Analysis of Cylindrical Granular Material Silos under Seismic Excitation

Abstract

:1. Introduction

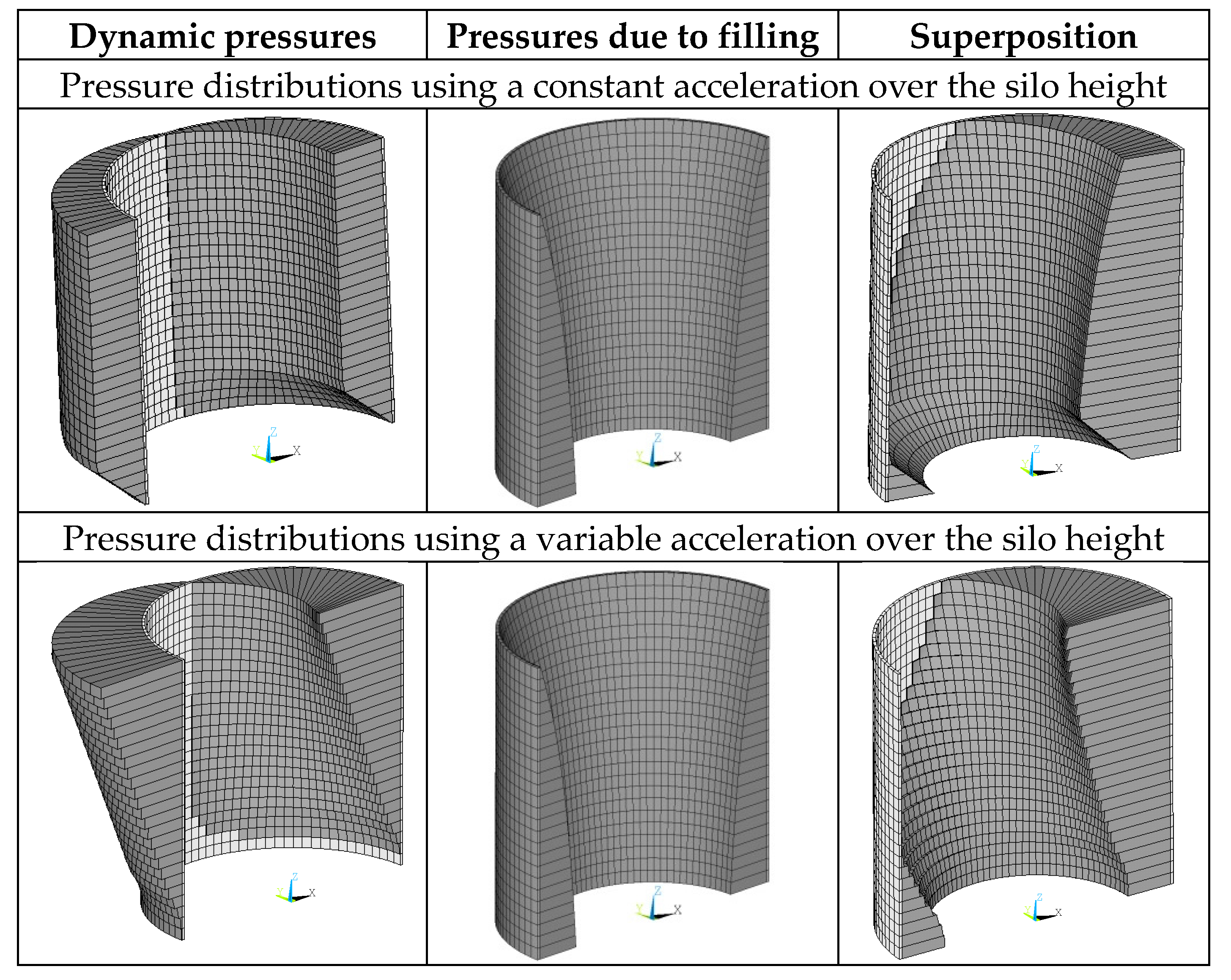

2. Equivalent Load Method

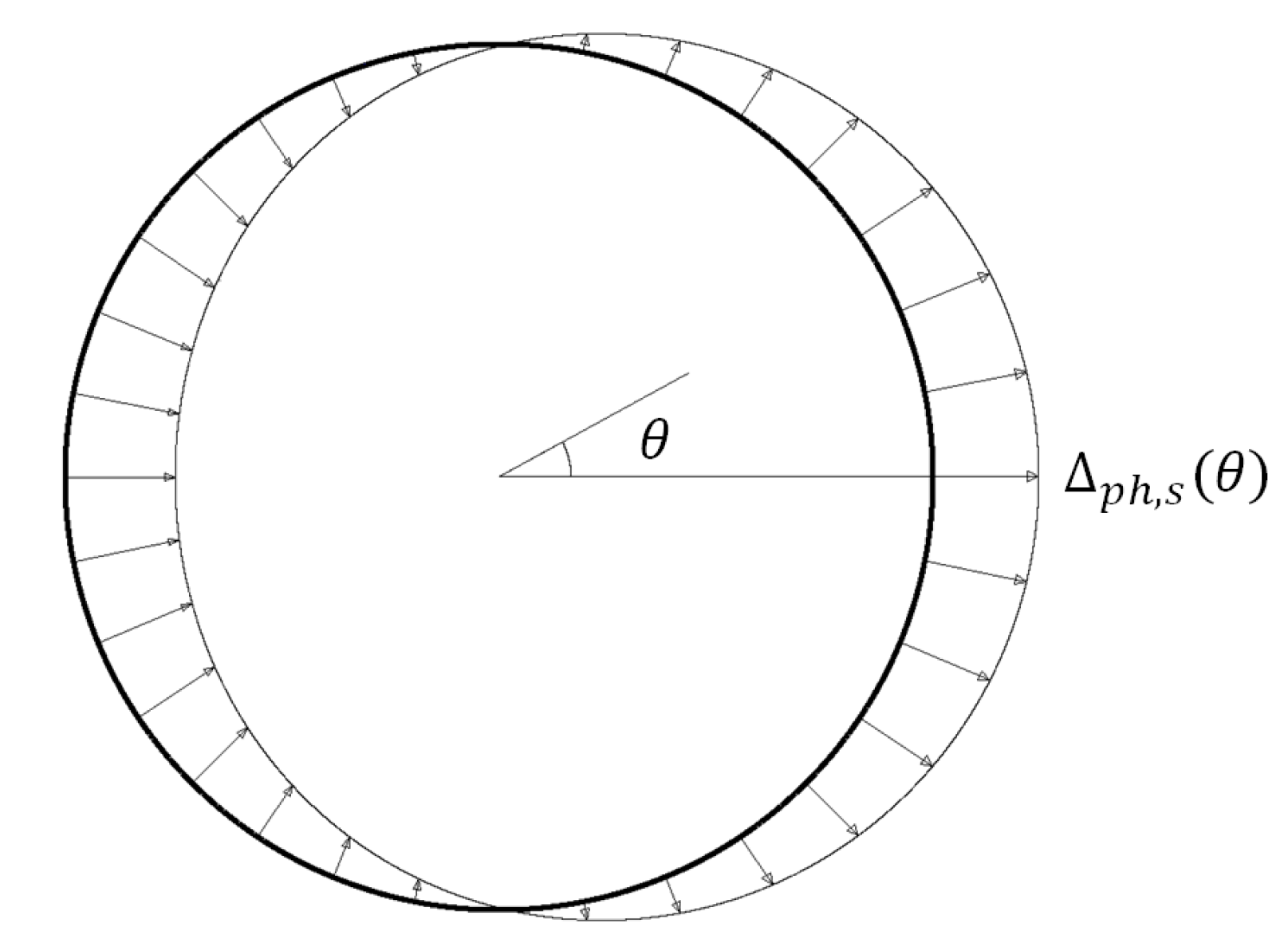

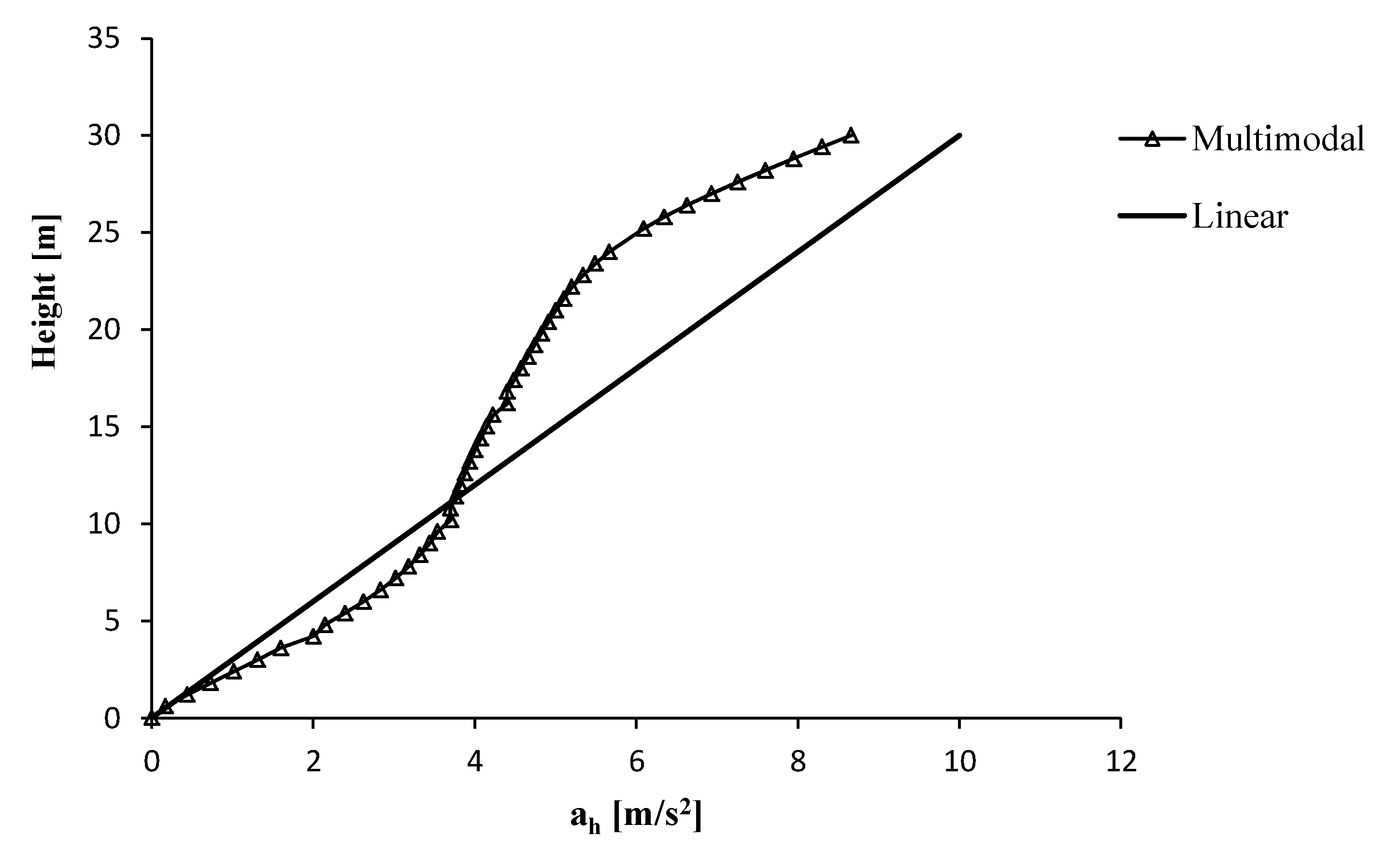

2.1. Equivalent Seismic Loads in Horizontal Direction

| response acceleration of the silo at a depth from the equivalent surface of the fill mass in g; | |

| characteristic value for the specific weight of the fill mass; | |

| ; | |

| total height of the silo from a flat floor or a hopper tip to the equivalent surface of the fill mass; | |

| interior diameter in cylindrical silos; | |

| angle relative to the direction of the seismic excitation (); | |

| slope of the hopper wall relative to a vertical axis or maximum wall slope (relative to the vertical) for pyramidal hoppers. |

