Study on Hot Deformation Behavior and Microstructure Evolution of Ti55 High-Temperature Titanium Alloy

Abstract

:1. Introduction

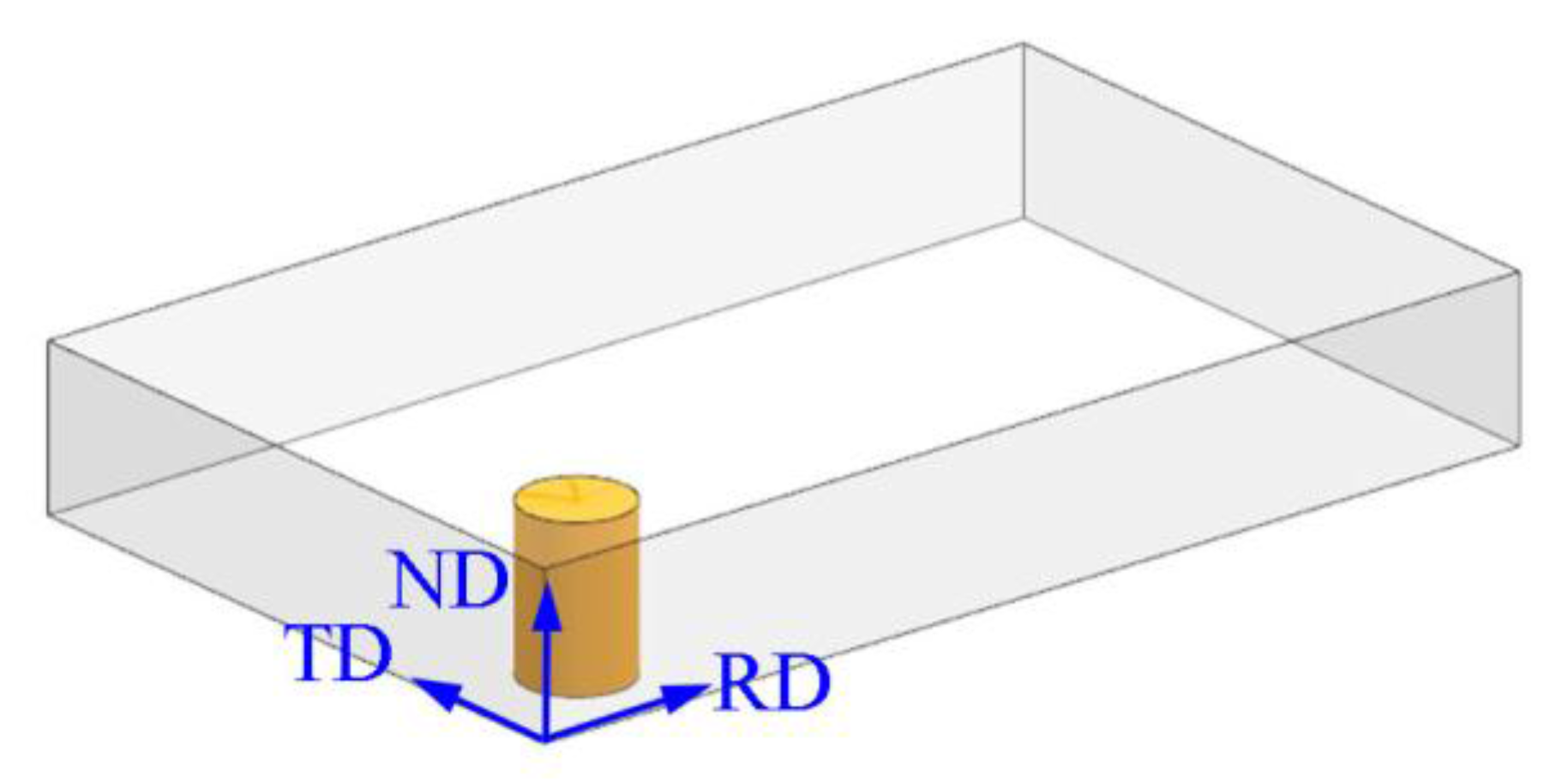

2. Materials and Methods

3. Results

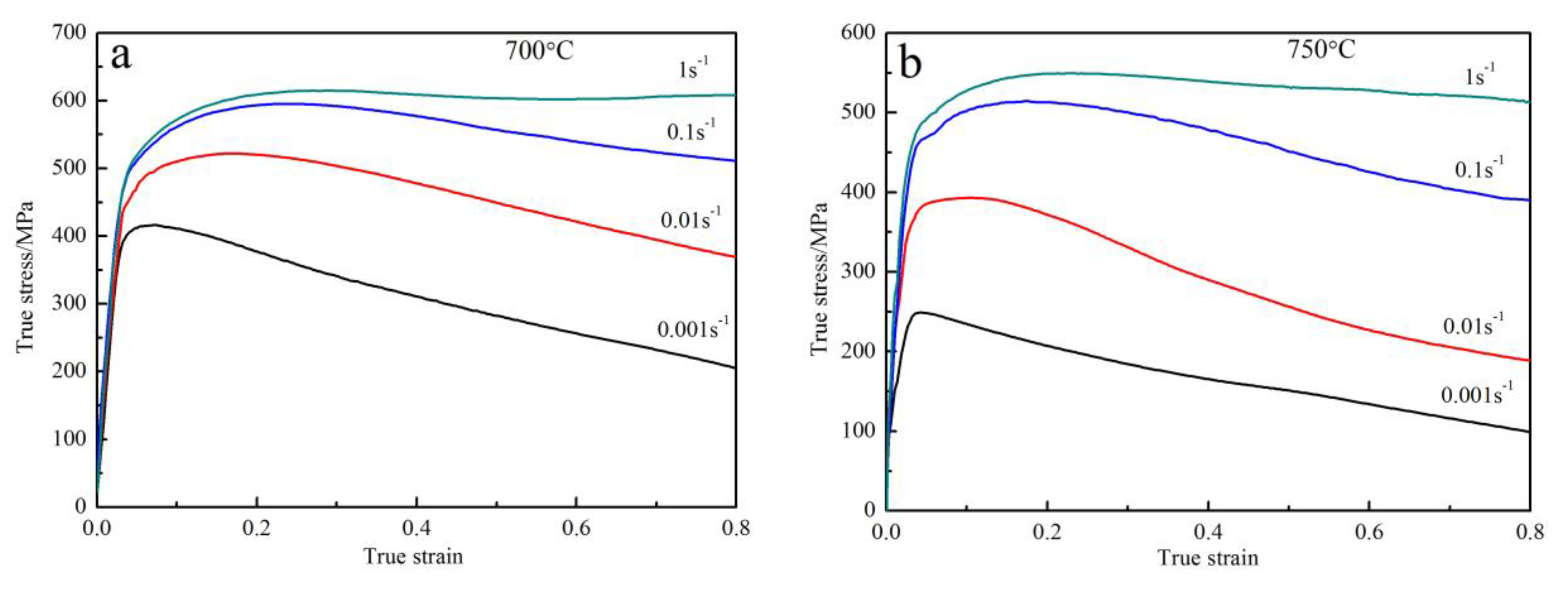

3.1. Flow Stress Behavior

3.1.1. Flow Stress-Strain Curves

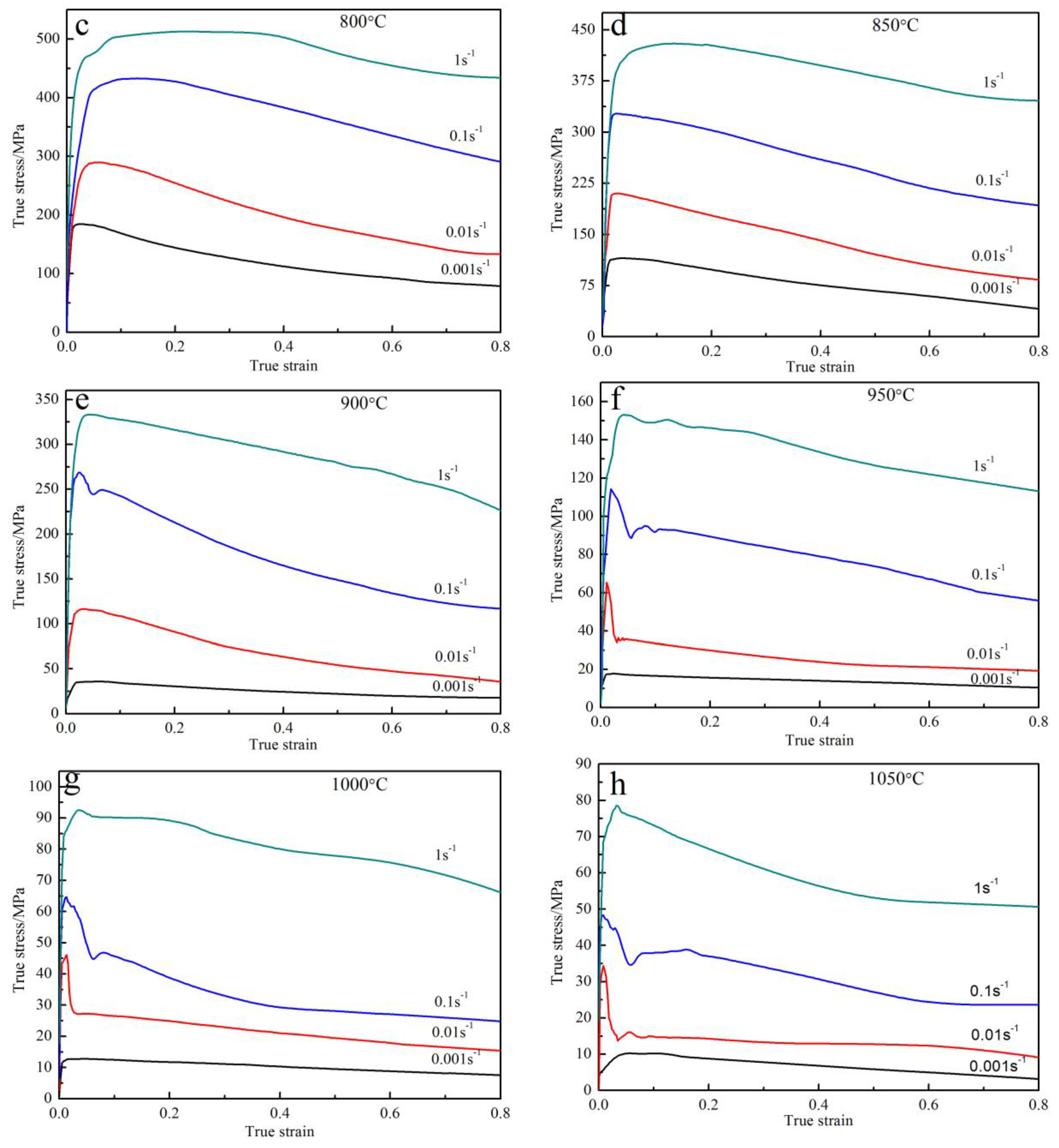

3.1.2. Discontinuous Yielding Behavior

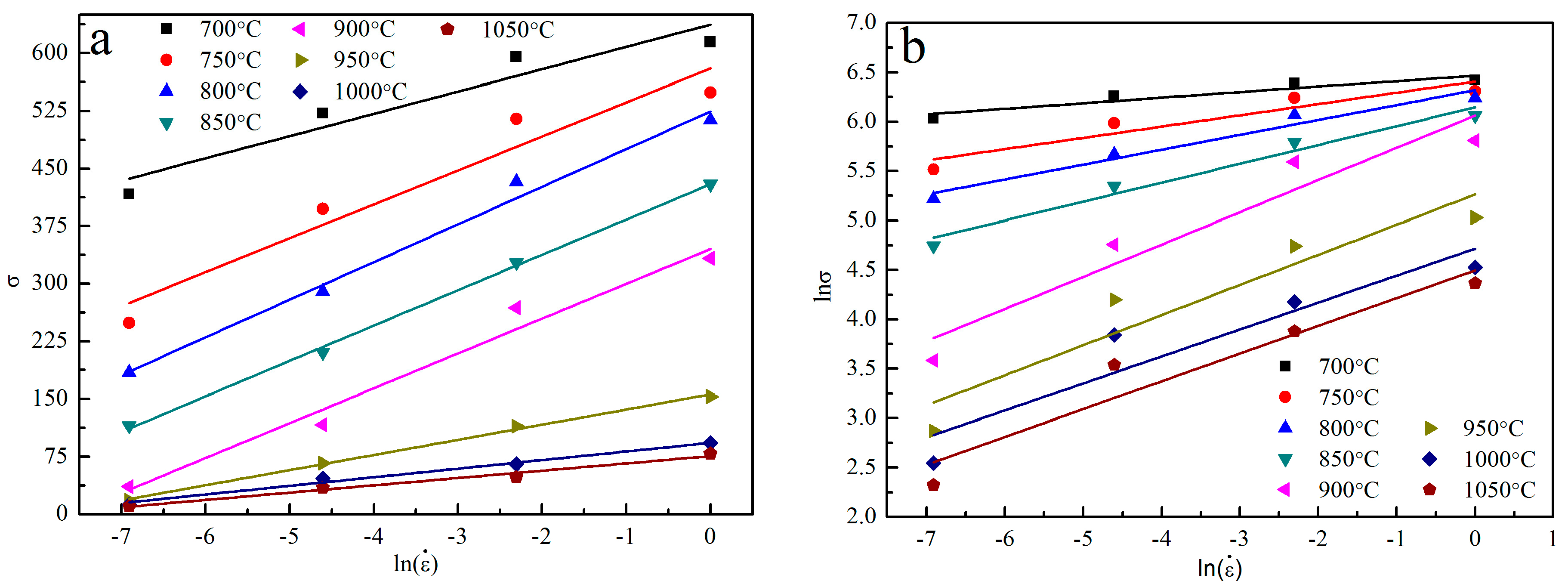

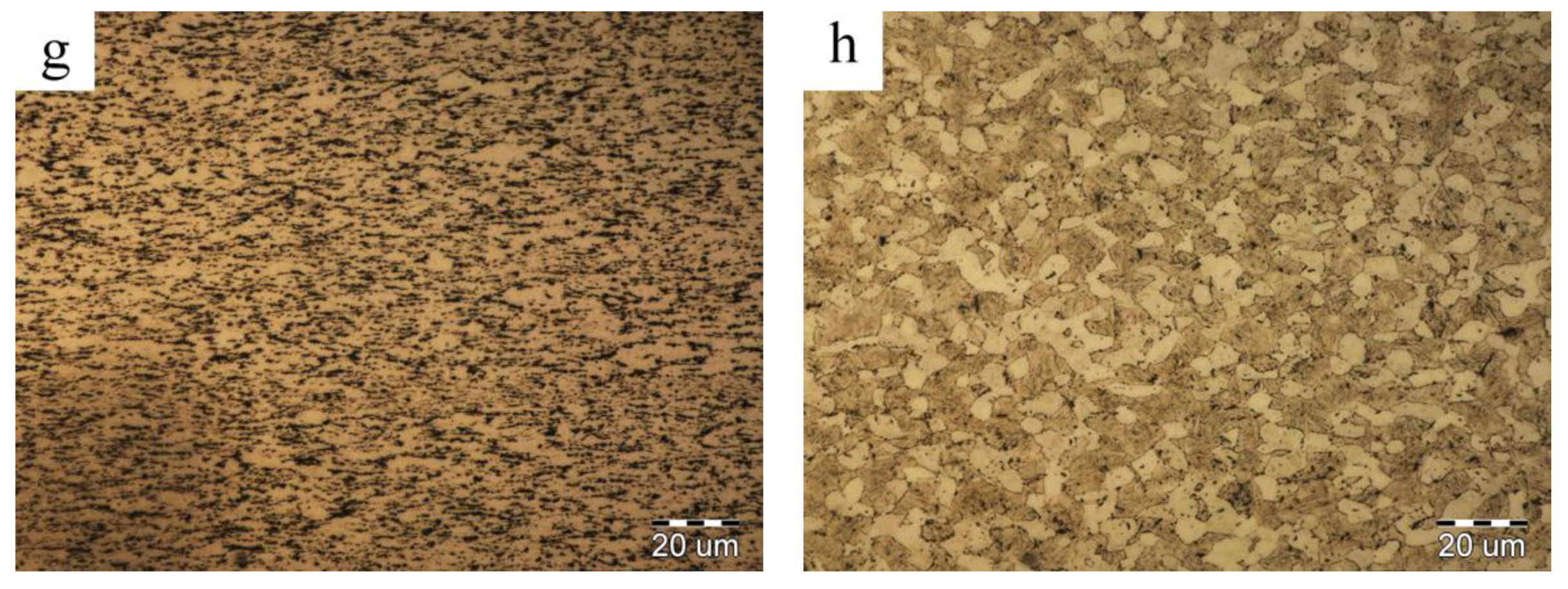

3.2. Kinetic Analysis

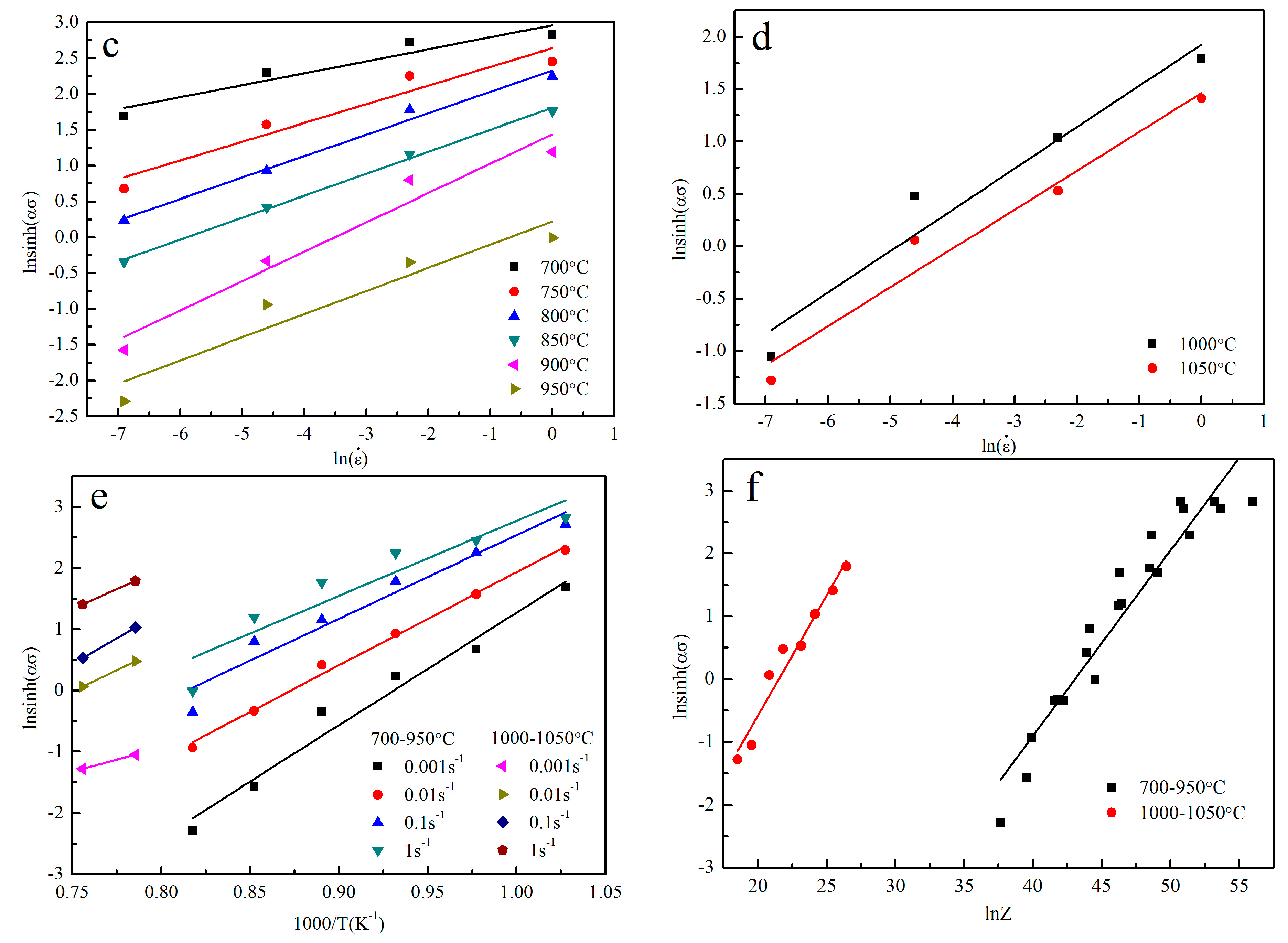

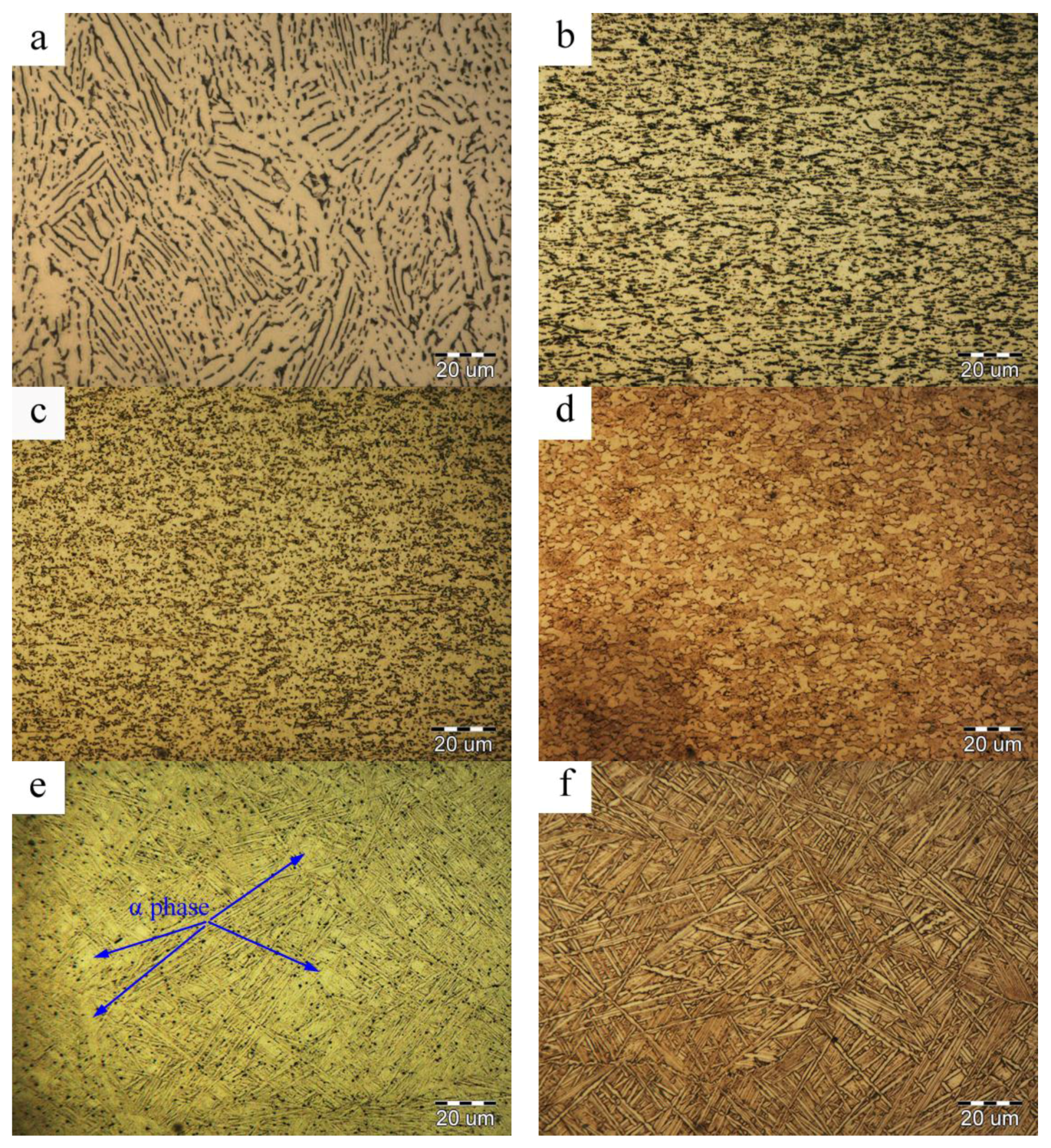

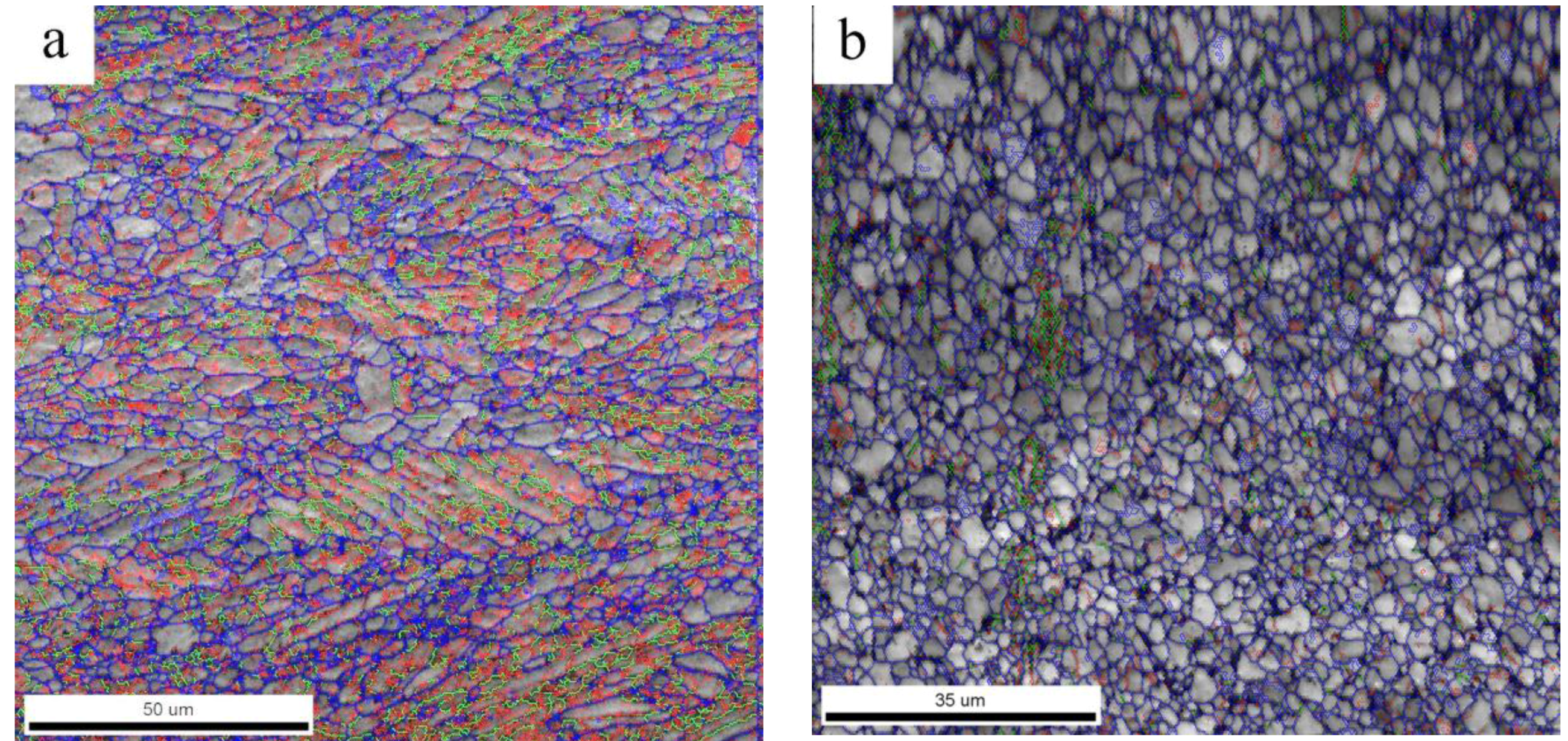

