2. Materials and Methods

The nominal chemical composition of AISI 316L austenitic stainless steel used in this investigation is C: 0.002, Mo: 2.47, Ni: 10.82, Cr: 17.41 wt. %, and Fe: balance. The low-cycle fatigue (LCF) test was performed in accordance with the procedure defined in the American Society for Testing and Materials (ASTM) standard E606-92 [

20] using a computer-controlled servo-hydraulic testing machine. A plate-type specimen with a gauge length of 15 mm and thickness of 10 mm was used for the LCF test under fully reversed total strain amplitude control in the air. The strain amplitude varied from 0.5% to 1.7%, and the strain rate was 3 × 10

−3/s.

Microstructural analyses were performed on samples prepared by mechanical polishing and vibration polishing followed by chemical etching. The surface microstructure was observed by optical microscopy (OM). To observe the dislocation substructures by transmission electron microscopy (TEM), thin foils were prepared by twin jet polishing in a solution made of 25% of perchloric acid. The magnetic phases such as delta ferrite and strain-induced martensite present in austenitic steel after fatigue damage were measured using a ferrite scope (PMP30). Additionally, a magnetic force microscope (MFM) was used to reconstruct the magnetic structures of the sample surface, including the domain walls (Bloch and Neel), closure domains, recorded magnetic bits, as well as other features.

To monitor the ferromagnetic α′-martensite transformation during fatigue deformation, the magnetic parameters were determined for all fatigue-failed specimens. The magnetic parameters, comprised of coercivity, remanence, and saturation magnetization, were determined from the magnetic hysteresis curve obtained with a vibrating sample magnetometer (VSM).

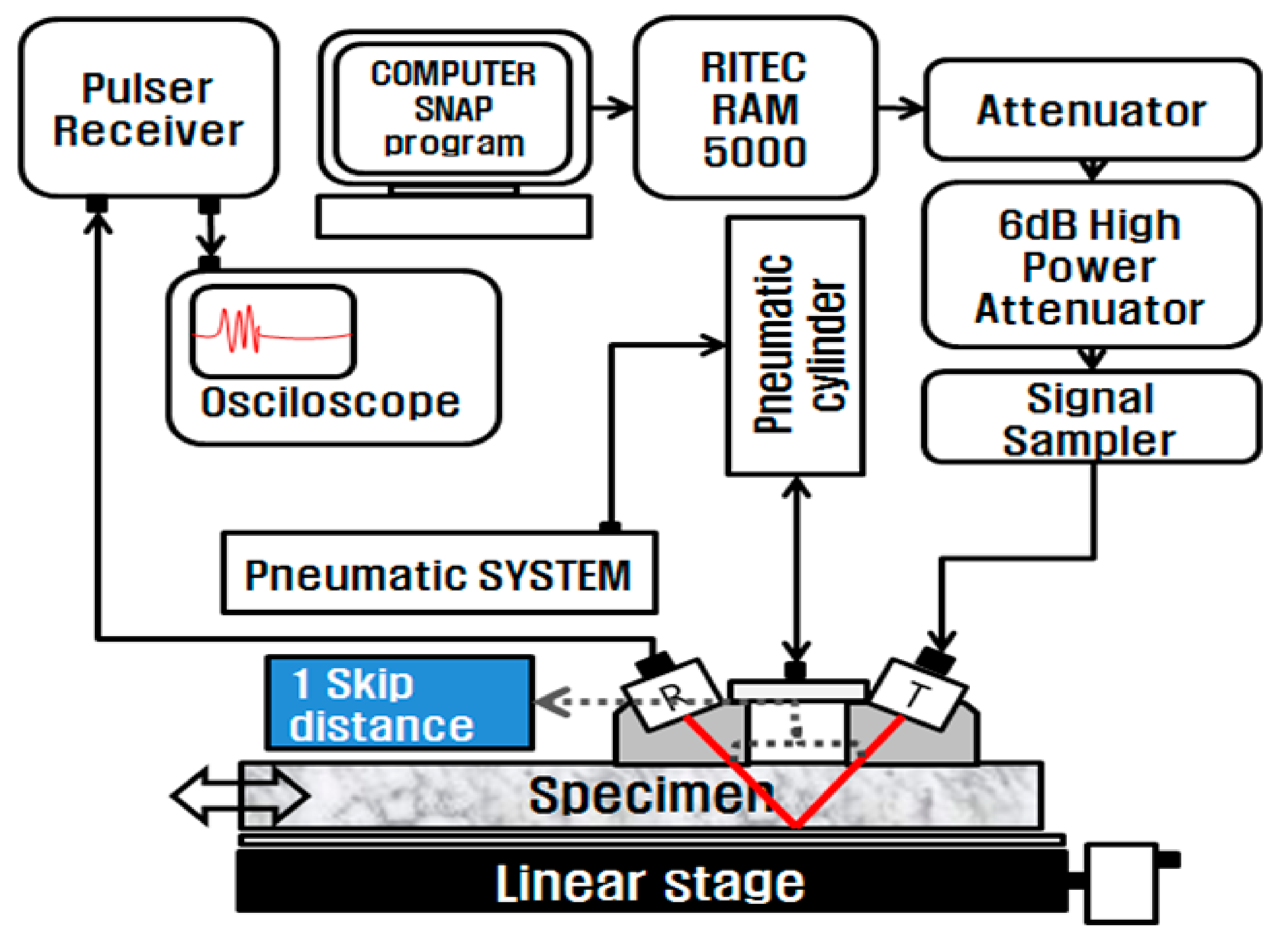

To avoid any inherent harmonic distortion from the transducer, the transmitting piezoelectric transducer must be driven at a low voltage. However, the input voltage for the transmitter must not be too low when attempting to observe the high-order harmonics. A high-power gate amplifier (Ritec, RAM5000 SNAP) was therefore used to provide high-power tone-burst signals to the transmitter. A schematic diagram of the experimental setup used to measure the acoustic nonlinearity of an oblique incidence measurement technique is shown in

