A New Cumulative Fatigue Damage Rule Based on Dynamic Residual S-N Curve and Material Memory Concept

Abstract

:1. Introduction

2. Formulation of the Proposed Model and Commonly Used Cumulative Damage Rules

2.1. Proposed Model

2.2. Typical Cumulative Damage Rules

2.2.1. Palmgren-Miner Rule (Miner Rule for Short)

2.2.2. Corten-Dolan Rule (Corten’s Model for Short)

2.2.3. Kwofie-Rahbar Rule (Kwofie’s Model for Short)

3. Experiments and Discussions

3.1. Two-Stage Fatigue Loading

3.1.1. Results from Manson

3.1.2. Results from Pavlou

3.1.3. Results from Dattoma

3.2. Multi-Stage Fatigue Loading

3.2.1. Results from CFD1 Test

3.2.2. Results from CFD2 Test

- (1)

- In the models, the damage variable can be characterized by a general form available for different loading amplitudes. Fatigue damage is accumulated by adding up the segmental damage caused by each loading stress level. These models are essentially the LDRs, and this makes it convenient to calculate damage and fatigue life, compared with various non-linear theories.

- (2)

- Miner rule defines the damage variable as a life fraction regardless of loading histories accountability, while three typical damage models improve this basic rule by multiplying a load effect coefficient, which tends to consider previous fatigue loadings on damage accumulation.

- (3)

- For constant amplitude loading, the proposed model, Corten’s model, and Kwofie’s model will degenerate to the Miner rule. It can be concluded that the Miner rule forms a particular basis for these linear extensions and should be sufficient to assess fatigue damage under constant amplitude loading because loading history effects can be ignored under such loading condition.

4. Conclusions

- (1)

