Integrated Lighting Efficiency Analysis in Large Industrial Buildings to Enhance Indoor Environmental Quality

Abstract

:1. Introduction

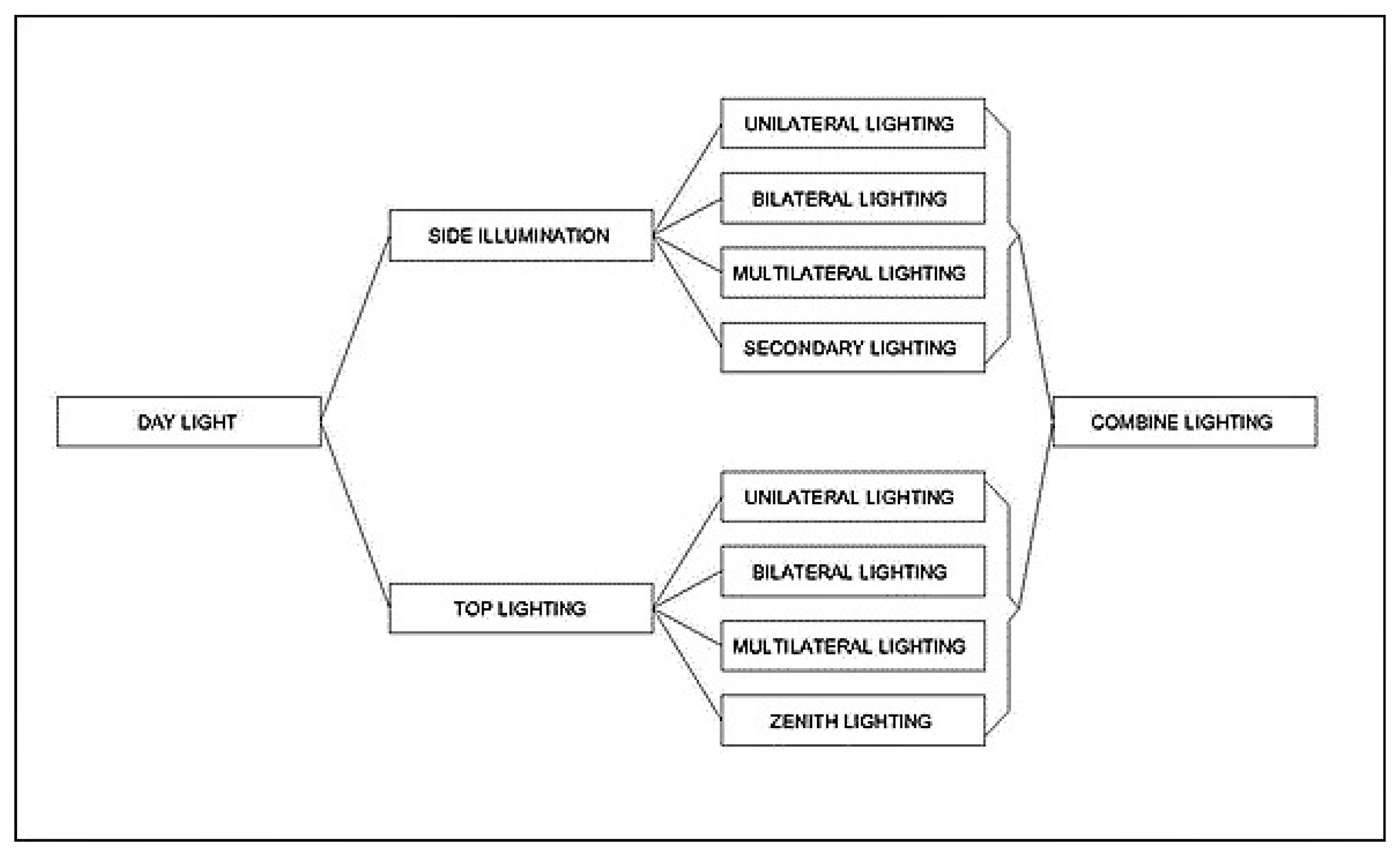

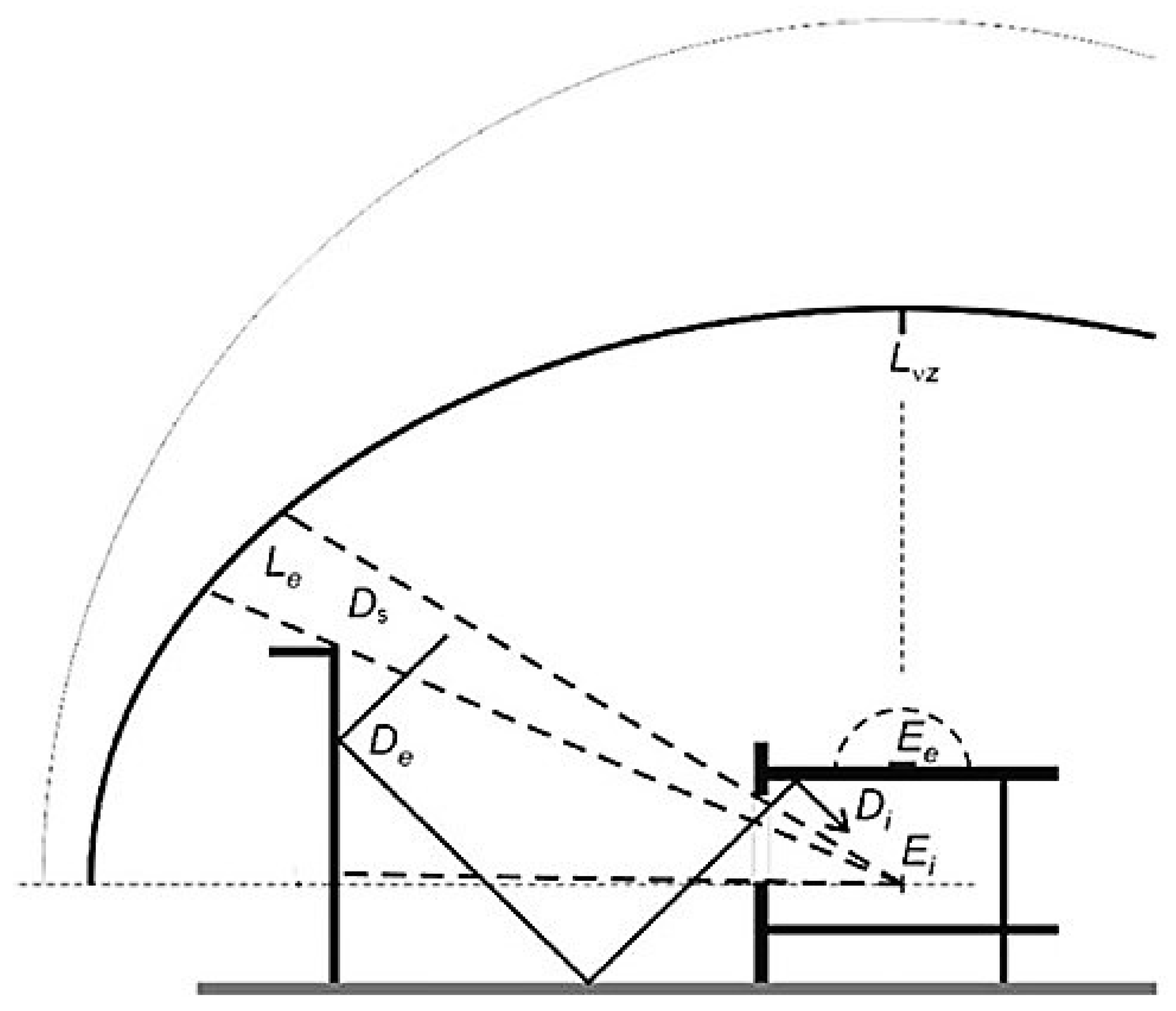

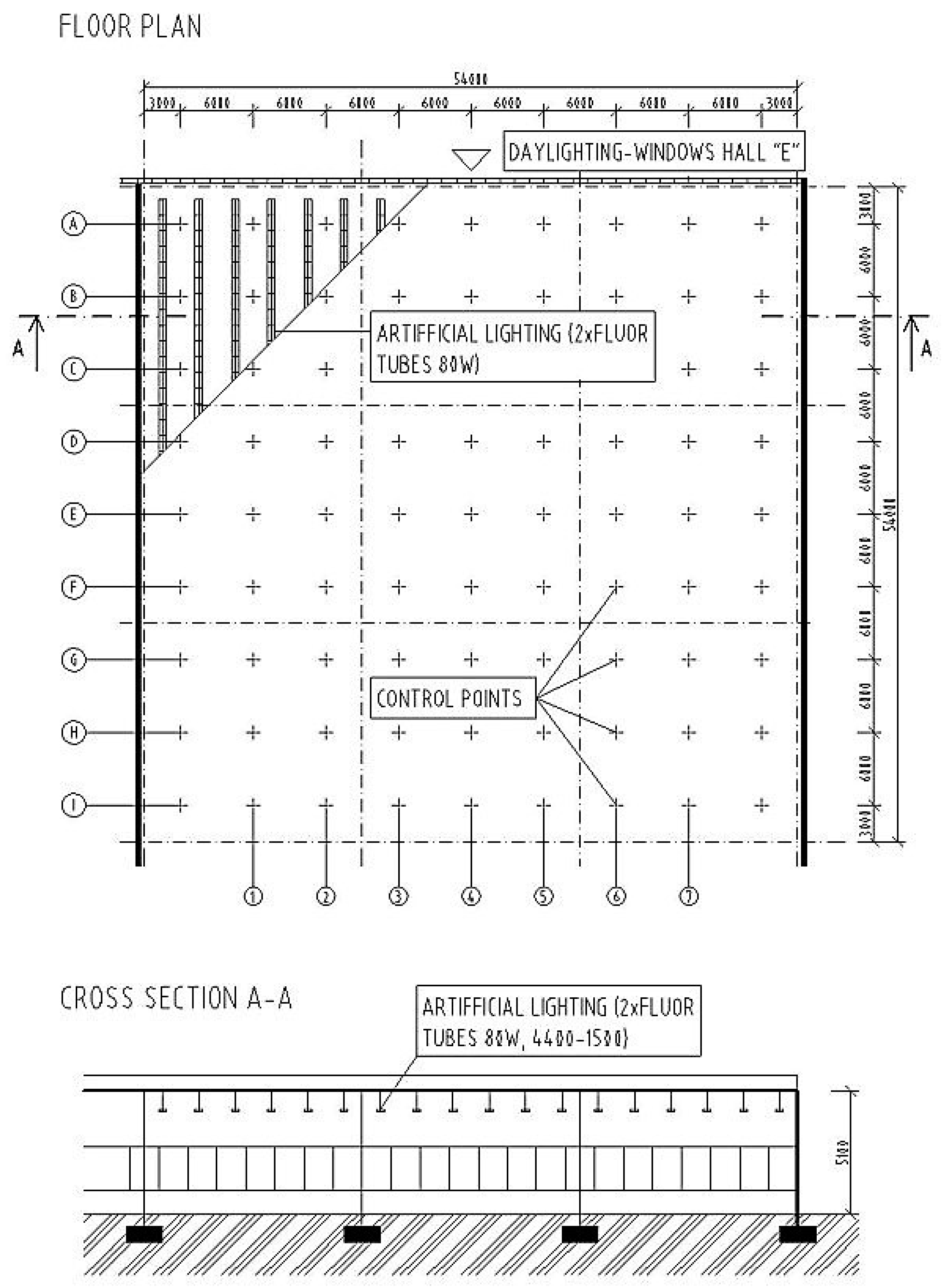

