Particle Size and Particle Percentage Effect of AZ61/SiCp Magnesium Matrix Micro- and Nano-Composites on Their Mechanical Properties Due to Extrusion and Subsequent Annealing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

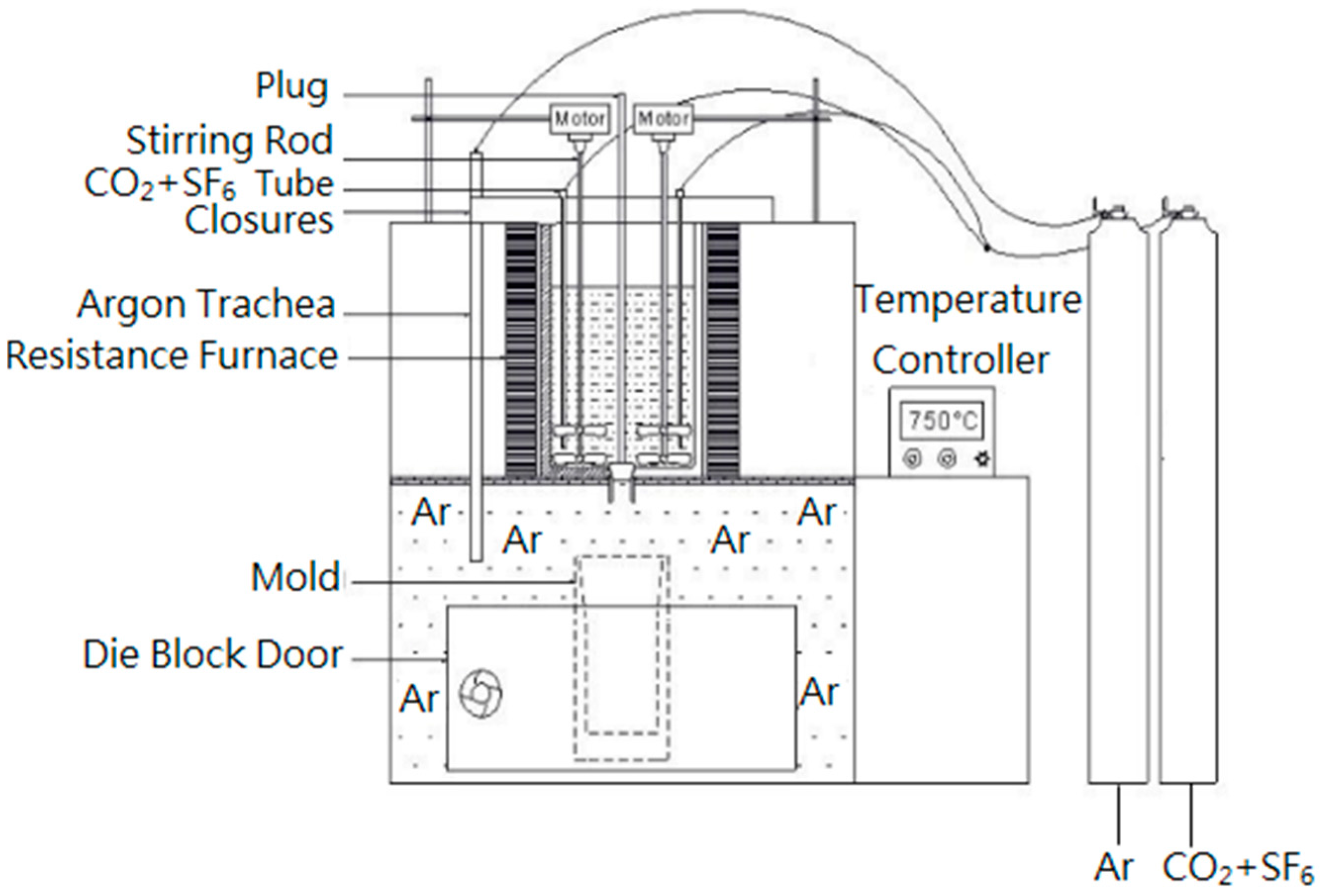

2.2. Fabrication of the Ingot and Plate of the Mg MMCs and Their Heat Treatments

2.3. Morphological and Mechanical Properties

3. Results and Discussion

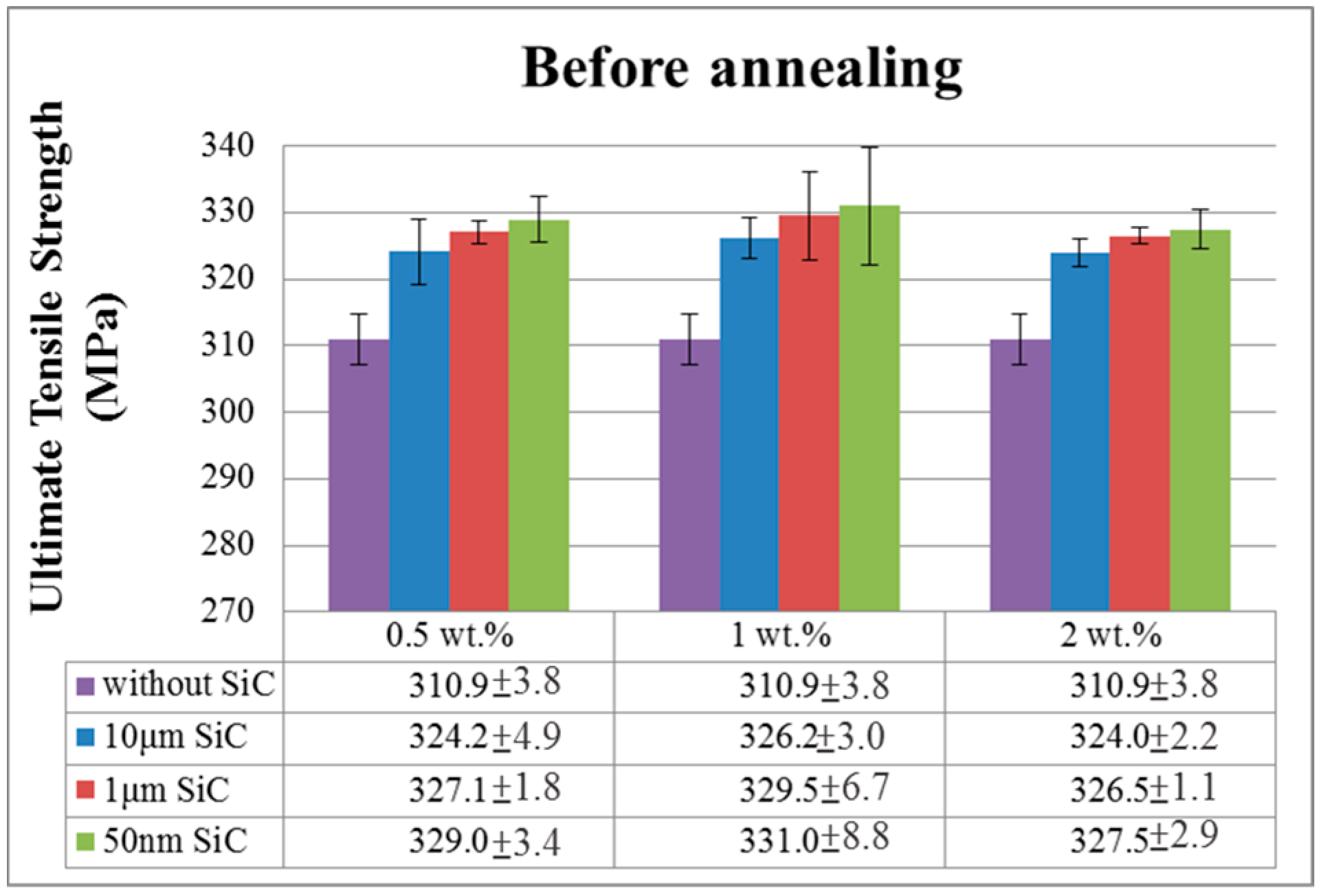

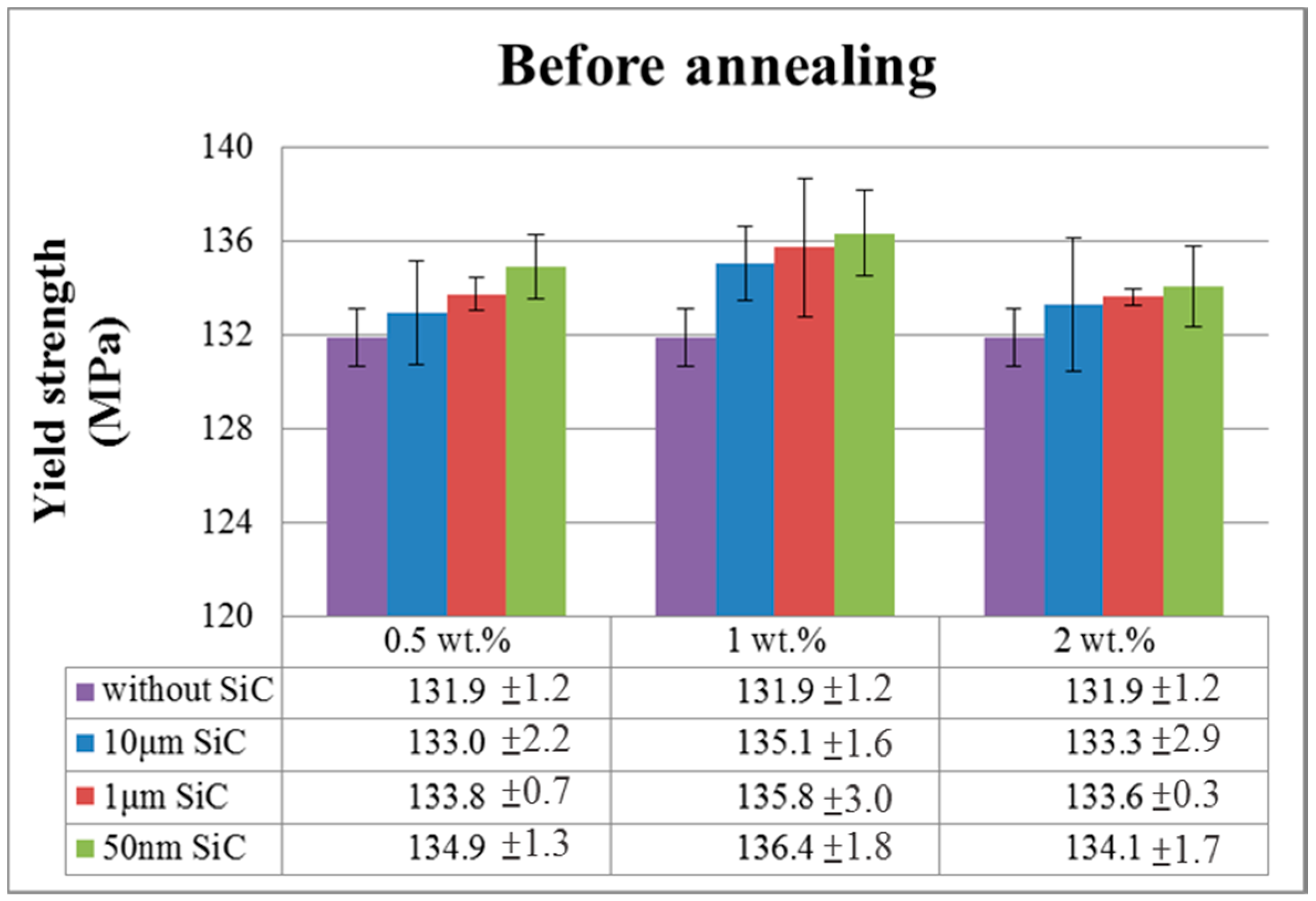

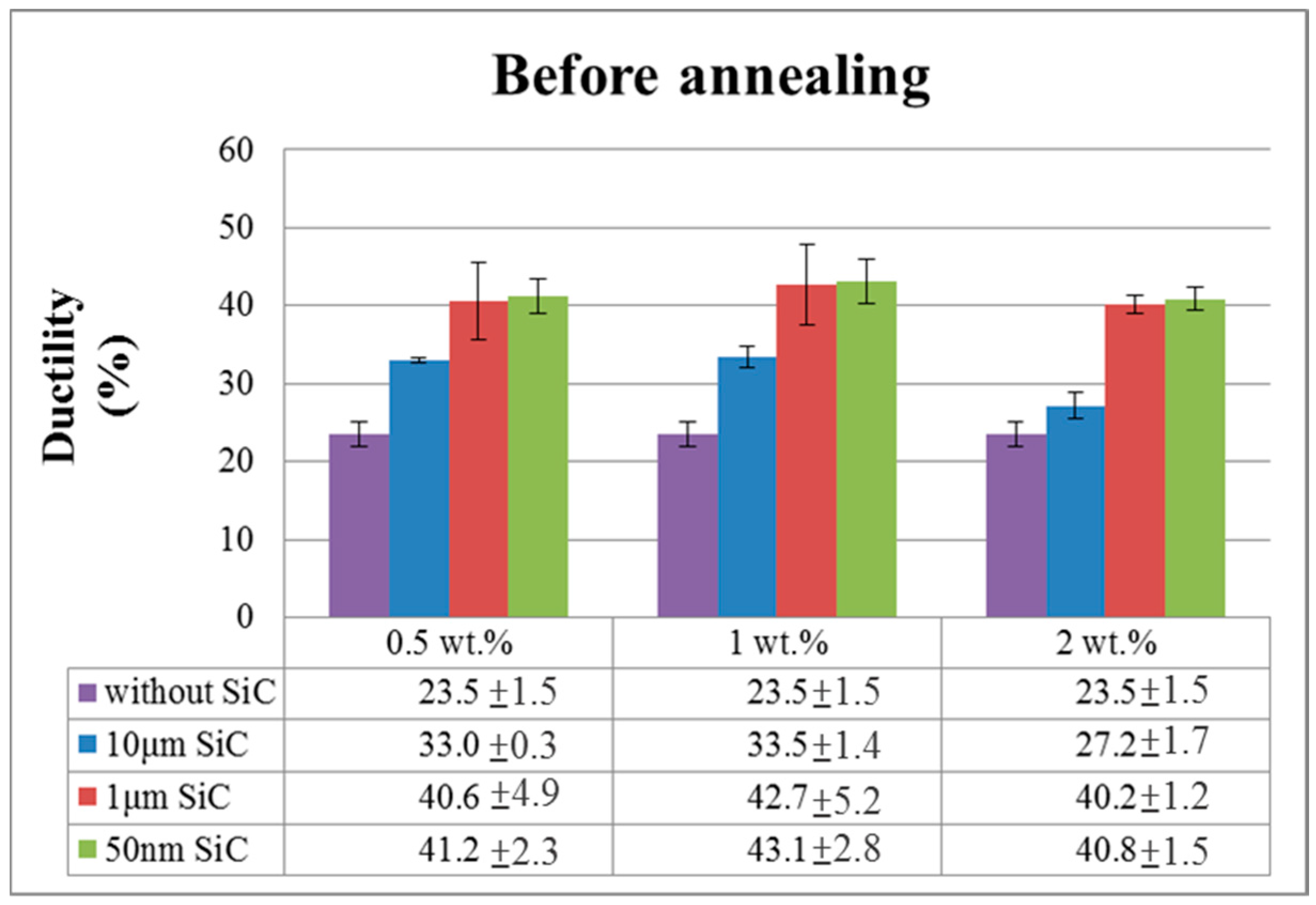

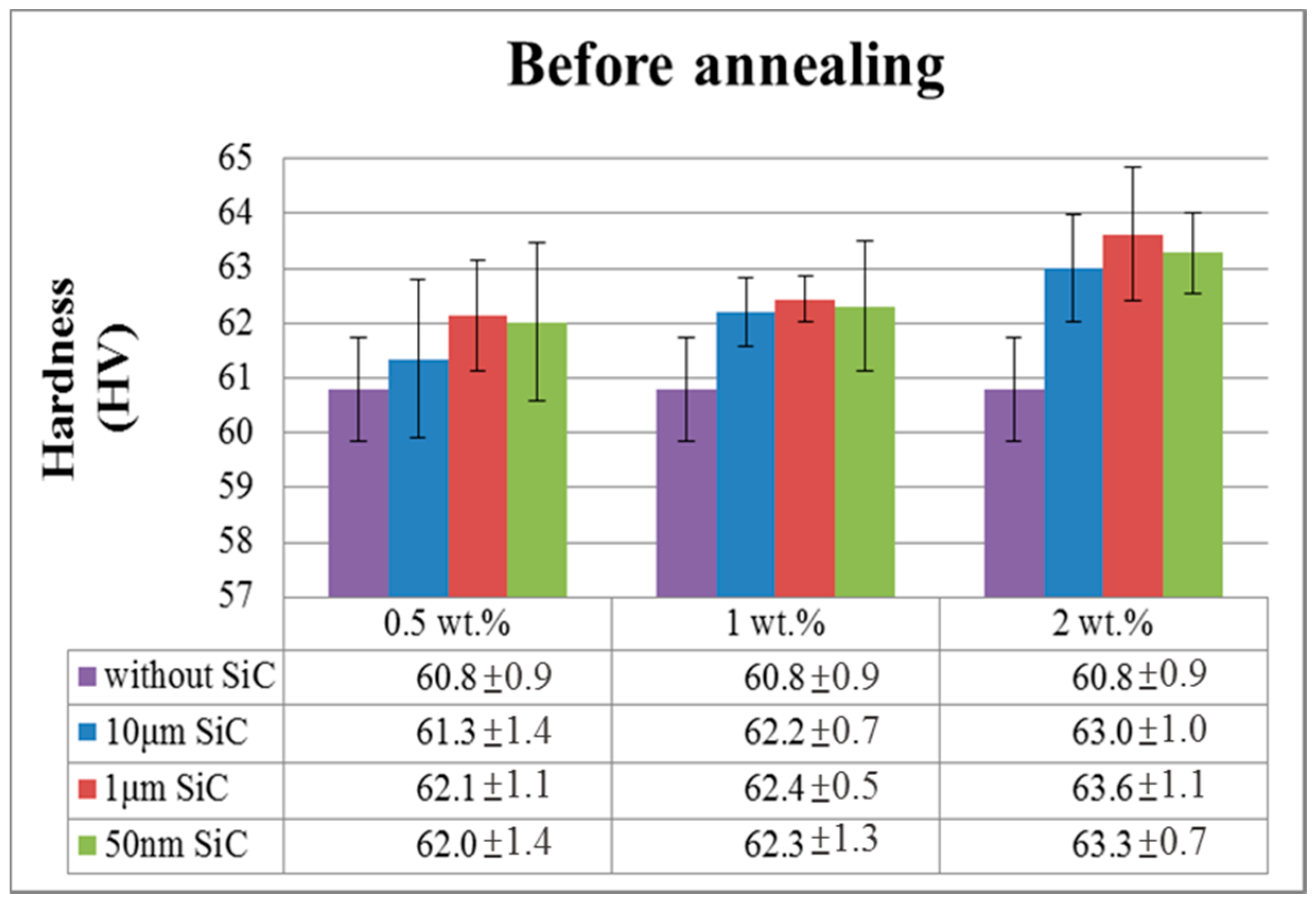

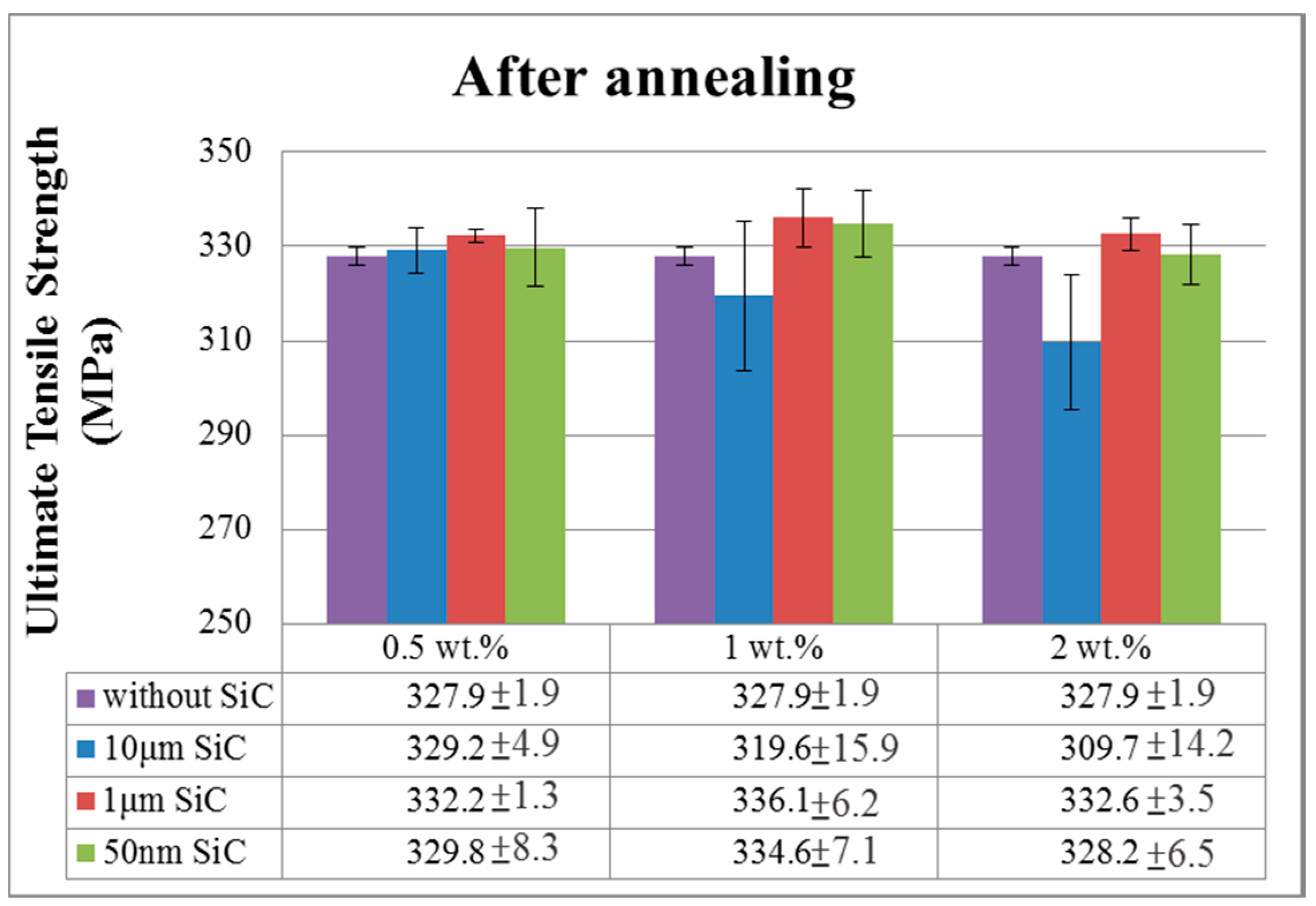

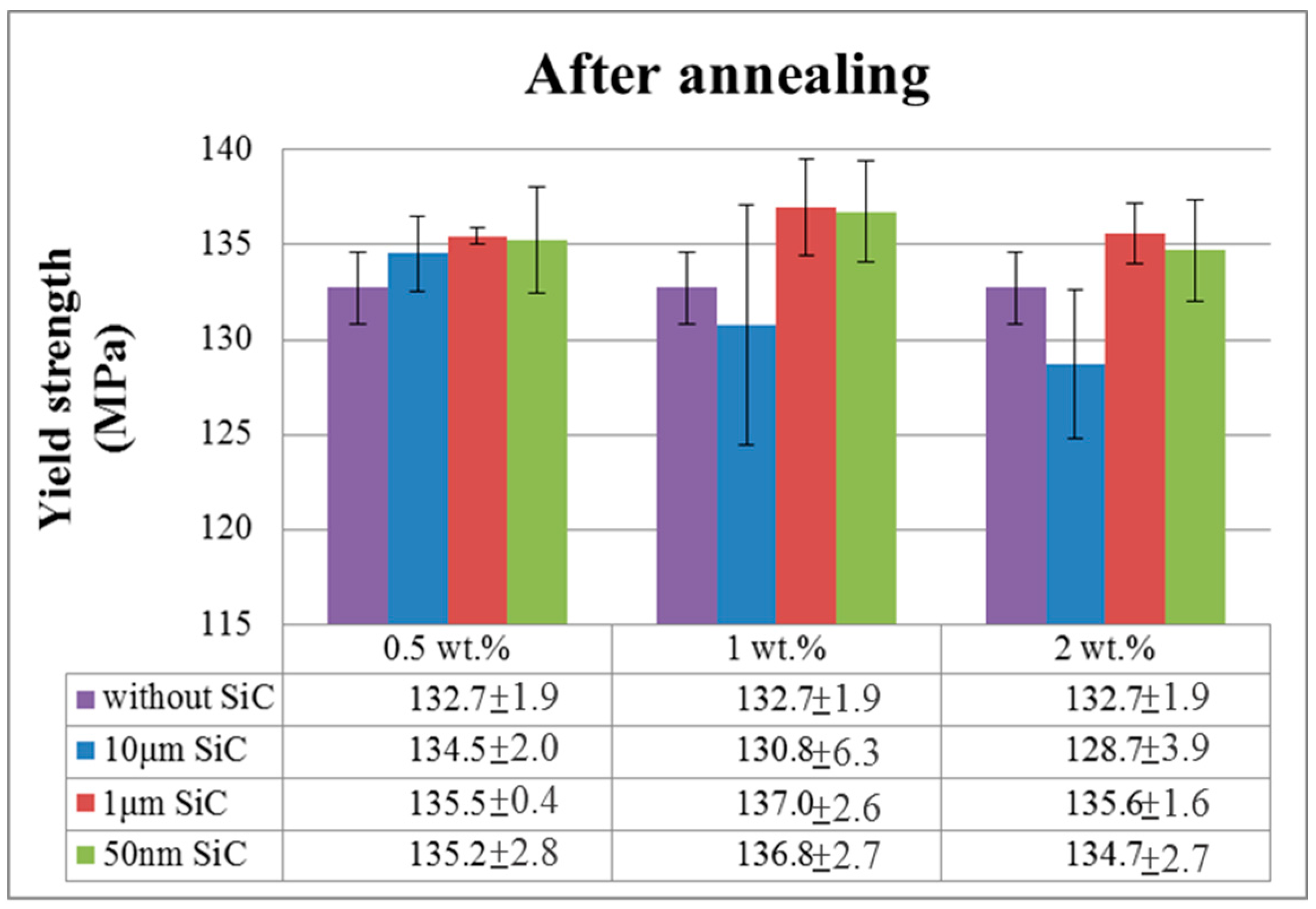

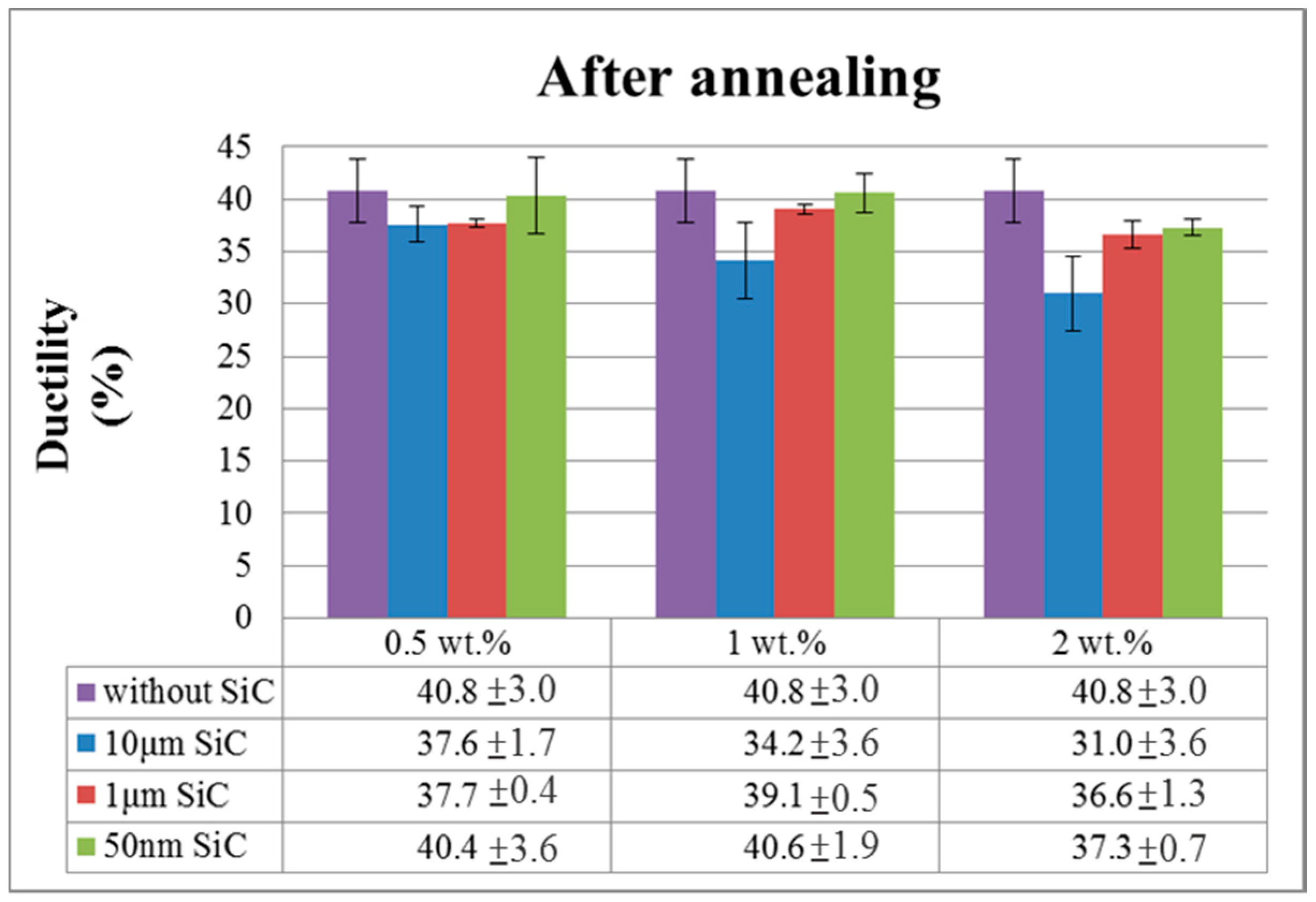

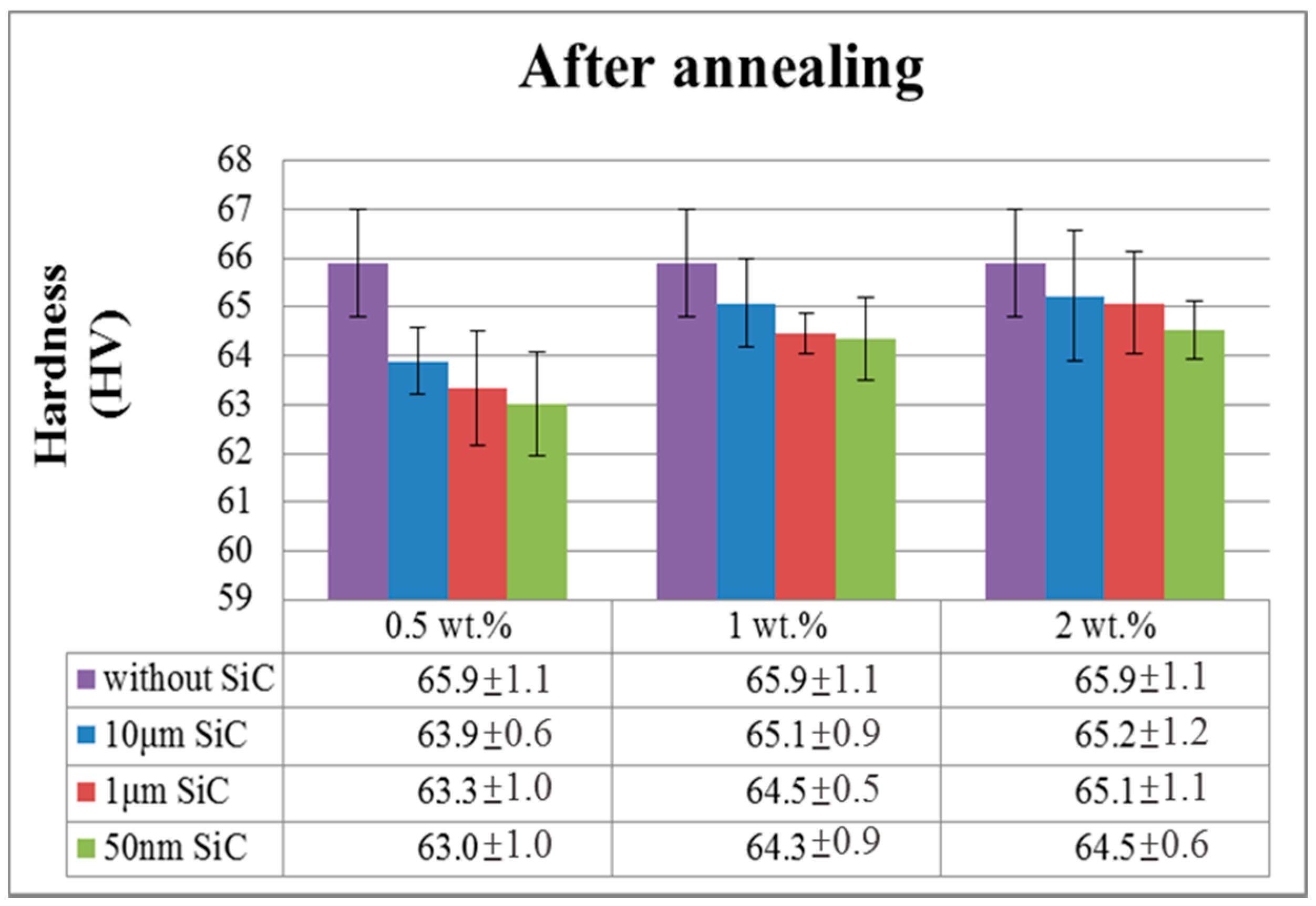

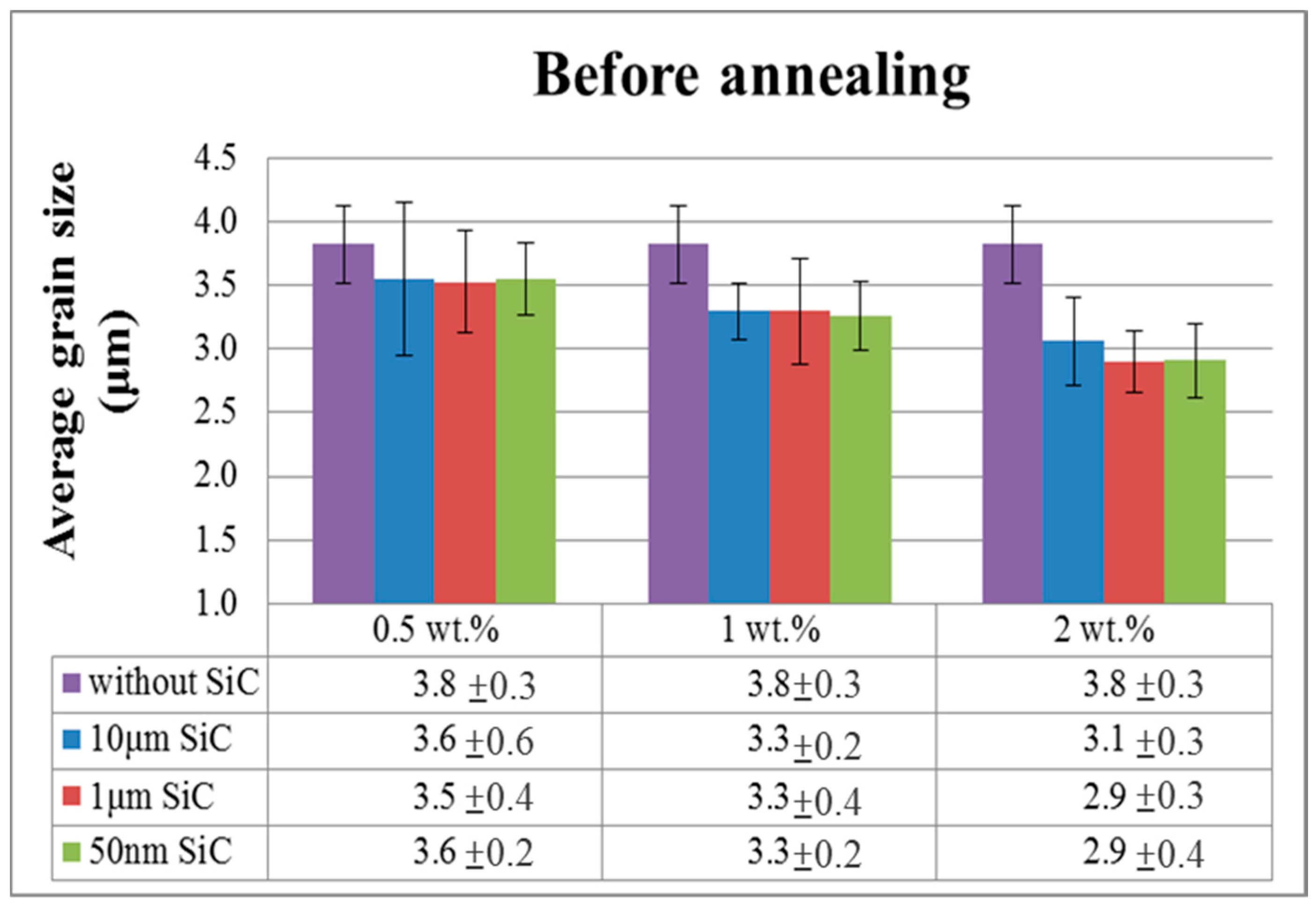

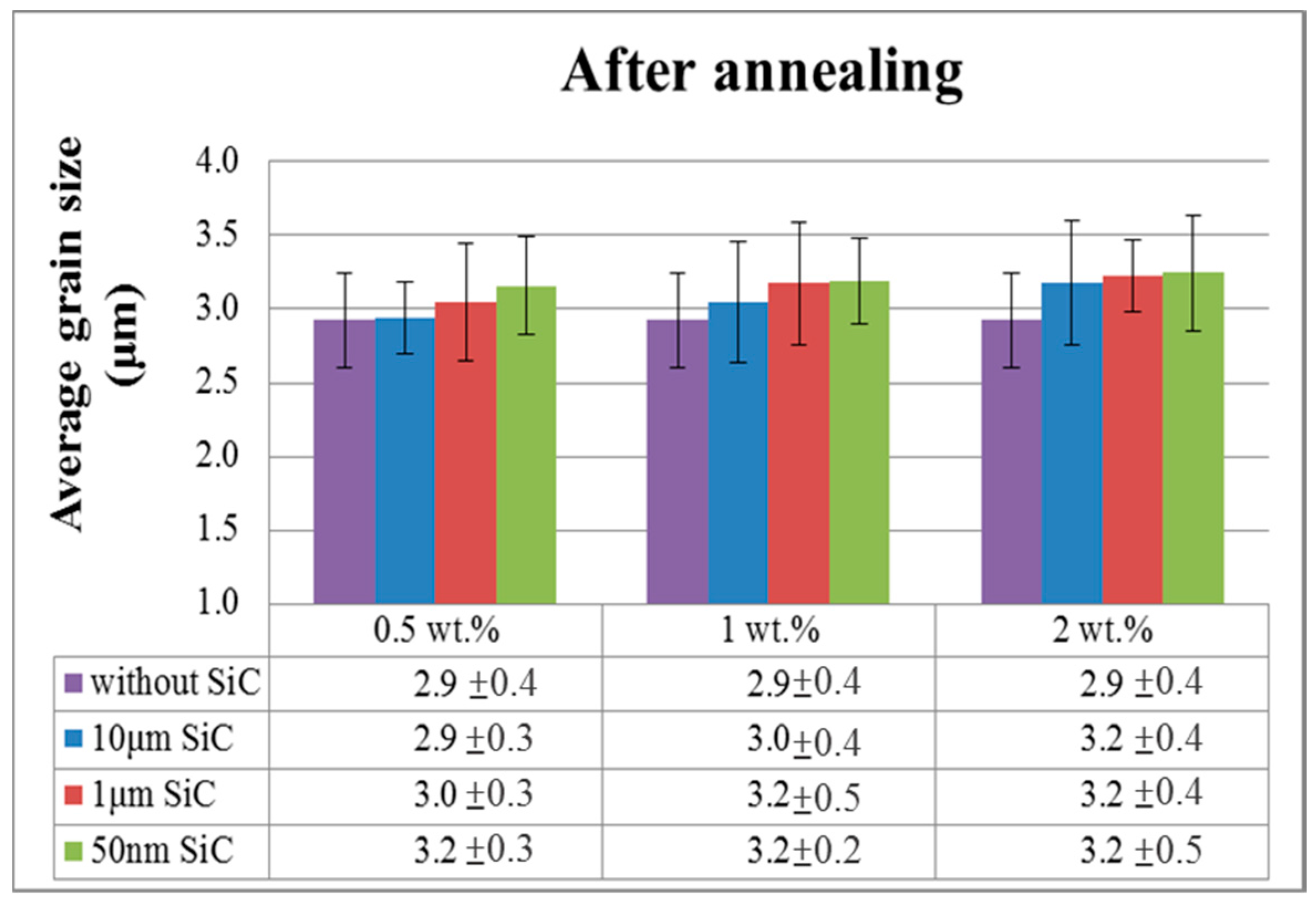

3.1. Mechanical Properties

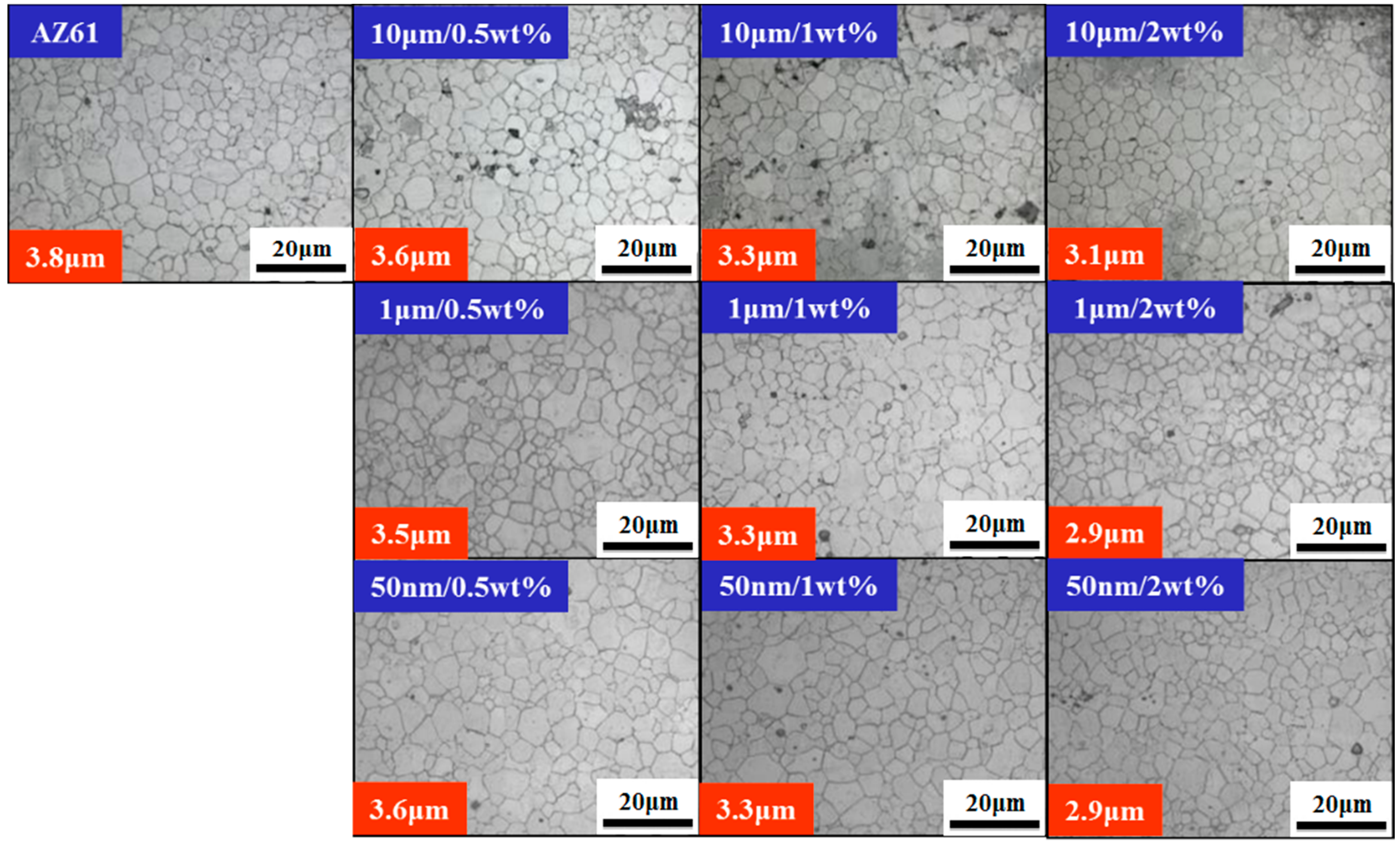

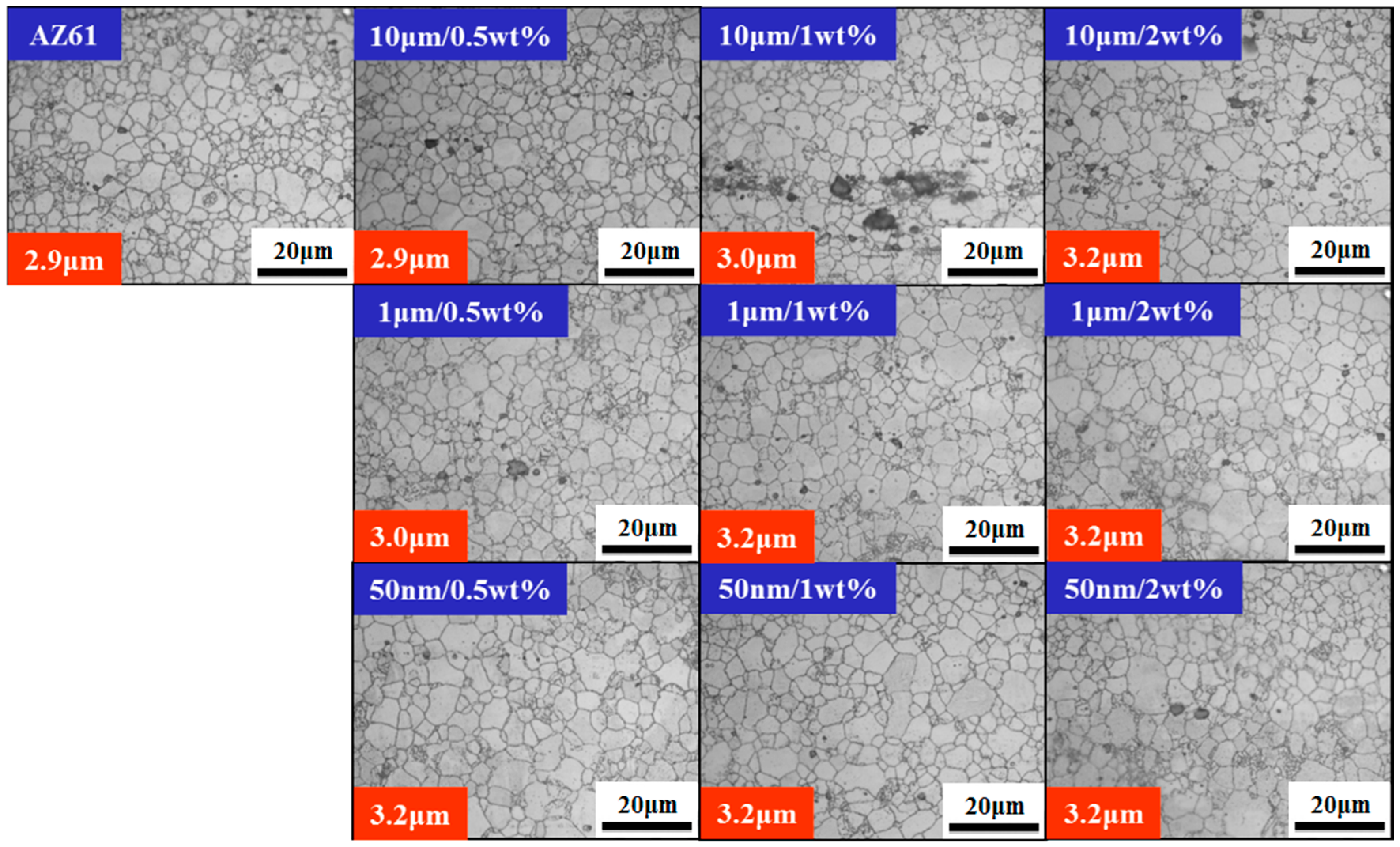

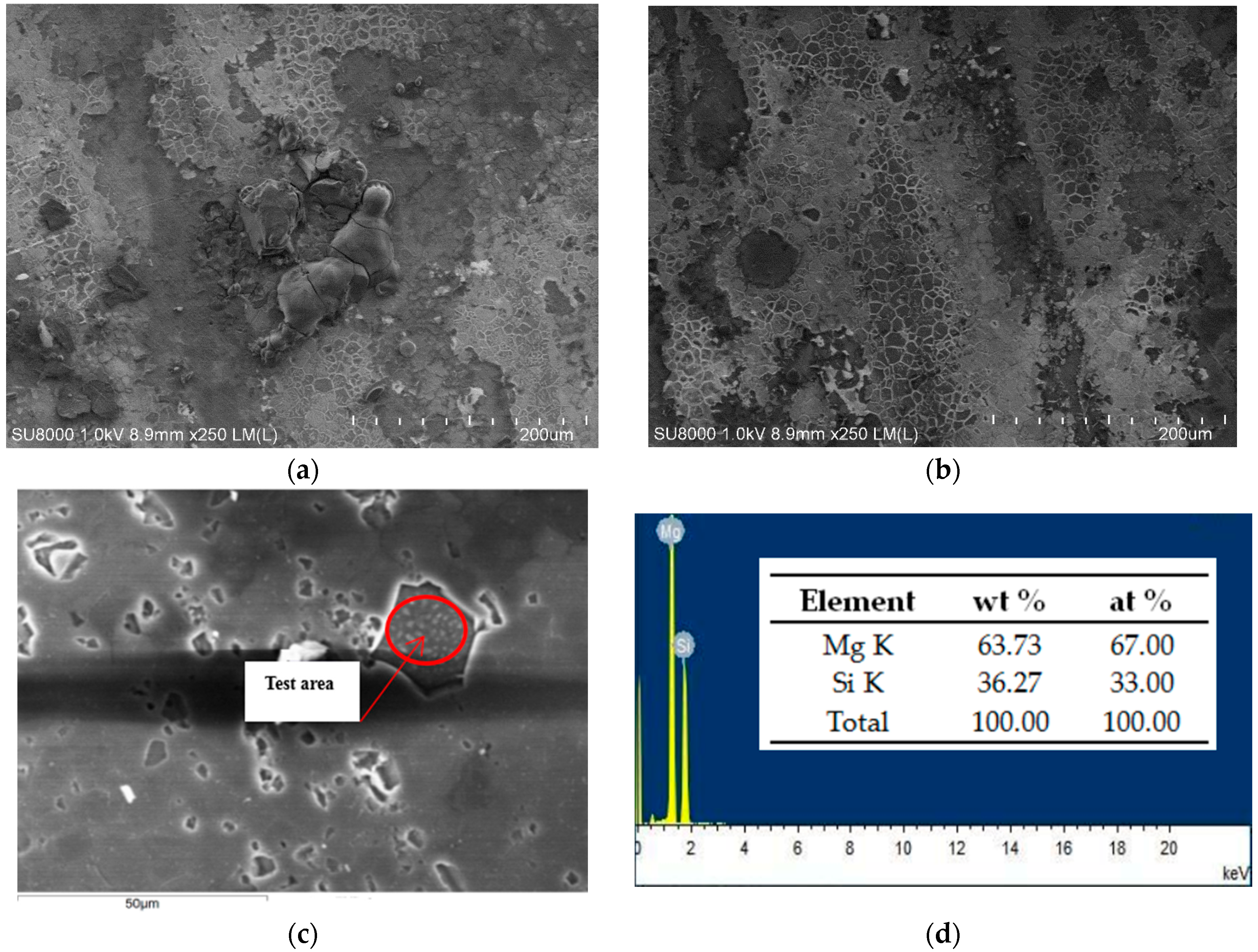