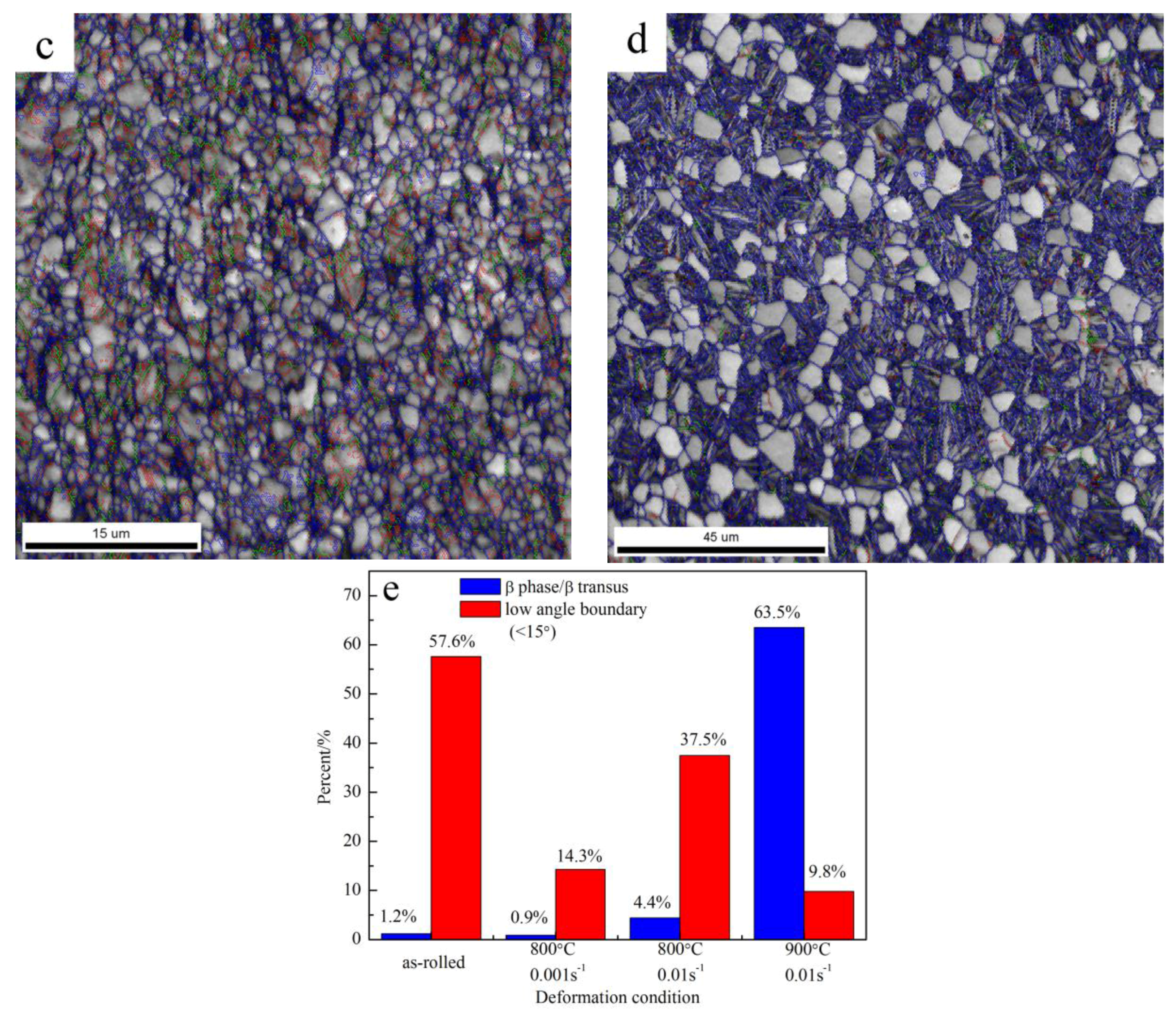

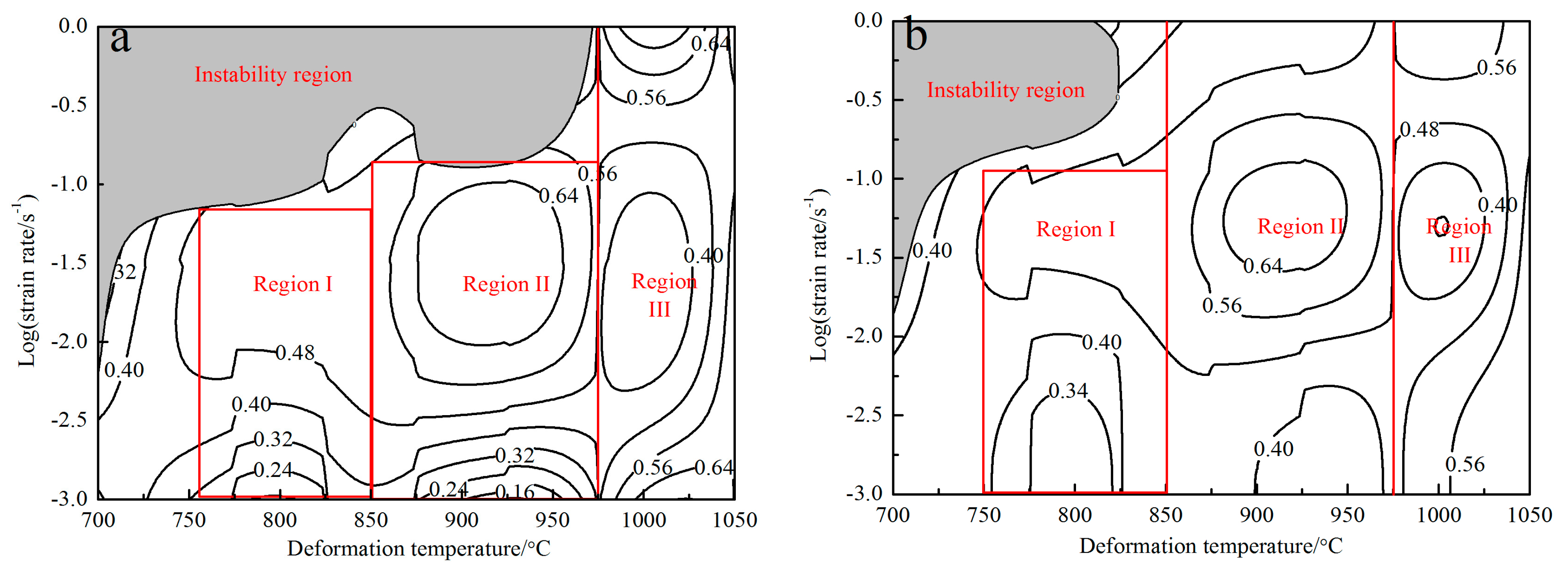

3.3. Microstructure Evolution and Softening Mechanism

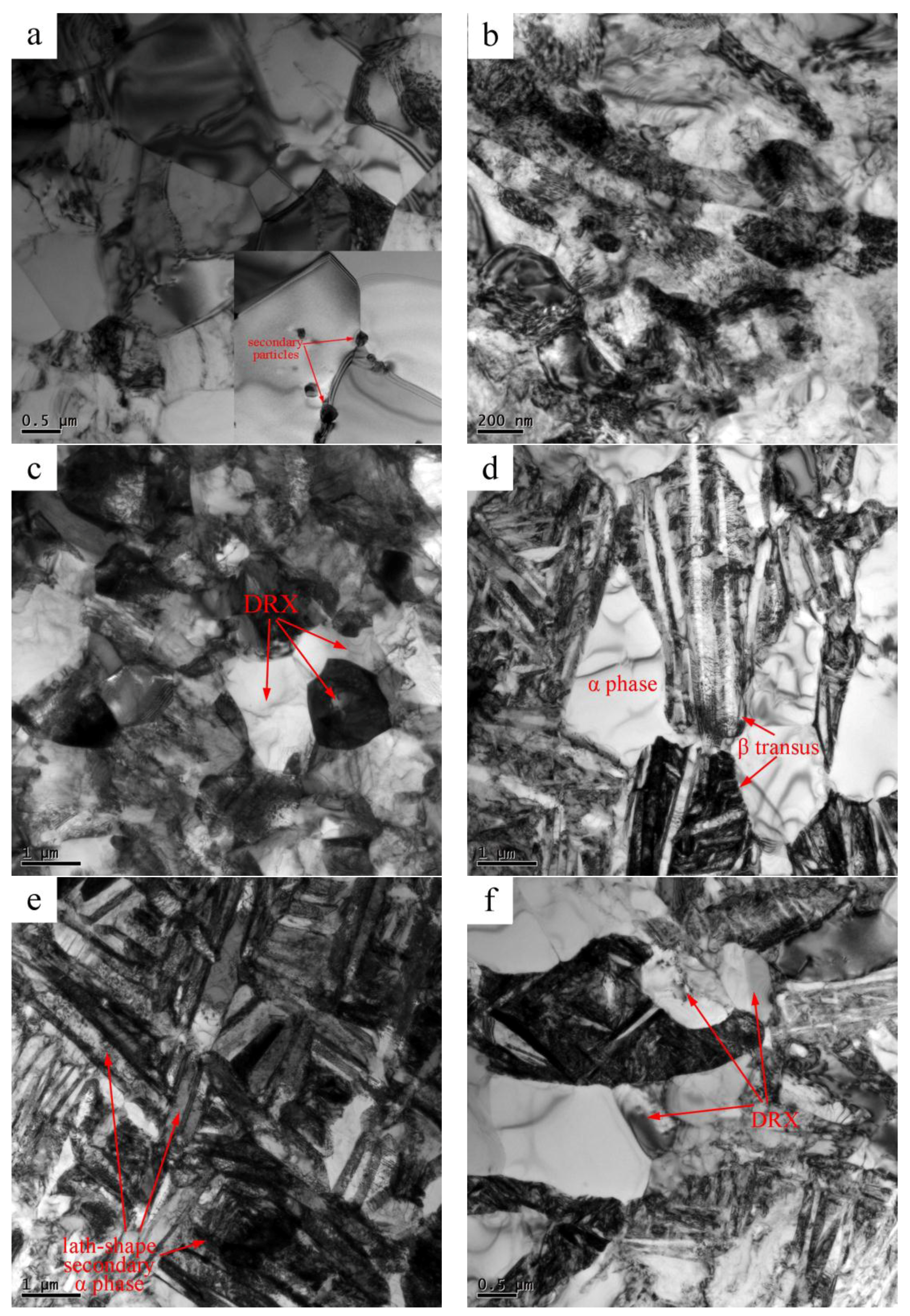

3.4. Processing Map

3.4.1. Processing Map Theory

3.4.2. Instability Region

3.4.3. Stability Region

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Guan, S.X.; Kang, Q.; Wang, Q.J.; Liu, Y.Y.; Li, D. Influence of long-term thermal exposure on the tensile properties of a high-temperature titanium alloy Ti-55. Mater. Sci. Eng. A 1998, 243, 182–185. [Google Scholar] [CrossRef]

