Effect of Carbon Content on the Properties of Iron-Based Powder Metallurgical Parts Produced by the Surface Rolling Process

Abstract

:1. Introduction

2. Materials and Methods

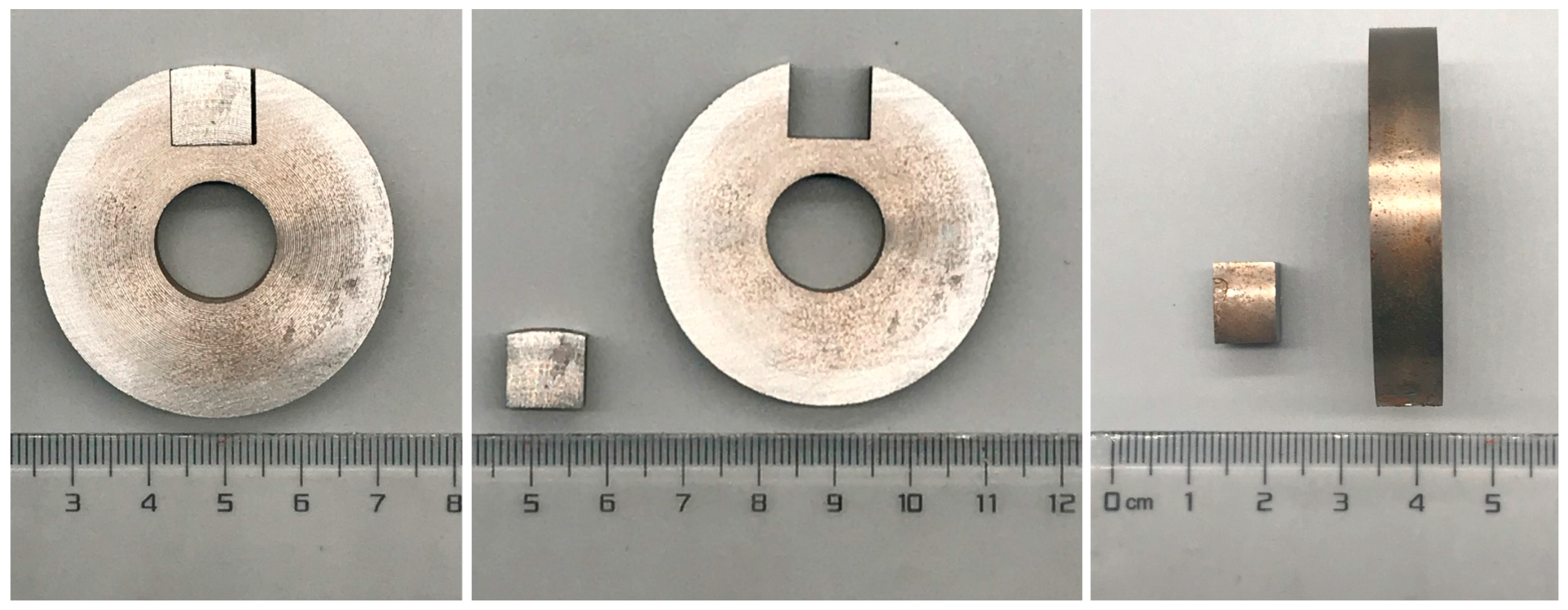

2.1. Preparation of PM Components

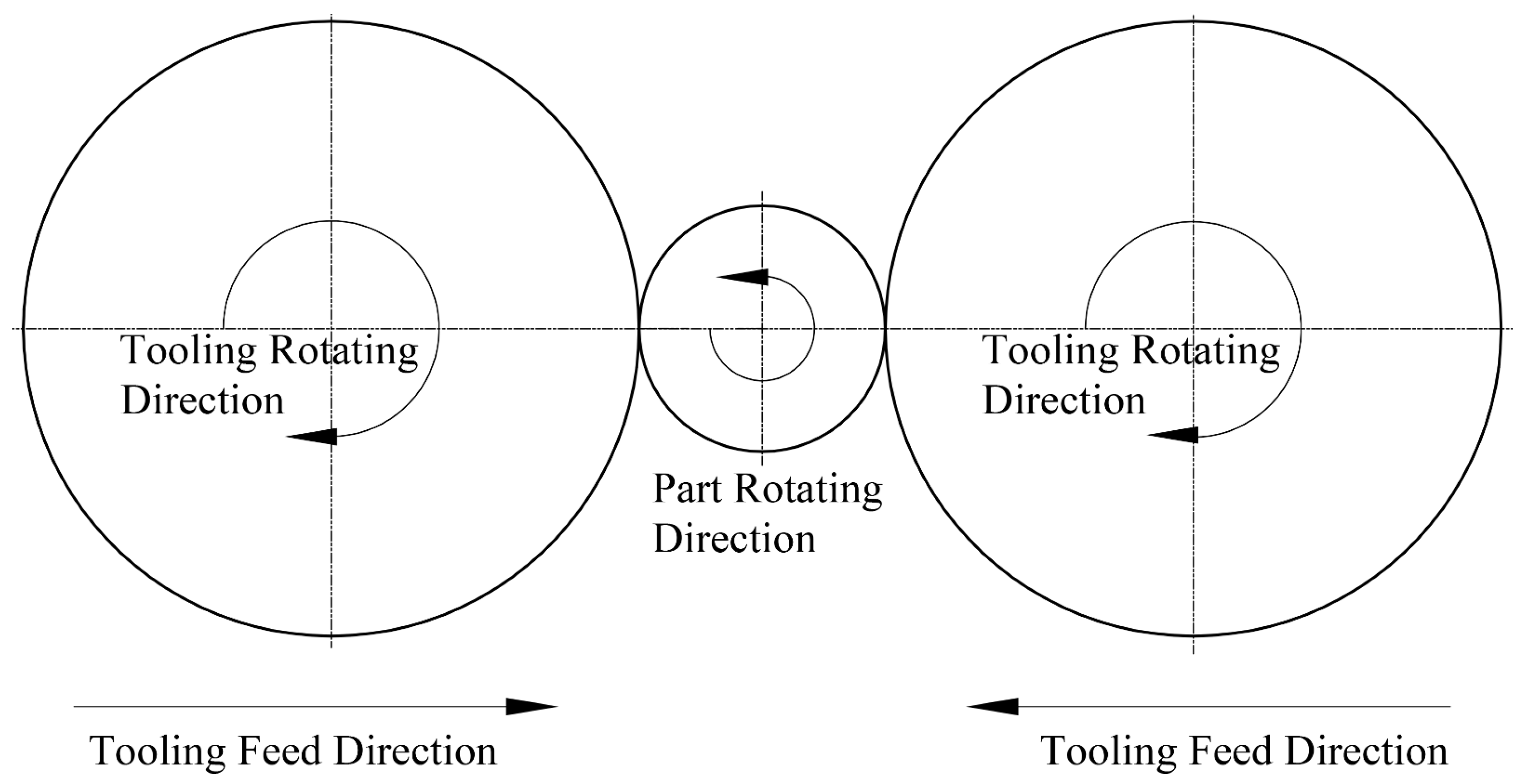