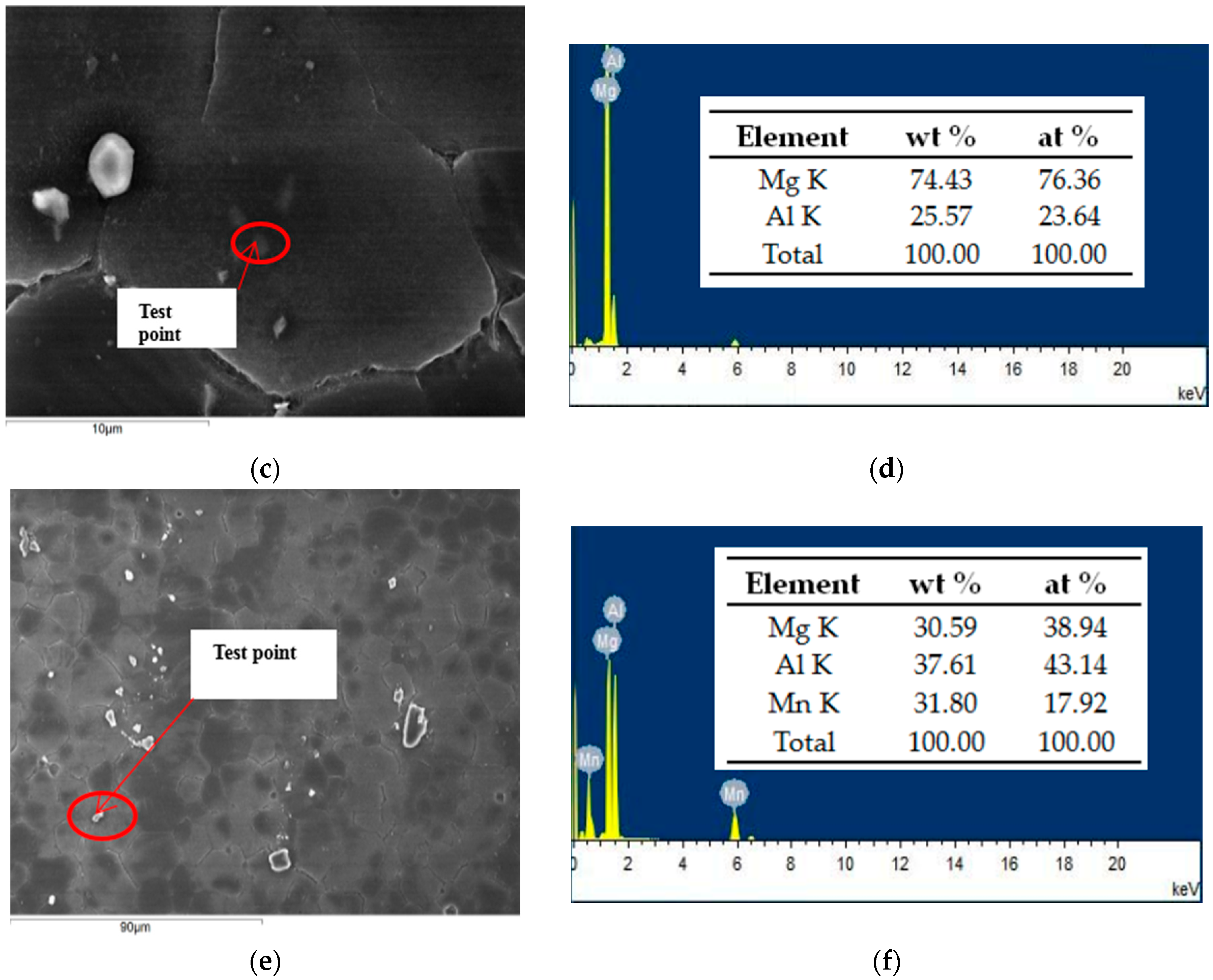

3.2. Morphology and SEM Observation

3.3. Comparison of the Mechanical Measurements of Mg MMCs

4. Conclusions

- The mechanical properties of the annealed SiCp-free AZ61 alloy plate are better than those of the unannealed SiCp-free AZ61 alloy plate.

- Both the annealed and unannealed AZ61/SiCp/1 μm and AZ61/SiCp/50 nm MMC plates exhibited greater strength, hardness, and ductility that did the SiCp-free (i.e., AZ61) MMC Mg alloy plate.

- The annealed AZ61/SiCp/1 μm and AZ61/SiCp/50 nm MMC plates exhibited improvements in hardness and strength, but ductility slightly decreased because of the precipitation of the β phase.

- Adding submicron SiCp and nano SiCp particles to AZ61 during processing resulted in the advantages of strengthening the mechanical properties and increasing ductility.

- Annealing can improve the ductility and formability of Mg alloys and Mg MMCs with micron SiCp, but it weakens those properties in Mg MMCs with submicron SiCp and nano SiCp.

