Effects of Trace Si Addition on the Microstructures and Tensile Properties of Ti-3Al-8V-6Cr-4Mo-4Zr Alloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

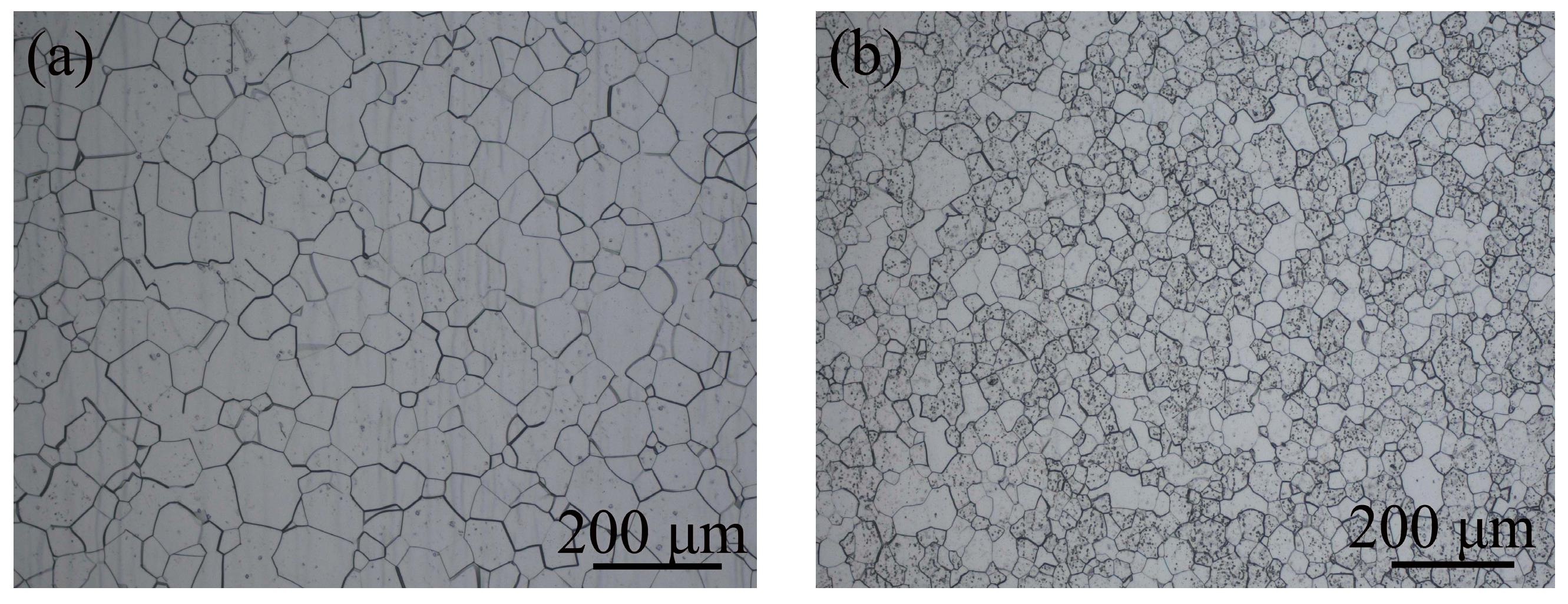

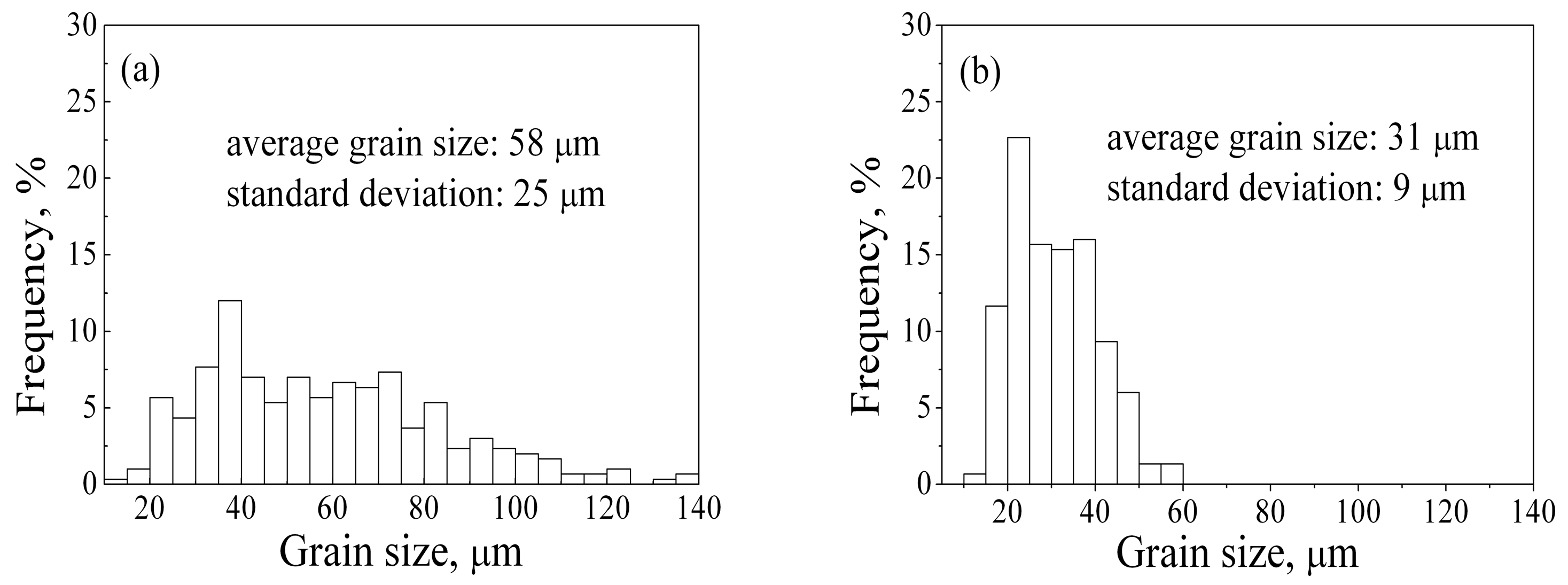

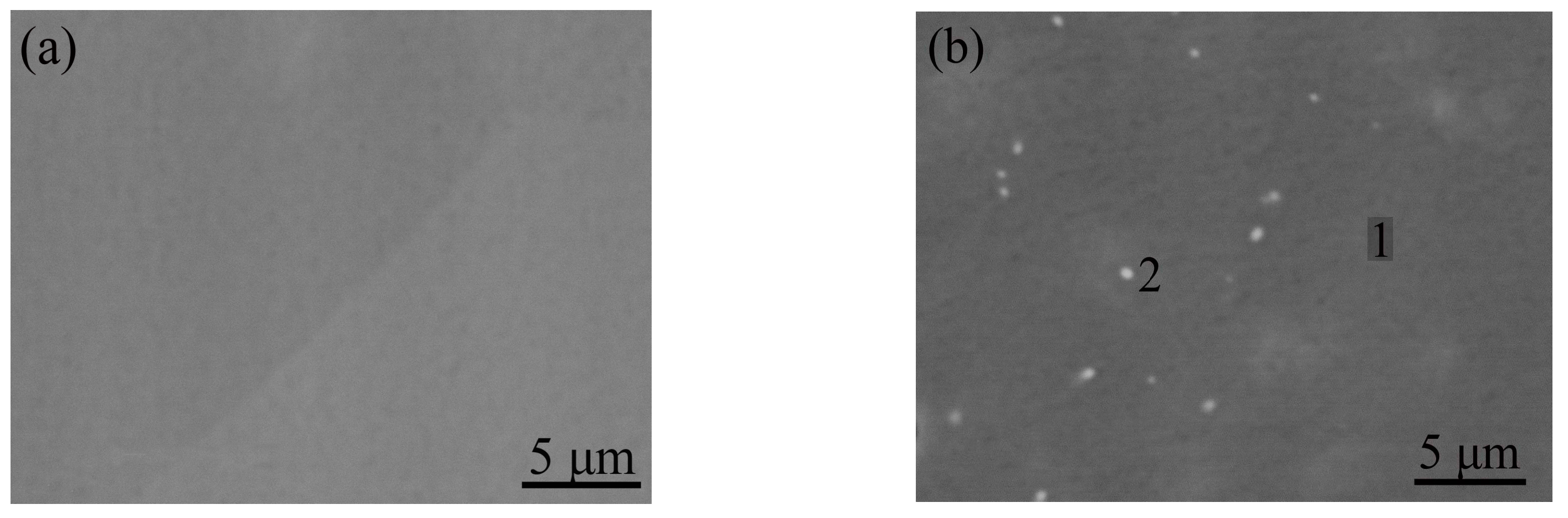

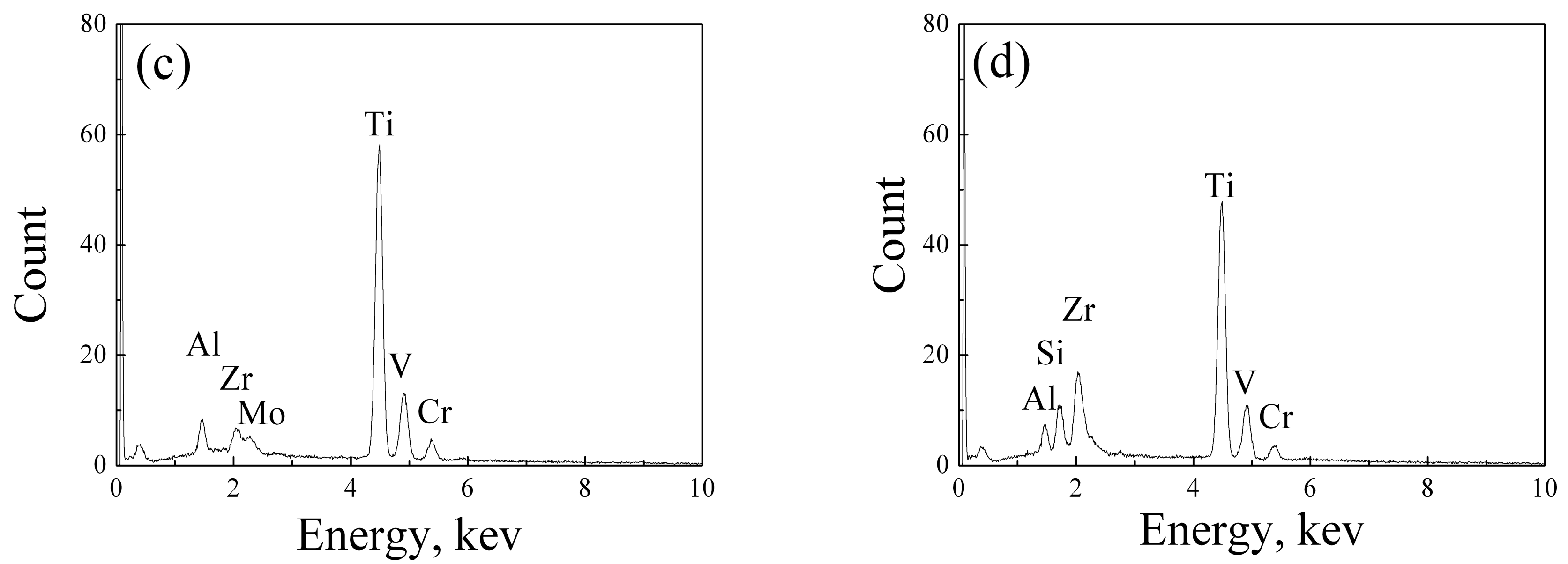

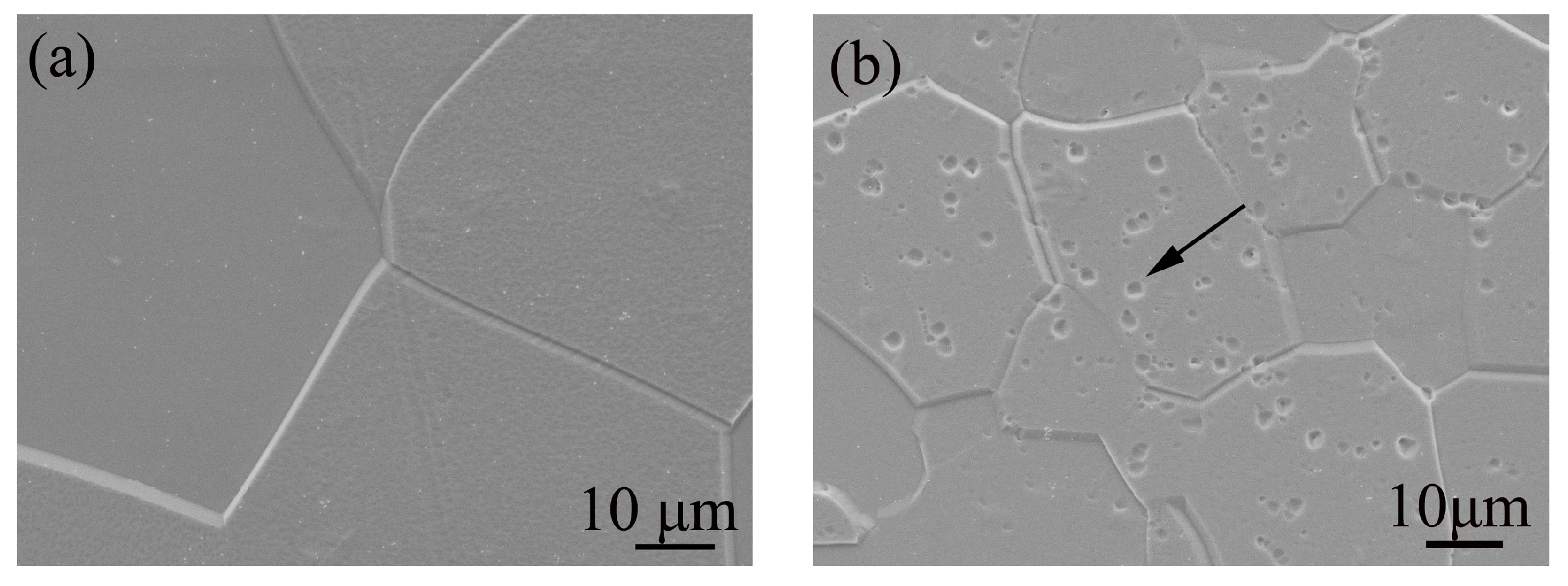

3.1. Microstructure Characteristics

3.2. Tensile Properties

4. Conclusions

- (1)

