Influence of Build Orientation, Heat Treatment, and Laser Power on the Hardness of Ti6Al4V Manufactured Using the DMLS Process

Abstract

:1. Introduction

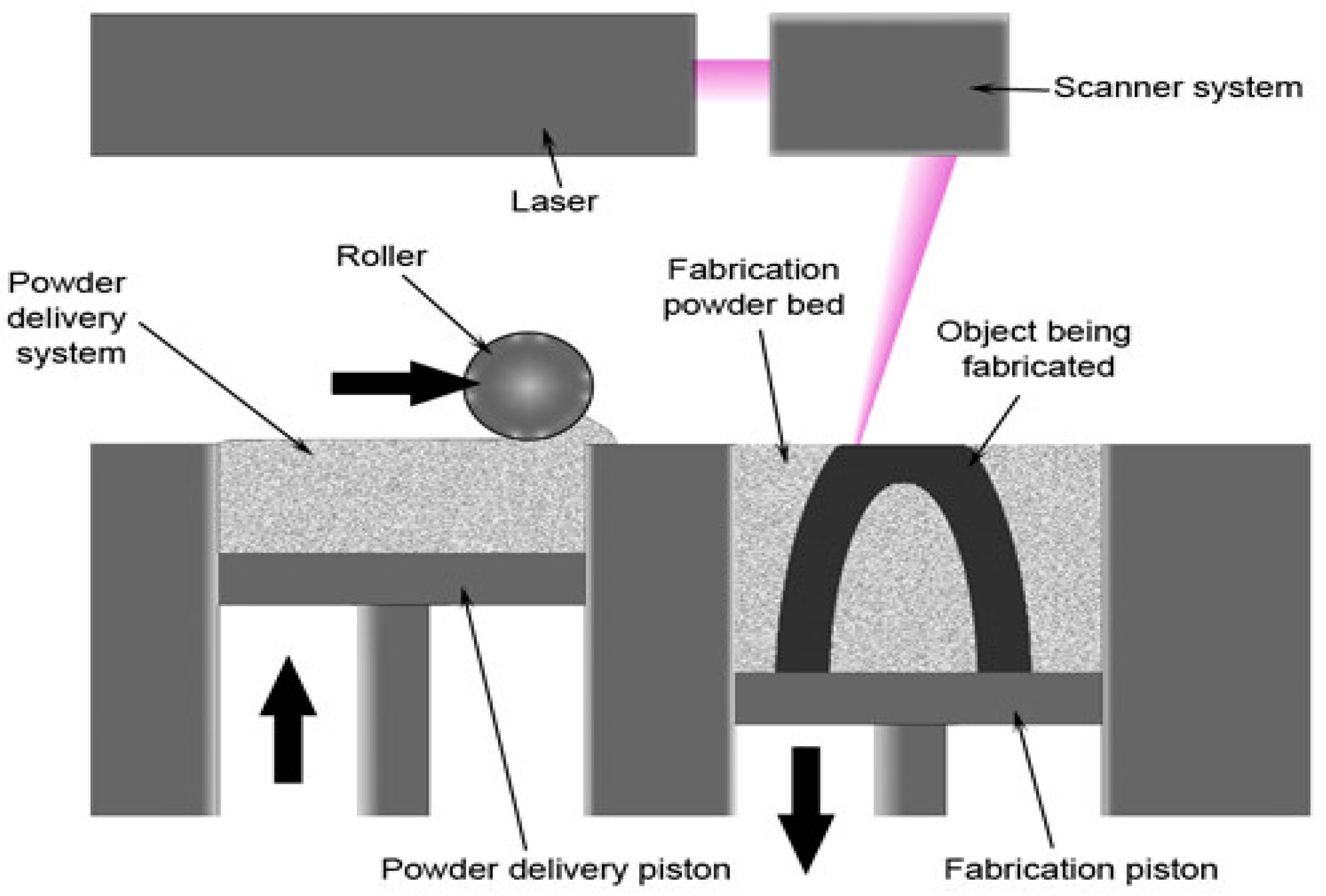

1.1. Direct Metal Laser Sintering (DMLS)

1.2. Research Activities Related to DMLS/SLM of Ti6Al4V

2. Materials and Methods

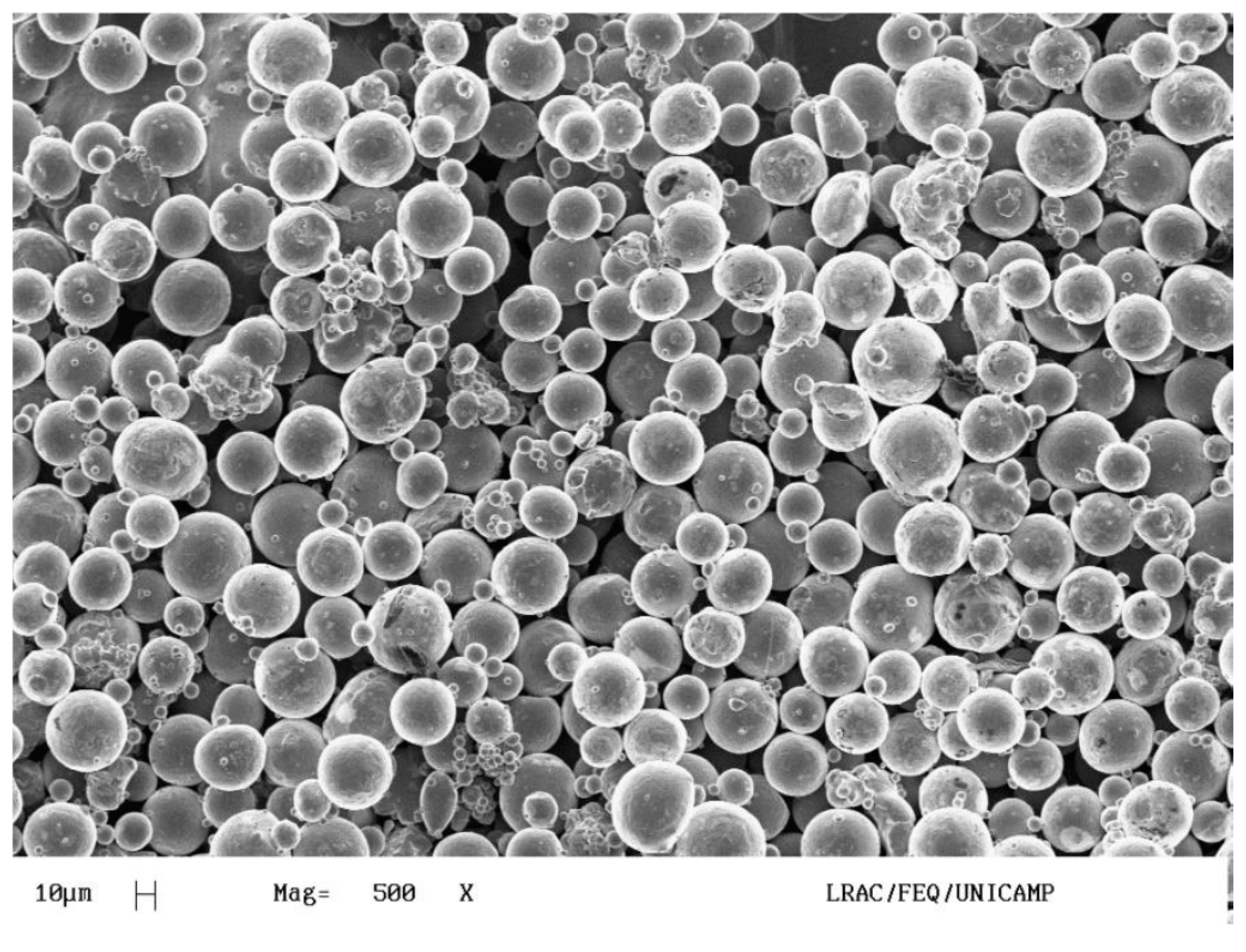

2.1. Material

2.2. DMLS Parameters

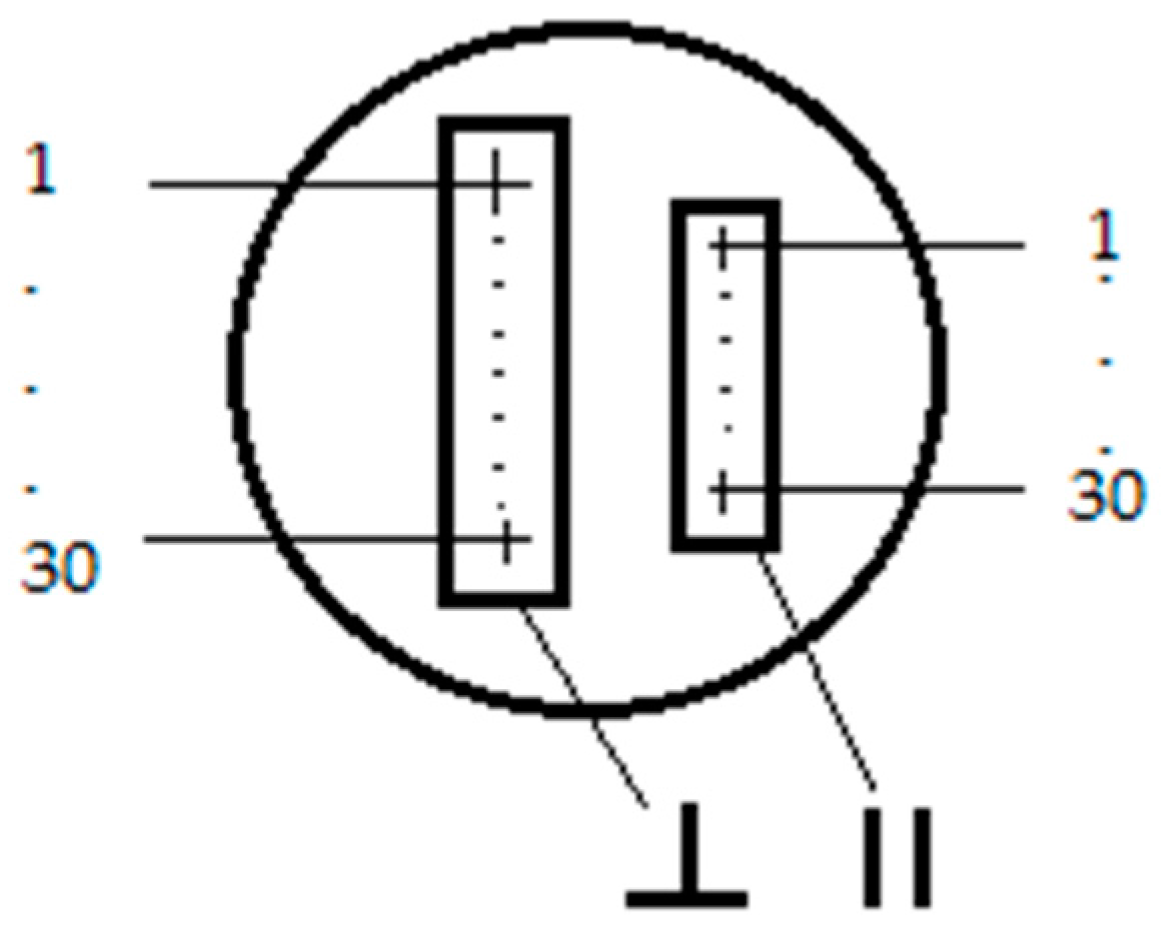

2.3. The Shape and Dimensions of the Test Samples

2.4. Heat Treatment of Materials

2.5. Metallographic Study of Materials

2.6. Hardness of Materials

2.7. Methods of Statistic Analysis

- in the hardness between the samples prepared at different laser power—the comparison within each of the four groups (A—sintered, perpendicular direction, B—sintered-annealed, perpendicular direction, C—sintered, parallel direction, D—sintered-annealed, parallel direction)

- in the hardness of the materials sintered and sintered-annealed in a particular direction—comparison between the two groups (A and B—sintered and sintered-annealed in the perpendicular direction, C and D—sintered and sintered-annealed in the parallel direction)

- in the hardness of the materials in two different directions—the comparison between the two groups (A and C—sintered in the perpendicular and parallel direction, B and D—sintered-annealed in the perpendicular and parallel direction)

- Independence of observations.