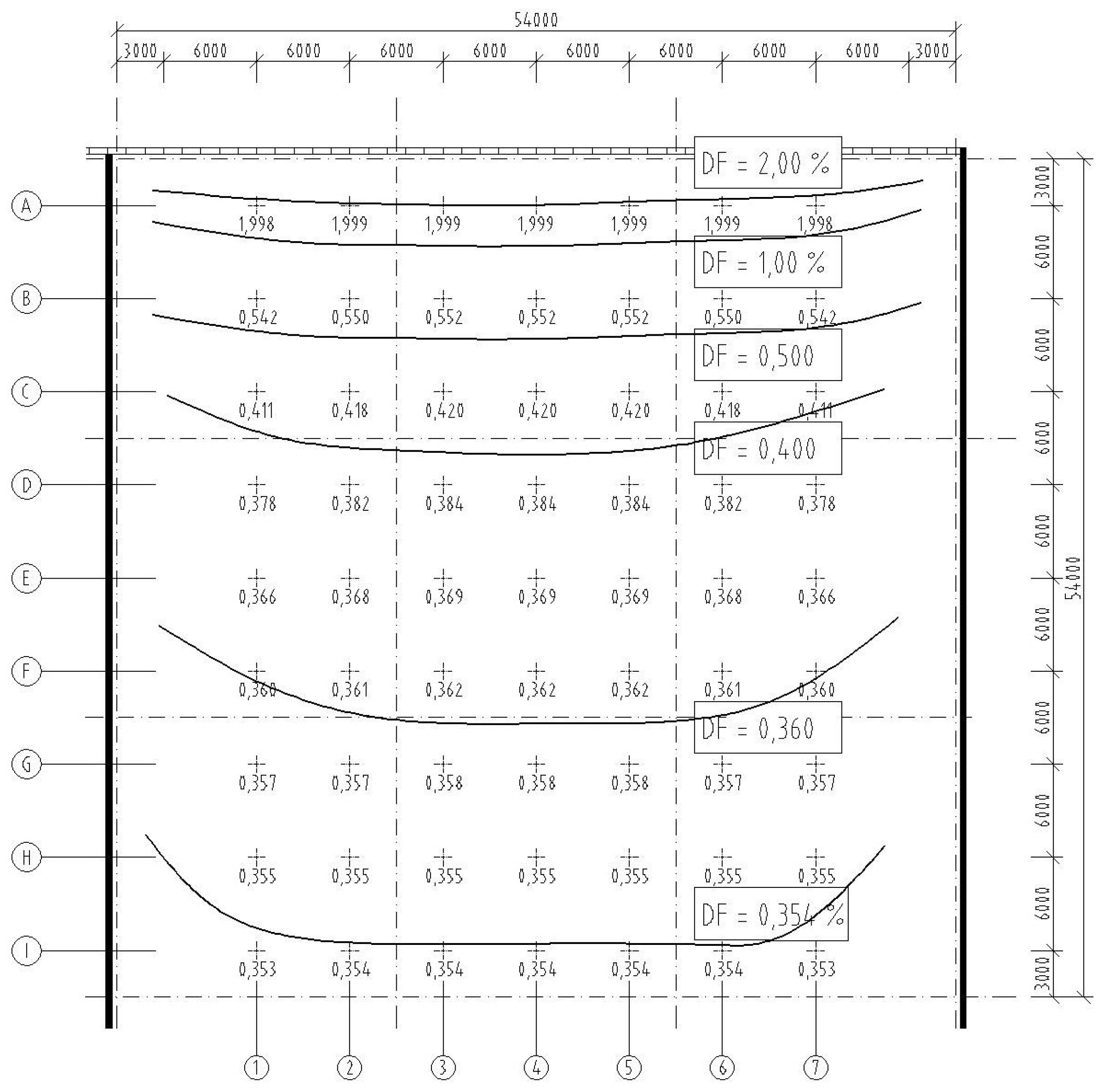

2. Design and Evaluation of Daylight in Manufacturing Hall

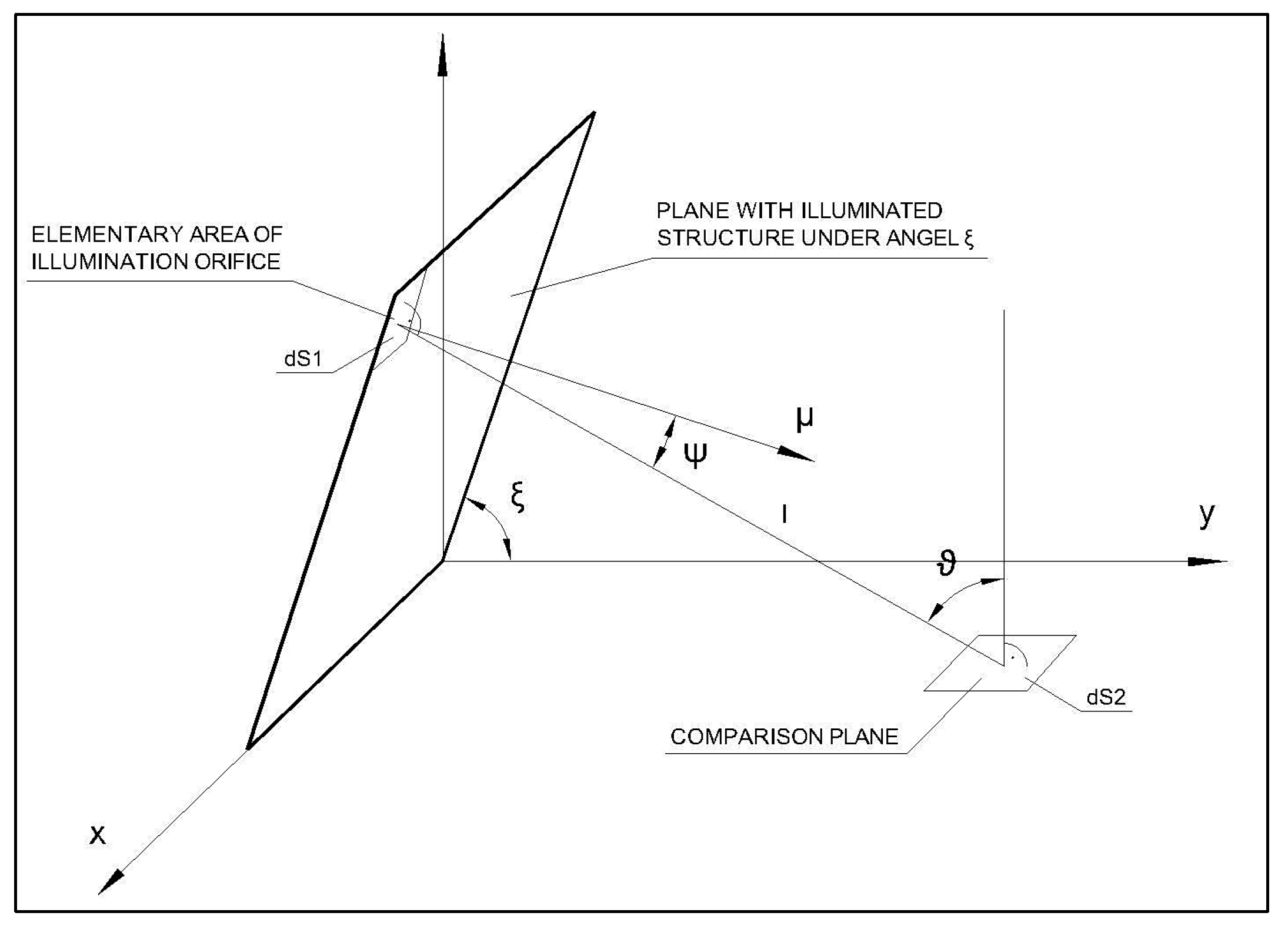

3. Evaluation and Computational Methods

- τn: Normal light transmittance (τn is substituted by τn,dif),

- ψ: Angle of deviation of light beam from windows plane (degrees),

- υ: Angle of incidence of light beam in the examination plane (degrees),

- l: Distance of examination point from elementary area dSt of elimination orifice (m),

- S: Window surface area (m2).