- The addition of trace amount of Si (~0.05 wt %) and the presence of 4 wt % Zr induced the formation of (TiZr)6Si3 silicides in Ti-3Al-8V-6Cr-4Mo-4Zr-0.05Si alloy.

- (2)

- The dispersed silicides refined β grains, and the average grain size of Ti-3Al-8V-6Cr-4Mo-4Zr-0.05Si alloy was more uniform than that of Ti-3Al-8V-6Cr-4Mo-4Zr alloy. Adding Si was an effective way to refine β grains for the Ti-3Al-8V-6Cr-4Mo-4Zr alloy.

- (3)

- The silicide precipitates enhanced the tensile strength of Ti-3Al-8V-6Cr-4Mo-4Zr-0.05Si alloy, and the change in ductility was slight. The increase in strength was attributed to both precipitation strengthening and grain refinement. The fracture mode of both alloys was ductile.

Author Contributions

Conflicts of Interest

References

- Williams, J.C.; Starke, E.A. Progress in structural materials or aerospace systems. Acta Mater. 2003, 51, 5775–5799. [Google Scholar] [CrossRef]

- Banerjee, D.; Williams, J.C. Perspectives on titanium science and technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Lei, X.F.; Dong, L.M.; Zhang, Z.Q.; Liu, Y.J.; Hao, Y.L.; Yang, R.; Zhang, L.C. Microstructure, texture evolution and mechanical properties of VT3-1 titanium alloy processed by multi-pass drawing and subsequent isothermal annealing. Metals 2017, 7, 131. [Google Scholar] [CrossRef]

- Kim, J.H.; Lee, C.H.; Hong, J.K.; Kim, J.H.; Yeom, J.T. Effect of surface treatment on the hot forming of the high strength Ti-6Al-4V fastener. Mater. Trans. 2009, 50, 2050–2056. [Google Scholar] [CrossRef]

