Aluminum alloy has been widely acknowledged in fabrication of lightweight structures especially for aviation, automobile and the entire transportation sector as it has high strength to weight ratio, corrosion resistance and good formability. Conventionally, for joining certain classes of aluminum alloys (e.g., age hardenable alloys), a new hot shear welding technique known as Friction Stir Welding (FSW), proved a great success [

1,

2,

3]. It is evident from the research available that flaws like porosity and hot cracking are not found in FSW [

4]. Moreover, the dendritic structure that is a characteristic feature of the fusion weld microstructure is not present in the FSW, thus any harm to the mechanical properties due its presence is just not possible [

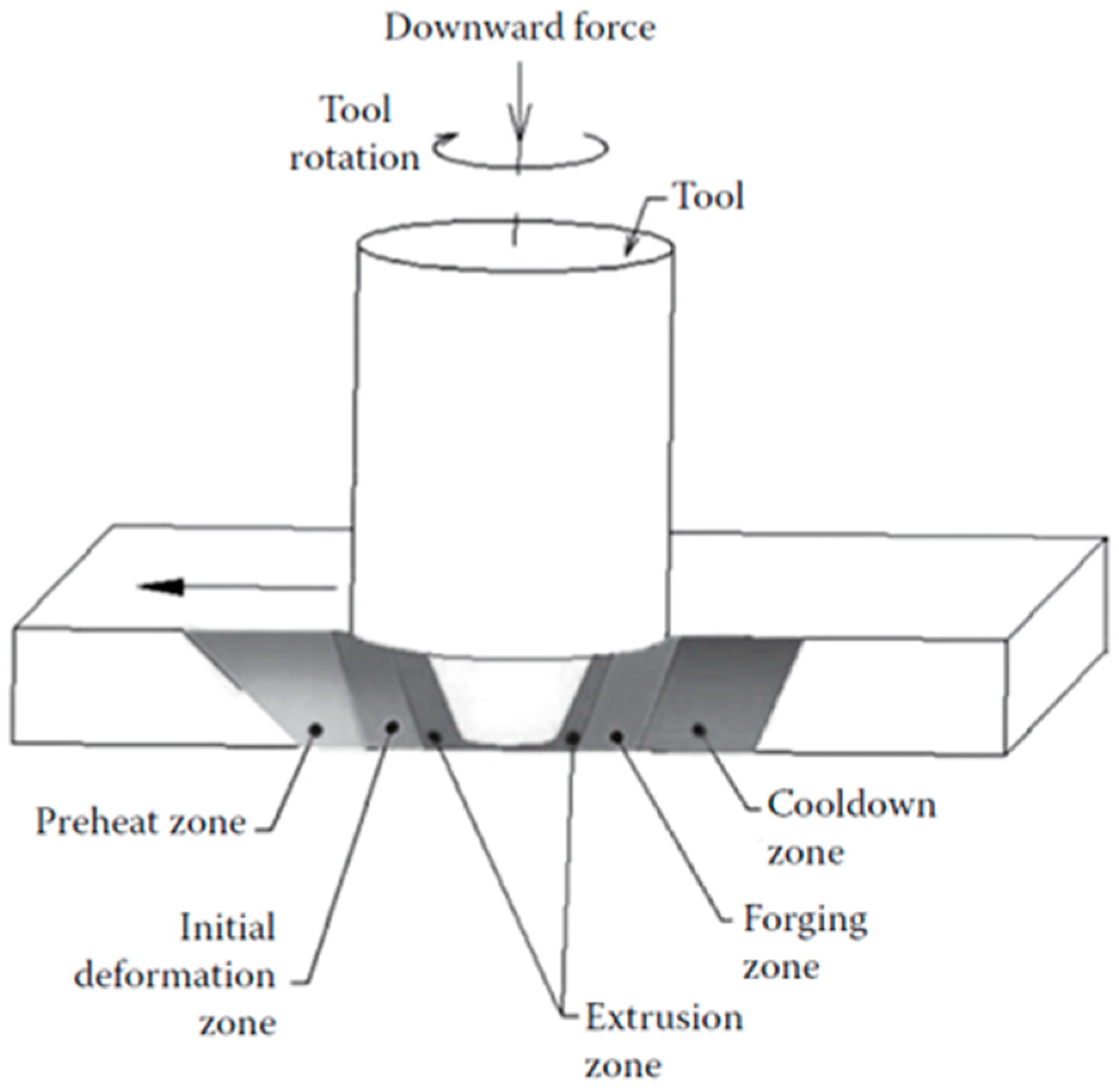

5]. There are a number of stages involved in the sequential progress of FSW process that is the pre-heating, initial deformation, extrusion, forging and metallurgical phases during heat rejection as shown in

Figure 1. This process is energy efficient and environmentally friendly too [

6]. Basically, the welding process operates by governing the amount of frictional heat generated between the rotating tool and the workpiece being welded, through a set of process parameters like tool rotation speed, plunge depth, welding speed, etc., in such a way so as to thermally condition the abutting joint surfaces in the severe plastically deformed region. Schematic of FSW process is presented in

