Influence of Ultrafine Particles on Structure, Mechanical Properties, and Strengthening of Ductile Cast Iron

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Mechanism of Interaction of Modifying Mixture with Ductile Cast Iron Melt

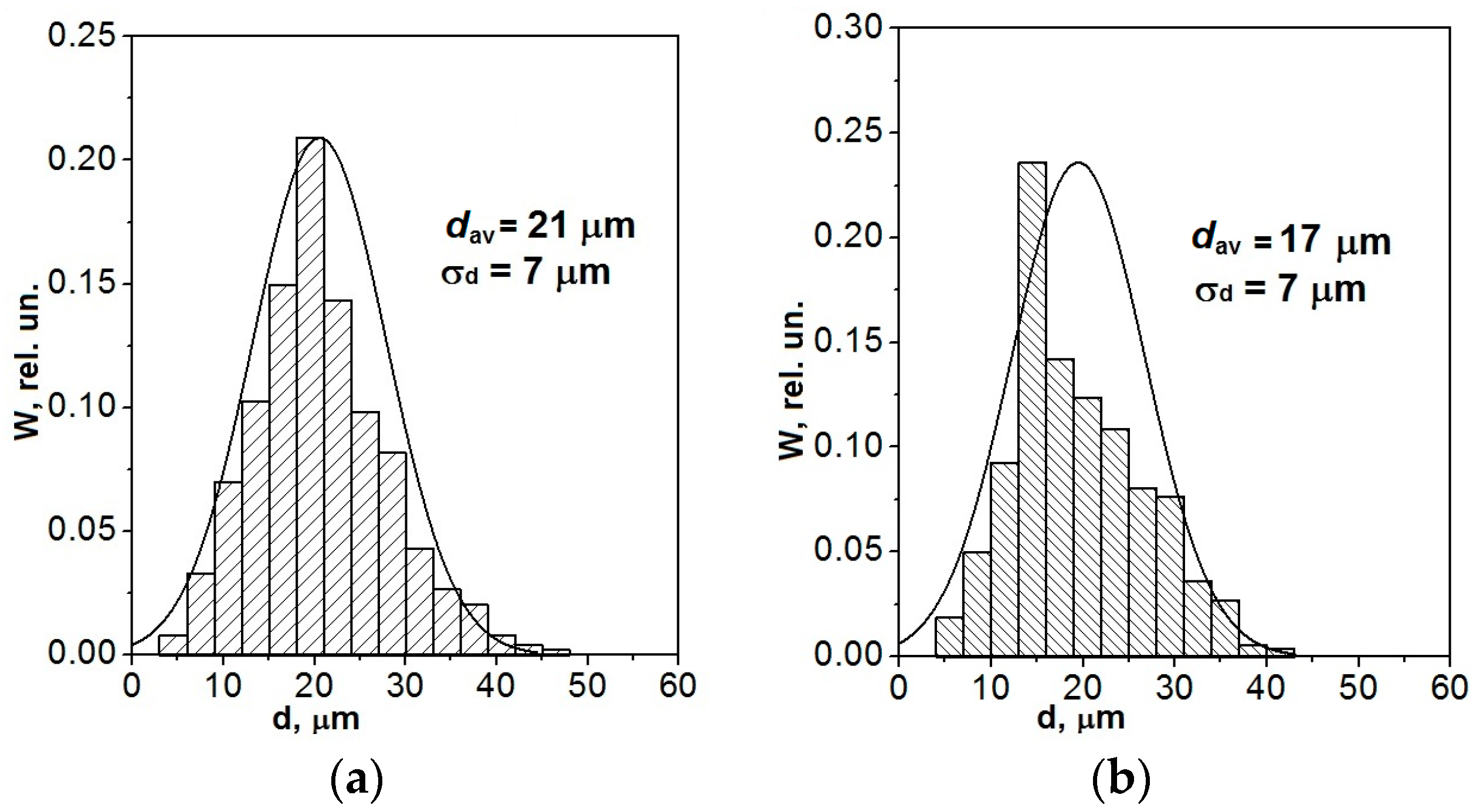

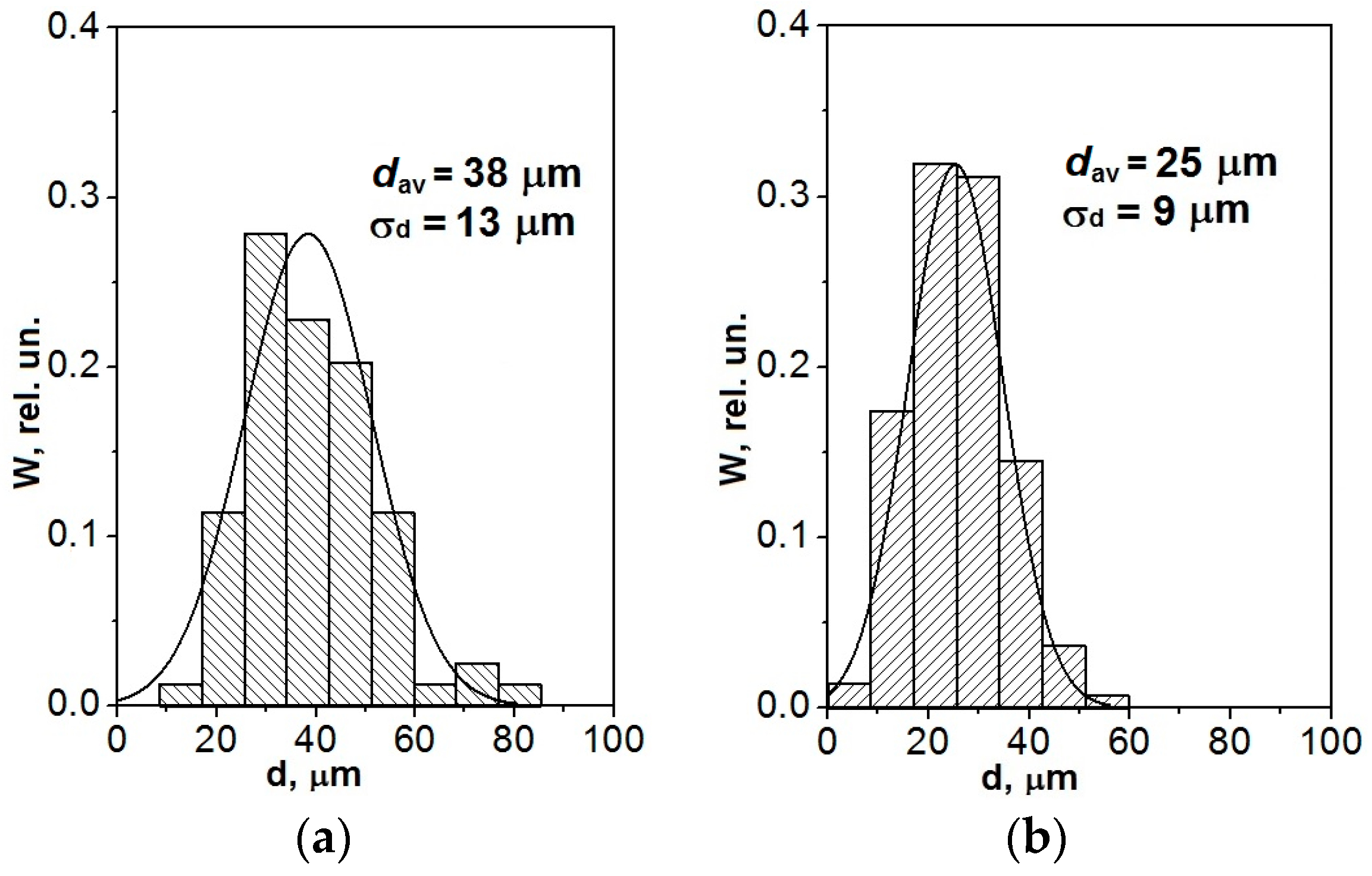

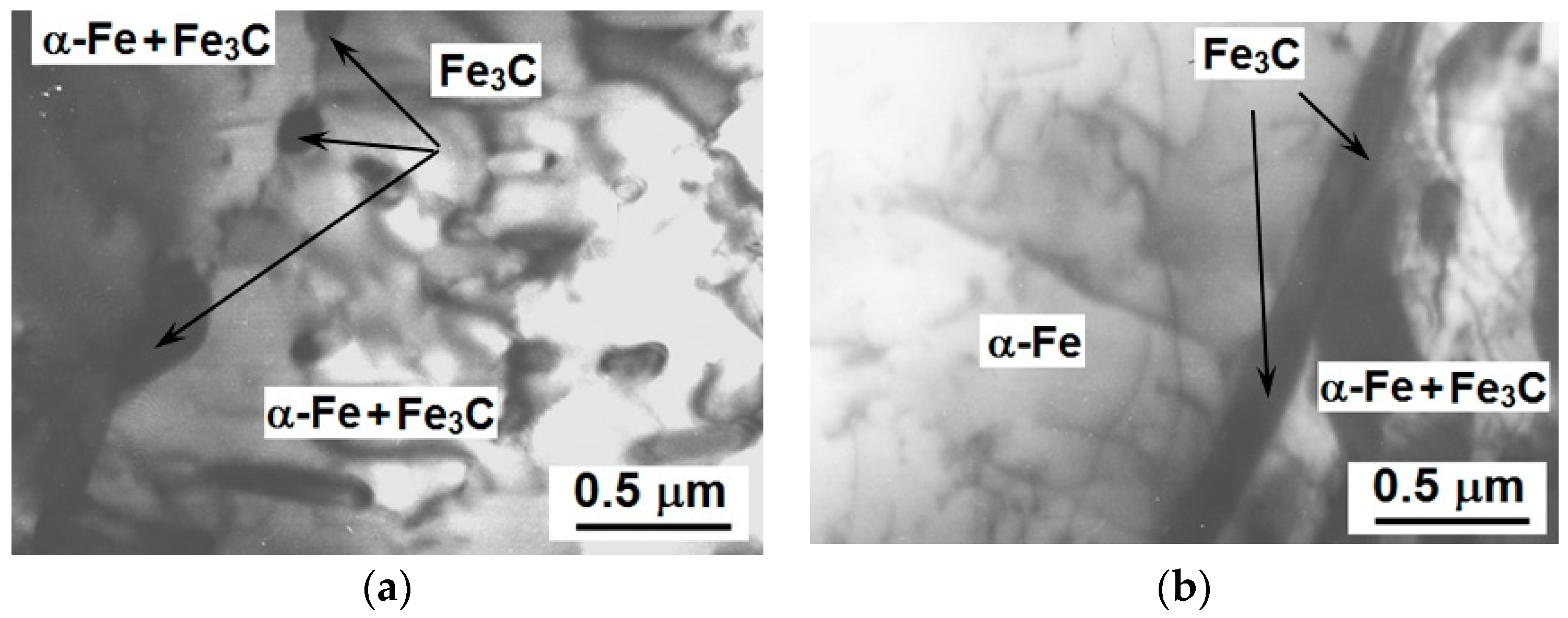

3.2. Influence of Modifying Mixture on Microstructure of Ductile Cast Iron

3.3. Influence of Modifying Mixture on Mechanical Properties and Strengthening of Ductile Cast Iron

3.4. Contribution of Physical Mechanisms to Yield Stress

4. Conclusions

- It has been demonstrated that the change of crystallisation conditions of ductile cast iron after MM introduction results in: (1) an increase of the volume fraction of ferrite by 19% and graphite rosettes by 2%; (2) a 1.5-fold reduction of the average grain size of the ferrite-perlite matrix; (3) an increase in dispersity of the ferrite-cementite structure of perlite grains; (4) a 1.5-fold increase of a number of graphite rosettes.

- It has been established that the changes in the structure of ductile cast irons after the MM introduction have led to a decrease of tensile strength by 160 MPa and to an increase of wear resistance by ~10%; at the same time, density, plasticity, and hardness of samples of ductile cast irons remain unchanged.