2.2. Surface Rolling Apparatus and Methods

3. Results

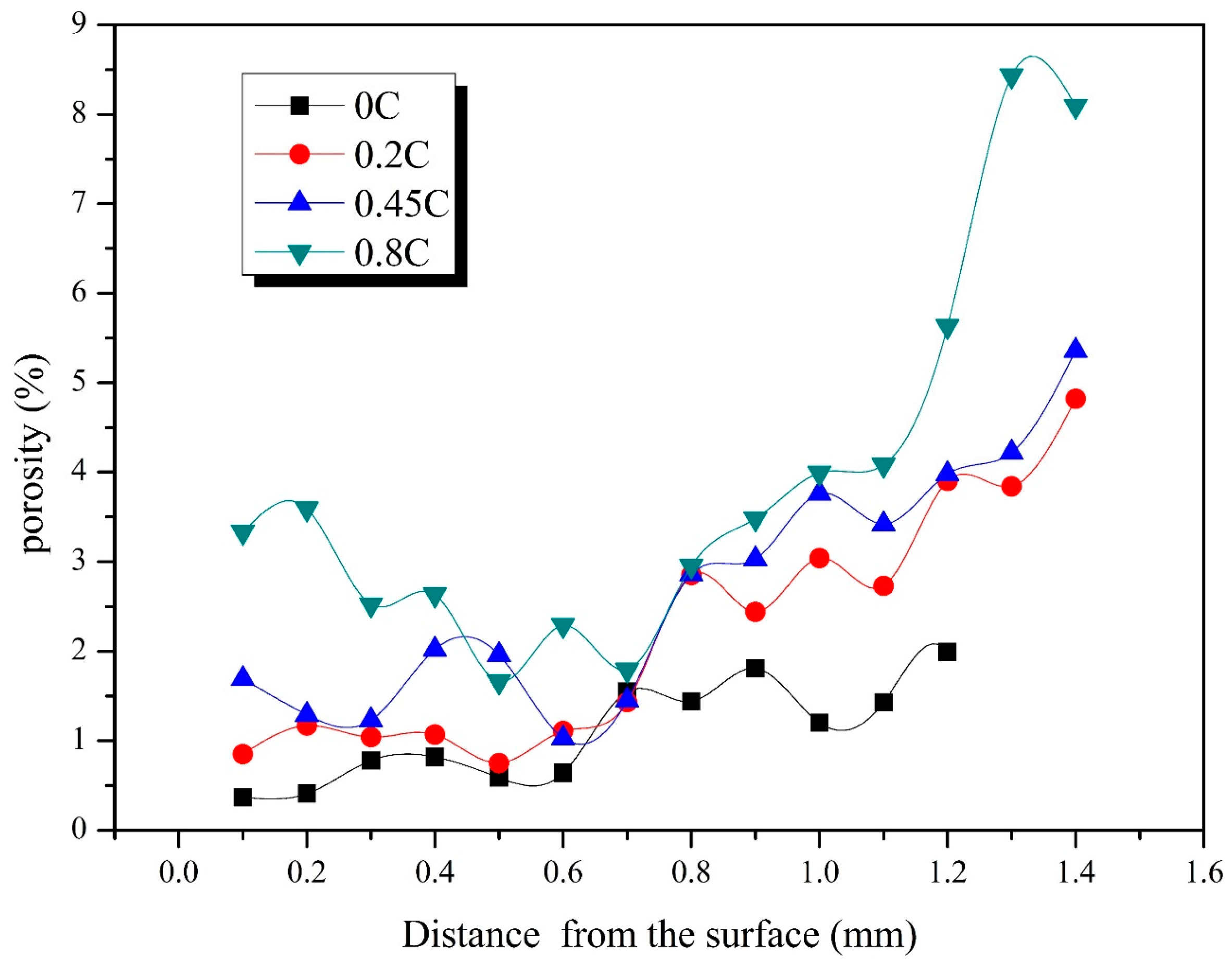

3.1. Surface-Densified Layer Properties

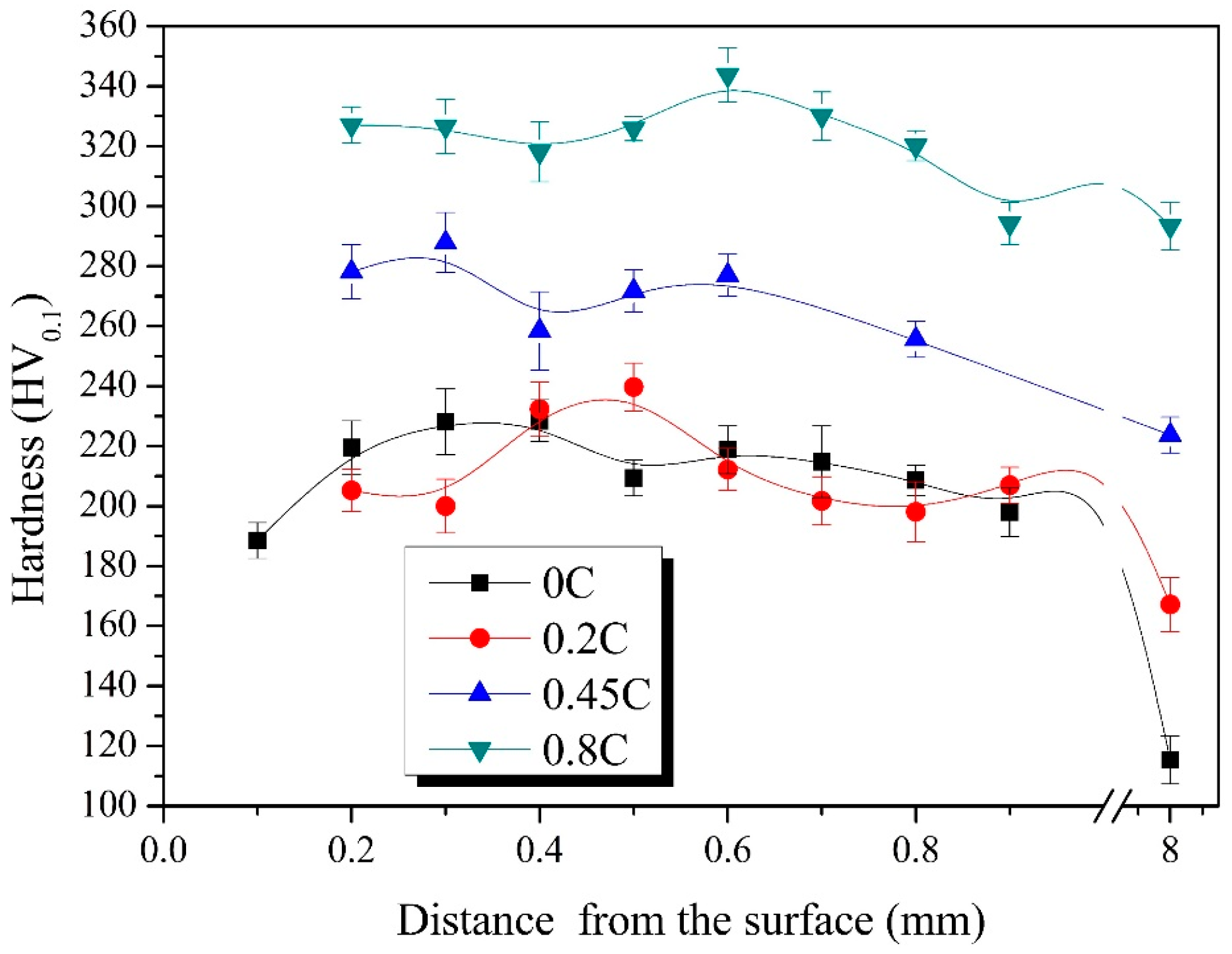

3.2. Micro-Hardness Analysis

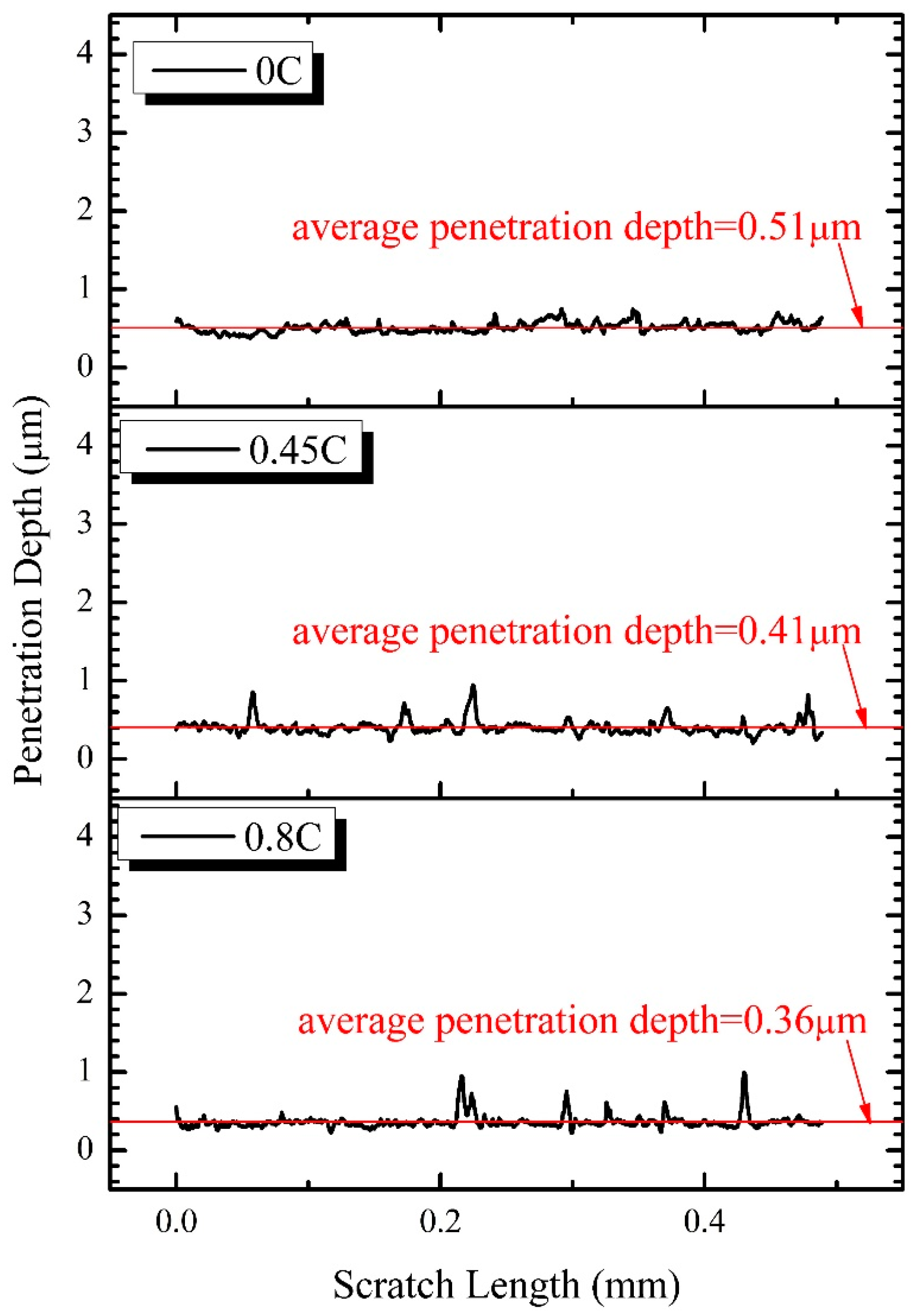

3.3. Roughness Analysis

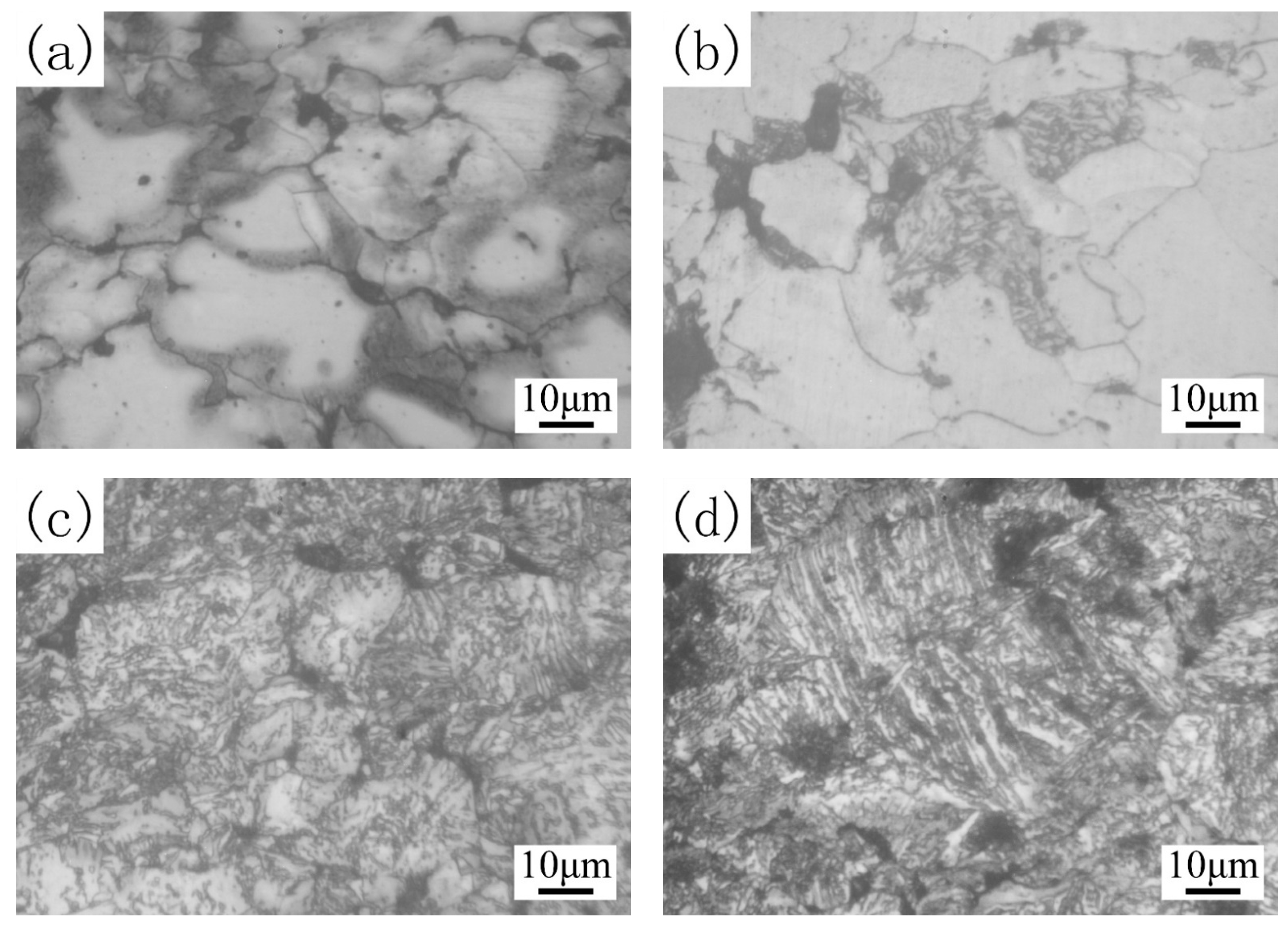

