Due to properties such as good mechanical strength, interesting fatigue resistance, adequate wear resistance, excellent machinability, low cost, good fluidity and castability, ductile cast irons (DCIs), also known as spheroidal graphite irons (SGIs), are widely used in several applications, such as machine tool beds, heavy-duty engine blocks, crankshafts, camshafts, pistons, cylinders, heavy section wind turbine components, railway brake disks, wheels, pipes, valves, pumps and gears, among others [

1,

2]. Moreover, DCIs and other cast irons, as well as castable special steels, allow us to obtain complex shapes through a single manufacturing operation: the casting process. Nevertheless, in this set of materials, DCIs present lower specific weights, enabling the casting of thinner-walled parts, while maintaining very attractive mechanical properties, namely the ductility and the fracture toughness, whose properties are significantly better than those presented by gray cast irons or white cast irons, in general. Indeed, it can be stated as well that DCIs present the highest mechanical strength and the best ductility among cast irons, combining the main advantages of gray cast irons (such as excellent machinability), with the properties of common steels (e.g., high mechanical strength, toughness, hardenability, ductility and hot workability) [

3,

4]. Further information regarding the mechanical properties of DCIs, as well as cast irons in general, can be found in [

5,

6]. The mechanical properties of DCIs arise from their microstructure (which is dependent on chemical composition), graphite nodule size, type of inoculation method that was carried out and balance between ferrite and the other phases in the matrix, among others [

7,

8]. In fact, DCIs are produced by inoculating the molten metal immediately before casting, through the addition of a small amount of Mg or Ce [

9], giving rise to the nodularization of the graphite previously dispersed in the matrix. Moreover, it can be stated as well that DCIs’ properties also depend on the process parameters used during their production [

10]. Usually, DCIs have carbon contents between 3.0% and 4.0%, also including Si, in the range of 1.8 to 2.8%, and Mn, between 0.1% and 1.0%, and small amounts of P and S [

6,

9]. These elements are responsible for some of the problems encountered during production and processing of DCIs, as they affect the material’s mechanical properties by promoting the appearance of harmful structures, such as carbides, chunky graphite, graphite flotation, irregular graphite, shrinkage, nodules alignment and gas holes, among others [

11,

12,

13,

14]. Regarding the demand for high strength materials with very good castability, new treatments of ductile irons [

15] or new compositions [

16] have been developed, widening the properties and application of these materials; however, problems related to their weldability remain similar (being better in the case of austempered ductile irons (ADIs)) [

15]. Nowadays, it is possible to find DCIs with ultimate tensile strengths of 700 MPa and greater, allowing castability parameters similar to what is seen on conventional DCI alloys, allowing a reduction of the overall dimension of products. This ability is very useful for the transportation industry (railways, trucks and cars), as weight reduction directly leads to a decrease in emissions and improves sustainability [

17].

The welding of DCIs is not performed routinely in the metalworking industry, due to the problems related to its composition [

18]. Effectively, DCI welding requires careful preparation; it is difficult to achieve similar mechanical properties after welding relative to the ones presented by the parent metal. The main problems related to the weldability of DCIs arise from the excessive content of carbon and related materials that promote martensite formation in the heat affected zone (HAZ) as well as iron carbides between the bead and the parent metal (interface). However, there are many situations where welding processes can help us to overcome some difficulties related to casting defects, machining mistakes, small cracks resulting from the cooling process, or cyclical workloads [

19]. Indeed, repairs via welding represent the most performed operation regarding DCIs [

20]. Thus, several processes have been tested with success in terms of joining DCIs, such as Manual Shielded Metal Arc Welding (SMAW), Oxyacetylene Welding (OAW), Gas Metal Arc Welding (GMAW), Gas Tungsten Arc Welding (GTAW), Flux Cored Arc Welding (FCAW) and Laser Welding (LW), among others [

19,

21,

22], while others were discarded. For instance, when using Friction Welding (FW) in DCIs, due to the lubricant effect of graphite, the necessary localized high temperature cannot be achieved in order to promote DCI fusion [

21]. Hence, there are studies on how to repair big components like heavy-duty engine blocks [

9].