- The SiC/AZ61 MMCs in the present study exhibited more complete mechanical property results compared with other studies.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rokhlin, L.L. The 7th International conference Magnesium alloys and their applications. Metalloved. I Term. Obrab. Met. 2008, 3, 22–23. [Google Scholar]

- Schindler, S.; Mergheim, J.; Zimmermann, M.; Aurich, J.C.; Steinmann, P. Numerical homogenization of elastic and thermal material properties for metal matrix composites (mmc). Contin. Mech. Thermodyn. 2017, 29, 1–25. [Google Scholar] [CrossRef]

- Abbott, T.B.; Rienass, G.; Zhen, Z.S. Property assessment of magnesium alloys for powertrain applications. VDI Ber. 2012, 2158, 321–332. [Google Scholar]

- Wang, M.; Xiao, D.H.; Liu, W.S. Effect of Si addition on microstructure and properties of magnesium alloys with high Al and Zn contents. Vacuum 2017, 141, 144–151. [Google Scholar] [CrossRef]

- Venkatachalam, G.; Kumaravel, A. Mechanical Behaviour of Aluminium Alloy Reinforced With SiC/Fly Ash/Basalt Composite for Brake Rotor. Polym. Polym. Compos. 2017, 25, 203–208. [Google Scholar]

- Dai, J.H.; Jiang, B.; Peng, C.; Pan, F.S. Effect of mn additions on diffusion behavior of Fe in molten magnesium alloys by solid-liquid diffusion couples. J. Alloys Compd. 2017, 710, 260–266. [Google Scholar] [CrossRef]

- Cui, S.; Wu, X.; Liu, R.; Teng, X.; Leng, J.; Geng, H. Effects of Te addition on microstructure and mechanical properties of AZ91 magnesium alloy. Mater. Res. Express 2017, 4, 016503. [Google Scholar] [CrossRef]

- Volkova, E.F. Modern magnesium-base deformable alloys and composite materials (a review). Met. Sci. Heat Treat. 2006, 48, 473–478. [Google Scholar] [CrossRef]

- Fridlyander, I.N. Modern aluminum and magnesium alloys and composite materials based on them. Met. Sci. Heat. Treat. 2002, 44, 292–296. [Google Scholar] [CrossRef]

