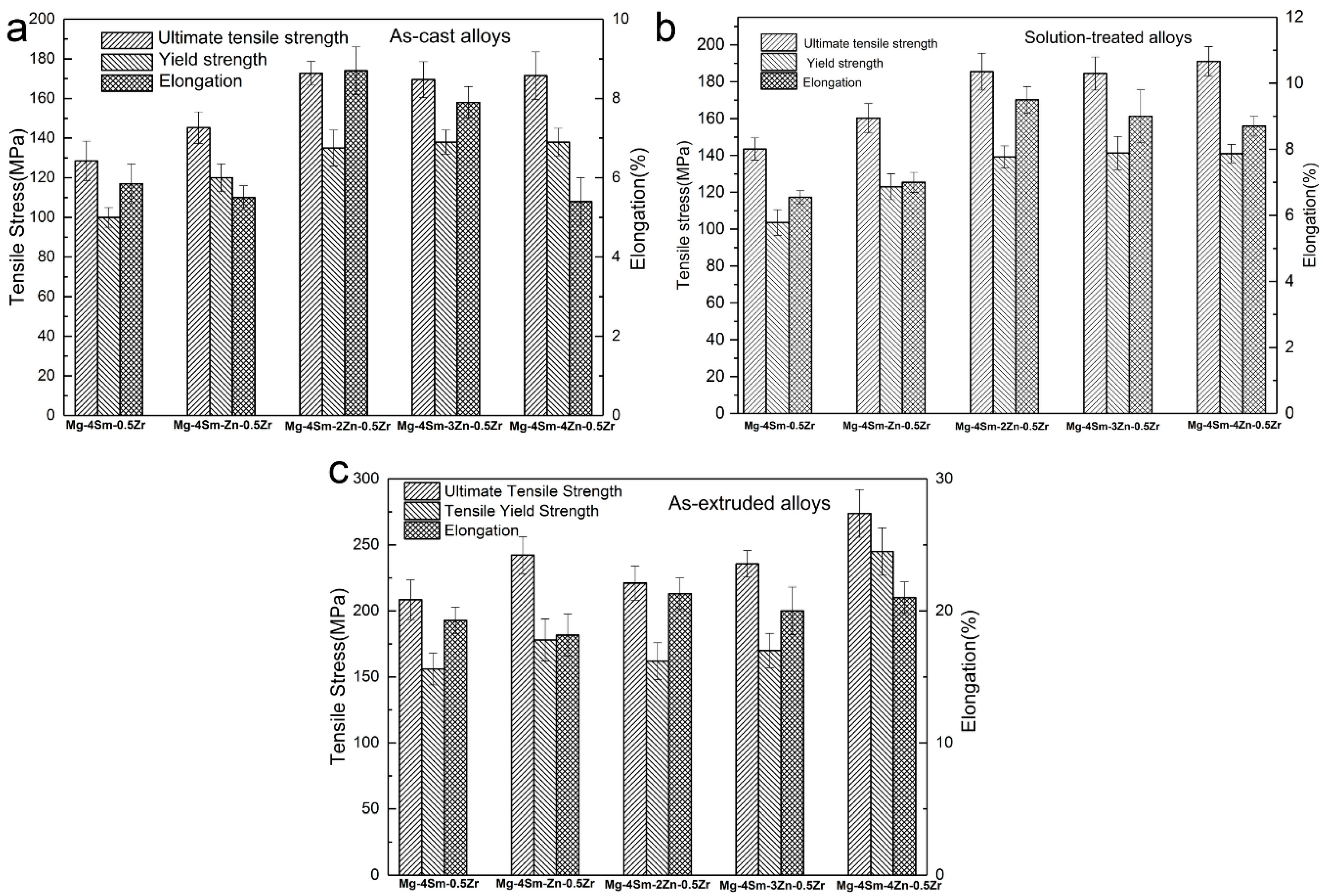

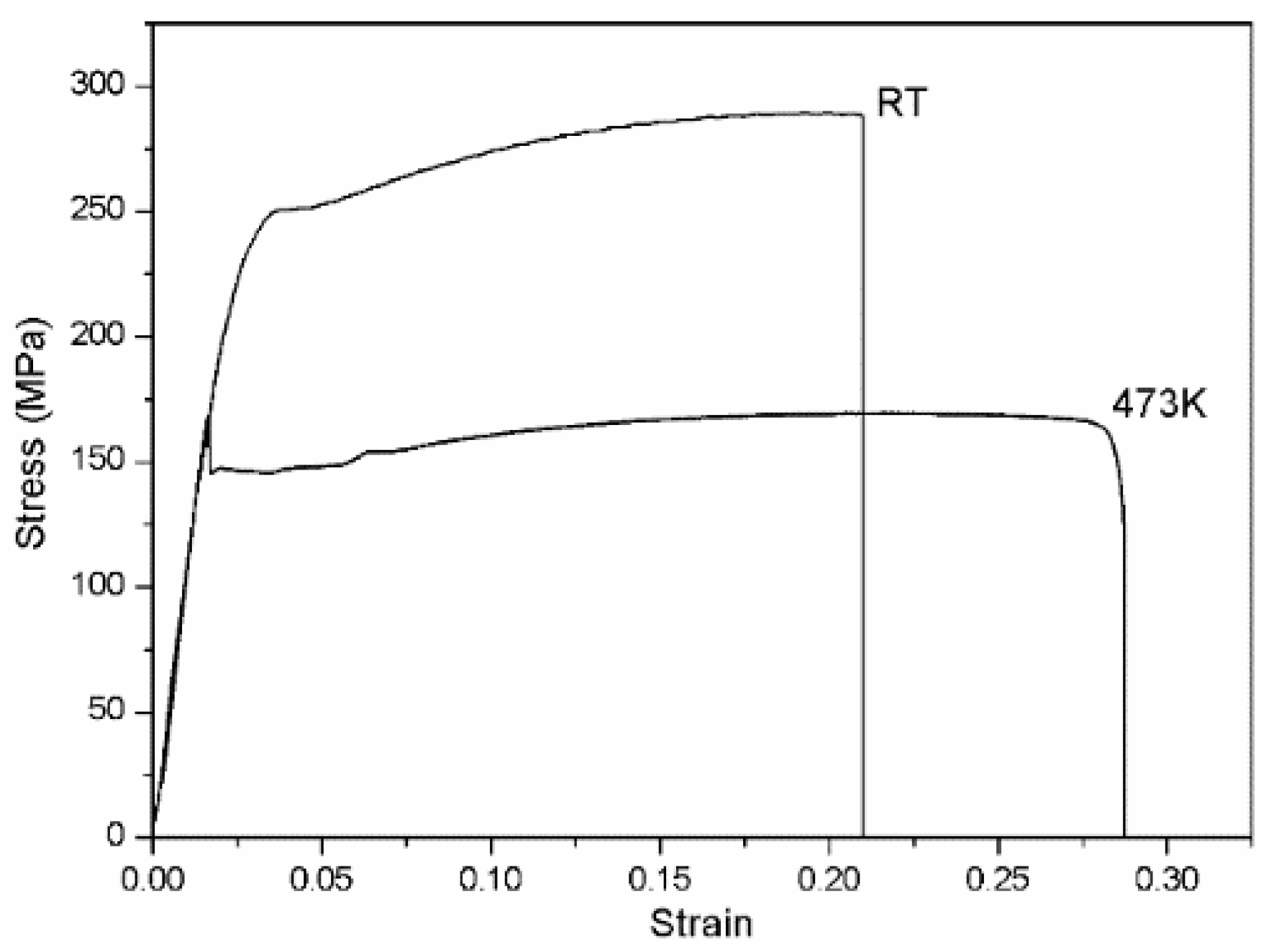

3.4. Mechanical Properties

3.5. Fracture