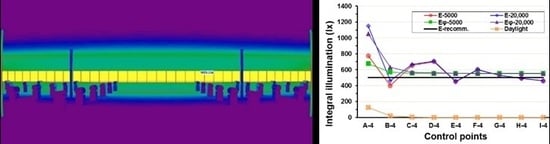

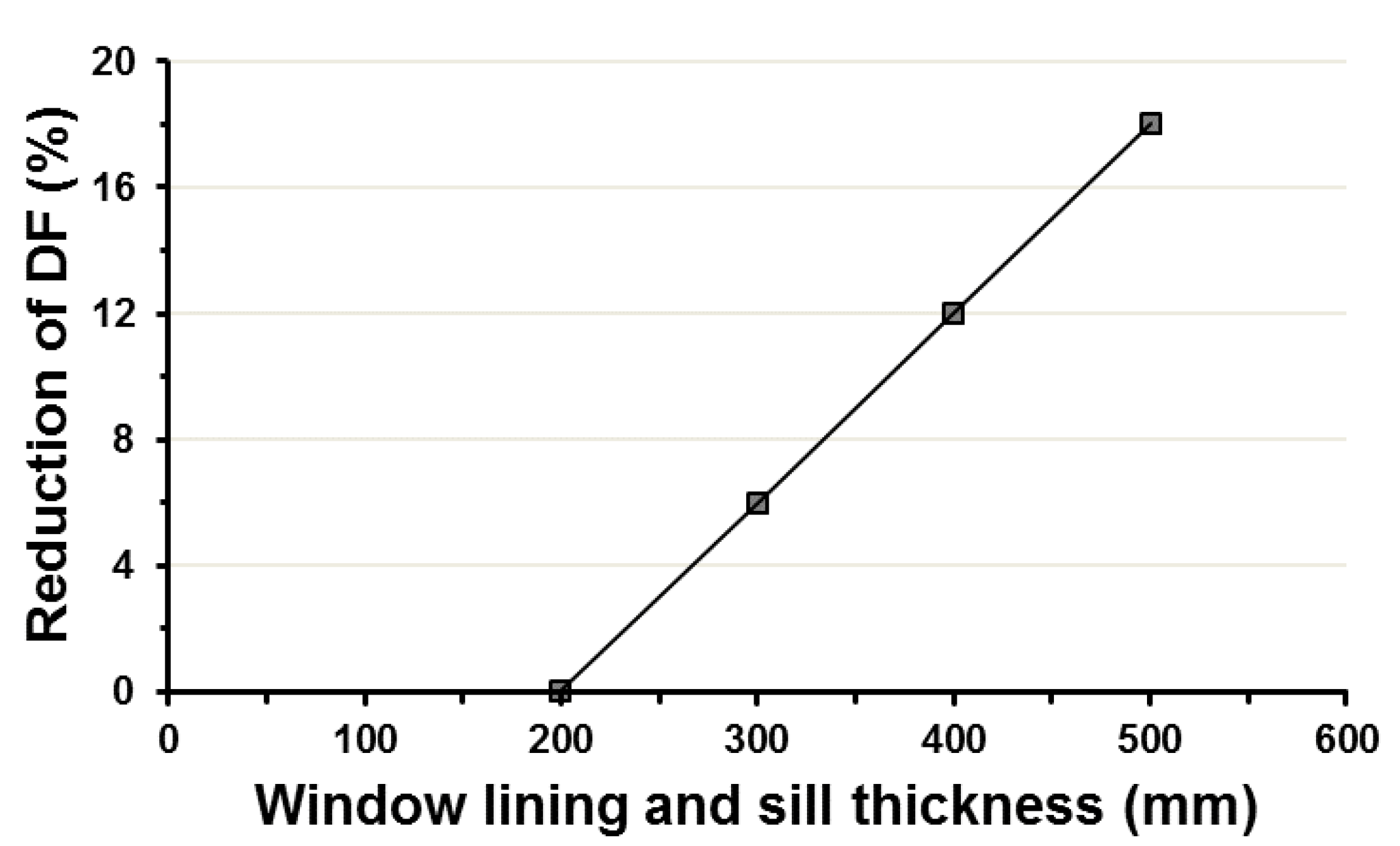

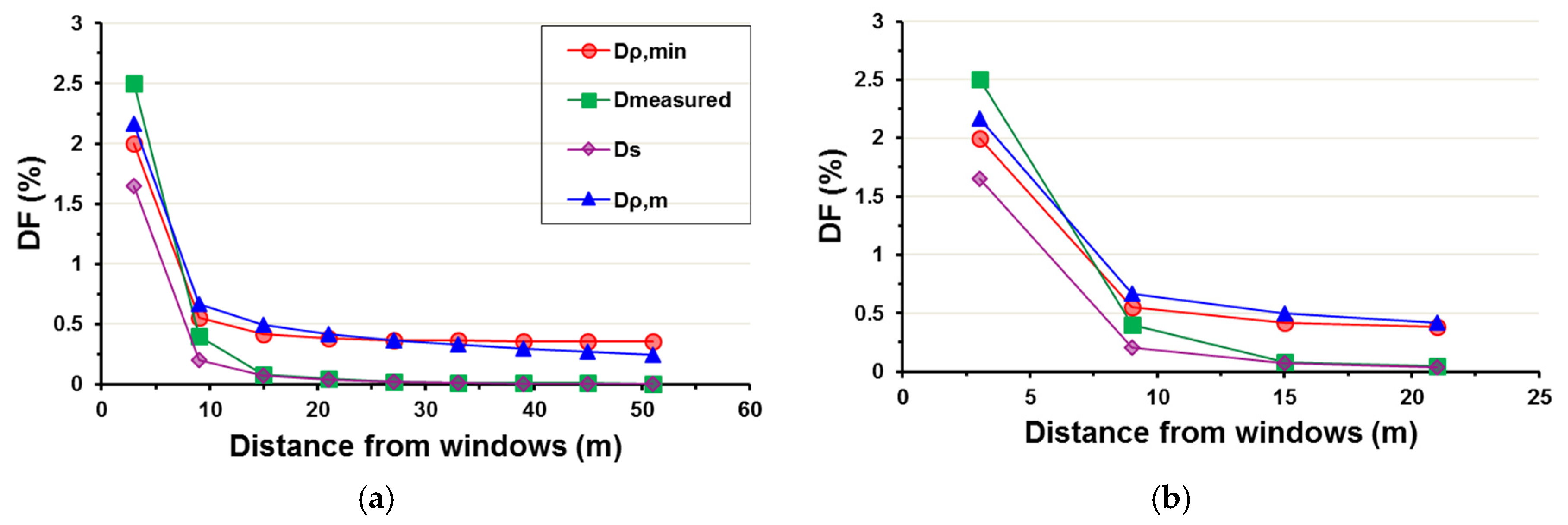

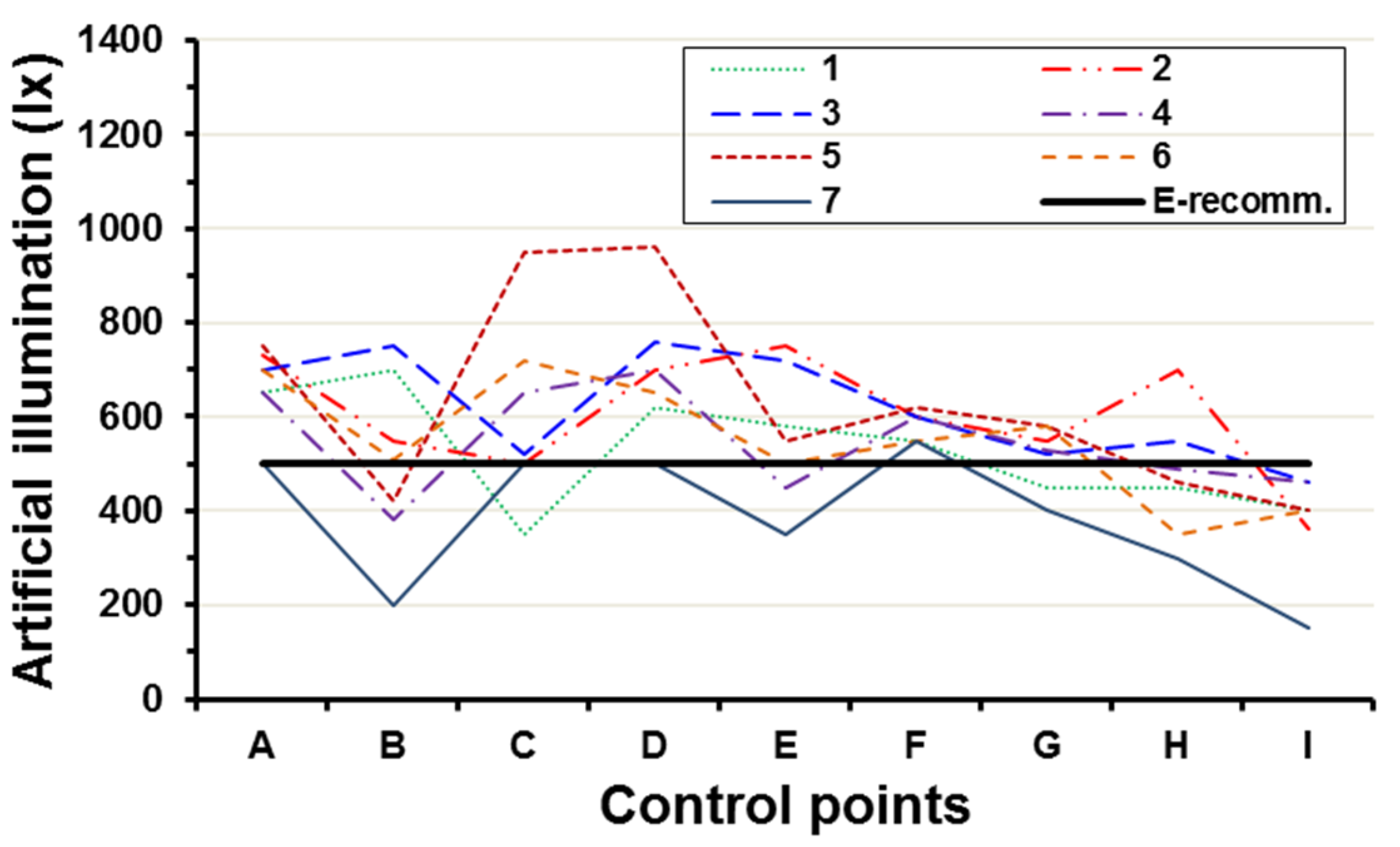

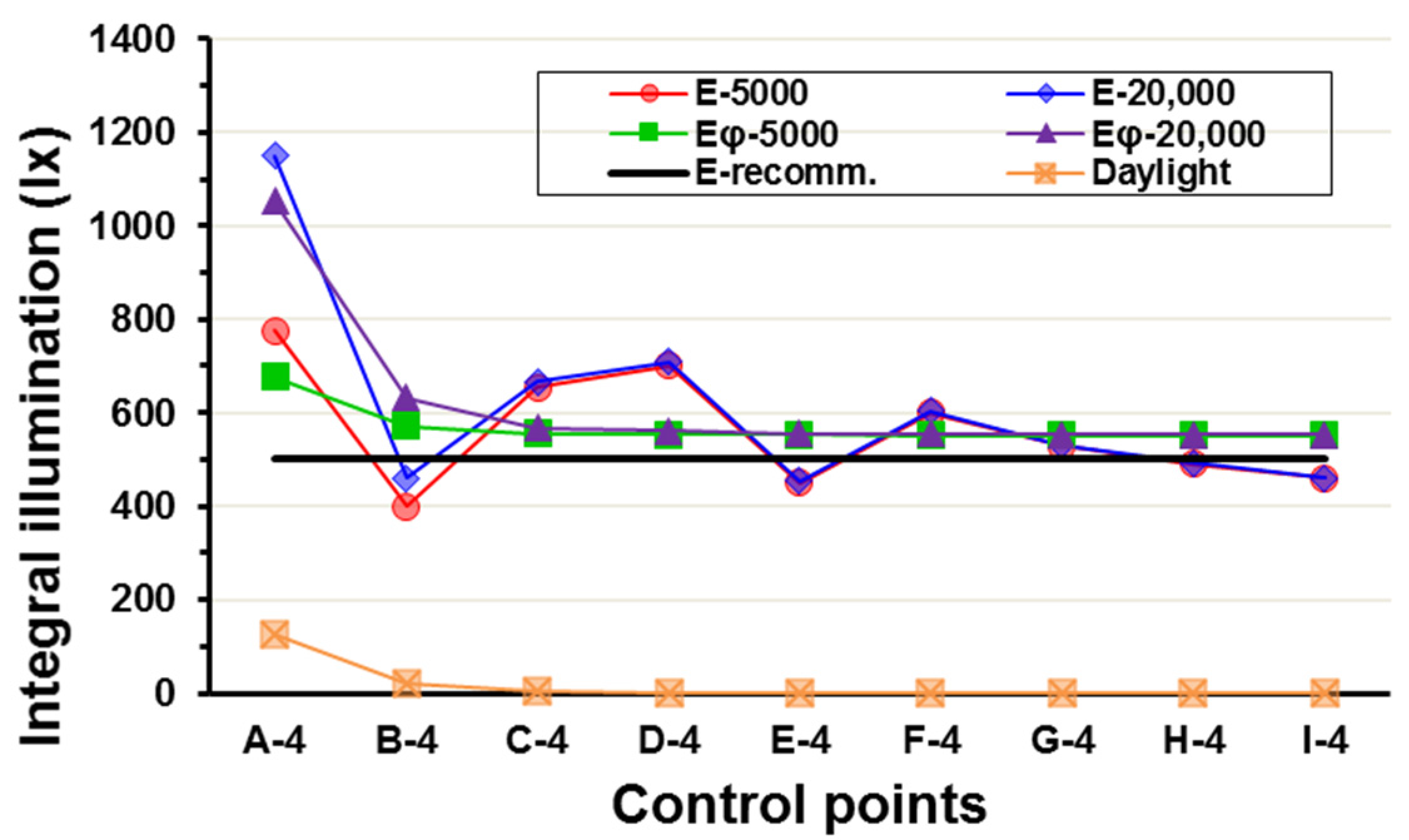

4. Case Study: Integral Lighting in Knitting Hall

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Nejat, P.; Jomehzadeh, F.; Taheri, M.M.; Gohari, M.; Majid, M.Z.A. A global review of energy consumption, CO2 emissions and policy in the residential sector (with an overview of the top ten CO2 emitting countries). Renew. Sustain. Energy Rev. 2015, 43, 843–862. [Google Scholar] [CrossRef]

- Napp, T.A.; Gambhir, A.; Hills, T.P.; Florin, N.; Fennell, P.S. A review of the technologies, economics and policy instruments for decarbonising energy-intensive manufacturing industries. Renew. Sustain. Energy Rev. 2014, 30, 616–640. [Google Scholar] [CrossRef]

- Deng, S.; Wang, R.Z.; Dai, Y.J. How to evaluate performance of net zero energy building—A literature research. Energy 2014, 71, 1–16. [Google Scholar] [CrossRef]

- International Energy Agency. Transition to Sustainable Buildings: Strategies and Opportunities to 2050; International Energy Agency (IEA): Paris, France, 2013. [Google Scholar]

- Alarcon, B.; Aguado, A.; Manga, R.; Josa, A. A value function for assessing sustainability application to industrial buildings. Sustainability 2011, 3, 35–50. [Google Scholar] [CrossRef]

- Lombera, J.T.; Rojo, J.C. Industrial building design stage based on a system approach to their environmental sustainability. Construct. Build. Mater. 2010, 24, 438–447. [Google Scholar] [CrossRef]

- Yan, B.; Long, E.; Meng, X.; Zhang, Y.; Hou, D.; Du, X. Influence of user behavior on unsatisfactory indoor thermal environment. Energy Convers. Manag. 2014, 86, 1–7. [Google Scholar] [CrossRef]

- Bawaneh, K.; Overcash, M.; Twomey, J. Climate zones and the influence on industrial nonprocess energy consumption. J. Renew. Sust. Energy 2011, 3, 063113. [Google Scholar] [CrossRef]