Figure 1. The oblique incidence technique has a practical utility for the structural facilities of mechanical plants due to how easily accessible the structure surfaces under investigation are [

21]. The amplified high-voltage signal passes through a 6-dB attenuator (RA-31) to decrease the driving voltage to less than 60 Vpp and 50 Ω termination, which impedes a transient electric current from the mismatch of electrical impedance between the amplifier and the piezoelectric transducer. In the oblique incidence measurement technique, the transmitting transducer and the receiving transducer are placed on the same side of the specimen. The transmitting and receiving transducers were attached via a 45-degree refractive angle wedge. Additionally, one skip distance was measured as 22 mm.

The received signal was digitally processed using fast Fourier transform (FFT) power spectral analysis to obtain the amplitudes of the fundamental and second-order harmonic frequencies.

If we assume that the attenuation can be neglected, then the motion equation for a longitudinal wave in a solid, using the generalization of Newton’s law, may be written as [

22,

23]:

where

t is time,

is the mass density of the solid,

ui and

Xi are the components of the displacement and the position vectors, and

is the stress tensor.

If we consider the one-dimensional wave propagation of a pure longitudinal wave in an isotropic solid material, we obtain [

14]:

where

is the longitudinal wave velocity, and

is the nonlinearity parameter.

An approximate solution of Equation (2) is

, where

at the boundary condition and

; the solution

can then be obtained via an iterative process [

14]:

where

is the particle displacement amplitude of the fundamental wave. For the second harmonic wave,

is

,

k is the propagation constant 2π/

λ with

λ defined as the wavelength, and

ω = 2π

f with

f defined as the frequency. Equation (3) indicates that the ultrasonic nonlinearity parameter may be obtained from measurements of the absolute amplitudes of the fundamental acoustic wave and second harmonic wave. Therefore, nonlinearity parameter

is determined as follows:

The amplitude of the fundamental wave (A1) and second harmonic wave (A2) can be measured from the fast Fourier transform (FFT) of the signal fed to the oscilloscope channel; the nonlinear ultrasonic parameter (β) is then measured using the proportional relationship, β ∝ A2/A12, which is the relative nonlinear parameter value.