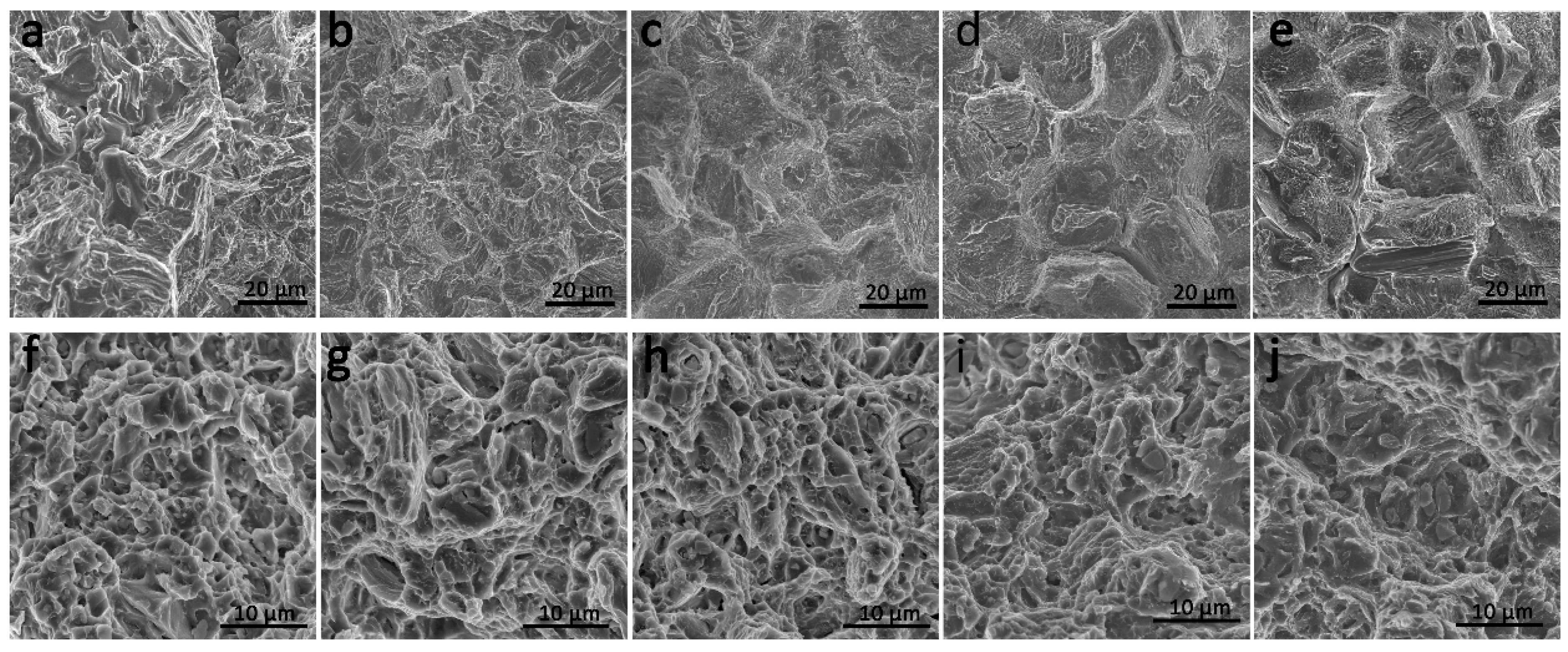

4. Conclusions

- (1)

- The as-cast Mg–4Sm–0.5Zr alloys contains α-Mg matrix and Mg41Sm5 phase. The microstructures of as-cast Mg–4Sm–xZn–0.5Zr (x = 1, 2, 3, 4 wt %) alloys mainly consist of α-Mg matrix, Mg41Sm5 and (Mg,Zn)3Sm.