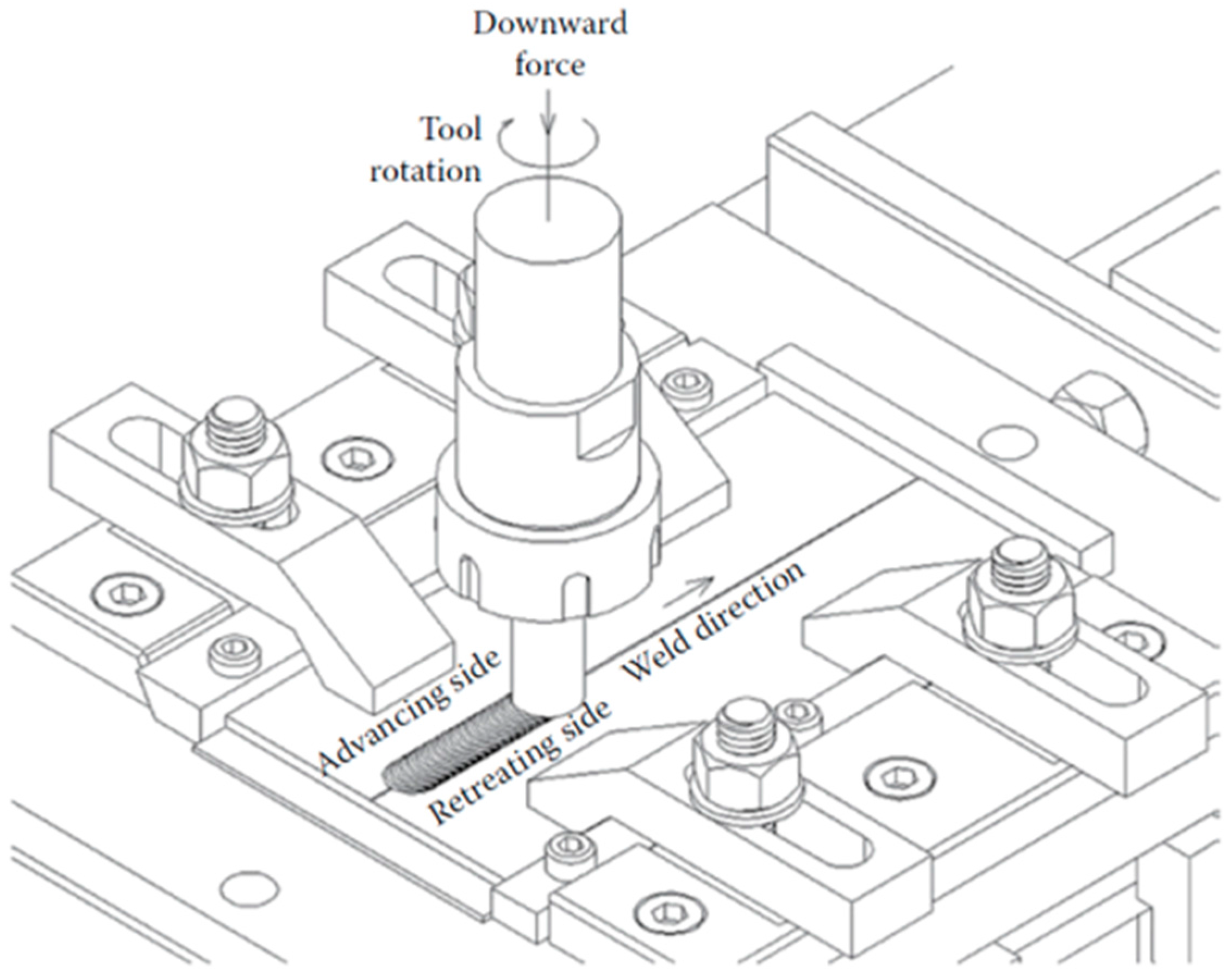

Figure 2.

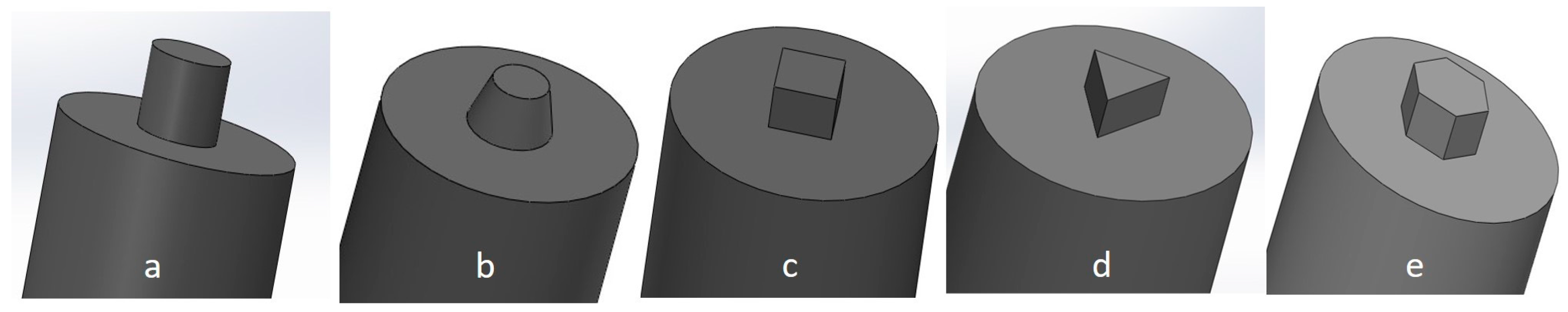

The rotating cylindrical tool used to perform FSW is comprised of a shoulder (with a specified diameter ‘

D’) and a small pin or probe (of a predefined diameter ‘

d’ and length ‘

l’) attached to the shoulder. The pin or probe can have various geometries, and it is plunged into the faying surface of the materials being welded. The size and designs of shoulder and pin (commonly referred to as tool design) have a significant effect on heat input and material movement. The study conducted by Vijayavel et al. [