- Zhivov, A.M.; Liesen, R.; Fisher, D.; Hand, J.; Wilson, B. Screening of energy efficient technologies for industrial buildings retrofits. In ASHRAE Transactions 116; American Society for Heating, Refrigerating and Air-Conditioning Engineers, ASHRAE: Albuquerque, NM, USA, 2011; pp. 401–411. [Google Scholar]

- Rezaie, B.; Esmailzadeh, E.; Dincer, I. Renewable energy options for buildings: Case studies. Energy Build. 2011, 43, 56–65. [Google Scholar] [CrossRef]

- Silvestre-Blanes, J.; Pérez-Lloréns, R. Energy efficiency improvements through surveillance applications in industrial buildings. Energy Build. 2011, 43, 1334–1340. [Google Scholar] [CrossRef]

- Ji, R.; Zhang, Z.; Liu, L.; Wang, X. Development of the random simulation model for estimating the effective thermal conductivity of insulation materials. Build. Environ. 2014, 80, 221–227. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, J.; Xing, X.; Liu, Y.; Meng, X. Measurement and evaluation of indoor thermal environment in a naturally ventilated industrial building with high temperature heat sources. Build. Environ. 2016, 96, 35–45. [Google Scholar] [CrossRef]

- Katunsky, D.; Korjenic, A.; Katunska, J.; Lopusniak, M.; Korjenic, S.; Doroudiani, S. Analysis of thermal energy demand and saving in industrial buildings: A case study in Slovakia. Build. Environ. 2013, 67, 138–146. [Google Scholar] [CrossRef]

- Wang, H.W.; Zheng, Y.D.; Tu, F.W. Influences of external windows on energy consumption of industrial buildings in cold areas. Adv. Mater. Res. 2011, 250, 3055–3058. [Google Scholar] [CrossRef]

- Cingoski, V.; Petrevska, B.; Trajkov, N.; Golubovski, R.; Gelev, S. Energy improvements in the hotel industry. Jökull J. 2015, 65, 145–150. Available online: http://eprints.ugd.edu.mk/id/eprint/13757 (accessed on 2 June 2017).