- (2)

- The as-cast Mg–4Sm–2Zn–0.5Zr alloy exhibits the best comprehensive tensile properties at room temperature among all the as-cast alloys, and YS, UTS and EL are 132 MPa, 175 MPa and 8.7%, respectively.

- (3)

- f Besides the block-shaped precipitates, some disc-like precipitates also are observed in the as-ex elongation are about 246 MPa, 273 MPa and 21%, respectively, which is attributed to the massive dispersed nanoscale particles effectively reducing the DRXed grain size and blocking slip of dislocation. The dynamic precipitates in as-extruded Mg–4Sm–4Zn–0.5Zr alloy containing basal precipitates having a hexagonal structure with a = 0.556 nm.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Pan, F.; Yang, M.; Chen, X. A review on casting magnesium alloys: Modification of commercial alloys and development of new alloys. J. Mater. Sci. Technol. 2016, 32, 1211–1221. [Google Scholar] [CrossRef]

- Sarker, D.; Friedman, J.; Chen, D.L. Twin growth and texture evolution in an extruded AM30 magnesium alloy during compression. J. Mater. Sci. Technol. 2014, 30, 884–887. [Google Scholar] [CrossRef]

- Mordike, B.L.; Ebert, T. Magnesium properties-applications-potential. Mater. Sci. Eng. A 2001, 302, 37–45. [Google Scholar] [CrossRef]

- Rokhlin, L.L.; Dobatkina, T.V.; Nikitina, N.I. Constitution and properties of the ternary magnesium alloys containing two rare-earth metals of different subgroups. Mater. Sci. Forum 2003, 419–422, 291–296. [Google Scholar] [CrossRef]

- Nie, J.F.; Muddle, B.C. Precipitation in magnesium alloy WE54 during isothermal ageing at 250 degrees C. Scr. Mater. 1999, 40, 1089–1094. [Google Scholar] [CrossRef]

- Li, D.; Wang, Q.; Ding, W. Characterization of phases in Mg–4Y–4Sm–0.5Zr alloy processed by heat treatment. Mater. Sci. Eng. A 2006, 428, 295–300. [Google Scholar] [CrossRef]

- Antion, C.; Donnadieu, P.; Perrard, F.; Deschamps, A.; Tassin, C.; Pisch, A. Hardening precipitation in a Mg-4Y-3Re alloy. Acta Mater. 2003, 51, 5335–5348. [Google Scholar] [CrossRef]

- Gröbner, J.; Kozlov, A.; Fang, X.Y.; Geng, J.; Nie, J.F.; Schmid-Fetzer, R. Phase equilibria and transformations in ternary Mg-rich Mg–Y–Zn alloys. Acta Mater. 2012, 60, 5948–5962. [Google Scholar] [CrossRef]

- He, S.M.; Zeng, X.Q.; Peng, L.M.; Gao, X.; Nie, J.F.; Ding, W.J. Microstructure and strengthening mechanism of high strength Mg–10Gd–2Y–0.5Zr alloy. J. Alloys Compd. 2007, 427, 316–323. [Google Scholar] [CrossRef]

- Li, D.J.; Zeng, X.Q.; Dong, J.; Zhai, C.Q.; Ding, W.J. Microstructure evolution of Mg–10Gd–3Y–1.2Zn–0.4Zr alloy during heat-treatment at 773k. J. Alloys Compd. 2009, 468, 164–169. [Google Scholar] [CrossRef]

- Hou, X.; Cao, Z.; Zhao, L.; Wang, L.; Wu, Y.; Wang, L. Microstructure, texture and mechanical properties of a hot rolled Mg–6.5Gd–1.3Nd–0.7Y–0.3Zn alloy. Mater. Des. 2012, 34, 776–781. [Google Scholar] [CrossRef]

- Zheng, K.Y.; Dong, J.; Zeng, X.Q.; Ding, W.J. Precipitation and its effect on the mechanical properties of a cast Mg–Gd–Nd–Zr alloy. Mater. Sci. Eng. A 2008, 489, 44–54. [Google Scholar] [CrossRef]