8] revealed the fluctuations in the tensile strength and hardness of the friction stir processed material because of the variation in the shoulder diameters to pin diameter (

D/d) ratio, and this was further linked with associated microstructural changes. Similarly, the research conducted by Khan et al. [

9] stated that a

D/d ratio of 2.6 gives the maximum tensile strength, whereas a

D/d ratio of 2.8 results in the minimum tensile strength and microstructures showed grain refinement in the zone where the material is mixed through stirring action (known as stir zone) due to dynamic recrystallization during FSW. Therefore, the present study used the optimized

D/d of 2.6 for all the experiments. Another pin/probe dimension i.e., ‘pin length’ controls the depth of penetration. The design of the probe is such that its length is less than the thickness of the plate and its diameter is typically a little larger than the thickness of the plate [

10]. An adequately chosen shoulder diameter provides two important functions: (a) prevents plasticized material, being stirred, from the out of the stir zone in the form of flash and (b) sufficient amount of frictional heat input that is necessary for the softening of material. Apparently, a truncated cone shaped pin akin to shape of flow vortex of the softened material is commonly used. Both the probe and shoulder generate a fair amount of frictional heat and heat of deformation that creates almost hydrostatic condition around the surface in contact with the probe and shoulder. Thus, under the correct conditions of heat and flow material in the front moves from the advancing side (AS) to the retreating side (RS) and consolidates at the back to form a sound joint. The material from the leading edge is exported towards the trailing edge where it is forged into a joint [

11]. Roughly, with every complete rotation of the tool, a sufficient amount of energy builds up to squeeze out semi-circular shells from the base material. This is exactly how the weld zone develops or it can be understood as an integrated effect of small extrusions [

12]. Moreover, the investigation done by Elangovan et al. [

13] shows that the shell extrusion process is responsible for grain refinement and enhancement of material properties. The enhancement of mechanical properties is mainly affected by the changes in the microstructure of the weld region resulting from dynamic recovery [

14].