3.4. Metallographs and SEM Analysis

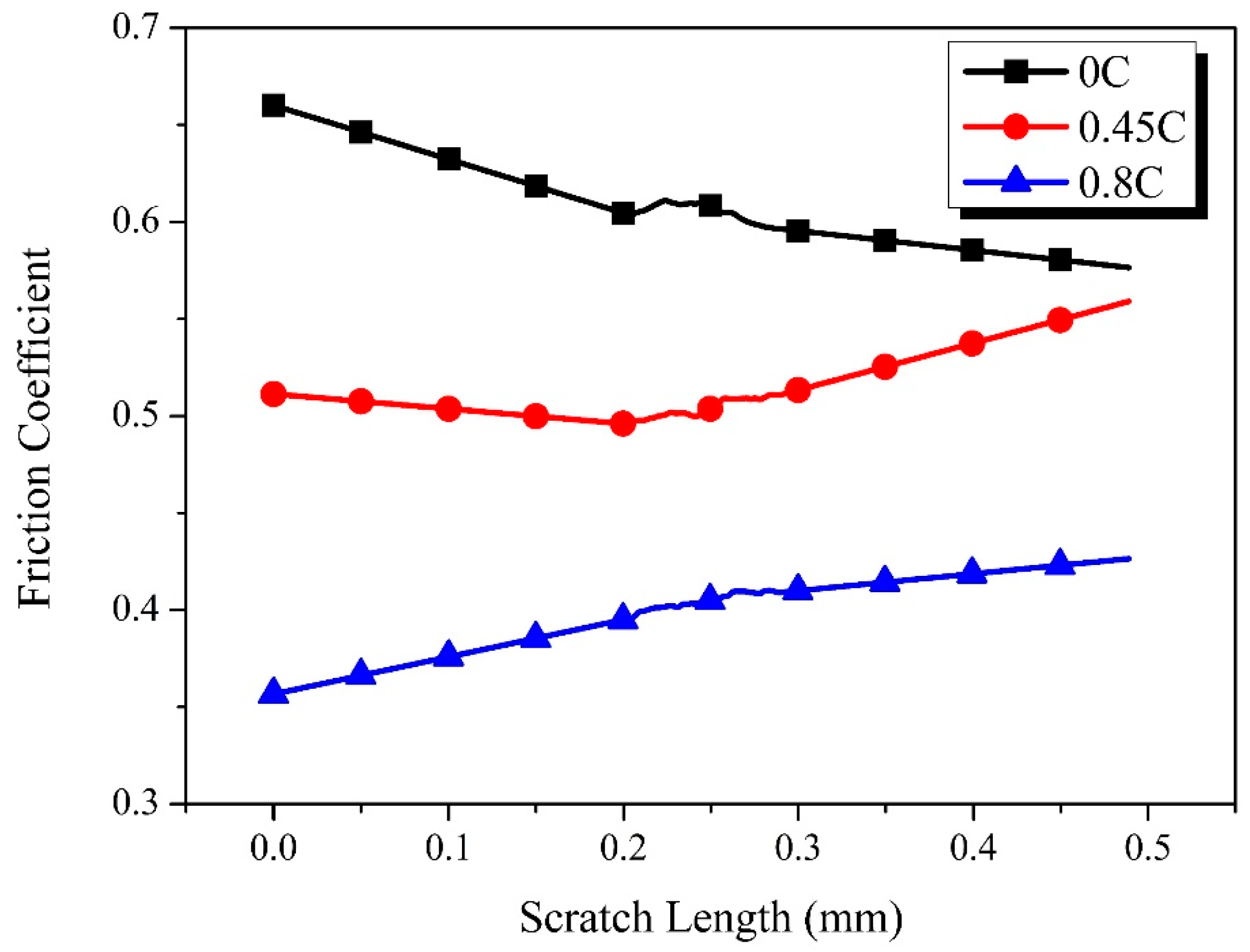

3.5. Friction Performance Analysis

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chen, D.; Li, D.; Peng, J.; Wang, T.; Yan, B.; Lu, W. The effect of rolling temperature on the microstructure and mechanical