- Bellia, L.; Bisegna, F.; Spada, G. Lighting indoor environment: Visual and non-visual light sources with different spectral power distribution. Build. Environ. 2011, 46, 1984–1992. [Google Scholar] [CrossRef]

- Shishegar, N.; Boubekri, M. Natural light and productivity: Analyzing the impacts of daylighting on students’ and workers’ health and alertness. In Proceedings of the International Conference on “Health, Biological and Life Science” (HBLS-16), Istanbul, Turkey, 18–19 April 2016. [Google Scholar]

- Boubekri, M. Daylighting, Architecture and Health; Architectural Press: New York, NY, USA, 2008. [Google Scholar]

- Wang, N.; Boubekri, M. Design recommendations based on cognitive, mood and preference assessments in a sunlit workspace. Light. Res. Technol. 2011, 43, 55–72. [Google Scholar] [CrossRef]

- McColl, S.L.; Veitch, J.A. Full-spectrum fluorescent lighting: A review of its effects on physiology and health. Psychol. Med. 2001, 31, 949–964. [Google Scholar] [CrossRef] [PubMed]

- Khanie, M.S. Human Responsive Daylighting in Offices. Ph.D. Thesis, École Polytechnique Fédérale de Lausanne, Lausanne, Switzerland, 2015. [Google Scholar]

- Amundadottir, M.L.; Rockcastle, S.; Khanie, M.S.; Andersen, M. A human-centric approach to assess daylight in buildings for non-visual health potential, visual interest and gaze behavior. Build. Environ. 2017, 113, 5–21. [Google Scholar] [CrossRef]

- Berardi, U.; Anaraki, H.K. The benefits of light shelves over the daylight illuminance in office buildings in Toronto. Indoor Built Environ. 2016, 1–19. [Google Scholar] [CrossRef]

- Yokoya, M.; Shimizu, H. Estimation of effective day length at any light intensity using solar radiation data. Int. J. Environ. Res. Public Health 2011, 8, 4272–4283. [Google Scholar] [CrossRef] [PubMed]

- Veitch, J.A. Investigating and influencing how buildings affect health: Interdisciplinary endeavors. Can. Psychol. 2008, 49, 281–288. [Google Scholar] [CrossRef]

- Smolders, K.C.; de Kort, Y.A. Bright light and mental fatigue: Effects on alertness, vitality, performance and physiological arousal. J. Environ. Psychol. 2014, 39, 77–91. [Google Scholar] [CrossRef]

- Friborg, O.; Rosenvinge, J.; Wynn, R.; Gradisar, M. Sleep timing, phonotype, mood, and behavior at an arctic latitude (69°N). Sleep Med. 2014, 15, 798–807. [Google Scholar] [CrossRef] [PubMed]

- Mistrick, R.; Casey, C.; Chen, L.; Sarith Subramaniam, S. Computer modeling of daylight-integrated photocontrol of electric lighting systems. Buildings 2015, 5, 449–466. [Google Scholar] [CrossRef]

- Dyke, C.; Van Den Wymelenberg, K.; Djunaedy, E.; Steciak, J. Comparing whole building energy implications of sidelighting systems with alternate manual blind control algorithms. Buildings 2015, 5, 467–496. [Google Scholar] [CrossRef]

- González, J.; Fiorito, F. Daylight design of office buildings: Optimisation of external solar shadings by using combined simulation methods. Buildings 2015, 5, 560–580. [Google Scholar] [CrossRef]

- Hirning, M.B.; Isoardi, G.L.; Garcia-Hansen, V.R. Prediction of discomfort glare from windows under tropical skies. Build. Environ. 2017, 113, 107–120. [Google Scholar] [CrossRef]

- Bellia, L.; Fragliasso, F.; Stefanizzi, E. Daylit offices: A comparison between measured parameters assessing light quality and users’ opinions. Build. Environ. 2017, 113, 92–106. [Google Scholar] [CrossRef]

- Gunay, H.B.; O’Brien, W.; Beausoleil-Morrison, I.; Gilani, S. Development and implementation of an adaptive lighting and blinds control algorithm. Build. Environ. 2017, 113, 185–199. [Google Scholar] [CrossRef]

- Pellegrino, A.; Cammarano, S.; Verso, V.R.; Corrado, V. Impact of daylighting on total energy use in offices of varying architectural features in Italy: Results from a parametric study. Build. Environ. 2017, 113, 151–162. [Google Scholar] [CrossRef]

- Hirning, M.B.; Isoardi, G.L.; Cowling, I. Discomfort glare in open plan green buildings. Energy Build. 2014, 70, 427–440. [Google Scholar] [CrossRef]

- Jia, L.; Afshari, S.; Mishra, S.; Radke, R.J. Simulation for pre-visualizing and tuning lighting controller behavior. Energy Build. 2014, 70, 287–302. [Google Scholar] [CrossRef]

- Xue, P.; Mak, C.M.; Huang, Y. Quantification of luminous comfort with dynamic daylight metrics in residential buildings. Energy Build. 2016, 117, 99–108. [Google Scholar] [CrossRef]

- Costanzo, V.; Donn, M. Thermal and visual comfort assessment of natural ventilated office buildings in Europe and North America. Energy Build. 2017, 140, 210–223. [Google Scholar] [CrossRef]

- Nasrollahi, N.; Shokri, E. Daylight illuminance in urban environments for visual comfort and energy performance. Renew. Sustain. Energy Rev. 2016, 66, 861–874. [Google Scholar] [CrossRef]

- Sokol, N.; Martyniuk-Peczek, J. The review of the selected challenges for an incorporation of daylight assessment methods into urban planning in Poland. Proc. Eng. 2016, 161, 2191–2197. [Google Scholar] [CrossRef]

- Li, D.H.; Lau, C.C.; Lam, J.C. Predicting daylight illuminance by computer simulation techniques. Light. Res. Technol. 2004, 36, 113–128. [Google Scholar] [CrossRef]

- Markou, M.T.; Kambezidis, H.D.; Bartzokas, A.; Katsoulis, B.D.; Muneer, T. Sky type classification in Central England during winter. Energy 2005, 30, 1667–1674. [Google Scholar] [CrossRef]

- Kittler, R. A universal calculation method for simple predetermination of natural radiation on building surfaces and solar collectors. Build. Environ. 1981, 16, 177–182. [Google Scholar] [CrossRef]

- Kittler, R.; Ruck, N. Definition of typical and average exterior daylight conditions in different climatic zones. Energy Build. 1984, 6, 253–259. [Google Scholar] [CrossRef]

- Leslie, R.P. Capturing the daylight dividend in buildings: Why and how? Build. Environ. 2003, 38, 381–385. [Google Scholar] [CrossRef]

- Ko, D.H.; Elnimeiri, M.; Clark, R.J. Assessment and prediction of daylight performance in high-rise office buildings. Struct. Des. Tall Spec. Build. 2008, 17, 953–976. [Google Scholar] [CrossRef]

- Krüger, E.L.; Dorigo, A.L. Daylighting analysis in a public school in Curitiba, Brazil. Renew. Energy 2008, 33, 1695–1702. [Google Scholar] [CrossRef]

- Moazzeni, M.H.; Ghiabaklou, Z. Investigating the influence of light shelf geometry parameters on daylight performance and visual comfort, a case study of educational space in Tehran, Iran. Buildings 2016, 6, 26. [Google Scholar] [CrossRef]

- Dahlan, N.D.; Jones, P.J.; Alexander, D.K.; Salleh, E.; Alias, J. Daylight ratio, luminance, and visual comfort assessments in typical Malaysian hostels. Indoor Built Environ. 2009, 18, 319–335. [Google Scholar] [CrossRef]

- Ihm, P.; Nemri, A.; Krarti, M. Estimation of lighting energy savings from daylighting. Build. Environ. 2009, 44, 509–514. [Google Scholar] [CrossRef]

- Reinhart, C.F.; Wienold, J. The daylighting dashboard—A simulation-based design analysis for daylit spaces. Build. Environ. 2011, 46, 386–396. [Google Scholar] [CrossRef]

- Reinhart, C.F.; Weissman, D.A. The daylit area—Correlating architectural student assessments with current and emerging daylight availability metrics. Build. Environ. 2012, 50, 155–164. [Google Scholar] [CrossRef]

- Sicurella, F.; Evola, G.; Wurtz, E. A statistical approach for the evaluation of thermal and visual comfort in free-running buildings. Energy Build. 2012, 47, 402–410. [Google Scholar] [CrossRef]

- Iringova, A. Impact of external shading on light comfort and energy efficiency in apartment buildings. Appl. Mech. Mater. 2017, 861, 485–492. [Google Scholar] [CrossRef]

- Brownson, J.R. Framing the sun and buildings as commons. Buildings 2013, 3, 659–673. [Google Scholar] [CrossRef]

- Fabi, V.; Andersen, R.K.; Corgnati, S. Accounting for the uncertainty related to building occupants with regards to visual comfort: A literature survey on drivers and models. Buildings 2016, 6, 5. [Google Scholar] [CrossRef]