- Nie, J.F.; Gao, X.; Zhu, S.M. Enhanced age hardening response and creep resistance of Mg–Gd alloys containing Zn. Scr. Mater. 2005, 53, 1049–1053. [Google Scholar] [CrossRef]

- Mostafa, A.; Medraj, M. Experimental investigation of the Mg-Nd-Zn isothermal section at 300 degrees C. Metals 2015, 5, 84–101. [Google Scholar] [CrossRef]

- Xia, X.; Sun, W.; Luo, A.A.; Stone, D.S. Precipitation evolution and hardening in Mg-Sm-Zn-Zr alloys. Acta Mater. 2016, 111, 335–347. [Google Scholar] [CrossRef]

- Qi, H.Y.; Huang, G.X.; Bo, H.; Xu, G.L.; Liu, L.B.; Jin, Z.P. Thermodynamic description of the Mg–Nd–Zn ternary system. J. Alloys Compd. 2011, 509, 3274–3281. [Google Scholar] [CrossRef]

- Zheng, X.; Dong, J.; Xiang, Y.; Chang, J.; Wang, F.; Jin, L.; Wang, Y.; Ding, W. Formability, mechanical and corrosive properties of Mg–Nd–Zn–Zr magnesium alloy seamless tubes. Mater. Des. 2010, 31, 1417–1422. [Google Scholar] [CrossRef]

- Saito, K.; Hiraga, K. The structures of precipitates in an Mg-0.5 at %Nd age-hardened alloy studied by HAADF-STEM technique. Mater. Trans. 2011, 52, 1860–1867. [Google Scholar] [CrossRef]

- Yuan, M.; Zheng, Z. Effects of Zn on the microstructures and mechanical properties of Mg–3Sm–0.5Gd–xZn–0.5Zr (x = 0, 0.3 and 0.6) alloy. J. Alloys Compd. 2014, 590, 355–361. [Google Scholar] [CrossRef]

- Xia, X.; Luo, A.A.; Stone, D.S. Precipitation sequence and kinetics in a Mg-4Sm-1Zn-0.4Zr (wt %) alloy. J. Alloys Compd. 2015, 649, 649–655. [Google Scholar] [CrossRef]

- Dogan, E.; Wang, S.; Vaughan, M.W.; Karaman, I. Dynamic precipitation in Mg-3Al-1Zn alloy during different plastic deformation modes. Acta Mater. 2016, 116, 1–13. [Google Scholar] [CrossRef]

- Kabir, A.S.H.; Sanjari, M.; Su, J.; Jung, I.H.; Yue, S. Effect of strain-induced precipitation on dynamic recrystallization in Mg-Al-Sn Alloys. Mater. Sci. Eng. A Struct. 2014, 616, 252–259. [Google Scholar] [CrossRef]

- Zhang, S.; Yuan, G.Y.; Lu, C.; Ding, W.J. The relationship between (mg,zn)3re phase and 14h-lpso phase in Mg–Gd–Y–Zn–Zr alloys solidified at different cooling rates. J. Alloys Compd. 2011, 509, 3515–3521. [Google Scholar] [CrossRef]

- Yuan, M.; Zheng, Z.Q. Effects of heat treatment on microstructure and mechanical properties of Mg–2.6Sm–1.3Gd–0.6Zn–0.5Zr alloy. Mater. Sci. Technol. 2014, 30, 261–267. [Google Scholar] [CrossRef]

- Ping, D.H.; Hono, K.; Nie, J.F. Atom probe characterization of plate-like precipitates in a Mg-Re-Zn-Zr casting alloy. Scr. Mater. 2003, 48, 1017–1022. [Google Scholar] [CrossRef]