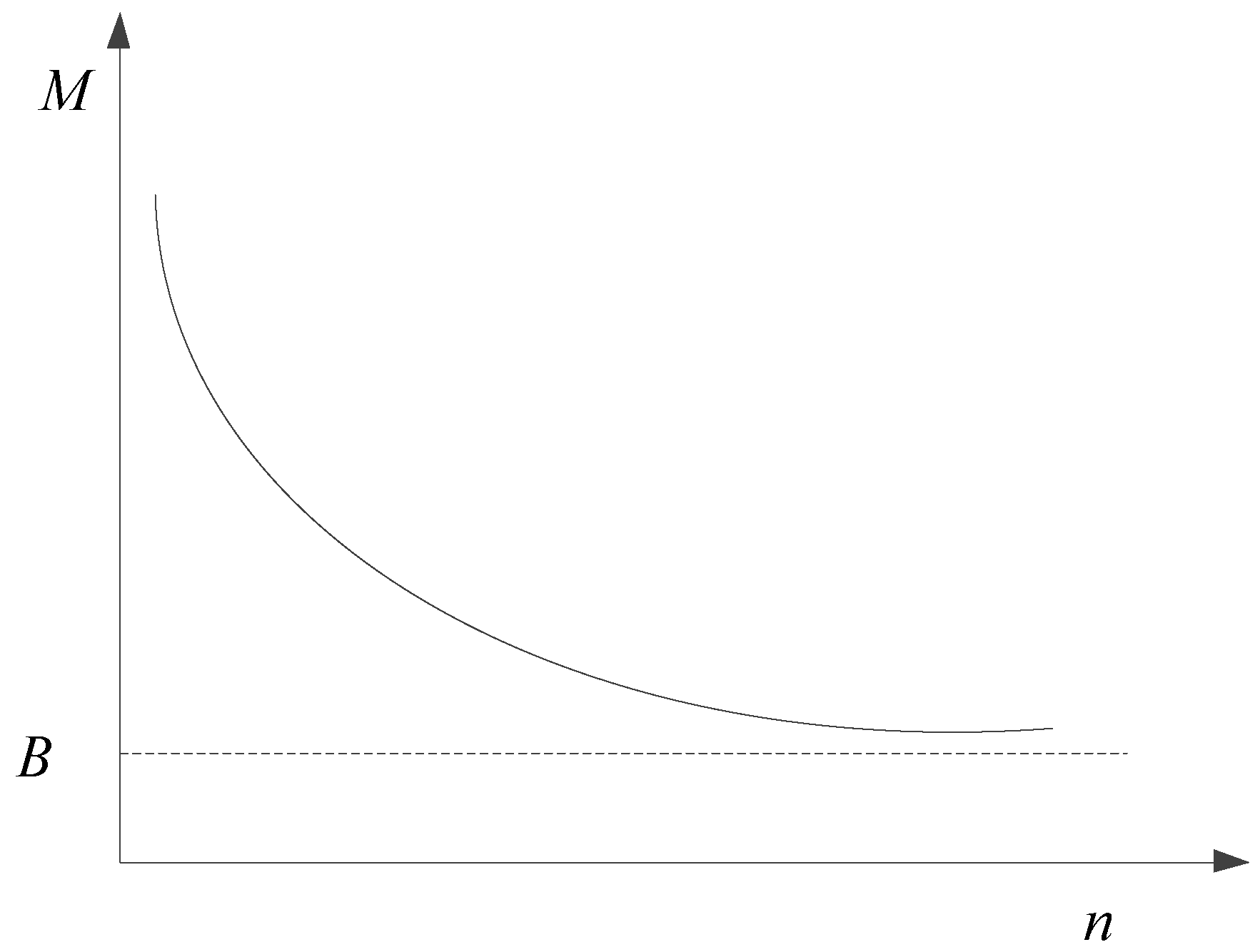

- A phenomenological cumulative damage rule is proposed by incorporating a dynamic residual S-N curve and material memory concept to describe damage accumulation behavior. The model follows a linear trend in accumulating damage and also takes the load-level dependence and loading sequences into account. It predicts the damage and fatigue life with a small amount of data necessary from the conventional S-N curve.

- (2)

- The proposed model is calibrated and verified by a series of non-uniform fatigue loading protocols. Comparing with the commonly used damage rules, the model predicts the cumulative damage closer to unity and more accurate fatigue lives. The present damage formula shows a high sensitivity to the details of previous fatigue loadings with more loading histories for consideration.

- (3)

- Several common characteristics and fundamental properties of the chosen fatigue models are briefly discussed. Miner rule is improved by multiplying a load effect coefficient with respect to previous fatigue loadings for three typical damage models. In particular, the Miner rule is also found to form a general basis for these linear extensions under constant amplitude loadings.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Chaboche, J.L. Continuous damage mechanics—A tool to describe phenomena before crack initiation. Nucl. Eng. Des. 1981, 64, 233–247. [Google Scholar] [CrossRef]

- Lubarda, V.A.; Krajcinovic, D. Damage tensors and the crack density distribution. Int. J. Solids Struct. 1993, 30, 2859–2877. [Google Scholar] [CrossRef]

- Voyiadjis, G.Z.; Kattan, P.I. A comparative study of damage variables in continuum damage mechanics. Int. J. Damage Mech. 2009, 18, 315–340. [Google Scholar] [CrossRef]

- Rejovitzky, E.; Altus, E. On single damage variable models for fatigue. Int. J. Damage Mech. 2013, 22, 268–284. [Google Scholar] [CrossRef]

- Peng, Z.; Huang, H.Z.; Wang, H.K.; Zhu, S.P.; Lv, Z. A new approach to the investigation of load interaction effects and its application in residual fatigue life prediction. Int. J. Damage Mech. 2016, 25, 672–690. [Google Scholar] [CrossRef]

- Hu, D.; Wang, R.; Fan, J.; Shen, X. Probabilistic damage tolerance analysis on turbine disk through experimental data. Eng. Fract. Mech. 2012, 87, 73–82. [Google Scholar] [CrossRef]

- Tanaka, K.; Mura, T. A dislocation model for fatigue crack initiation. J. Appl. Mech. 1981, 48, 97–103. [Google Scholar] [CrossRef]

- Fedelich, B. A stochastic theory for the problem of multiple surface crack coalescence. Int. J. Fract. 1998, 91, 23–45. [Google Scholar] [CrossRef]

- Pavlou, D.G. A phenomenological fatigue damage accumulation rule based on hardness increasing, for the 2024-T42 aluminum. Eng. Struct. 2002, 24, 1363–1368. [Google Scholar] [CrossRef]

- Naderi, M.; Khonsari, M.M. A thermodynamic approach to fatigue damage accumulation under variable loading. Mater. Sci. Eng. A-Struct. 2010, 527, 6133–6139. [Google Scholar] [CrossRef]