properties of surface-densified powder metallurgy Fe-based gears prepared by the surface rolling process. Metals 2017, 7, 420. [Google Scholar] [CrossRef]

- Capus, J. Industry roadmap update from MPIF. Met. Powder Rep. 2012, 67, 10–11. [Google Scholar] [CrossRef]

- Takemasu, T.; Koide, T.; Shinbutsu, T.; Sasaki, H.; Takeda, Y.; Nishida, S. Effect of surface rolling on load bearing capacity of pre-alloyed sintered steel gears with different densities. Procedia Eng. 2014, 81, 334–339. [Google Scholar] [CrossRef]

- Lee, J.G.; Lim, C.H.; Kim, H.S.; Hong, S.J.; Kim, M.T.; Kang, B.C.; Park, D.K.; Lee, M.K.; Rhee, C.K. Highly dense steel components prepared by magnetic pulsed compaction of iron-based powders. Powder Technol. 2012, 228, 254–257. [Google Scholar] [CrossRef]

- Shanmugasundaram, D.; Chandramouli, R.; Kandavel, T.K. Cold and hot deformation and densification studies on sintered Fe-C-Cr-Ni low alloy P/M steels. Int. J. Adv. Manuf. Technol. 2009, 41, 8–15. [Google Scholar] [CrossRef]

- Liu, X.; Xiao, Z.Y.; Guan, H.J.; Zhang, W.; Li, F.L. Friction and wear behaviours of surface densified powder metallurgy Fe-2Cu-0.6C material. Powder Metall. 2016, 59, 329–334. [Google Scholar] [CrossRef]

