Inspection of Prebaked Carbon Anodes Using Multi-Spectral Acousto-Ultrasonic Excitation

Abstract

:1. Introduction

2. Materials and Experimental Data Acquisition

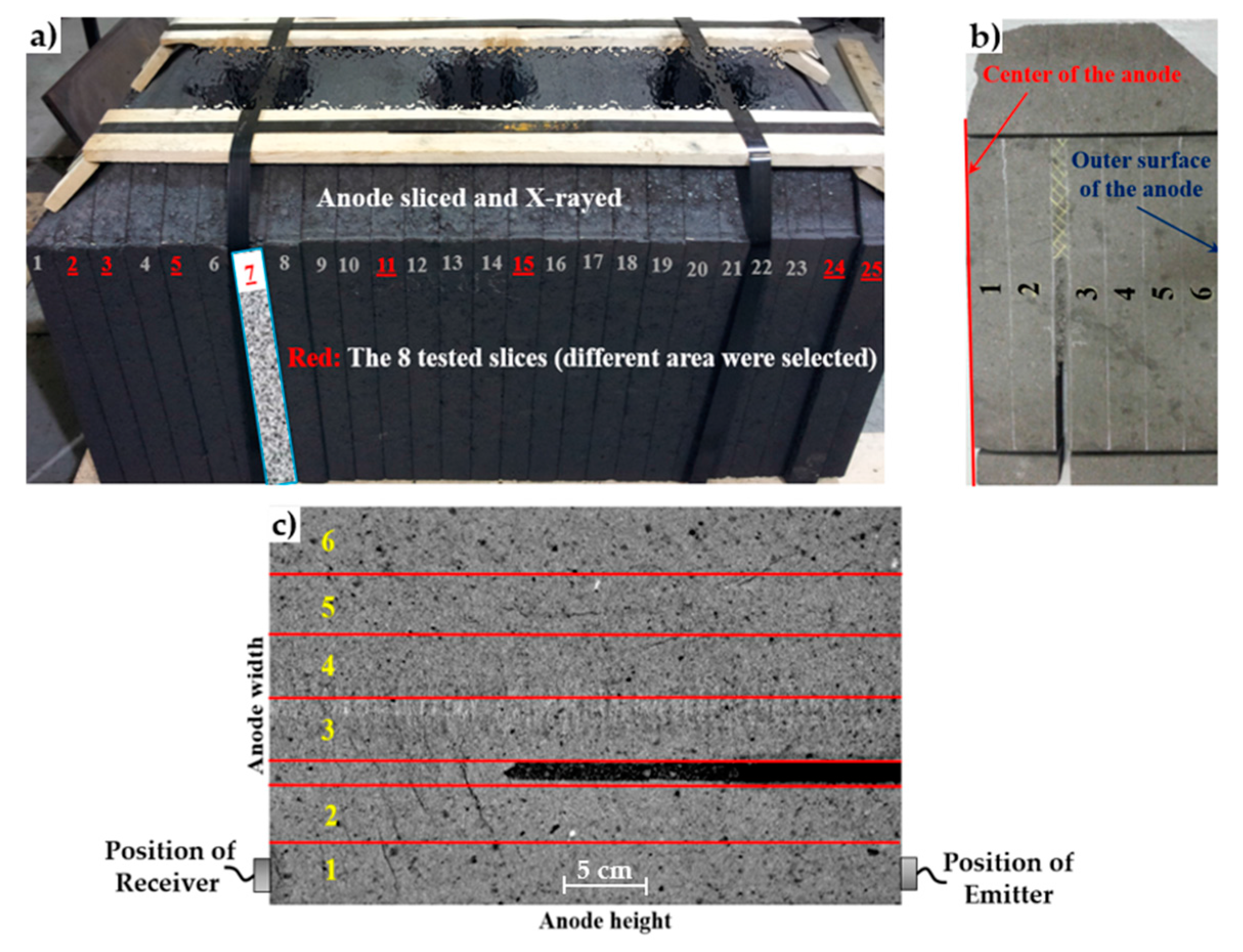

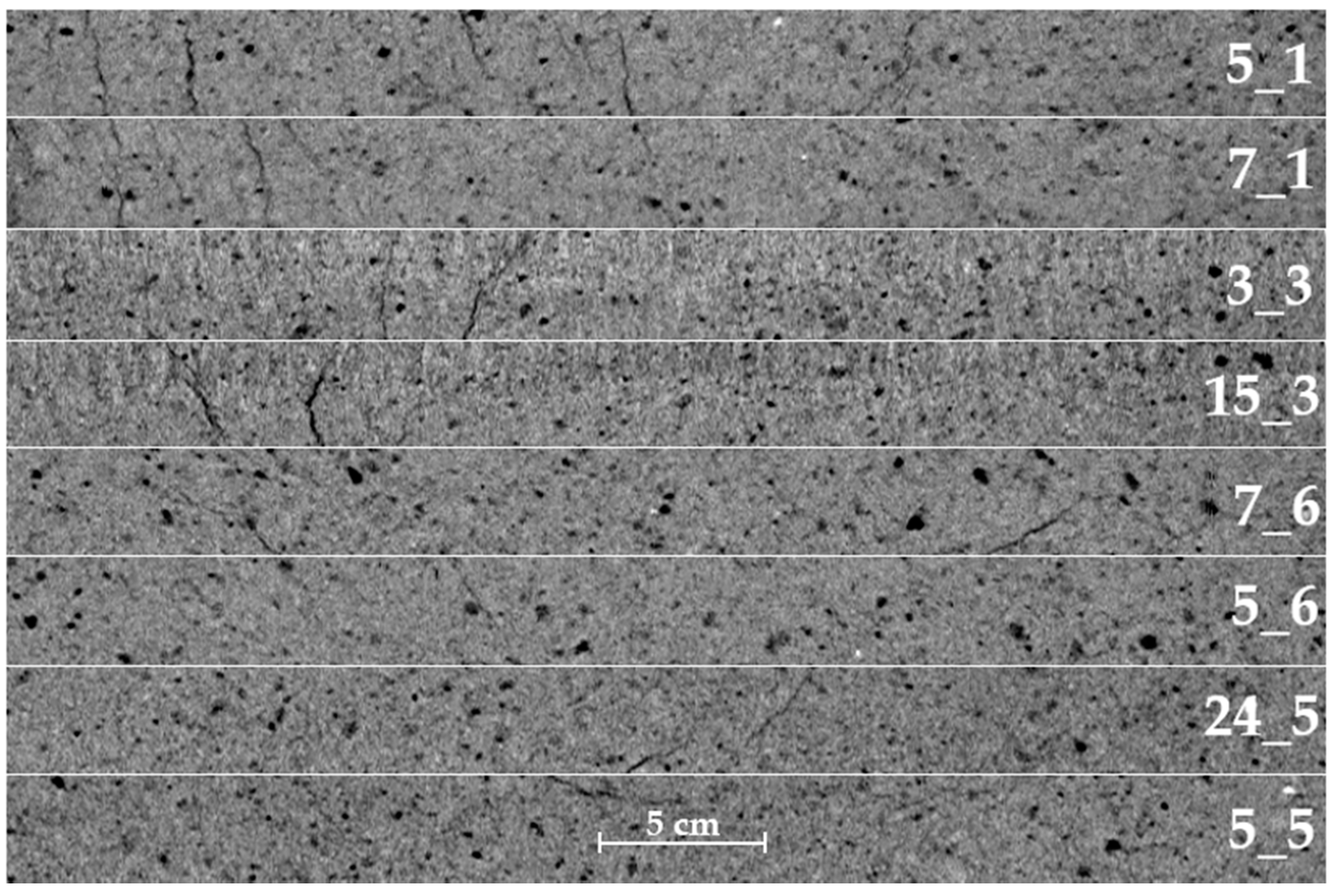

2.1. Baked Anode Samples and X-ray Images

2.2. Acousto-Ultrasonic (AU) Signal Acquisition

3. Extraction of Features from Acoustic Signals and X-ray Images

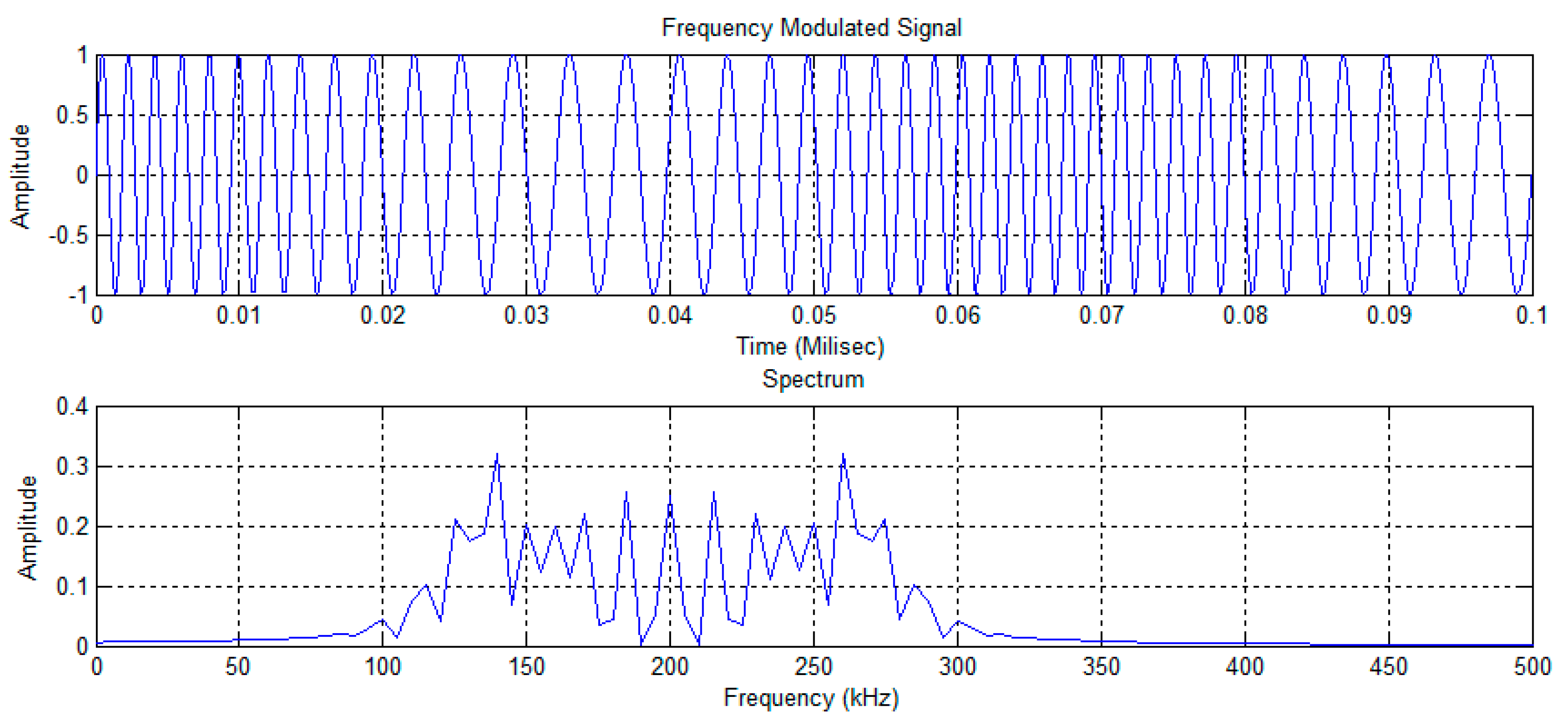

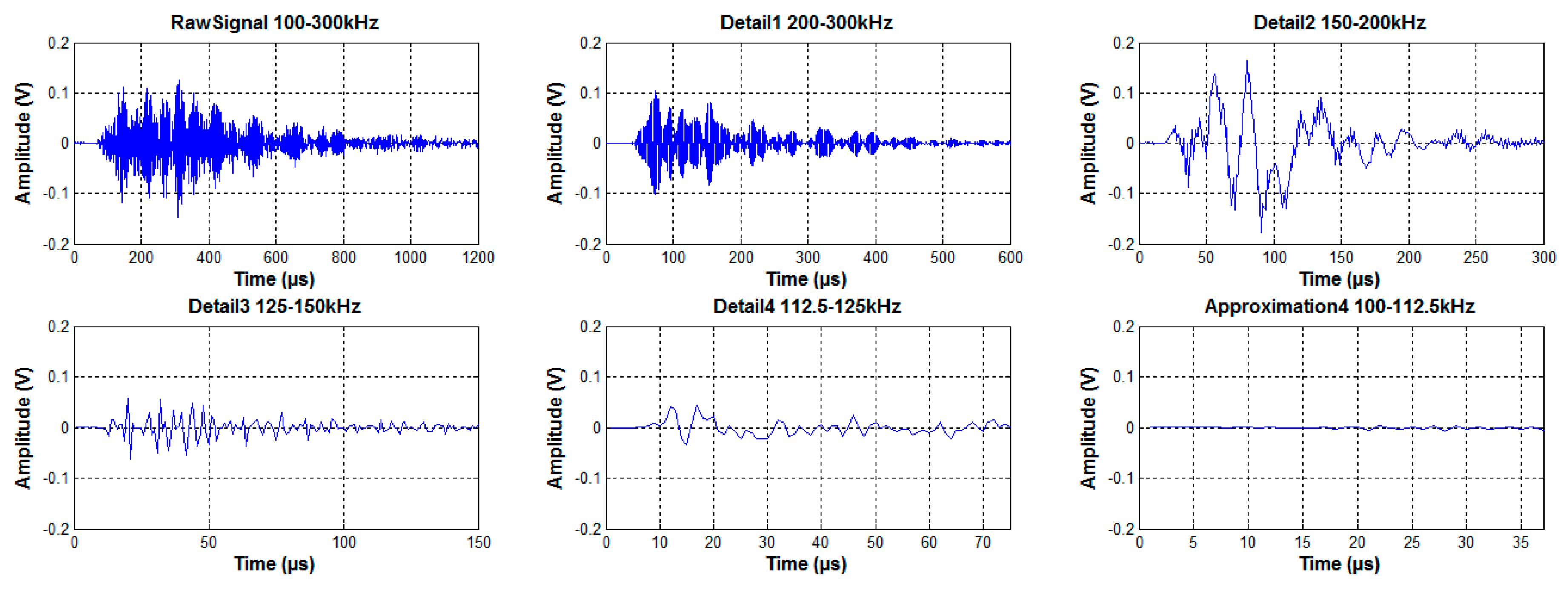

3.1. Acousto-Ultrasonic Signals