- Uriarte, U.; Hernández, R.J.; Zamora, J.L.; Isalgue, A. Side-view atmospheres under outdoor midday high luminance. Buildings 2016, 6, 53. [Google Scholar] [CrossRef]

- Lee, J.H.; Moon, J.W.; Kim, S. Analysis of occupants’ visual perception to refine indoor lighting environment for office tasks. Energies 2014, 7, 4116–4139. [Google Scholar] [CrossRef]

- Shen, E.; Hu, J.; Patel, M. Energy and visual comfort analysis of lighting and daylight control strategies. Build. Environ. 2014, 78, 155–170. [Google Scholar] [CrossRef]

- Konis, K. Evaluating daylighting effectiveness and occupant visual comfort in a side-lit open-plan office building in San Francisco, California. Build. Environ. 2013, 59, 662–677. [Google Scholar] [CrossRef]

- Mohsenin, M.; Hu, J. Assessing daylight performance in atrium buildings by using Climate Based Daylight Modeling. Solar Energy 2015, 119, 553–560. [Google Scholar] [CrossRef]

- Piderit Moreno, M.B.; Labarca, C.Y. Methodology for assessing daylighting design strategies in classroom with a climate-based method. Sustainability 2015, 7, 880–897. [Google Scholar] [CrossRef]

- Lee, K.S.; Han, K.J.; Lee, J.W. Feasibility study on parametric optimization of daylighting in building shading design. Sustainability 2016, 8, 1220. [Google Scholar] [CrossRef]

- Gou, Z.; Lau, S.S.; Ye, H. Visual alliesthesia: The gap between comfortable and stimulating illuminance settings. Build. Environ. 2014, 82, 42–49. [Google Scholar] [CrossRef]

- Gou, Z.; Lau, S.S.; Qian, F. Comparison of mood and task performance in naturally-lit and artificially-lit environments. Indoor Built Environ. 2015, 24, 27–36. [Google Scholar] [CrossRef]

- Perez, R.; Seals, R.; Michalsky, J. All weather model for sky luminance distribution—Preliminary configuration and validation. Solar Energy 1993, 50, 235–245. [Google Scholar] [CrossRef]

- Igawa, N.; Koga, Y.; Matsuzawa, T.; Nakamura, H. Models of sky radiance distribution and sky luminance distribution. Solar Energy 2004, 77, 137–157. [Google Scholar] [CrossRef]

- Katunsky, D. Approximate determination of the factor of daylight lighting for areas with combined lighting. Trans. Tech. Univ. Kosice 1993, 3, 192–199. [Google Scholar]

- Van Bommel, W.J.M.; van den Beld, G.J. Lighting for work: A review of visual and biological effects. Lighting Res. Technol. 2004, 36, 255–269. [Google Scholar] [CrossRef]

- Veitch, J.A. Light, lighting, and health: Issues for consideration. Leukos 2005, 2, 85–96. [Google Scholar]

- Kondas, K.; Darula, S. Daylighting on the working plane in oriented attic rooms under overcast and clear sky. J. Civ. Eng. 2014, 9, 33–40. [Google Scholar] [CrossRef]

- International Energy Agency (IEA) Solar and Heating Cooling Program, Task 31—Daylighting Buildings in the 21st Century. Available online: http://task31.iea-shc.org/ (accessed on 2 May 2017).

- Integral Lighting, 2007, ČSN 360020; Czech Office of Standards, Metrology and Testing: Prague, Czech Republic, 2015.

- EN 12464-1:2011. Light and Lighting—Lighting of Work Places—Part 1: Indoor Work Places; European Committee for Standardization (CEN): Brussels, Belgium, 2011. [Google Scholar]

- STN 730580-1/Z2:2000. In Daylight in Buildings; Basic Requirements. Slovak Republic Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2000. [Google Scholar]

- Rybar, P. Daylighting in Building (Czech Standard), ČSN 730580; Priestup Svetla Cez Ploché Stavebné Sklo. Světelná Technika 3; Czech Office of Standards, Metrology and Testing: Prague, Czech Republic, 1987. [Google Scholar]

- Kittler, R.; Kittlerová, L. Návrh a Hodnotenie Denného Osvetlenia; Alfa: Bratislava, Slovakia, 1975. [Google Scholar]

- Kittler, R.; Mikler, J. Základy Využívania Slnečného Žiarenia; Veda: Bratislava, Slovakia, 1986. [Google Scholar]

- Kittler, R.; Pulpitlová, J. Základy Využívania Prírodného Svetla; Veda: Bratislava, Slovakia, 1988. [Google Scholar]

- ISO/TC 274. N 284 Internal Ballot (CIB) for ISO/TC 205—ISO/FDIS 16817 Building Environment Design—Indoor Environment—Design Process for the Visual Environment; International Organization for Standardization: Geneva, Switzerland, 2017. [Google Scholar]

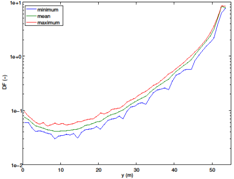

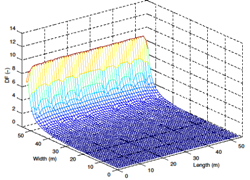

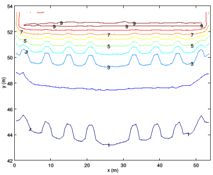

| Spatial Distribution of DF | Distribution of DF Isocontour Maps | DF |

|---|---|---|

|  |  |

| (a) | ||

|  |  |

| (b) | ||

|  |  |

| (c) |

| Illumination (lx) | DF (%) | Brightness (cd/m2) |

|---|---|---|

|  |  |

| (a) | ||

|  |  |

| (b) | ||

|  |  |

| (c) |

| Category | Min. Standard DF (%) | Min. Recommended DF (%) | Mean Recommended DF (%) |