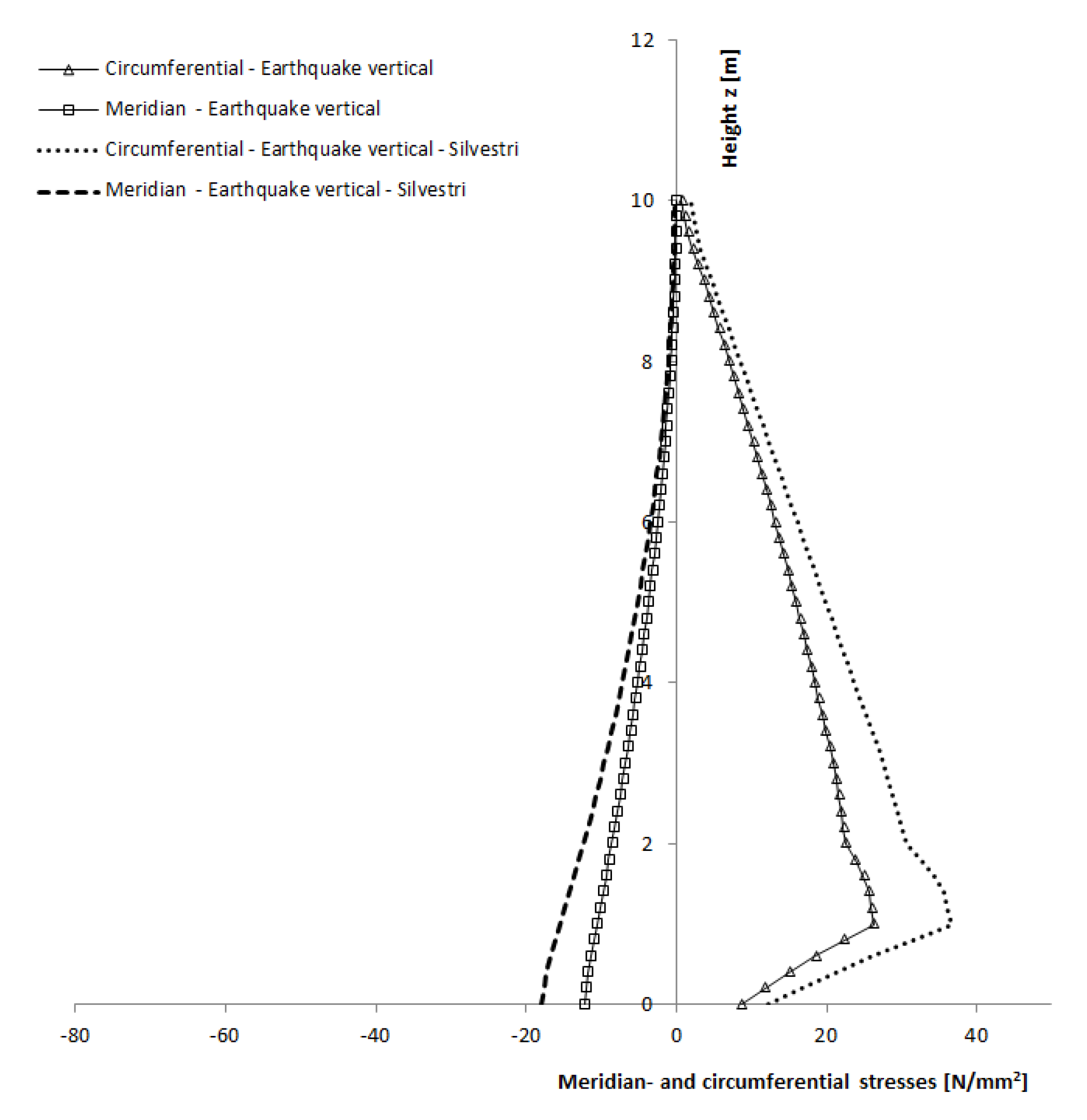

2.2. Equivalent Seismic Loads in Vertical Direction

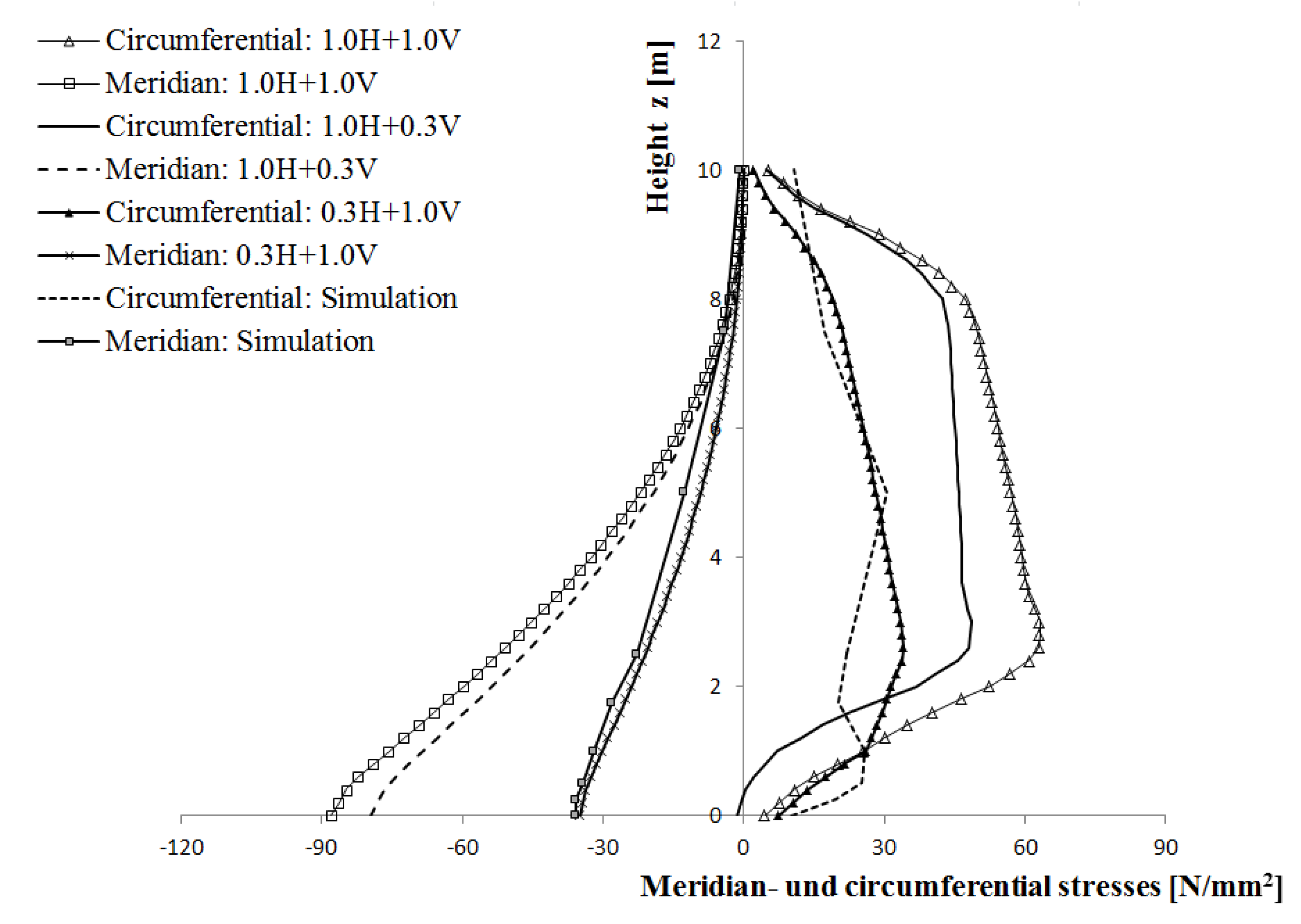

2.3. Combination of Equivalent Seismic Loads in Horizontal and Vertical Directions

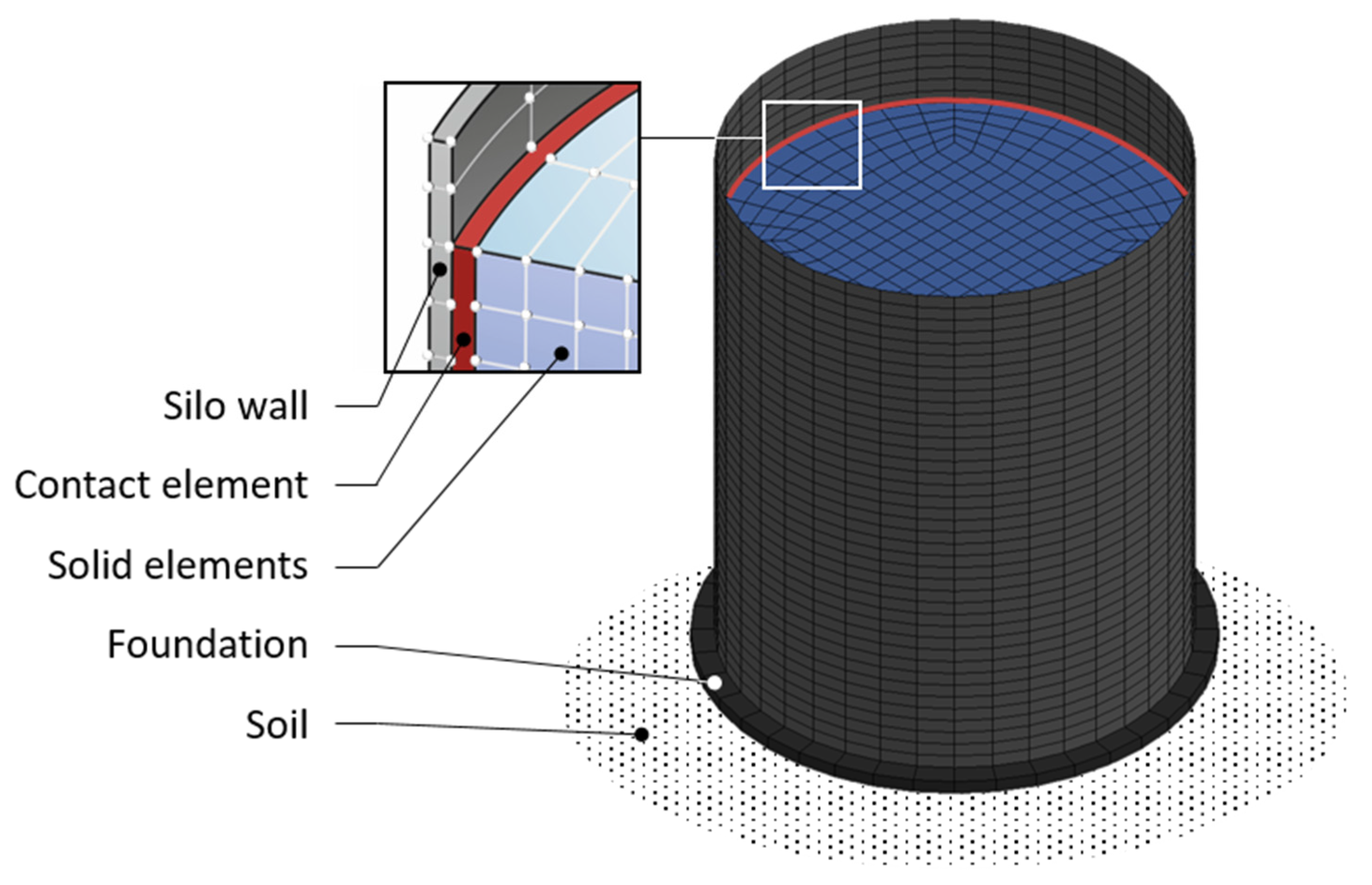

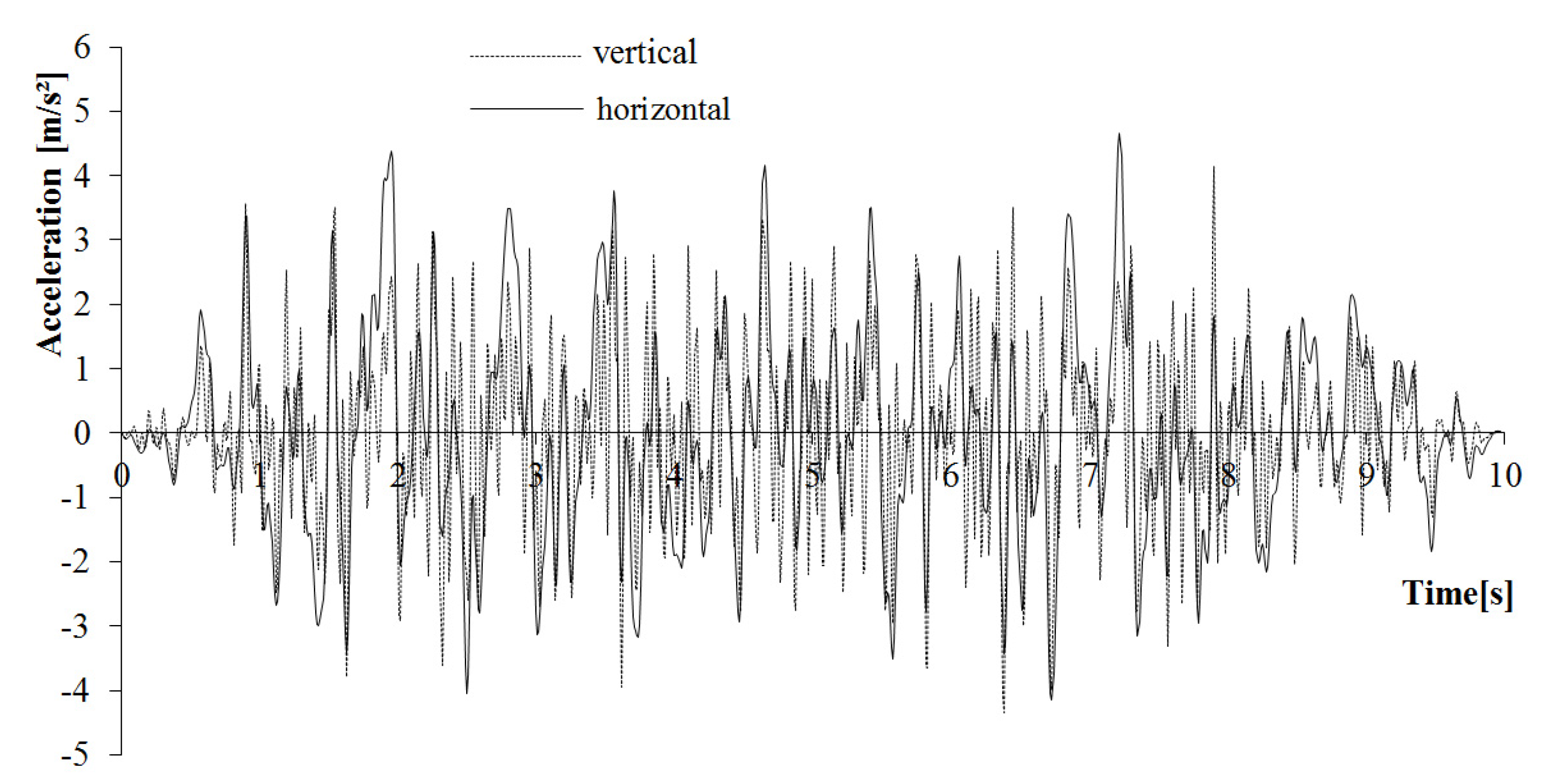