- Li, Y.F.; Lv, Z.; Cai, W.; Zhu, S.P.; Huang, H.Z. Fatigue life analysis of turbine disks based on load spectra of aero-engines. Int. J. Turbo Jet-Eng. 2016, 33, 27–33. [Google Scholar] [CrossRef]

- Yu, L.; Chen, H.; Zhou, J.; Yin, H.; Huang, H.Z. Fatigue life prediction of low pressure turbine shaft of turbojet engine. Int. J. Turbo Jet-Eng. 2017, 34, 149–154. [Google Scholar] [CrossRef]

- Hou, S.Q.; Cai, X.J.; Xu, J.Q. A life evaluation formula for high cycle fatigue under uniaxial and multiaxial loadings with mean stresses. Int. J. Mech. Sci. 2015, 93, 229–239. [Google Scholar] [CrossRef]

- Zhang, W.; Zhou, Z.; Zhang, B.; Zhao, S. A phenomenological fatigue life prediction model of glass fiber reinforced polymer composites. Mater. Des. 2015, 66, 77–81. [Google Scholar] [CrossRef]

- Fatemi, A.; Yang, L. Cumulative fatigue damage and life prediction theories: A survey of the state of the art for homogeneous materials. Int. J. Fatigue 1998, 20, 9–34. [Google Scholar] [CrossRef]

- Schijve, J. Fatigue of Structures and Materials; Springer Science & Business Media: Berlin, Germany, 2001. [Google Scholar]

- Miner, M.A. Cumulative damage in fatigue. J. Appl. Mech. 1945, 12, 159–164. [Google Scholar]

- Manson, S.S.; Halford, G.R. Practical implementation of the double linear damage rule and damage curve approach for treating cumulative fatigue damage. Int. J. Fract. 1981, 17, 169–192. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Mahadevan, S. Stochastic fatigue damage modeling under variable amplitude loading. Int. J. Fatigue 2007, 29, 1149–1161. [Google Scholar] [CrossRef]

- Mi, J.; Li, Y.F.; Peng, W.; Huang, H.Z. Reliability analysis of complex multi-state system with common cause failure based on evidential networks. Reliab. Eng. Syst. Saf. 2018, 174, 71–81. [Google Scholar] [CrossRef]

- Li, X.Y.; Huang, H.Z.; Li, Y.F.; Zio, E. Reliability assessment of multi-state phased mission system with non-repairable multi-state components. Appl. Math. Model. 2018, 61, 181–199. [Google Scholar] [CrossRef]

- Huang, H.Z.; Huang, C.G.; Peng, Z.; Li, Y.F.; Yin, H. Fatigue life prediction of fan blade using nominal stress method and cumulative fatigue damage theory. Int. J. Turbo Jet Eng. 2017. [Google Scholar] [CrossRef]

- Lv, Z.; Huang, H.Z.; Zhu, S.P.; Gao, H.; Zuo, F. A modified nonlinear fatigue damage accumulation model. Int. J. Damage Mech. 2015, 24, 168–181. [Google Scholar] [CrossRef]

- Zuo, F.J.; Huang, H.Z.; Zhu, S.P.; Lv, Z.; Gao, H. Fatigue life prediction under variable amplitude loading using a non-linear damage accumulation model. Int. J. Damage Mech. 2015, 24, 767–784. [Google Scholar] [CrossRef]

- Corten, H.T.; Dolan, T.J. Cumulative fatigue damage. In Proceedings of the International Conference on Fatigue of Metals, London, UK, 10–14 September 1956. [Google Scholar]

- Freudenthal, A.M.; Heller, R.A. On stress interaction in fatigue and a cumulative damage rule. J. Aerosp. Sci. 1959, 26, 431–442. [Google Scholar] [CrossRef]

- Subramanyan, S. A cumulative damage rule based on the knee point of the S-N curve. J. Eng. Mater. Technol. 1976, 98, 316–321. [Google Scholar] [CrossRef]

- Hashin, Z.; Rotem, A. A cumulative damage theory of fatigue failure. Mater. Sci. Eng. 1978, 34, 147–160. [Google Scholar] [CrossRef]

- Leipholz, H.H.E. On the modified S-N curve for metal fatigue prediction and its experimental verification. Eng. Fract. Mech. 1986, 23, 495–505. [Google Scholar] [CrossRef]

- EI Aghoury, I.; Galal, K. A fatigue stress-life damage accumulation model for variable amplitude fatigue loading based on virtual target life. Eng. Struct. 2013, 52, 621–628. [Google Scholar] [CrossRef]