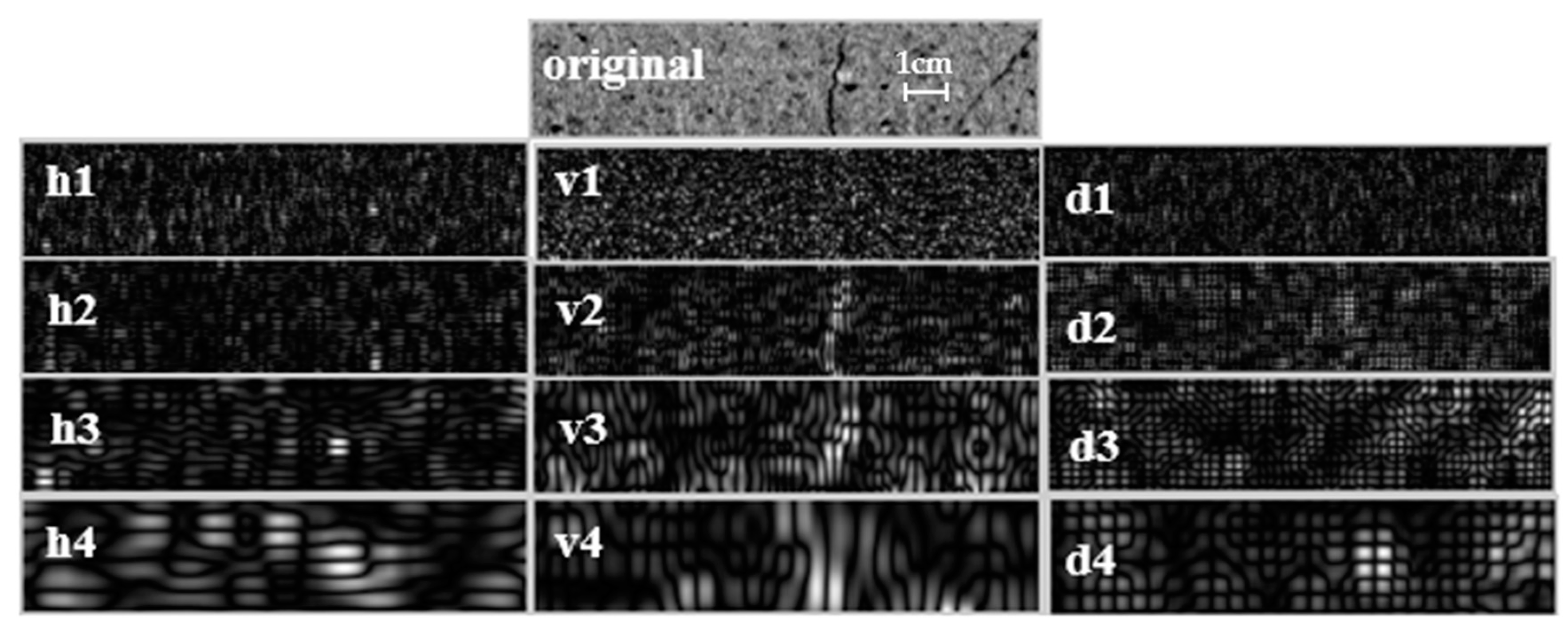

3.2. X-ray Image Texture Analysis

4. Multivariate Statistical Methods for Analysis of the Acousto-Ultrasonic Signal and Image Features

4.1. Principal Component Analysis

4.2. Partial Least Squares Regression

5. Results and Discussion

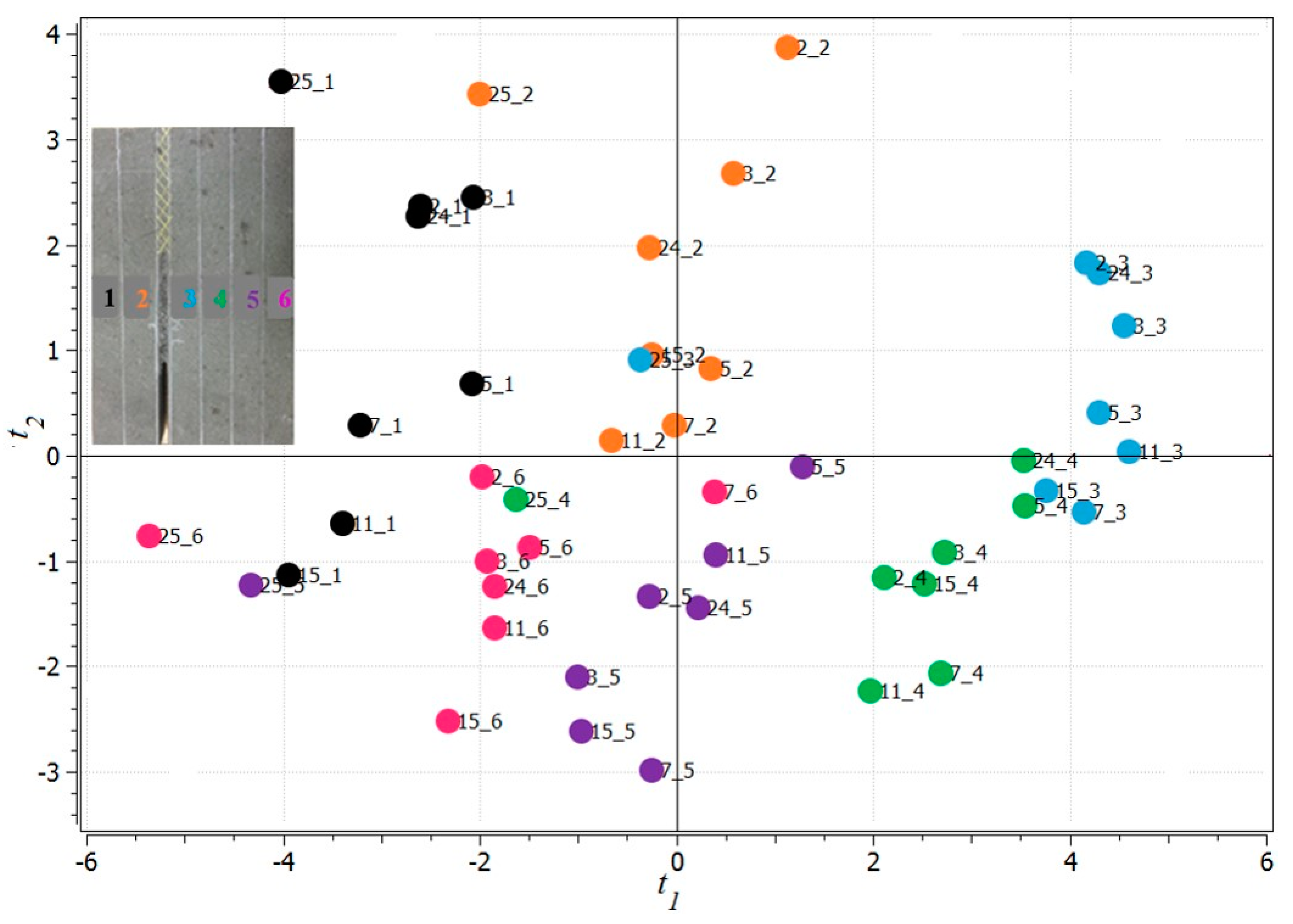

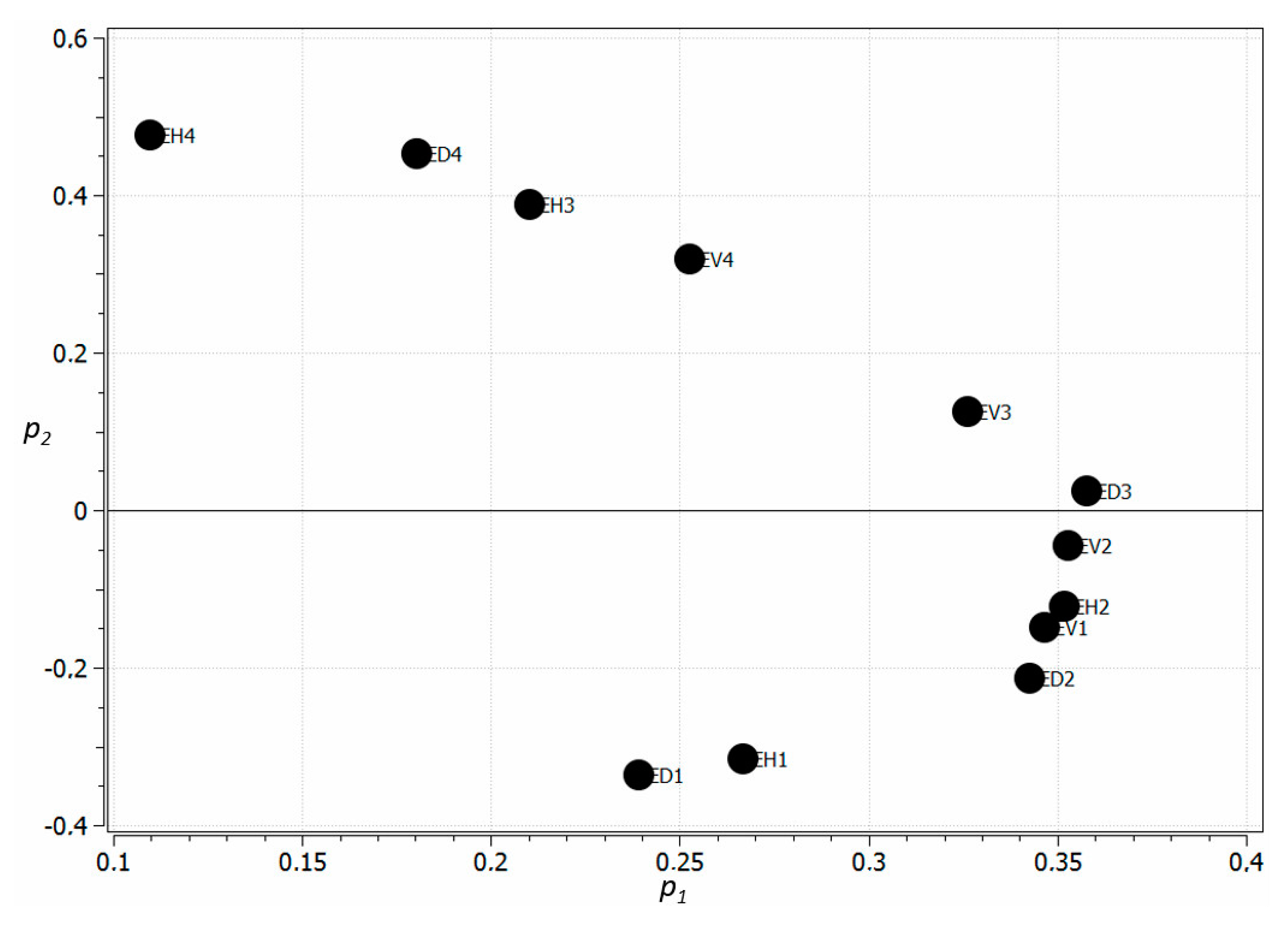

5.1. Texture Analysis of X-ray Images

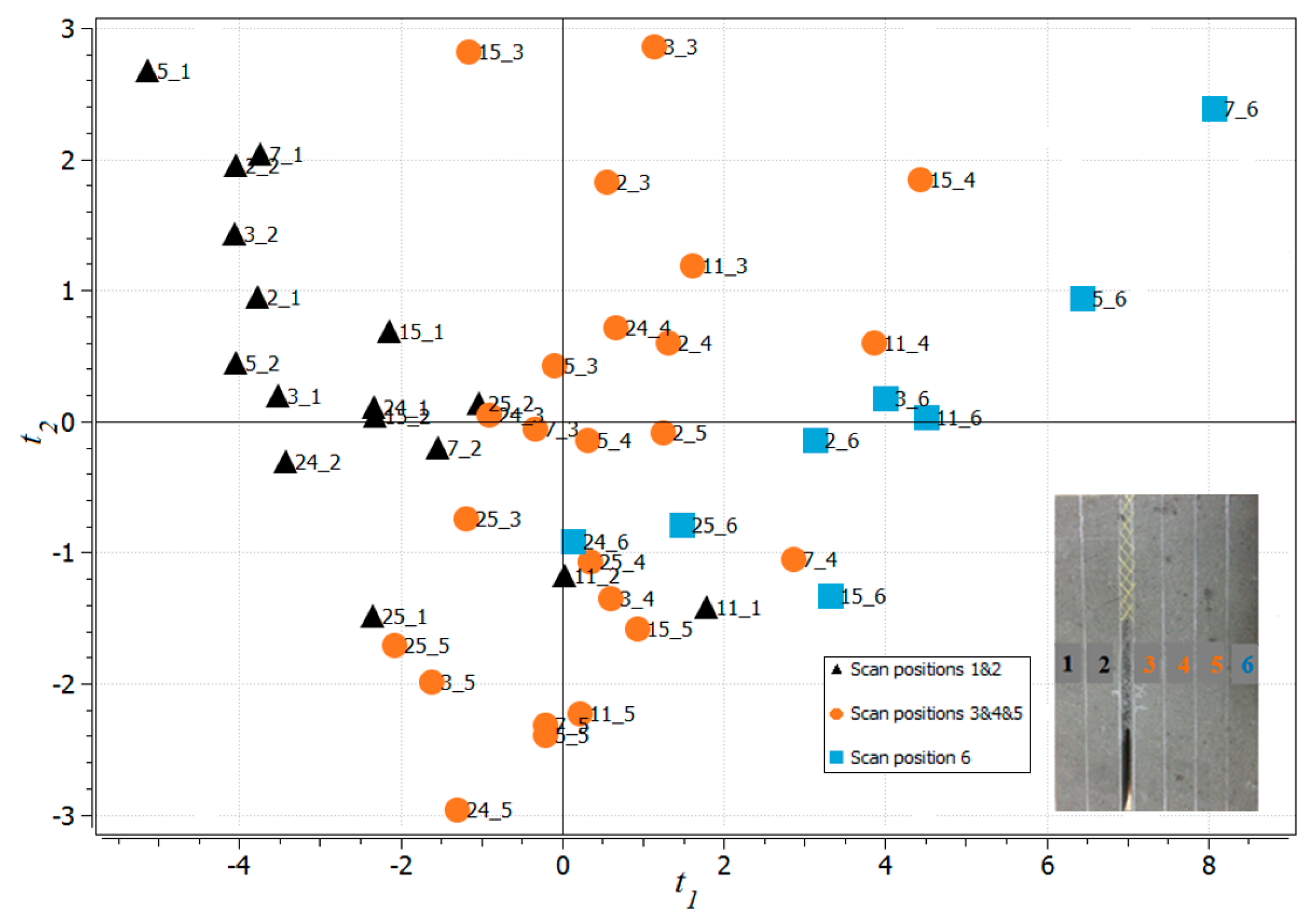

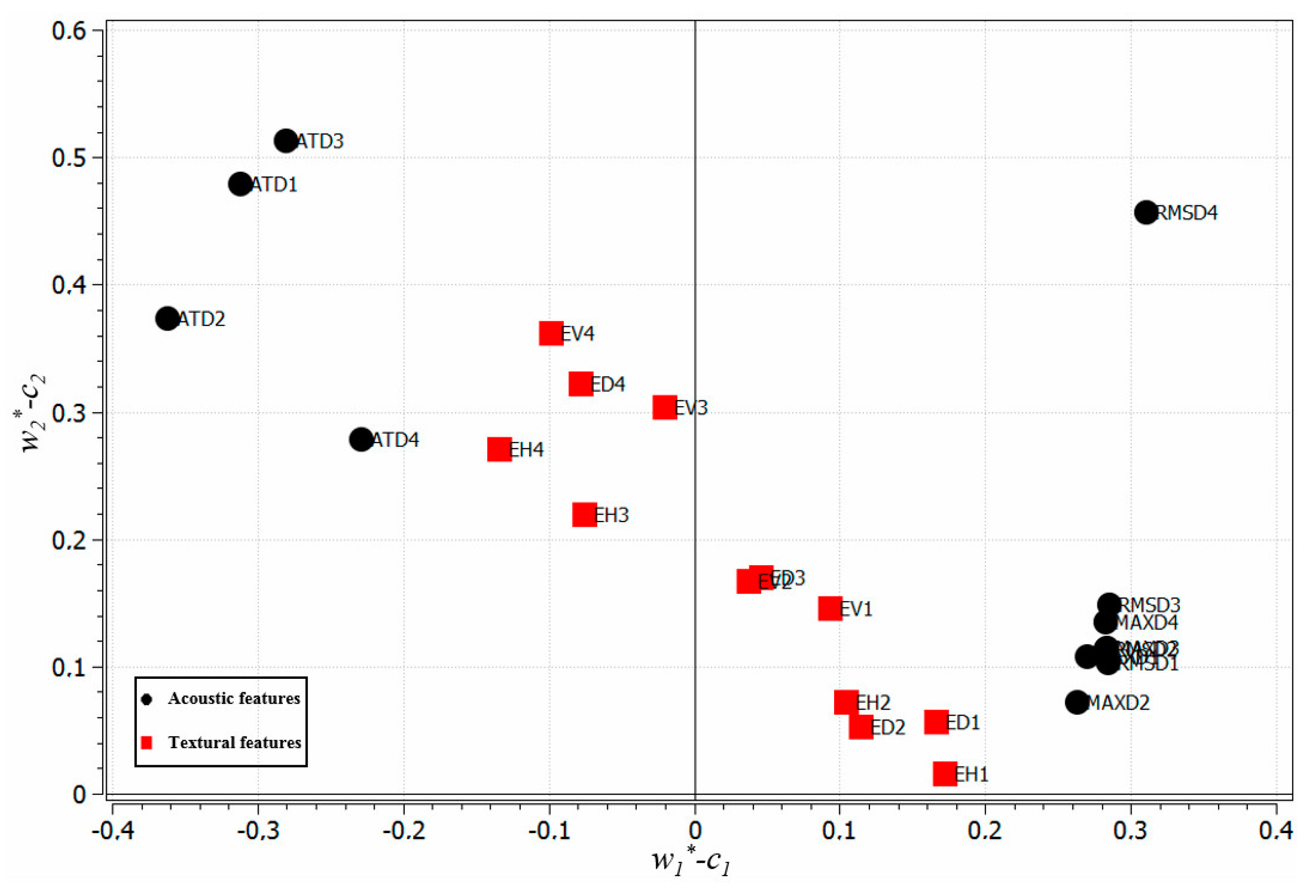

5.2. Regression of X-ray Image Textural Features on Acousto-Ultrasonic Features