- A quantitative assessment of contributions of mechanisms of ductile cast iron strengthening has been made. The reduction of the yield point of ductile cast iron after the MM introduction occurs owing to the reduction of the following contributions: (1) solid-solution strengthening owing to the lowering of the Si content by 0.2 mass. %; (2) substructural strengthening owing to a two-time reduction of dislocations density; (3) perlite strengthening owing to a decrease of the volume fraction of perlite by 19%. In all probability, the retention of the plasticity of the modified alloy is connected with interference of two opposite mechanisms: a plasticity increase owing to the increase of ferrite areas around graphite impurities, and a plasticity reduction owing to a 1.5-fold increase in a number of graphite rosettes being potential spots of initiation and propagation of cracks.

Author Contributions

Funding

Conflicts of Interest

References

- Kalinin, V.T.; Hrychikov, V.E.; Krivosheev, V.A.; Menyailo, E.V. Theory and practice of modifying iron ultra- and nanodispersed materials. Metall. Min. Ind. 2010, 2, 341–347. [Google Scholar]

- Hou, Y.; Wang, Y.; Pan, Z.; Yu, L. Influence of rare earth nanoparticles and inoculants on performance and microstructure of high chromium cast iron. J. Rare Earths 2012, 30, 283–288. [Google Scholar] [CrossRef]

- Saburov, V.P. Suspension modifying of steels and alloys with ultradispersed powders. Liteinoe Proizv. 1991, 4, 14–19. [Google Scholar]

- Ferro, P.; Fabrizi, A.; Cervo, R.; Carollo, C. Effect of inoculant containing rare earth metals and bismuth on microstructure and mechanical properties of heavy-section near-eutectic ductile iron castings. J. Mater. Process. Technol. 2013, 213, 1601–1608. [Google Scholar] [CrossRef]

- Chung, R.J.; Tang, X.; Li, D.Y.; Hinckley, B.; Dolman, K. Effects of titanium addition on microstructure and wear resistance of hypereutectic high chromium cast iron Fe–25wt.%Cr–4wt.%C. Wear 2009, 267, 356–361. [Google Scholar] [CrossRef]

- Opsen, S.O.; Scaland, T.; Hartung, K. Modification of grey and high-strength cast irons. Comparison of crystallisation centres of graphite and some practical recommendations on modification. Liteyshchik Rossii 2011, 2, 29–34. [Google Scholar]

- Kopycinski, D. Inoculation of chromium white cast iron. Arch. Foundry Eng. 2009, 9, 191–194. [Google Scholar]

- Venkatraman, M.; Neumann, J.P. The Cr-C System. Bull. Alloy Ph. Diagr. 1990, 11, 152–164. [Google Scholar] [CrossRef]

- Zhi, X.H.; Xing, J.D.; Fu, H.G.; Xiao, B. Effect of niobium on the as-cast microstructure of hypereutectic high chromium cast iron. Mater. Lett. 2008, 62, 857–860. [Google Scholar] [CrossRef]

- Collini, L.; Nicoletto, G.; Konecna, R. Microstructure and mechanical properties of pearlitic gray cast iron. Mater. Sci. Eng. A 2008, 488, 529–539. [Google Scholar] [CrossRef]

- Borse, S.C.; Mangulkar, Y.E. Review on grey cast iron inoculation. Int. J. Innov. Res. Sci. 2004, 3, 30–36. [Google Scholar]

- Olsen, S.O.; Skaland, T.; Hartung, C. Inoculation of grey and ductile iron a comparison of nucleation sites and some practical advises. In Proceedings of the 66th World Foundry Congress, Istanbul, Turkey, 6–9 September 2004; Volume 1, p. 12. [Google Scholar]

- Cho, G.S.; Choe, K.H.; Lee, K.W.; Ikenaga, A. Effects of alloying elements on the microstructures and mechanical properties of heavy section ductile cast iron. J. Mater. Sci. Technol. 2007, 23, 97–101. [Google Scholar]

- Alasoluyi, J.O.; Omotoyinbo, J.A.; Olusunle, S.O.O.; Adewoye, O.O. Investigation of the mechanical properties of ductile iron produced from hybrid inoculants using rotary furnace. Int. J. Sci. Technol. 2013, 2, 388–393. [Google Scholar]