- Normality of sampling distribution

- Equal variance (homogeneity)

- Equal variances

- Unequal variances

- Paired samples

3. Results and Discussion

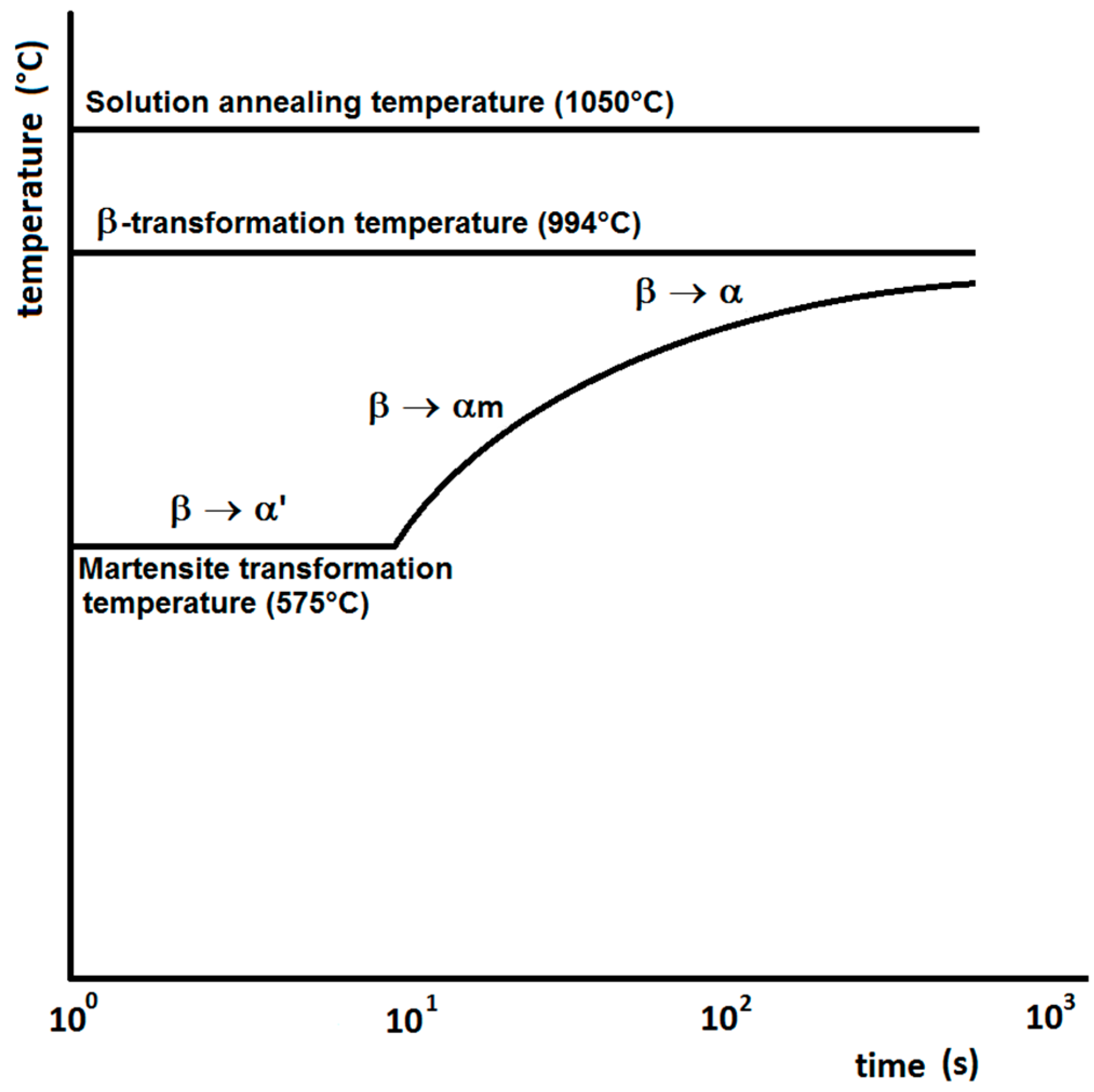

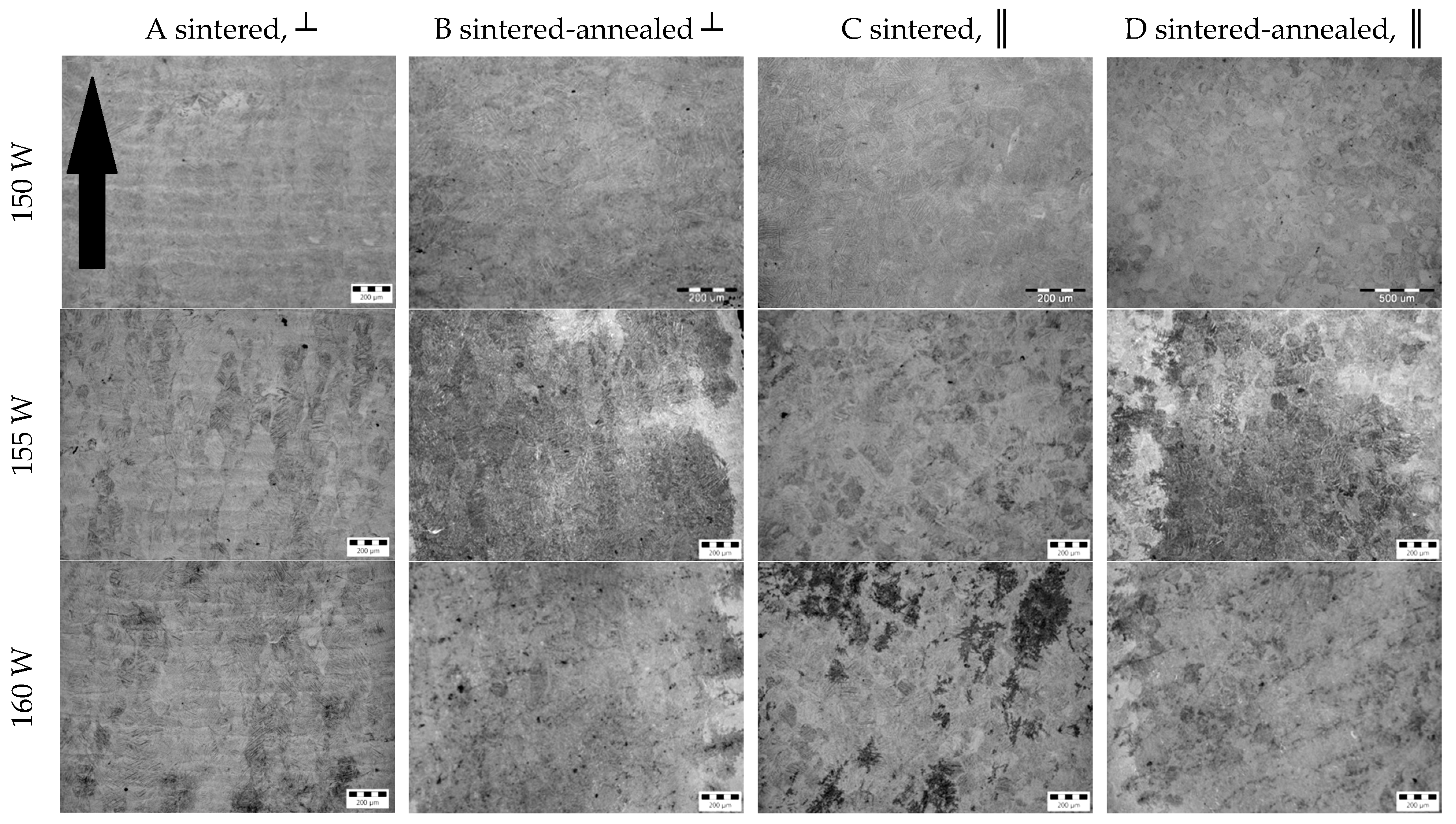

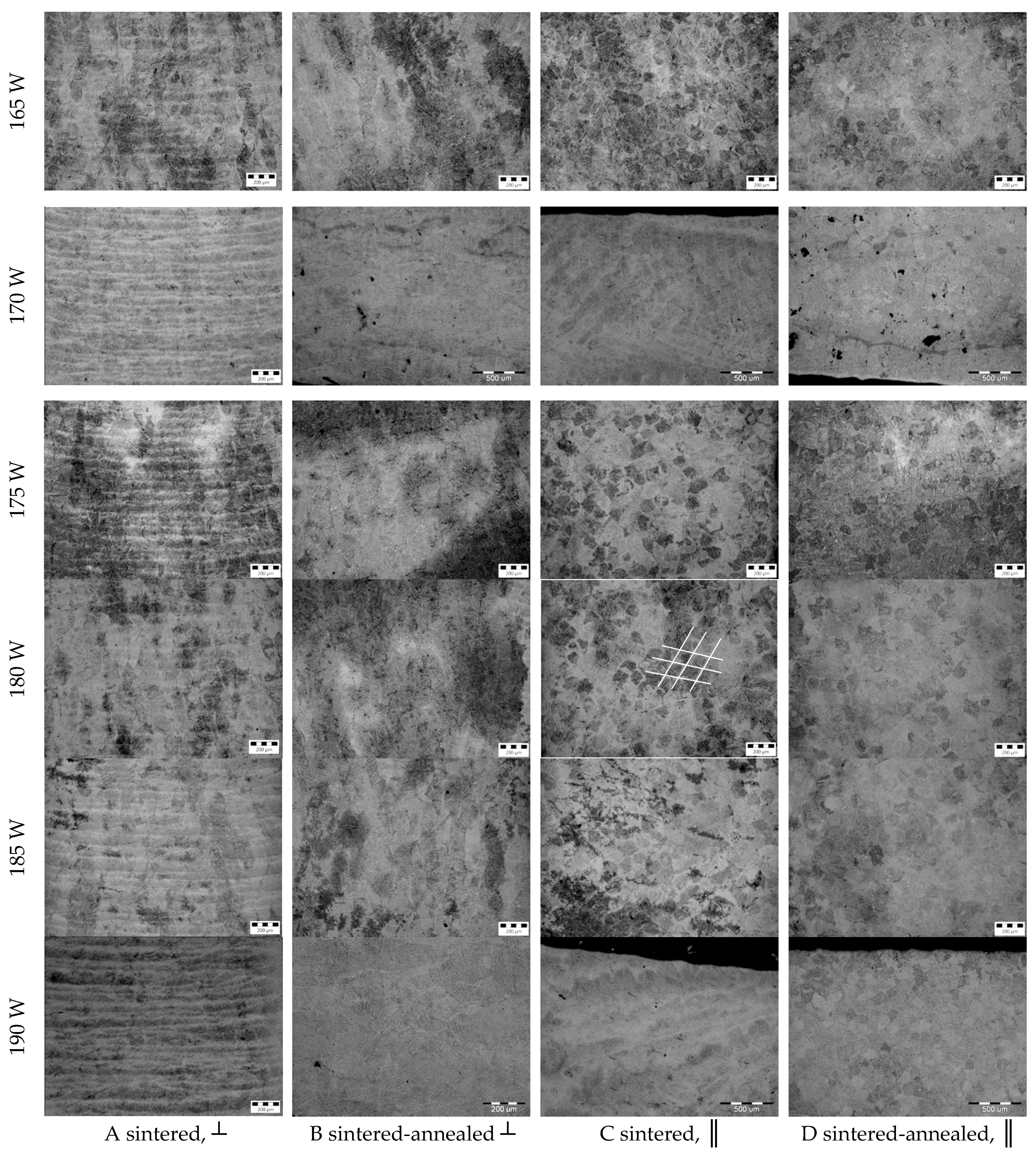