- Fang, B.; Chen, Z.Y.; Chen, Z.Q.; Liu, J.H.; Wang, Q.J.; Liu, Y.; Feng, Z.W.; Liu, J.R.; Song, X.Y.; Wei, M.X.; et al. Continuous cooling transformation diagram and microstructure evolution of Ti-55 alloy. Chin. J. Nonferrous Met. 2010, 20, s32–s35. [Google Scholar]

- Li, X.F.; Jiang, J.; Wang, S.; Chen, J.; Wang, Y.Q. Effect of hydrogen on the microstructure and superplasticity of Ti-55 alloy. Int. J. Hydrogen Energy 2017, 42, 6338–6349. [Google Scholar] [CrossRef]

- Wanjara, P.; Jahazi, M.; Monajati, H.; Yue, S.; Immarigeon, J.P. Hot working behavior of near-α alloy IMI834. Mater. Sci. Eng. A 2005, 396, 50–60. [Google Scholar] [CrossRef]

- Wanjara, P.; Jahazi, M.; Monajati, H.; Yue, S. Influence of thermomechanical processing on microstructural evolution in near-α alloy IMI834. Mater. Sci. Eng. A 2006, 416, 300–311. [Google Scholar] [CrossRef]

- Liu, Y.; Baker, T.N. Deformation characteristics of IMI685 titanium alloy under β isothermal forging conditions. Mater. Sci. Eng. A 1995, 197, 125–131. [Google Scholar] [CrossRef]

- Niua, Y.; Houb, H.L.; Li, M.Q.; Li, Z.Q. High temperature deformation behavior of a near alpha Ti600 titanium alloy. Mater. Sci. Eng. A 2008, 492, 24–28. [Google Scholar] [CrossRef]