- Kwofie, S.; Rahbar, N. A fatigue driving stress approach to damage and life prediction under variable amplitude loading. Int. J. Damage Mech. 2013, 22, 393–404. [Google Scholar] [CrossRef]

- Peng, Z.; Huang, H.Z.; Zhu, S.P.; Gao, H.; Lv, Z. A fatigue driving energy approach to high—cycle fatigue life estimation under variable amplitude loading. Fatigue Fract. Eng. Mater. 2016, 39, 180–193. [Google Scholar] [CrossRef]

- Mesmacque, G.; Garcia, S.; Amrouche, A.; Rubio-Gonzalez, C. Sequential law in multiaxial fatigue, a new damage indicator. Int. J. Fatigue 2005, 27, 461–467. [Google Scholar] [CrossRef]

- Aïd, A.; Amrouche, A.; Bouiadjra, B.B.; Benguediab, M.; Mesmacque, G. Fatigue life prediction under variable loading based on a new damage model. Mater. Des. 2011, 32, 183–191. [Google Scholar] [CrossRef]

- Aid, A.; Bendouba, M.; Aminallah, L.; Amrouche, A.; Benseddiq, N.; Benguediab, M. An equivalent stress process for fatigue life estimation under multiaxial loadings based on a new non linear damage model. Mater. Sci. Eng. A Struct. 2012, 538, 20–27. [Google Scholar] [CrossRef]

- Djebli, A.; Aid, A.; Bendouba, M.; Amrouche, A.; Benguediab, M.; Benseddiq, N. A non-linear energy model of fatigue damage accumulation and its verification for Al-2024 aluminum alloy. Int. J. Nonlinear Mech. 2013, 51, 145–151. [Google Scholar] [CrossRef]

- Benkabouche, S.; Guechichi, H.; Amrouche, A.; Benkhettab, M. A modified nonlinear fatigue damage accumulation model under multiaxial variable amplitude loading. Int. J. Mech. Sci. 2015, 100, 180–194. [Google Scholar] [CrossRef]

- Rege, K.; Pavlou, D.G. A one-parameter nonlinear fatigue damage accumulation model. Int. J. Fatigue 2017, 98, 234–246. [Google Scholar] [CrossRef]

- Pavlou, D.G. The theory of the s-n fatigue damage envelope: Generalization of linear, double-linear, and non-linear fatigue damage models. Int. J. Fatigue 2018, 110, 204–214. [Google Scholar] [CrossRef]

- Böhm, E.; Kurek, M.; Junak, G.; Cieśla, M.; Łagoda, T. Accumulation of fatigue damage using memory of the material. Procedia Mater. Sci. 2014, 3, 2–7. [Google Scholar] [CrossRef]

- Basquin, O.H. The Exponential Law of Endurance Tests; American Society for Testing and Materials: Phildelphia, PA, USA, 1910. [Google Scholar]

- Böhm, E.; Kurek, M.; Łagoda, T. Accumulation of fatigue damages for block-type loads with use of material memory function. In Solid State Phenomena; Trans Tech Publications: Zürich, Switzerland, 2015; Volume 224, pp. 39–44. [Google Scholar]

- Ebbinghaus, H. Memory; Columbia University, Teachers College: New York, NY, USA, 1913. [Google Scholar]

- Richart, F.E.; Newmark, N.M. A Hypothesis for the Determination of Cumulative Damage in Fatigue; American Society for Testing and Materials: Phildelphia, PA, USA, 1948. [Google Scholar]

- Li, M.; Otto, B. Anti-Fatigue Design for Structural Components; China Machine Press: Beijing, China, 1987. [Google Scholar]

- Manson, S.S.; Freche, J.C.; Ensign, C.R. Application of a double linear damage rule to cumulative fatigue. In Fatigue Crack Propagation; ASTM STP 415; American Society for Testing and Materials: Philadelphia, PA, USA, 1967. [Google Scholar]

- Dattoma, V.; Giancane, S.; Nobile, R.; Panella, F.W. Fatigue life prediction under variable loading based on a new non-linear continuum damage mechanics model. Int. J. Fatigue 2006, 28, 89–95. [Google Scholar] [CrossRef]

- Giancane, S.; Nobile, R.; Panella, F.W.; Dattoma, V. Fatigue life prediction of notched components based on a new nonlinear continuum damage mechanics model. Procedia Eng. 2010, 2, 1317–1325. [Google Scholar] [CrossRef]