3. Results and Discussion

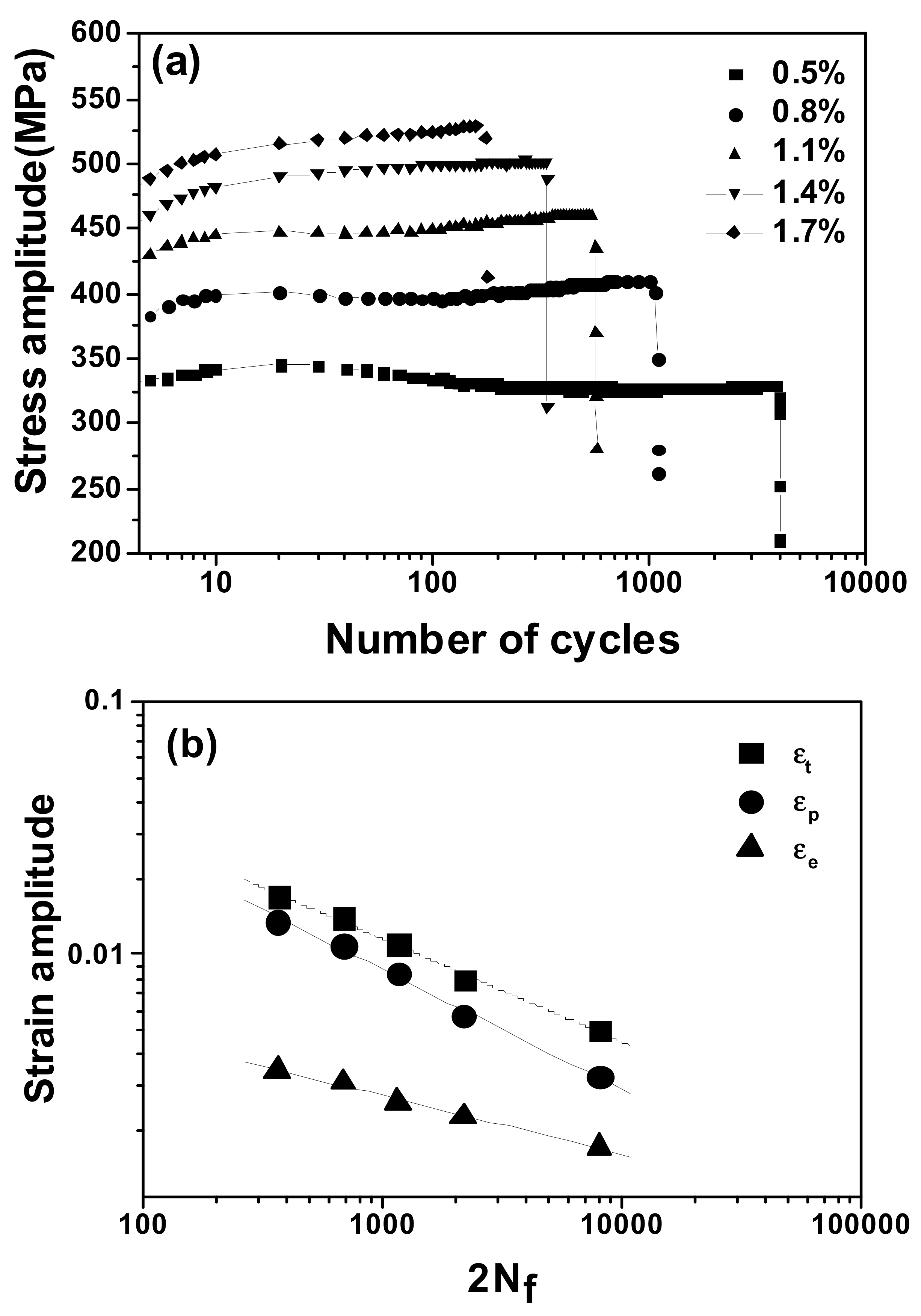

Figure 2 shows the low-cycle fatigue properties of austenitic AISI 316L stainless steels. Cyclic stress response curves showing the relationship between the stress amplitude and the number of cycles at five different total strain amplitudes are shown in

Figure 1a. The number of fatigue cycles to failure decreased with an increasing strain amplitude. This allowed an examination of the variation in the maximum load with the number of cycles, which could indicate whether the material cyclically hardened, softened, or was stable.

Cyclic hardening was observed in the initial cycles within several tens of cycles; this was followed by slight second hardening at strain amplitudes ranging from 0.8% to 1.1%, and slight softening following the initial hardening was observed at a strain amplitude of 0.5%. At strain amplitudes greater than 1.1%, the material exhibited strain hardening without reaching its saturated value until the final fracture. The initial hardening and subsequent second hardening are believed to result, respectively, from the increased dislocation density and from the α′-martensite transformation. The specimens were subjected to fully reversed cyclic loading under strain control. The number of stress reversals to failure was monitored and derived from the resulting strain-life plot, shown in

Figure 2. The constants in the Manson-Coffin equation were derived by performing linear regression on the elastic and plastic lines. To determine the Basquin and Coffin-Manson parameters, the number of fatigue cycles to failure (

Nf) is presented as a function of the total plastic and elastic strain amplitudes [

24]. The Basquin and Coffin-Manson parameters are summarized in

Table 1. These Coffin-Manson parameters are consistent with previous reports [

25].