3.1. Microstructure of Materials

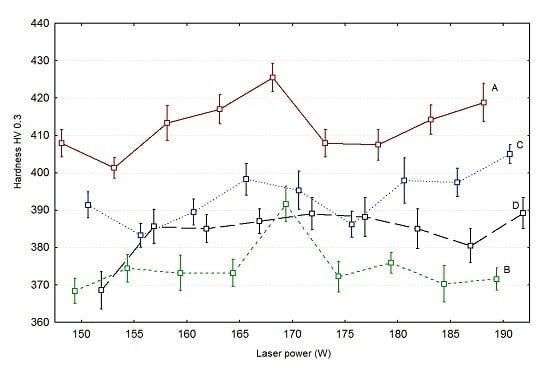

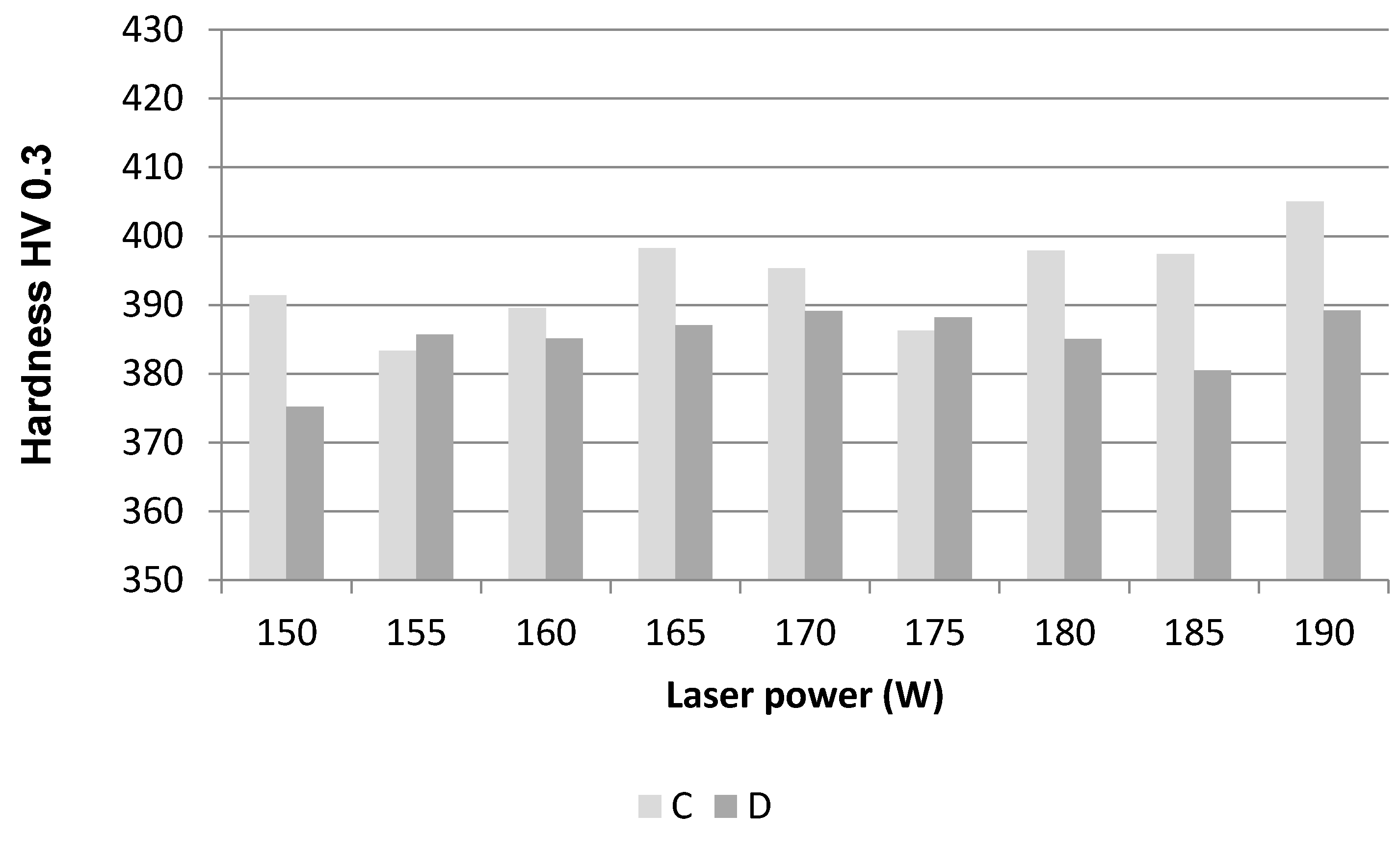

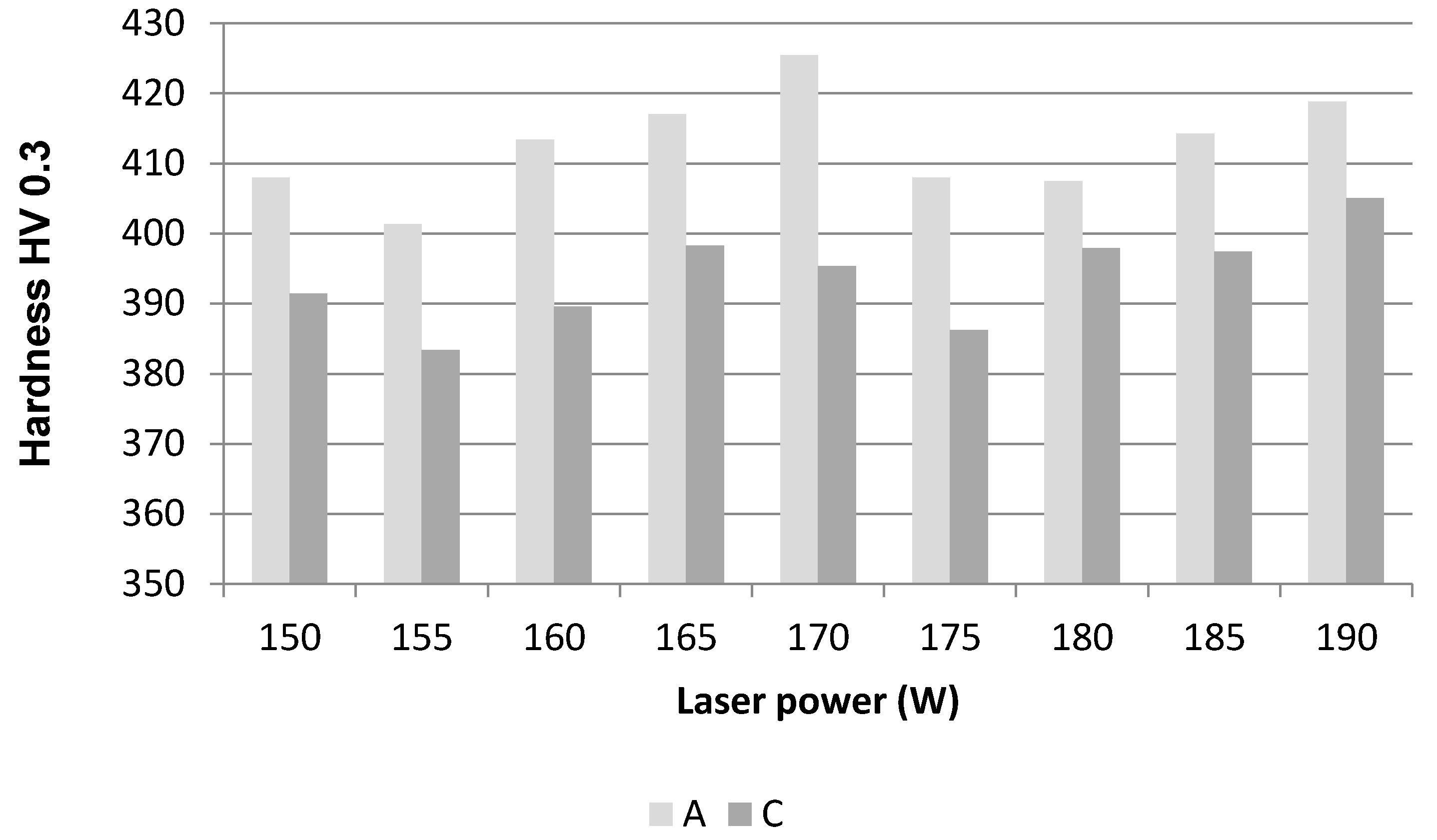

3.2. Effect of Laser Power on the Hardness

3.3 Comparison of the Hardness of Sintered and Sintered-Annealed Materials

3.4. Comparison of the Hardness of Materials in Two Different Directions

4. Conclusions

- -

- The microstructure is characterized by large, elongated prior β-phase grain boundaries that are filled with very fine needles of acicular α′-martensite.