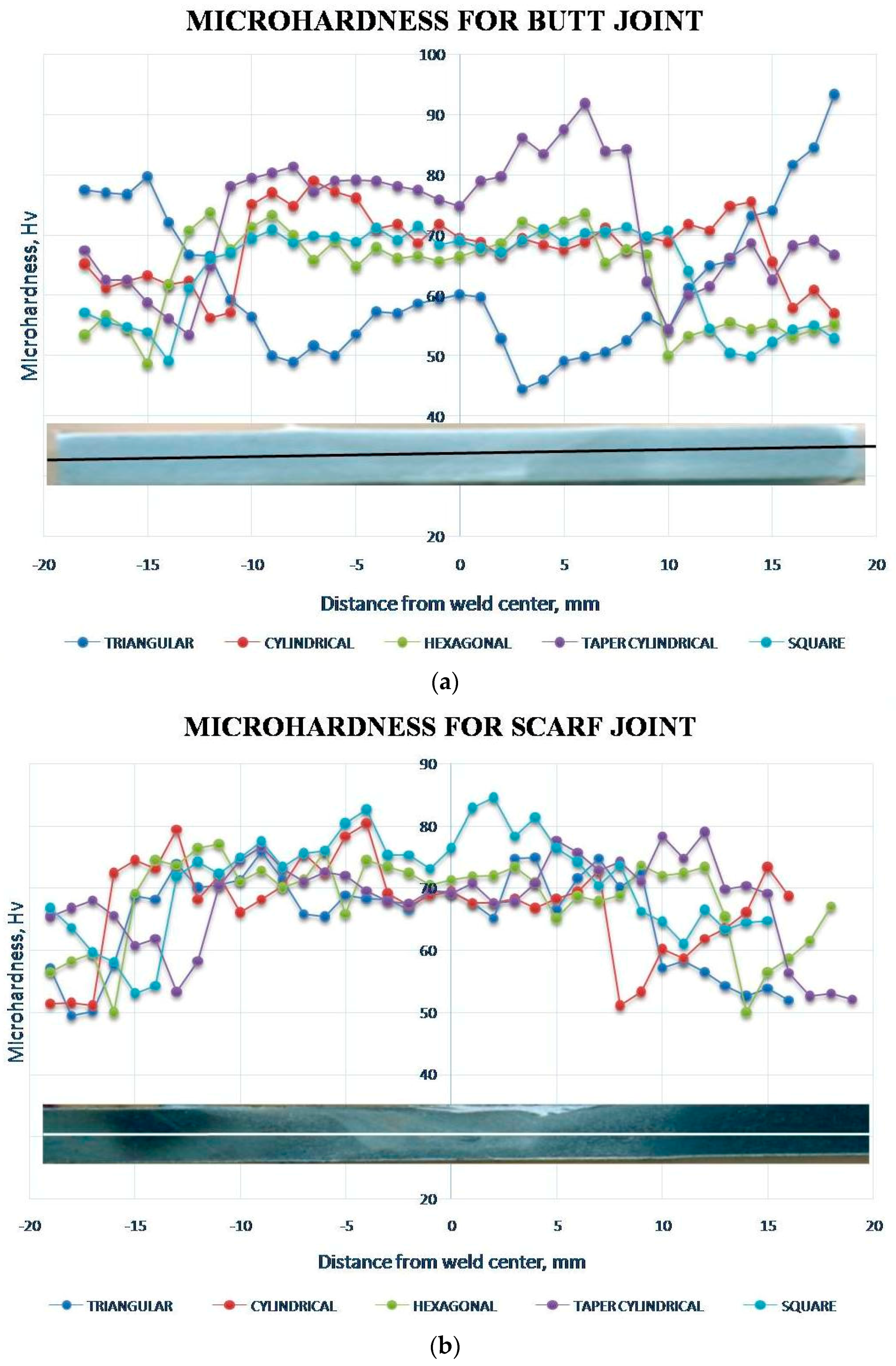

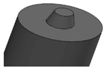

Parameters like tool geometry and joint configuration have a considerable effect on the material flow and temperature evolution, and the same is reflected in the microstructure of joints. Furthermore, as a result of this combination of frictional heat and mechanical intermixing of materials, typical micro-structural zones are evolved after FSW such as (a) the stir zone (SZ), consist of fine and re-crystallized grains, (b) the thermo mechanically affected zone (TMAZ), comprising of plastically deformed grains, and (c) the heat affected zone (HAZ) containing grains similar to base material. The fine grains structure of SZ was a result of severe plastic deformation caused by stirring action of the tool. The region next to SZ is less plastically deformed and is subjected to partial dynamical re-crystallization, and it is named TMAZ. However, no plastic deformation is seen in the HAZ region, and it only experiences a thermal effect [

9].

Figure 3 shows the friction-stir welding micro-structural zones.

In case of age-hardenable alloys, the softening temperature is so high that it may lead to coarsening or dissolution of the strengthening precipitate and consequently may adversely affect the joint properties. Available literature reveals that the density, size, and distribution of the strengthening precipitates strongly affect the mechanical properties of the friction-stir welded precipitation-hardenable Al alloys [

15,

16,

17,

18,

19]. Usually, during the welding thermal cycle [

17,

19], the strengthening precipitates are dissolved due to the heat generation and thus mechanical properties in the region around the weld may decrease.