- Liu, Z.G.; Li, P.J.; Xiong, L.T.; Liu, T.Y.; He, L.J. High-temperature tensile deformation behavior and microstructure evolution of Ti-55 titanium alloy. Mater. Sci. Eng. A 2017, 680, 259–269. [Google Scholar] [CrossRef]

- Seshacharyulu, T.; Medeiros, S.C.; Frazier, W.G.; Prasad, Y.V.R.K. Hot working of commercial Ti-6 Al-4 V with an equiaxed α-β microstructure: Materials modeling considerations. Mater. Sci. Eng. A 2000, 284, 184–194. [Google Scholar] [CrossRef]

- Jia, W.J.; Zeng, W.D.; Zhou, Y.G.; Liu, J.R.; Wang, Q.J. High-temperature deformation behavior of Ti60 titanium alloy. Mater. Sci. Eng. A 2011, 528, 4068–4074. [Google Scholar] [CrossRef]

- Balasubrahmanyam, V.V.; Prasad, Y.V.R.K. Deformation behaviour of beta titanium alloy Ti-10 V-4.5 Fe-1.5 Al in hot upset forging. Mater. Sci. Eng. A 2002, 336, 150–158. [Google Scholar] [CrossRef]

- Philippart, I.; Rack, H.J. High temperature dynamic yielding in metastable Ti-6.8 Mo-4.5 F-1.5 Al. Mater. Sci. Eng. A 1998, 243, 196–200. [Google Scholar] [CrossRef]

- Zhu, Y.C.; Zeng, W.D.; Zhao, Y.Q.; Shu, Y.; Zhang, X.M. Effect of processing parameters on hot deformation behavior and microstructural evolution during hot compression of Ti40 titanium alloy. Mater. Sci. Eng. A 2012, 552, 384–391. [Google Scholar] [CrossRef]

- Li, L.X.; Lou, Y.; Yang, L.B.; Peng, D.S.; Rao, K.P. Flow stress behavior and deformation characteristics of Ti-3 Al-5 V-5 Mo compressed at elevated temperatures. Mater. Des. 2002, 23, 451–457. [Google Scholar] [CrossRef]

- Wang, K.; Li, M.Q. Characterization of discontinuous yielding phenomenon in isothermal compression of TC8 titanium alloy. Trans. Nonferrous Met. Soc. China 2016, 26, 1583–1588. [Google Scholar] [CrossRef]

- Robertson, D.G.; McShane, H.B. Isothermal hot deformation behaviour of (α + β) titanium alloy Ti-4 Al-4 Mo-2 Sn-0.5 Si (IMI 550). Mater. Sci. Technol. 1997, 13, 459–468. [Google Scholar] [CrossRef]