- -

- The pattern of sintered layers is evident on metallographic cross-sections in the direction perpendicular to the sintered layers (layer thickness) and in the parallel direction (grid plan pattern) as well. After annealing, these patterns disappear.

- -

- Annealing has led to a reduction in hardness regardless of the direction of material assessment

- -

- ANOVA showed a statistically significant effect of the laser power on the hardness of both sintered and sintered-annealed materials, both in the perpendicular and parallel directions.

- -

- Post hoc analysis defined specific laser power couples, between which a statistically significant difference in material hardness was expressed; after stress-relief annealing statistically significant differences decrease in both the perpendicular and parallel directions.

- -

- Larger differences in material hardness due to annealing occur in the perpendicular direction compared to the parallel.

- -

- Statistically significant differences were found in the hardness of the materials in the perpendicular and parallel build directions.

- -

- Stress-relief annealing reduces differences in Ti6Al4V hardness between the two directions, contributing to the even distribution of hardness and, finally, isotropy of the mechanical properties of the final product sintered using DMLS technology.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- De Damborenea, J.J.; Larosa, M.A.; Arenas, M.A.; Hernández-López, J.M.; Jardini, A.L.; Ierardi, M.C.F.; Zavaglia, C.A.C.; Filho, R.M.; Conde, A. Functionalization of Ti6Al4V scaffolds produced by direct metal laser for biomedical applications. Mater. Des. 2015, 83, 6–13. [Google Scholar] [CrossRef]

- Palmquist, A.; Shah, F.A.; Emanuelsson, L.; Omar, O.; Suska, F. A technique for evaluating bone ingrowth into 3D printed, porous Ti6Al4V implants accurately using X-ray micro-computedtomography and histomorphometry. Micron 2017, 94, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Kucukkoc, I.; Zhang, D.Z. Production planning in additive manufacturing and 3D printing. Comput. Oper. Res. 2017, 83, 157–172. [Google Scholar] [CrossRef]

- Bertol, L.S.; Júnior, W.K.; da Silva, F.P.; Aumund-Kopp, C. Medical design: Direct metal laser sintering of Ti-6Al-4V. Mater. Des. 2010, 31, 3982–3988. [Google Scholar] [CrossRef]

- Song, B.; Dong, S.; Liao, H.; Coddet, C. Process parameter selection for selective laser melting of Ti6Al4V based on temperature distribution simulation and experimental sintering. Int. J. Adv. Manuf. Technol. 2012, 61, 967–974. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Krakhmalev, P.; Yadroitsava, I. Selective laser melting of Ti6Al4V alloy for biomedical applications: Temperature monitoring and microstructural evolution. J. Alloys Compd. 2014, 583, 404–409. [Google Scholar] [CrossRef]

- Sedlák, J.; Ptáčková, M.; Nejedlý, J.; Madaj, M.; Dvořáček, J.; Zouhar, J.; Charvát, O.; Píška, M.; Rozkošný, L. Material analysis of titanium alloy produced by direct metal laser sintering. Int. J. Metalcast. 2013, 7, 43–50. [Google Scholar] [CrossRef]

- Petroušek, P.; Bidulská, J.; Bidulský, R.; Kočiško, R.; Fedoriková, A.; Hudák, R.; Rajťúková, V.; Živčák, J. Mechanical properties and porosity of Ti-6Al-4V alloy prepared by AM technology. MM Sci. J. 2017, 2, 1752–1755. [Google Scholar] [CrossRef]

- Živčák, J.; Šarik, M.; Hudák, R. FEA simulation of thermal processes during the direct metal laser sintering of Ti64 titanium powder. Measurement 2016, 94, 893–901. [Google Scholar] [CrossRef]

- Schnitzer, M.; Lisý, M.; Hudák, R.; Živčák, J. Experimental measuring of the roughness of test samples made using DMLS technology from the Titanium alloy Ti-6Al-4V. In Proceedings of the SAMI, Herľany, Slovakia, 22–24 January 2015; IEEE: Košice, Slovakia, 2015. [Google Scholar]

- Wikipedia. Selective Laser Sintering. Available online: http://en.wikipedia.org/wiki/Selective_laser_sintering (accessed on 30 April 2017).

- Patterson, A.E.; Messimer, S.L.; Farrington, P.A. Overhanging Features and the SLM/DMLS Residual Stresses Problem: Review and Future Research Need (Special Issue in Additive Manufacturing Technologies and Applications). Technologies 2017, 5, 1–21. [Google Scholar] [CrossRef]

- Brezinová, J.; Hudák, R.; Guzanová, A.; Draganovská, D.; Ižaríková, G.; Koncz, J. Direct Metal Laser Sintering of Ti6Al4V for Biomedical Applications: Microstructure, Corrosion Properties and Mechanical Treatment of Implants. Metals 2016, 6, 171. [Google Scholar] [CrossRef]

- Khairallah, S.A.; Anderson, A.T. Mesoscopic simulation model of selective laser melting of stainless steel powder. J. Mater. Process. Technol. 2014, 214, 2627–2636. [Google Scholar] [CrossRef]

- Kruth, J.-P.; Mercelis, P.; van Vaerenbergh, J.; Froyen, L.; Rombouts, M. Binding mechanisms in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2005, 11, 26–36. [Google Scholar] [CrossRef]

- Weißmann, V.; Bader, R.; Hansmann, H.; Laufer, N. Influence of the structural orientation on the mechanical properties of selective laser melted Ti6Al4V open-porous scaffolds. Mater. Des. 2016, 95, 188–197. [Google Scholar] [CrossRef]

- Konečná, R.; Kunz, L.; Bača, A.; Nicoletto, G. Long fatigue crack growth in Ti6Al4V produced by direct metal laser sintering. Procedia Eng. 2016, 160, 69–76. [Google Scholar] [CrossRef]

- Milton, S.; Morandeau, A.; Chalon, F.; Leroy, R. Influence of finish machining on the surface integrity of Ti6Al4V produced by Selective Laser Melting. Procedia CIRP 2016, 45, 127–130. [Google Scholar] [CrossRef]

- Bača, A.; Konečná, R.; Nicoletto, G.; Kunz, L. Influence of build direction on the fatigue behaviour of Ti6Al4V alloy produced by direct metal laser sintering. Mater. Today Proc. 2016, 3, 921–924. [Google Scholar] [CrossRef]