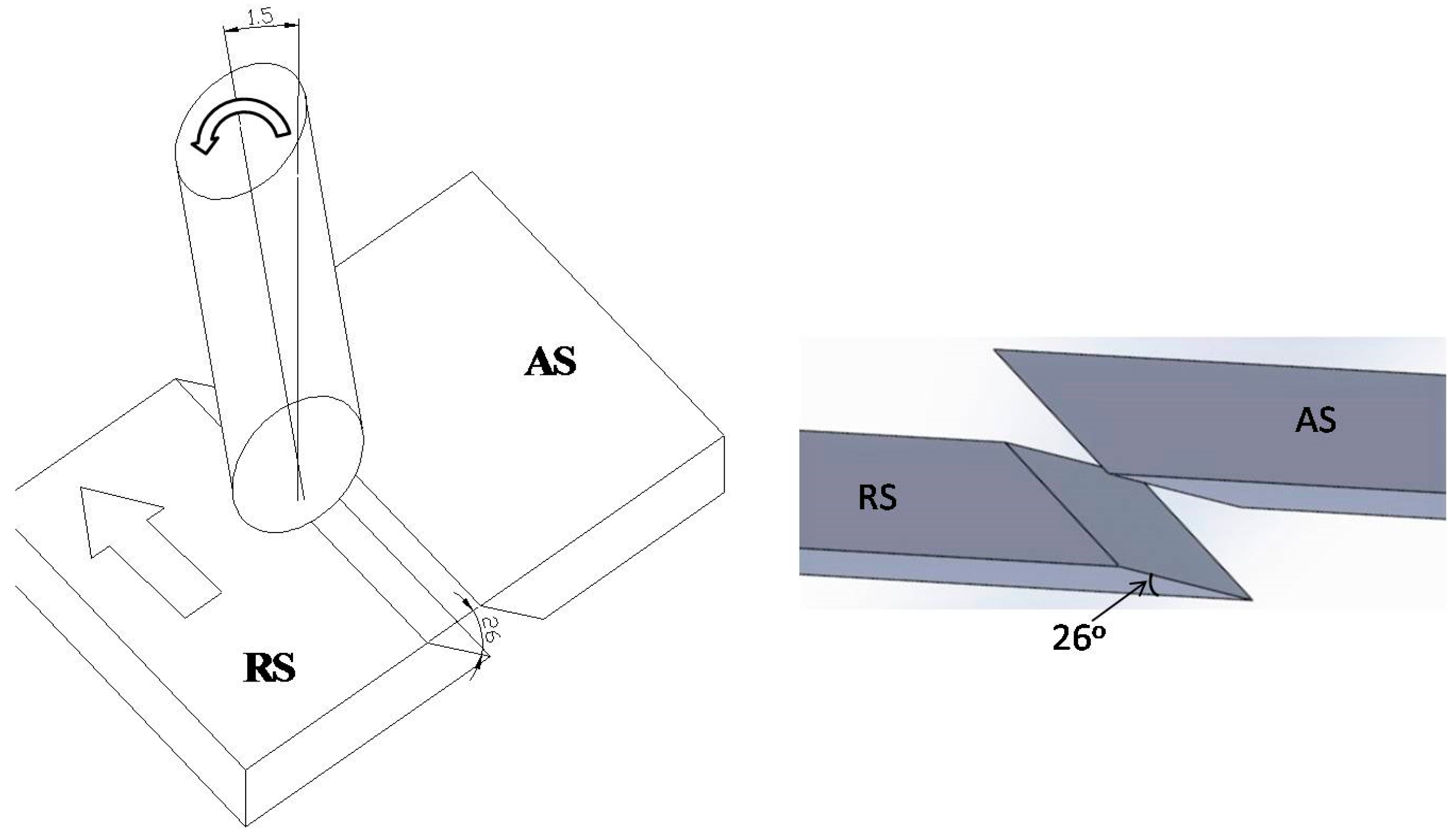

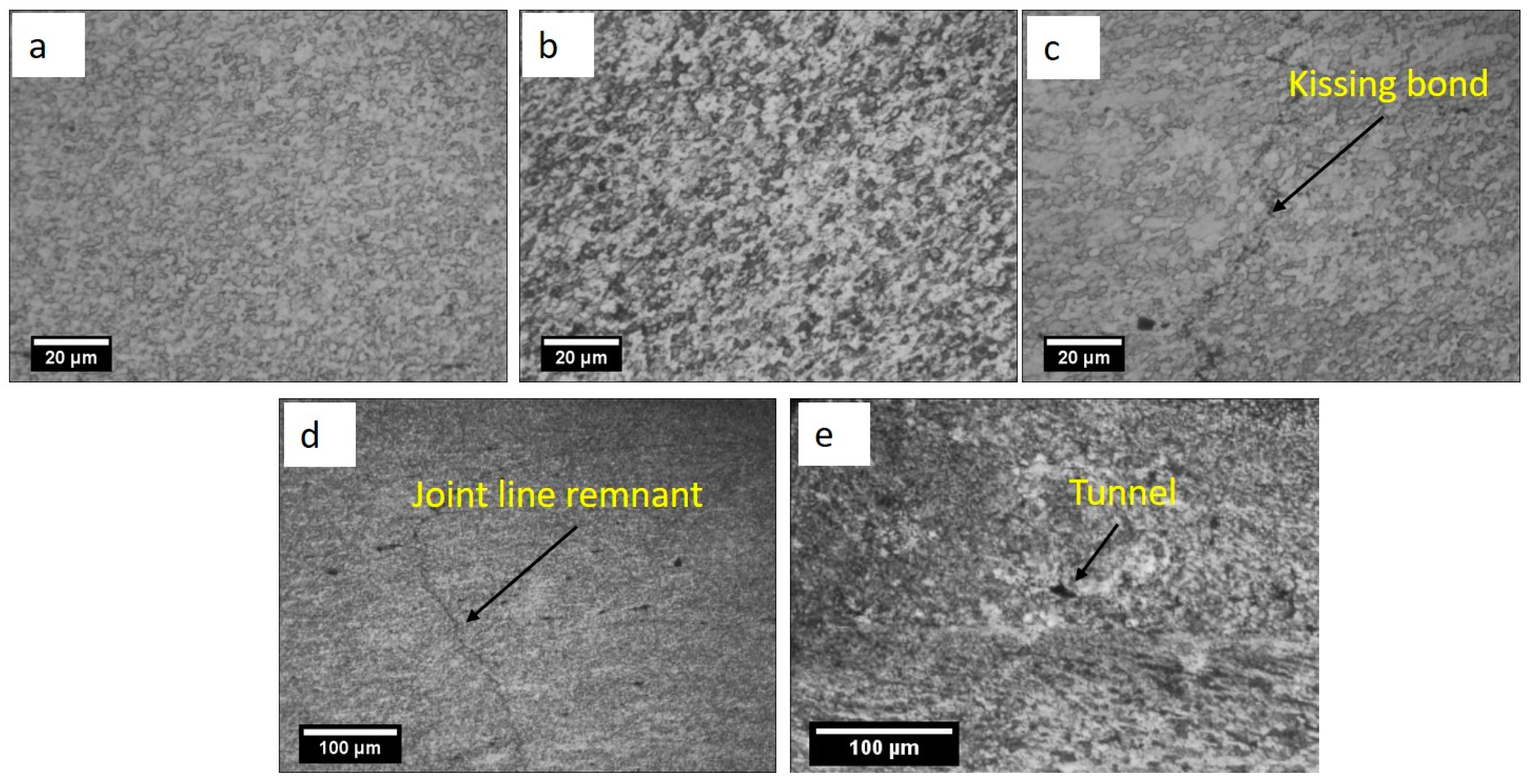

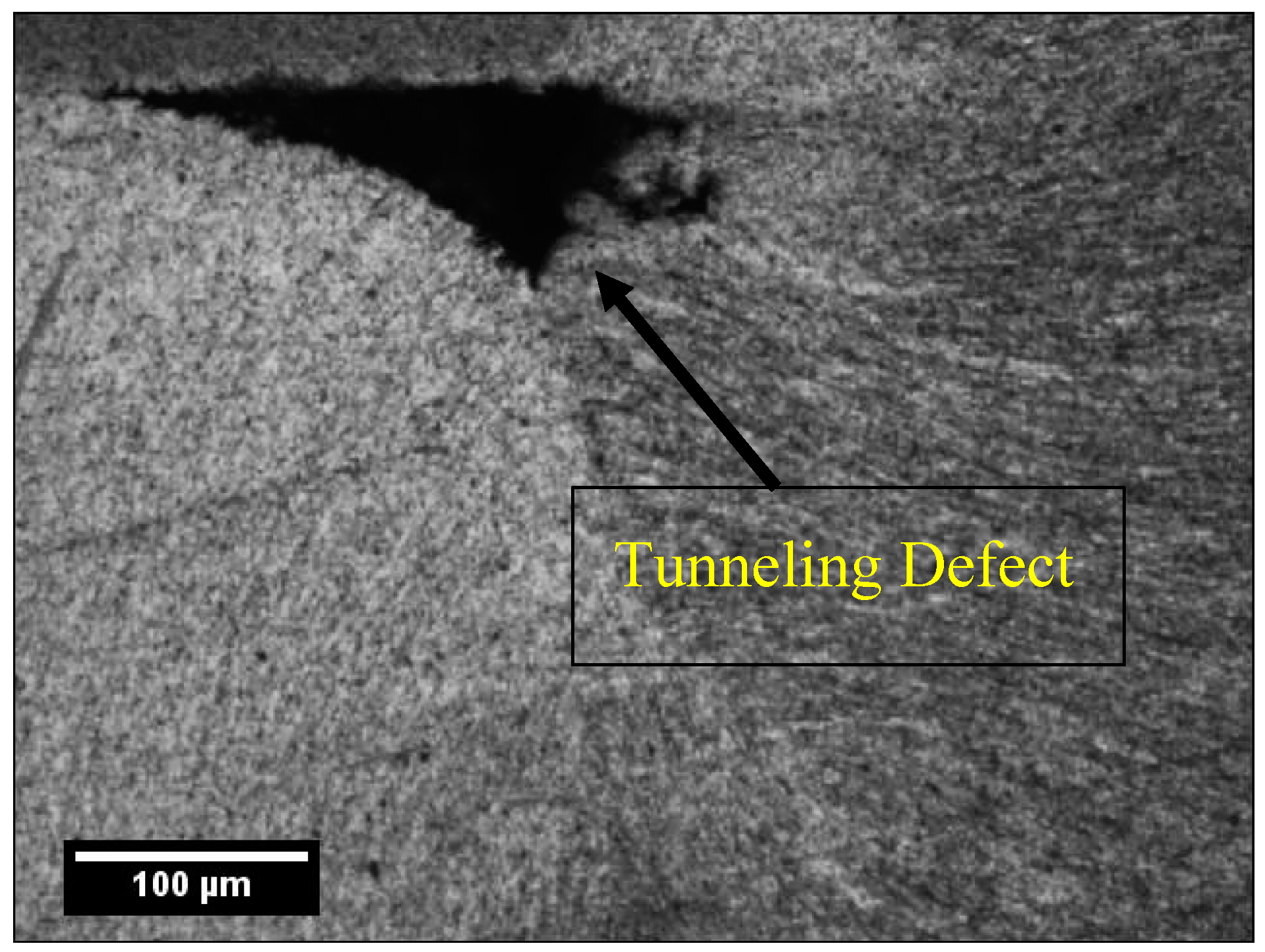

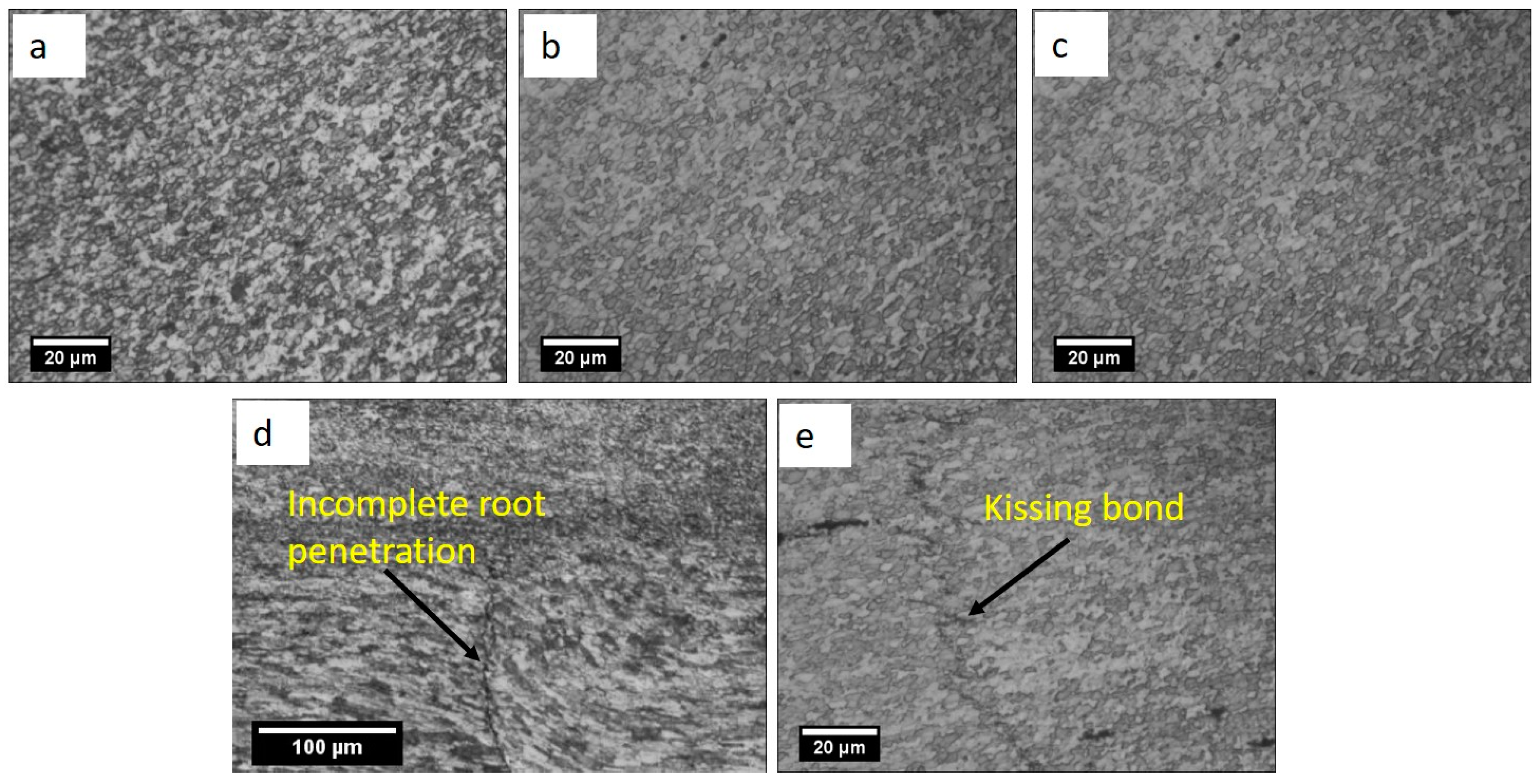

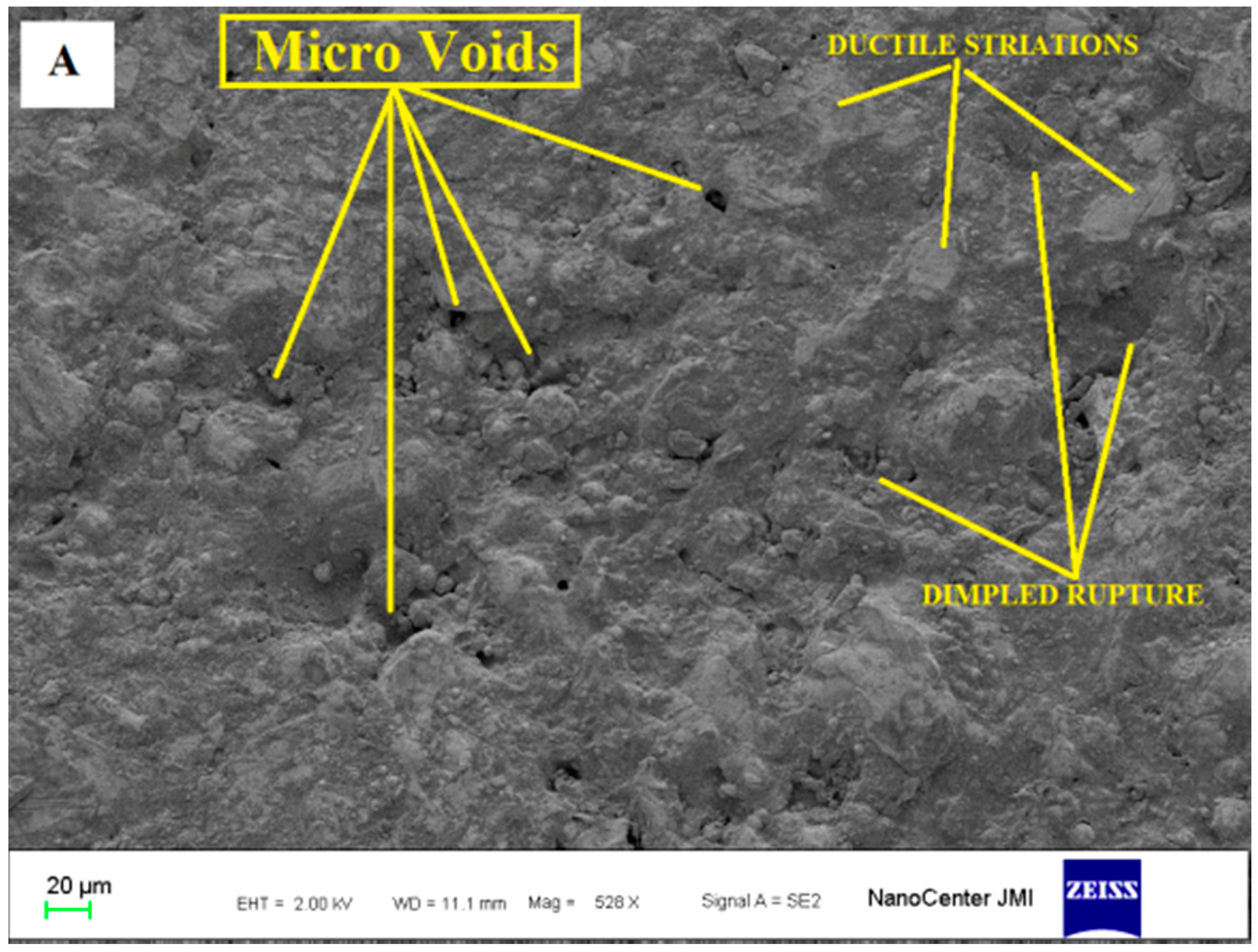

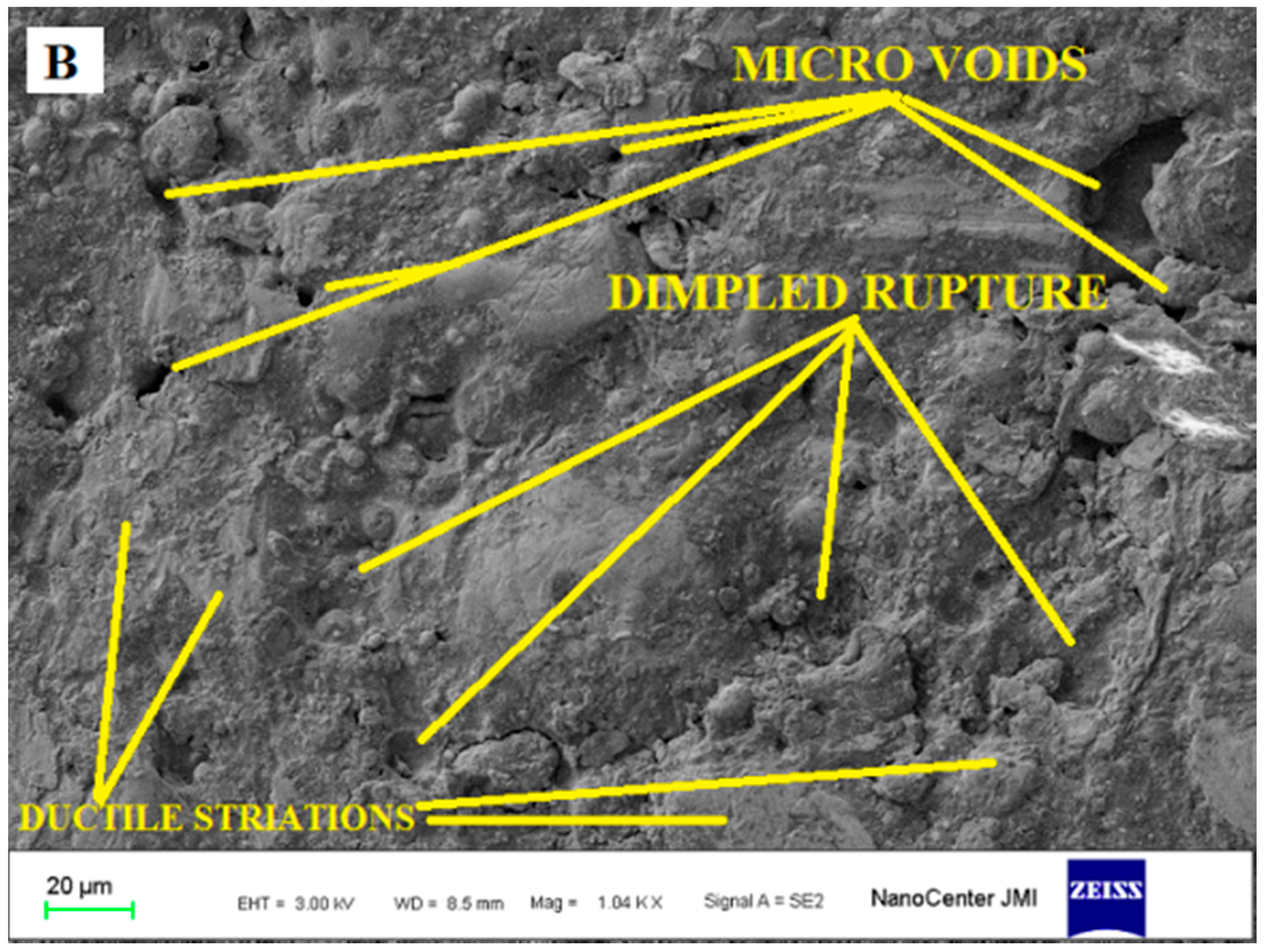

Owing to various advantages over fusion welding processes, the FSW process has its own defect such as tunneling defect, kissing bond (KB), joint line remnant, hooking defect, voids, and incomplete root penetration. These defects form due to improper material movement and inadequate heat generation caused by improper selection of process parameters, tool geometry and joint configuration. Material movement depends on several parameters including tool pin profile. These defects, if not minimized or eliminated, may lead to the degradation of mechanical properties of the joints. Defect formation in butt and lap joint configuration were investigated by many researchers [