- Fan, J.K.; Kou, H.C.; Lai, M.J.; Tang, B.; Chang, H.; Li, J.S. High Temperature Discontinuous Yielding in a New Near β Titanium Alloy Ti-7333. Rare Metal Mater. Eng. 2014, 43, 0808–0812. [Google Scholar] [CrossRef]

- He, G.A.; Liu, F.; Si, J.Y.; Yang, C.; Jiang, L. Characterization of hot compression behavior of a new HIPed nickel-based P/M superalloy using processing maps. Mater. Des. 2015, 87, 256–265. [Google Scholar] [CrossRef]

- Zener, C.; Hollomon, J.H. Effect of strain rate upon plastic flow of steel. J. Appl. Phys. 1944, 15, 22–32. [Google Scholar] [CrossRef]

- Wang, K.L.; Lu, S.Q.; Fu, M.W.; Li, X.; Dong, X.J. Identification of the optimal (α + β) forging process parameters of Ti-6.5 Al-3.5 Mo-1.5 Zr-0.3 Si based on processing-maps. Mater. Sci. Eng. A 2010, 527, 7279–7285. [Google Scholar] [CrossRef]

- Zhao, H.Z.; Xiao, L.; Ge, P.; Sun, J.; Xi, Z.P. Hot deformation behavior and processing maps of Ti-1300 alloy. Mater. Sci. Eng. A 2014, 604, 111–116. [Google Scholar] [CrossRef]

- Li, M.Q.; Pan, H.S.; Lin, Y.Y.; Luo, J. High temperature deformation behavior of near alpha Ti-5.6 Al-4.8 Sn-2.0 Zr alloy. J. Mater. Process. Tech. 2007, 183, 71–76. [Google Scholar] [CrossRef]

- Seshacharyulu, T.; Medeiros, S.C.; Morgan, J.T.; Mala, J.C.; Frazier, W.G.; Prasad, Y.V.R.K. Hot deformation mechanisms in ELI grade Ti-6 A1–4 V. Scripta Mater. 1999, 41, 283–288. [Google Scholar] [CrossRef]

- Dong, Y.Y.; Zhang, C.S.; Zhao, G.Q.; Guan, Y.J.; Gao, A.J.; Sun, W.C. Constitutive equation and processing maps of an Al-Mg-Si aluminum alloy: Determination and application in simulating extrusion process of complex profiles. Mater. Des. 2016, 92, 983–997. [Google Scholar] [CrossRef]

- He, D.G.; Lin, Y.C.; Chen, M.S.; Chen, J.; Wen, D.X.; Chen, X.M. Effect of pre-treatment on hot deformation behavior and processing map of an aged nickel-based superalloy. J. Alloy Compd. 2015, 649, 1075–1084. [Google Scholar] [CrossRef]

- Zhao, Z.L.; Li, H.; Fu, M.W.; Guo, H.Z.; Yao, Z.K. Effect of the initial microstructure on the deformation behavior of Ti60 titanium alloy at high temperature processing. J. Alloy Compd. 2014, 617, 525–533. [Google Scholar] [CrossRef]

- Xia, X.S.; Chen, Q.; Li, J.P.; Shu, D.Y.; Hu, C.K.; Huang, S.H.; Zhao, Z.D. Characterization of hot deformation behavior of as-extruded Mg-Gd-Y-Zn-Zr alloy. J. Alloy Compd. 2014, 610, 203–211. [Google Scholar] [CrossRef]

- Liu, J.; Cui, Z.S.; Li, C.X. Analysis of metal workability by integration of FEM and 3-D processing maps. J. Mater. Process. Technol. 2008, 205, 497–505. [Google Scholar] [CrossRef]

- Gupta, R.K.; Narayana Murtya, S.V.S.; Panta, B.; Agarwalab, V.; Sinha, P.P. Hot workability of γ+α2 titanium aluminide: Development of processing map and constitutive equations. Mater. Sci. Eng. A 2012, 551, 169–186. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Gegel, H.L.; Doraivelu, S.M.; Malas, J.C.; Morgan, J.T.; Lark, K.A.; Barker, D.R. Modeling of Dynamic Material Behavior in Hot Deformation: Forging of Ti-6242. Metall. Trans. A 1984, 15, 1884–1891. [Google Scholar] [CrossRef]

- Narayana Murty, S.V.S.; Nageswara Rao, B. Instability map for hot working of 6061 Al-10 vol% Al2 O3 metal matrix composite. J. Phys. D 1998, 31, 3306–3311. [Google Scholar] [CrossRef]

- Xia, X.S.; Chen, Q.; Zhang, K.; Zhao, Z.D.; Ma, M.L.; Li, X.G.; Li, Y.J. Hot deformation behavior and processing map of coarse-grained Mg-Gd-Y-Nd-Zr alloy. Mater. Sci. Eng. A 2013, 587, 283–290. [Google Scholar] [CrossRef]

- Kong, F.T.; Cui, N.; Chen, Y.Y.; Wang, X.P.; Xiong, N.N. Characterization of hot deformation behavior of as-forged TiAl alloy. Intermetallics 2014, 55, 66–72. [Google Scholar] [CrossRef]

| Elements | Ti | Al | Sn | Zr | Mo | Ta | Nb | Si |

|---|---|---|---|---|---|---|---|---|

| Weight % | 67.86 | 1.26 | 4.83 | 2.32 | 16.98 | 2.55 | 3.41 | 0.75 |

| Atomic % | 79.39 | 2.61 | 2.28 | 1.42 | 9.91 | 0.79 | 2.05 | 1.50 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, F.; Xu, W.; Jin, X.; Zhong, X.; Wan, X.; Shan, D.; Guo, B. Study on Hot Deformation Behavior and Microstructure Evolution of Ti55 High-Temperature Titanium Alloy. Metals 2017, 7, 319. https://doi.org/10.3390/met7080319

Wu F, Xu W, Jin X, Zhong X, Wan X, Shan D, Guo B. Study on Hot Deformation Behavior and Microstructure Evolution of Ti55 High-Temperature Titanium Alloy. Metals. 2017; 7(8):319. https://doi.org/10.3390/met7080319

Chicago/Turabian StyleWu, Fengyong, Wenchen Xu, Xueze Jin, Xunmao Zhong, Xingjie Wan, Debin Shan, and Bin Guo. 2017. "Study on Hot Deformation Behavior and Microstructure Evolution of Ti55 High-Temperature Titanium Alloy" Metals 7, no. 8: 319. https://doi.org/10.3390/met7080319