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kocaefe, Y.; Kocaefe, D.; Bhattacharyay, D. Quality Control via Electrical Resistivity Measurement of Industrial Anodes. In Light Metals; John Wiley & Sons: Hoboken, NJ, USA, 2015; pp. 1097–1102. [Google Scholar]

- Andoh, M.A.; Kocaefe, Y.; Kocaefe, D.; Bhattacharyay, D.; Marceau, D.; Morais, B. Mesurement of the Electric Current Distribution in An Anode. In Light Metals; John Wiley & Sons: Hoboken, NJ, USA, 2016; pp. 889–894. [Google Scholar]

- Ziegler, D.P.; Secasan, J. Methods for Determining Green Electrode Electrical Resistivity and Methods for Making Electrodes. U.S. Patent 9,416,458, 16 August 2016. [Google Scholar]

- Chollier-Brym, M.J.; Laroche, D.; Alexandre, A.; Landry, M.; Simard, C.; Simard, L.; Ringuette, D. New Method for Representative Measurement of Anode Electrical Resistance. In Light Metals; John Wiley & Sons: Hoboken, NJ, USA, 2012; pp. 1299–1302. [Google Scholar]

- Léonard, G.; Guérard, S.; Laroche, D.; Arnaud, J.C.; Gourmaud, S.; Gagnon, M.; Marie-Chollier, M.J.; Perron, Y. Anode Electrical