3. Nonlinear Numerical Simulation Model

4. Calculation Examples

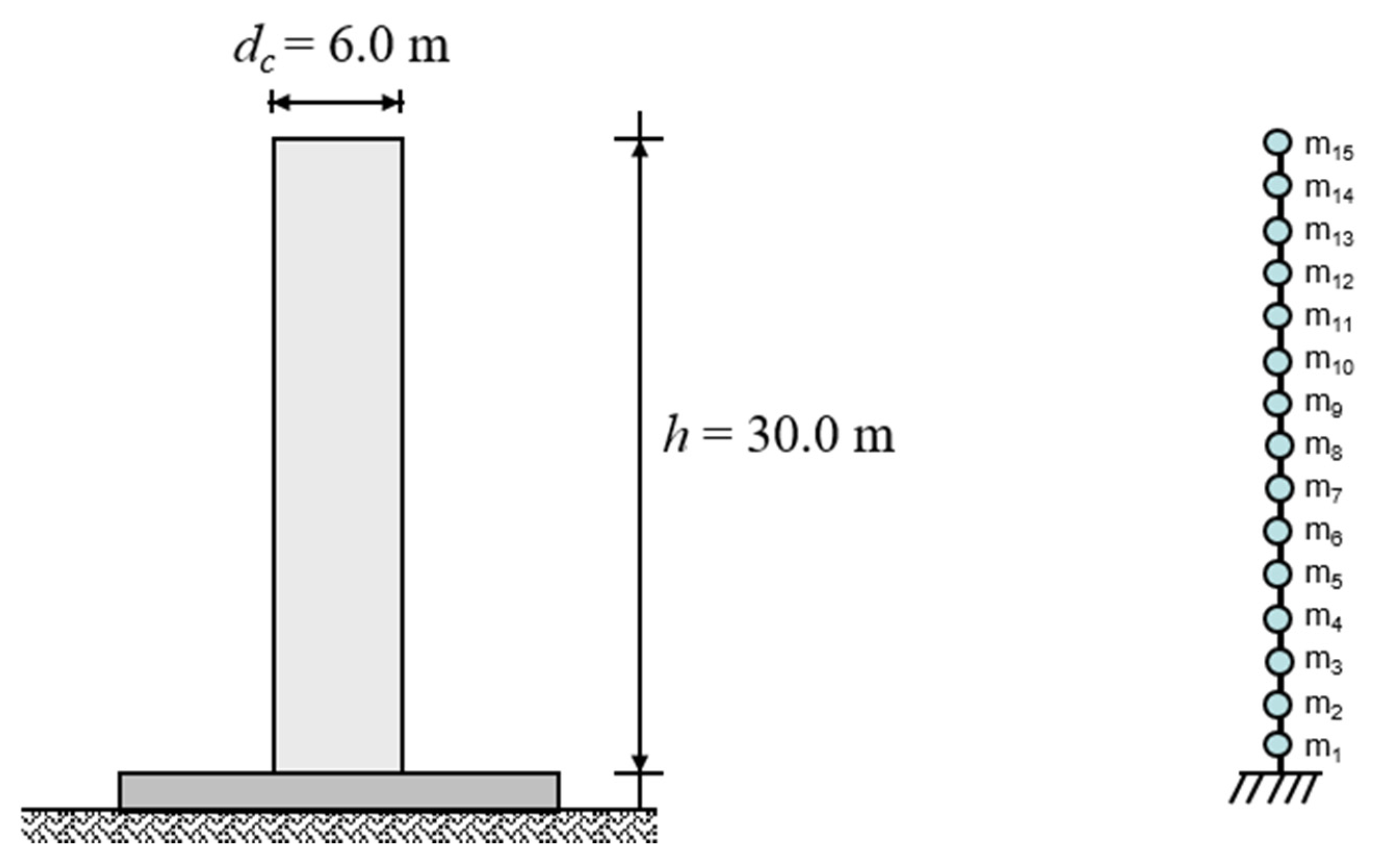

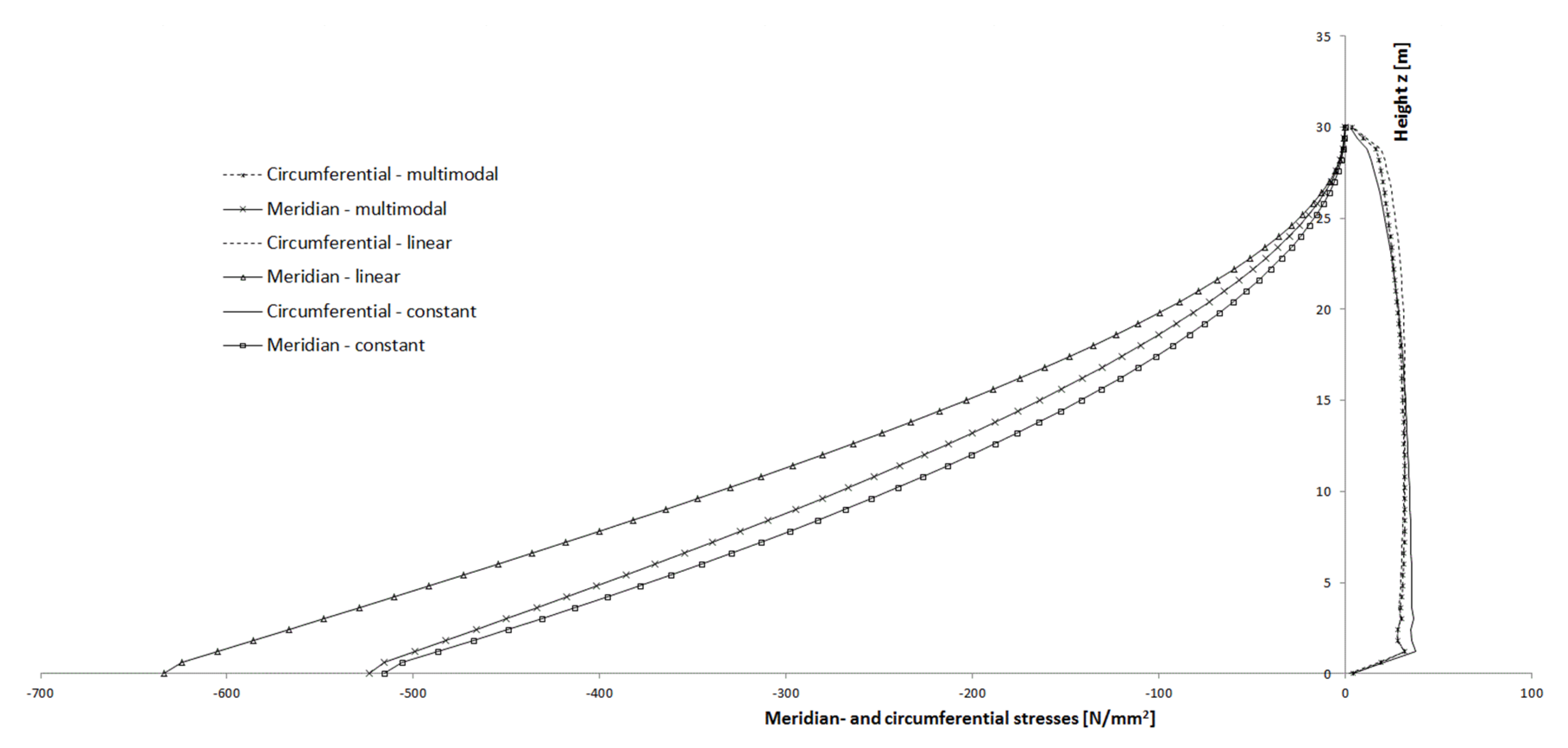

4.1. Slender Silo

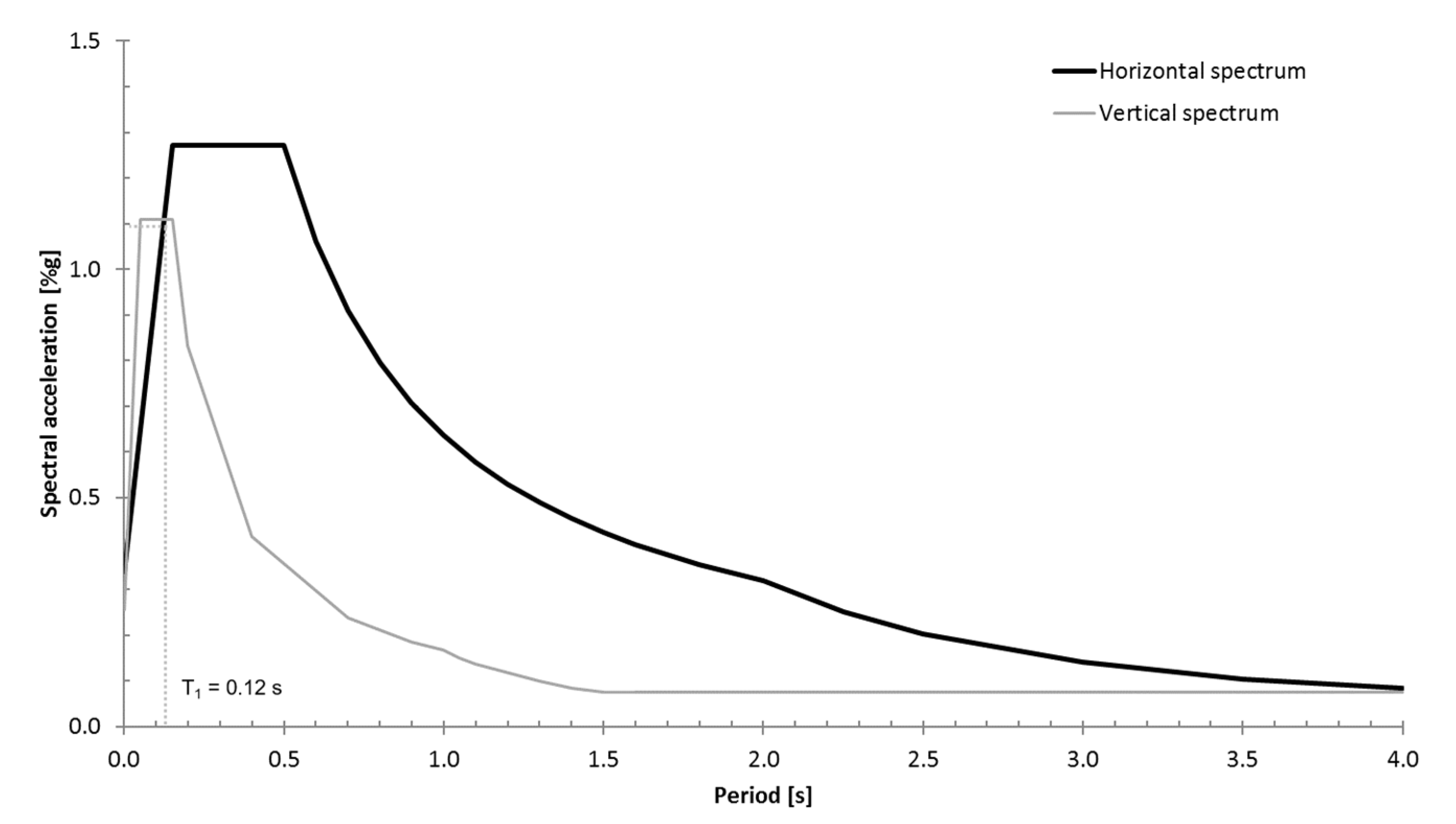

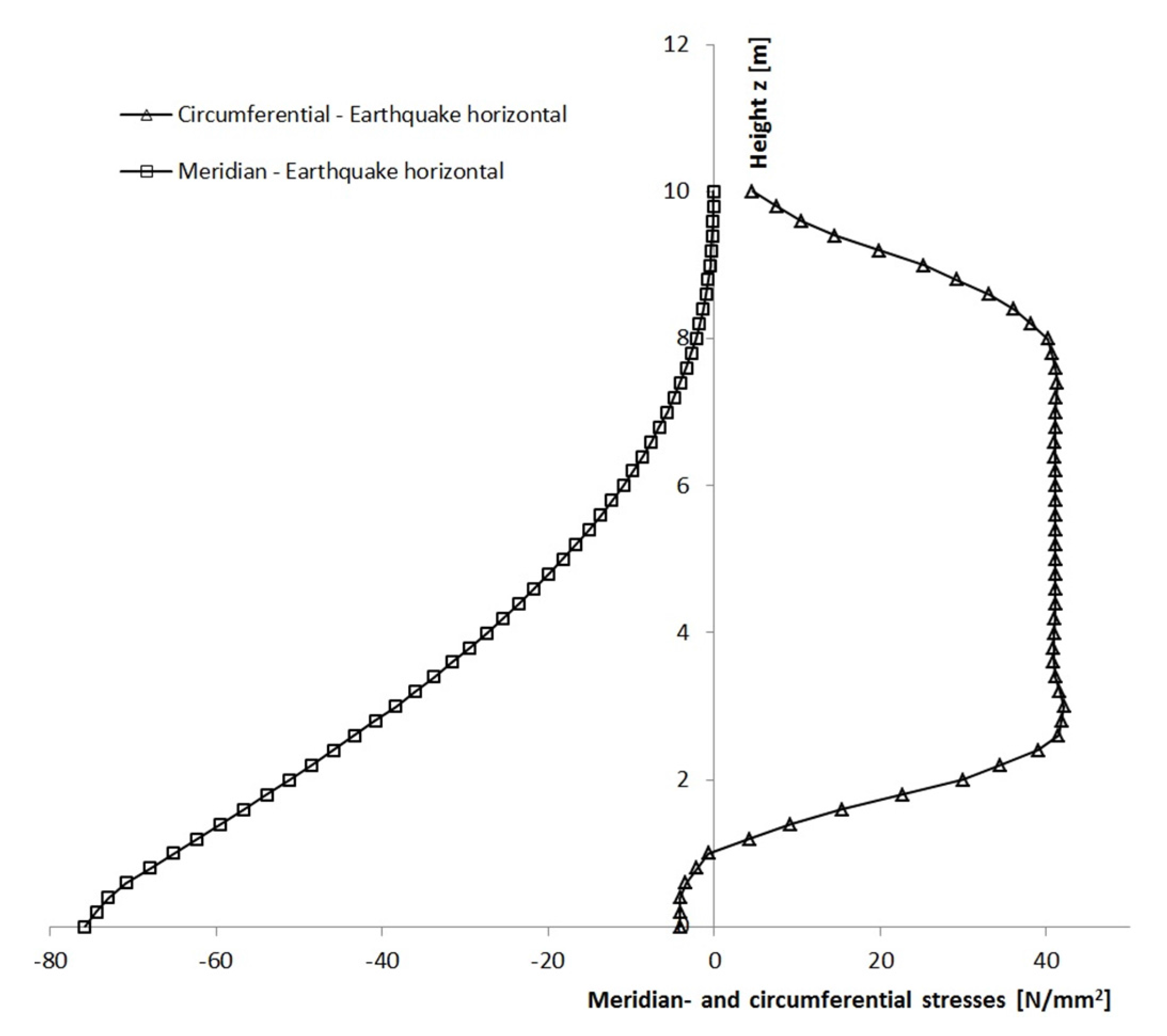

4.2. Squat Silo

5. Conclusions

Author Contributions

Conflicts of Interest

References

- Rotter, J.M.; Hull, T.S. Wall loads in squat steel silos during earthquake. Eng. Struct. 1989, 11, 139–147. [Google Scholar] [CrossRef]

- Rotter, J.M. Structures, stability, silos and granular solids: A personal adventure. In Structures and Granular Solids: From Scientific Principles to Engineering Application; Chen, J.F., Ooi, J.Y., Teng, J.G., Eds.; Taylor & Francis Group: London, UK, 2008; pp. 1–20. [Google Scholar]

- Rotter, J.M. Silos and tanks in research and practice: State of the art and current challenges. In Proceedings of the International Association for Shell and Spatial Structures (IASS) Symposium 2009—Evolution and Trends in Design, Analysis and Construction of Shell and Spatial Structures, Valencia, Spain, 28 September–2 October 2009; Domingo, A., Lazaro, C., Eds.; Universitat Politècnica de València: Valencia, Spain, 2009. [Google Scholar]