- Kume, K.; Furui, M.; Ikeno, S.; Ishisaka, Y.; Yamamoto, M. Screw form rolling of beta type titanium alloy preliminary worked by torsion. Mater. Sci. Forum 2010, 654, 906–909. [Google Scholar] [CrossRef]

- Solek, A.L.; Krawczyk, J. The analysis of the hot deformation behaviour of the Ti-3Al-8V-6Cr-4Zr-4Mo alloy, using processing maps, a map of microstructure and of hardness. Mater. Des. 2015, 65, 165–173. [Google Scholar] [CrossRef]

- Salam, A.; Hammond, C. Superplasticity and associated activation energy in Ti-3Al-8V-6Cr-4Mo-4Zr alloy. J. Mater. Sci. 2005, 40, 5475–5482. [Google Scholar] [CrossRef]

- Boyer, R.; Welsch, G.; Collings, E.W. Materials Properties Handbook: Titanium Alloys, 1st ed.; ASM International: Materials Park, OH, USA, 1994; pp. 797–828. [Google Scholar]

- Scmidt, P.; El-chaikl, A.; Christ, H.J. Effect of duplex aging on the initiation and propagation of fatigue cracks in the solute-rich metastable β titanium alloy Ti 38–644. Metall. Mater. Trans. A 2011, 42, 2652–2667. [Google Scholar] [CrossRef]

- Es-souni, M. Creep behaviour and creep microstructures of a high-temperature titanium alloy Ti-5.8Al-4.0Sn-3.5Zr-0.7Nb-0.35Si-0.06C (Timetal 834): Part I. Primary and steady-state creep. Mater. Charact. 2001, 46, 365–379. [Google Scholar] [CrossRef]

- Gu, Y.; Zeng, F.H.; Qi, Y.L.; Xia, X.Q.; Xiong, X. Tensile creep behavior of heat-treated TC11 titanium alloy at 450–550 °C. Mater. Sci. Eng. A 2013, 575, 74–85. [Google Scholar] [CrossRef]

- Singh, A.K.; Ramachandra, C. Characterization of silicides in high-temperature titanium alloys. J. Mater. Sci. 1996, 32, 229–234. [Google Scholar] [CrossRef]

- Li, J.X.; Wang, L.Q.; Qin, J.N.; Chen, Y.F.; Lu, W.J.; Zhang, D. The effect of heat treatment on thermal stability of Ti matrix composite. J. Alloys Compd. 2011, 509, 52–56. [Google Scholar] [CrossRef]

- Ramachandra, C.; Singh, V. Silicide precipitation in alloy Ti-6Al-5Zr-0.5Mo-0.25Si. Metall. Trans. A 1982, 13, 771–775. [Google Scholar] [CrossRef]

- Flower, H.M.; Swann, P.R.; West, D.R.F. Silicide precipitation in the Ti-Zr-Al-Si system. Metall. Mater. Trans. B 1971, 2, 3289–3297. [Google Scholar] [CrossRef]

- Bermingham, M.J.; Mcdonald, S.D.; Dargusch, M.S.; Stjohn, D.H. The mechanism of grain refinement of titanium by silicon. Scr. Mater. 2008, 58, 1050–1053. [Google Scholar] [CrossRef]

- Tavares, A.M.G.; Ramos, W.S.; Blas, J.C.G.; Lopes, E.S.N.; Caram, R.; Batista, W.W.; Souza, S.A. Influence of Si addition on the microstructure and mechanical properties of Ti-35Nb alloy for applications in orthopedic implants. J. Mech. Behav. Biomed. Mater. 2015, 51, 74–87. [Google Scholar] [CrossRef] [PubMed]

- Ramachandra, C.; Singh, V. Effect of silicide precipitation on tensile properties and fracture of alloy Ti-6Al-5Zr-0.5Mo-0.25Si. Metall. Trans. A 1985, 16, 227–231. [Google Scholar] [CrossRef]