Resistance Measurements: Learning and Industrial On-line Measurement Equipment Development. In Light Metals; John Wiley & Sons: Hoboken, NJ, USA, 2014; pp. 1269–1274. [Google Scholar]

- Ben Boubaker, M.; Picard, D.; Duchesne, C.; Tessier, J.; Alamdari, H.; Fafard, M. The Potential of Acousto-Ultrasonic Techniques for Inspection of Baked Carbon Anodes. Metals 2016, 6, 151. [Google Scholar] [CrossRef]

- Suzuki, M.; Nazanishi, H.; Iwamoto, M. Relationship between acoustic emission characteristics and structural factors of composite materials. In Proceedings of the Third Japan-U.S. Conference on Composite Materials, Tokyo, Japan, 23–25 June 1986; pp. 631–638. [Google Scholar]

- Ni, Q.-Q.; Jinen, E. Acoustic emission and fracture of carbon fiber reinforced thermosoftening plastic (CFRTP) materials under monotonous tensile loading. Eng. Fract. Mech. 1993, 45, 611–625. [Google Scholar]

- Ni, Q.-Q.; Jinen, E. Fracture behavior and acoustic emission of SFC. J. Soc. Mater. Sci. 1993, 42, 561–567. [Google Scholar] [CrossRef]

- Ni, Q.-Q.; Jinen, E. Acoustic emission technique in the single-filament-composite test. In Proceedings of the First International Conference on Composite Engineering (ICCE/1), New Orleans, LA, USA, 28–31 August 1994; pp. 883–884. [Google Scholar]

- Serrano, E.P.; Fabio, M.A. Application of the wavelet transform to acoustic emission signal processing. IEEE Trans. Signal Process. 1996, 44, 1270–1275. [Google Scholar] [CrossRef]

- Suzuki, H.; Kinjo, T.; Hayashi, Y.; Takemoto, M.; Ono, K. Wavelet transform of acoustic emission signals. J. Acoust. Emiss. 1996, 14, 69–84. [Google Scholar]