- Zheng, J.X.; Zhou, W.M.; Chen, B. Precipitation in Mg-Sm binary alloy during isothermal ageing: Atomic-scale insights from scanning transmission electron microscopy. Mater. Sci. Eng. A Struct. 2016, 669, 304–311. [Google Scholar] [CrossRef]

- Nie, J.F. Precipitation and hardening in magnesium alloys. Metall. Mater. Trans. A 2012, 43, 3891–3939. [Google Scholar] [CrossRef]

- Su, J.; Kaboli, S.; Kabir, A.S.H.; Jung, I.H.; Yue, S. Effect of dynamic precipitation and twinning on dynamic recrystallization of micro-alloyed Mg–Al–Ca alloys. Mater. Sci. Eng. A 2013, 587, 27–35. [Google Scholar] [CrossRef]

- Robson, J.D.; Henry, D.T.; Davis, B. Particle effects on recrystallization in magnesium–manganese alloys: Particle-stimulated nucleation. Acta Mater. 2009, 57, 2739–2747. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena, 2nd ed.; Elsevier: Oxford, UK, 2004. [Google Scholar]

- Chen, Z.H.; Xu, F.Y.; Fu, D.F.; Xia, W.J. The dynamic recrystallization of magnesium alloys. Chem. Ind. Eng. Prog. 2006, 25, 7. [Google Scholar]

- Barnett, M.R. Recrystallization during and following hot working of magnesium alloy az31. Mater. Sci. Forum 2003, 419–422, 503–508. [Google Scholar] [CrossRef]

- Barnett, M.R.; Beer, A.G.; Atwell, D.; Oudin, A. Influence of grain size on hot working stresses and microstructures in Mg-3Al-lZn. Scr. Mater. 2004, 51, 19–24. [Google Scholar] [CrossRef]

| Nominal Alloys | Composition (wt %) | |||

|---|---|---|---|---|

| Mg–4Sm–xZn–0.5Zr | Mg | Sm | Zn | Zr |

| Mg–4Sm–0.5Zr | Balance | 3.50 | - | 0.40 |

| Mg–4Sm–1Zn–0.5Zr | Balance | 3.74 | 0.82 | 0.40 |

| Mg–4Sm–2Zn–0.5Zr | Balance | 4.06 | 1.80 | 0.51 |

| Mg–4Sm–3Zn–0.5Zr | Balance | 4.21 | 2.79 | 0.60 |

| Mg–4Sm–4Zn–0.5Zr | Balance | 4.10 | 3.67 | 0.40 |

| Position | Elements | ||||

|---|---|---|---|---|---|

| Mg K | Sm L | Zn K | Zr L | ||

| Point A | Wt % | 53.53 | 43.61 | - | 2.86 |

| At % | 87.27 | 11.49 | - | 1.24 | |

| Point D | Wt % | 47.78 | 26.13 | 23.29 | 2.79 |

| At % | 77.81 | 6.88 | 14.10 | 1.21 | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Che, C.; Cai, Z.; Cheng, L.; Meng, F.; Yang, Z. The Microstructures and Tensile Properties of As-Extruded Mg–4Sm–xZn–0.5Zr (x = 0, 1, 2, 3, 4 wt %) Alloys. Metals 2017, 7, 281. https://doi.org/10.3390/met7070281

Che C, Cai Z, Cheng L, Meng F, Yang Z. The Microstructures and Tensile Properties of As-Extruded Mg–4Sm–xZn–0.5Zr (x = 0, 1, 2, 3, 4 wt %) Alloys. Metals. 2017; 7(7):281. https://doi.org/10.3390/met7070281

Chicago/Turabian StyleChe, Chaojie, Zhongyi Cai, Liren Cheng, Fanxing Meng, and Zhen Yang. 2017. "The Microstructures and Tensile Properties of As-Extruded Mg–4Sm–xZn–0.5Zr (x = 0, 1, 2, 3, 4 wt %) Alloys" Metals 7, no. 7: 281. https://doi.org/10.3390/met7070281