- Wauthle, R.; Vrancken, B.; Beynaerts, B.; Jorissen, K.; Schrooten, J.; Kruth, J.-P.; Humbeeck, J.V. Effects of build orientation and heat treatment on the microstructure and mechanical properties of selective laser melted Ti6Al4V lattice structures. Addit. Manuf. 2015, 5, 77–84. [Google Scholar] [CrossRef]

- Sidambe, A.T. Three dimensional surface topography characterization of the electron beam melted Ti6Al4V. Met. Powder Rep. 2017, 72, 200–205. [Google Scholar] [CrossRef]

- Vastola, G.; Zhang, G.; Pei, Q.X.; Zhang, Y.-W. Controlling of residual stress in additive manufacturing of Ti6Al4V by finite element modeling. Addit. Manuf. 2016, 12, 231–239. [Google Scholar] [CrossRef]

- Abe, F.; Santos, E.C.; Kitamura, Y.; Osakada, K.; Shiomi, M. Influence of forming conditions on the titanium model in rapid prototyping with the selective laser melting process. J. Mech. Eng. Sci. 2003, 217, 119–126. [Google Scholar] [CrossRef]

- De Damboreneaa, J.J.; Arenasa, M.A.; Larosa, M.A.; Jardini, A.L.; de Carvalho Zavaglia, C.A.; Condea, A. Corrosion of Ti6Al4V pins produced by direct metal laser sintering. Appl. Surf. Sci. 2017, 393, 340–347. [Google Scholar] [CrossRef]

- Zatkalíková, V.; Palček, P.; Markovičová, L.; Chalupová, M. Analysis of fractured screw shaped Ti6Al4V dental implant. Mater. Today Proc. 2016, 3, 1216–1219. [Google Scholar] [CrossRef]

- Pyka, G.; Kerckhofs, G.; Papantoniou, I.; Speirs, M.; Schrooten, J.; Wevers, M. Surface Roughness and Morphology Customization of Additive Manufactured Open Porous Ti6Al4V. Struct. Mater. 2013, 6, 4737–4757. [Google Scholar] [CrossRef] [PubMed]

- Lawley, A.; Murphy, F.T. Metallography of powder metallurgy materials. Mater. Charact. 2003, 51, 315–327. [Google Scholar] [CrossRef]

- Hong, K.-M.; Shin, Y.C. Analysis of microstructure and mechanical properties change in laserwelding of Ti6Al4V with a multiphysics prediction model. J. Mater. Process. Technol. 2016, 237, 420–429. [Google Scholar] [CrossRef]

- Li, X.; Van Humbeeck, J.; Kruth, J.-P. Selective laser melting of weak-textured commercially pure titanium with high strength and ductility: A study from laser power perspective. Mater. Des. 2017, 116, 352–358. [Google Scholar] [CrossRef]

- Mercelis, P.; Kruth, J.-P. Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2006, 12, 254–265. [Google Scholar] [CrossRef]

- Kruth, J.-P.; Deckers, J.; Yasa, E.; Wauthlé, R. Assessing and comparing influencing factors of residual stresses in selective laser melting using a novel analysis method. Proc. Inst. Mech. Eng. 2012, 226, 980–991. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; van Humbeeckm, J.; Kruth, J.-P. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Raju, R.; Duraiselvam, M.; Petley, V.; Verma, S.; Rajendran, R. Microstructural and mechanical characterization of Ti6Al4V refurbished parts obtained by laser metal deposition. Mater. Sci. Eng. A 2015, 643, 64–71. [Google Scholar] [CrossRef]

- Konečná, R.; Kunz, L.; Bača, A.; Nicoletto, G. Resistance of direct metal laser sintered Ti6Al4V alloy against growth of fatigue cracks. Eng. Fract. Mech. 2017. [Google Scholar] [CrossRef]

- EOS e-Manufacturing Solutions. Available online: https://cdn2.scrvt.com/eos/fe8d0271508e1e03/d6e4d305e880/EOS_Titanium_Ti64_en.pdf (accessed on 5 July 2017).

- Standard by ASTM International. ASTM F136-13, Standard Specification for Wrought Titanium-6Aluminum-4Vanadium ELI (Extra Low Interstitial) Alloy for Surgical Implant Applications (UNS R56401); ASTM International: West Conshohocken, PA, USA, 2013; Available online: https://www.astm.org (accessed on 30 May 2017).

- Longhitano, G.; Larosa, M.; Munhoz, A.; Zavaglia, C.; Ierardi, M. Surface Finishes for Ti-6Al-4V Alloy Produced by Direct Metal Laser Sintering. Mater. Res. 2015, 18, 838–842. [Google Scholar] [CrossRef]

- Laser Sintering System EOSINT M 280. Available online: https://webbuilder5.asiannet.com/ftp/2684/TD_M280_en_2011-03-29.pdf (accessed on 20 July 2017).

- Montgomery, D.C. Design and Analysis of Experiments, 8th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013; Available online: http://eu.wiley.com/WileyCDA/WileyTitle/productCd-1118097939.html (accessed on 14 August 2017).

| Element | Al | V | O | N | H | Fe | Si | C | Ti |

|---|---|---|---|---|---|---|---|---|---|

| Wt. % | 6.05 | 4.04 | 0.120 | 0.001 | 0.001 | 0.05 | 0.05 | 0.03 | Bal. |

| ASTM F136 | 5.50–6.50 | 3.50–4.50 | - | ||||||

| Microhardness | 400–430 HV |

| Ultimate tensile strength | 1290 ± 50 MPa |

| Young’s modulus | 110 ± 15 GPa |

| Yield strength | 1140 ± 50 MPa |

| Density | 4.41 kg/dm3 |

| Thermal conductivity | 6.6 W/m °C |

| Max. long-term operating temperature | 350 °C |

| Melting point | 1670 °C |

| Relative elongation | 7 ± 3% |

| Min. thickness of layer | 30 μm |

| Min. Thickness of Wall | 0.3–0.4 mm |

| Laser Power (W) | 150 | 155 | 160 | 165 | 170 | 175 | 180 | 185 | 190 | Group |

|---|---|---|---|---|---|---|---|---|---|---|

| Sintered | ┴ | ┴ | ┴ | ┴ | ┴ | ┴ | ┴ | ┴ | ┴ | A |

| ‖ | ‖ | ‖ | ‖ | ‖ | ‖ | ‖ | ‖ | ‖ | C | |

| Sintered-annealed | ┴ | ┴ | ┴ | ┴ | ┴ | ┴ | ┴ | ┴ | ┴ | B |

| ‖ | ‖ | ‖ | ‖ | ‖ | ‖ | ‖ | ‖ | ‖ | D |

| Variable | One-Way ANOVA, Marked Effects are Significant at p < 0.0500 | |||||||