Regarding the need to use welding processes in a reliable way, some studies have been carried out in an effort to determine how to achieve the best results in terms of mechanical strength, fatigue resistance and wear behavior [

22,

23,

24,

25,

26]. Furthermore, other studies have been performed in order to evaluate how to improve surface wear resistance using filler metal (FM) as a thick surface layer [

1]. The use of heat treatments is a common way to overcome the traditional four difficulties encountered when welding DCI [

23,

24]. Usually, when a preheating stage is performed, the UTS (Ultimate Tensile Stress) is not severely affected by the cooling process [

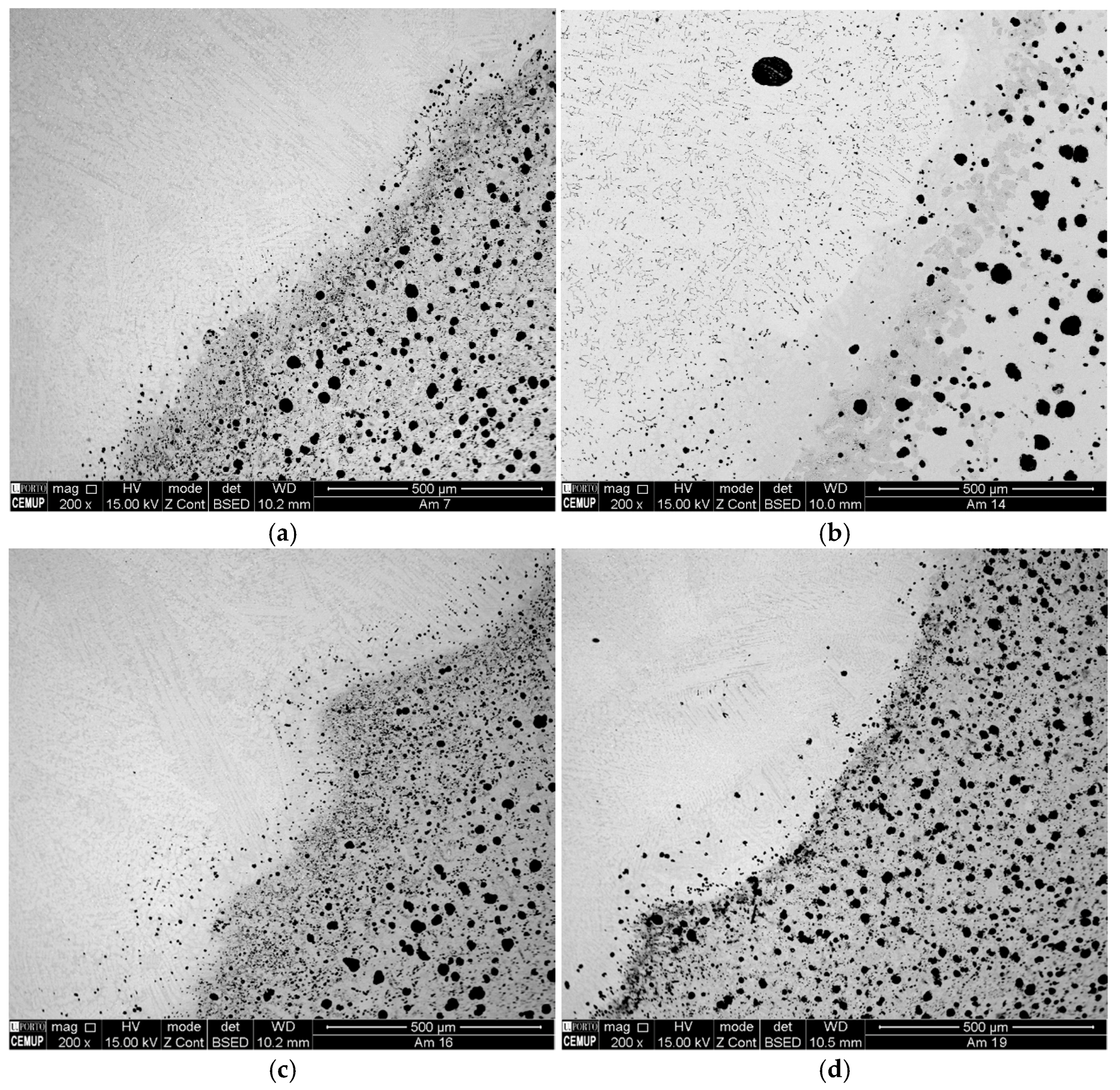

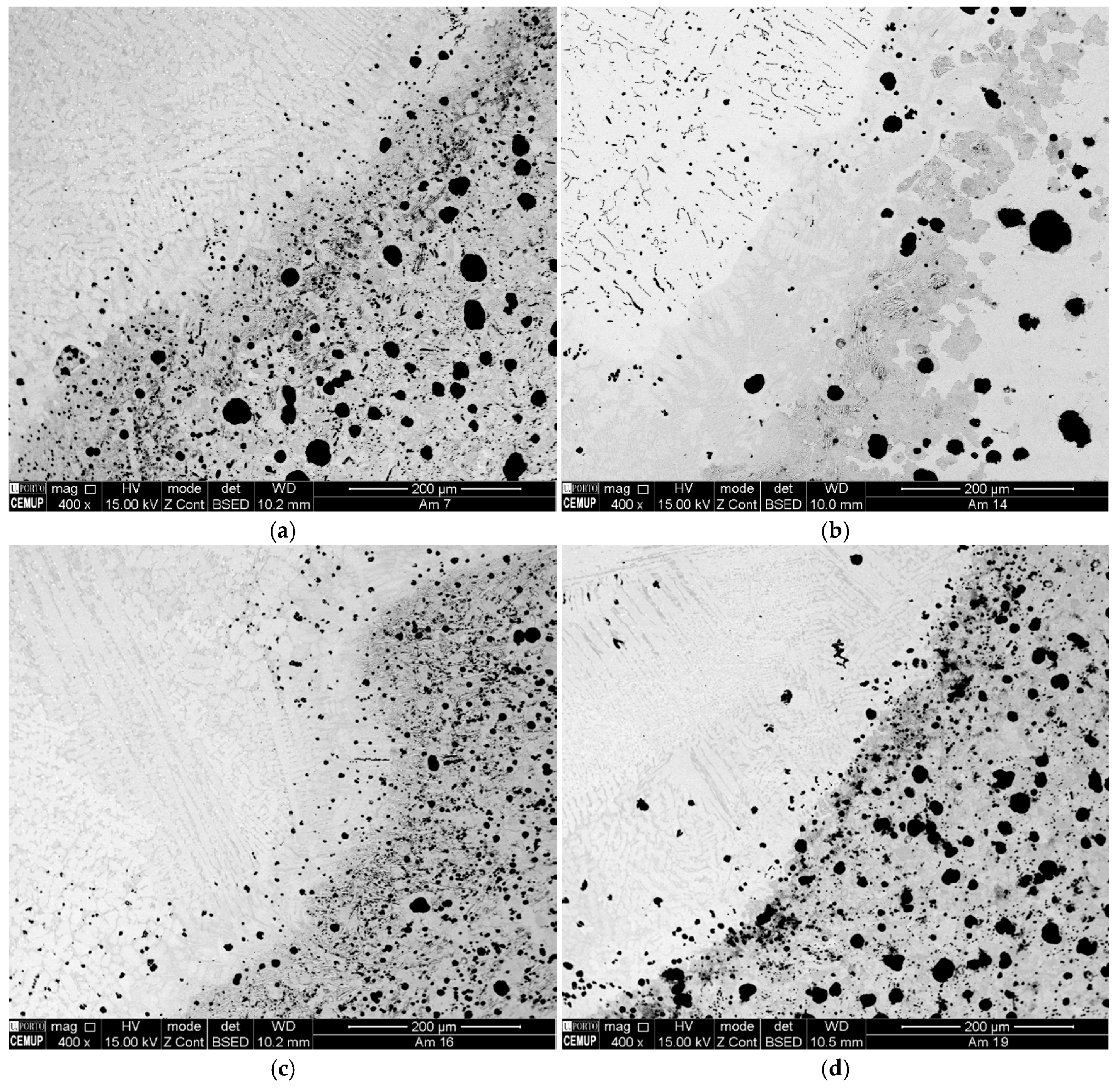

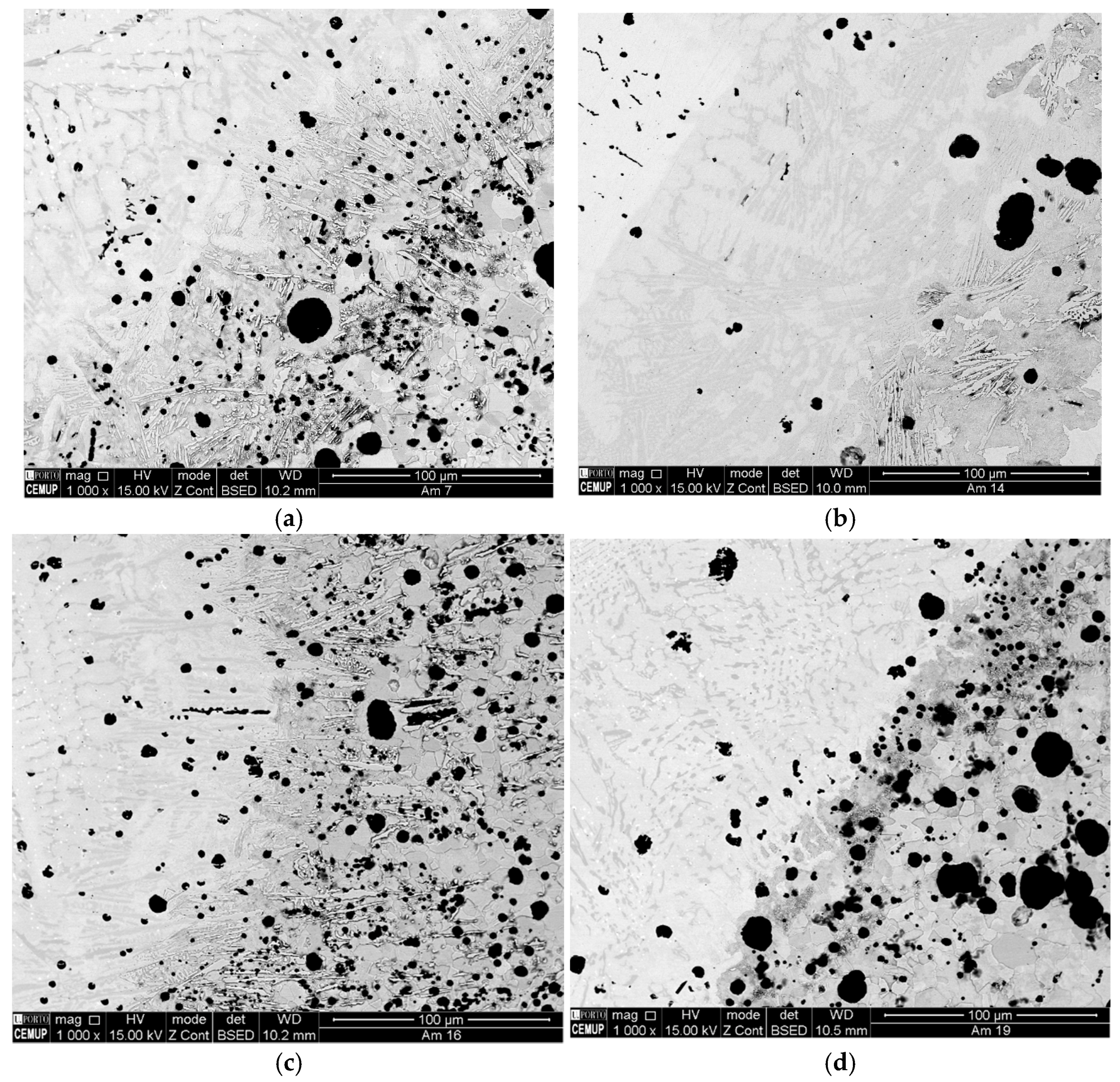

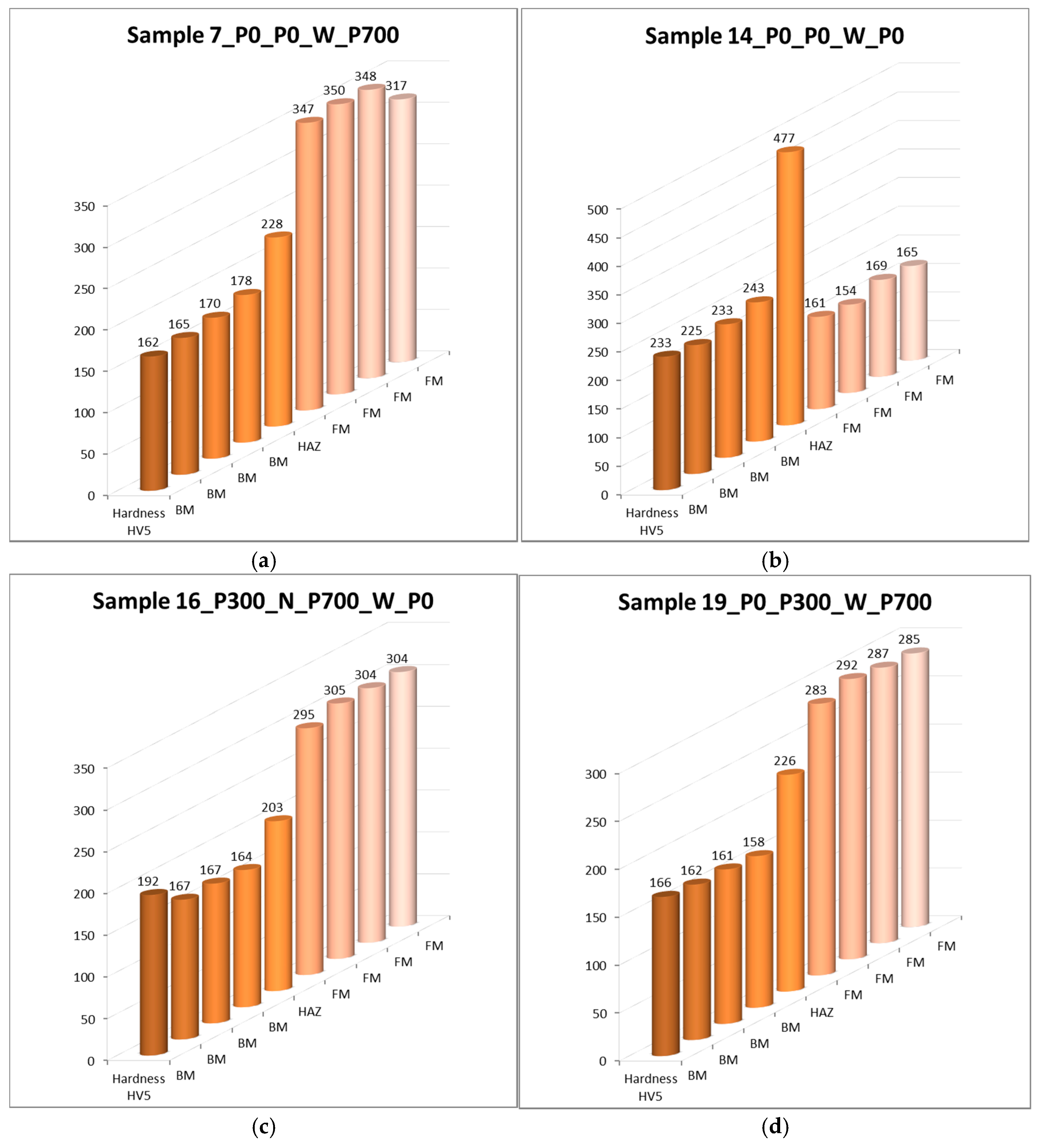