- Ni, Q.-Q.; Misada, Y. Analysis of AE signals by wavelet transform. J. Soc. Mater. Sci. 1998, 47, 305–311. [Google Scholar] [CrossRef]

- Cohen, L. Time-Frequency Analysis; Prentice Hall PTR: Englewood Cliffs, NJ, USA, 1995. [Google Scholar]

- Kronland-Martinet, R.; Morlet, J.; Grossmann, A. Analysis of sound patterns through wavelet transforms. Int. J. Pattern Recognit. Artif. Intell. 1987, 1, 273–302. [Google Scholar] [CrossRef]

- Aussel, J.D.; Monchalin, J.P. Structure noise reduction and deconvolution of ultrasonic data using wavelet decomposition (ultrasonic flaw detection). In Proceedings of the Ultrasonics Symposium, Montreal, QC, Canada, 3–6 October 1989; pp. 1139–1144. [Google Scholar]

- Loe, R.S.; Jung, K.; Anderson, K.; Abatzoglou, A.; Regan, J.; Arnold, H.; Lawton, W. Status report on wavelets in signal detection and identification: Comparative processing and technology evaluation. In Proceedings of the IEEE Sixth SP Workshop on Statistical Signal and Array Processing, Susono, Japan, 7–9 October 1992; pp. 46–49. [Google Scholar]

- Qi, G.; Barhorst, A.; Hashemi, J.; Kamala, G. Discrete wavelet decomposition of acoustic emission signals from carbon-fiber reinforced composites. Compos. Sci. Technol. 1997, 57, 389–403. [Google Scholar] [CrossRef]

- Qi, G. Wavelet-based AE characterization of composite materials. NDT E Int. 2000, 33, 133–145. [Google Scholar] [CrossRef]

- Sandirasegaram, N.; English, R. Comparative analysis of feature extraction (2D FFT and wavelet) and classification (Lp metric distances, MLP NN, and HNeT) algorithms for SAR imagery. In Proceedings of the SPIE 5808, Algorithms for Synthetic Aperture Radar Imagery XII, Orlando, FL, USA, 14 June 2005; pp. 314–325. [Google Scholar]

- Mallat, S.G. A theory for multiresolution signal decomposition: The wavelet representation. IEEE Trans. Pattern Anal. Mach. Intell. 1989, 11, 674–693. [Google Scholar] [CrossRef]

- Boespflug, X. Axial tomodensitometry—Relation between the Ct intensity and the density of the sample. Can. J. Earth Sci. 1994, 31, 426–434. [Google Scholar] [CrossRef]

- Picard, D.; Alamdari, H.; Ziegler, D.; Dumas, B.; Fafard, M. Characterization of a full-scale prebaked carbon anode using X-ray computerized tomography. In Light Metals; John Wiley & Sons: Hoboken, NJ, USA, 2011; pp. 973–978. [Google Scholar]

- Borah, S.; Hines, E.L.; Bhuyan, M. Wavelet transform based image texture analysis for size estimation applied to the sorting of tea granules. J. Food Eng. 2007, 79, 629–639. [Google Scholar] [CrossRef]

- Bharati, M.H.; Liu, J.J.; MacGregor, J.F. Image texture analysis: Methods and comparisons. Chemom. Intell. Lab. Syst. 2004, 72, 57–71. [Google Scholar] [CrossRef]

- Geladi, P.; Grahn, H. Multivariate Image Analysis; John Wiley & Sons: Hoboken, NJ, USA, 1996. [Google Scholar]

- Wold, S.; Esbensen, K.; Geladi, P. Principal component analysis. Chemom. Intell. Lab. Syst. 1987, 2, 37–52. [Google Scholar] [CrossRef]

- Höskuldsson, A. PLS regression methods. J. Chemom. 1988, 2, 211–228. [Google Scholar] [CrossRef]

- Wold, S.; Sjöström, M.; Eriksson, L. PLS-regression: A basic tool of chemometrics. Chemom. Intell. Lab. Syst. 2001, 58, 109–130. [Google Scholar] [CrossRef]

- Wold, S. Cross-validatory estimation of the number of components in factor and principal component models. Technometrics 1978, 20, 397–405. [Google Scholar] [CrossRef]

| Component | R2 (%) | Q2 (%) |

|---|---|---|

| 1 | 60.3 | 58.7 |

| 2 | 84.0 | 83.2 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ben Boubaker, M.; Picard, D.; Duchesne, C.; Tessier, J.; Alamdari, H.; Fafard, M. Inspection of Prebaked Carbon Anodes Using Multi-Spectral Acousto-Ultrasonic Excitation. Metals 2017, 7, 305. https://doi.org/10.3390/met7080305

Ben Boubaker M, Picard D, Duchesne C, Tessier J, Alamdari H, Fafard M. Inspection of Prebaked Carbon Anodes Using Multi-Spectral Acousto-Ultrasonic Excitation. Metals. 2017; 7(8):305. https://doi.org/10.3390/met7080305

Chicago/Turabian StyleBen Boubaker, Moez, Donald Picard, Carl Duchesne, Jayson Tessier, Houshang Alamdari, and Mario Fafard. 2017. "Inspection of Prebaked Carbon Anodes Using Multi-Spectral Acousto-Ultrasonic Excitation" Metals 7, no. 8: 305. https://doi.org/10.3390/met7080305