- Zhou, J.; Huang, H.Z.; Peng, Z. Fatigue life prediction of turbine blades based on modified equivalent strain model. J. Mech. Sci. Technol. 2017, 31, 4203–4213. [Google Scholar] [CrossRef]

- Hu, D.; Ma, Q.; Shang, L.; Gao, Y.; Wang, R. Creep-fatigue behavior of turbine disc of superalloy GH720Li at 650 C and probabilistic creep-fatigue modeling. Mater. Sci. Eng. A-Struct. 2016, 670, 17–25. [Google Scholar] [CrossRef]

- Zheng, B.; Huang, H.Z.; Guo, W.; Li, Y.F.; Mi, J. Fault diagnosis method based on supervised particle swarm optimization classification algorithm. Intell. Data Anal. 2018, 22, 191–210. [Google Scholar] [CrossRef]

- Li, X.Y.; Huang, H.Z.; Li, Y.F. Reliability analysis of phased mission system with non-exponential and partially repairable components. Reliab. Eng. Syst. Saf. 2018, 175, 119–127. [Google Scholar] [CrossRef]

| Stress Amplitude (MPa) | 1372 | 1303 | 1111 | 1095 | 833 | 751 |

| Fatigue Life (Cycles) | 12,000 | 15,925 | 44,000 | 47,625 | 244,000 | 584,740 |

| Experimental Data | Predicted Results Using Different Models | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Miner Rule | Corten’s Model | Kwofie’s Model | Proposed Model | |||||||

| n1 | n2 | Nexp | Npre | ΣDi | Npre | ΣDi | Npre | ΣDi | Npre | ΣDi |

| High-low loading sequence: σ1 = 1111 MPa, σ2 = 833 MPa | ||||||||||

| 11,968 | 49,044 | 61,012 | 128,990 | 0.4730 | 126,630 | 0.4818 | 120,770 | 0.5052 | 93,120 | 0.6552 |

| 16,412 | 33,672 | 50,084 | 98,010 | 0.5110 | 96,870 | 0.5170 | 93,950 | 0.5331 | 72,190 | 0.6938 |

| 24,420 | 21,228 | 45,648 | 71,100 | 0.6420 | 70,680 | 0.6458 | 69,600 | 0.6559 | 54,940 | 0.8309 |

| 31,900 | 9028 | 40,928 | 53,710 | 0.7620 | 53,600 | 0.7636 | 53,300 | 0.7679 | 46,790 | 0.8747 |

| High-low loading sequence: σ1 = 1372 MPa, σ2 = 1111 MPa | ||||||||||

| 960 | 24,684 | 25,644 | 40,010 | 0.6410 | 37,440 | 0.6850 | 35,690 | 0.7186 | 34,800 | 0.7370 |

| 948 | 40,832 | 41,780 | 41,490 | 1.0070 | 38,700 | 1.0797 | 36,800 | 1.1354 | 35,900 | 1.1638 |

| 4944 | 12,364 | 17,308 | 24,980 | 0.6930 | 24,210 | 0.7150 | 23,650 | 0.7319 | 17,760 | 0.9745 |

| 7404 | 8580 | 15,984 | 19,680 | 0.8120 | 19,320 | 0.8273 | 19,050 | 0.8390 | 14,280 | 1.1194 |

| High-low loading sequence: σ1 = 1303 MPa, σ2 = 751 MPa | ||||||||||

| 971 | 367,810 | 368,781 | 534,470 | 0.6900 | 366,470 | 1.0063 | 399,030 | 0.9242 | 391,320 | 0.9424 |

| 1991 | 93,560 | 95,551 | 335,270 | 0.2850 | 261,430 | 0.3655 | 277,280 | 0.3446 | 218,350 | 0.4376 |

| 3790 | 45,610 | 49,400 | 156,330 | 0.3160 | 139,080 | 0.3552 | 143,190 | 0.3450 | 99,020 | 0.4989 |

| 7166 | 19,300 | 26,466 | 54,800 | 0.4830 | 52,970 | 0.4996 | 53,430 | 0.4953 | 37,260 | 0.7104 |

| 10,001 | 18,130 | 28,131 | 42,690 | 0.6590 | 41,700 | 0.6746 | 41,960 | 0.6705 | 26,280 | 1.0704 |