- Yokota, H.; Sugita, M.; Mita, I. Vibration tests and analyses of coal-silo model. In Proceedings of the 2nd International Conference on the Design of Silos for Strength and Flow, Stratford-upon-Avon, UK, 7–9 November 1983; pp. 107–116. [Google Scholar]

- Shimamoto, A.; Kodama, M.; Yamamura, M. Vibration tests for scale model of cylindrical coal storing silo. In Proceedings of the 8th World Conference on Earthquake Engineering, San Francisco, CA, USA, 21–28 July 1984; Volume 5, pp. 287–294. [Google Scholar]

- Sakai, M.; Matsumura, H.; Sasaki, M.; Nakamura, N.; Kobayashi, M.; Kitagawa, Y. Study on the dynamic behavior of coal silos against earthquakes. Bulk Solids Handl. 1985, 5, 1021. [Google Scholar]

- Younan, A.H.; Veletsos, A.S. Dynamics of solid-containing tanks I: Rigid tanks. J. Struct. Eng. 1998, 124, 52–61. [Google Scholar] [CrossRef]

- Veletsos, A.S.; Younan, A.H. Dynamics of solid-containing tanks II: Flexible tanks. J. Struct. Eng. 1998, 124, 62–70. [Google Scholar] [CrossRef]

- Bauer, E. Zum Mechanischen Verhalten Granularer Stoffe unter Vorwiegend ödometrischer Beanspruchungen. Veröffentlichungen des Institutes für Bodenmechanik und Felsmechanik der University Fridericiana in Karlsruhe, No 130. Ph.D. Thesis, Universität Fridericiana zu Karlsruhe, Karlsruhe, Germany, 1992. [Google Scholar]

- Braun, A. Schüttgutbeanspruchungen von Silozellen unter Erdbebeneinwirkungen. Institut für Massivbau und Baustofftechnologie. Ph.D. Thesis, Karlsruhe Institute of Technology, Karlsruhe, Germany, 1997. [Google Scholar]

- Eurocode 8: Design of Structures for Earthquake Resistance—Part 4: Silos, Tanks and Pipelines, German Version EN 1998-4:2006; Deutsches Institut für Normung e.V., Beuth-Verlag GmbH: Berlin, Germany, 2006.

- Holler, S.; Meskouris, K. Granular Material Silos under dynamic excitation: Numerical simulation and experimental validation. J. Struct. Eng. 2006, 1320, 1573–1579. [Google Scholar] [CrossRef]

- Silvestri, S.; Ivorra, S.; Chiacchio, L.D.; Trombetti, T.; Foti, D.; Gasparini, G.; Taylor, C. Shaking-table tests of flat-bottom circular silos containing grain-like material. Earthq. Eng. Struct. Dyn. 2016, 45, 69–89. [Google Scholar] [CrossRef]

- Silvestri, S.; Gasparini, G.; Trombetti, T.; Foti, D. On the evaluation of the horizontal forces produced by grain-like material inside silos during earthquakes. Bull. Earthq. Eng. 2012, 65, 69–89. [Google Scholar] [CrossRef]

- Pieraccini, L.; Silvestri, S.; Trombetti, T. Refinements to the Silvestri’s theory for the evaluation of the seismic actions in flat-bottom silos containing grain-like material. Bull. Earthq. Eng. 2015, 131, 3493–3525. [Google Scholar] [CrossRef]

- Eurocode 1: Actions on Structures—Part 4: Silos and Tanks. German Version EN 1991-4:2006; Deutsches Institut für Normung e.V., Beuth-Verlag GmbH: Berlin, Germany, 2006.

- Eurocode 8: Design of Structures for Earthquake Resistance—Part 1: General Rules, Seismic Actions and Rules for Buildings, German Version EN 1998-1:2004 + AC: 2009; Deutsches Institut für Normung e.V., Beuth-Verlag GmbH: Berlin, Germany, 2010.

- Gudehus, G. A comprehensive equation for granular materials. Soils Found. 1996, 36, 1–12. [Google Scholar] [CrossRef]

- Niemunis, A.; Herle, I. Hypoplastic model for cohesionsless soils with elastic strain range. Mech. Cohesive-Frict. Mater. 1997, 2, 279–299. [Google Scholar] [CrossRef]

- Wagner, R. Seismisch Belastete Schüttgutsilos. Ph.D. Thesis, Lehrstuhl für Baustatik und Baudynamik, RWTH Aachen University, Aachen, Germany, 2009. [Google Scholar]

- Wolf, J.P. Foundation Vibration Analysis Using Simple Physical Models; PTR Prentice Hall Inc.: Upper Saddle River, NJ, USA, 1994; p. 27. [Google Scholar]

- New Zealand Standard 1170.5: Structural Design Actions, Part 5: Earthquake Actions; Standards New Zealand: Wellington, New Zealand, 2004.

- Janssen, H.A. Getreidedruck in Silozellen. Z. Ver. Dt. Ing. 1895, 39, 1045–1049. [Google Scholar]

| Silos | |||

| Height (squat/slender) | 10.0/30.0 | m | |

| Inner diameter (squat/slender) | 10.0/6.0 | m | |

| Thickness silo wall (squat/slender) | 10.0/8.0 | mm | |

| Young’s modulus | 210.000 | N/mm2 | |

| Poisson’s ratio | 0.3 | [-] | |

| Bulk Material | |||

| Bulk unit weight | γ | 15.0 | kN/m3 |

| Horizontal load ratio | 0.45 | [-] | |

| Wall friction angle | μ | 0.40 | [-] |

| Amplification factor | 1.00 | [-] | |

| Amplification factor pressure on the bottom | 1.00 | [-] | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Butenweg, C.; Rosin, J.; Holler, S. Analysis of Cylindrical Granular Material Silos under Seismic Excitation. Buildings 2017, 7, 61. https://doi.org/10.3390/buildings7030061

Butenweg C, Rosin J, Holler S. Analysis of Cylindrical Granular Material Silos under Seismic Excitation. Buildings. 2017; 7(3):61. https://doi.org/10.3390/buildings7030061

Chicago/Turabian StyleButenweg, Christoph, Julia Rosin, and Stefan Holler. 2017. "Analysis of Cylindrical Granular Material Silos under Seismic Excitation" Buildings 7, no. 3: 61. https://doi.org/10.3390/buildings7030061