|---|---|---|---|

| I | 1.0 | 1.2 | 3.0 |

| II | 1.0 | 1.0 | 2.5 |

| III | 0.7 | 0.7 | 2.0 |

| IV | 0.5 | 0.5 | 1.5 |

| V | 0.5 | 0.3 | 1.0 |

| VI | 0.5 | 0.1 | 0.7 |

| VII | 0.5 | 0.1 | 0.35 |

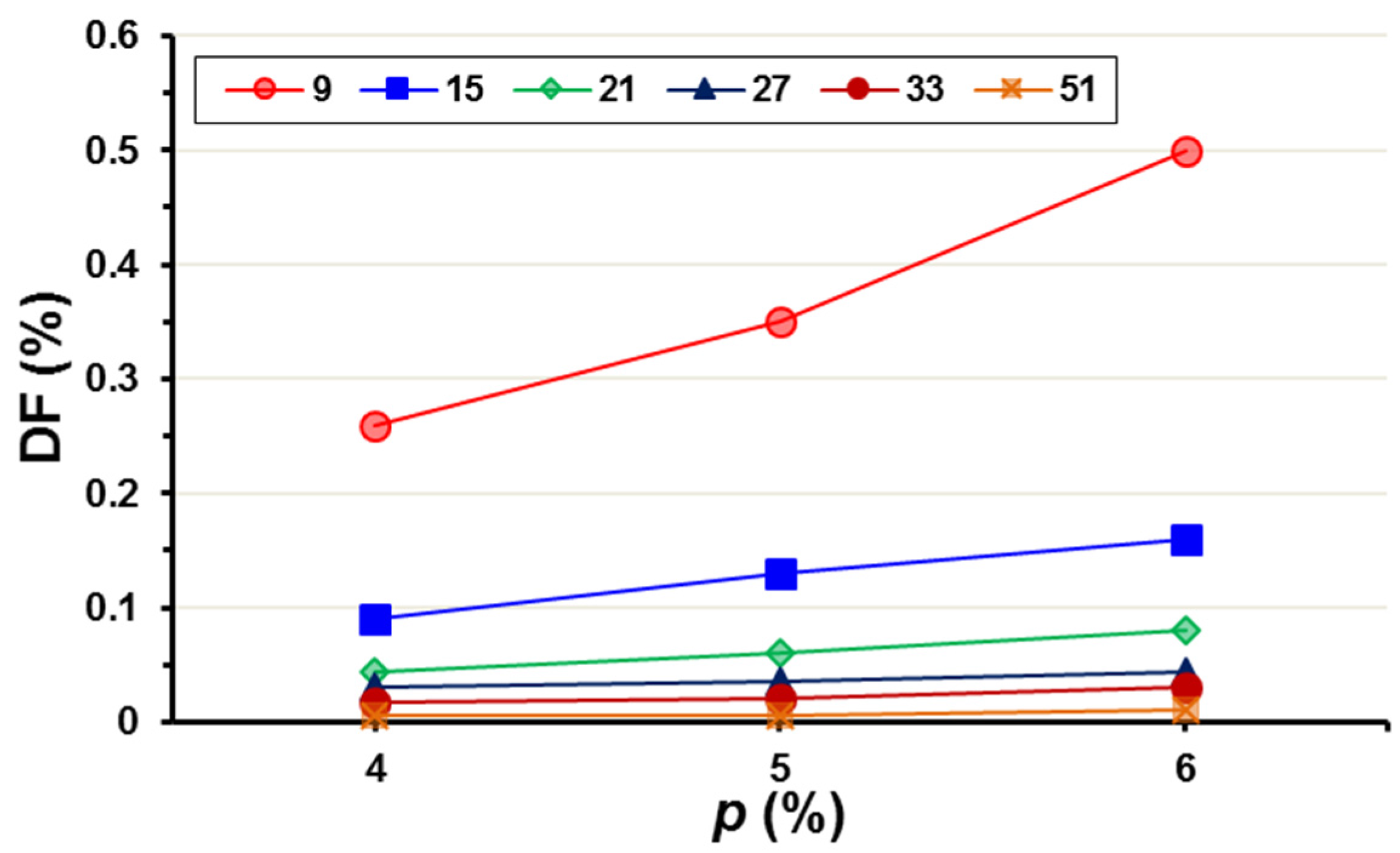

| Hall E (36 windows) | ||

|---|---|---|

| Alternative | Size (mm) | Lining (mm) |

| 1 | 1500/2400 | 150 |

| 2 | 1500/2400 | 250 |

| 3 | 1500/2400 | 300 |

| 4 | 1500/2400 | 400 |

| 5 | 1500/2100 | 400 |

| 6 | 1500/1800 | 400 |

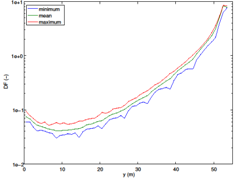

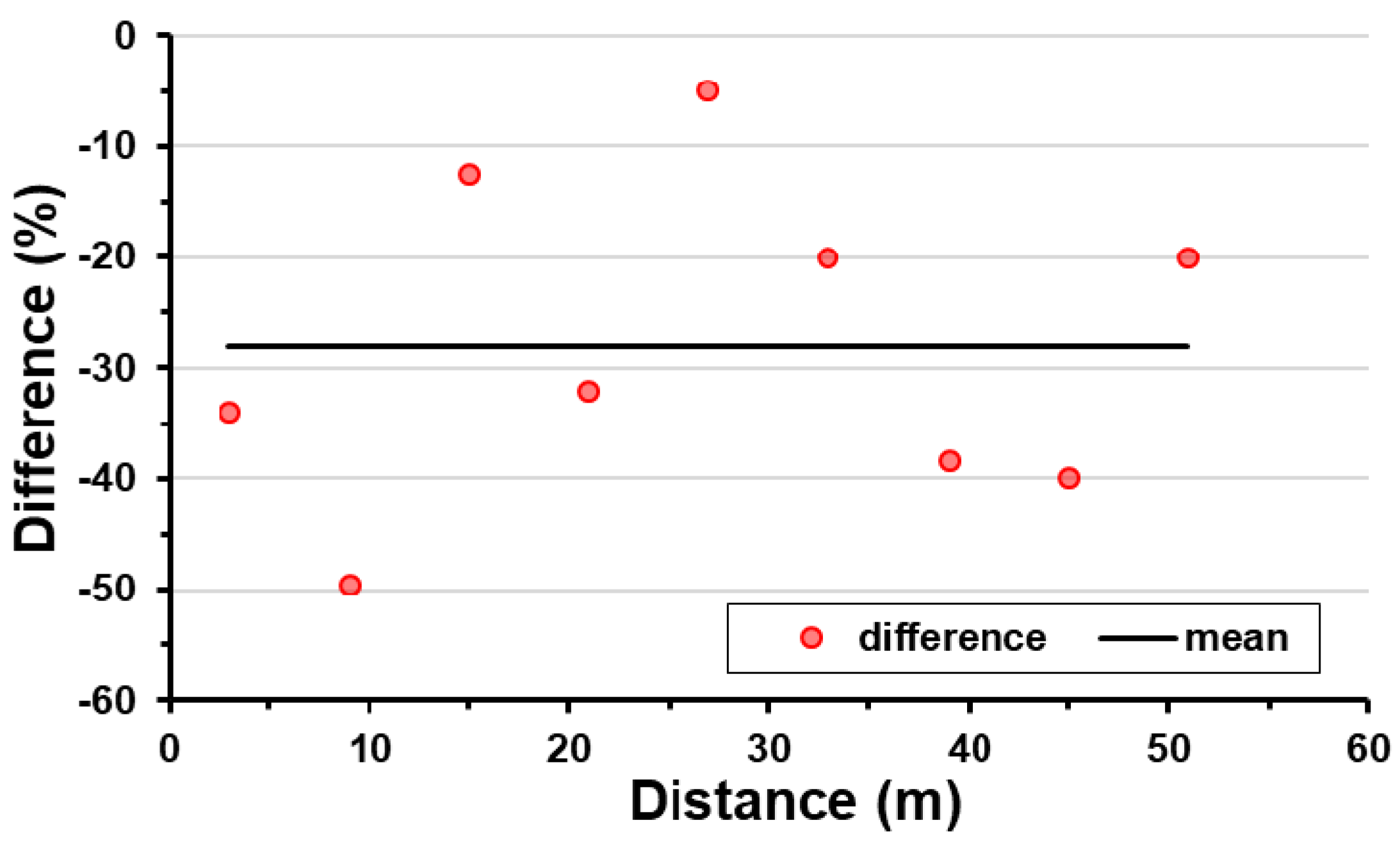

| Point | Dρ (%) | Ds (%) | Dρ,mean (%) |

|---|---|---|---|

| A4 | 2.500 | 1.649 | 2.165 |

| B4 | 0.400 | 0.202 | 0.670 |

| C4 | 0.080 | 0.070 | 0.495 |

| D4 | 0.050 | 0.034 | 0.420 |

| E4 | 0.020 | 0.019 | 0.369 |

| F4 | 0.015 | 0.012 | 0.330 |

| G4 | 0.013 | 0.008 | 0.296 |

| H4 | 0.010 | 0.006 | 0.268 |

| I4 | 0.005 | 0.004 | 0.242 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Katunský, D.; Dolníková, E.; Doroudiani, S. Integrated Lighting Efficiency Analysis in Large Industrial Buildings to Enhance Indoor Environmental Quality. Buildings 2017, 7, 47. https://doi.org/10.3390/buildings7020047

Katunský D, Dolníková E, Doroudiani S. Integrated Lighting Efficiency Analysis in Large Industrial Buildings to Enhance Indoor Environmental Quality. Buildings. 2017; 7(2):47. https://doi.org/10.3390/buildings7020047

Chicago/Turabian StyleKatunský, Dušan, Erika Dolníková, and Saeed Doroudiani. 2017. "Integrated Lighting Efficiency Analysis in Large Industrial Buildings to Enhance Indoor Environmental Quality" Buildings 7, no. 2: 47. https://doi.org/10.3390/buildings7020047