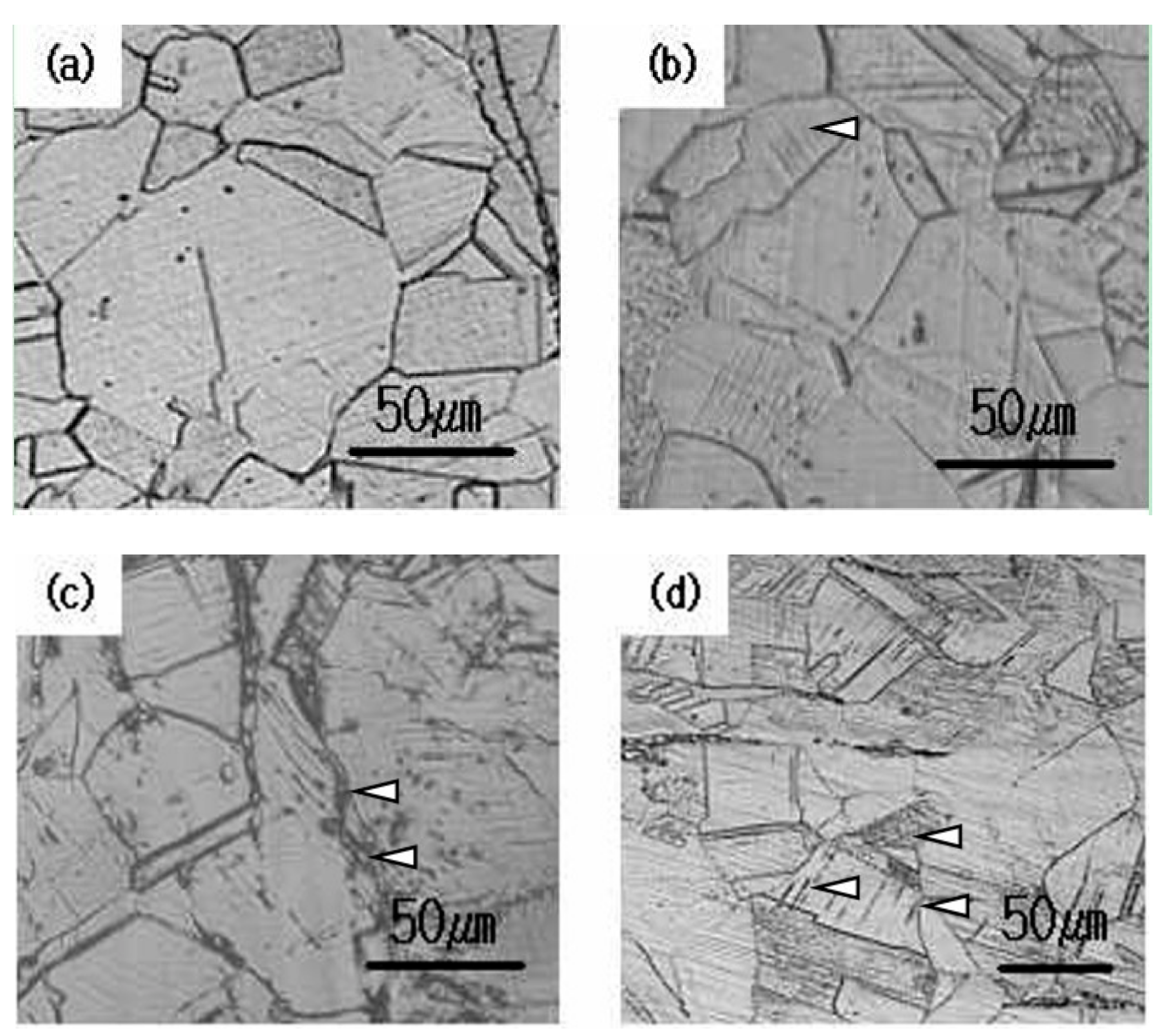

The optical microstructures of the AISI 316L stainless steel after fatigue failure under various strain amplitudes are shown in

Figure 3, and they are compared with the microstructrue of the as-received specimen. The as-received specimen consisted of a single austenite phase, whereas the austenite and α′ martensite phases were observed in all fatigue-failed specimens; the α′-martensite phase is denoted by arrows near the grain boundaries. The α′-martensite phases observed in the fatigue-failed AISI 316L stainless steel were induced by fatigue strain. The amount of α′-martensite increases with increasing strain amplitude in these optical micrographs and develops near grain boundaries and near the inter-regions of slips.

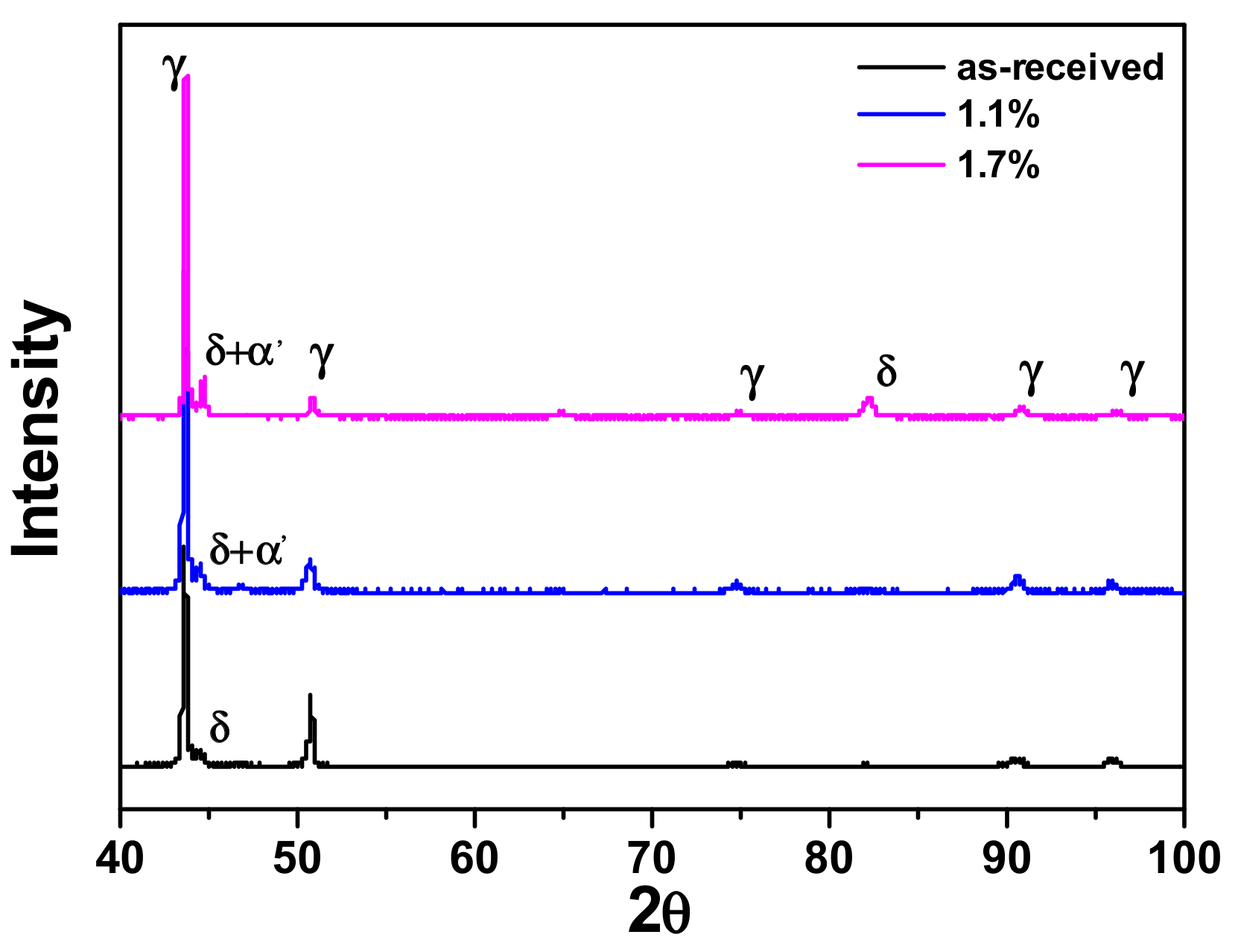

Figure 4 shows transmission electron micrographs of the dislocation substructure both in the as-received specimen and after fatigue failure at a strain amplitude of 1.7%. The typical dislocation cell microstructure was well-developed. The initial cyclic hardening was attributed to the increased dislocation density, and the subsequent softening was ascribed to the formation of dislocation cells resulting from fatigue. To investigate the transportation of the martensite phase in the AISI 316 steel specimen, we conducted X-ray diffraction (XRD) tests. The XRD profiles of the fatigue-failed specimens under various strain amplitudes are shown in

Figure 5. The diffraction peak of 2θ = 44.5 is identified in the as-received sample as delta ferrite. The intensity of this peak increased with a higher strain amplitude, as indexed with δ + α′. This increase in XRD intensity was caused by the strain-induced formation of martensite (α′). Additionally, the intensity of the α′-martensite diffraction peaks increased along with the strain amplitude.