19], due to the hardness associated with the phases (martensite, bainite, pearlite and ledeburite) formed in each zone (fusion zone (FZ), HAZ (heat affected zone) and partially melted zone (PMZ)). Therefore, the main goal of a pre-heating procedure is to reduce residual stresses and distortions, preventing, as well, a rapid cooling rate and consequent cracking risk, providing the HAZ with higher ductility [

23]. A temperature of 300 °C is referred to in the literature as the most convenient to achieve good results in terms of mechanical properties of DCI welded joints [

20], conferring a bainitic HAZ and a discontinuous presence of carbides. PWHT is referred to as useful for slightly reducing the HAZ hardness, improving the ductility in this area and reducing the residual stresses imposed by the welding thermal cycle. A similar effect is produced when performing further welding passes relative to the former ones. In a recent study, authors found that when welding a similar high strength DCI to the one discussed in this work, a pre-heating stage of 300 °C for 2 h along with multi-pass welds promoted the best outcome in terms of mechanical properties [

24]. Buttering was used successfully in the preparation of the SMAW process, conferring a higher ductility to the weldment [

19]. Pouranvari [

25] carried out experiments, using 870 °C with a 1 h holding time and furnace cooling, with PWHT in gray cast irons joined with Ni based FM, promoting martensite dissolution and graphitization in the HAZ, reducing, as well, the hardness in the PMZ and conferring a smooth hardness profile through the welded area.

FM has been one of the most interesting topics discussed in the last two decades regarding DCI welding [

15]. Indeed, studies have been carried out allowing us to state that Ni, as a FM, allows better mechanical properties than nodular cast iron electrodes [