- Yamane, K.; Yasuda, H.; Sugiyama, A.; Nagira, T.; Yoshiya, M.; Morishita, K.; Uesugi, K.; Takeuchi, A.; Suzuki, Y. Influence of Mg on solidification of hypereutectic cast iron: X-ray radiography study. Metall. Mater. Trans. A 2015, 46, 4937–4946. [Google Scholar] [CrossRef]

- Dasgupta, R.K.; Mondal, D.K.; Chakrabarti, A.K. Evolution of microstructures during austempering of ductile irons alloyed with manganese and copper. Metall. Mater. Trans. A 2013, 44, 1376–1387. [Google Scholar] [CrossRef]

- Kovalevich, E.V. Methods of cast iron inoculation to produce globular shape of graphite. Liteynoye Proizv. 2006, 4, 2–5. [Google Scholar]

- Anikin, A.A.; Venig, S.B.; Bilenko, D.I.; Gribov, A.N.; Zhukov, A.G. Globular graphite: Structure, composition. Met. Sci. Heat Treat. 2014, 56, 113–117. [Google Scholar] [CrossRef]

- Larrañaga, P.; Asenjo, I.; Sertucha, J.; Suarez, R.; Ferrer, I.; Lacaze, J. Effect of antimony and cerium on the formation of chunky graphite during Solidification of heavy-section castings of near-eutectic spheroidal graphite irons. Metall. Mater. Trans. A 2009, 40, 654–661. [Google Scholar] [CrossRef] [Green Version]

- Bedolla-Jacuinde, A.; Solis, E.; Hernandez, B. Effect of niobium in medium alloyed ductile cast irons. Int. J. Cast Met. Res. 2003, 16, 3–9. [Google Scholar] [CrossRef]

- Konca, E.; Tur, K.; Koc, E. Effects of alloying elements (Mo, Ni, and Cu) on the austemperability of GGG-60 ductile cast iron. Metals 2017, 7, 320. [Google Scholar] [CrossRef]

- Song, L.; Guo, E.; Wang, L.; Liu, D. Effects of silicon on mechanical properties and fracture toughness of heavy-section ductile cast iron. Metals 2015, 5, 150–161. [Google Scholar] [CrossRef]

- Sluzov, A.; Sedunov, V.; Korovin, V.; Leushin, I. Improvement of the process of modifying high-strength cast iron. Liteyshchik Rossii 2015, 7, 9–12. [Google Scholar]

- Shen, X.P.; Harris, S.J.; Noble, B. Influence of small vanadium and cobalt additions on microstructure and properties of ductile iron. J. Mater. Sci. Technol. 1995, 11, 893–900. [Google Scholar] [CrossRef]

- Minkoff, I. The Physical Metallurgy of Cast Iron; John Wiley Sons Ltd.: Hoboken, NJ, USA, 1983; p. 318. [Google Scholar]

- Petrov, V.A. Fluorinated Heterocyclic Compounds: Synthesis, Chemistry, and Applications; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2009; p. 533. [Google Scholar]

- Zykova, A.P.; Kurzina, I.A.; Lychagin, D.V.; Chumaevsky, A.V.; Kachaev, A.A.; Bataev, V.A. Structural state, phase composition and mechanical properties of wear-resistant cast iron modified by ultrafine powders. Adv. Mater. Res. 2014, 872, 84–88. [Google Scholar]

- Zykova, A.P.; Lychagin, D.V.; Chumaevsky, A.V.; Kurzina, I.A.; Novomeysky, M.Y. Influence of modifying of cast iron SCH25 (russian grade) with ultrafine powders of refractory metal oxide and cryolite on structure, mechanical properties and fracture. Izvestiya Vysshikh Uchebnykh Zavedenij. Chernaya Metallurgiya 2014, 57, 37–42. [Google Scholar] [CrossRef]

- Zykova, A.P.; Popova, N.A.; Kurzina, I.A. Influence of ultradispersed powders TiO2, ZrO2 and cryolithe for the strengthening of SCH25. Russ. J. Bas. Probl. Mater. Sci. 2016, 13, 204–209. [Google Scholar]