- Si, C.; Tang, X.; Zhang, X.; Wang, J.; Wu, W. Microstructure and mechanical properties of particle reinforced metal matrix composites prepared by gas-solid two-phase atomization and deposition technology. Mater. Lett. 2017, 201, 78–81. [Google Scholar] [CrossRef]

- Tjong, S.C. Novel nanoparticle-reinforced metal matrix composites with enhanced mechanical properties. Adv. Eng. Mater. 2007, 9, 639–652. [Google Scholar] [CrossRef]

- Grishina, O.I.; Serpova, V.M. Aspects of mechanical properties of metal matrix composites reinforced with continuous unidirectional fibers (review). Trudy VIAM 2017. [Google Scholar] [CrossRef]

- Shirvanimoghaddam, K.; Hamim, S.U.; Akbari, M.K.; Fakhrhoseini, S.M.; Khayyam, H.; Pakseresht, A.H. Carbon fiber reinforced metal matrix composites: Fabrication processes and properties. Compos. Part A Appl. Sci. Manuf. 2016, 92, 70–96. [Google Scholar] [CrossRef]

- Yong, H.P.; Bang, J.; Oak, J.J.; Lee, Y.C.; Jung, K.H. The effect of the addition of Ti metal fiber and Al-Mg alloy binder on the mechanical properties of Al-Si/SiCp metal matrix composites fabricated by powder metallurgy. J. Korean Inst. Met. Mater. 2016, 54, 400–408. [Google Scholar] [CrossRef]