18,

26]. In fact, nickel is able to dissolve graphite contained in the DCI parent metal, germinating as low average size spherulites, preventing the formation of martensite or fragile carbides and promoting a more uniform weldment structure with the ability to deform without cracking. Welds performed with FM based on Ni alloys have given an advantage in the last decade [

27,

28], due to the microstructure achieved, mainly composed of Ni-rich solid solution dendrites together with some M23C6 carbides interdendritic eutectics [

1]. Studies carried out by Pascual et al. [

18] allowed us to observe that ductility is improved when stainless steel or Ni–Fe alloys are used as FM in DCI welding relative to gray iron FM, which presents the worse results in terms of mechanical properties. Moreover, the same authors concluded that Ni alloys provide the best results in terms of mechanical properties, with stainless steel being a cheaper alternative as FM, ensuring, as well, satisfactory results. Effectively, using Ni alloys as FM when welding DCIs avoids carbide formation, contributing in this way to an increase in ductility in the joint, mainly when used together with a preheating treatment [

24]. However, many years ago, Kelly et al. [

29] studied the suitability of Ni–Fe–Mn alloys as FM for DCI welding, concluding that these alloys may be able to be used without the necessity of preheating or PWHT processes, maintaining the properties of the parent metal in the joint, stating that the presence of some martensite and carbides in the HAZ can help tensile properties on welded DCI, concluding in this way that the microstructure of the HAZ is not enough by itself to characterize the performance of a joint.