| High-low loading sequence: σ1 = 1095 MPa, σ2 = 751 MPa | ||||||||||

| 3953 | 479,500 | 483,453 | 535,390 | 0.9030 | 398,590 | 1.2129 | 441,950 | 1.0939 | 400,310 | 1.2077 |

| 11,811 | 183,610 | 195,421 | 347,720 | 0.5620 | 287,090 | 0.6807 | 307,700 | 0.6351 | 195,710 | 0.9985 |

| 15,192 | 90,640 | 105,832 | 223,270 | 0.4740 | 198,710 | 0.5326 | 207,470 | 0.5101 | 136,190 | 0.7771 |

| 31,575 | 26,900 | 58,475 | 82,480 | 0.7090 | 80,500 | 0.7264 | 81,250 | 0.7197 | 59,810 | 0.9777 |

| Experimental Data | Predicted Results Using Different Models | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Miner Rule | Corten’s Model | Kwofie’s Model | Proposed Model | |||||||

| n1 | n2 | Nexp | Npre | ΣDi | Npre | ΣDi | Npre | ΣDi | Npre | ΣDi |

| High-low loading sequence: σ1 = 200 MPa, σ2 = 150 MPa | ||||||||||

| 30,000 | 259,100 | 289,100 | 360,020 | 0.8030 | 549,620 | 0.5260 | 337,730 | 0.8560 | 284,830 | 1.0150 |

| 233,400 | 263,400 | 354,510 | 0.7430 | 534,280 | 0.4930 | 333,000 | 0.7910 | 282,010 | 0.9340 | |

| 193,500 | 223,500 | 343,850 | 0.6500 | 504,510 | 0.4430 | 323,910 | 0.6900 | 276,270 | 0.8090 | |

| 60,000 | 90,300 | 150,300 | 246,390 | 0.6100 | 292,410 | 0.5140 | 238,950 | 0.6290 | 196,730 | 0.7640 |

| 98,250 | 158,250 | 251,590 | 0.6290 | 302,000 | 0.5240 | 243,840 | 0.6490 | 198,810 | 0.7960 | |

| 114,600 | 174,600 | 261,770 | 0.6670 | 320,960 | 0.5440 | 253,040 | 0.6900 | 202,550 | 0.8620 | |

| 90,000 | 86,000 | 176,000 | 220,000 | 0.8000 | 248,590 | 0.7080 | 215,160 | 0.8180 | 171,880 | 1.0240 |

| 42,300 | 132,300 | 189,540 | 0.6980 | 202,600 | 0.6530 | 187,130 | 0.7070 | 163,540 | 0.8090 | |

| 99,800 | 189,800 | 228,130 | 0.8320 | 261,790 | 0.7250 | 222,510 | 0.8530 | 173,810 | 1.0920 | |

| Low-high loading sequence: σ1 = 150 MPa, σ2 = 200 MPa | ||||||||||

| 86,000 | 138,000 | 224,000 | 200,000 | 1.1200 | 217,900 | 1.0280 | 214,350 | 1.0450 | 254,550 | 0.8800 |

| 147,000 | 233,000 | 197,460 | 1.1800 | 214,150 | 1.0880 | 211,820 | 1.1000 | 251,890 | 0.9250 | |

| 148,500 | 234,500 | 197,060 | 1.1900 | 213,570 | 1.0980 | 211,260 | 1.1100 | 251,610 | 0.9320 | |

| 172,000 | 138,000 | 310,000 | 234,850 | 1.3200 | 272,890 | 1.1360 | 249,000 | 1.2450 | 332,980 | 0.9310 |

| 139,500 | 311,500 | 234,210 | 1.3300 | 271,820 | 1.1460 | 248,210 | 1.2550 | 332,440 | 0.9370 | |

| 123,000 | 295,000 | 241,800 | 1.2200 | 284,750 | 1.0360 | 255,850 | 1.1530 | 337,920 | 0.8730 | |

| 258,000 | 89,000 | 347,000 | 290,860 | 1.1930 | 378,000 | 0.9180 | 303,060 | 1.1450 | 394,320 | 0.8800 |

| 81,000 | 339,000 | 297,370 | 1.1400 | 392,360 | 0.8640 | 309,310 | 1.0960 | 396,490 | 0.8550 | |