- Iqbal, A.A.; Arai, Y.; Araki, W. Fatigue crack growth mechanism in cast hybrid metal matrix composite reinforced with SiC particles and Al2O3 whiskers. Trans. Nonferrous Met. Soc. China 2014, 241, S1–S13. [Google Scholar] [CrossRef]

- Li, A.B.; Geng, L.; Meng, Q.Y.; Zhang, J. Simulation of the large compressive deformation of metal matrix composites with misaligned whiskers. Mater. Sci. Eng. A 2003, 358, 324–333. [Google Scholar] [CrossRef]

- Huang, C.C. Effect of Reinforcement Size on the Mechanical Properties of as Cast and Extruded AZ61/SiCp Magnesium Matrix Composites. Master’s Thesis, National Taiwan University of Science and Technology, Taipei, Taiwan, 2013. [Google Scholar]

- Chen, T.J.; Jiang, X.D.; Ma, Y.; Li, Y.D.; Hao, Y. Grain refinement of AZ91D magnesium alloy by SiC. J. Alloys Compd. 2010, 496, 218–225. [Google Scholar] [CrossRef]

- Chua, B.W.; Lu, L.; Lai, M.O. Influence of SiC particles on mechanical properties of Mg based composite. Compos. Struct. 1999, 47, 595–601. [Google Scholar] [CrossRef]

- Zhang, B.H.; Zhang, Z.M. Influence of homogenizing on mechanical properties of as-cast AZ31 magnesium alloy. Trans. Nonferrous Met. Soc. China 2010, 20, 439–443. [Google Scholar] [CrossRef]

- Li, J.Y.; Xie, J.X.; Jin, J.B.; Wang, Z.X. Microstructural evolution of AZ91 magnesium alloy during extrusion and heat treatment. Trans. Nonferrous Met. Soc. China 2012, 22, 1028–1034. [Google Scholar] [CrossRef]

- Chen, Q.; Zhao, Z.; Shu, D.; Zhao, Z. Microstructure and mechanical properties of AZ91D magnesium alloy prepared by compound extrusion. Mater. Sci. Eng. A 2011, 528, 3930–3934. [Google Scholar] [CrossRef]

- Hassan, S.F.; Gupta, M. Effect of length scale of Al2O3 particulates on microstructural and tensile properties of elemental Mg. Mater. Sci. Eng. A 2006, 425, 22–27. [Google Scholar] [CrossRef]