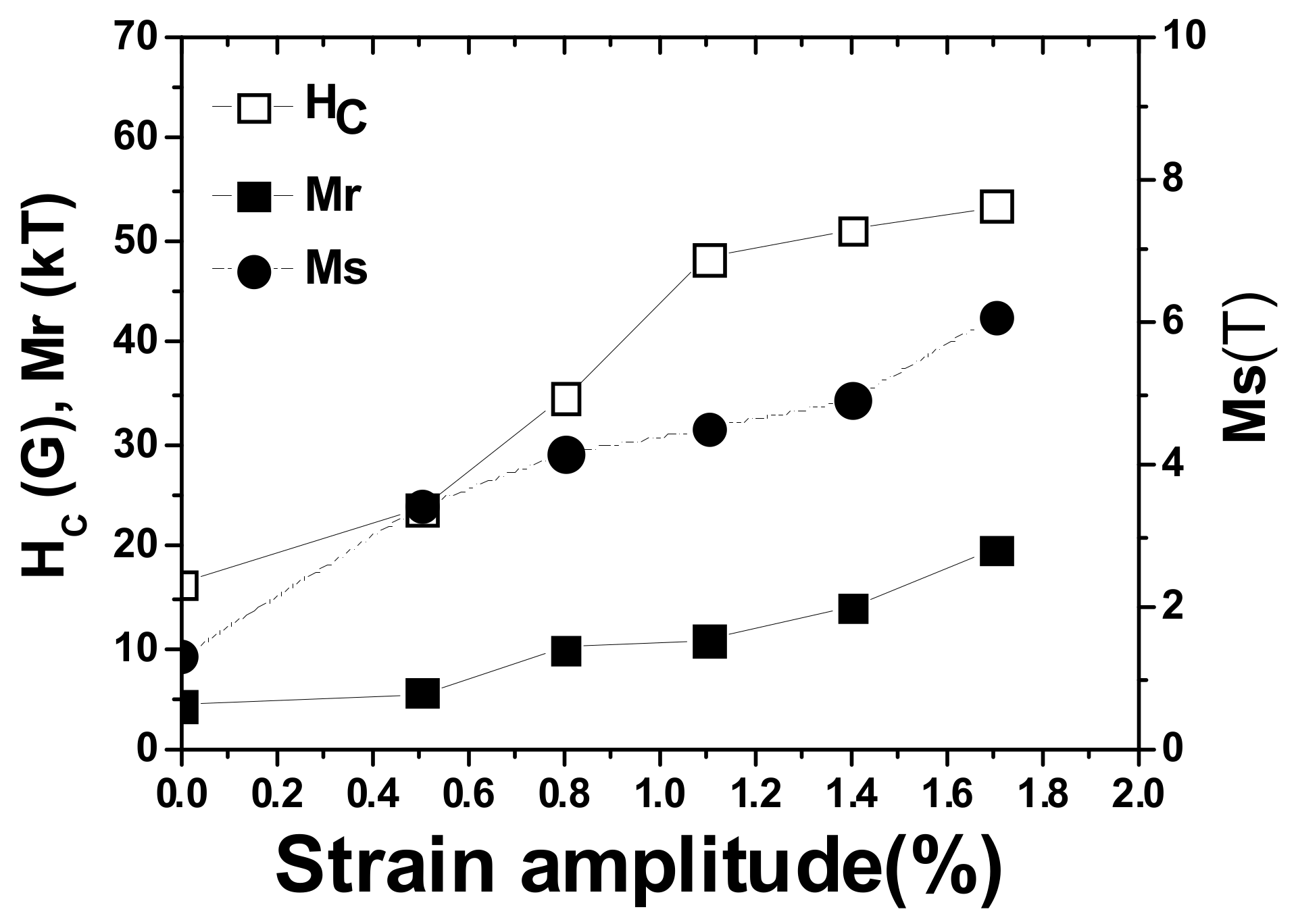

Figure 6 shows the changes in the magnetic properties of the fatigue-failed specimens as a function of the total strain amplitude. The magnetic coercivity, the saturation magnetization, and the remanence increased with an increasing strain amplitude. The monotonic increase of the magnetic parameters with the strain amplitude could be closely related to the presence of magnetic particles in austenitic AISI 316L stainless steels. However, as mentioned earlier, the austenite matrix is a non-ferromagnetic phase. Consequently, there must be another reason for the increase in the material’s magnetic parameters.

The strain-induced martensite could have a reasonable influence on the magnetic properties of the specimen. The slip and twin boundaries could present an obstacle to the movement of the magnetic domain, resulting in an increase in the magnetic parameters [

26]. In addition, dislocations may have a primary effect on the domain wall movement, and this would be another reasonable cause for variation in magnetic parameters. Principally, the strain-induced martensite had a reasonable influence on the increase of the material’s magnetic properties because of its ferromagnetic property. The austenite phase is non-ferromagnetic, whereas α′-martensite is ferromagnetic. The magnetic parameters of the fatigued specimens consisting of austenite and α′-martensite can be correlated with the level of the strain-induced α′-martensite present in the specimens. The volume fraction of

α′-martensite (V

α′) was calculated using Equation (5) [

27]:

In Equation (5), (σs)f = 1 is the specifically saturated magnetization for a purely martensitic state (i.e., f = 1), 143 emu/g, and (σs) is that of the fatigued specimen.