| 75,000 | 333,000 | 302,730 | 1.1000 | 404,130 | 0.8240 | 314,450 | 1.0590 | 398,330 | 0.8360 | |

| Experimental Data | Predicted Results Using Different Models | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Miner Rule | Corten’s Model | Kwofie’s Model | Proposed Model | |||||||

| n1 | n2 | Nexp | Npre | ΣDi | Npre | ΣDi | Npre | ΣDi | Npre | ΣDi |

| High-low loading sequence: σ1 = 485 MPa, σ2 = 400 MPa | ||||||||||

| 13,749 | 51,304 | 65,053 | 108,060 | 0.6020 | 117,190 | 0.5551 | 102,700 | 0.6334 | 87,310 | 0.7451 |

| 27,499 | 45,765 | 73,264 | 90,000 | 0.8140 | 94,880 | 0.7722 | 87,010 | 0.8420 | 68,090 | 1.0760 |

| 41,249 | 16,032 | 57,281 | 66,610 | 0.8600 | 67,760 | 0.8453 | 65,860 | 0.8698 | 57,390 | 0.9981 |

| High-low loading sequence: σ1 = 465 MPa, σ2 = 420 MPa | ||||||||||

| 17,013 | 66,845 | 83,858 | 100,190 | 0.8370 | 105,570 | 0.7943 | 97,040 | 0.8642 | 88,000 | 0.9529 |

| 34,027 | 30,405 | 64,432 | 84,010 | 0.7670 | 86,190 | 0.7476 | 82,670 | 0.7794 | 74,240 | 0.8679 |

| 51,040 | 38,262 | 89,302 | 82,230 | 1.0860 | 84,120 | 1.0616 | 81,070 | 1.1015 | 70,520 | 1.2664 |

| High-low loading sequence: σ1 = 450 MPa, σ2 = 420 MPa | ||||||||||

| 20,082 | 79,372 | 99,454 | 105,020 | 0.9470 | 109,030 | 0.9122 | 102,690 | 0.9685 | 95,860 | 1.0375 |

| 40,165 | 24,711 | 64,876 | 90,480 | 0.7170 | 91,870 | 0.7062 | 89,640 | 0.7237 | 84,300 | 0.7696 |

| 60,248 | 15,943 | 76,191 | 85,610 | 0.8900 | 86,290 | 0.8830 | 85,200 | 0.8943 | 81,290 | 0.9373 |

| Low-high loading sequence: σ1 = 400 MPa, σ2 = 485 MPa | ||||||||||

| 36,440 | 53,348 | 89,788 | 73,600 | 1.2200 | 75,660 | 1.1867 | 78,730 | 1.1405 | 95,550 | 0.9397 |

| 72,870 | 45,373 | 118,243 | 89,240 | 1.3250 | 93,960 | 1.2584 | 94,040 | 1.2574 | 124,490 | 0.9498 |

| 109,310 | 46,693 | 156,003 | 97,560 | 1.5990 | 104,060 | 1.4991 | 102,000 | 1.5294 | 138,500 | 1.1264 |

| Low-high loading sequence: σ1 = 420 MPa, σ2 = 465 MPa | ||||||||||

| 28,469 | 58,594 | 87,063 | 78,360 | 1.1110 | 79,670 | 1.0928 | 81,150 | 1.0729 | 89,840 | 0.9691 |

| 56,938 | 56,416 | 113,354 | 85,290 | 1.3290 | 87,690 | 1.2926 | 87,710 | 1.2923 | 102,890 | 1.1017 |

| 85,407 | 48,998 | 134,405 | 91,430 | 1.4700 | 94,960 | 1.4154 | 93,450 | 1.4382 | 110,300 | 1.2185 |

| Low-high loading sequence: σ1 = 420 MPa, σ2 = 450 MPa | ||||||||||

| 28,469 | 70,530 | 98,999 | 87,770 | 1.1280 | 88,750 | 1.1155 | 89,860 | 1.1017 | 96,390 | 1.0271 |

| 56,938 | 39,362 | 96,300 | 97,270 | 0.9900 | 99,790 | 0.9650 | 98,740 | 0.9753 | 107,680 | 0.8943 |

| 85,407 | 10,523 | 95,930 | 108,890 | 0.8810 | 113,720 | 0.8436 | 109,370 | 0.8771 | 113,140 | 0.8479 |

| Stress Level | Stress Amplitude, σi (MPa) | ni (Cycles) | Nfi (Cycles) | Segmental Damage Caused by Each Stress Level | |||