|---|---|---|---|---|---|---|---|---|

| SS Effect | df Effect | MS Effect | SS Error | df Error | MS Error | F | P | |

| A | 12,676.03 | 8 | 1584.504 | 30,090.93 | 261 | 115.2909 | 13.74532 | <0.00005 |

| B | 11,040.63 | 8 | 1380.019 | 29,191.8 | 261 | 111.846 | 12.3391 | <0.00005 |

| C | 11,086.07 | 8 | 1385.758 | 30,735.43 | 261 | 117.7603 | 11.76762 | <0.00005 |

| D | 4952.941 | 8 | 619.1176 | 35,401.00 | 261 | 135.6360 | 4.654552 | 0.000032 |

| A | Tukey HSD Test, Error: MS = 115.29, df = 261 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 150 | 155 | 160 | 165 | 170 | 175 | 180 | 185 | 190 | |

| 150 | - | 0.2878 | 0.5717 | 0.0309 | <0.00005 | 1.0000 | 1.0000 | 0.3665 | 0.0030 |

| 155 | 0.2878 | - | 0.0005 | <0.00005 | <0.00005 | 0.2878 | 0.3896 | 0.0001 | <0.00005 |

| 160 | 0.5717 | 0.0005 | - | 0.9321 | 0.0005 | 0.5717 | 0.4538 | 0.9999 | 0.5802 |

| 165 | 0.0309 | <0.00005 | 0.9321 | - | 0.0576 | 0.0309 | 0.0177 | 0.9862 | 0.9993 |

| 170 | <0.00005 | <0.00005 | 0.0005 | 0.0576 | - | <0.00005 | <0.00005 | 0.0017 | 0.0281 |

| 175 | 1.0000 | 0.2878 | 0.5717 | 0.0309 | <0.00005 | - | 1.0000 | 0.3665 | 0.0030 |

| 180 | 1.0000 | 0.3896 | 0.4538 | 0.0177 | <0.00005 | 1.0000 | - | 0.2681 | 0.0015 |

| 185 | 0.3665 | 0.0001 | 0.9999 | 0.9862 | 0.0017 | 0.3665 | 0.2681 | - | 0.7785 |

| 190 | 0.0030 | <0.00005 | 0.5802 | 0.9993 | 0.0281 | 0.0030 | 0.0015 | 0.7785 | - |

| B | Tukey HSD Test, Error: MS = 115.29, df = 261 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 150 | 155 | 160 | 165 | 170 | 175 | 180 | 185 | 190 | |

| 150 | - | 0.4154 | 0.7101 | 0.7101 | <0.00005 | 0.9014 | 0.1278 | 0.9999 | 0.9647 |

| 155 | 0.4154 | - | 0.9999 | 0.9999 | <0.00005 | 0.9971 | 0.9997 | 0.8553 | 0.9835 |

| 160 | 0.7101 | 0.9999 | - | 1.0000 | <0.00005 | 0.9999 | 0.9859 | 0.9779 | 0.9996 |

| 165 | 0.7101 | 0.9999 | 1.0000 | - | <0.00005 | 0.9999 | 0.9859 | 0.9779 | 0.9996 |

| 170 | <0.00005 | <0.00005 | <0.00005 | <0.00005 | - | <0.00005 | <0.00005 | <0.00005 | <0.00005 |

| 175 | 0.9014 | 0.9971 | 0.9999 | 0.9999 | <0.00005 | - | 0.9102 | 0.9987 | 1.0000 |

| 180 | 0.1278 | 0.9997 | 0.9859 | 0.9859 | <0.00005 | 0.9102 | - | 0.4904 | 0.8057 |

| 185 | 0.9999 | 0.8553 | 0.9779 | 0.9779 | <0.00005 | 0.9987 | 0.4904 | - | 0.9999 |

| 190 | 0.9647 | 0.9835 | 0.9996 | 0.9996 | <0.00005 | 1.0000 | 0.8057 | 0.9999 | - |

| Laser Power (W) | ┴ | ║ | Sintered | Sintered-Annealed |

|---|---|---|---|---|

| A-B | C-D | A (┴)-C (║) | B (┴)-D (║) | |

| 150 | 3.80 × 10−23 | 7.94 × 10−9 | 8.57 × 10−9 | 0.0059 |

| 155 | 6.24 × 10−17 | 0.3900 | 4.14 × 10−12 | 0.0002 |

| 160 | 5.40 × 10−17 | 0.0800 | 2.54 × 10−11 | 0.0002 |

| 165 | 5.83 × 10−24 | 7.04 × 10−5 | 1.10 × 10−8 | 3.13 × 10−7 |

| 170 | 7.31 × 10−27 | 0.0600 | 2.11 × 10−13 | 2.22 × 10−5 |

| 175 | 3.83 × 10−19 | 0.5200 | 2.33 × 10−12 | 8.26 × 10−6 |

| 180 | 2.68 × 10−17 | 0.0019 | 0.0103 | 0.0032 |

| 185 | 1.95 × 10−19 | 2.26 × 10−7 | 3.71 × 10−8 | 0.0028 |

| 190 | 7.01 × 10−21 | 3.17 × 10−8 | 7.84 × 10−6 | 5.10 × 10−9 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guzanová, A.; Ižaríková, G.; Brezinová, J.; Živčák, J.; Draganovská, D.; Hudák, R. Influence of Build Orientation, Heat Treatment, and Laser Power on the Hardness of Ti6Al4V Manufactured Using the DMLS Process. Metals 2017, 7, 318. https://doi.org/10.3390/met7080318

Guzanová A, Ižaríková G, Brezinová J, Živčák J, Draganovská D, Hudák R. Influence of Build Orientation, Heat Treatment, and Laser Power on the Hardness of Ti6Al4V Manufactured Using the DMLS Process. Metals. 2017; 7(8):318. https://doi.org/10.3390/met7080318

Chicago/Turabian StyleGuzanová, Anna, Gabriela Ižaríková, Janette Brezinová, Jozef Živčák, Dagmar Draganovská, and Radovan Hudák. 2017. "Influence of Build Orientation, Heat Treatment, and Laser Power on the Hardness of Ti6Al4V Manufactured Using the DMLS Process" Metals 7, no. 8: 318. https://doi.org/10.3390/met7080318