- Takemasu, T.; Koide, T.; Takeda, Y.; Kamimura, D.; Nakamoto, M. Properties of densification by surface rolling and load bearing capacity of 1.5Cr-0.2Mo high density sintered steel rollers and gears. J. Solid Mech. Mater. Eng. 2011, 5, 825–837. [Google Scholar] [CrossRef]

- Ibrahim, A.M.; Bishop, D.P.; Kipouros, G.J. Effect of swaging and rolling post sintering treatments on the corrosion behaviour of alumix 321 PM alloy. Powder Technol. 2017, 320, 89–98. [Google Scholar] [CrossRef]

- Lawcock, R. Rolling-contact fatigue of surface-densified gears. Int. J. Powder Metall. 2006, 42, 17–29. [Google Scholar] [CrossRef]

- Forden, L.; Bengtsson, S.; Bergstrom, M. Comparison of high performance PM gears manufactured by conventional and warm compaction and surface densification. Powder Metall. 2005, 48, 10–12. [Google Scholar] [CrossRef]

- Whittaker, D. PM structural parts move to higher density and performance. Powder Metall. 2007, 50, 99–105. [Google Scholar] [CrossRef]

- Liu, X.; Xiao, Z.Y.; Guan, H.J.; Zhang, W. Experimental study on the surface densification of Fe-2Cu-0.6C powder metallurgy material. Mater. Manuf. Process. 2016, 31, 1621–1627. [Google Scholar] [CrossRef]

- Yu, Y.; Linnea, F. Surface densification-an effective way to improve the performance of sintered gears. Powder Metall. Technol. 2005, 23, 62–74. [Google Scholar] [CrossRef]

- Jones, P.; Buckley-Golder, K.; Lawcock, R.; Shivanath, R. Densification strategies for high endurance pm components. Int. J. Powder Metall. 1997, 33, 37–44. [Google Scholar] [CrossRef]

- Bengtsson, S.; Dizdar, S.; Svensson, M. Material aspects of selectively densified transmission gears. In Proceedings of the 2000 Powder Metallurgy World Congress, Kyoto, Japan, 12–16 November 2000. [Google Scholar]

- Peng, J.G.; Zhao, Y.; Chen, D.; Li, K.D.; Lu, W.; Yan, B.A. Effect of surface densification on the microstructure and mechanical properties of powder metallurgical gears by using a surface rolling process. Materials 2016, 9, 846. [Google Scholar] [CrossRef] [PubMed]

- Bengtsson, S.; Fordén, L.; Dizdar, S.; Johansson, P. Surface densified P/M transmission gear. In Proceedings of the 2001 International Conference on “Power Transmission Components. Advances in High Performance Powder Metallurgy Applications”, Ypsilanti, MI, USA, 16–17 October 2001. [Google Scholar]

| Specimen | Astaloy85Mo | Graphite | Cu |

|---|---|---|---|

| 0 C | Bal. | - | 1.4 |

| 0.2 C | 0.2 | 1.4 | |

| 0.45 C | 0.45 | 1.4 | |

| 0.8 C | 0.8 | 1.4 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Chen, D.; Li, D.; Peng, J.; Yan, B. Effect of Carbon Content on the Properties of Iron-Based Powder Metallurgical Parts Produced by the Surface Rolling Process. Metals 2018, 8, 91. https://doi.org/10.3390/met8020091

Zhao Y, Chen D, Li D, Peng J, Yan B. Effect of Carbon Content on the Properties of Iron-Based Powder Metallurgical Parts Produced by the Surface Rolling Process. Metals. 2018; 8(2):91. https://doi.org/10.3390/met8020091

Chicago/Turabian StyleZhao, Yan, Di Chen, Dekai Li, Jingguang Peng, and Biao Yan. 2018. "Effect of Carbon Content on the Properties of Iron-Based Powder Metallurgical Parts Produced by the Surface Rolling Process" Metals 8, no. 2: 91. https://doi.org/10.3390/met8020091