- Ramachandra, C.; Singh, V. Effect of silicides on tensile properties and fracture of alloy Ti-6Al-5Zr-0.5Mo-0.25Si from 300 to 823 K. J. Mater. Sci. 1988, 23, 835–841. [Google Scholar] [CrossRef]

- Morito, F.; Muneki, S.; Takahashi, J.; Kainuma, T. The effect of Silicon Addition on the Microstructure and the Aging Behavior of Ti-3Al-8V-6Cr-4Mo-4Zr Alloy. In Proceedings of the Titanium 95: Eighth World Congress on Titanium, Birmingham, UK, 22–26 October 1995; pp. 2494–2501. [Google Scholar]

- Singh, A.K.; Roy, T.; Ramachandra, C. Microstructural stability on aging of an α + β titanium alloy: Ti-6Al-1.6Zr-3.3Mo9-0.30Si. Metall. Mater. Trans. A 1996, 27, 1167–1173. [Google Scholar] [CrossRef]

- Singh, A.K.; Ramachandra, C.; Tavafoghi, M.; Singh, V. Microstructure of β-solution-treated, quenched and aged α + β titanium alloy Ti-6Al-1.6Zr-3.3Mo9-0.30Si. J. Alloys Compd. 1992, 179, 125–135. [Google Scholar] [CrossRef]

- Jayaprakash, M.; Ping, K.H.; Yamabe-mttaeai, Y. Effect of Zr and Si addition on high temperature mechanical properties of near-α Ti-Al-Zr-Sn based alloys. Mater. Sci. Eng. A 2014, 612, 456–461. [Google Scholar] [CrossRef]

- Popov, A.; Rossina, N.; Popova, M. The effect of alloying on the ordering processes in near-alpha titanium alloys. Mater. Sci. Eng. A 2013, 564, 284–287. [Google Scholar] [CrossRef]

- Jia, W.; Zeng, W.; Yu, H. Effect of aging on the tensile properties and microstructures of a near-alpha titanium alloy. Mater. Des. 2014, 58, 108–115. [Google Scholar] [CrossRef]

- Tsai, Y.L.; Wang, S.F.; Bor, H.Y.; Hsu, Y.F. Effects of Zr addition on the microstructure and mechanical behavior of a fine-grained nickel superalloy at elevated temperatures. Mater. Sci. Eng. A 2014, 607, 294–301. [Google Scholar] [CrossRef]

- Muszka, K.; Majta, J.; Bienias, L. Effect of grain refinement on mechanical properties of microalloyed steels. Metall. Found. Eng. 2006, 32, 87–97. [Google Scholar] [CrossRef]

| Alloy | Composition (wt %) | ||||||

|---|---|---|---|---|---|---|---|

| Al | V | Cr | Mo | Zr | Si | Ti | |

| C1 | 3.54 | 8.00 | 6.02 | 4.05 | 4.00 | 0.02 | Bal. |

| C2 | 3.48 | 8.00 | 5.95 | 4.05 | 4.00 | 0.06 | Bal. |

| Alloy | YS, MPa | UTS, MPa | El, % | RA, % |

|---|---|---|---|---|

| C1 | 852 | 853 | 29.0 | 73 |

| 852 | 854 | 27.5 | 76 | |

| C2 | 888 | 891 | 23.5 | 62 |

| 893 | 896 | 24.0 | 61 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ba, H.; Dong, L.; Zhang, Z.; Lei, X. Effects of Trace Si Addition on the Microstructures and Tensile Properties of Ti-3Al-8V-6Cr-4Mo-4Zr Alloy. Metals 2017, 7, 286. https://doi.org/10.3390/met7080286

Ba H, Dong L, Zhang Z, Lei X. Effects of Trace Si Addition on the Microstructures and Tensile Properties of Ti-3Al-8V-6Cr-4Mo-4Zr Alloy. Metals. 2017; 7(8):286. https://doi.org/10.3390/met7080286

Chicago/Turabian StyleBa, Hongbo, Limin Dong, Zhiqiang Zhang, and Xiaofei Lei. 2017. "Effects of Trace Si Addition on the Microstructures and Tensile Properties of Ti-3Al-8V-6Cr-4Mo-4Zr Alloy" Metals 7, no. 8: 286. https://doi.org/10.3390/met7080286