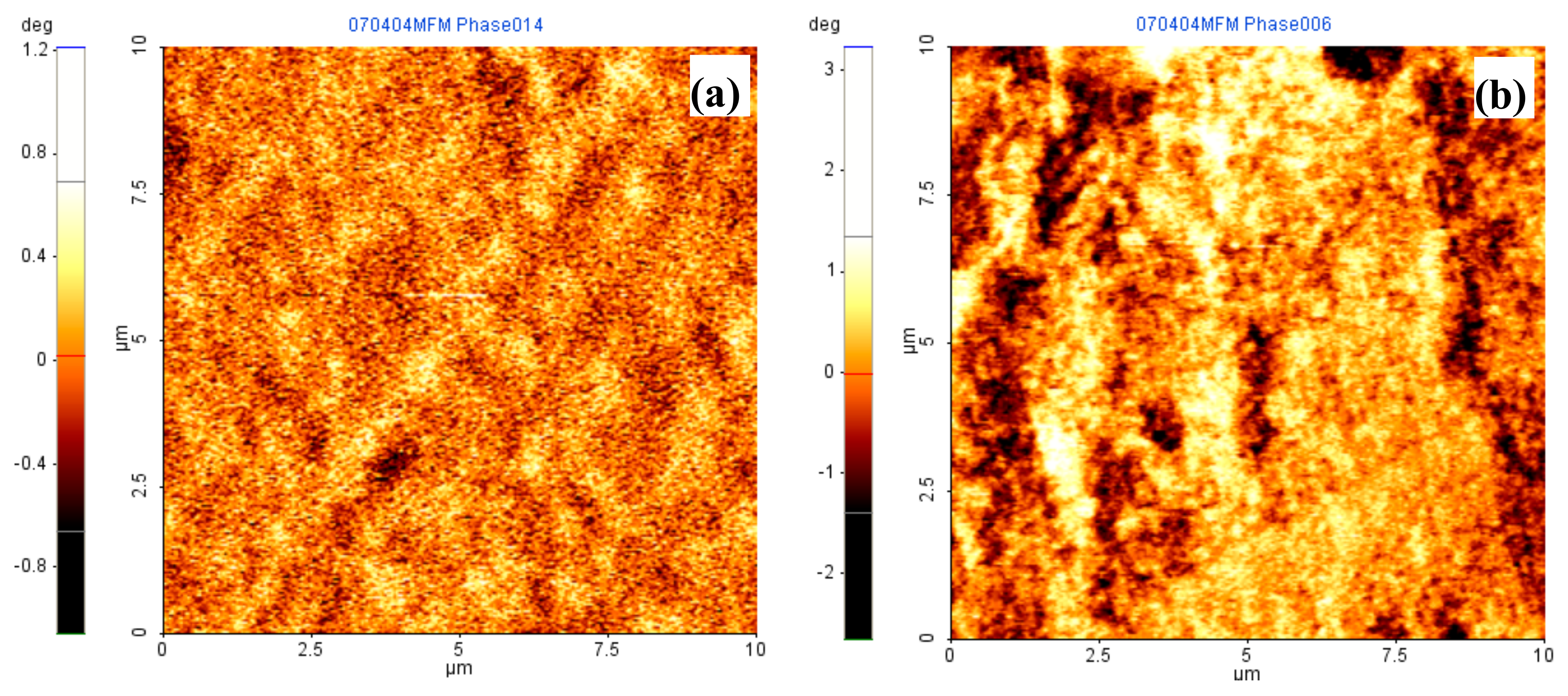

Figure 7 shows the volume fraction of α′-martensite as a function of the strain amplitude. It shows that there is a monotonic increase in the volume fraction of α′-martensite in austenitic AISI 316L stainless steel consistent with an increase in the strain amplitude. Both the ferrite scope and value stream mapping (VSM) technologies are based on variations in the magnetic properties of test materials. According to this study, delta ferrite could be a primary microstructure before fatigue deformation, with magnetic characteristics. Additionally, after fatigue deformation, the α′-martensite must represent an important phase of the magnetic property exhibited by austenitic AISI 316L stainless steel. The fact that the volume fraction of the strain-induced martensite increases with an increased strain amplitude is a very reasonable result of the plastic deformation. The MFM image was generated by measuring the amplitude or phase change of the cantilever’s oscillations, produced by the magnetic force between the structure’s surface and the magnetized cantilever. MFM images contain information on magnetic domain distributions of a sample surface.

Figure 8 shows MFM images of both the domain structures in the as-received specimens and of the specimens after subjection to a 1.7% strain amplitude. While the as-received specimen reveals no distinct domain structure, the specimen subjected to a 1.7% strain amplitude exhibits a clear domain structure caused by the strain-induced martensite formation resulting from fatigue deformation.

In general, magnetic force microscopy was developed as a scanning probe technique for mapping magnetic field distributions in test materials on a microscopic scale. The color-contrast MFM images in

Figure 8 show distinct, dark and bright stripes, indicating the presence of a magnetic domain structure. Because the MFM tip is magnetized downward, the bright stripe domains are magnetized in an upward direction, whereas the dark domains are magnetized in a downward direction [

28].