- Zykova, A.P.; Popova, N.A.; Nikonenko, E.L.; Kurzina, I.A. Effect of ultradisperse TiO2, ZrO2, and cryolite powders on high-chromium cast iron hardening. Bull. Russ. Acad. Sci. Phys. 2017, 80, 1317–1321. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H.; Honeycombe, R.W.K. Steels: Microstructure and Properties. Textbook, 3rd ed.; Butterworth-Heinemann: Oxford, UK, 2006; p. 360. [Google Scholar]

- Goldstein, M.I.; Farber, V.M. Dispersion Steel Strengthening; Metallurgy: Moscow, Russia, 1979; p. 208. [Google Scholar]

- Koneva, N.A.; Kozlov, E.V. Regularities of substructural strengthening. Sov. Phys. J. 1991, 34, 224–236. [Google Scholar] [CrossRef]

- Tushinskii, L.I.; Bataev, A.A. Substructural strengthening of steel. Sov. Phys. J. 1991, 34, 237–243. [Google Scholar] [CrossRef]

- Lin, D.M. Mechanical Properties of Metals; Metallurgy: Moscow, Russia, 1965; p. 618. [Google Scholar]

| Ductile Cast Iron | C | Si | Mn | Ni | Mo | Cr | P | Ca | Al | S | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Unmodified | 3.4 | 1.8 | 0.1 | 0.7 | 0.2 | 0.03 | 0.01 | 0.4 | 0.02 | 0.01 | Bal. |

| Modified | 3.4 | 1.6 | 0.1 | 0.8 | 0.2 | 0.03 | 0.01 | 0.4 | 0.02 | 0.01 | Bal. |

| Ductile Cast Iron | σ0,2, MPa | σB, MPa | δ, % | ΔεIII, % | ΔεIV, % | σIV, MPa | ΘIV, MPa |

|---|---|---|---|---|---|---|---|

| Unmodified | 450 | 1780 | 39.0 | 6.0 | 33 | 1030 | 2300 |

| Modified | 410 | 1620 | 39.5 | 6.5 | 33 | 880 | 2200 |

| Ductile Cast Iron | Scalar Density of Dislocations, ρ × 10−10 cm−2 | Δσd, MPa | Scalar Density of Dislocations on Average throughout Matrix, ρ × 10−10 cm−2 | Δσd on Average throughout Matrix, MPa | ||

|---|---|---|---|---|---|---|

| F | P | F | P | |||

| Unmodified | 1.0 | 1.2 | 55 | 64 | 1.1 | 60 |

| Modified | 0.5 | 0.6 | 38 | 43 | 0.55 | 41 |

| Ductile Cast Iron | σ0,2, MPa | σB, MPa | Δσ0, MPa | Δσsol.s, MPa | Δσd, MPa | ΔσP, MPa | Δσg, MPa | Δσy Considering PF and PP, MPa | Δσy, MPa | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| F | P | F | P | ||||||||

| Unmodified | 450 | 1780 | 30 | 192 | 55 | 64 | 120 | 107 | 19 | 349 | 475 |

| Modified | 410 | 1620 | 30 | 176 | 38 | 43 | 140 | 120 | 59 | 261 | 440 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zykova, A.; Lychagin, D.; Chumaevsky, A.; Popova, N.; Kurzina, I. Influence of Ultrafine Particles on Structure, Mechanical Properties, and Strengthening of Ductile Cast Iron. Metals 2018, 8, 559. https://doi.org/10.3390/met8070559

Zykova A, Lychagin D, Chumaevsky A, Popova N, Kurzina I. Influence of Ultrafine Particles on Structure, Mechanical Properties, and Strengthening of Ductile Cast Iron. Metals. 2018; 8(7):559. https://doi.org/10.3390/met8070559

Chicago/Turabian StyleZykova, Anna, Dmitry Lychagin, Andrey Chumaevsky, Natalya Popova, and Irina Kurzina. 2018. "Influence of Ultrafine Particles on Structure, Mechanical Properties, and Strengthening of Ductile Cast Iron" Metals 8, no. 7: 559. https://doi.org/10.3390/met8070559