20,

21,

22,

23,

24]. Moreover, some defects such as kissing bond and joint line remnants, are typical to FSW. The main reason for these joints lies in the fact that, in the case of butt joint, the faying surface and the tool axis coincide. The velocities and flow of material at and near the tool axis are negligible and contributes to these defects. To overcome these defects, higher rpm and/or slower traverse speed are suggested. However, these conditions also add more heat, which is detrimental to age-hardenable alloys. Thus, alternate ways such as a change in joint configuration need to be explored so that they produce stronger joints of age-hardenable materials can be better understood. Incidentally, most butt welds by FSW are made in square joint configuration, which makes faying line coincidental to the tool axis. It is worthwhile to mention that shear movement is maximum at the tool periphery and ideally zero at the tool axis. In the case of a regular butt joint, the faying surface and the tool axis coincide and, because of deficient shear and flow, the chances of defect such as joint line remnant and kissing bond are high. The scarf joint has an advantage in which the abutting surface is inclined to the tool axis and can thus assist in alleviating issues that lead to some FSW defects. To the knowledge of the authors, no literature is available for the FSW with scarf joints. This paper has made an attempt to be the torch bearer in investigating the effect of scarf joints. Any further attempt to separately optimize the parameters for scarf configuration may uncover the complete potential of this type of joint. During FSW, the material undergoes extrusion at the leading edge in the AS, which churns around the edge and finally forged behind on the RS at trailing edge, thus consolidating the joint. During the course of this action, the material moves under shear through a set of stick-and-slip actions around the pin and undergoes severe plastic deformation. If the lateral surface of pins has flat faces such as in prismatic/pyramid shape, the material, which otherwise moves purely under shear, experiences support to its flow through pulsating action of the flats. Thus, the pin profile plays a significant role in material movement around the pin. While the effect of pin profiles on square butt joints has been explored by some researchers, its effect on scarf joint is not explored.