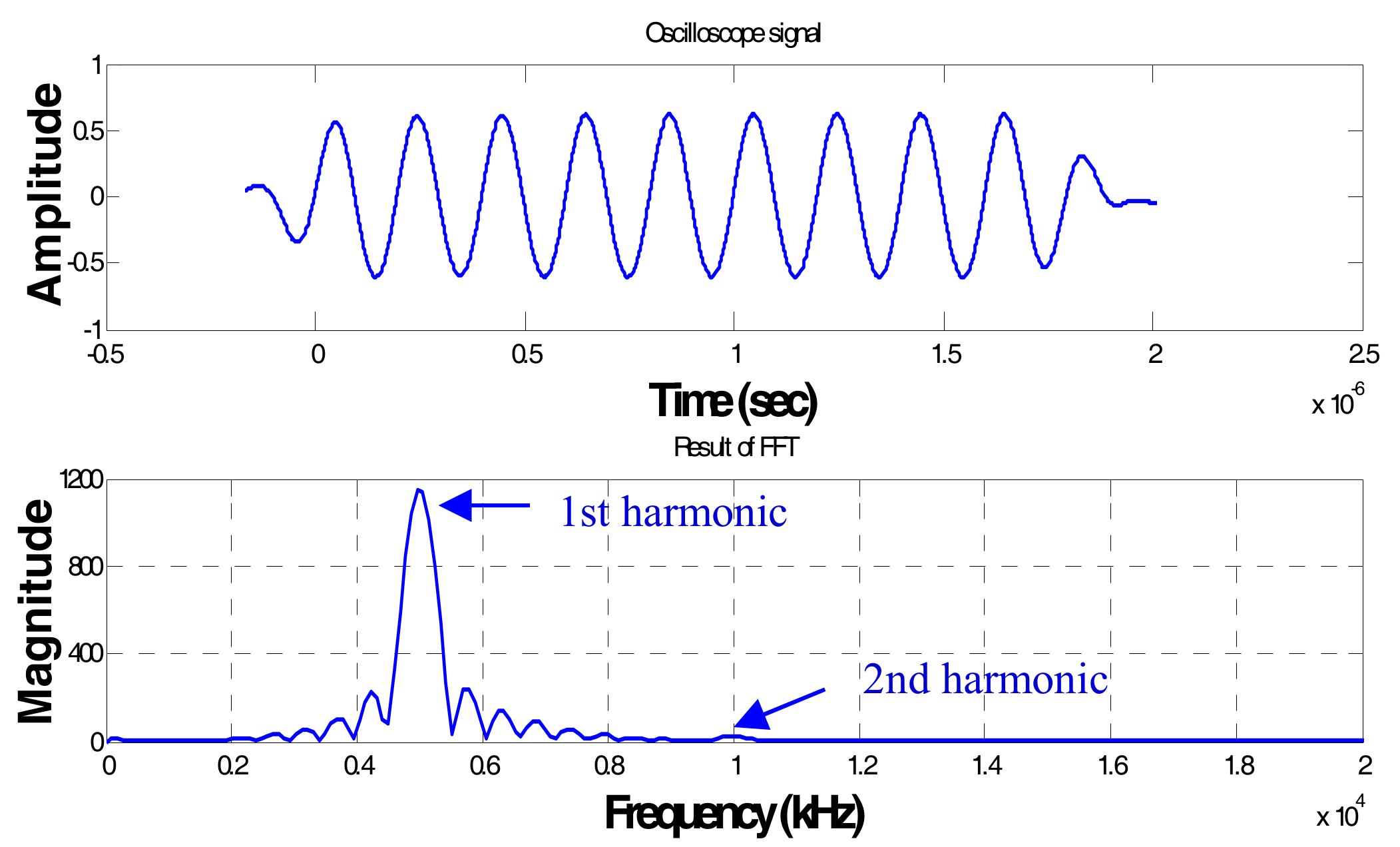

Figure 9 shows the acoustic signal and the spectrum of the ultrasonic wave. In this test, a narrow-band 5-MHz transducer was used as a transmitter, and a wide-band 10-MHz transducer was used as a receiver. Because a narrow band signal is advantageous for effectively detecting higher harmonic amplitudes, a 5-MHz toneburst signal with a Hanning window was used to transmit the waveform. The length of the burst was 10 cycles, ensuring that both the fundamental frequency, as well as its double frequency for the second-order harmonic wave, were detected well.

The second-order harmonic amplitude depends on the fundamental frequency amplitude, as shown by Equation (4). Based on the theoretical background, the second-order harmonic amplitude is linearly proportional to the square of the fundamental amplitude, as shown in Equation (1). This means that when the wave number and propagation distance are fixed, the parameter

β′ is constant regardless of the variation in the fundamental frequency amplitude.

Figure 10 shows the relationship between

A12 and

A2 when the input signal amplitude is increased. The slope of the relationship between

A1 and

A2 is the nonlinearity parameter of the ultrasonic wave.

The measurement was made ten times under the same conditions. The results show a linearly proportional relationship and consistency with the above theoretical expectation.