|---|---|---|---|---|---|---|---|

| Miner Rule | Corten’s Model | Kwofie’s Model | Proposed Model | ||||

| 1 | 505 | 4 | 9.00 × 103 | 0.0004 | 0.0004 | 0.0004 | 0.0004 |

| 2 | 475 | 32 | 1.16 × 104 | 0.0028 | 0.0025 | 0.0029 | 0.0028 |

| 3 | 423 | 560 | 2.10 × 104 | 0.0267 | 0.0223 | 0.0292 | 0.0268 |

| 4 | 362 | 5440 | 4.70 × 104 | 0.1158 | 0.0877 | 0.1368 | 0.1206 |

| 5 | 287 | 40,000 | 1.55 × 105 | 0.2580 | 0.1676 | 0.3387 | 0.3458 |

| 6 | 212 | 184,000 | 8.70 × 105 | 0.2110 | 0.1328 | 0.3169 | 0.6645 |

| 7 | 137 | 560,000 | ∞ | 0 | 0 | 0 | 0 |

| 8 | 63 | 1,210,000 | ∞ | 0 | 0 | 0 | 0 |

| Prediction Performance | Experimetal Result | Miner Rule | Corten’s Model | Kwofie’s Model | Proposed Model |

|---|---|---|---|---|---|

| 1 | 0.6147 | 0.4133 | 0.8249 | 1.1609 | |

| Predicted fatigue life Npre (cycles) | 2.00 × 106 | 3.25 × 106 | 4.84 × 106 | 2.42 × 106 | 1.72 × 106 |

| Relative forecast error δ (%) | — | 62.50 | 142.00 | 21.00 | 14.00 |

| Stress Level | Stress Amplitude, σi (MPa) | ni (cycles) | Nfi (cycles) | Segmental Damage Caused by Each Stress Level | |||

|---|---|---|---|---|---|---|---|

| Miner Rule | Corten’s Model | Kwofie’s Model | Proposed Model | ||||

| 1 | 350 | 44 | 5.60 × 104 | 0.0008 | 0.0008 | 0.0008 | 0.0008 |

| 2 | 332 | 352 | 7.40 × 104 | 0.0047 | 0.0046 | 0.0048 | 0.0047 |

| 3 | 298 | 6160 | 1.30 × 105 | 0.0475 | 0.0434 | 0.0512 | 0.0477 |

| 4 | 254 | 59,840 | 2.80 × 105 | 0.2140 | 0.1667 | 0.2455 | 0.2290 |

| 5 | 201 | 440,000 | 1.25 × 106 | 0.3520 | 0.3149 | 0.4520 | 0.6468 |

| 6 | 149 | 2,024,000 | ∞ | 0 | 0 | 0 | 0 |

| 7 | 96 | 6,160,000 | ∞ | 0 | 0 | 0 | 0 |

| 8 | 44 | 13,310,000 | ∞ | 0 | 0 | 0 | 0 |

| Prediction Performance | Experimetal Result | Miner Rule | Corten’s Model | Kwofie’s Model | Proposed Model |

|---|---|---|---|---|---|

| 1 | 0.6190 | 0.6631 | 0.7543 | 0.9290 | |

| Predicted fatigue life Npre (cycles) | 2.20 × 107 | 3.55 × 107 | 3.32 × 107 | 2.92 × 107 | 2.37 × 107 |

| Relative forecast error δ (%) | — | 61.36 | 50.91 | 32.73 | 7.73 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, Z.; Huang, H.-Z.; Zhou, J.; Li, Y.-F. A New Cumulative Fatigue Damage Rule Based on Dynamic Residual S-N Curve and Material Memory Concept. Metals 2018, 8, 456. https://doi.org/10.3390/met8060456

Peng Z, Huang H-Z, Zhou J, Li Y-F. A New Cumulative Fatigue Damage Rule Based on Dynamic Residual S-N Curve and Material Memory Concept. Metals. 2018; 8(6):456. https://doi.org/10.3390/met8060456

Chicago/Turabian StylePeng, Zhaochun, Hong-Zhong Huang, Jie Zhou, and Yan-Feng Li. 2018. "A New Cumulative Fatigue Damage Rule Based on Dynamic Residual S-N Curve and Material Memory Concept" Metals 8, no. 6: 456. https://doi.org/10.3390/met8060456