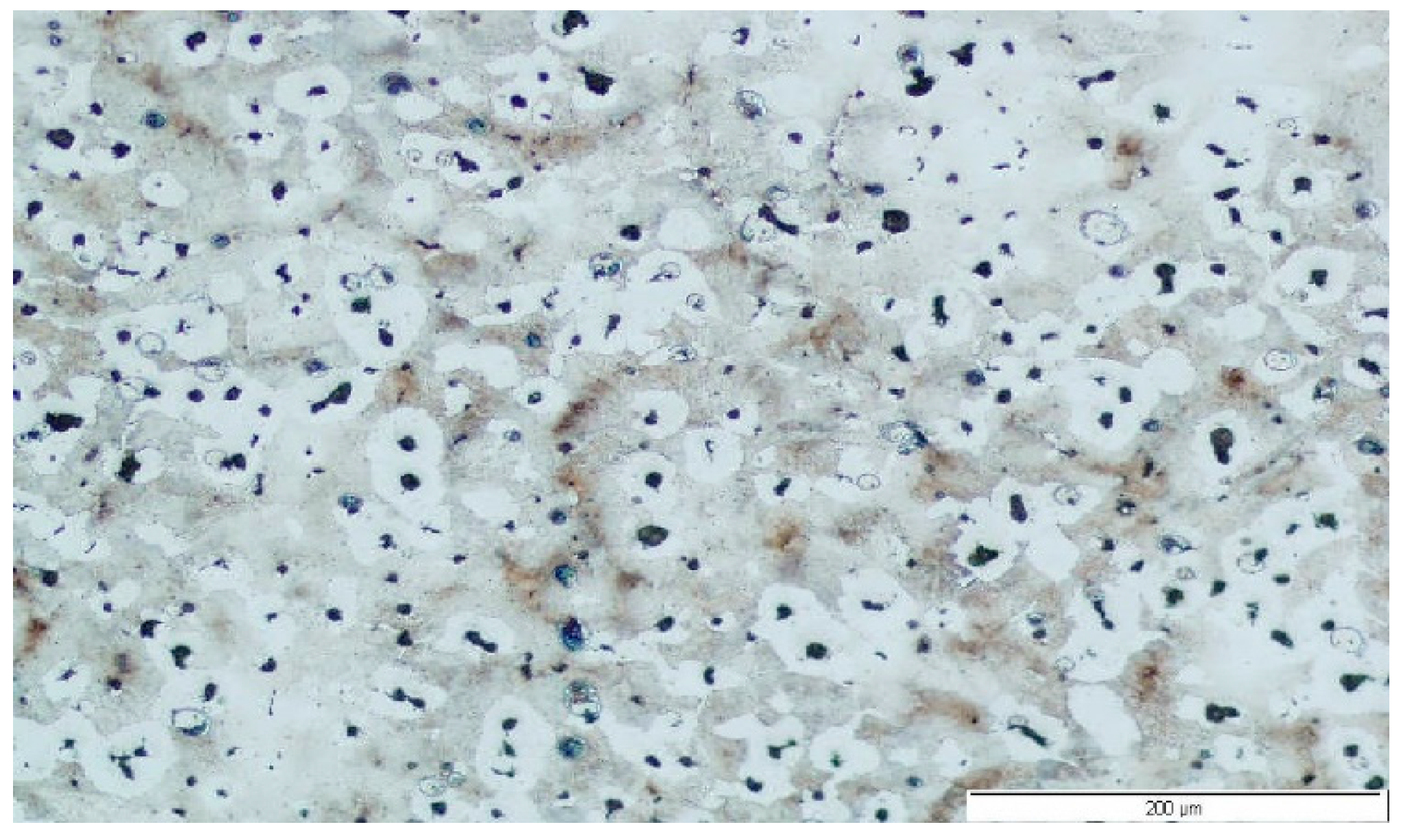

This work aimed to investigate the weldability of a high strength ductile cast iron with 700 MPa tensile strength. Its microstructure was composed mainly of graphite nodules surrounded by ferrite rings in a structure typically designated by “bull’s eye”. Different preheating and PWHT were carried out in order to determine the conditions that allow attainment of the highest value in terms of tensile strength, studying, as well, the hardness profile in the welded area as well as potential material phase transformations.