- Agrawal, P.; Sun, C.T. Fracture in metal—Ceramic composites. Compos. Sci. Technol. 2004, 64, 1167–1178. [Google Scholar] [CrossRef]

- Psakhie, S.; Ovcharenko, V.; Yu, B.; Shilko, E.; Astafurov, S.; Ivanov, Y.; Byeli, A.; Mokhovikov, A. Influence of Features of Interphase Boundaries on Mechanical Properties and Fracture Pattern in Metal-Ceramic Composites. J. Mater. Sci. Technol. 2013, 29, 1025–1034. [Google Scholar] [CrossRef]

- Ma, G.; Han, G.; Liu, X. Grain refining efficiency of a new Al-1B-0.6C master alloy on AZ63 magnesium alloy. J. Alloys Compd. 2010, 491, 165–169. [Google Scholar]

- Habibnejad-Korayem, M.; Mahmudia, R.; Pooleb, W.J. Enhanced properties of Mg-based nano-composites reinforced with Al2O3 nano-particles. Mater. Sci. Eng. A 2009, 519, 198–203. [Google Scholar] [CrossRef]

- Huang, S.J.; Lin, P.C. Grain refinement of AM60/Al2O3p Megnesium Metal-matrix Composites Processed by ECAE. Kov. Mater. Met. Mater. 2013, 51, 357–366. [Google Scholar]

- Hassan, S.F.; Gupta, M. Development of high performance magnesium nanocomposites using solidification processing route. Mater. Sci. Technol. 2004, 20, 1383–1388. [Google Scholar] [CrossRef]

- Besterci, M.; Huang, S.-J.; Sülleiová, K.; Balloková, B.; Velgosová, O. Fracture analysis of AZ61-F magnesium composite materials at quasi-superplastic state. Kov. Mater. 2017, 55, 217–221. [Google Scholar]

- Wu, X.; Yang, X.; Ma, J.; Huo, Q.; Wang, J.; Sun, H. Enhanced stretch formability and mechanical properties of a magnesium alloy processed by cold forging and subsequent annealing. Mater. Des. 2013, 43, 206–212. [Google Scholar] [CrossRef]

- Miao, Q.; Hu, L.; Wang, G.; Wang, E. Fabrication of excellent mechanical properties AZ31 magnesium alloy sheets by conventional rolling and subsequent annealing. Mater. Sci. Eng. A 2011, 528, 6694–6701. [Google Scholar] [CrossRef]

- Sun, H.F.; Li, C.J.; Yang, X.; Fang, W.B. Microstructures and mechanical properties of pure magnesium bars by high ratio extrusion and its subsequent annealing treatment. Trans. Nonferrous Met. Soc. China 2012, 22, 445–449. [Google Scholar] [CrossRef]

- Huang, S.J.; Hwang, Y.M.; Huang, Y.S. Grain Refinement of AZ61/SiCp Magnesium Matrix Composites for Tubes Extruded by Hot Extrusion Processes. Key Eng. Mater. 2013, 528, 135–143. [Google Scholar] [CrossRef]

- Hong, Y.; Xiaowu, H.; Qiao, N.; Lei, C. Aging behavior of nano-SiCp reinforced AZ61 magnesium matrix composites. Res. Dev. 2011, 8, 269–273. [Google Scholar]

- Zulkoffli, Z.; Syarif, J.; Sajuri, Z. Fabrication of AZ61/SIC composites by powder metallurgy process. Int. J. Mech. Mater. Eng. 1970, 4, 156–159. [Google Scholar]

- Hu, Q.; Jie, X.P.; Yan, H.; Zhang, F.Y.; Chen, G.X. Mechanical properties and damping capacity of AZ61 magnesium alloy matrix composites with SiC particulates. Forg. Stamp. Technol. 2008, 33, 106–109. [Google Scholar]

- Yan, H.; Fu, M.F.; Zhang, F.Y.; Chen, G.X. Research on properties of SiCp/AZ61 magnesium matrix composites in fabrication processes. Mater. Sci. Forum 2007, 561, 945–948. [Google Scholar] [CrossRef]

| Al | Zn | Mn | Fe | Si | Cu | Ni | Mg |

|---|---|---|---|---|---|---|---|

| 5.95 | 0.64 | 0.26 | 0.005 | 0.009 | 0.0008 | 0.0007 | Bal. |

| Notation | Specification | Yield Strength, [MPa] (% Change) | Ultimate Tensile Strength, [MPa] (% Change) | Hardness [HV] (% Change) | Elongation (% Change) | Reference |

|---|---|---|---|---|---|---|

| AZ61/BA | Extruded AZ61 Mg alloy before annealing | 131.9 ± 1.2 (0) | 310.9 ± 3.8 (0) | 60.8 ± 0.9 (0) | 23.5 ± 1.5% (0) | This study |

| AZ61/AA | Extruded AZ61 Mg alloy after annealing | 132.7 ± 1.9 (+0.6) | 327.9 ± 1.9 (+5.5) | 65.9 ± 1.1 (+8.4) | 40.8 ± 3.0% (+73.6) | This study |

| AZ61/10 μm SiC/BA | Extruded AZ61 with 0.5, 1, 2 wt % 10 μm SiCp AZ61 MMCs plate before annealing | 133.0–135.1 (+1.6) | 324.2–326.2 (+4.6) | 61.3–63.0 (+2.2) | 27.2–33.5% (+29.1) | This study |

| AZ61/10 μm SiC/AA | Extruded AZ61 with 0.5, 1, 2 wt % 10 μm SiCp AZ61 MMCs plate after annealing | 128.7–134.5 (−0.2) | 309.7–329.2 (+2.8) | 63.9–65.2 (+6.2) | 31.0–37.6% (+46.0) | This study |

| AZ61/1 μm SiC/BA | Extruded AZ61 with 0.5, 1, 2 wt % 1 μm SiCp AZ61 MMCs plate before annealing | 133.6–135.8 (+2.1) | 326.5–329.5 (+5.5) | 62.1–63.6 (+3.1) | 40.2–42.7% (+76.4) | This study |

| AZ61/1 μm SiC/AA | Extruded AZ61 with 0.5, 1, 2 wt % 1 μm SiCp AZ61 MMCs plate after annealing | 135.5–137.0 (+3.3) | 332.2–336.1 (+7.5) | 63.3–65.1 (+5.6) | 36.6–39.1% (+61.1) | This study |

| AZ61/50 nm SiC/BA | Extruded AZ61 with 0.5, 1, 2 wt % 50 nm SiCp AZ61 MMCs plate before annealing | 134.1–136.4 (+2.5) | 327.5–331.0 (+5.9) | 62.0–63.3 (+3.0) | 40.8–43.1% (+78.5) | This study |

| AZ61/50 nm SiC/AA | Extruded AZ61 with 0.5, 1, 2 wt % 50 nm SiCp AZ61 MMCs plate after annealing | 134.7–136.8 (+2.9) | 328.2–334.6 (+6.6) | 63.0–64.5 (+4.9) | 37.3–40.6% (+65.0) | This study |

| AZ61/4.5 μm SiC/T5 | Extruded AZ61 with 1, 2, 5 wt % 4.5μm SiCp AZ61 MMCs tube after T5 treatment | 136.0–145.0 (+4.9) | 291.0–315.0 (+2.9) | 67.2–75.6 (+2.7) | NA | [34] |

| AZ61/100 nmSiC/AA | AZ61 with 1 wt % 100 nm SiCp AZ61 MMCs after annealing | NA | NA | 68–78 (+2.1) | NA | [35] |

| AZ61/20 μmSiC/sintered | Sintered AZ61 with 5 wt % 20μm SiCp AZ61 MMCs | NA | NA | 71–96 (NA) | NA | [36] |

| AZ61/10μm SiC | Casted AZ61 with 3, 6, 18 vol % 10μm SiCp AZ61 MMCs | 168–186 (+5.9) | NA | NA | 17–45% (−48.7) | [37] |

| AZ61/10 μmSiC | Casted AZ61 with 3, 6, 9 vol % 10 μm SiCp AZ61 MMCs | NA | NA | 79–115 (+48.7) | NA | [38] |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, W.; Huang, S.-J.; Wu, Y.-J.; Kang, C.-W. Particle Size and Particle Percentage Effect of AZ61/SiCp Magnesium Matrix Micro- and Nano-Composites on Their Mechanical Properties Due to Extrusion and Subsequent Annealing. Metals 2017, 7, 293. https://doi.org/10.3390/met7080293

Zhao W, Huang S-J, Wu Y-J, Kang C-W. Particle Size and Particle Percentage Effect of AZ61/SiCp Magnesium Matrix Micro- and Nano-Composites on Their Mechanical Properties Due to Extrusion and Subsequent Annealing. Metals. 2017; 7(8):293. https://doi.org/10.3390/met7080293

Chicago/Turabian StyleZhao, Weigang, Song-Jeng Huang, Yi-Jhang Wu, and Cheng-Wei Kang. 2017. "Particle Size and Particle Percentage Effect of AZ61/SiCp Magnesium Matrix Micro- and Nano-Composites on Their Mechanical Properties Due to Extrusion and Subsequent Annealing" Metals 7, no. 8: 293. https://doi.org/10.3390/met7080293