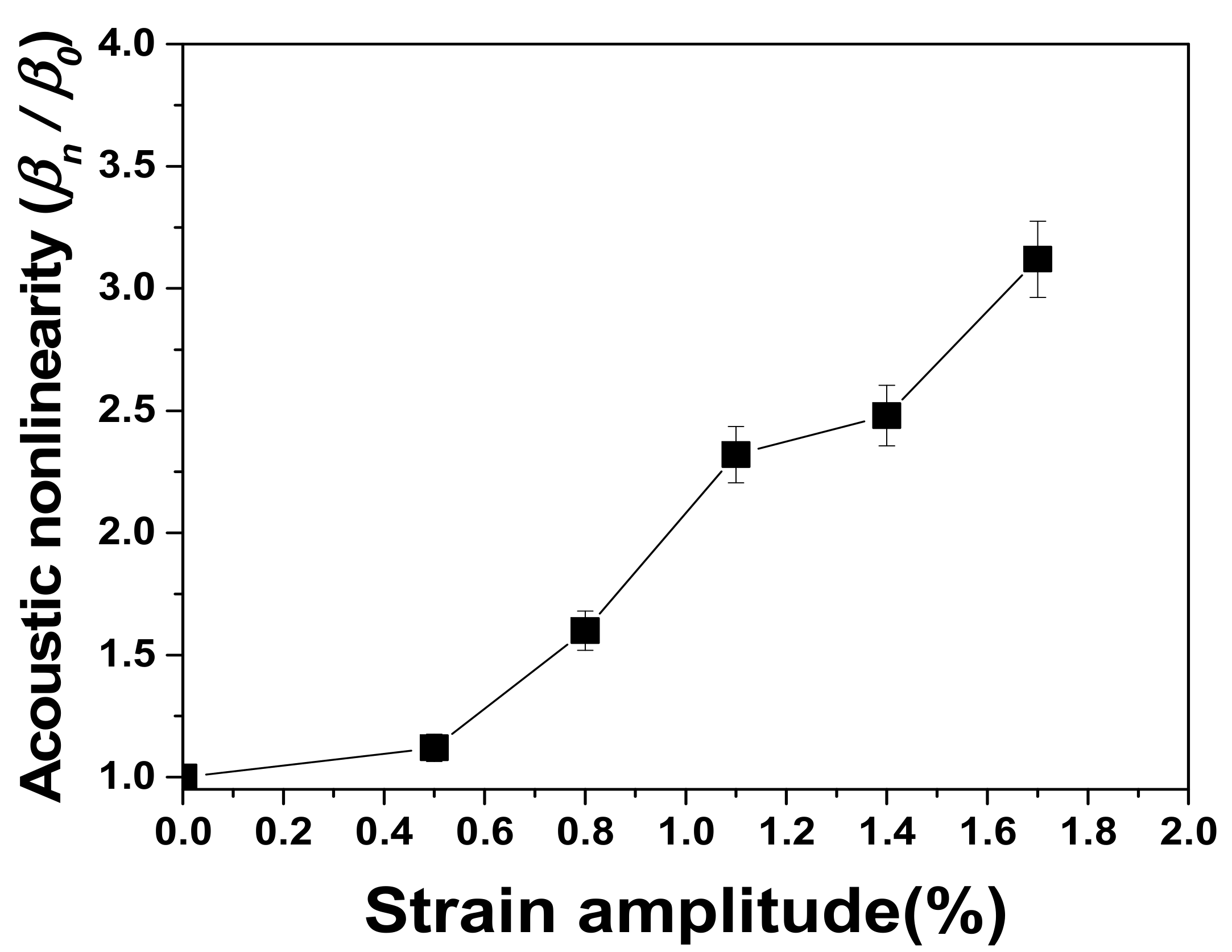

Figure 11 depicts the variation in the acoustic nonlinearity of AISI 316L stainless steel fatigue-failed specimens under various strain amplitudes. The acoustic nonlinearity increased with strain amplitude due to the occurrence of fatigue-driven plastic deformation, and is therefore closely related to the strain amplitude and to the accumulation of fatigue deformation [

29]. To understand the microstructural features that influence the distortion of the acoustic wave and result in superharmonic generation, we refer to the previously shown and discussed microstructural evolution during fatigue damage.

Many authors have discussed and explained that dislocations that occur during fatigue play an important role in generating ultrasonic wave super-harmonics. Suzuki et al. [

10] explains that the acoustic nonlinearity parameter is related to the dislocation loop length (

L), the dislocation density (Δ), and the stress (

σ), by using the following equation [

30]:

Equation (6) shows that

β is linearly dependent on the stress and the dislocation density. Here, we considered the effects of both parameter strain and microstructural changes during fatigue when discussing the variation of the acoustic nonlinearity parameter in relation to the strain amplitude.

Figure 4 shows that the TEM microstructure exhibited increased dislocation densities, while we also observed clear dislocation cell structures. The cell interior was dislocation-free and corresponded to fatigue strain softening. Martensite, located in steel crystal areas, is a distorted body-centered cubic (BCC) ferrite lattice that still contains dissolved carbon and is full of defects. There is far more atomically dissolved carbon in the martensite than would be acceptable for stable ferrite, and this dissolved carbon distorts the lattice. This lattice distortion could be the primary reason for the wave distortion that occurs when the ultrasonic wave propagates through the test materials. From this wave distortion, super-harmonics may be generated due to the nucleation of strain-induced martensite, which strongly depends on the strain amplitude.

The dependence of the magnetic coercivity and the acoustic nonlinearity on the volume fraction of α′-martensite shows a good linear relationship with a high R-squared value, as shown in

Figure 12. We note that, because of the NDE technique’s availability, the coercivity and the acoustic nonlinearity parameter could be successfully used to characterize α′-martensite during the fatigue deformation of austenitic stainless steel. Consequently, both the coercivity parameter and the acoustic nonlinearity parameter offer a potential approach for evaluating the fatigue-mediated damage of austenitic AISI 316L stainless steel.